Gasification combustor of solid fuel cooking range

A solid fuel and burner technology, which is applied in the field of gasification burners, can solve the problems of short sustainable combustion time, slow ignition and ignition of cold furnaces, and high fuel requirements, so as to improve the heat radiation effect, prolong the combustion time, and strengthen the combustion. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

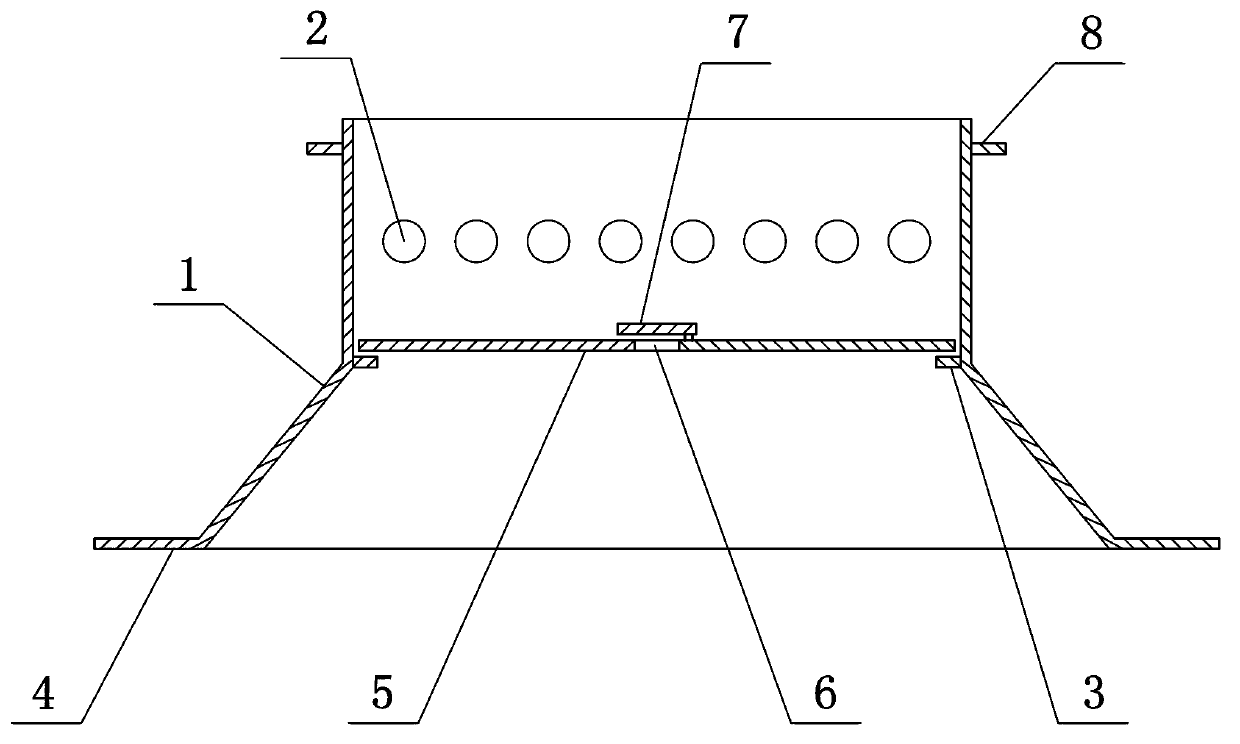

[0027] as attached figure 1 As shown, the gasification burner of the solid fuel stove in this embodiment includes a first core body 1 and a movable fire sealing cover 5; the upper part of the first core body 1 is provided with a plurality of first air inlet gasification combustion-supporting holes 2, and the first air inlet gas The combustion-supporting hole 2 is arranged above the movable fire sealing cover 5, and the inner wall of the first core body 1 is provided with a fire sealing cover baffle plate 3, and the fire sealing cover baffle plate 3 is used to support the movable fire sealing cover 5 and the fire sealing cover 5 when sealing the fire. When the fuel burns, it increases the turbulence of the flame and flue gas and air in the furnace core 18 of the stove, further mixes the combustible flue gas with the air, and prolongs the combustion of combustible flue gas and carbon particles in the flue gas. The residence time in the stove is conducive to heat exchange, prolon...

Embodiment 2

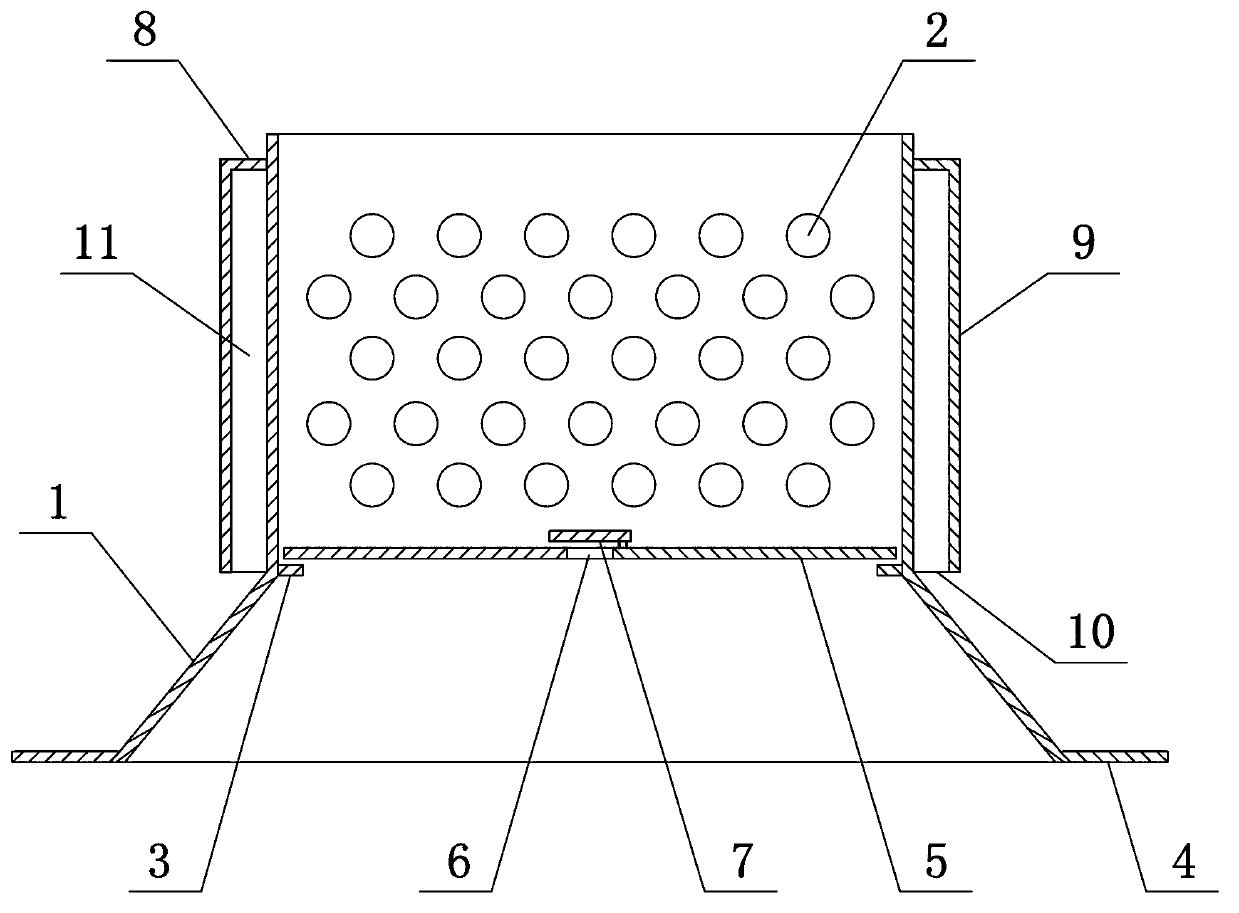

[0030] as attached figure 2As shown, the difference between the gasification burner of the solid fuel stove in this embodiment and the first embodiment is that an outer cover 9 is arranged around the upper part of the first core 1 . A burner air inlet 10 is set between the lower end of the outer cover 9 and the first core 1, the upper end of the outer cover 9 is sealed with the first core 1, and the gap between the outer cover 9 and the first core 1 is a jacket structure. , Between the outer cover 9 and the first core 1 is a burner air intake channel 11 . The top edge of the outer cover 9 and the lower edge of the first core 1 have edges extending outward. When the present embodiment is in use, it is placed on the stove core 18 of the stove just in time to form a sealed structure with the stove body and the stove core 18 (such as Figure 6 shown), on the first core 1 there are multiple rows of first air intake gasification combustion-supporting holes 2 arranged along the ci...

Embodiment 3

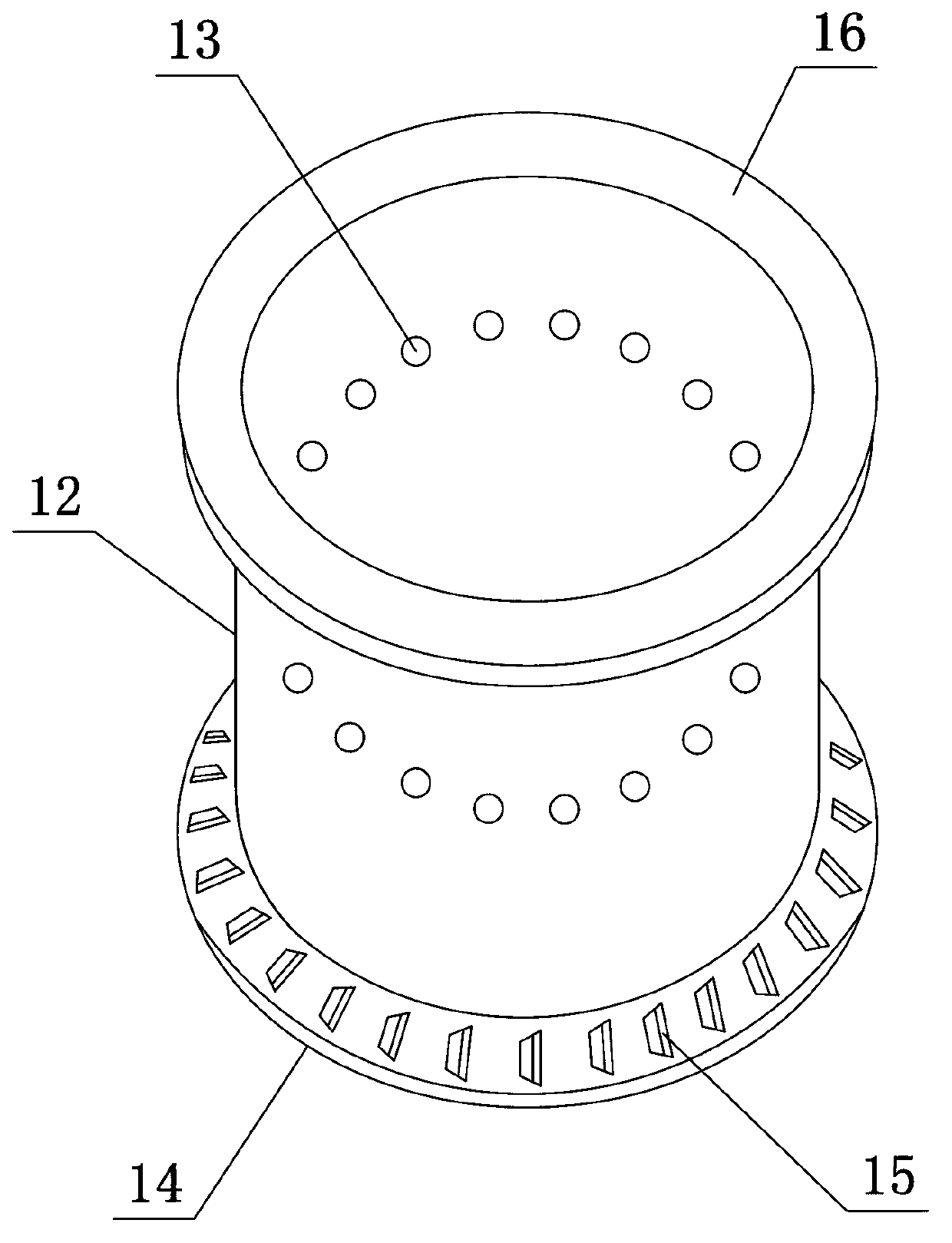

[0032] as attached image 3 , 4 As shown, the gasification burner of the solid fuel stove in this embodiment is provided with a movable cyclone combustion supporter in the first core 1, and the upper and lower parts of the cyclone combustion supporter are provided with butt joints with the first core body 1 of the burner. The sealed second core 12 has a bottom wall 14 and a top wall 16 .

[0033] The upper and lower ends of the cyclone burner are through structures, and its shape can be a cylinder, a cone, an ellipsoid or a square. This embodiment is a cylinder, and the bottom wall 14 of the second core 12 is provided with a plurality of Or circular third air intake gasification combustion-supporting hole 15, the third air intake gasification combustion-supporting hole 15 is an oblique hole with the same oblique direction, and a plurality of second air intake gasification combustion-supporting holes arranged along the circumference of the side wall of the second core body 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com