Patents

Literature

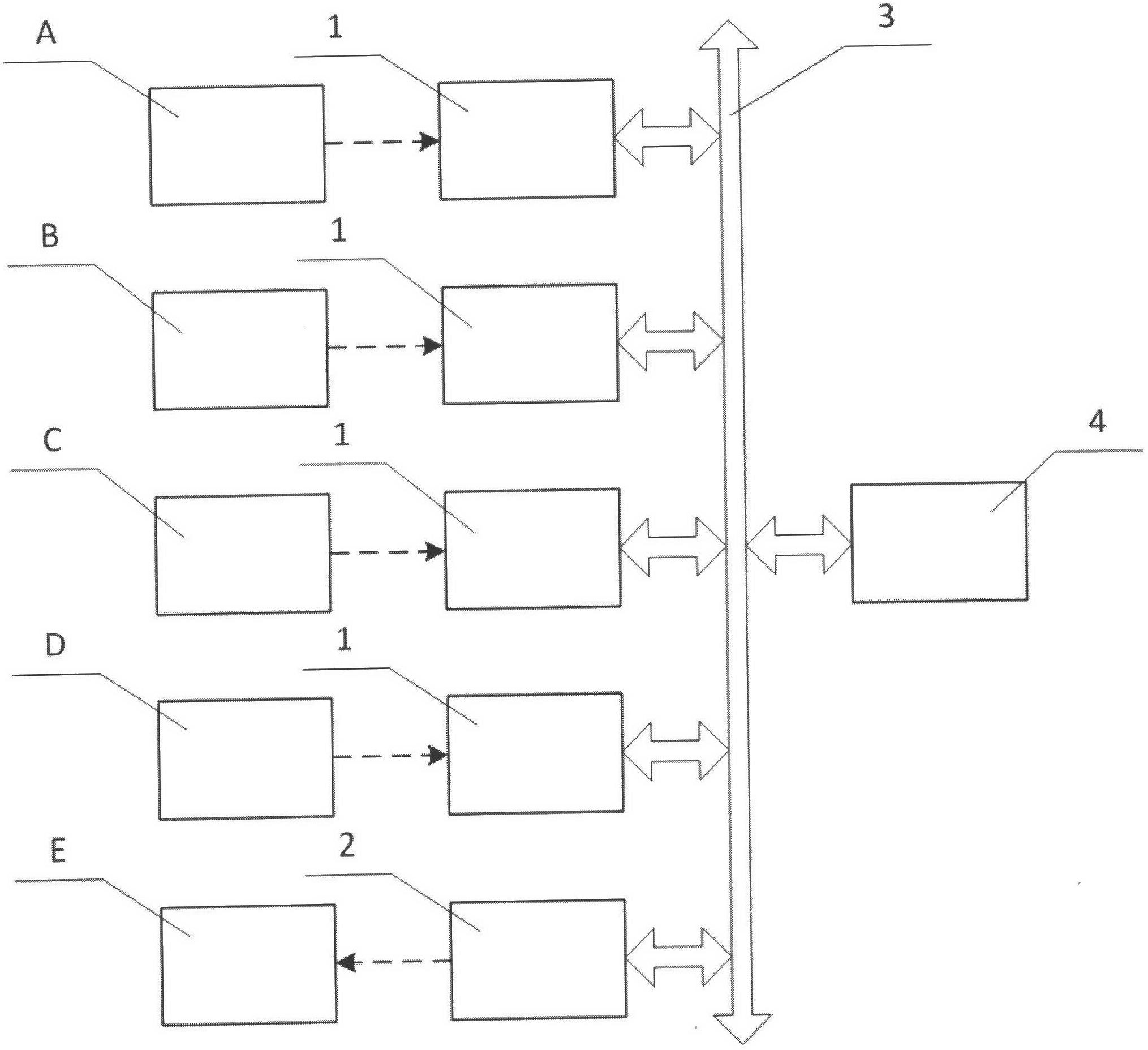

102results about How to "Improve heat radiation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

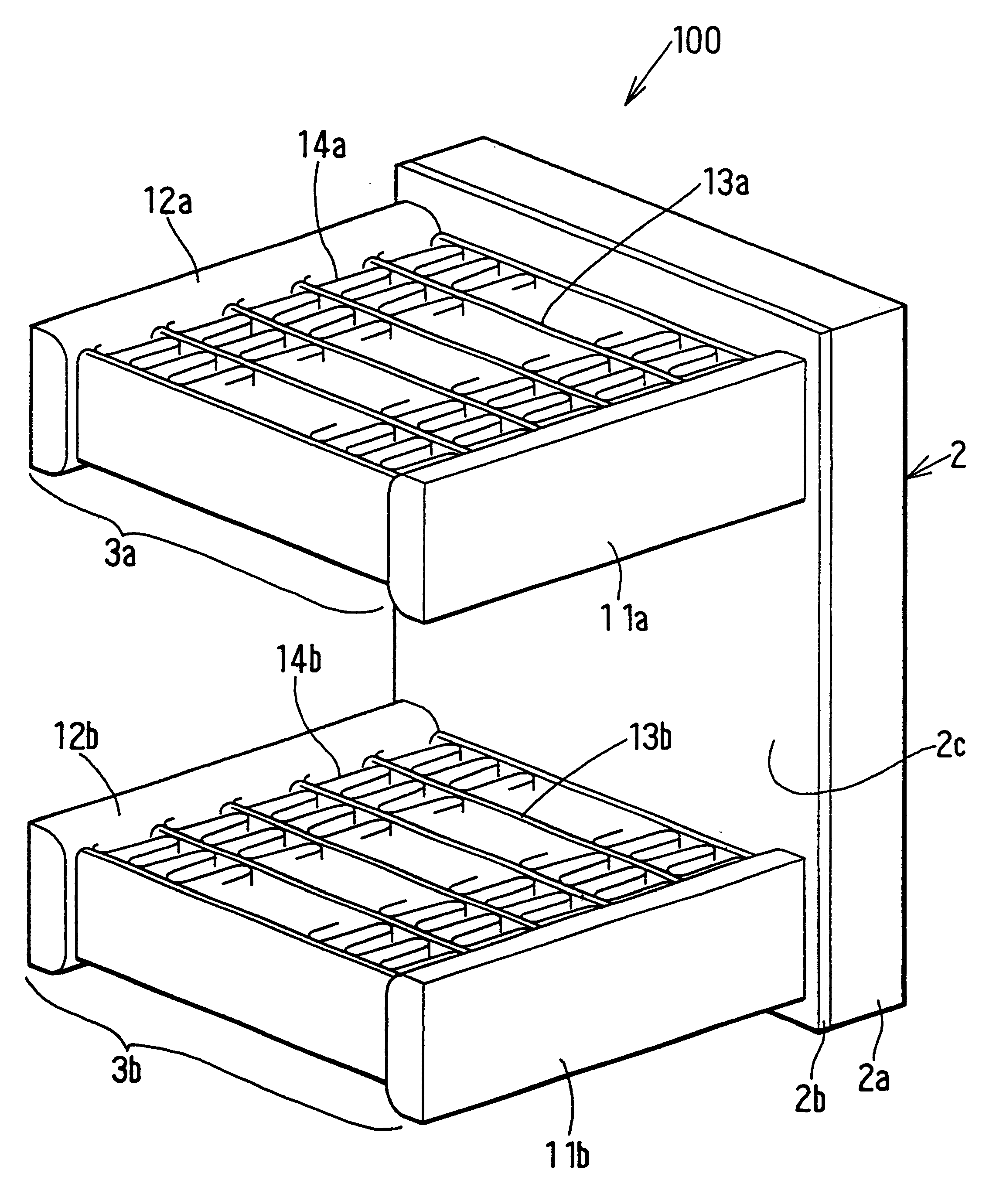

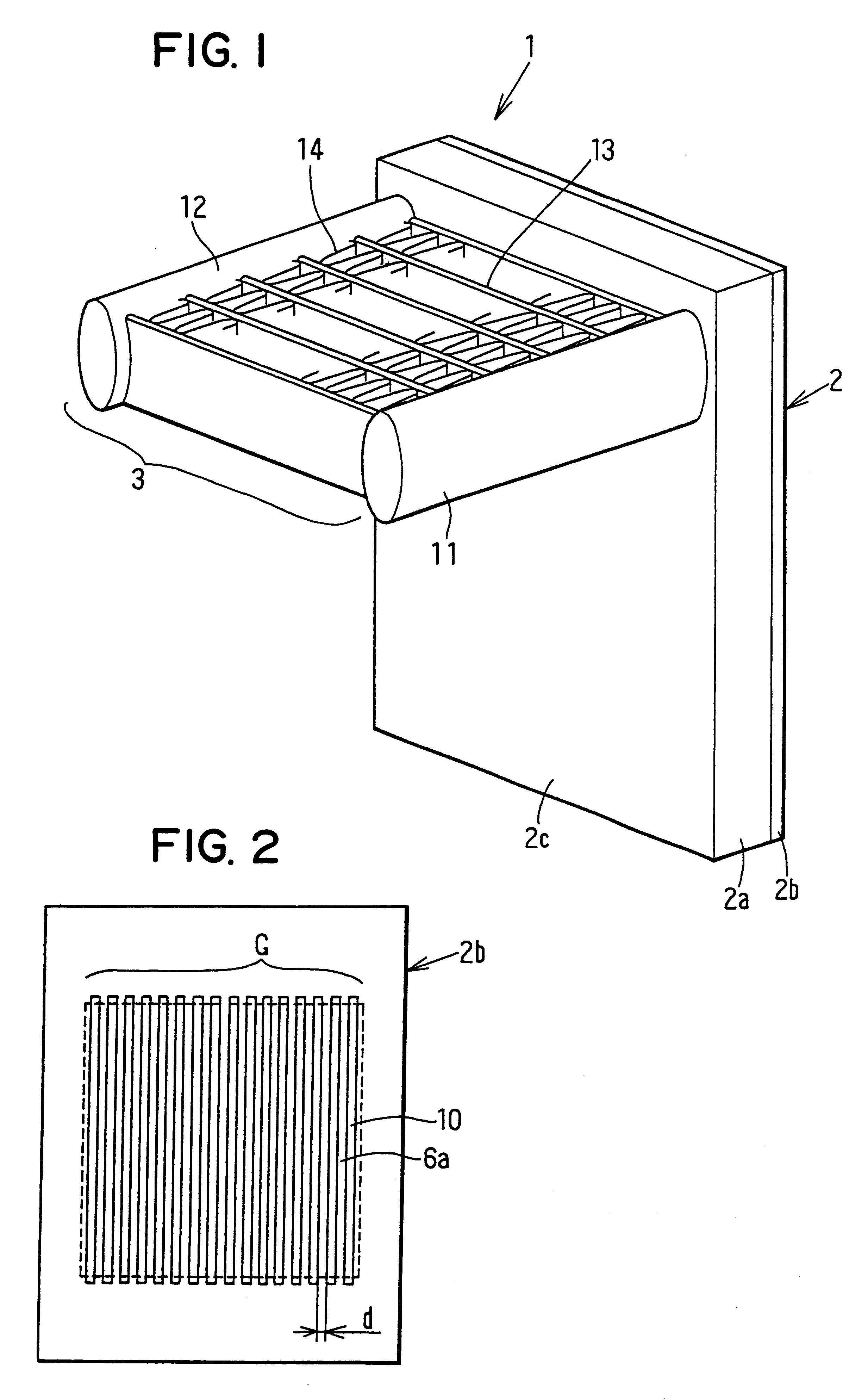

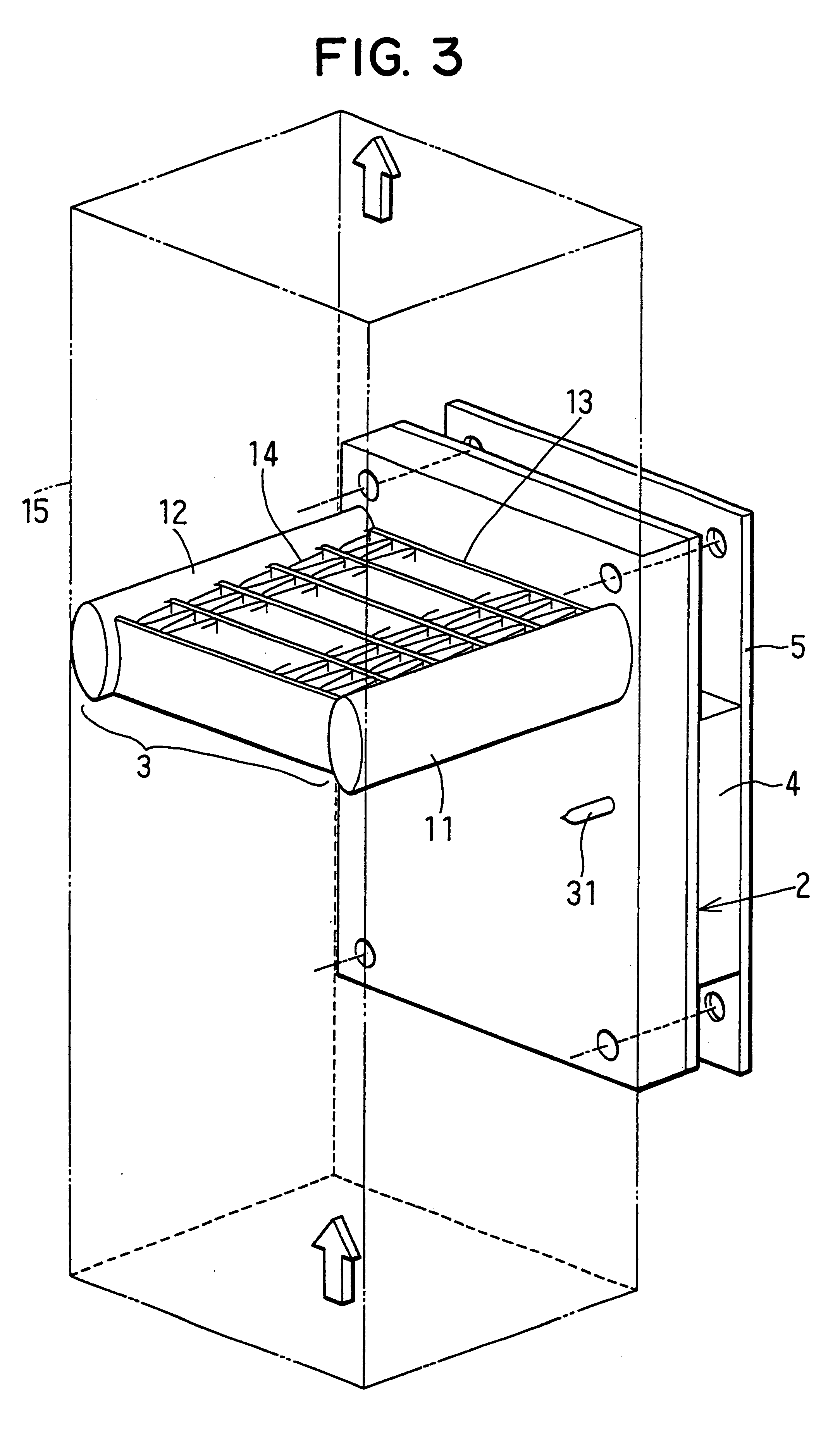

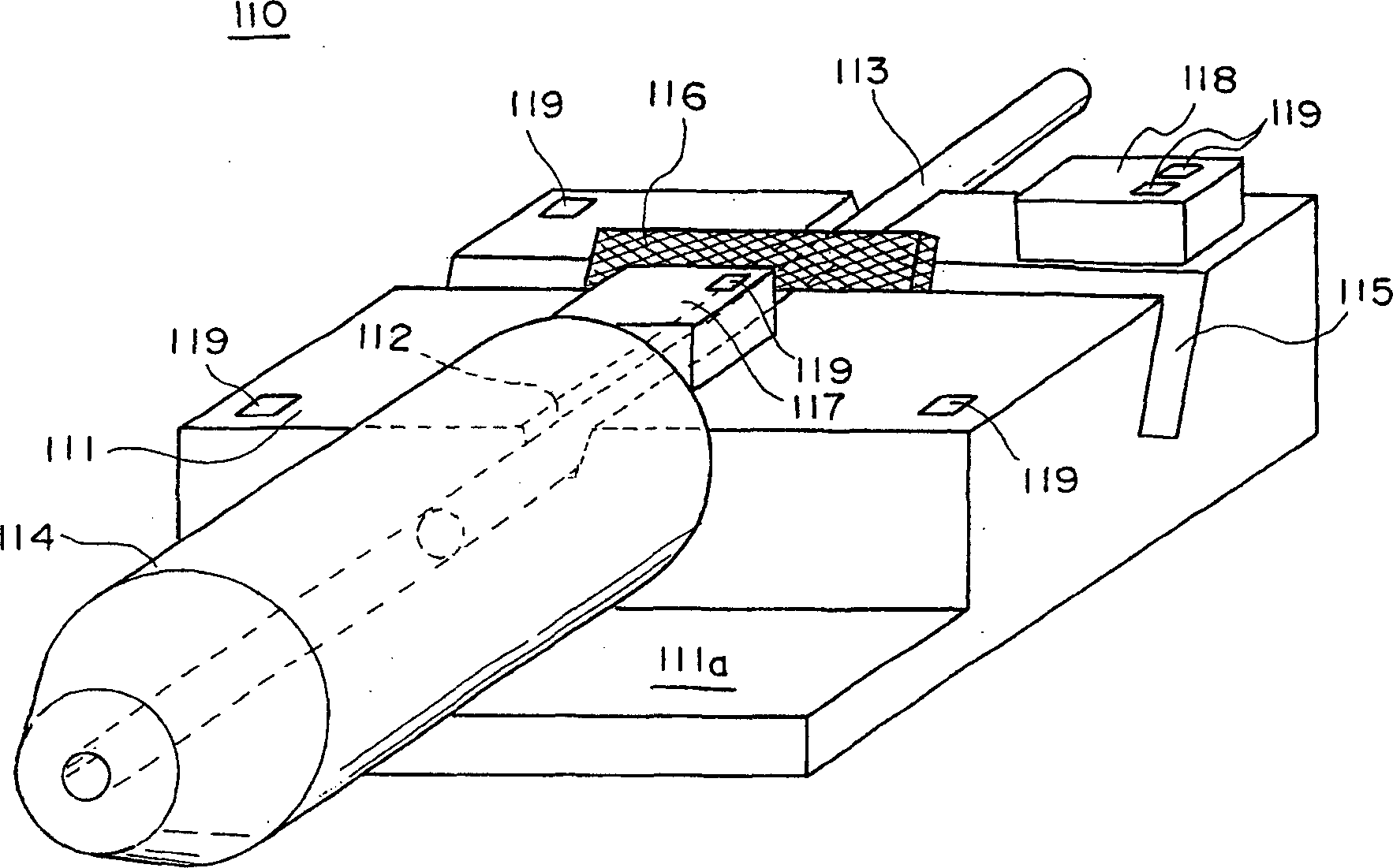

Cooling device boiling and condensing refrigerant

InactiveUS6360814B1Simple structureImprove performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringRefrigerant

A cooling device for cooling a heat-generating member includes a refrigerant tank for boiling liquid refrigerant by heat from the heat-generating member and a radiator for cooling and condensing gas refrigerant from the refrigerant tank. The refrigerant tank has therein a plurality of refrigerant passages defined by ribs which are integrally formed with any one of opposite wall parts of the refrigerant tank. The ribs continuously extend in an up-down direction to be slightly longer than an up-down dimension of a boiling surface of the refrigerant tank. In the cooling device, because each passage width of the refrigerant passages is set to be equal to or smaller than double Laplace length, an outer diameter of bubbles in the refrigerant passages becomes larger, and liquid refrigerant can be moved upwardly by bubbles. Accordingly, it can restrict liquid refrigerant surface from being lowered even when gas-generating amount is increased.

Owner:DENSO CORP

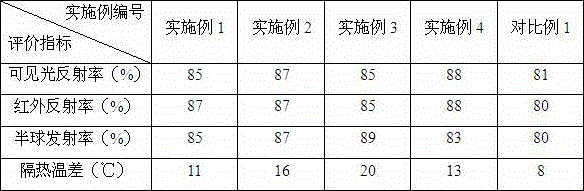

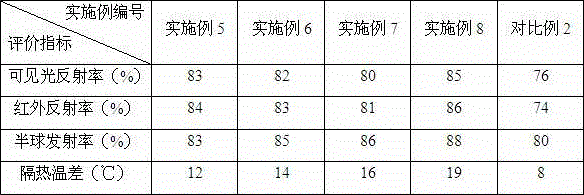

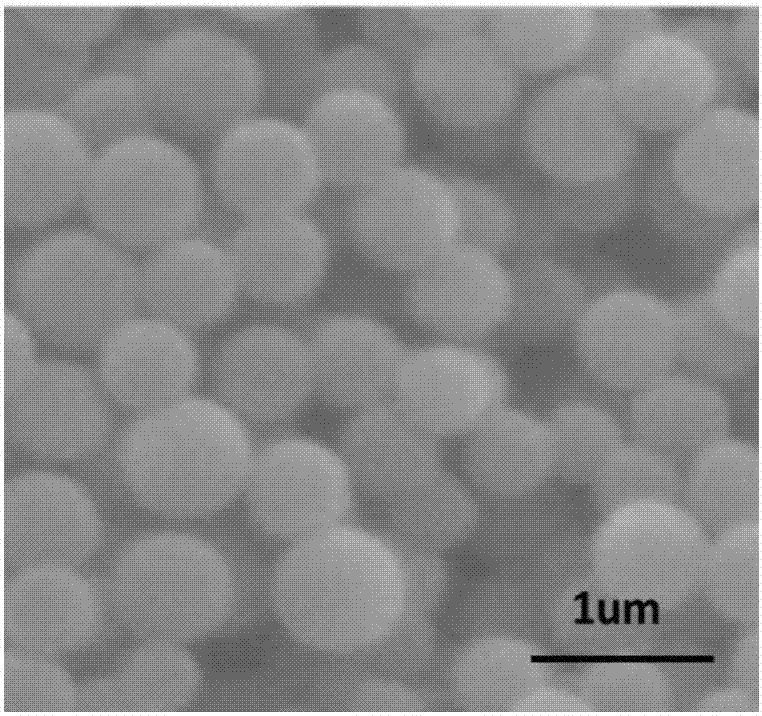

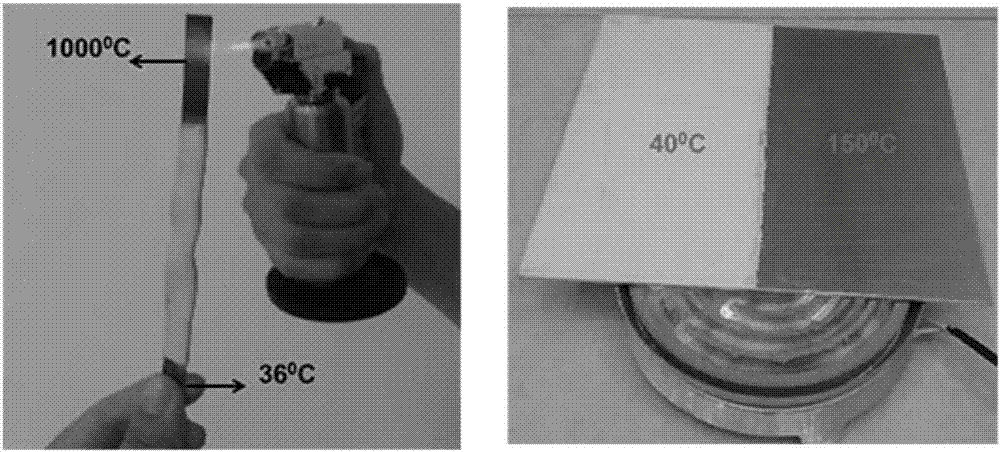

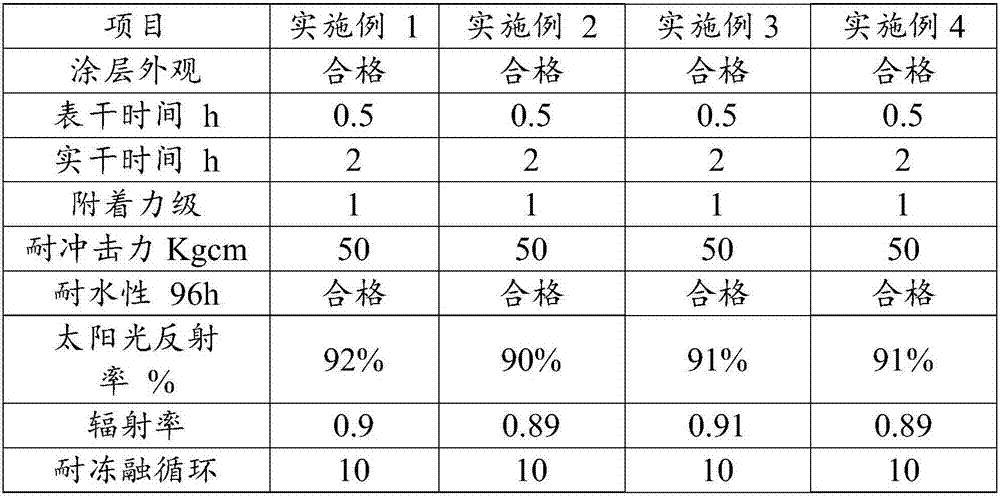

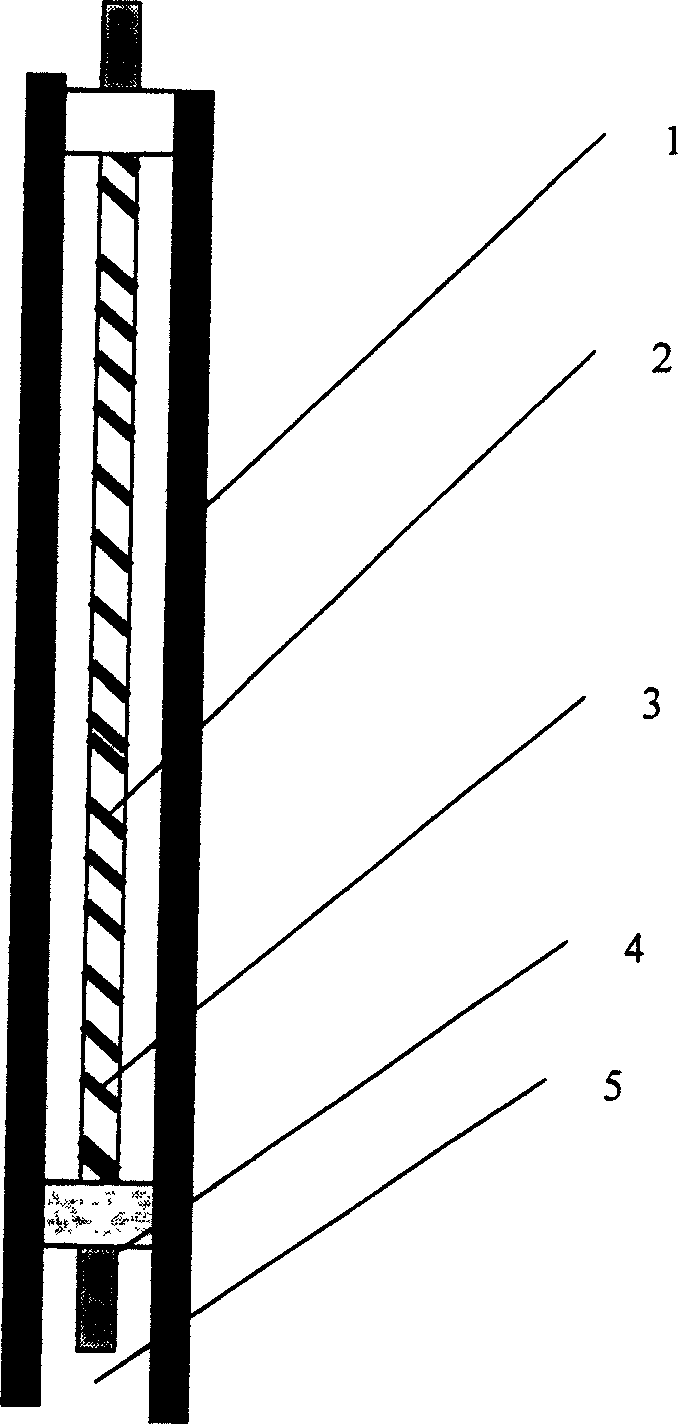

Building coating with heat insulation function and preparation method thereof

InactiveCN106118307AGood thermo-optic comprehensive performanceWith thermal insulation functionReflecting/signal paintsBuilding energyMetallurgy

The invention provides a building coating with a heat insulation function and a preparation method thereof. The building coating with the heat insulation function is divided into an internal wall coating and an external wall coating, wherein each of the internal wall coating and the external wall coating is composed of a basic carrier for film forming of the coating, a heat insulating material, a heat reflecting material, a heat radiating material, filler, an assistant and water. The preparation method comprises the following steps: preparation of heat insulating material slurry, preparation of function material slurry, grinding of slurry, and paint mixing. The film forming thickness of the building coating is 0.2-0.3mm, so that the building coating belongs to a thin building energy-saving coating; the internal and external wall building coatings have higher heat conducting resistance and lower convection heat transfer, so that the building coating has different heat radiating effects under different temperature environments in different seasons and has the heat insulation function; the building coating is high in safety and long in service life; and the preparation method is simple and is suitable for industrial production.

Owner:马承银

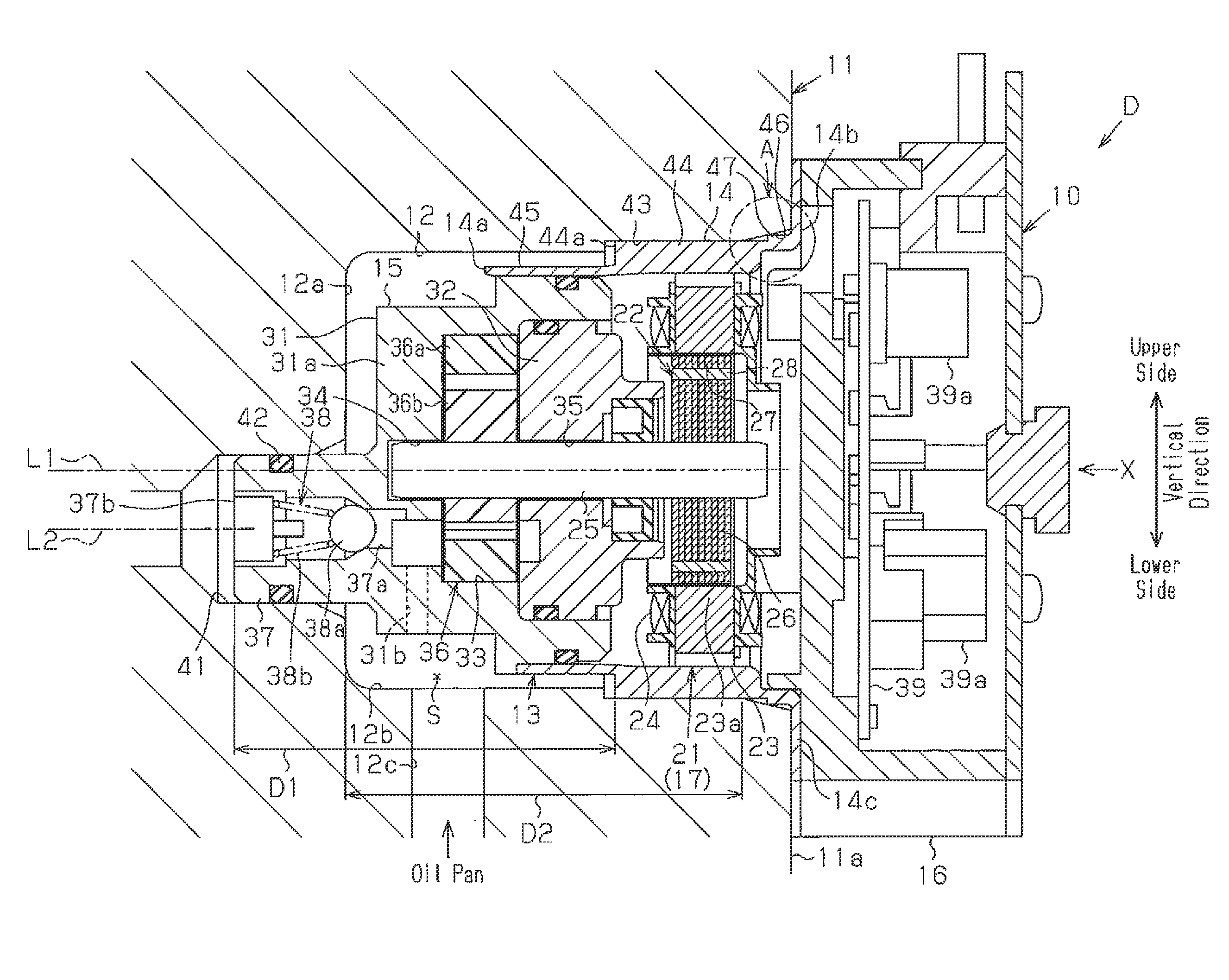

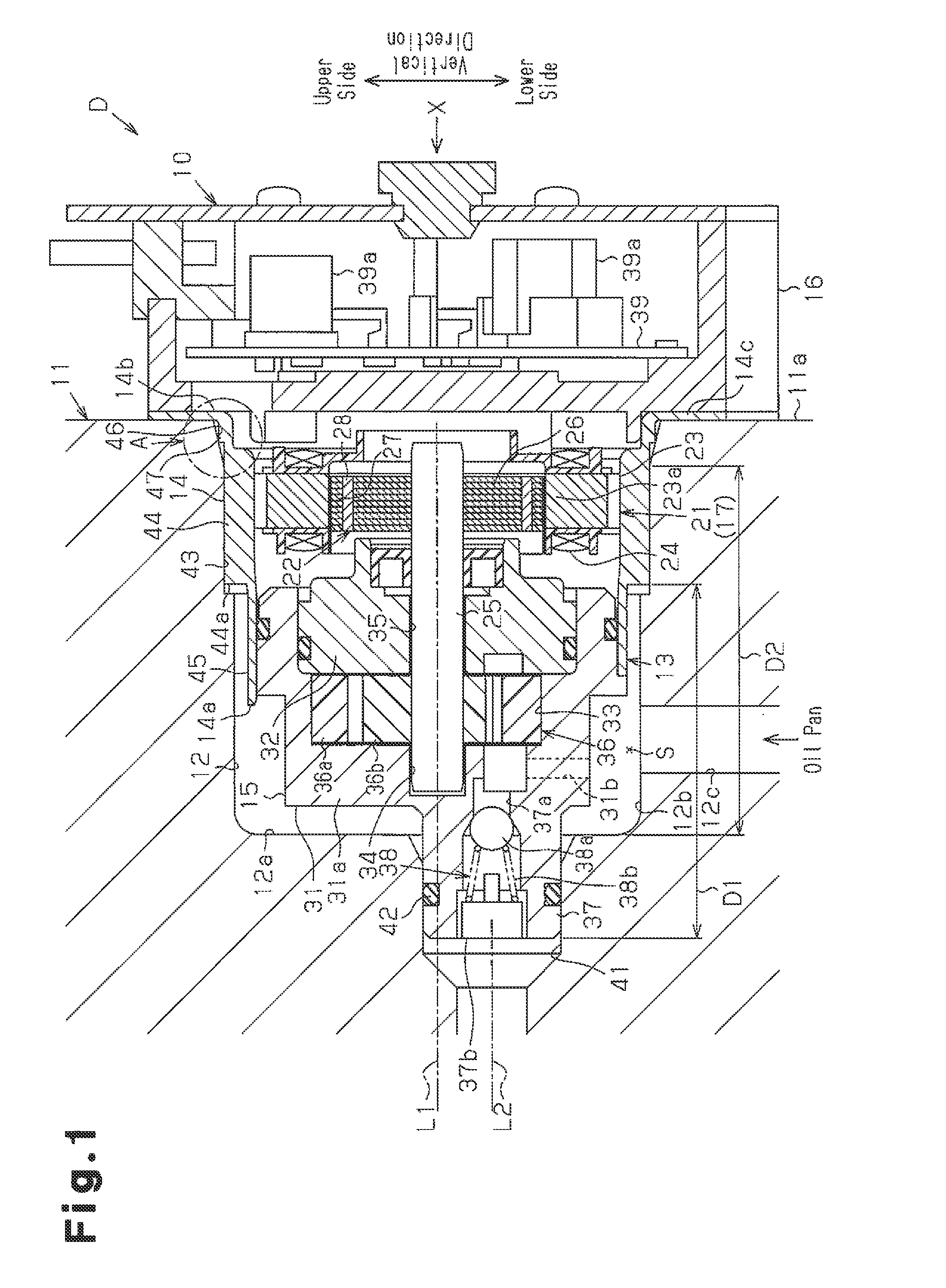

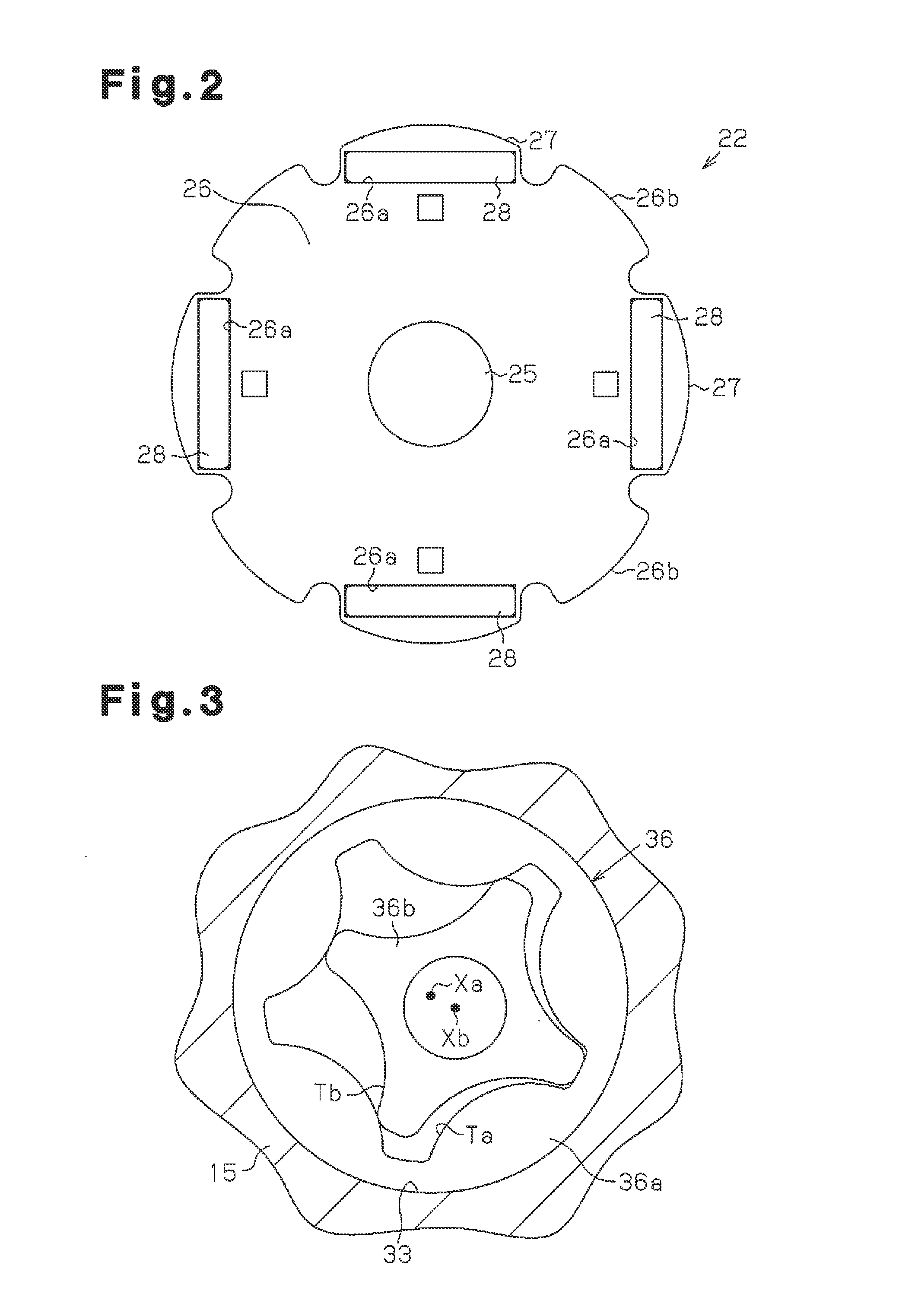

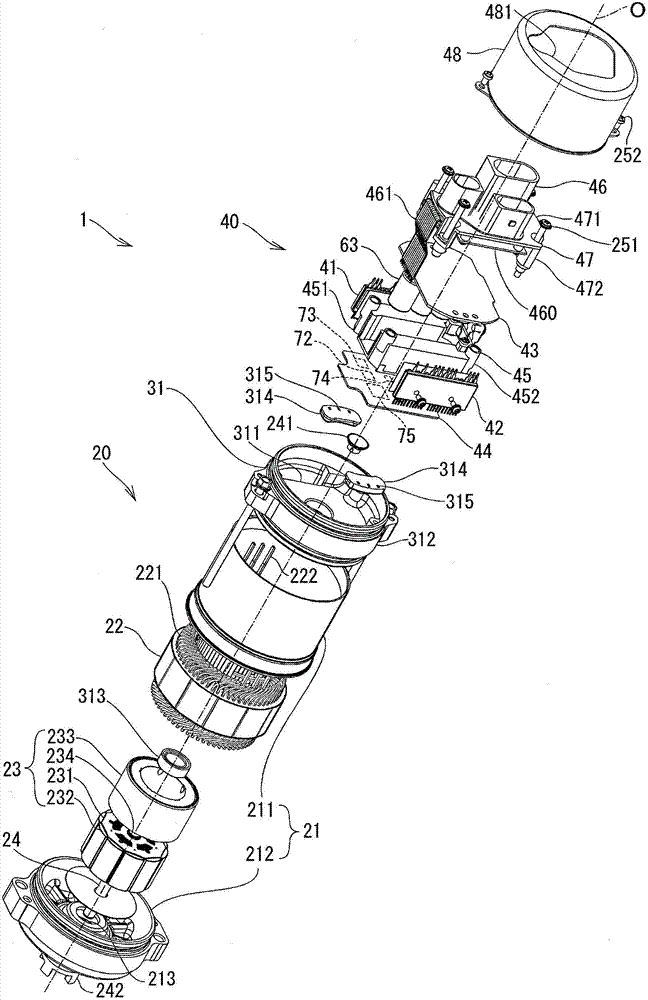

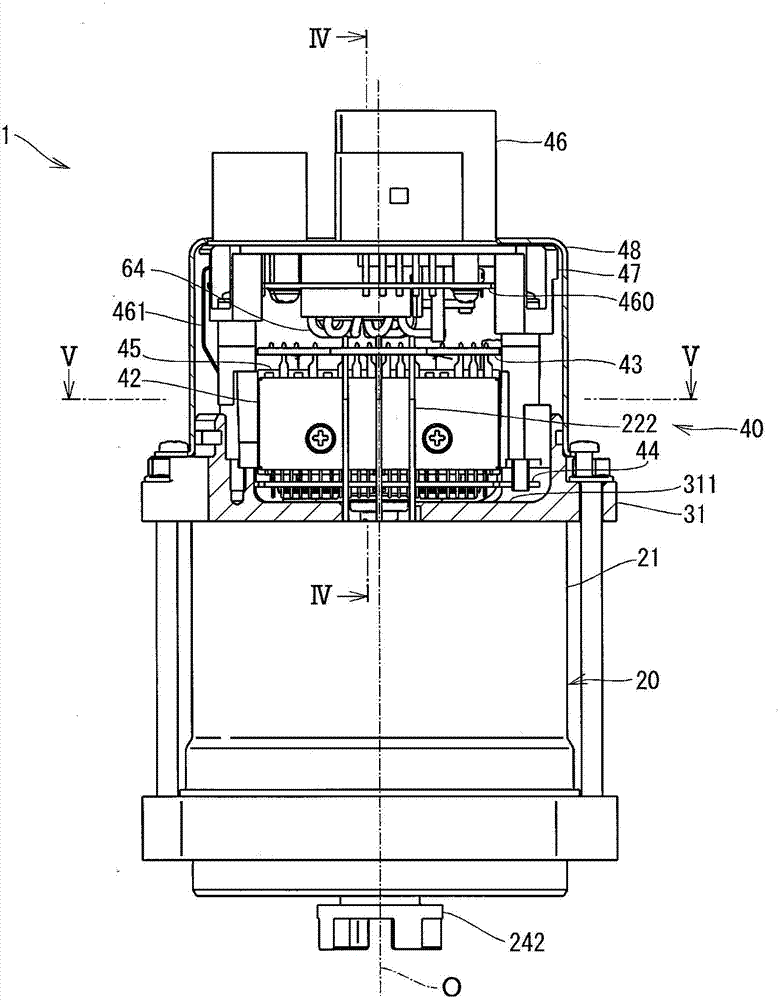

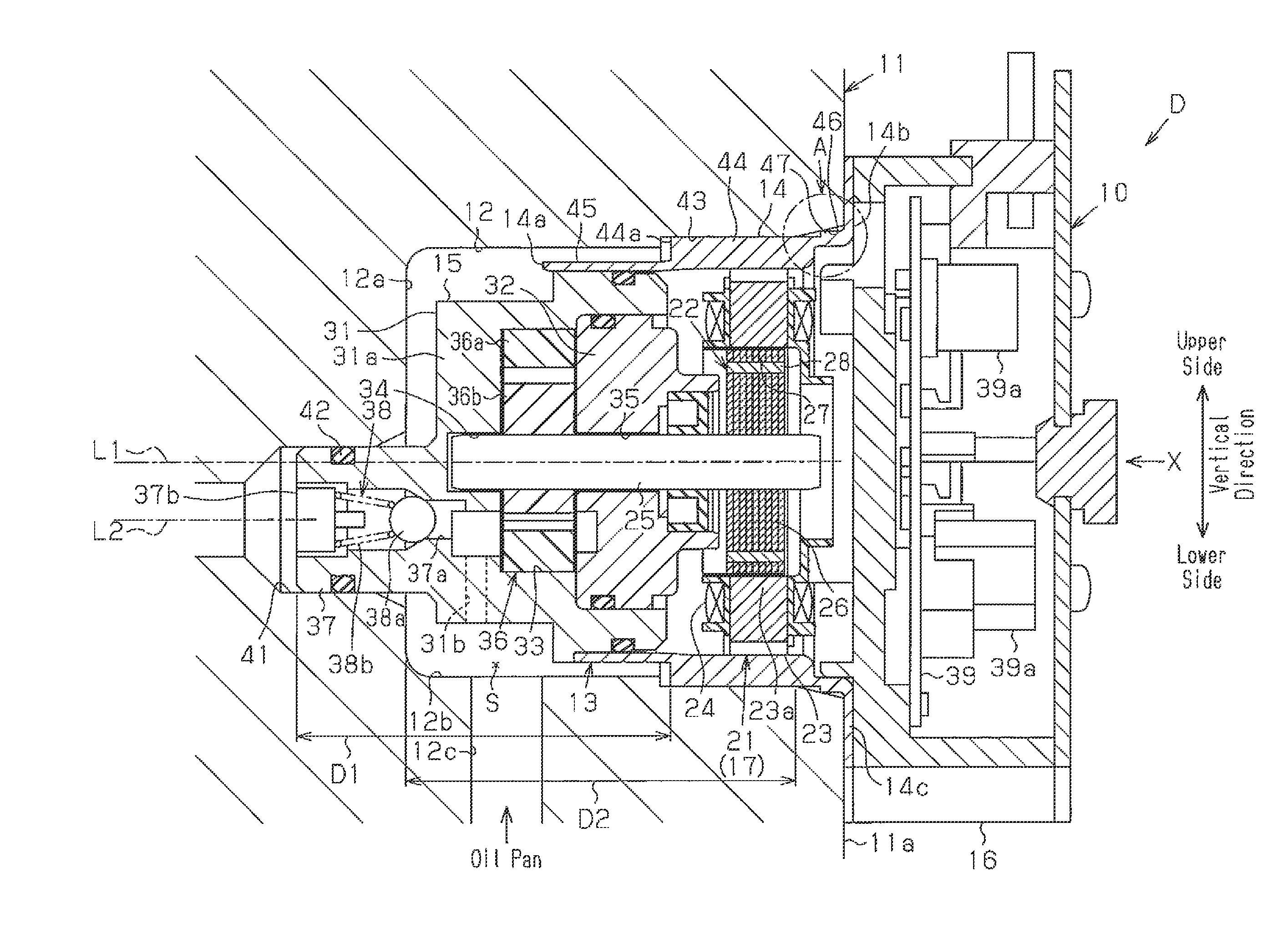

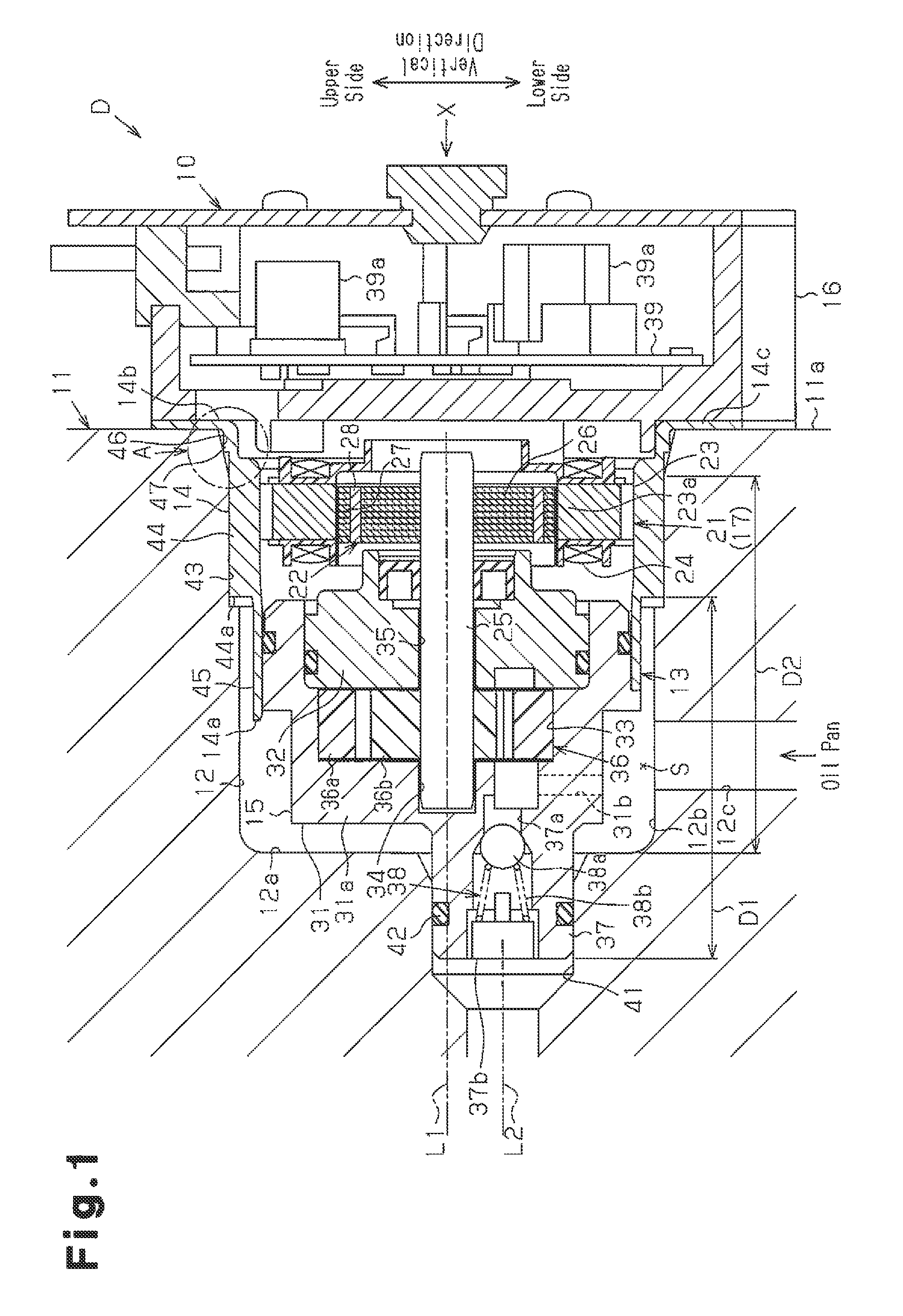

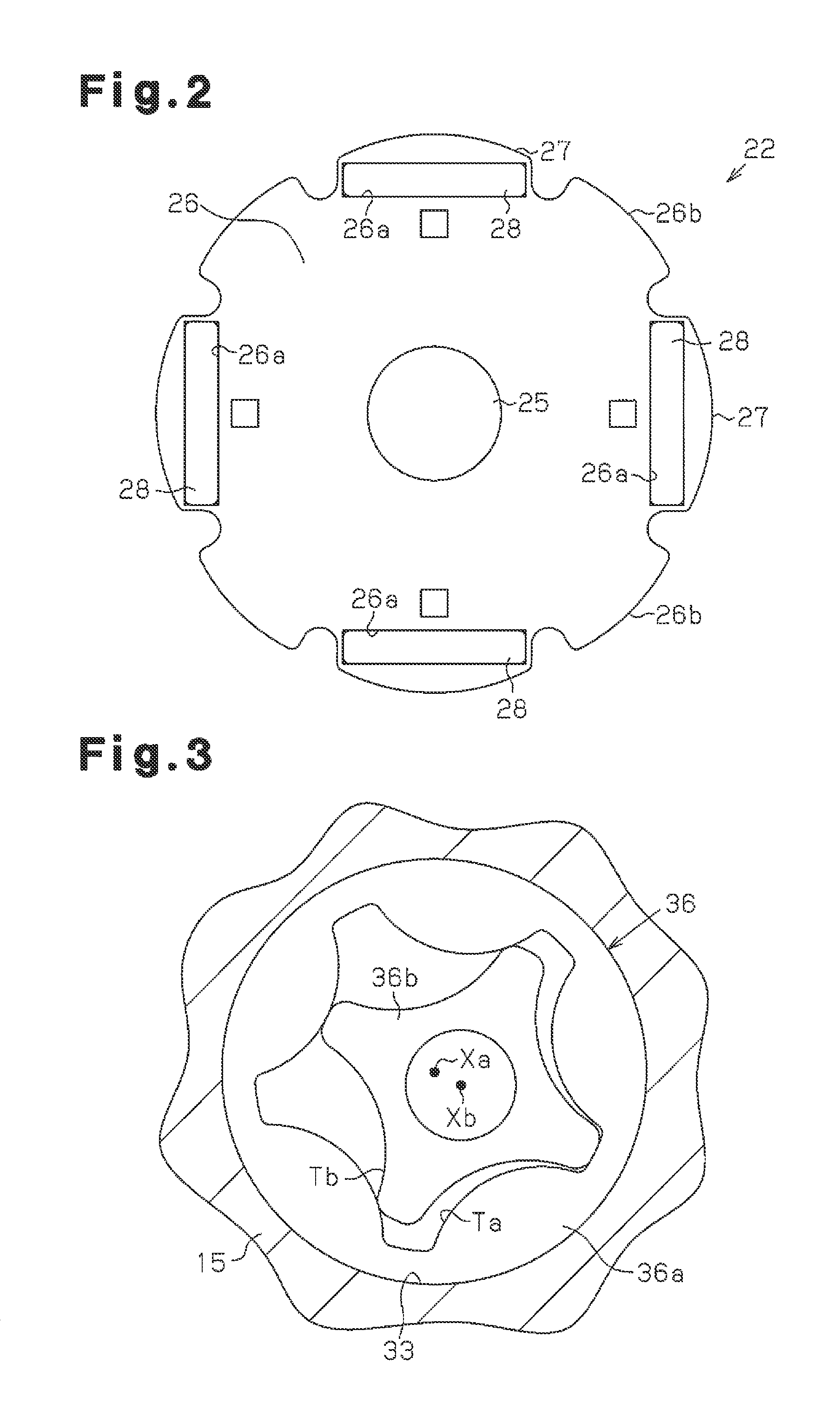

Electric oil pump and hydraulic pressure supply device

ActiveUS20140241917A1Improve heat radiation abilityRotary piston pumpsRotary/oscillating piston combinationsCheck valvePetroleum engineering

An electric oil pump is coupled to a pump receptacle including an oil inflow passage and an oil outflow passage. The electric oil pump includes a motor, a pump rotor, a housing, and a check valve. The housing accommodates the motor and the pump rotor. The housing closes an opening of the pump receptacle and includes at least a fitted portion fitted into the pump receptacle. An oil compartment is formed between the pump receptacle and the housing. Oil flows into the oil compartment from the oil inflow passage when the pump rotor is rotated. The fitted portion is partially immersed in the oil collected in the oil compartment. The housing includes a suction port and a discharge port. A check valve, located in the housing, limits reversed flow of the oil from the oil compartment to the oil inflow passage.

Owner:DENSO CORP

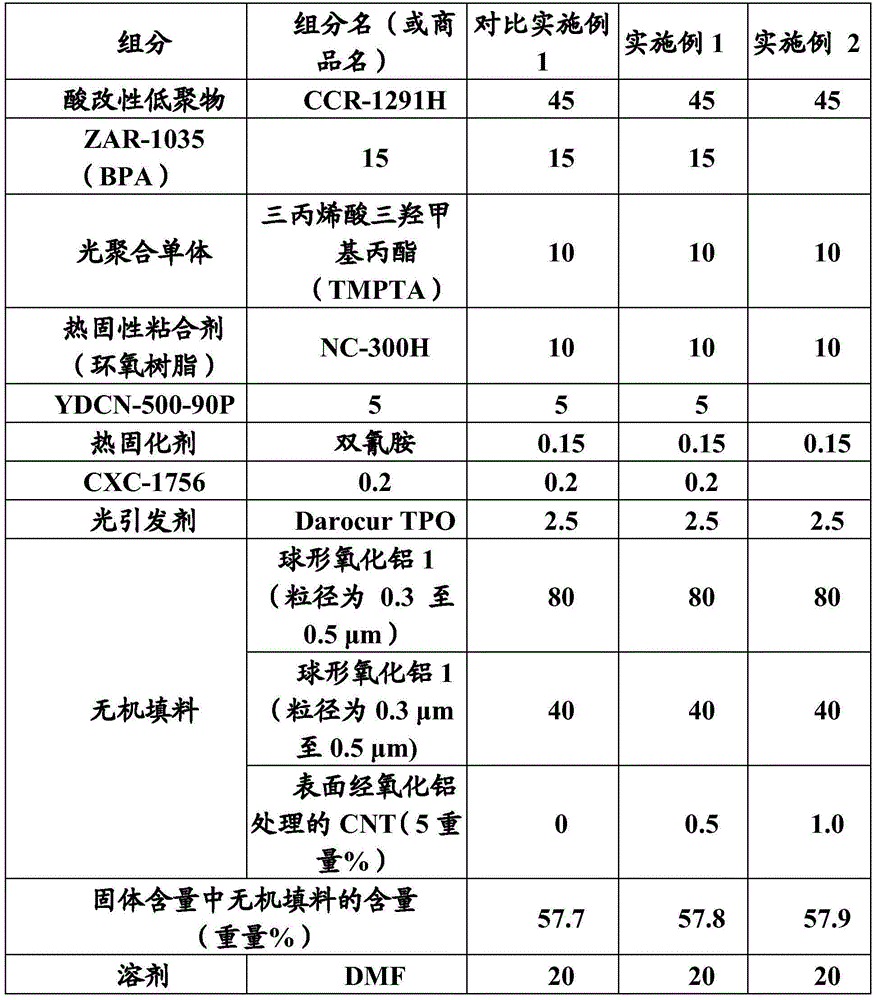

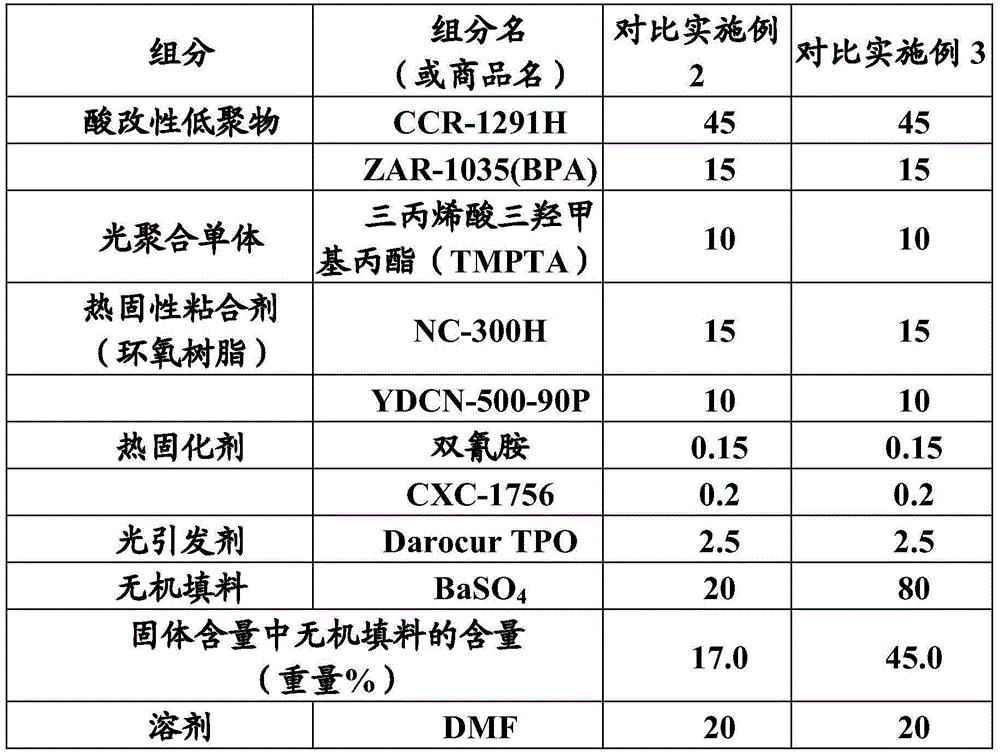

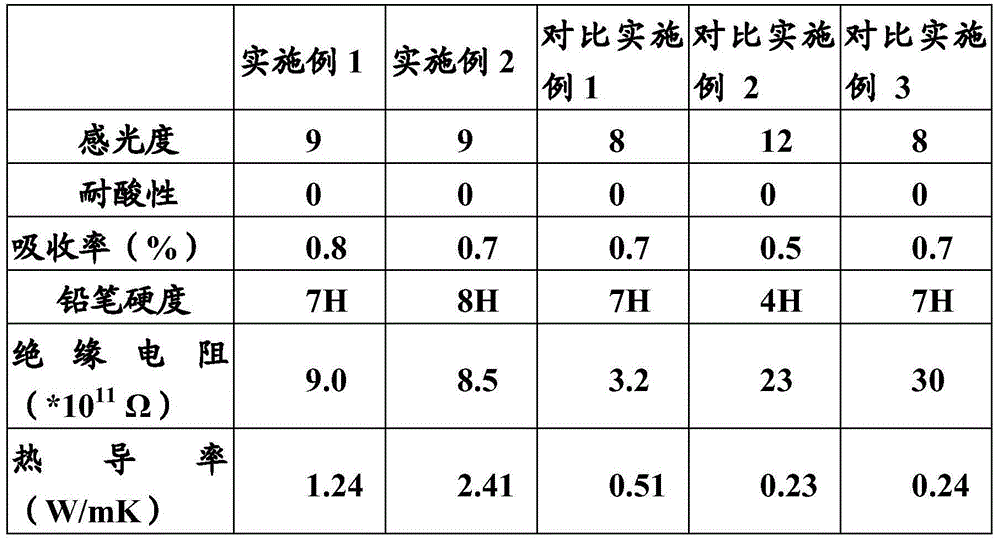

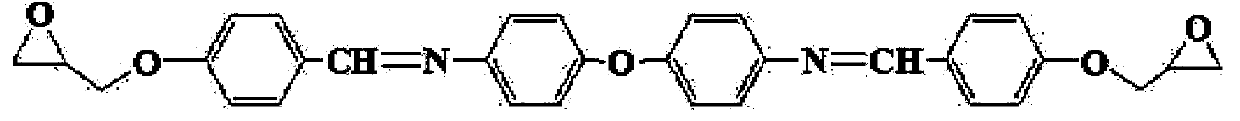

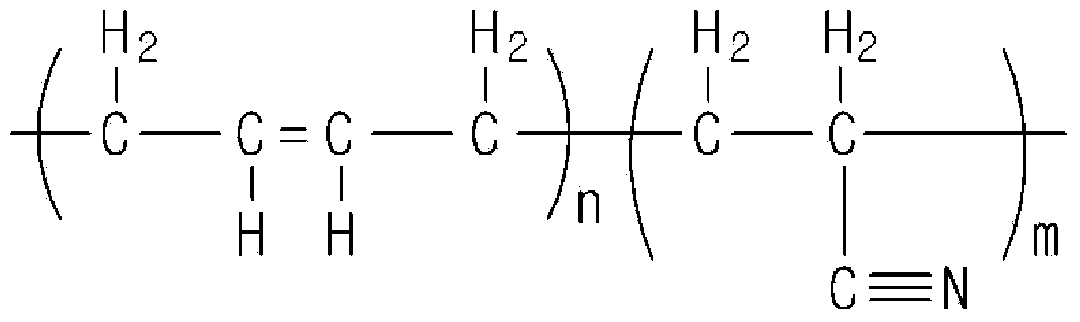

PHOTOCURABLE AND THERMOSETTING RESIN COMPOSITION, DRY FILM SOLDER RESIST fabricated therefrom and circuit board comprising dry film solder resist

ActiveCN104380196AReduce linear expansion coefficientGood thermal radiation performancePhotosensitive materials for photomechanical apparatusOrganic solventPhotoinitiator

The present invention relates to a resin composition which is photocurable and thermosetting, and which comprises an acid-modified oligomer, a photo-polymerizable monomer, a thermosetting binder resin, a photoinitiator, at least two types of spherical alumina particles having mutually different particle sizes, and an organic solvent; a dry film solder resist obtained from the resin composition; and a circuit board comprising the dry film solder resist.

Owner:LG CHEM LTD

Alumina-based ceramic, ceramic radiating substrate and preparation method for ceramic radiating substrate

ActiveCN102795841AImprove overall heat dissipationImprove cooling effectSemiconductor devicesCeramicLanthanum

The invention provides alumina-based ceramic. The alumina-based ceramic contains 100 weight parts of alumina, 10 to 20 weight parts of strontium lanthanum manganate and 5 to 50 weight parts of sintering aid; and the chemical formula of the strontium lanthanum manganate is LaxSr1-xMnO3, wherein x is 0.15 to 0.20. The invention also provides a ceramic radiating substrate using the alumina-based ceramic and a preparation method for the ceramic radiating substrate. The alumina-based ceramic has a good radiating effect, so that the ceramic radiating substrate using the alumina-based ceramic has good radiating performance.

Owner:BYD CO LTD

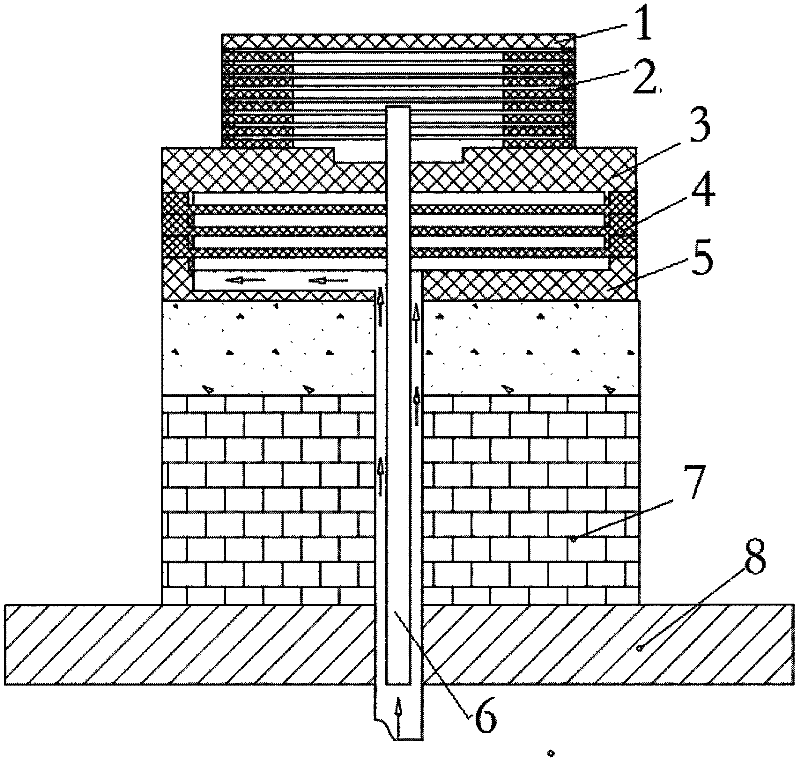

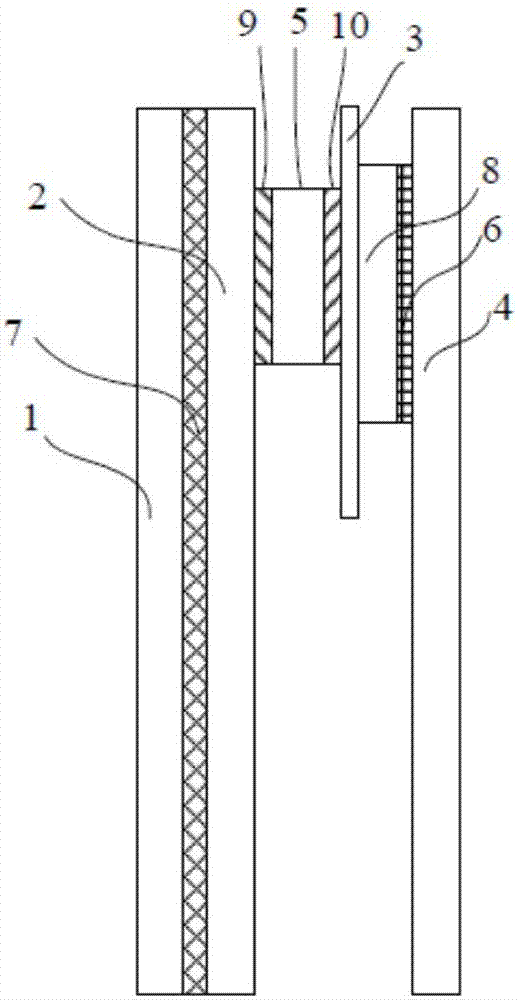

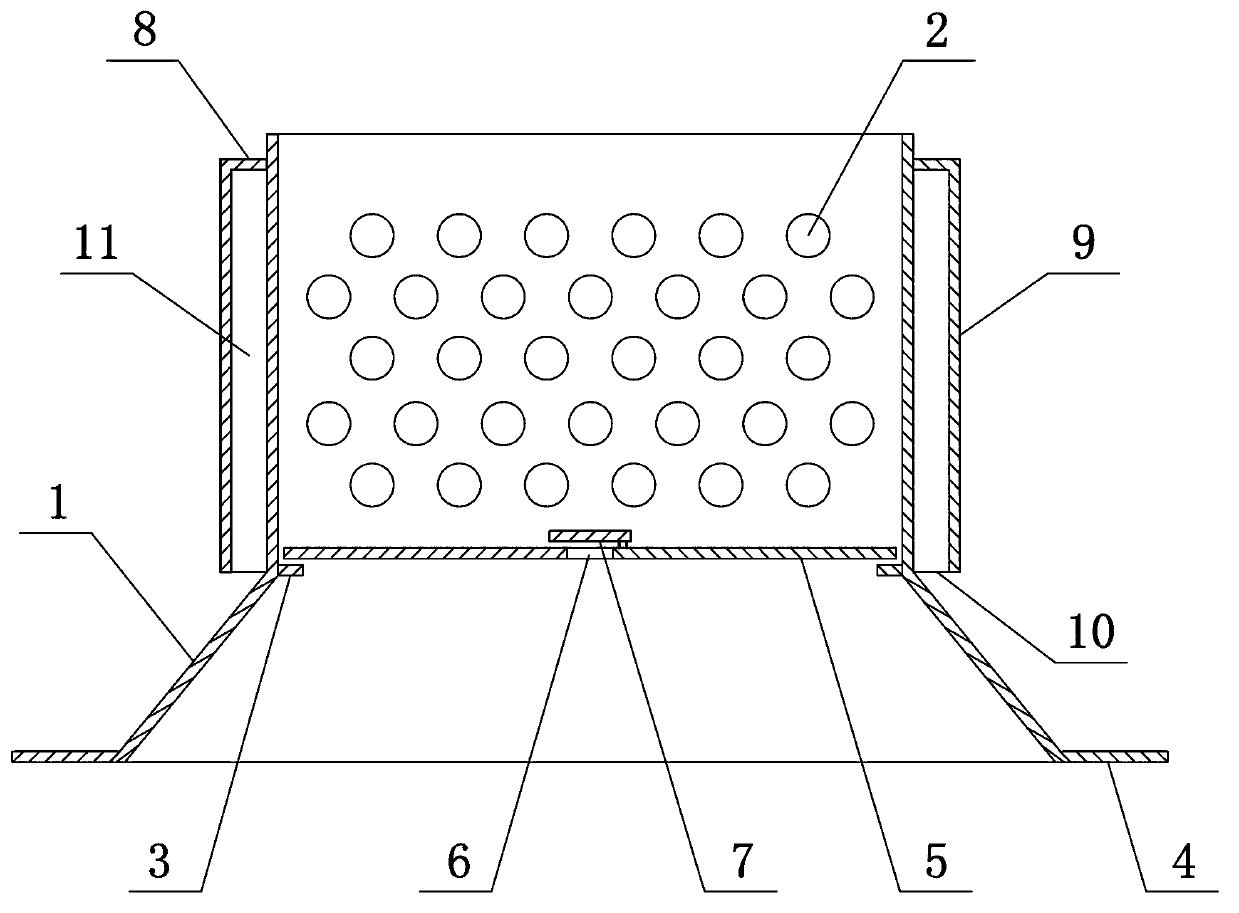

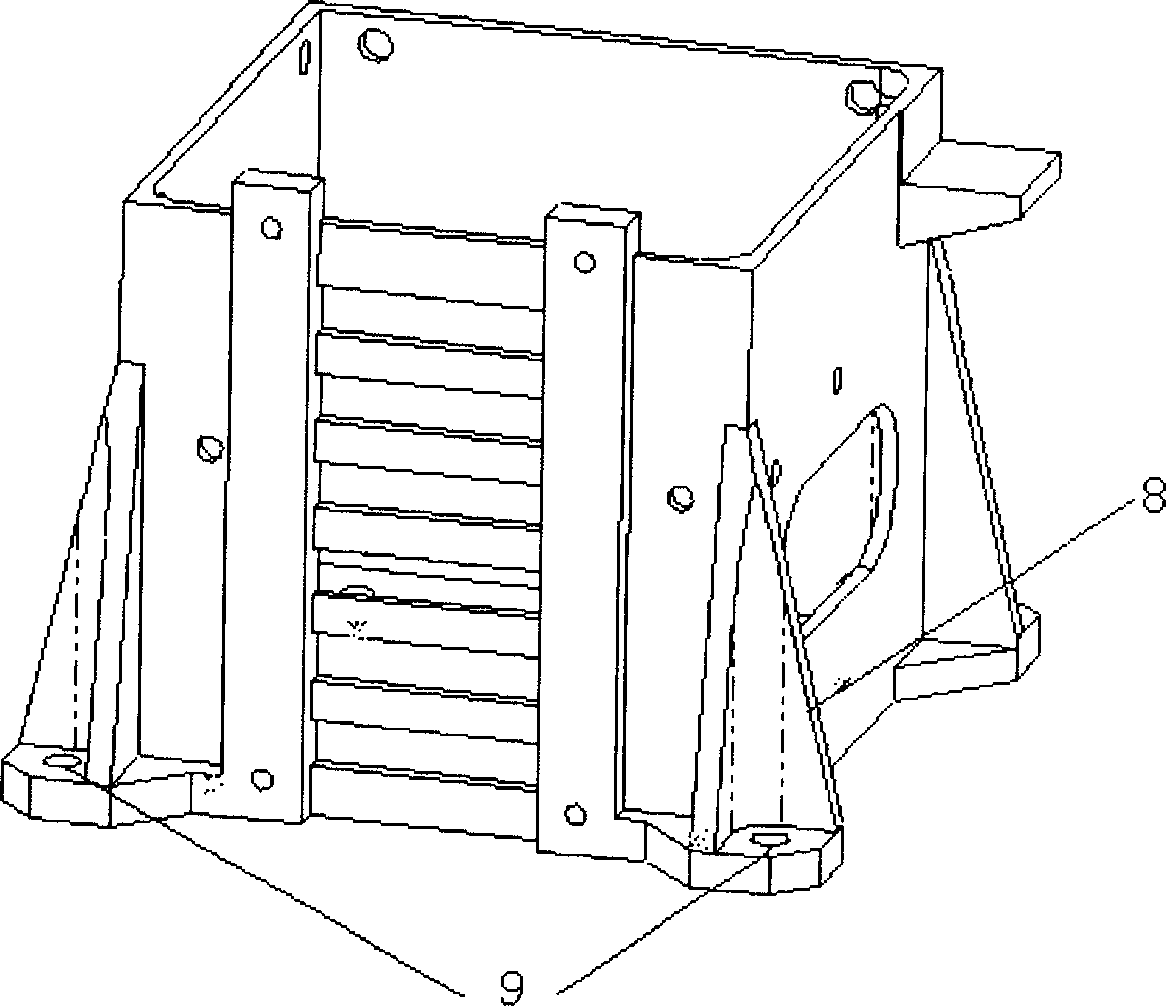

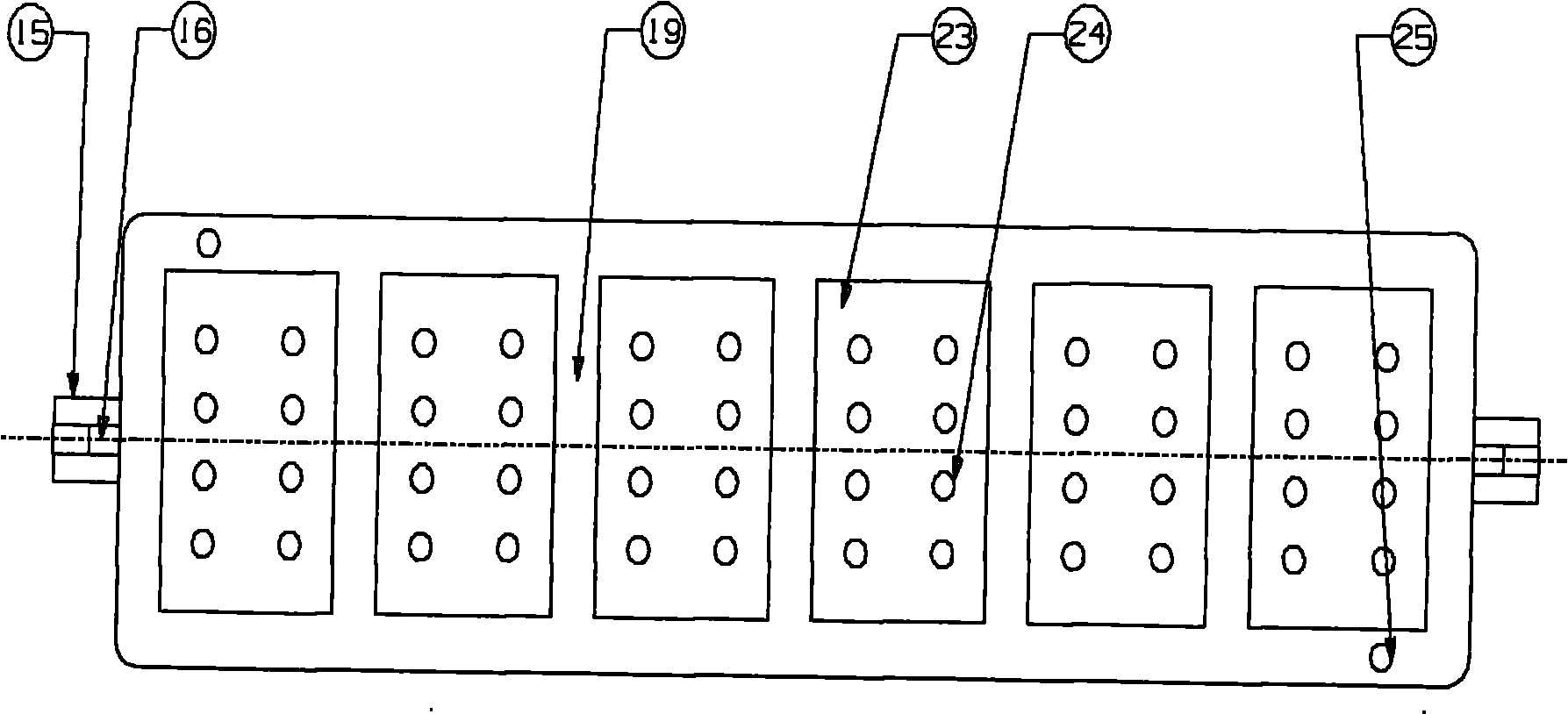

Preheating device for chemical vapor deposition furnace

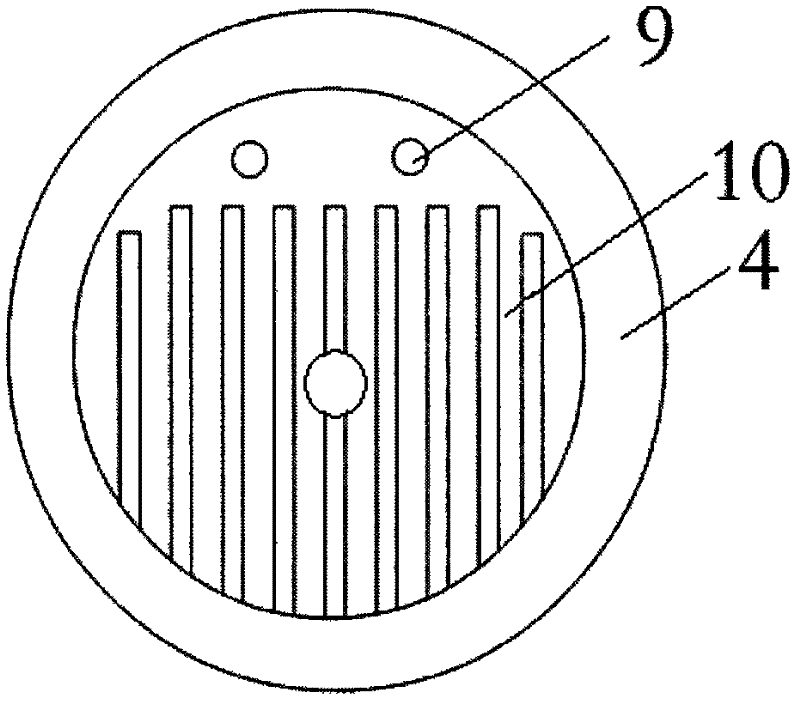

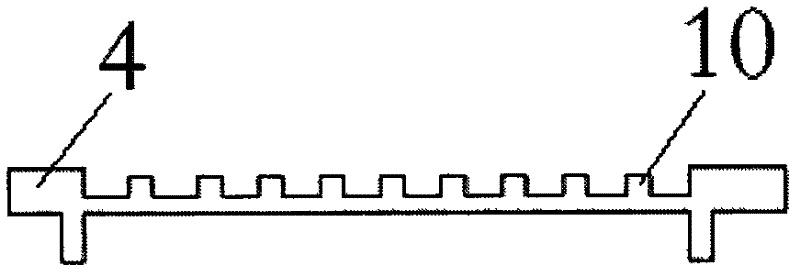

ActiveCN102363878ASimple processExtend heating timeChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention discloses a preheating device for a chemical vapor deposition furnace. Air flow plates which are arranged in parallel so as to increase air processes and prolong heating time, and beams are arranged simultaneously so as to improve heat radiation capacity; therefore, the aims of fully and uniformly preheating organic air can be fulfilled. An outlet is provided with disturbance holes which are positioned on the same circumference; and a certain included angle is formed between the axial direction of the disturbance holes and a horizontal plane; after preheated air enters the disturbance holes, the preheated air is forced to be sprayed along the axial direction of the disturbance holes to form strong rotation air flow under the collision action of disturbance walls, and organic air which is decomposed in advance forms macromolecules under the actions of centrifugal force and polymerization along with the rising of the rotation air flow; and the macromolecules preferentially enter the bottom of a stock column under the double actions of inertia force and centrifugal force, so axial back mixing probability is reduced, the macromolecules are diffused and deposited in a prefabrication body to achieve the effect of densifying the bottom, the air which is not decomposed rises continuously to ensure that top pressure and air pressure are reduced, and finally the aims of densifying the whole carbon disc stock column can be fulfilled.

Owner:XIAN AVIATION BRAKE TECH

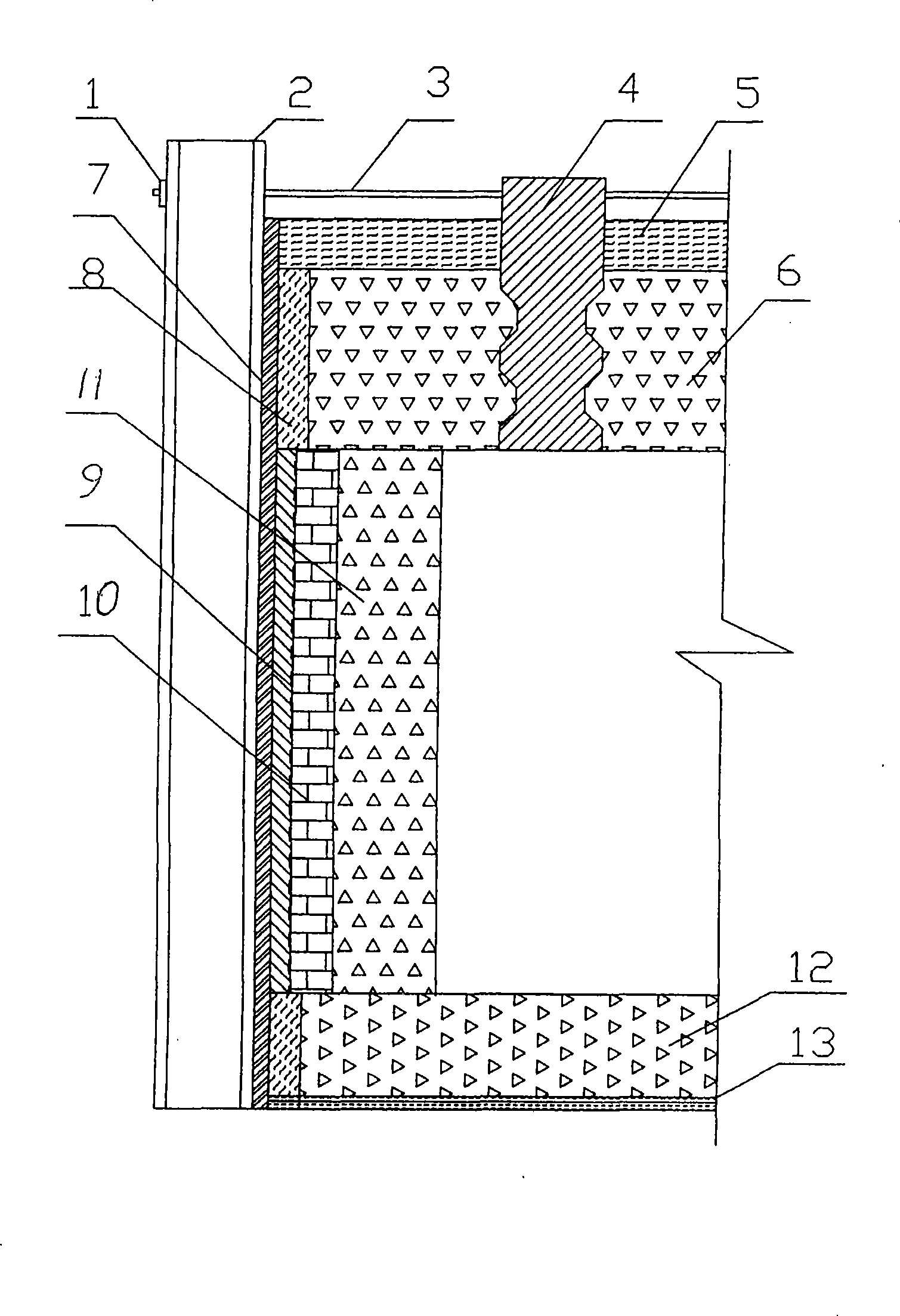

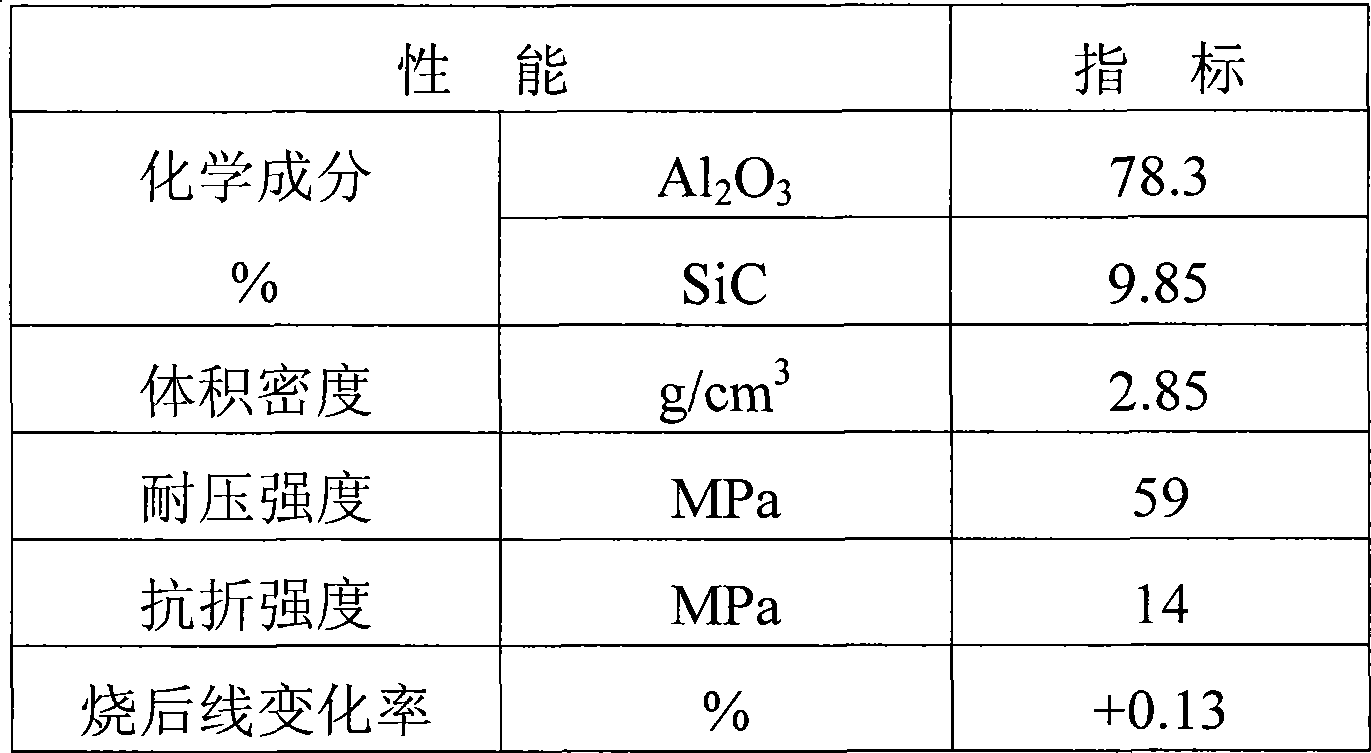

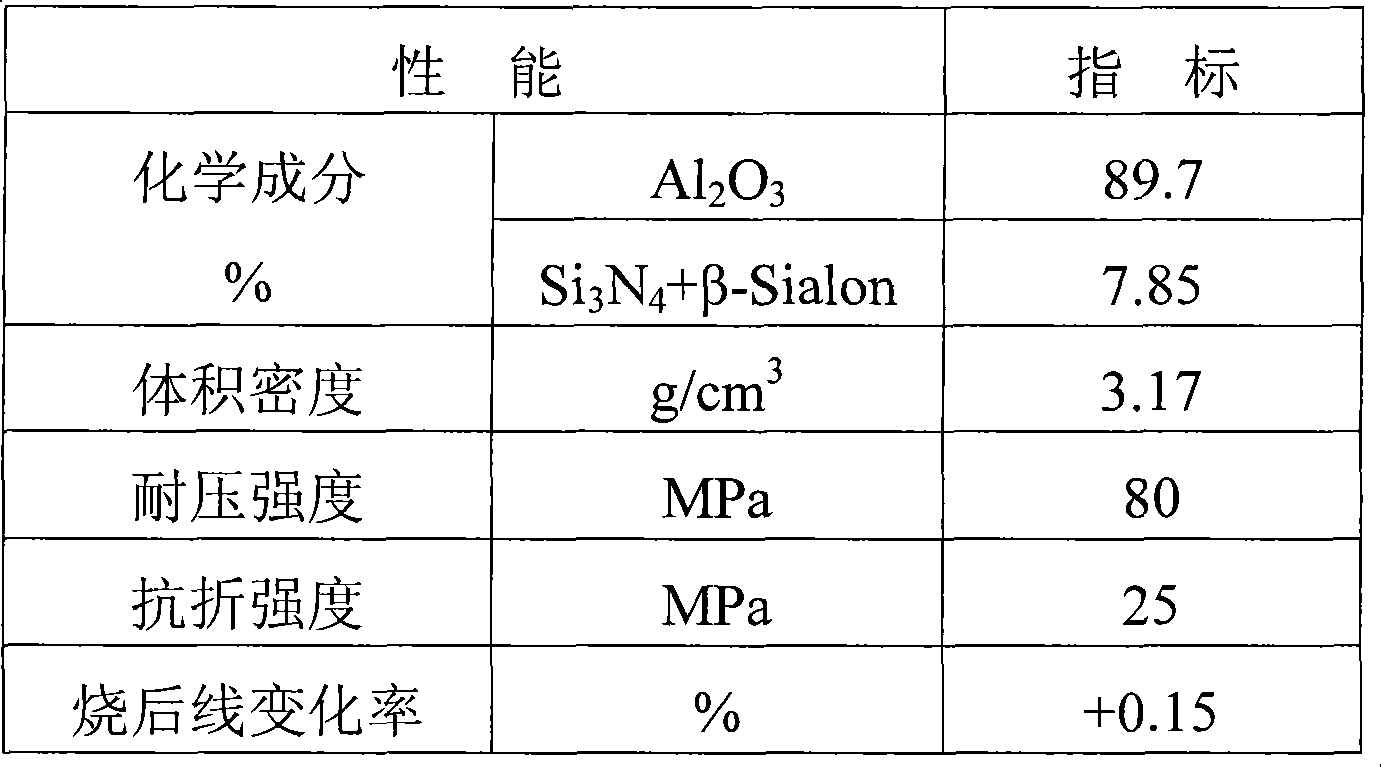

Aluminum melting furnace capable of improving service life and thermal efficiency

InactiveCN101413757AImprove heat radiation abilityGood energy saving effectMonolithic liningsHeating efficiencyThermal efficiency

An aluminum melting furnace capable of increasing service life and heat efficiency comprises a shell body and a lining layer covered on the inner wall of the shell body. The furnace is characterized in that work layers in the lining layer, namely the work layers of the furnace bottom, the furnace wall and the furnace top, are integrally cast from castable refractory and constructed; wherein, the furnace top is in a flattopping structure as well as the integral cast structure with hanging anchorage bricks, the furnace wall is in a composite structure belonging to a straight vertical surface structure. Being fully cast, the lining of the aluminum melting furnace has no seam, smooth surface, high integral strength, good air tightness and stable structure in use, and can greatly reduce radiation loss and improve the heat efficiency; with nonoxides used in the lining casting material, the material does not shrink, crack, aluminize, uneasily adhere with slag and is not eroded by aluminum alloy melt with high thermal shock stability in the state of smelting operation. Compared with the service life of a traditional brick structure, the service life is improved more than 3 times.

Owner:巩义市嘉丰耐火材料有限公司

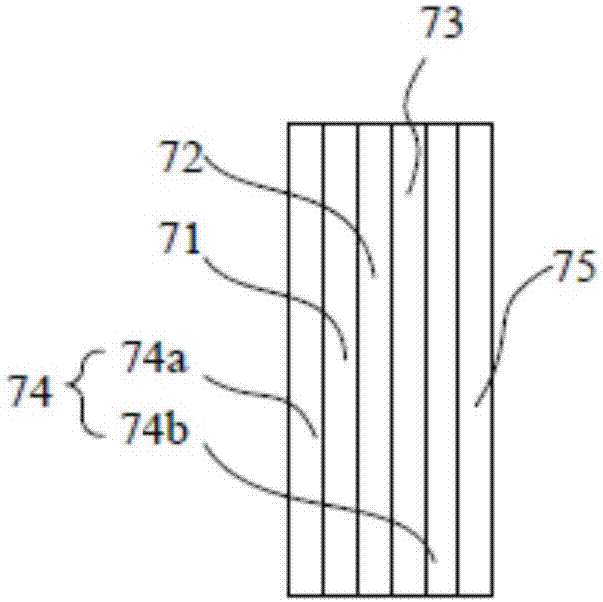

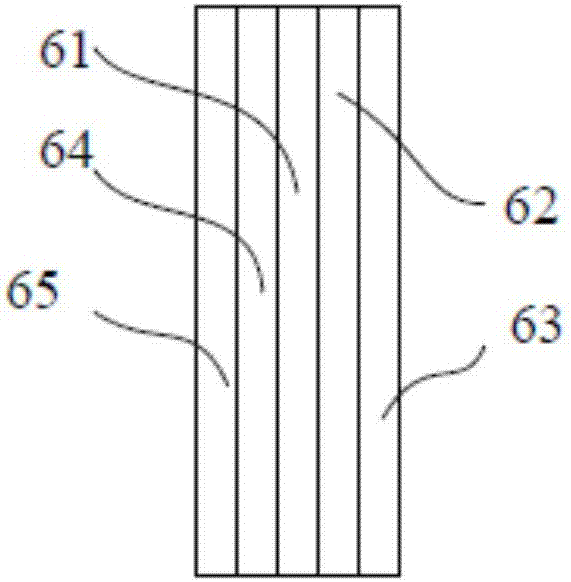

Mobile terminal

InactiveCN107249283AImprove cooling efficiencyReduce surface temperatureCooling/ventilation/heating modificationsSoftware engineeringThermal radiation

The invention discloses a mobile terminal. The mobile terminal comprises a display module, an intermediate frame, a printed circuit board (PCB) and a rear shell which are sequentially arranged in a lamination way, wherein a heat source piece is arranged between the intermediate frame and the PCB, an uniform heat radiation assembly is arranged between the PCB and the rear shell and is used for radiating heat generated by the heat source piece to the rear shell, the uniform heat radiation assembly has relatively high heat conduction capability and heat radiation capability, the heat generated by the heat source piece is transferred to the uniform heat radiation assembly and then is uniformly dissipated, meanwhile, the uniform heat radiation assembly can be used for effectively radiating the heat to the rear shell, so that the surface temperature of the mobile terminal is reduced, and the heat dissipation efficiency is improved.

Owner:TP-LINK

Environmentally-friendly coating

ActiveCN107312426AHarm reductionIncrease the ability to reflect sunlight and heat radiationAntifouling/underwater paintsPaints with biocidesEmulsionEnvironmentally friendly

The invention discloses an environmentally-friendly coating. The environmentally-friendly coating is prepared from the following components in parts by weight: 11 to 34 parts of resin emulsion, 6 to 22 parts of nano-ceramics, 12 to 19 parts of filler, 8 to 38 parts of pigments, 0.9 to 6 parts of adjuvants, 5 to 16 parts of auxiliary heat-insulating materials, 0.8 to 3 parts of lotus leaf hydrophobic agent, and 10 to 26 parts of deionized water. The environmentally-friendly coating disclosed by the invention has low damage to an environment and a human body, and has good heat insulation and self-cleaning effects.

Owner:广东恩贝得节能环保科技有限公司

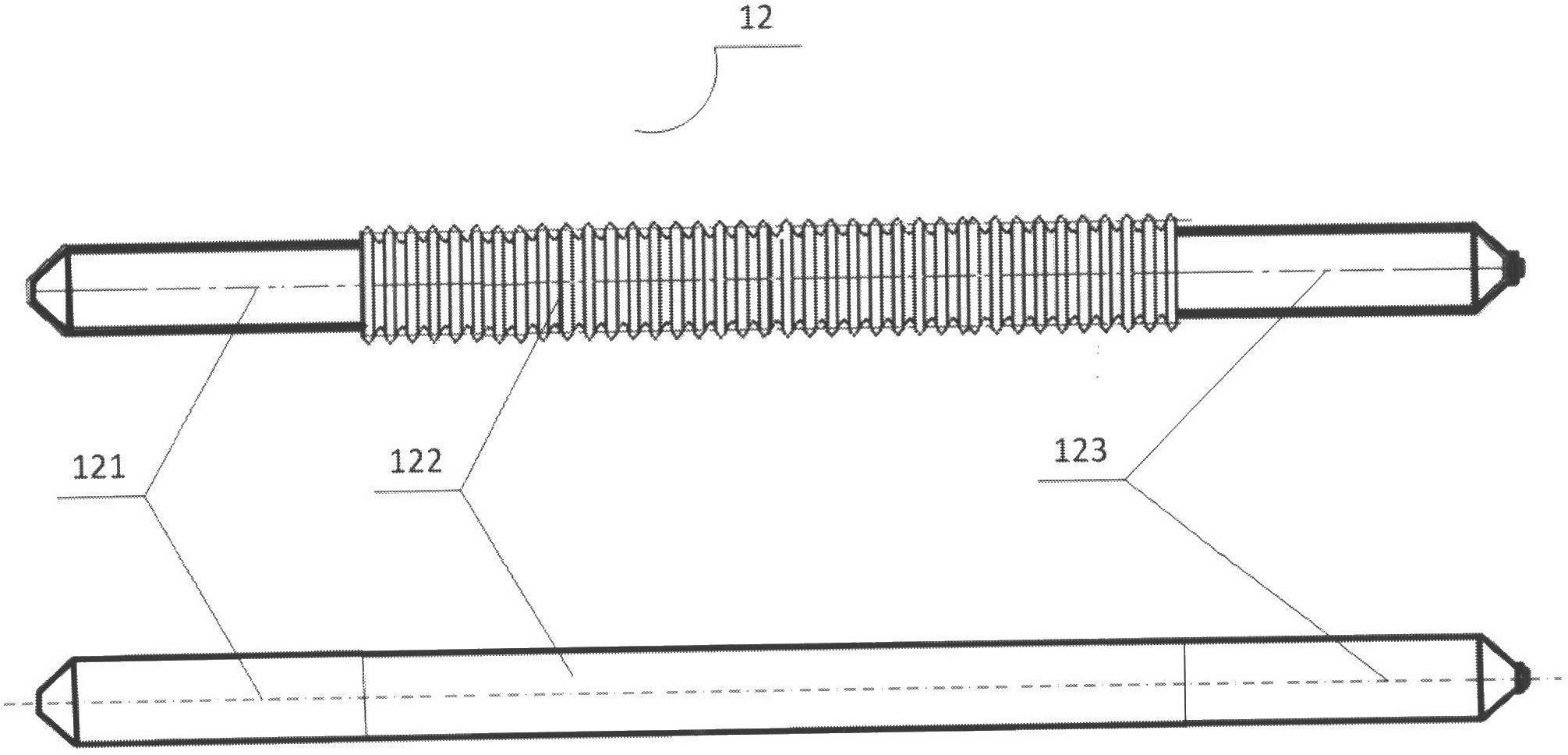

Low temp high radiation carbon fiber electrothermal radiation tube

InactiveCN1564636AHigh electrothermal conversion efficiencyImprove heat radiation abilityHot plates heating arrangementsHeating element shapesFiberCarbon fibers

The method is: its heating component is carbon fiber that is spiral wrap on the insulation framework, the joint is heat resisting steel joint having enclosed end; the heating component is blocked in the quartz capsule coated with infra red radiation paint, the quartz capsule is filled with high purity inert gases or is vacuum. The invention is specially applied in low temp baking and heating equipment.

Owner:SHANDONG UNIV

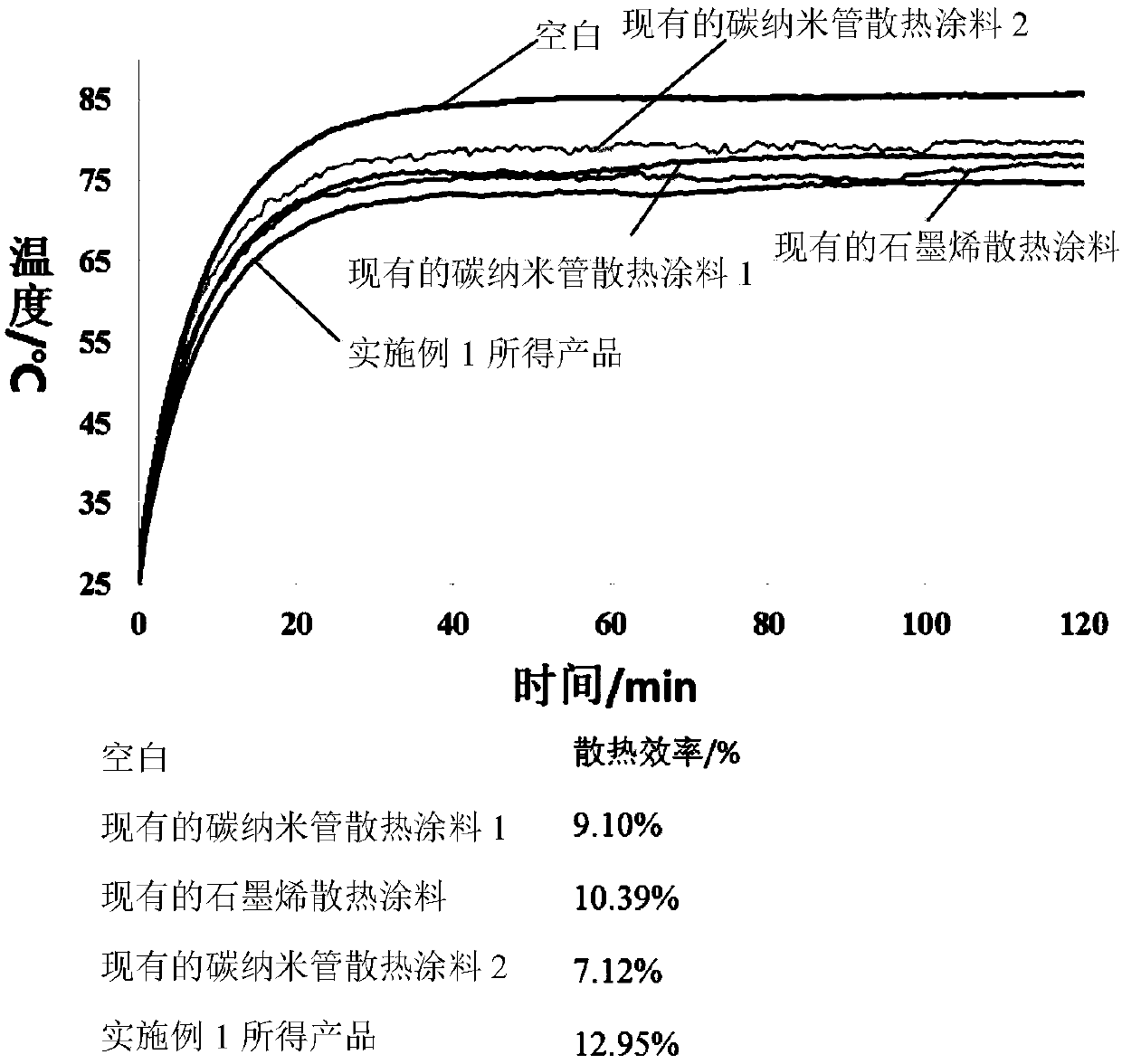

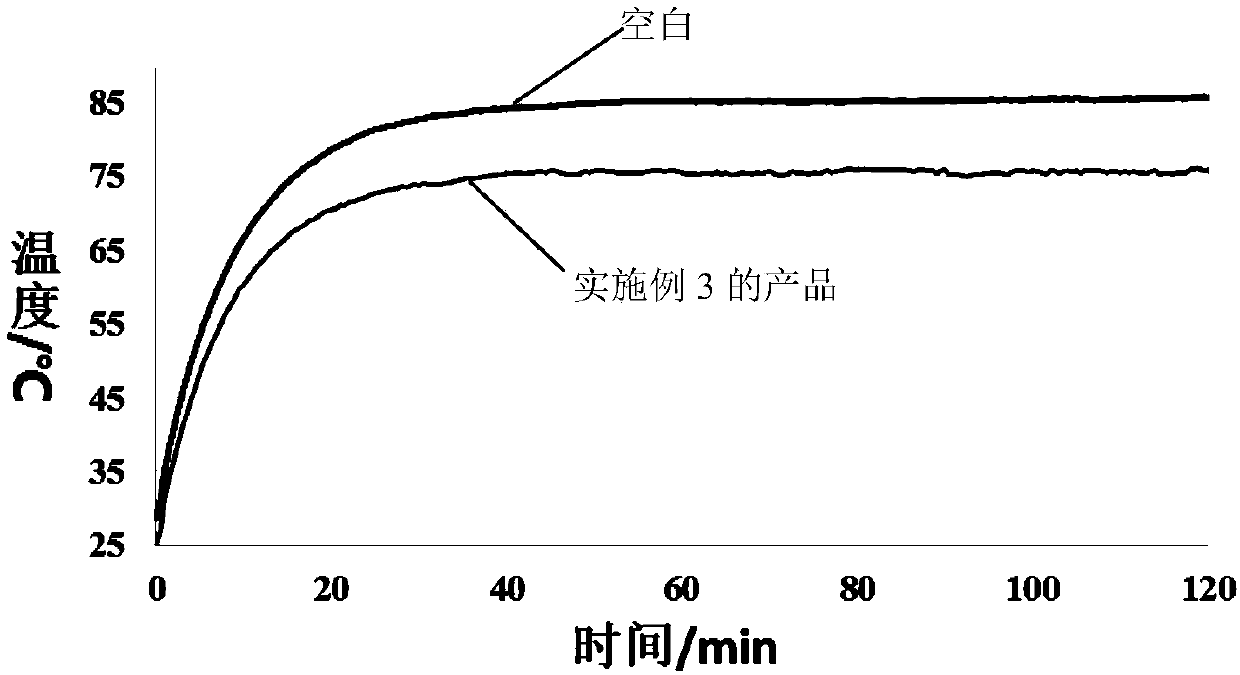

Functional nanometer heat dissipation coating and preparation method and application thereof

InactiveCN109627879AHigh thermal conductivityHigh emissivityAnti-corrosive paintsEpoxy resin coatingsWater solubleDefoaming Agents

The invention discloses a functional nanometer heat dissipation coating and a preparation method and application thereof. The functional nanometer heat dissipation coating is prepared from, by weight,20-60 parts of water soluble resin, 1-12 parts of a water soluble curing agent, 0.1-2 parts of a thickening agent, 40-70 parts of water, 0.1-0.5 part of a defoaming agent, 0.5-5 parts of a flatteningagent, 0.5-30 parts of auxiliaries and 0.5-5 parts of nanometer carbon materials. The heat dissipation coating contains various nanometer raw materials, when the coating is used for coating the surface of a heat dissipation device, the heat dissipation efficiency of the heat dissipation device can be greatly improved, the temperature of an electronic device is lowered, and therefore the service life of the electronic device is prolonged; meanwhile, the coating further has the functions of resisting corrosion, water, acid, soil, insulation and the like, no antiseptic and other treatment needsto be performed on the heat dissipation device, and the coating has the advantages of being environmentally friendly, safe, green and the like; the nanometer heat dissipation coating has the wide application prospect and the practical value in the field of electronic heat dissipation, and meanwhile the coating is simple in preparation technology, low in cost and suitable for large-scale production.

Owner:SUN YAT SEN UNIV

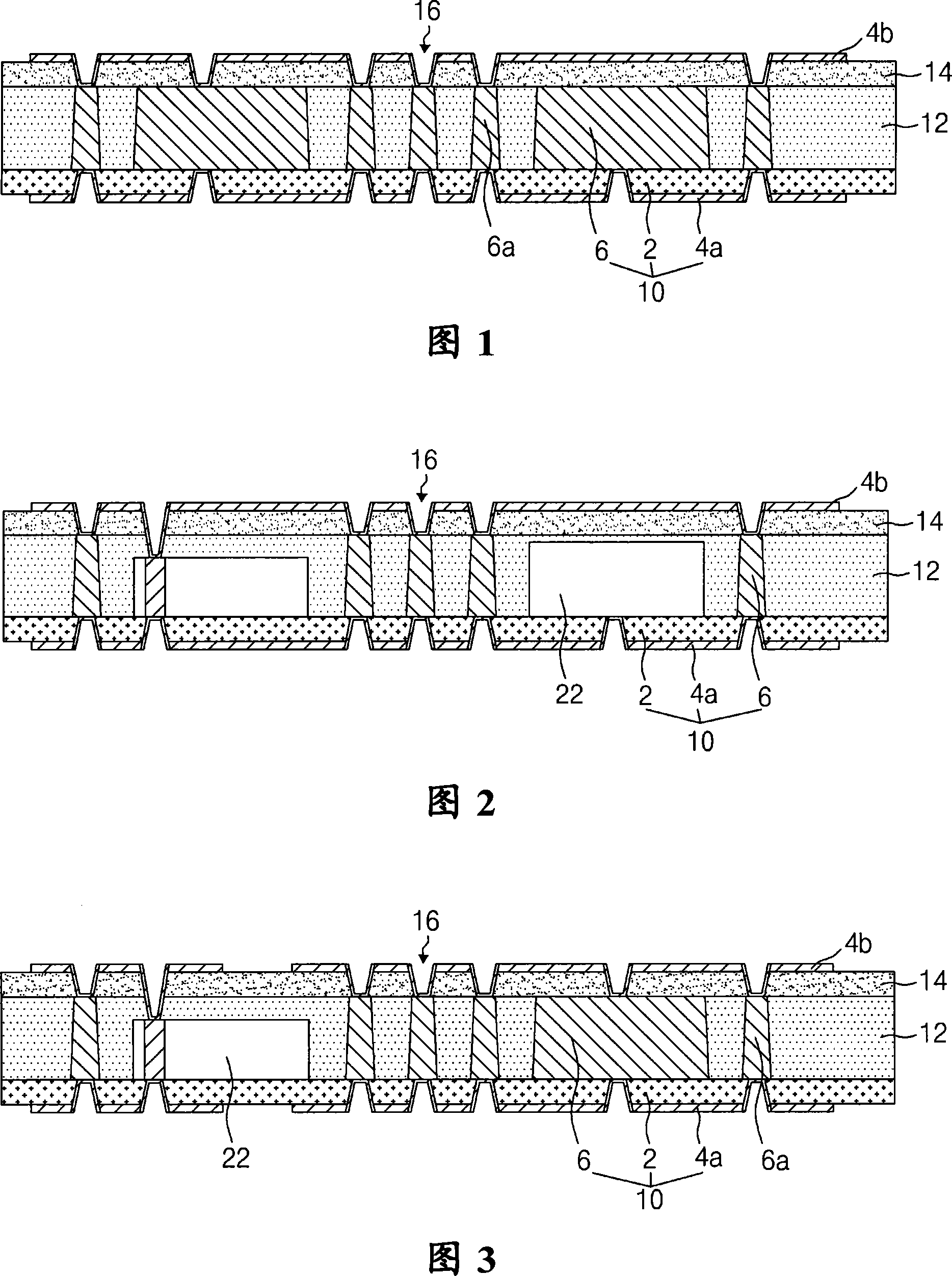

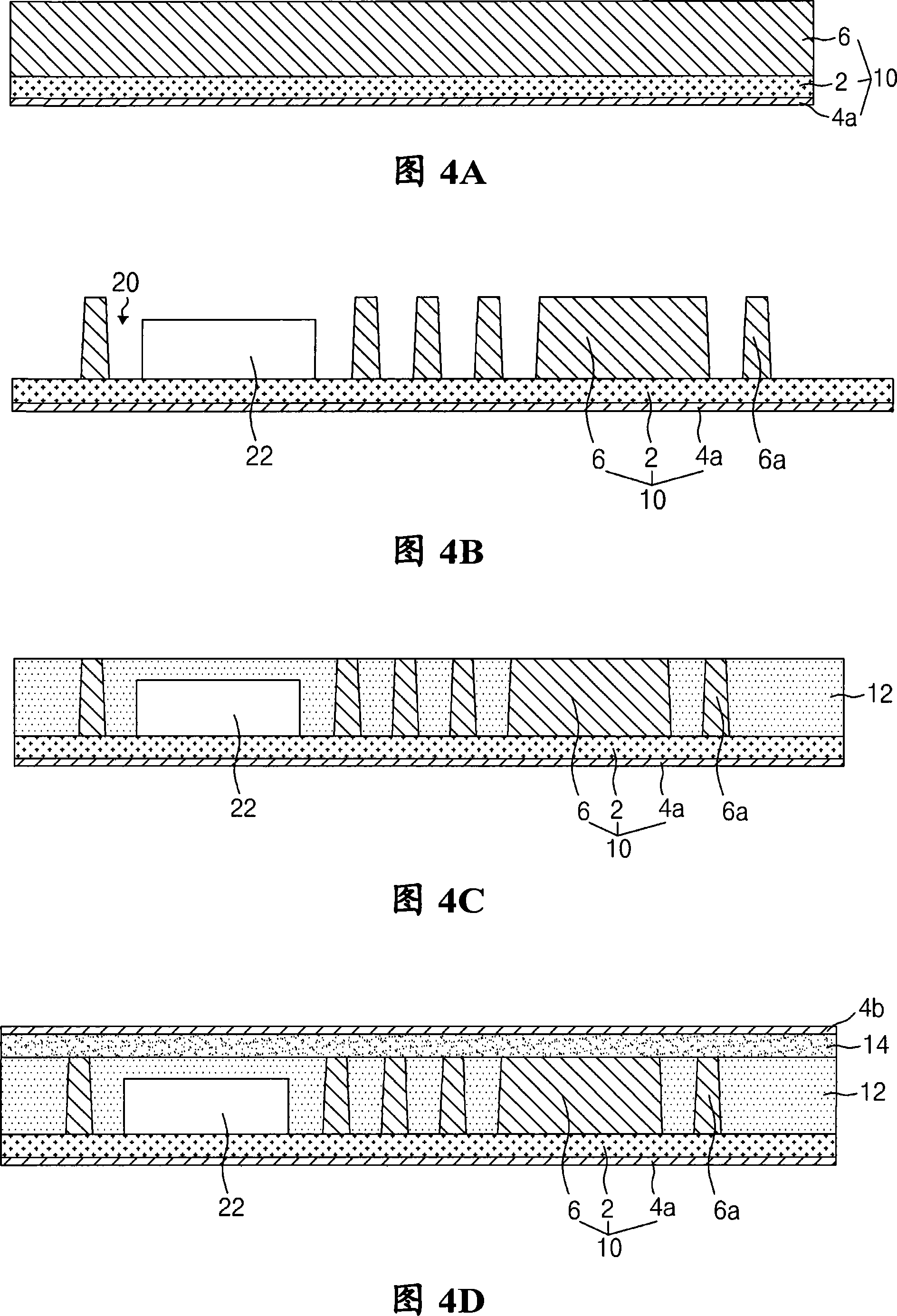

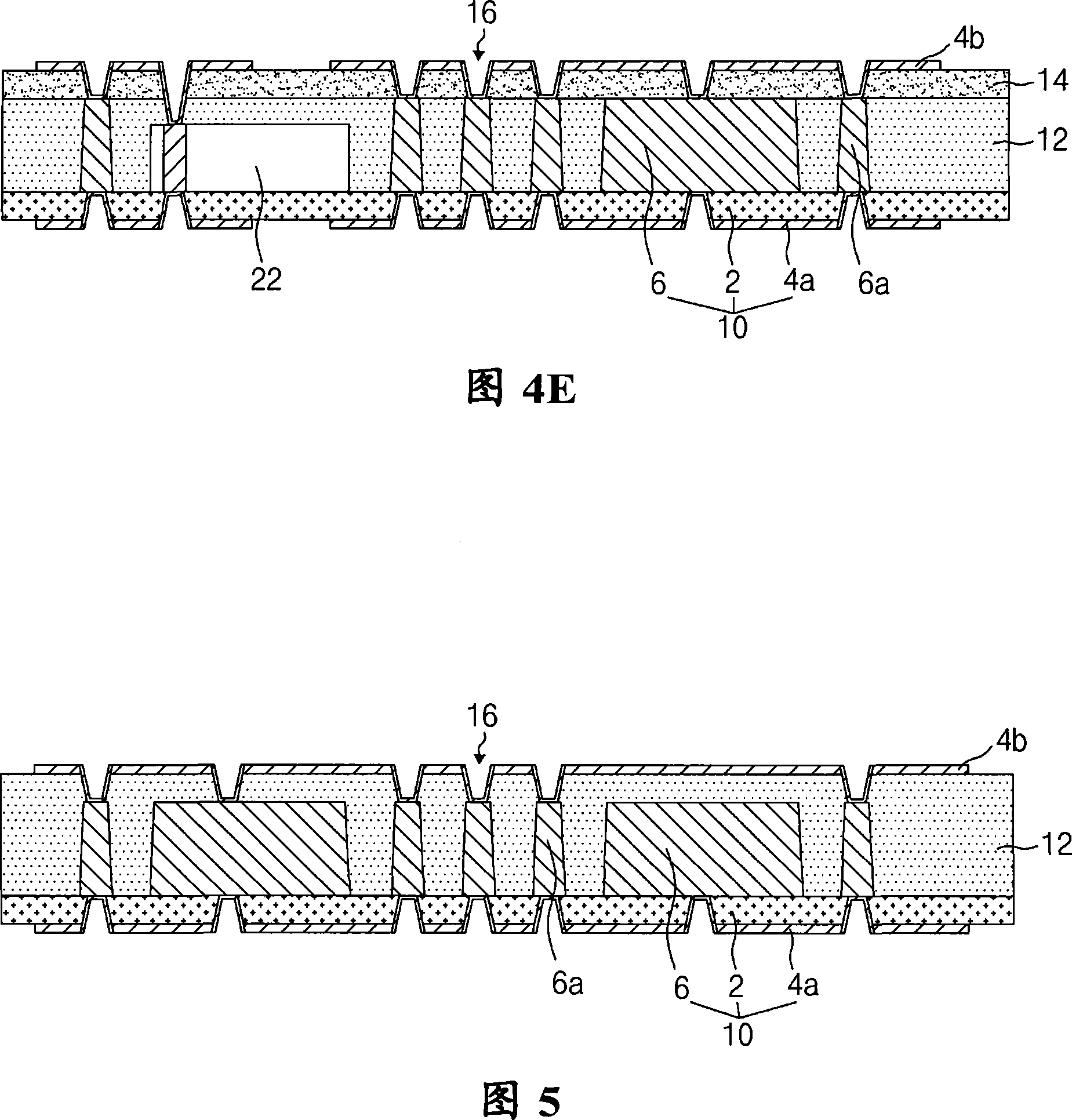

Printed circuit board and method of manufacturing the same

InactiveCN101098584AReduce processing costsReduce processing timeSemiconductor/solid-state device detailsPrinted circuit aspectsHeat resistanceThermal radiation

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Multilayer single-face aluminum-based circuit board and manufacturing method thereof

InactiveCN102448251AImprove thermal conductivityImprove adhesionSynthetic resin layered productsPrinted circuit manufactureGlass fiberEpoxy

The invention relates to a multilayer single-face aluminum-based circuit board, which is characterized by being manufactured by using a method comprising the following steps of: (1) preparing an epoxy resin glue solution; (2) preparing nanometer inorganic composite filler; (3) preparing a high-heat-conduction insulated adhesive solution; (4) soaking glass fiber cloth in the high-heat-conduction insulated adhesive solution and drying to obtain prepregs; and (5) manufacturing the multilayer single-face aluminum-based circuit board: respectively manufacturing an inner layer board and an outer layer board from a plurality of prepregs manufactured in the step (4) and copper foils and aluminum plates according to a conventional general method, and laminating and pressing to obtain the multilayer single-face aluminum-based circuit board. The multilayer single-face aluminum-based circuit board has a favorable heat dissipation effect; when the weight part ratio of epoxy resin to the nanometer inorganic composite filler is 100: 45, the heat conduction effect of the insulated bonding layer is optimal; the nanometer inorganic filler is filled in the epoxy region adhesive instead of the common filler, the heat conduction effect of the insulated bonding layer is greatly promoted.

Owner:秦会斌

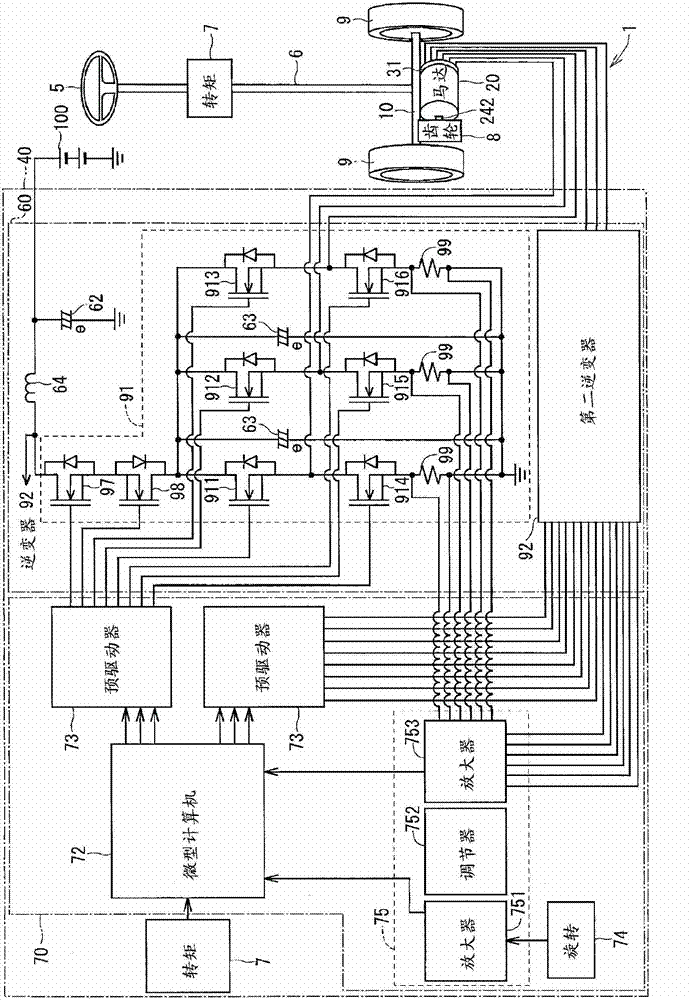

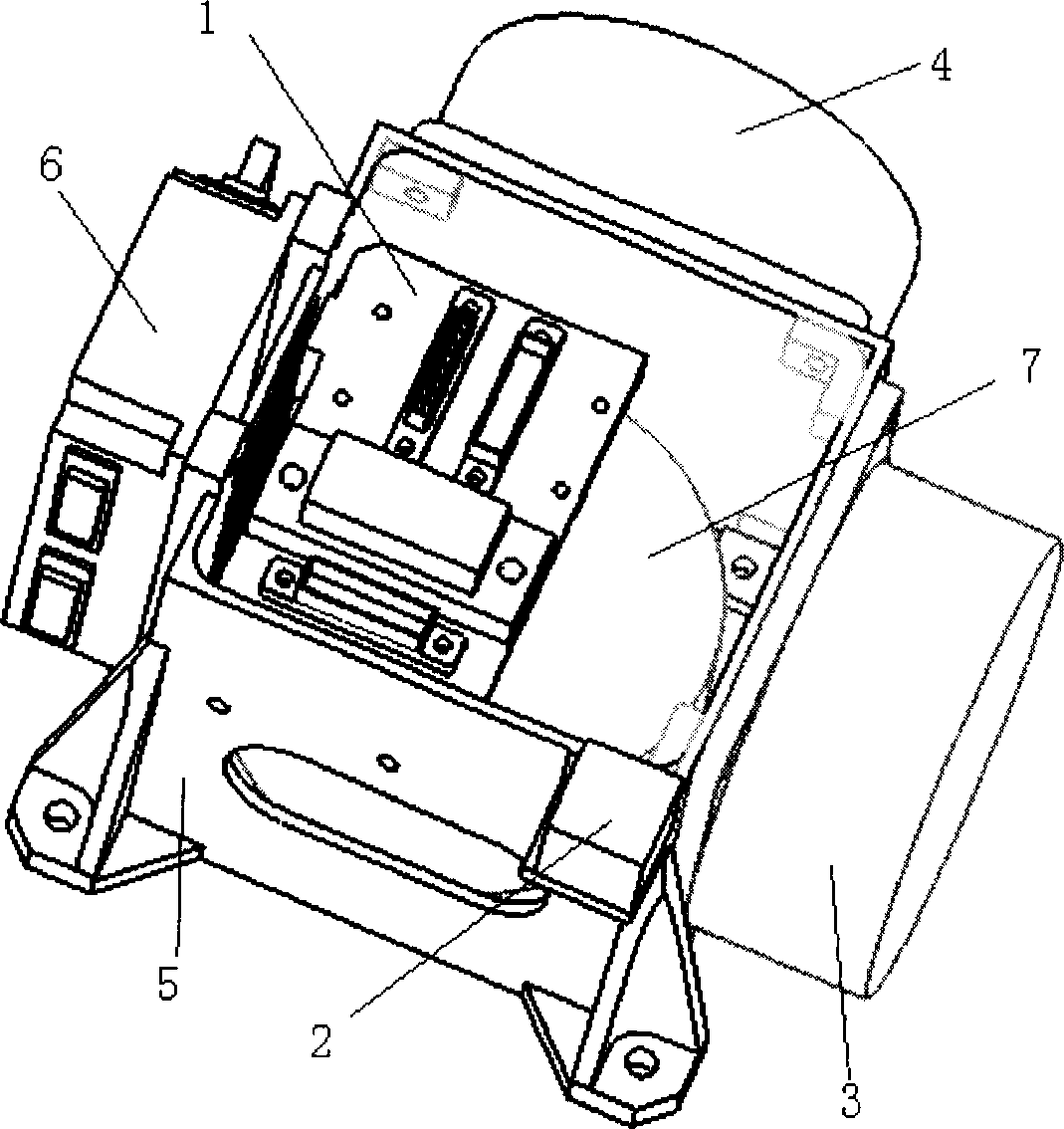

Motor drive apparatus

ActiveCN103368334ASmall sizeIncrease contact areaAssociation with control/drive circuitsCooling/ventillation arrangementMotor driveHeat sink

A motor drive apparatus includes a motor having a shaft, an end frame, and a control unit having a heat sink. The end fame and the heat sink are arranged to overlap at least partly when the end frame and the heat sink are projected on a plane, which is parallel with a rotation axis of the shaft. This arrangement improves heat radiation performance of the motor drive apparatus.

Owner:DENSO CORP +1

Electric heating tube

InactiveCN104010394AImprove heat transfer performanceImprove heat radiation abilityOhmic-resistance waterproof/air-tight sealsHeating element shapesEngineeringFar infrared

The invention discloses an electric heating tube which comprises a tubular shell, end sockets, a resistance wire and crystal magnesia powder. The end sockets are arranged on the two sides of the shell and used for sealing the ends of the shell, the resistance wire is arranged in the shell and used for heating, the crystal magnesia powder is arranged in the gap of the shell and the resistance wire to be used for heat conduction and insulation, and the outer surface of the shell is provided with an antirust coating. The electric heating tube is characterized in that a far-infrared radiating coating is arranged on the outer surface of the antirust coating, a waterproof layer is arranged on the connecting portion of a sealing opening and the shell, and a quartz sand layer is further sprayed between the antirust coating and the far-infrared radiating coating. The electric heating tube has the advantages of being reasonable in structure, good in using effect and long in service life.

Owner:TAIZHOU MAHENGDA MACHINERY

High temperature far infrared insulated energy-saving paint and method for preparing same

ActiveCN100381516CImprove general performanceImprove energy savingCellulose coatingsSoluble glassRare earth

The invention provides a high temperature far infrared insulation energy-saving coating material and its preparing process, wherein the coating material comprises zircon sand, aluminium oxide, porcelain clay, rare-earth oxide, boron nitride, silicasol, phosphoric acid, soluble glass, cellulose methyl or cellulose glycolate. The preparing process consists of batching, immersing, agitating, mixing, filtering and loading.

Owner:娄底市华晟节能材料有限公司

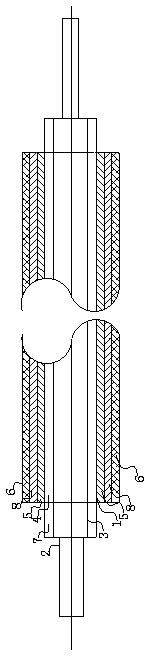

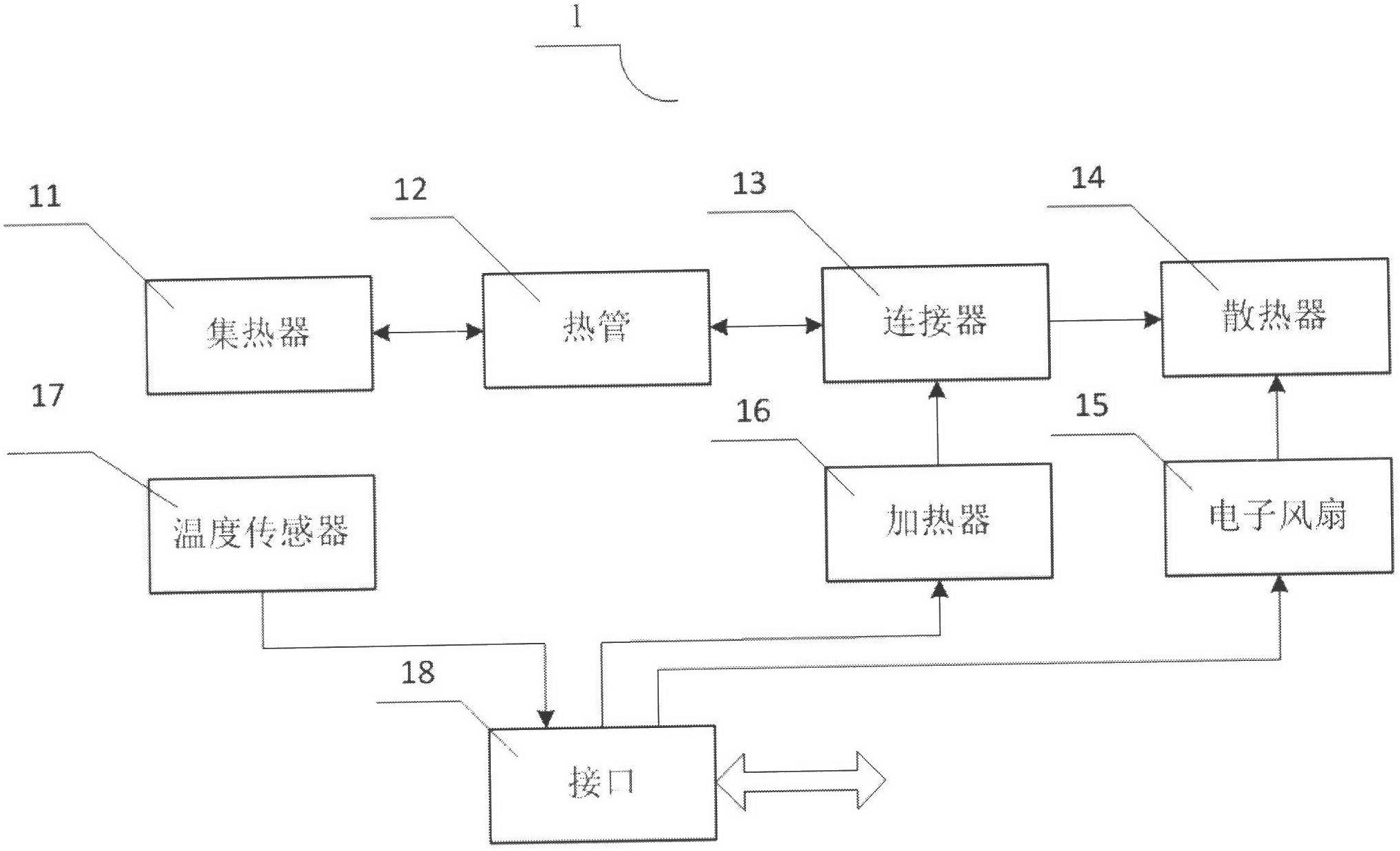

Low-carbon and environment-friendly distributed cooling system for engine and heat management method

InactiveCN102678253AImprove heat radiation abilityReduce speedAir-treating devicesCoolant flow controlHeat managementCollector device

The invention discloses a low-carbon and environment-friendly distributed cooling system for an engine and a heat management method. The low-carbon and environment-friendly distributed cooling system for the engine comprises a plurality of sets of distributed cooling devices, a compartment heating device, a bus and an electronic control unit, wherein the distributed cooling devices are respectively used for cooling a cylinder cover, a cylinder body, pressurized air and an oilpan of the engine, and the compartment heating device is used for heating a compartment. Each set of distributed cooling device comprises a heat collector, one or more heat pipes, a connector, a heat radiator, an electronic fan, a heater, a temperature sensor and an interface; in the cold starting stage of the engine, the electronic fan is closed by an electronic control unit, the heater is started, and the cooled parts are preheated by utilizing the two-way heat-transfer characters of the heat pipes, so that the time consumed for cold starting is shortened, and the engine is enabled to rapidly enter a working state; and after the engine normally runs, the heater is closed by the electronic control unit, and the electronic fan is started, so that the distributed cooling devices are changed into a cooling working state. The low-carbon and environment-friendly distributed cooling system is particularly suitable for military or para-military application occasions requiring high response speed and high reliability.

Owner:SHANGHAI ZHONGFANG BAODA TEXTILE INTELLIGENT INSTR +2

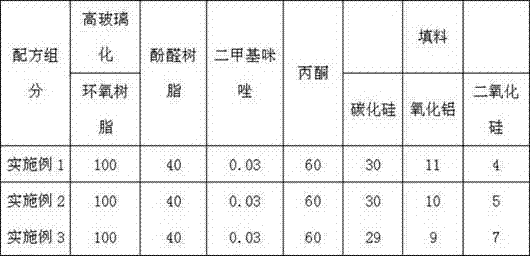

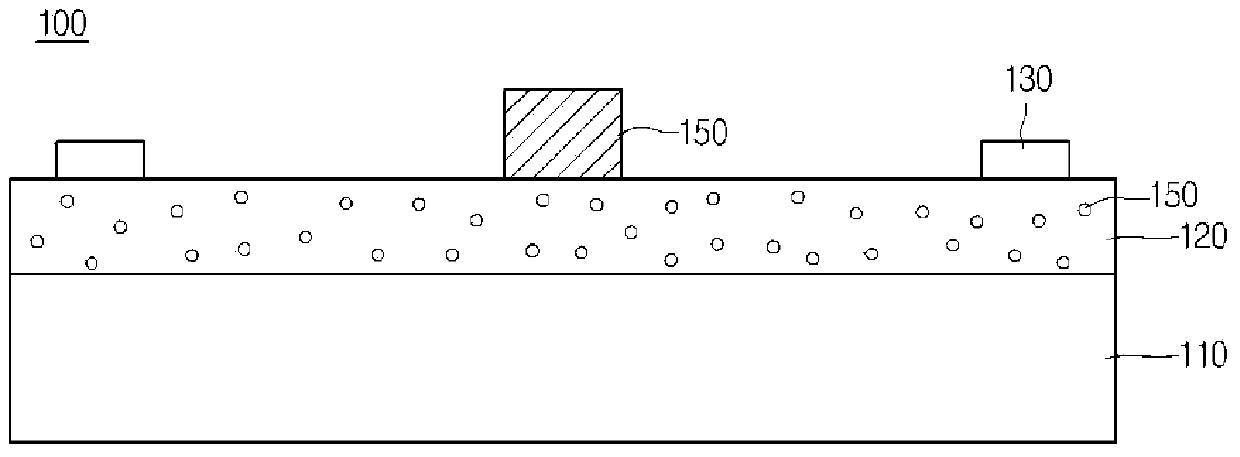

Epoxy resin compound and radiant heat circuit board using the same

ActiveCN103827205AImprove thermal conductivityImprove heat radiation abilityCircuit susbtrate materialsCooling/ventilation/heating modificationsEpoxyRadiant heat

Disclosed are an epoxy resin compound and a radiant heat circuit board using the same. The epoxy resin compound mainly includes an epoxy resin, a curing agent, and an inorganic filler. The epoxy resin includes a crystalline epoxy resin and a rubber additive to disperse the inorganic filler into the epoxy resin. The epoxy resin is used on a printed circuit board as an insulating material, so that a substrate having a high heat radiation property is provided.

Owner:LG INNOTEK CO LTD

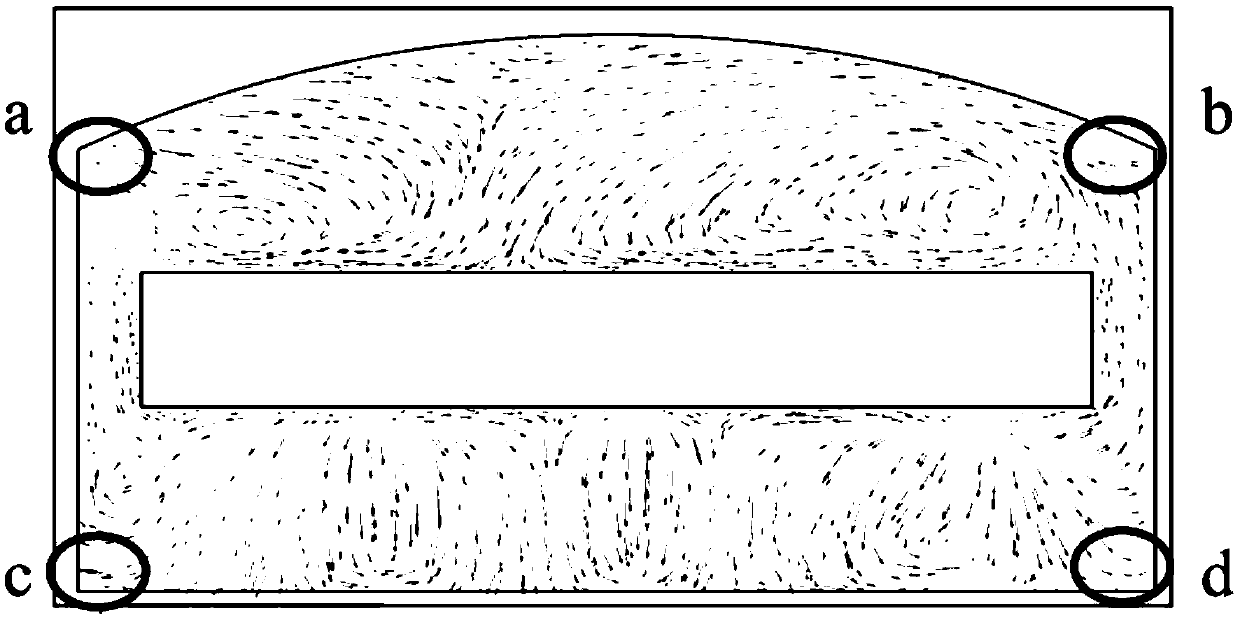

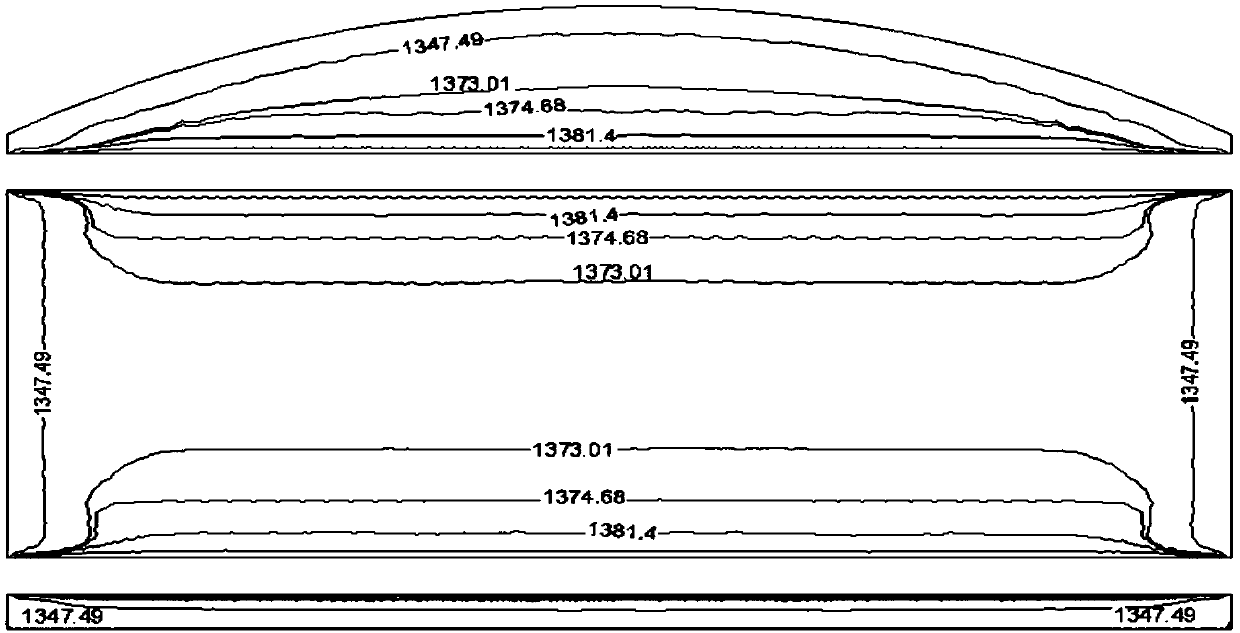

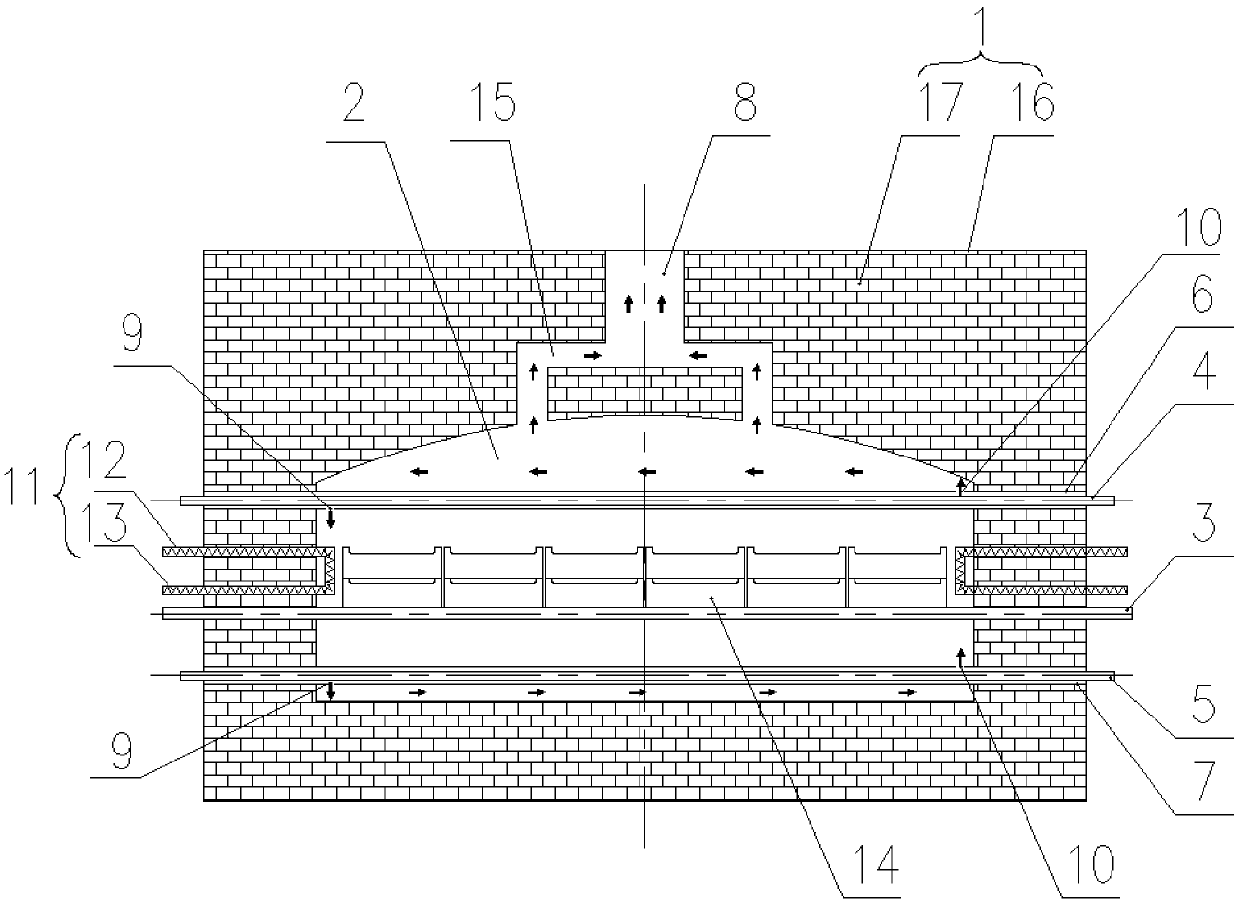

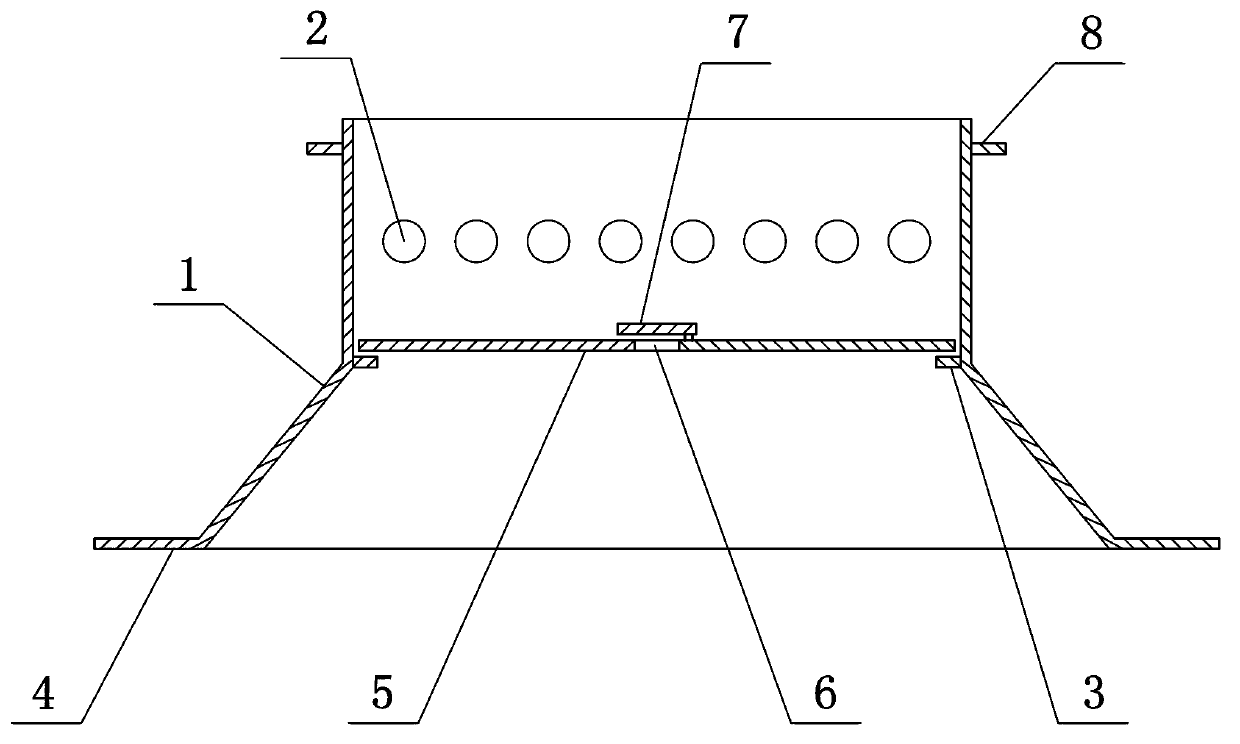

Roller way sintering furnace with uniform hearth temperature

The invention discloses a roller way sintering furnace with uniform hearth temperature. The roller way sintering furnace comprises a furnace body and a hearth, wherein a transmission roller way, an upper heating element and a lower heating element are arranged in the hearth, the upper heating element and the lower heating element are arranged above and below the transmission roller way correspondingly, the upper heating element is correspondingly provided with an upper protective sleeve, the lower heating element is correspondingly provided with a lower protective sleeve, and the top of the furnace body is provided with an exhaust port. One end of the upper protective sleeve is provided with at least one first air inlet hole, the other end of the upper protective sleeve is provided with atleast one second air inlet hole, one end of the lower protective sleeve is provided with at least one first air inlet hole, the other end of the lower protective sleeve is provided with at least onesecond air inlet hole, the first air inlet holes are the same in size and orientation, the second air inlets are the same in size and orientation, the orientations of the first air inlet holes are opposite to the orientations of the second air inlet holes, and the orientations are all located in the vertical face of the hearth. Uniformity of the flow field and the temperature inside the hearth canbe improved, and the comprehensive performance of sintered products is ensured.

Owner:湖南烁科热工智能装备有限公司

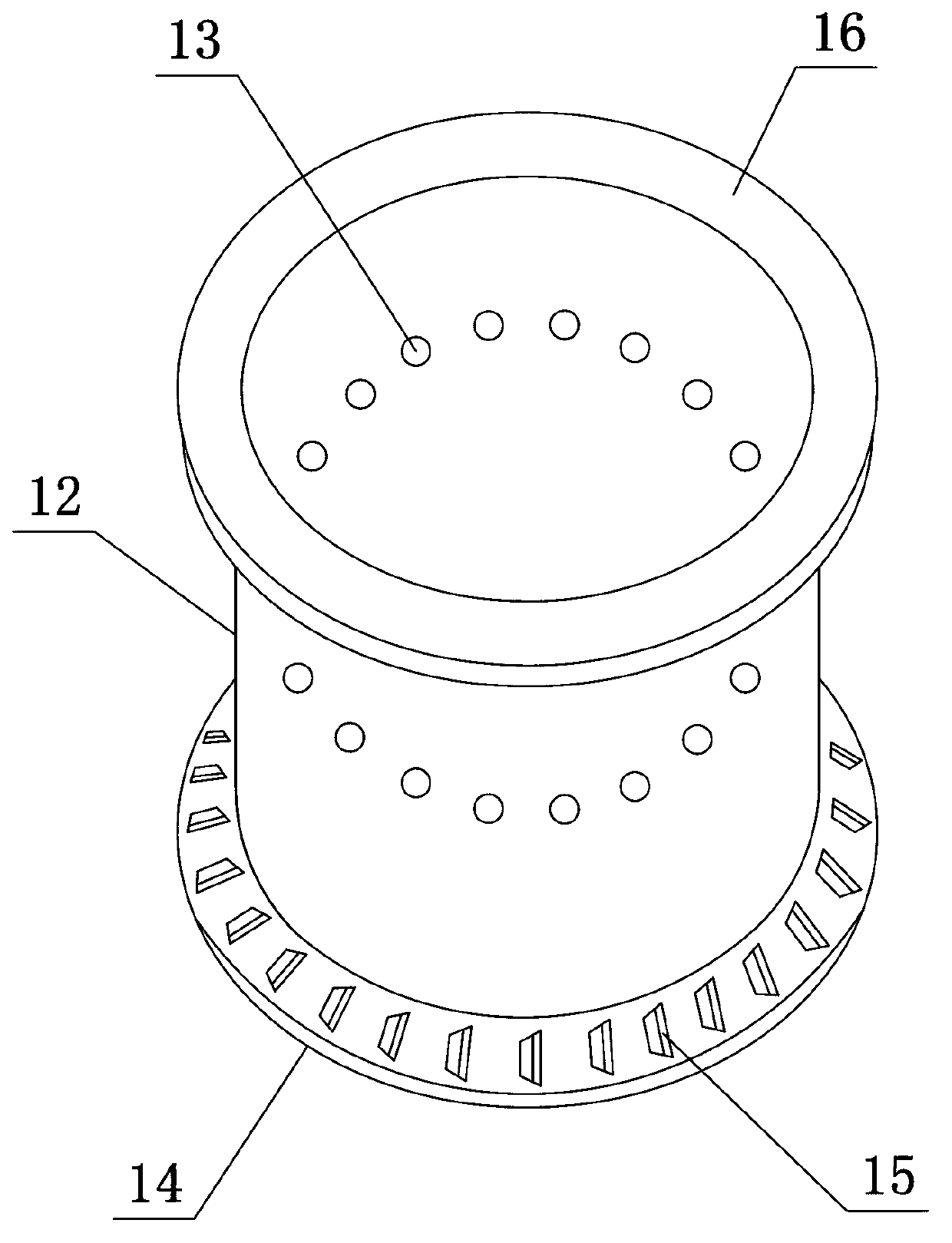

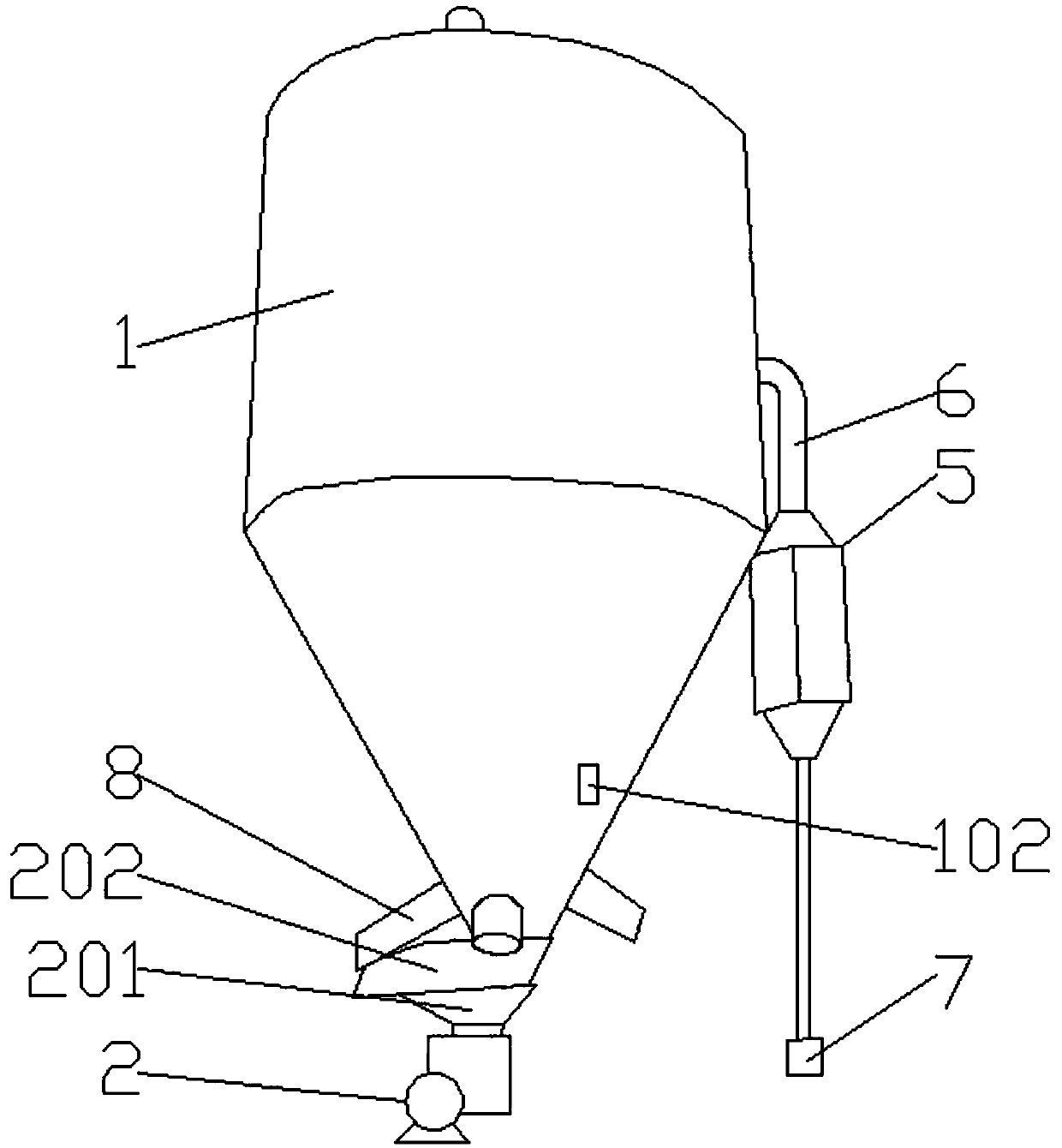

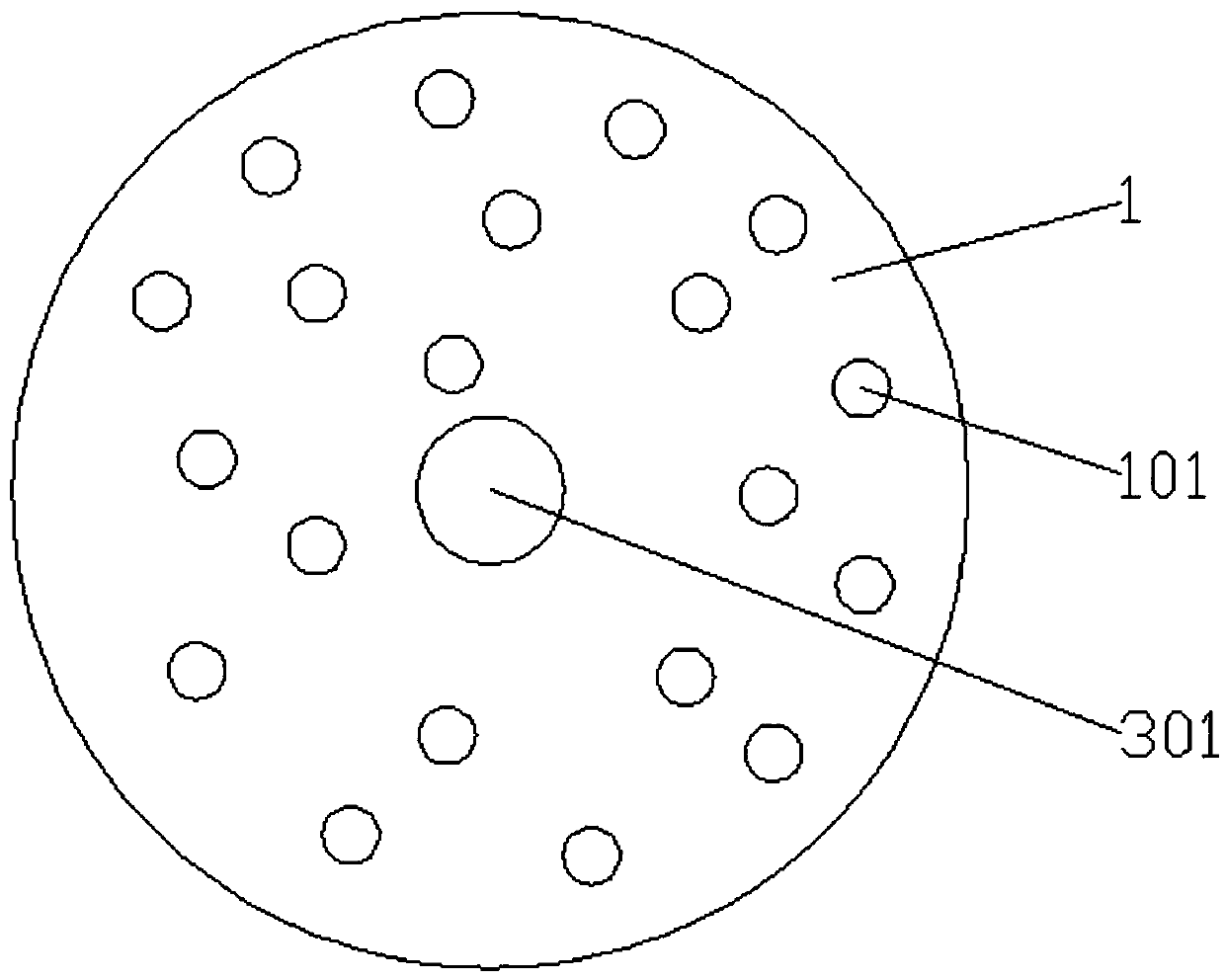

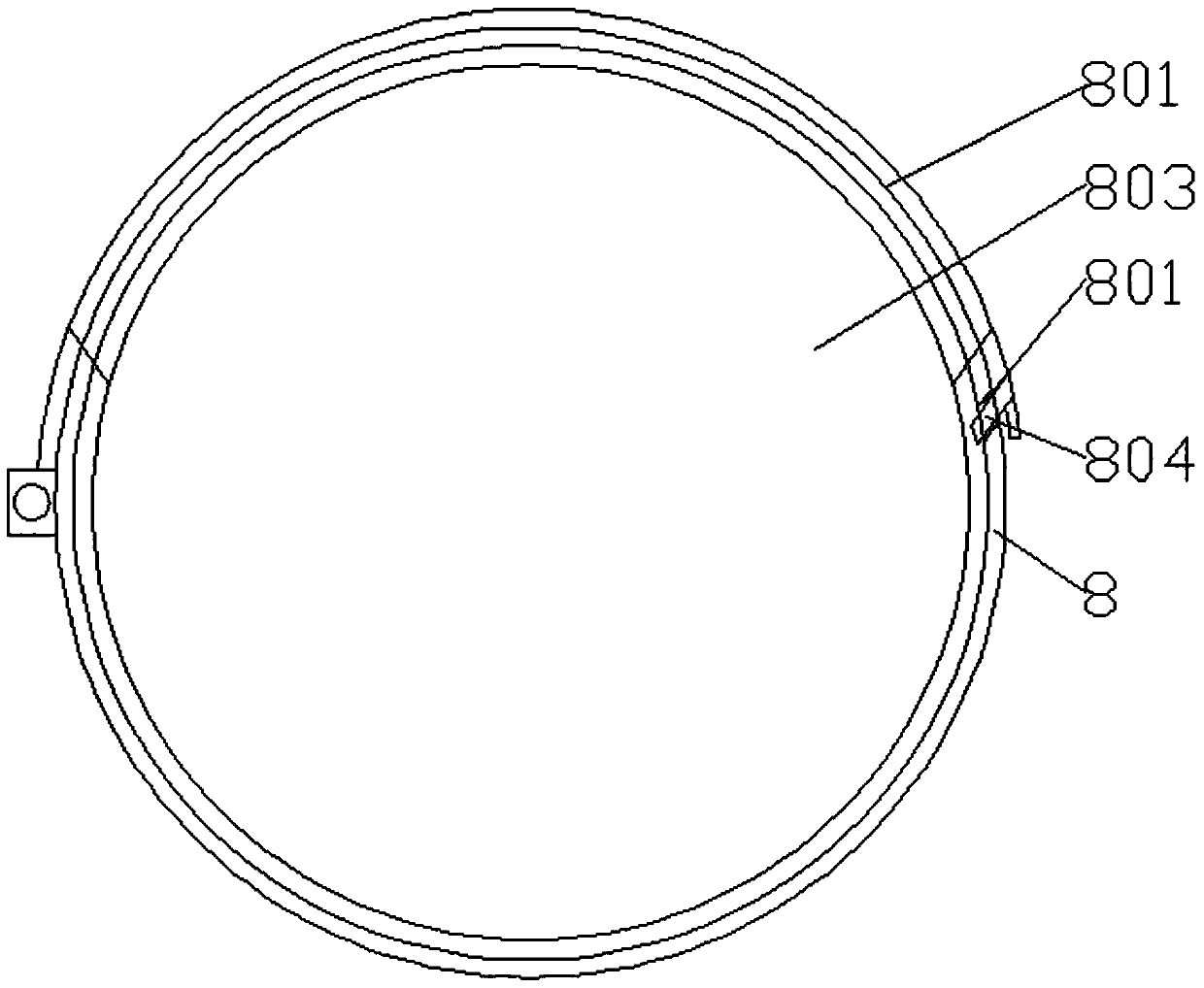

Gasification combustor of solid fuel cooking range

ActiveCN103123109ABurn fullyEasy to igniteSolid fuel combustionCombustion apparatusCombustorSolid fuel

The invention provides a gasification combustor of a solid fuel cooking range which comprises a first core body and a movable whirlwind combustion-supporting device. A plurality of air-in and gasification combustion-supporting holes are arranged on the first core body, a fire-sealing cover baffle plate is arranged on the inner wall of the first core body, and when an air blower is used for compulsorily supporting air for combustion supporting, the movable whirlwind combustion-supporting device is arranged on the fire-sealing cover baffle plate in the first core body. The movable whirlwind combustion-supporting device comprises a second core body, a top wall and a bottom wall, wherein the top wall is arranged on the upper portion of the second core body, and the bottom wall is arranged on the lower portion of the second core body. A plurality of second air-in and gasification combustion-supporting holes are arranged on the periphery of the second core body, and the bottom wall of the second core body is provided with a plurality of third air-in and gasification combustion-supporting holes which are coincident in slant directions. A cold furnace is easy to fire up and fast to inflame; flame rotates for combustion; and heat power is strong. The gasification combustor saves energy and is environment-friendly; and when fire is sealed, the movable whirlwind combustion-supporting holes are taken out, and the movable fire-sealing cover is arranged on the fire-sealing cover baffle plate to seal the fire. The gasification combustor is applicable to a boiler or a hot blast stove with solid fuel combusted, and use of combustion equipment with any structure such as the cooking range in a matched mode.

Owner:陕西华能恒大科技有限公司 +1

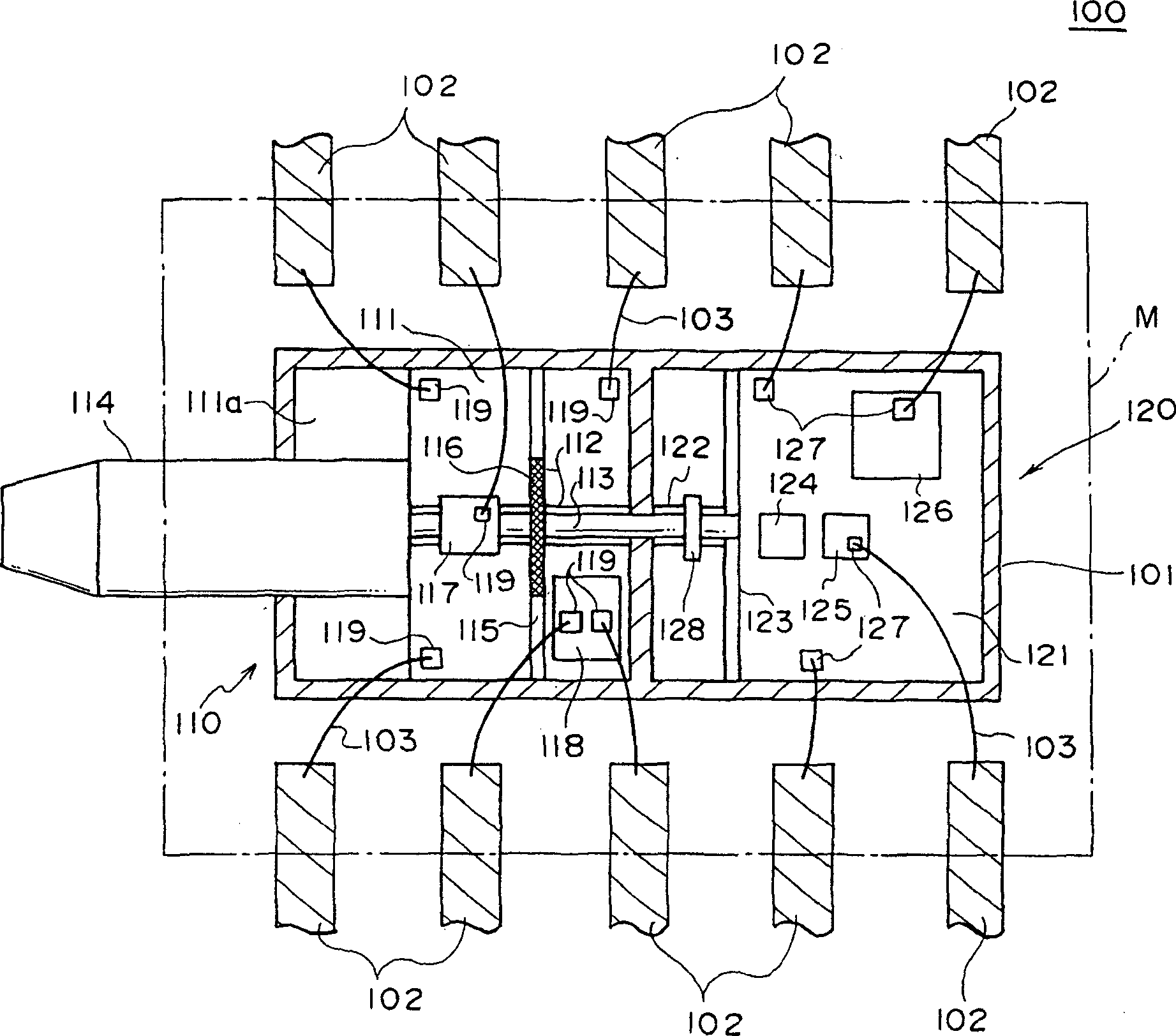

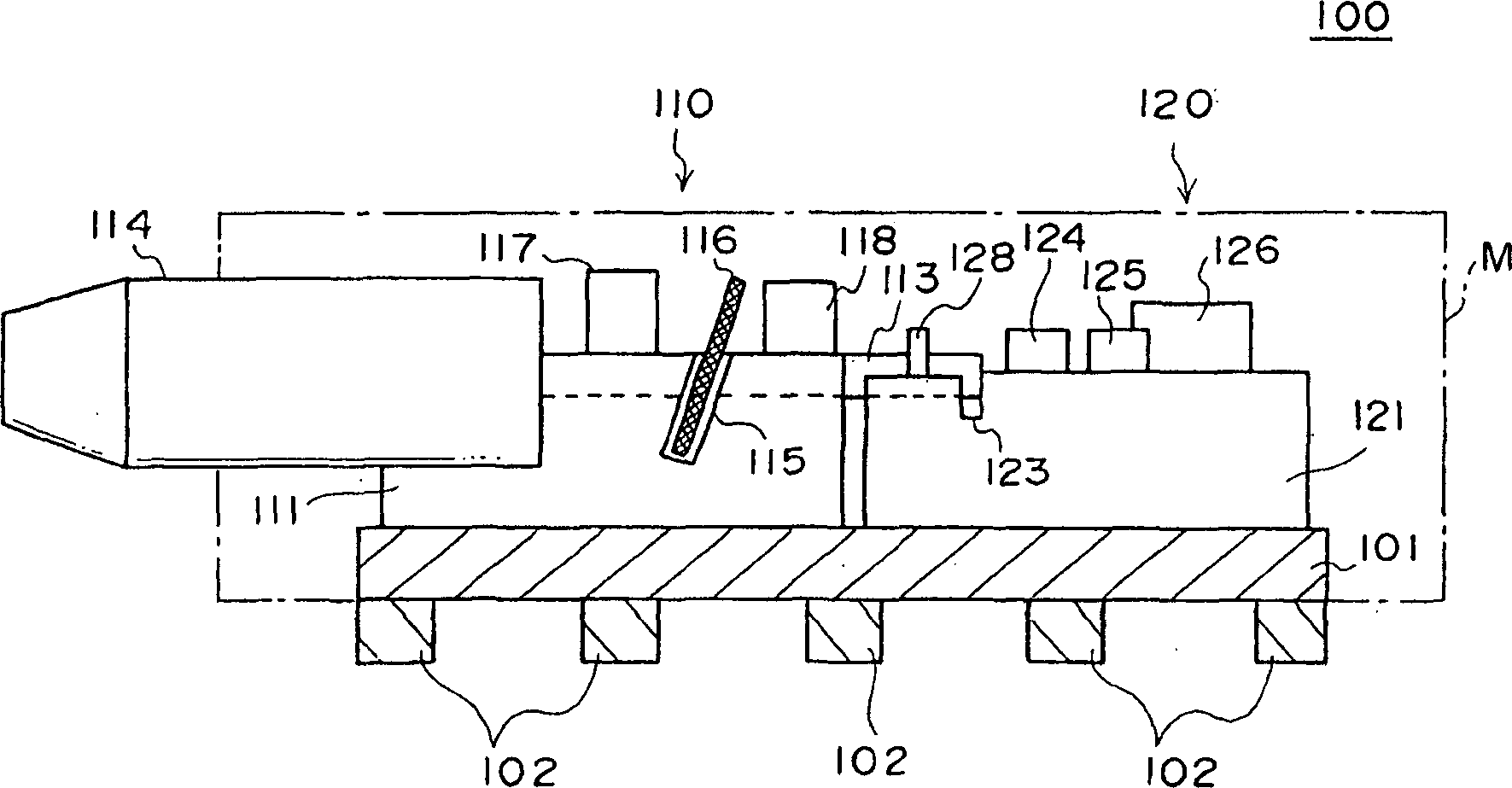

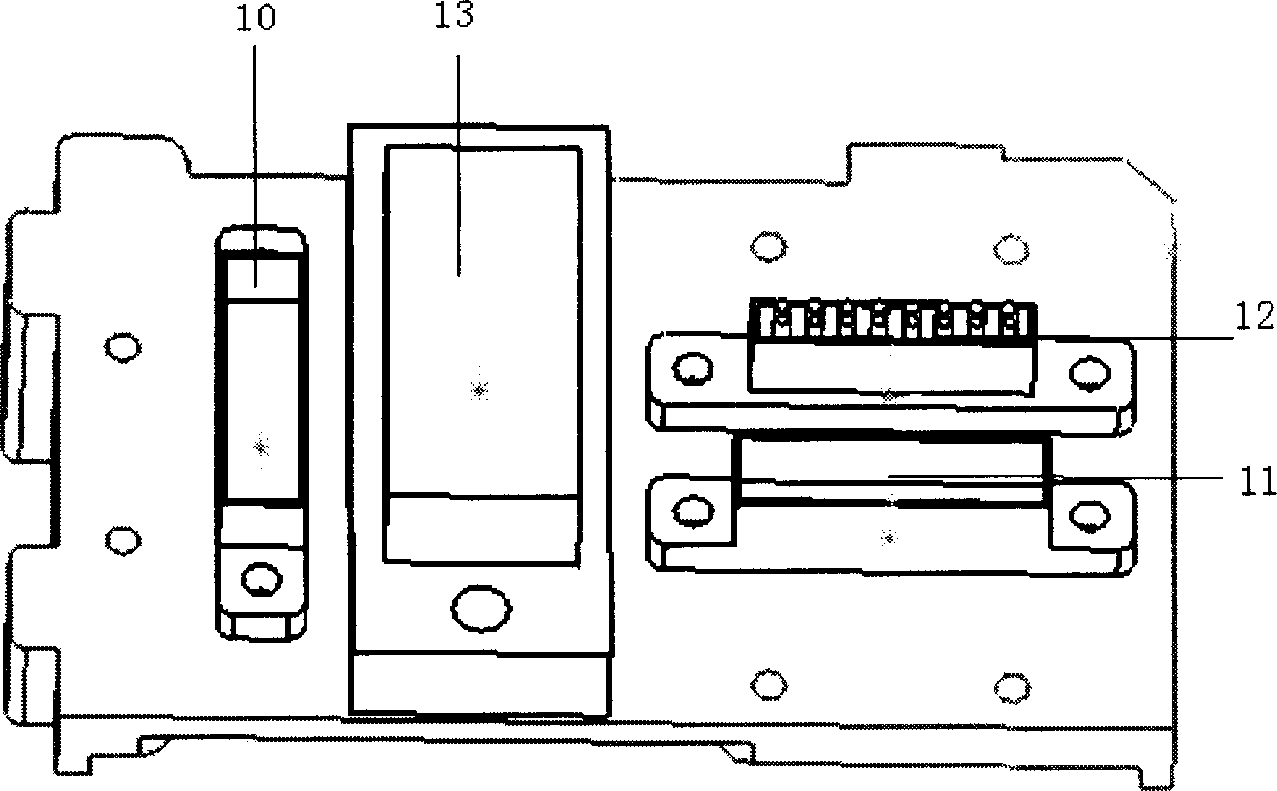

Optical module and method for manufacturing same

InactiveCN1720473AEasy to prepareSimplify the manufacturing processLaser detailsSolid-state devicesOptical ModuleComputer module

An optical module which can be manufactured by a simple process at low cost is disclosed. A method for manufacturing such an optical module is also disclosed. An optical module (100) comprises a die pad (101), a plurality of leads (102), and a first platform (110) and a second platform (120) mounted on the die pad (101). At least an optical fiber (113) is fixed to the main body (111) of the first platform (110), and at least a light emitter (124) is mounted on the main body (121) of the second platform (120). The light emitter (124) generates an optical signal to be transmitted through the optical fiber (113).

Owner:TDK CORPARATION

Light assembling structure for optical fiber gyro-space application

InactiveCN1888821AReduce volumeIncrease heat conduction areaSagnac effect gyrometersAttitude controlHeat resistance

Optical fiber peg-top space applied light combination structure has a perpendicular configuration reality and its side faces are vertical with the underside. The outside of two side faces and the inside of underside are the fixing plane to three peg-tops. The rest side faces use to fix the electrical source box and cube mirror. The three peg-tops are perpendicular setting, and the peg-top of x axis and y axis is fixed on the outside of the reality side faces, the peg-top of z axis is fixed on the inside of the reality underside. Their fixing surfaces contact completely to increase the heat exchange area of the peg-top to reduce the heat resistance effectively. The three joining pieces connecting with peg-tops fix on one joining piece plane and put the three joining piece planes into one to connect with the jack of the reality connecting with system. The three peg-tops can debug alone and this is fit for fixing and maintenance the optical fiber peg-top. It is suitable for the gesture controlling of the space aerocraft with small volume, light weight, little heat resistance, high reliability security, well diathermancy.

Owner:BEIHANG UNIV

Broken plastic stirring device

The invention relates to the technical field of waste plastic reprocessing equipment and particularly discloses a broken plastic stirring device. The broken plastic stirring device comprises a material cylinder, a feeding device, a stirring device body, an air uniformizing device and a temperature increasing device. The feeding device comprises a feeding bin, feeding hoppers, a first screw rod, asecond screw rod, a first spiral blade and a second spiral blade, and the spiral direction of the second spiral blade is opposite to the spiral direction of the first spiral blade. The stirring devicebody comprises a stirring motor, a stirring shaft, a spiral stirring blade and a spreading disk, and the spiral stirring blade is of a structure gradually becoming larger from bottom to top on the stirring shaft. The air uniformizing device comprises a main air pipe, annular air uniformizing pipes and gourd-shaped air uniformizing nozzles. The temperature increasing device comprises a shell, twosupporting plates, insulating rings and heating pipes. The broken plastic stirring device has the characteristics that stirring is uniform, the manpower cost and the material resource cost are both low, and dust and moisture are easy to discharge.

Owner:德清意欣塑料制品有限公司

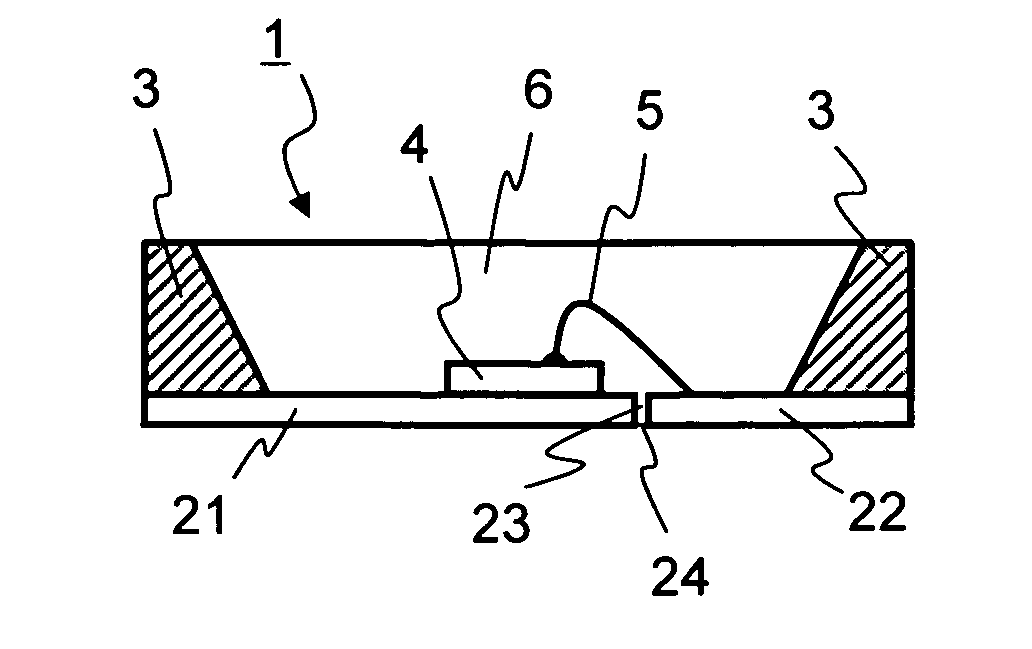

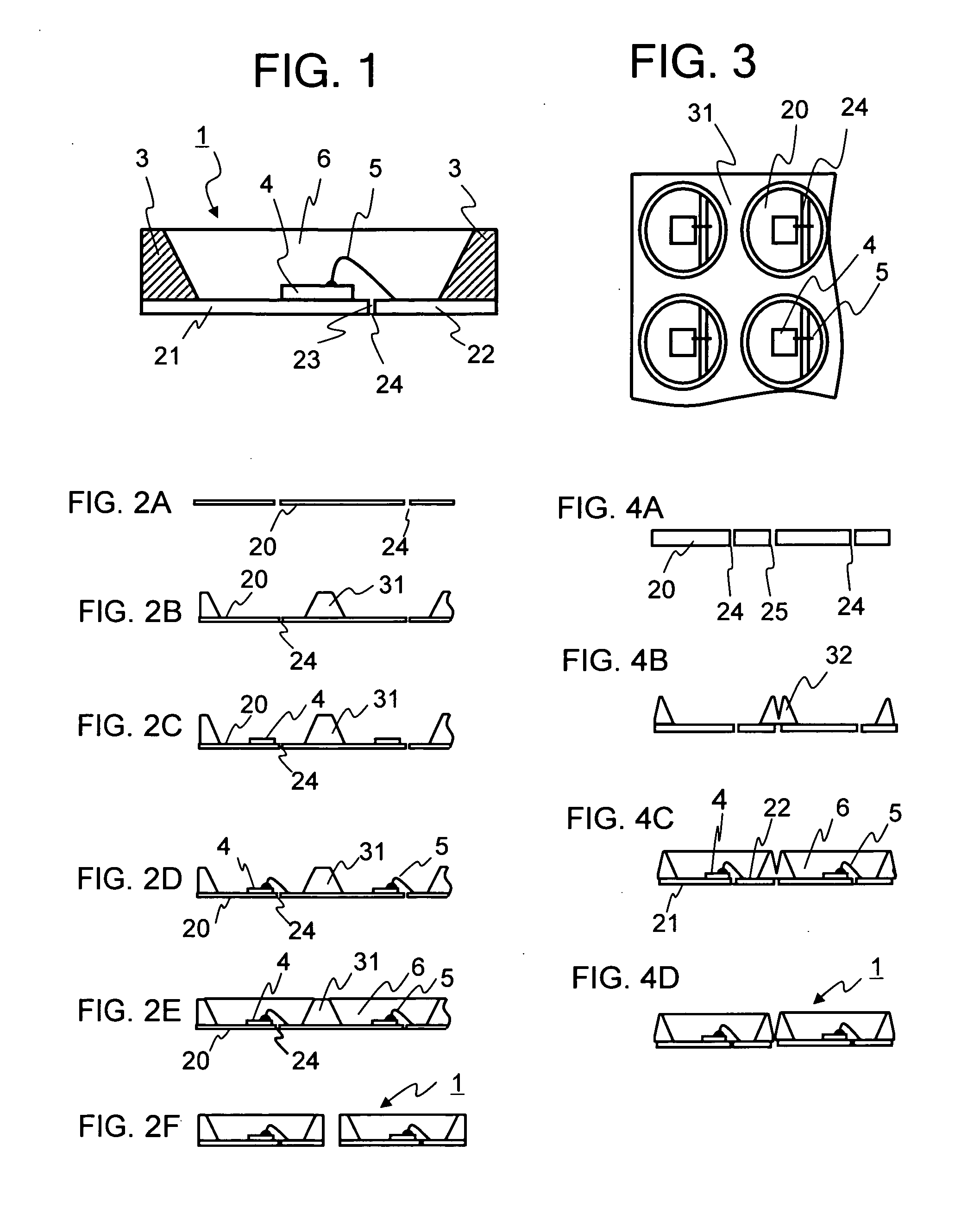

Light emitting device and manufacturing method therefor

InactiveUS20110140590A1Improve heat radiation abilityLow thermal conductivityPrinted circuit assemblingIncadescent screens/filtersElectricityLight emitting device

Provided is a highly-reliable light emitting device which has good heat radiation capacity and uses a light emitting diode (LED) having high luminance and high output as a light source. The light emitting device includes: the light source; a first metal substrate on which the light source is mounted; a wire connected to the light source; a second metal substrate electrically connected to the light source by the wire and formed on the same plane as the first metal substrate to be insulated from the first metal substrate; a planar reflecting member placed on the first metal substrate and the second metal substrate, having a through hole that is smaller in diameter on the light source side than on a side opposite to the light source side, and having a side surface formed of an inclined reflecting surface on the through hole side; an encapsulant for covering the light source; a slit formed between the first metal substrate and the second metal substrate; and an insulating material for filling the slit.

Owner:SEIKO INSTR INC

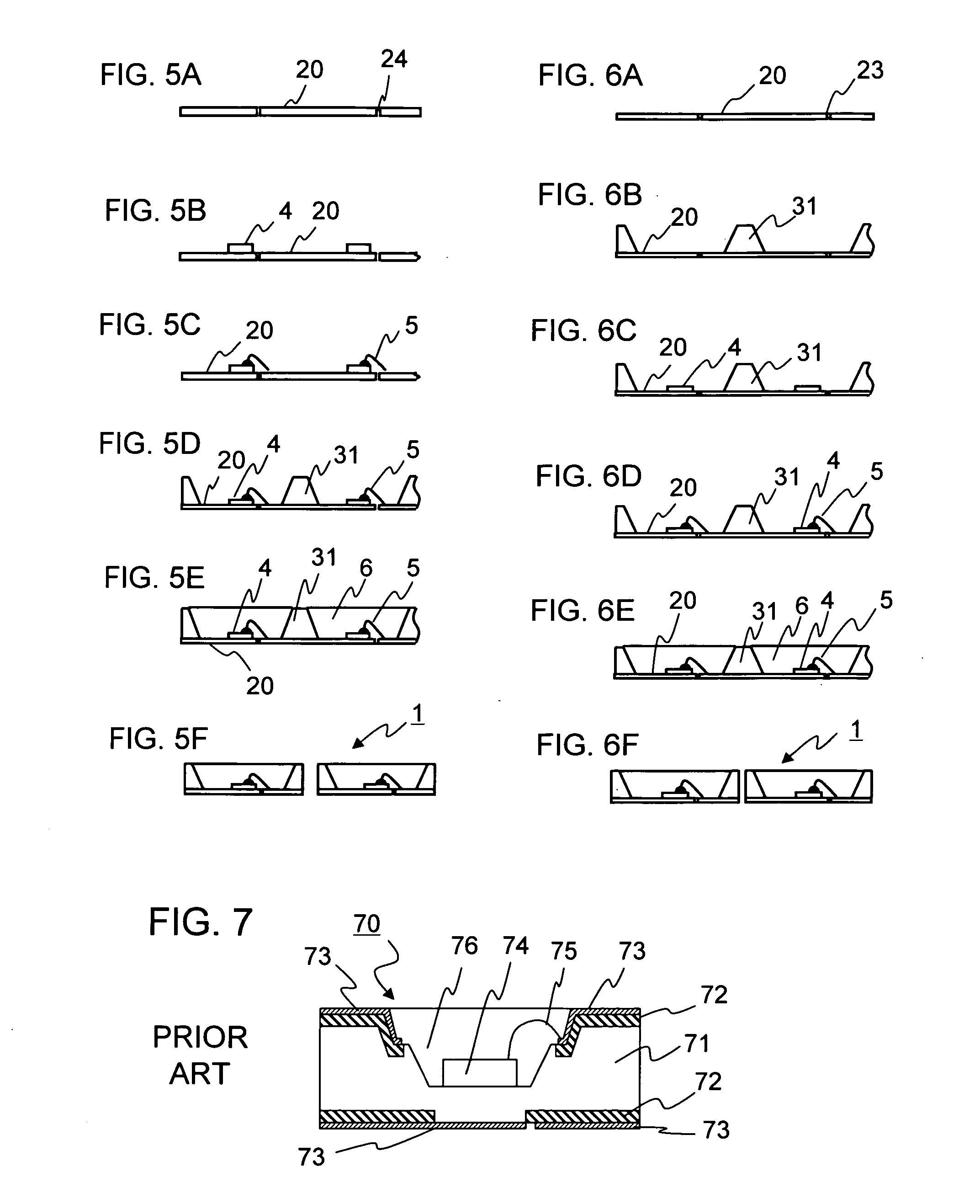

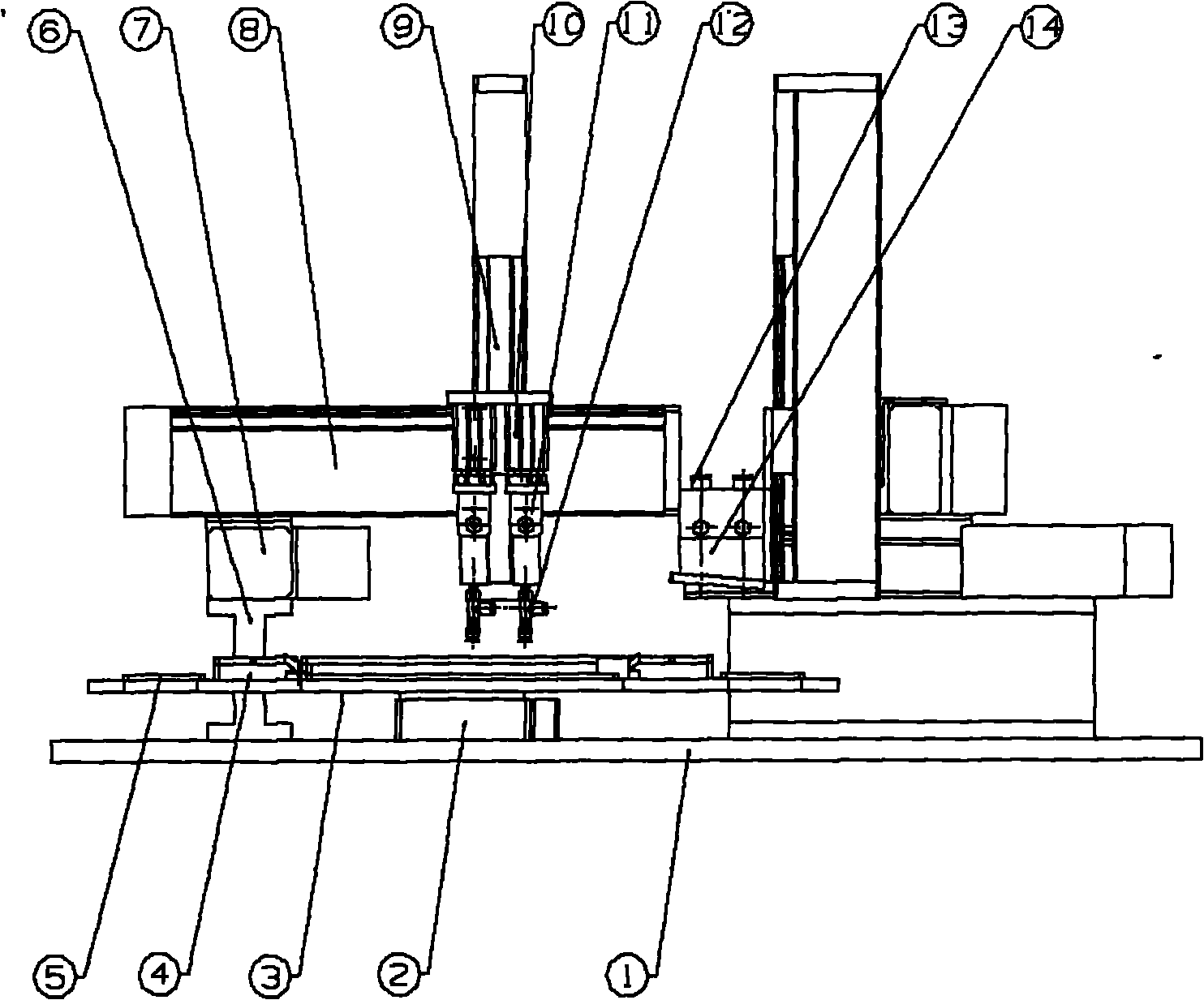

Ultrathin spatial solar battery gluing and encapsulating mechanism

InactiveCN102054892AProtection against mechanical damageImprove heat radiation abilityFinal product manufactureSemiconductor devicesEngineeringCover glass

The invention relates to an ultrathin spatial solar battery gluing and encapsulating mechanism, which comprises a working platform, a rotary table, a working rotary plate, two three-degree-of-freedom (X-axis, Y-axis and Z-axis) mobile mechanisms, a fixed tray, a carrying tray, a clamping mechanism, a cover glass tray, a needle tube fixing and refrigerating device and a sucker positioning clamp. The mechanism is designed into a four-station circular operating system, so operation can be performed on four stations simultaneously; therefore, the gluing work and the encapsulating work of an ultrathin spatial solar battery can be carried out simultaneously. On the premise of no influence on the systematic performance index, the ultrathin spatial solar battery gluing and encapsulating mechanism greatly improves the efficiency, saves the labor cost and enhances the reliability, and can be popularized in the encapsulating field of surface protection layers of integrated chip (IC) instruments.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

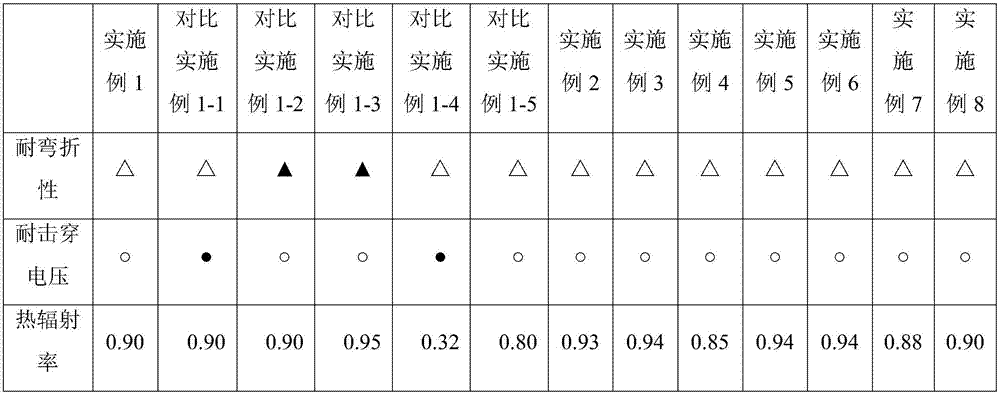

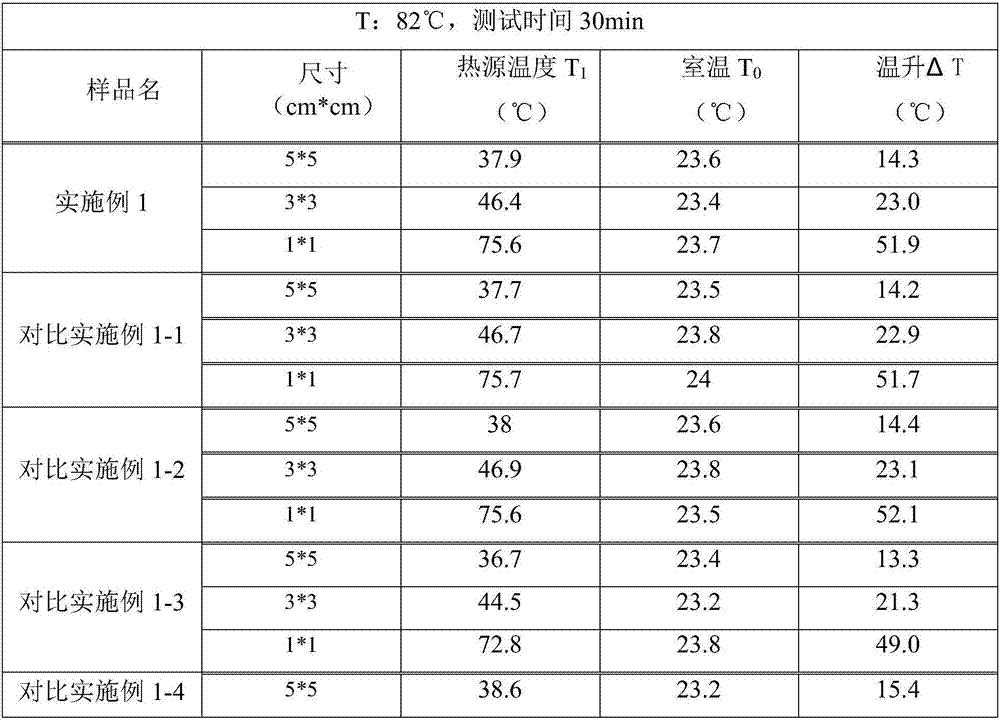

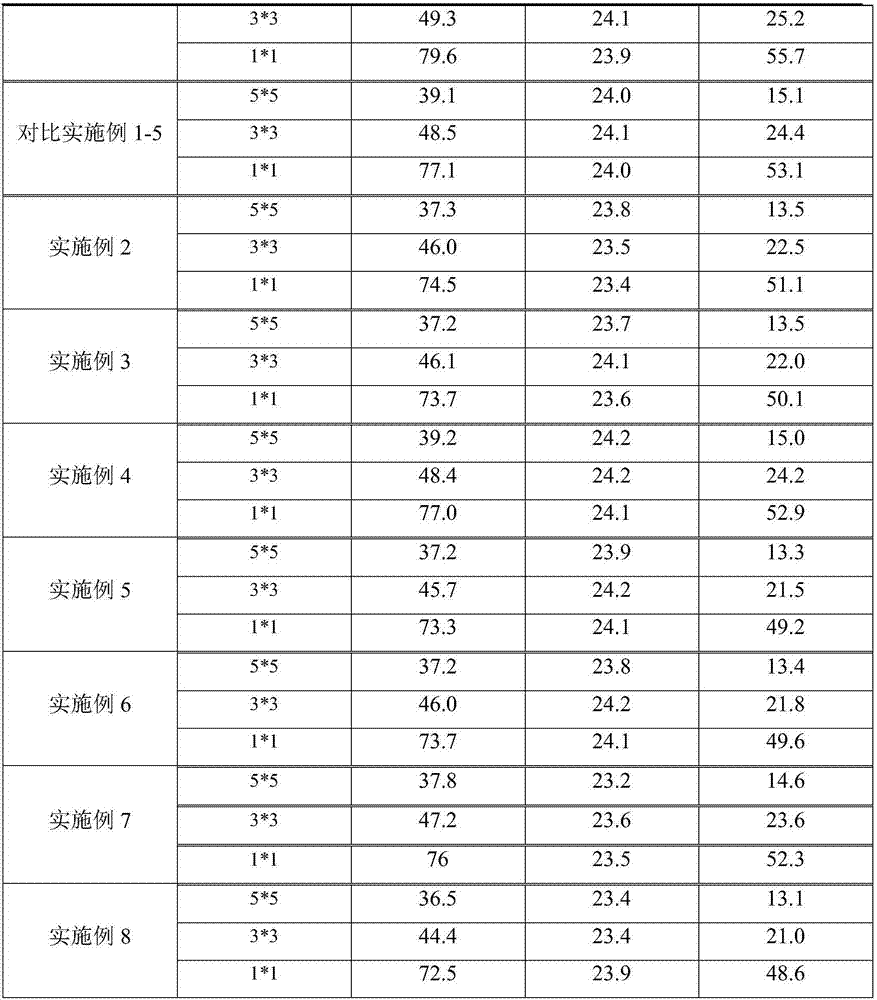

Thermal conduction coating material, thermal conduction coating, and composite heat dissipation film

ActiveCN107286837AImprove bending resistanceImprove voltage breakdown performancePlastic/resin/waxes insulatorsFilm/foil adhesivesPhotoinitiatorAdhesive

The present invention provides a thermal conduction coating material, which comprises 50-75% of a PUA oligomer, 0.5-20% of 2-(2-ethoxyethoxy)ethyl acrylate, 0.2-10% of ethylene glycol diacrylate, 1-10% of a photoinitiator, 1-10% of nanometer powder, 0.2-1% of a dispersant, and 0.2-1% of a coupling agent, and can form a thermal conduction coating after the coating material is subjected to ultraviolet light curing. The invention further provides a composite heat dissipation film, which sequentially comprises a thermal conduction coating (I), a graphite sheet (II) and a double-sided adhesive layer (V) from top to bottom, has advantages of excellent bending resistance, excellent voltage breakdown resistance and excellent radiation heat dissipation performance, can effectively reduce the heat source temperature, and can meet the use requirements in the heat dissipation field.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Electric oil pump and hydraulic pressure supply device

ActiveUS9453508B2Improve heat radiation abilityRotary piston pumpsRotary/oscillating piston combinationsCheck valvePetroleum engineering

An electric oil pump is coupled to a pump receptacle including an oil inflow passage and an oil outflow passage. The electric oil pump includes a motor, a pump rotor, a housing, and a check valve. The housing accommodates the motor and the pump rotor. The housing closes an opening of the pump receptacle and includes at least a fitted portion fitted into the pump receptacle. An oil compartment is formed between the pump receptacle and the housing. Oil flows into the oil compartment from the oil inflow passage when the pump rotor is rotated. The fitted portion is partially immersed in the oil collected in the oil compartment. The housing includes a suction port and a discharge port. A check valve, located in the housing, limits reversed flow of the oil from the oil compartment to the oil inflow passage.

Owner:DENSO CORP

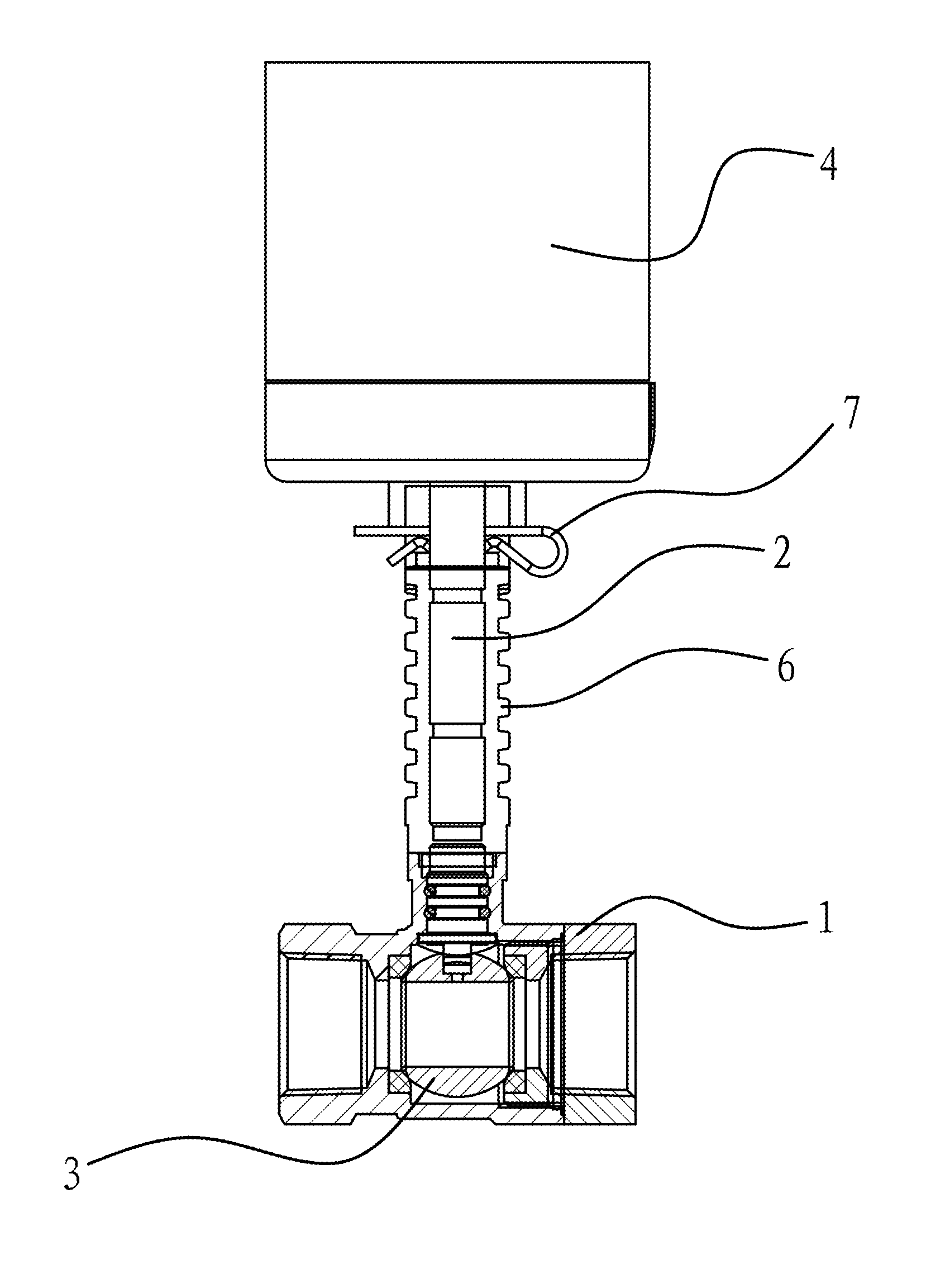

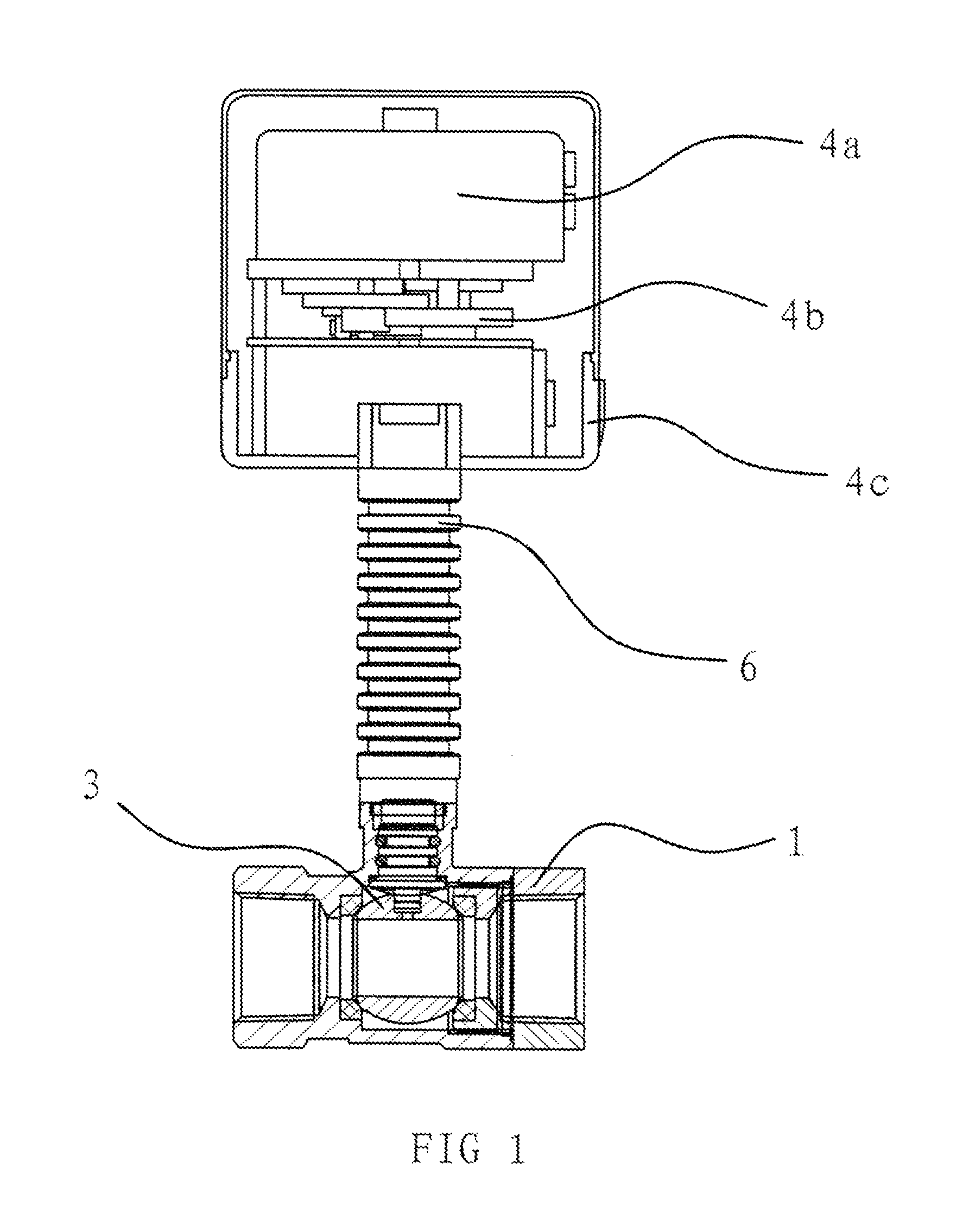

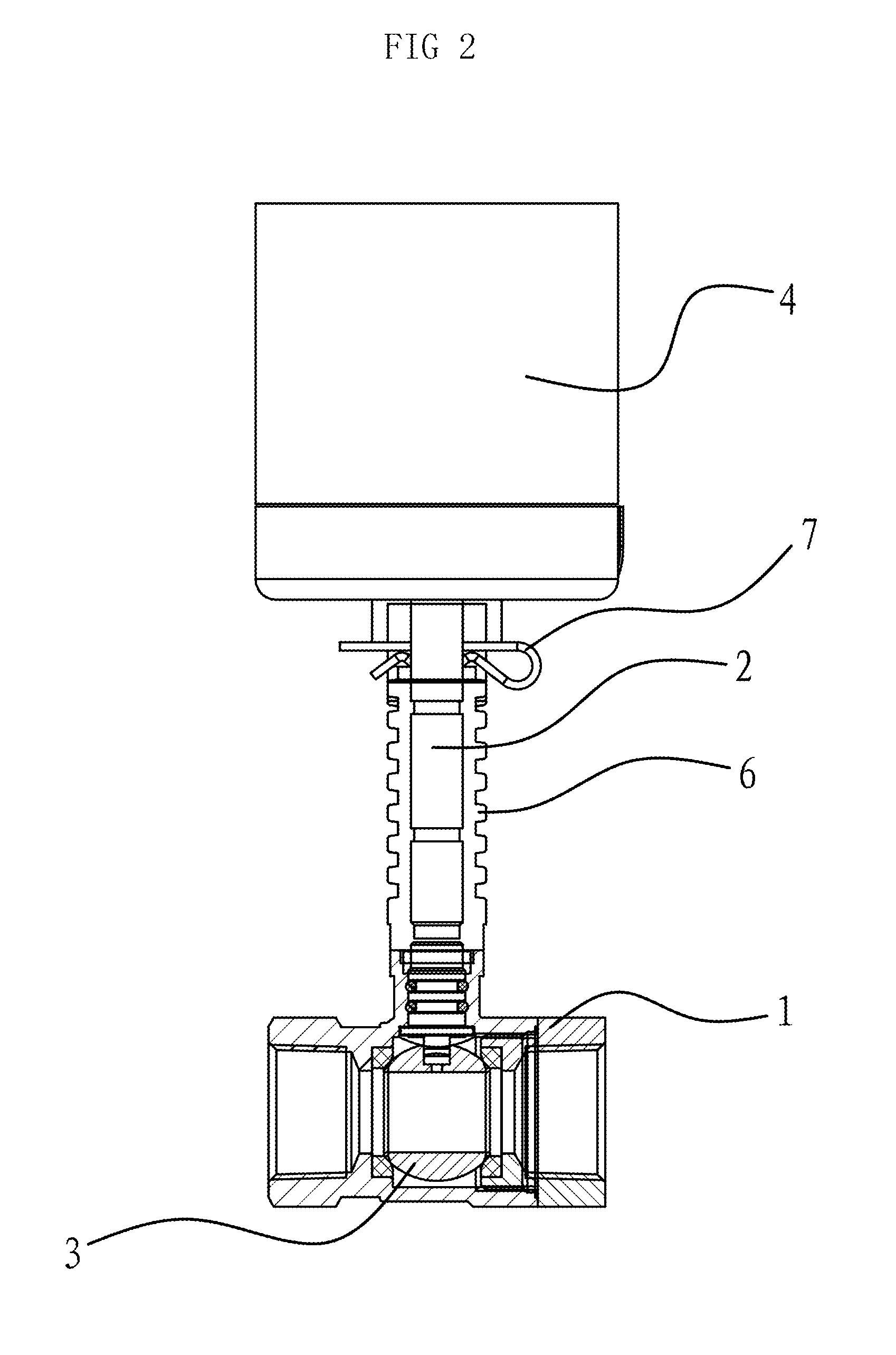

Electric floating ball valve

InactiveUS9052019B2Improve driving conditionsImprove electrical stabilityPlug valvesOperating means/releasing devices for valvesMetallic materialsValve stem

The present invention discloses an electric floating ball valve. The electric floating ball valve addresses the problems of the existing electric floating ball valve, such as poor reliability, high tendency to be damaged, poor control precision, high noises in operation as well as high costs for maintenance and replacement. The electric floating ball valve includes a valve body, a valve stem, a valve core and a drive mechanism. The drive mechanism is connected with the outer end of the valve stem and could drive the said valve stem to rotate. The external side of the valve stem is covered with a cylindrical heat sink made of metallic materials. Said heat sink is fixedly connected with said valve body. The heat sink of the electric floating valve could significantly improve the heat radiation capacity, which efficiently guarantees the stable and reliable operation of the drive mechanism.

Owner:ZHEJIANG JULONG INTELLIGENT FLUID CONTROL SYST CO LTD

Far infrared energy-saving paint and preparation method therefor

InactiveCN104844139ASuitable for a wide temperature rangeImprove general performanceFar infraredKiln

The present invention relates to a far infrared energy-saving paint and a preparation method therefor, which belong to the technical field of ceramic paint, and are mainly used for high-temperature kiln furnaces, steam boilers, fuel automobiles, ships and other industries to achieve energy saving purposes. The paint includes the following components in parts by weight: 20 to 40 parts of ceramic micro powder, 30 to 50 parts of binding agent, 1 to 5 parts of accessory ingredient, and 10 to 30 parts of water. The preparation method comprises: first the accessory ingredient and water are added to a reaction kettle in proportion and uniformly mixed, then the ceramic micro powder and the binding agent are added to the reaction kettle in proportion, and the mixture is stirred at 300 to 600 rev / min for 30 to 60 minutes, finally the far infrared energy saving paint of the present invention is obtained.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

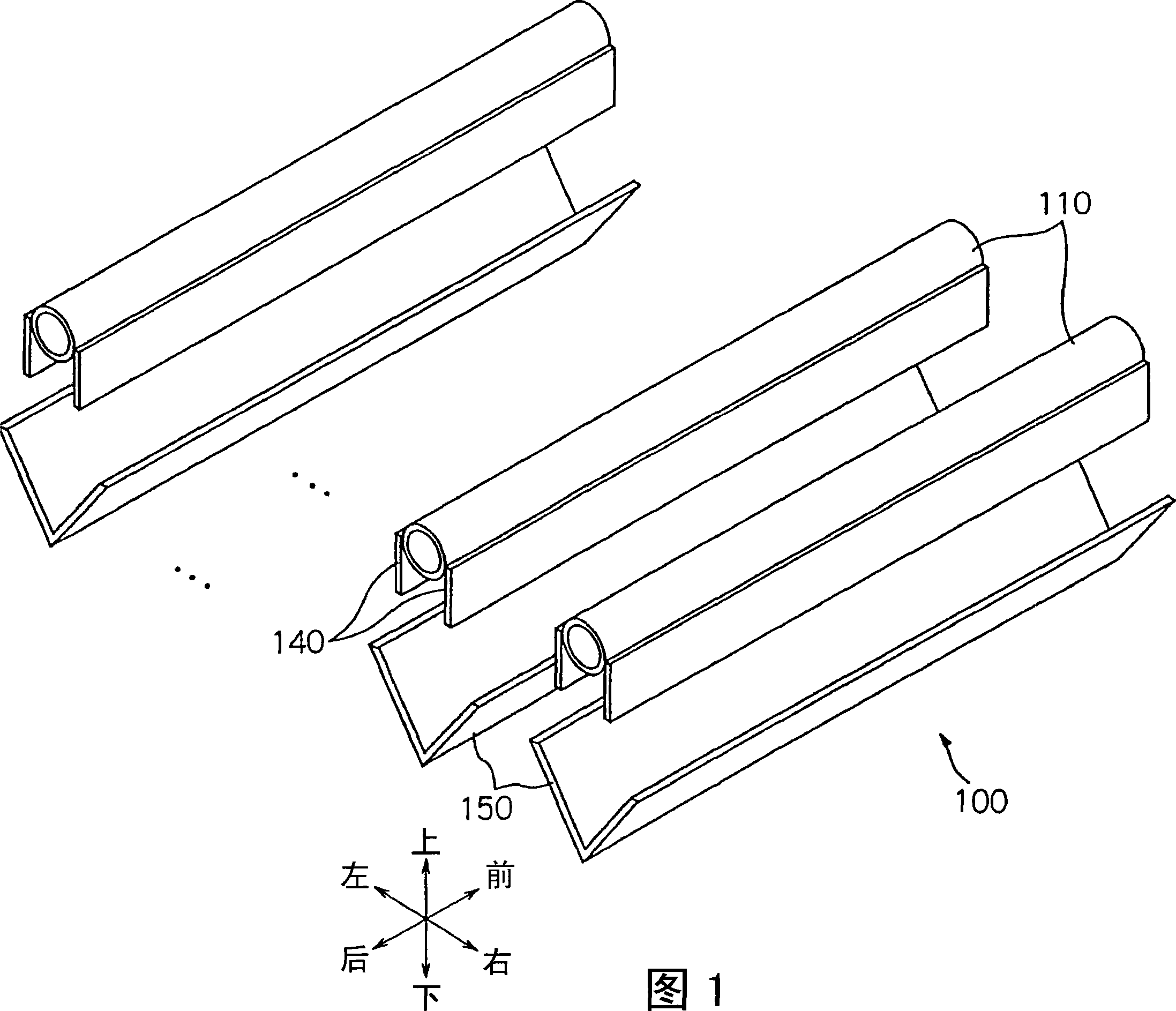

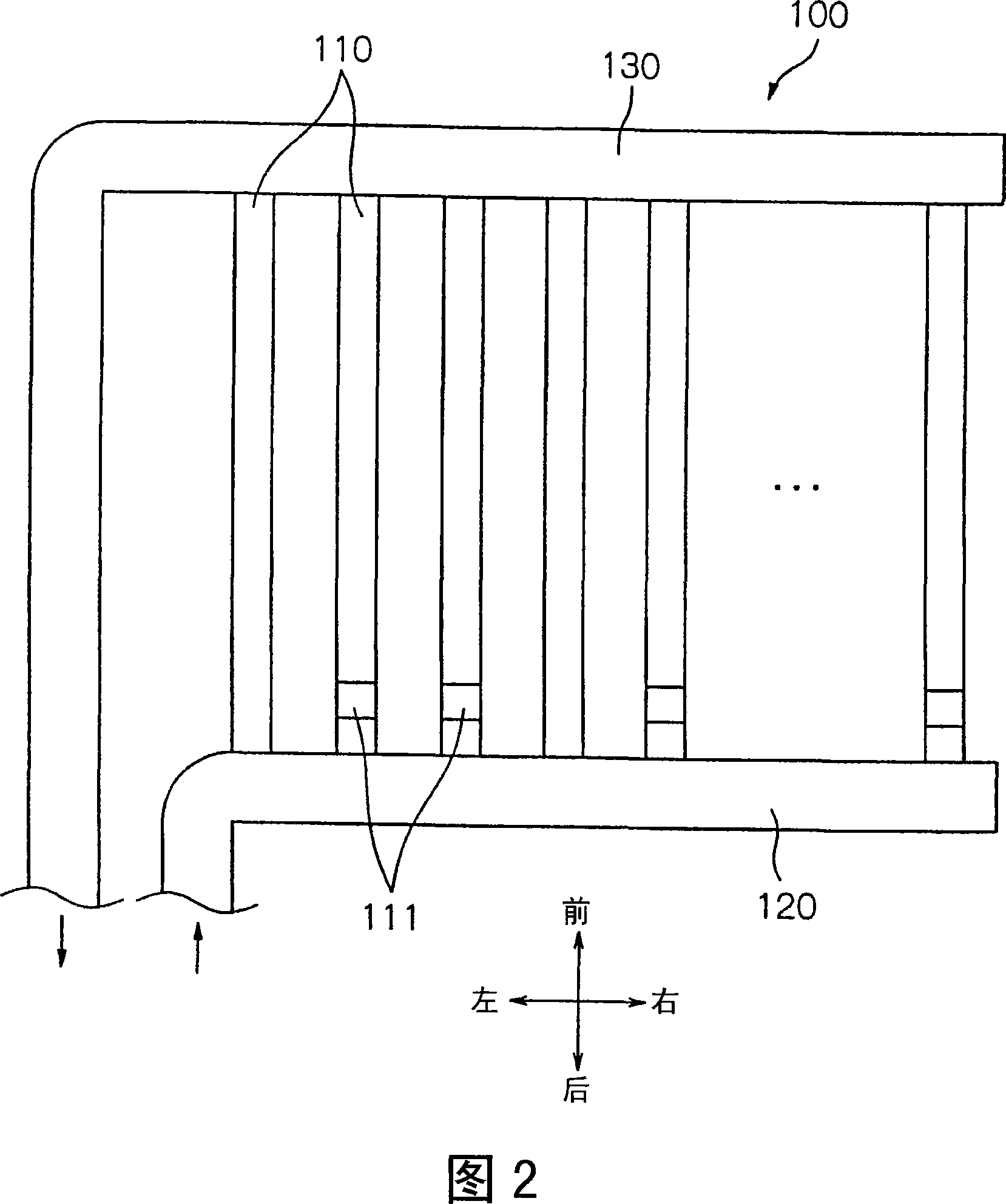

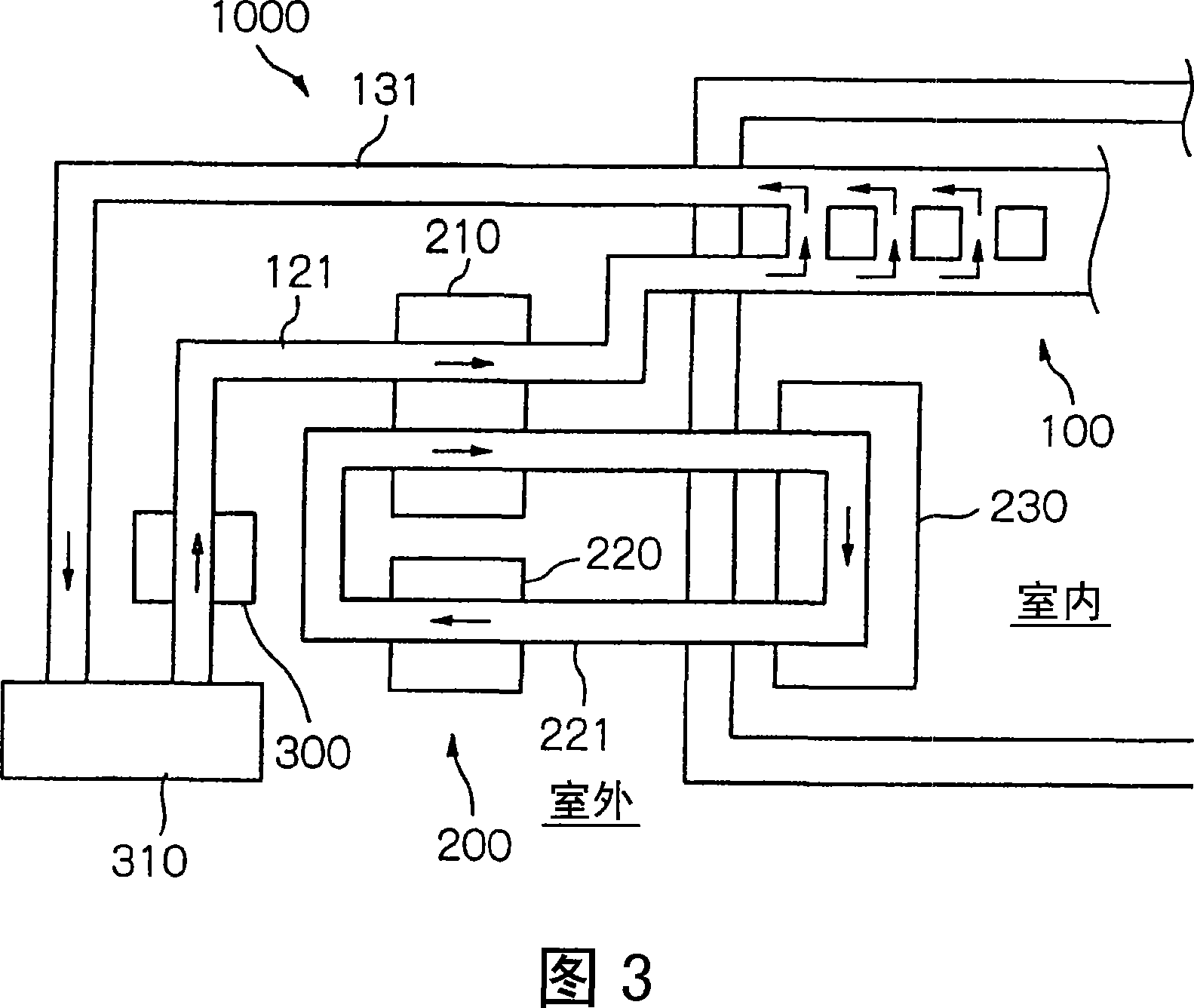

Ceiling radiation system

ActiveCN101050878AImprove heat radiation abilityReliable recyclingLighting and heating apparatusAir conditioning systemsWater flowEngineering

A ceiling radiation system for carrying out indoor refrigeration is prepared for making cold water flow in multiple heat radiation tube for carrying out indoor refrigeration through heat radiation of heat radiation tubes and plates, condensing water on surfaces of heat radiation tubes and plates when cooled water is flowed in said heat radiation tube and plates, recovering condensed water through water drainage groove for increasing refrigeration performance.

Owner:青木住宅机材贩卖株式会社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com