Ceiling radiation system

A radiant system and ceiling technology, applied in air conditioning systems, household heating, lighting and heating equipment, etc., can solve problems such as the obstruction of cooling effect of heat pipes, and achieve the effect of improving performance and efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

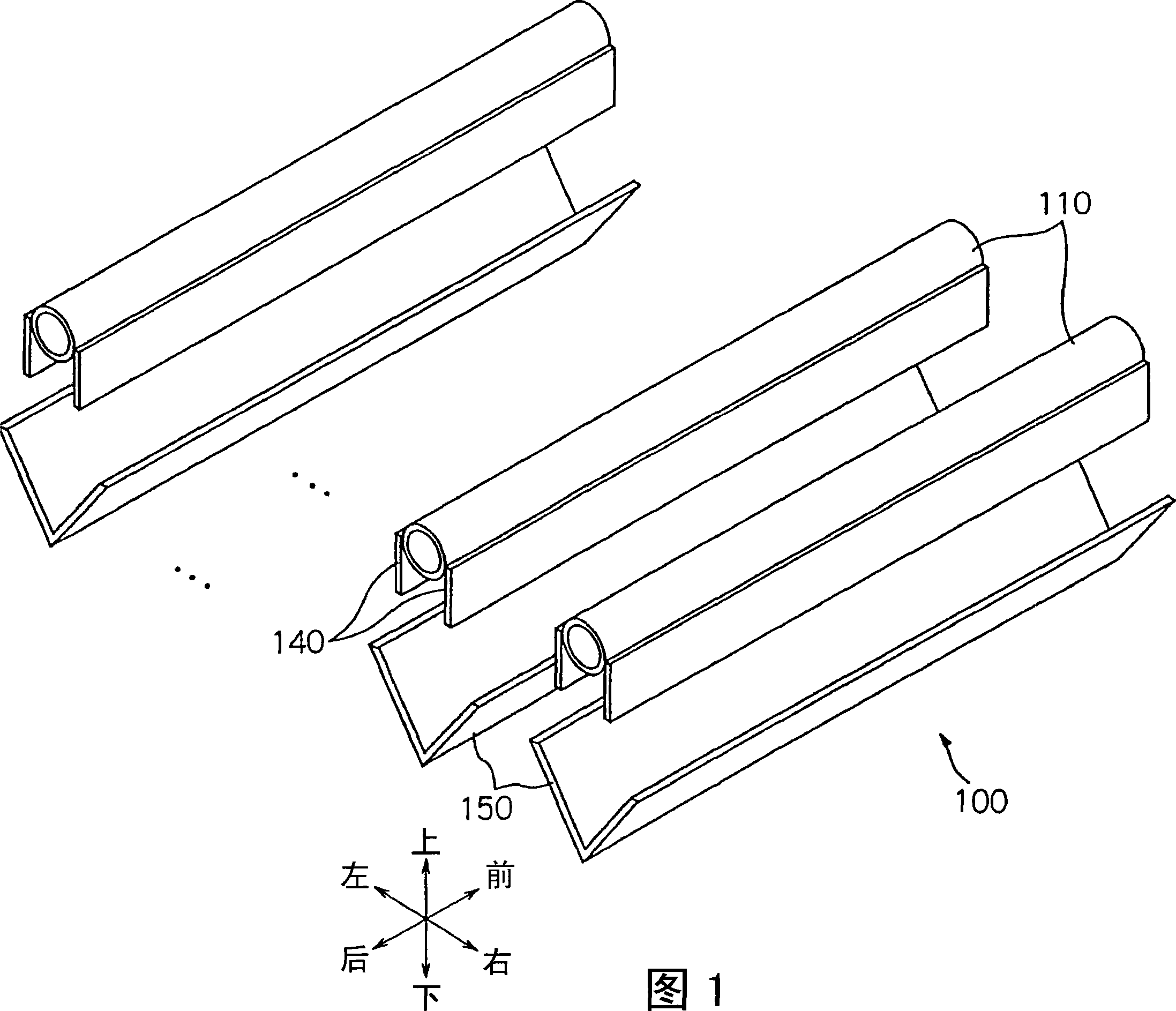

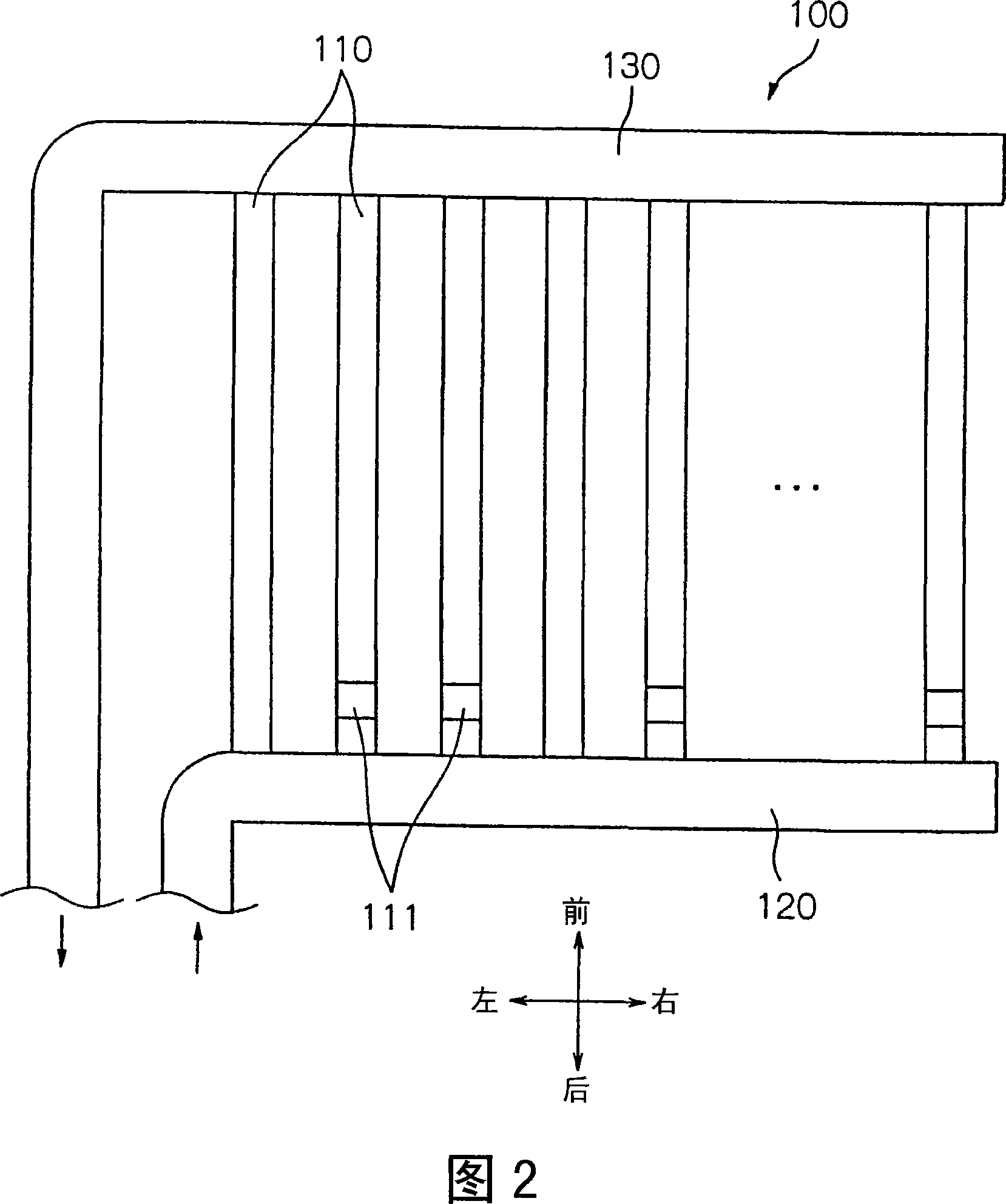

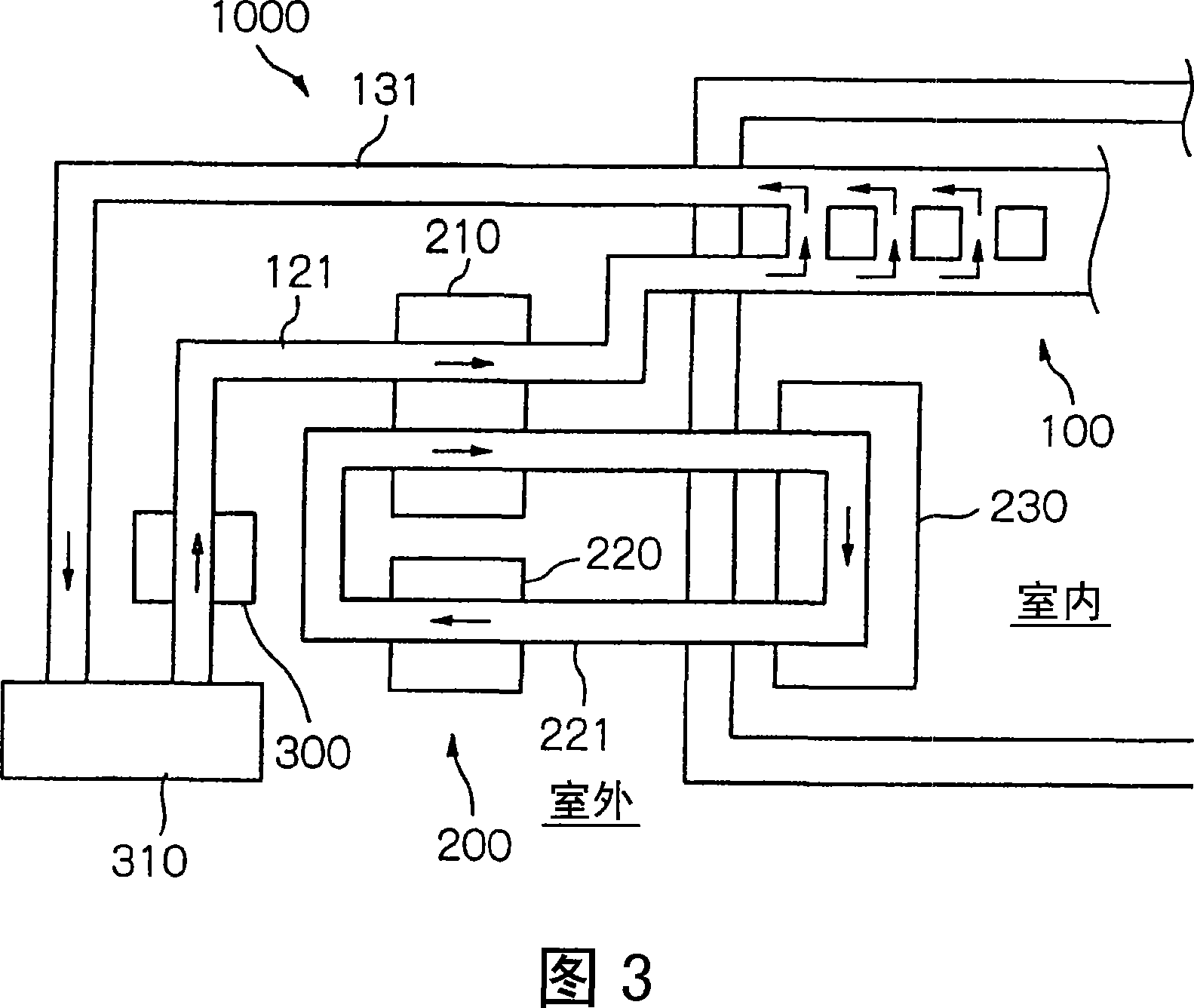

[0023] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. As shown in FIG. 3 , a ceiling radiation system 1000 according to the present embodiment includes a ceiling unit 100 , a cold water generation mechanism 200 , a pump device 300 as a cold water flow mechanism, and the like. As shown in FIGS. 1 and 2 , the ceiling unit 100 is composed of a plurality of heat dissipation pipes 110 , a water supply pipe 120 , a recovery pipe 130 , a plurality of heat dissipation plates 140 , and a plurality of drainage grooves 150 .

[0024] The water supply pipe 120 and the recovery pipe 130 are composed of elongated copper pipes with an outer diameter of 30 mm and a wall thickness of 2.0 mm, for example, and are formed to have a predetermined overall length corresponding to the ceiling surface. The heat radiation pipe 110 is made of, for example, an elongated copper pipe with an outer diameter of 20 mm and a wall thickness of 2.0 mm, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com