Ultrathin spatial solar battery gluing and encapsulating mechanism

A solar cell, ultra-thin technology, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., to achieve the effects of protecting mechanical damage, reducing operating temperature, and improving power output capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

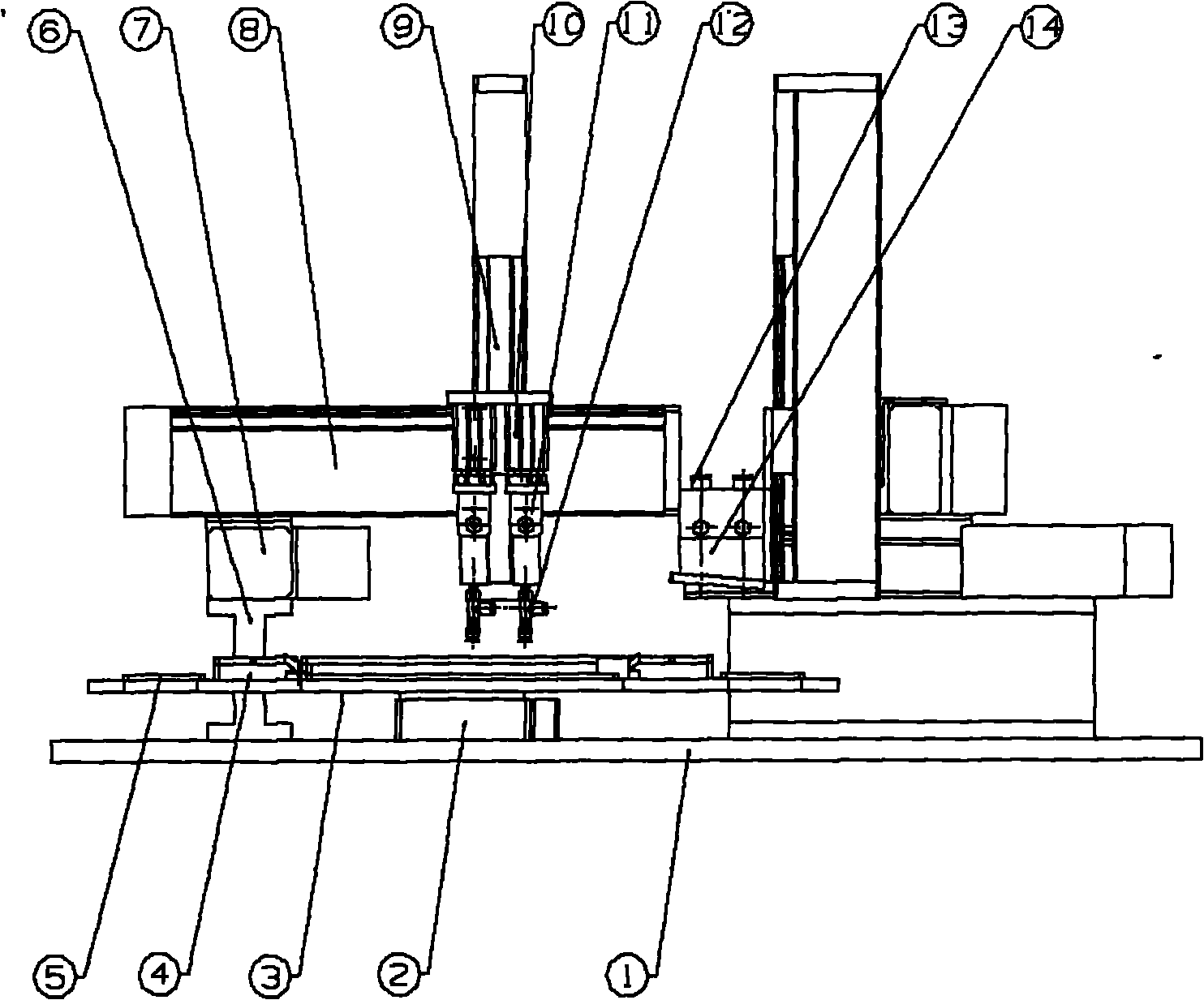

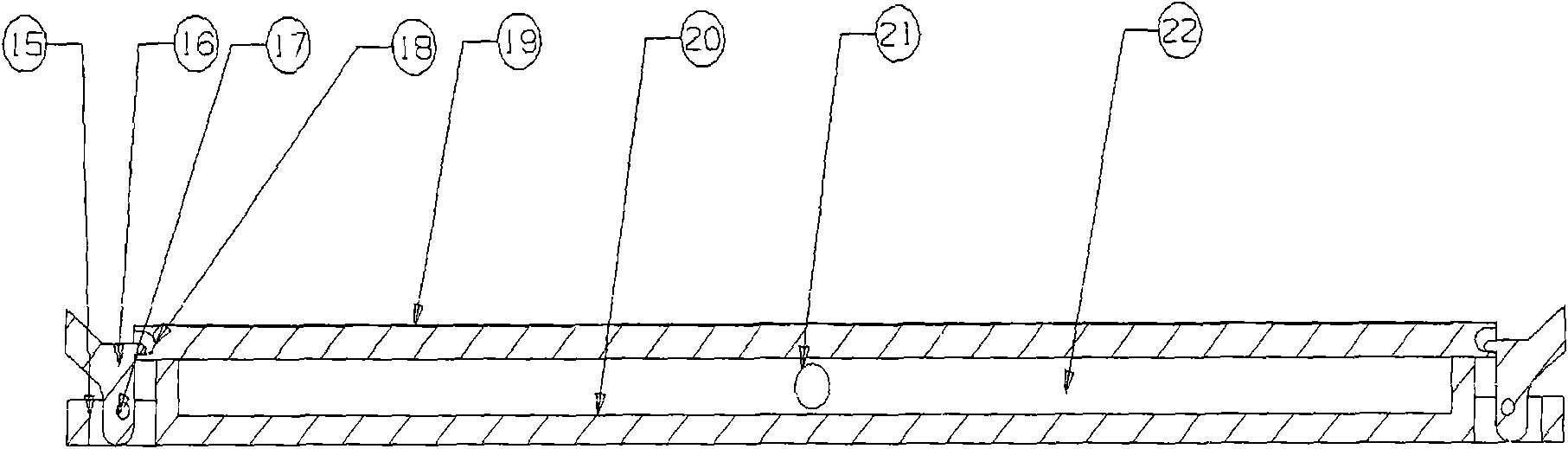

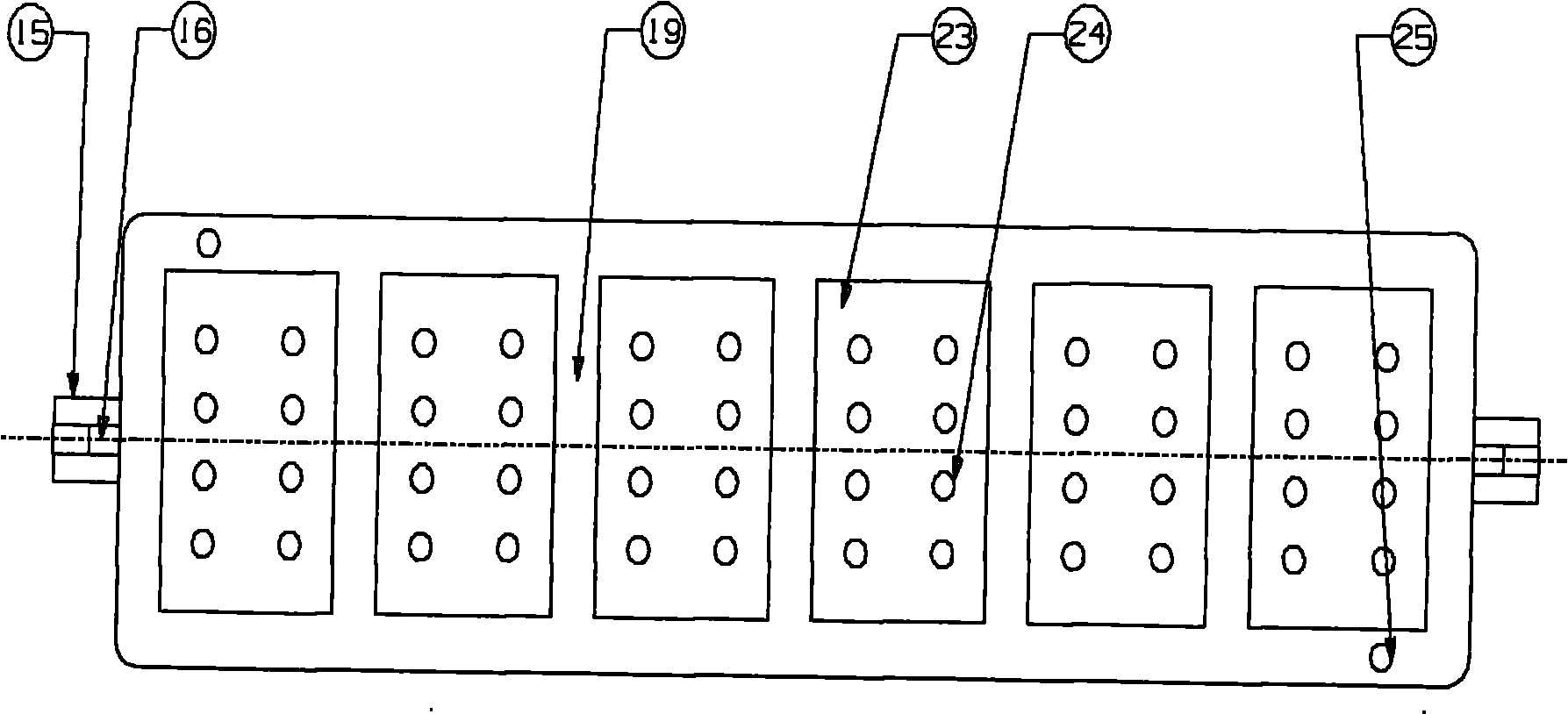

[0026] The overall structure of the preferred embodiment of the present invention is as figure 1As shown, the ultra-thin space solar cell glue coating and packaging mechanism includes a working platform 1, a turntable 2, a working turntable 3, a solar cell tray as a whole 4, a glass cover tray 5, a base 6, an X-axis moving unit 7, and a Y-axis moving unit Unit 8, Z-axis moving unit 9 (two sets of 6, 7, 8, and 9), cylinder 10, suction cup positioning fixture 11, and syringe fixing refrigeration device 14. The turntable 2 is fixed on the working platform 1, the working turntable 3 is fixed on the turntable 2, and the solar battery tray 4 and the glass cover tray 5 are installed on the working turntable 3 through the positioning holes. Two XYZ three-degree-of-freedom moving mechanisms are respectively installed at 90° and 180° s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com