Patents

Literature

121results about How to "Reduce stress damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

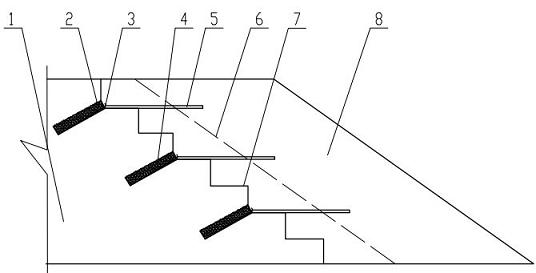

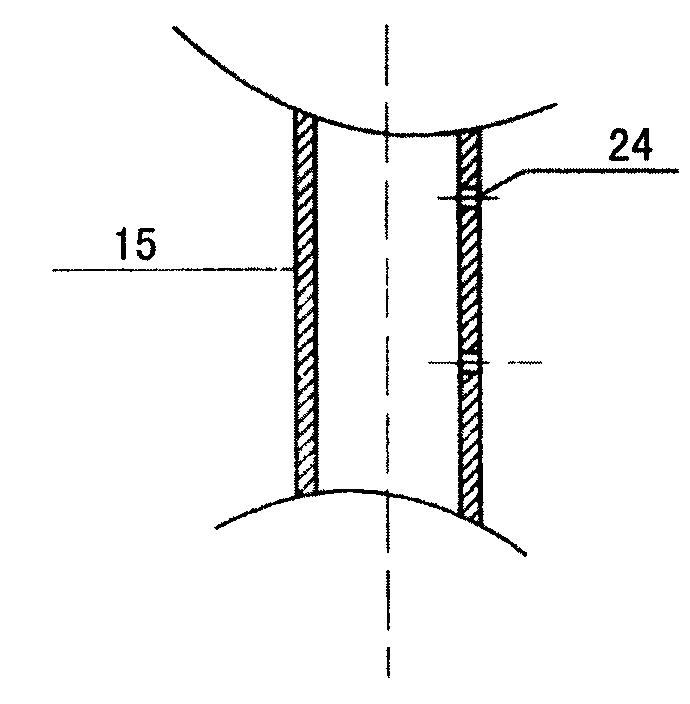

Anchored roadbed widening method

InactiveCN102619150AReduce shear deformationGuaranteed carrying capacityRoadwaysVertical planeEngineering

The invention discloses an anchored roadbed widening method, which belongs to the technical field of road construction. The anchored roadbed widening method comprises the following steps of: firstly performing slope cutting on an old roadbed slope, then excavating a step on the old roadbed slope from the ground, obliquely drilling an anchorage hole into an old roadbed at the joint of the vertical plane of the step and the horizontal plane, placing a steel bar into the anchorage hole, and casting the steel bar and the old roadbed into a whole by pouring cement grout; laying a new roadbed in layers, rolling, flatly laying a geogrid on the step of the old roadbed when the new roadbed is filled to be aligned with the step of the old roadbed provided with the anchorage drilled hole, connecting a transverse rib of the geogrid with an end hook which is bent upwards of the exposed part of the steel bar, tensing the geogrid, fixing with the lower layer of a soil body, and finally filling soil on the geogrid and rolling. According to the anchored roadbed widening method disclosed by the invention, an anchor rod technology is used for reinforcing the old roadbed slope, the geogrid and the old roadbed are connected into a whole, the geogrid can be prevented from sliding on the step of the old roadbed, the stability of the new roadbed and the old roadbed is improved, and non-uniform sedimentation can be effectively controlled.

Owner:SHIJIAZHUANG TIEDAO UNIV

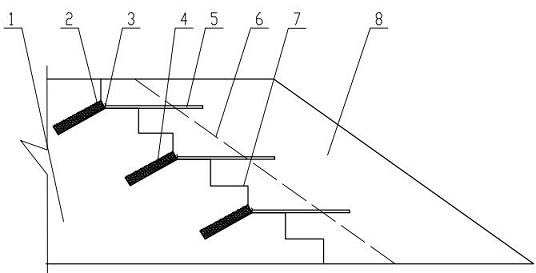

Ultraviolet curing adhesive

ActiveCN102079961ASolve the problem of unexposed initial tackHigh softening pointPolyureas/polyurethane adhesivesPhotosensitive materials for photomechanical apparatusAcrylic resinAdhesive

The invention discloses an ultraviolet curing adhesive comprising a resin main body, a dissolvent, an ultraviolet light initiator and an addition agent, wherein the resin main body is composed of a resin R and a resin H; the R resin is an active polyurethane acrylic resin with a main chain containing a polyether structure and a branch chain containing a vinyl optical active group as well as with a lower molecular weight; and the H resin is an inert polyurethane acrylic resin with a main chain containing a polydiene and aryloxide structure and with a relatively higher molecular weight. The adhesive contains no monomer or prepolymer, has high softening point, can be precoated on a base material, has super strong cohesive force on a high-oilness contact surface and has characteristics of high-temperature resistance, small internal stress and good flexibility.

Owner:LUCKY HUAGUANG GRAPHICS

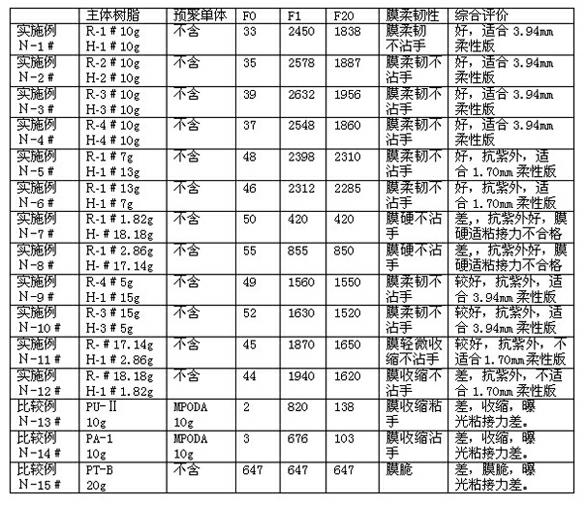

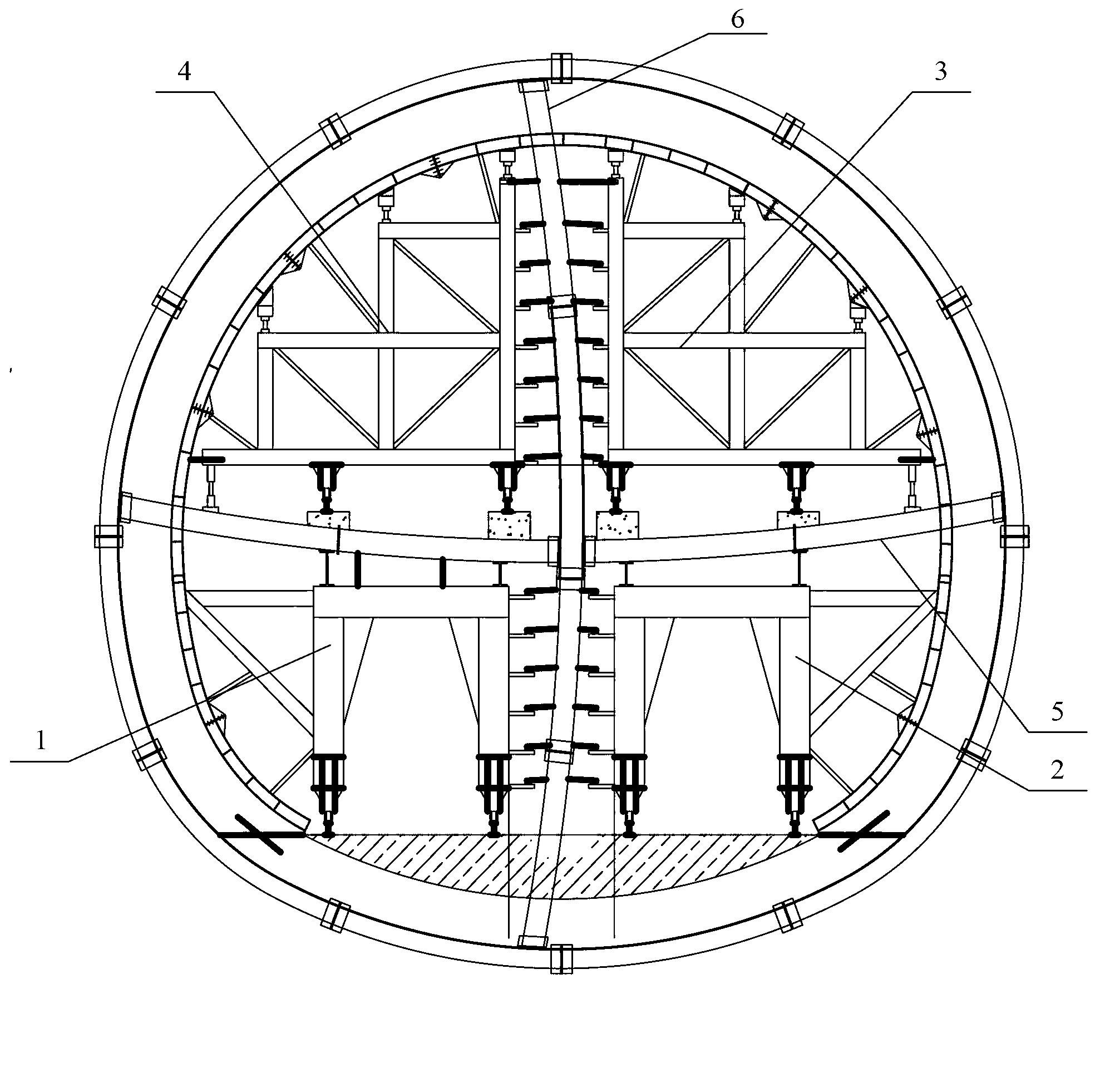

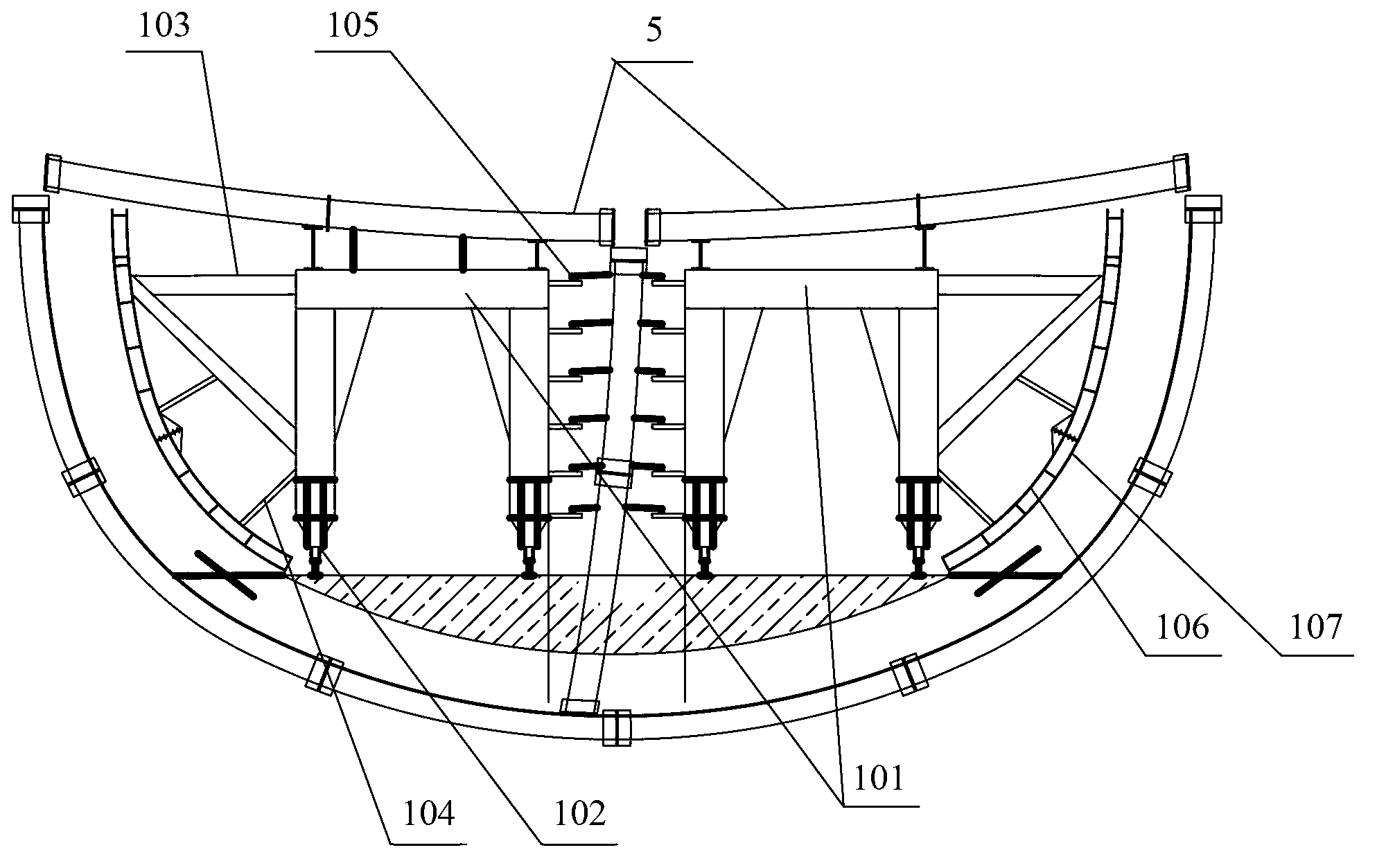

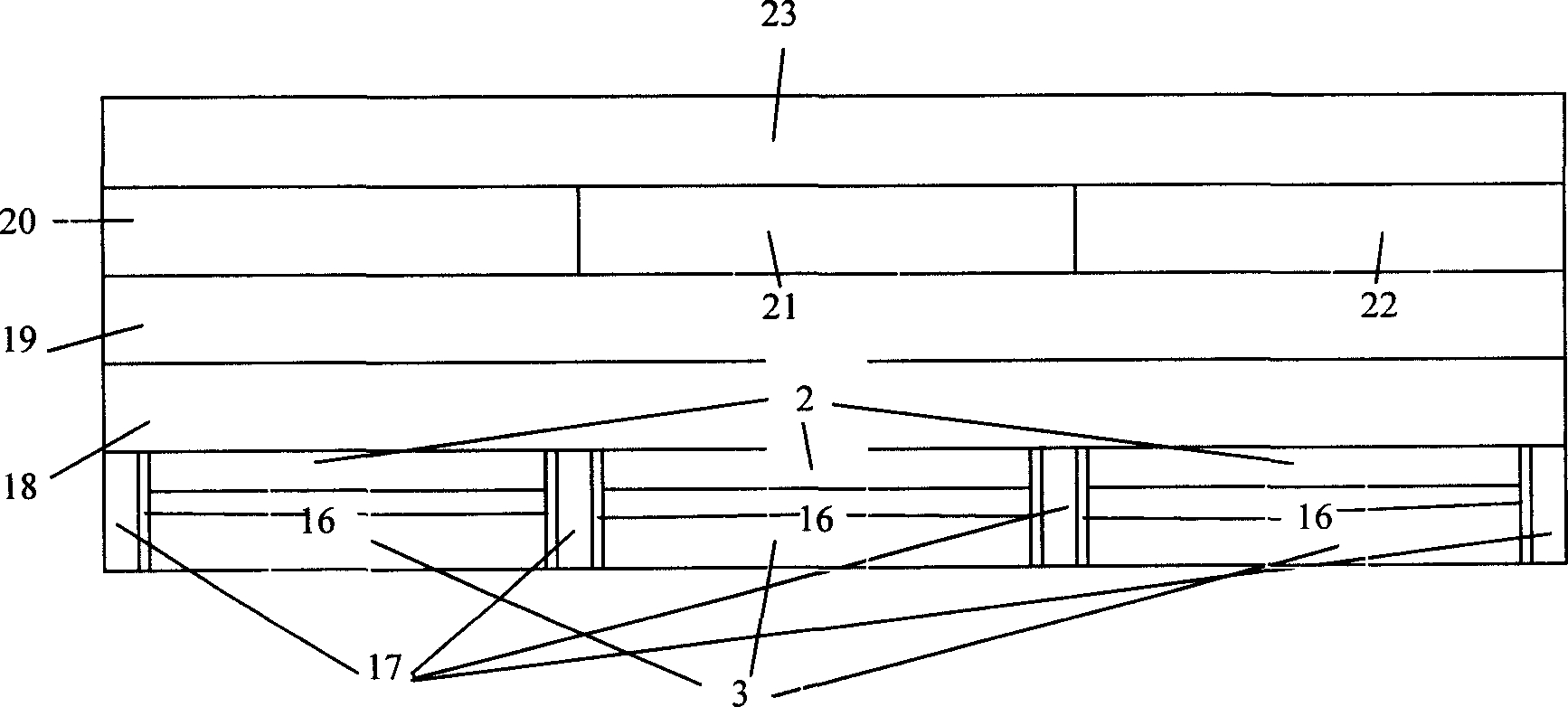

Grouped second liner construction method for large cross-section tunnel

ActiveCN103016029AIncrease the construction processLong construction periodUnderground chambersTunnel liningSocial benefitsArchitectural engineering

The invention discloses a grouped second liner construction method for a large cross-section tunnel. A whole toroidal second liner is constructed after being divided into 6 parts. The method comprises the following steps: 1), pouring and backfilling an inverted arch of a left lower hole; 2), pouring and backfilling an inverted arch of a right lower hole; 3), pouring a side wall second liner of the left lower hole through a lower hole trolley; 4), moving the lower hole trolley to the right lower hole to pour a side wall second liner of the right lower hole; 5), erecting a bracket in the right lower hole, assembling a right upper hole trolley, and pouring a right upper arch second liner; 6), erecting a bracket in the left lower hole, assembling a left upper hole trolley, and pouring a left upper arch second liner. According to the grouped second liner construction method, a relatively large cross section is divided into a plurality of small cross sections to carry out construction, although the construction procedures the time limit for a product are slightly increased in comparison with those of a traditional two-step construction method, the construction risk is yet reduced to a great extent, the construction safety guarantee coefficient is increased, an extremely important guide value is provided for the tunnel constructed with a CRD (center cross diaphragm) method in certain special urban environment conditions, the construction is smoothly completed on the premise of guaranteeing safety, and remarkable social benefits are achieved.

Owner:RANKEN RAILWAY CONSTR GROUP

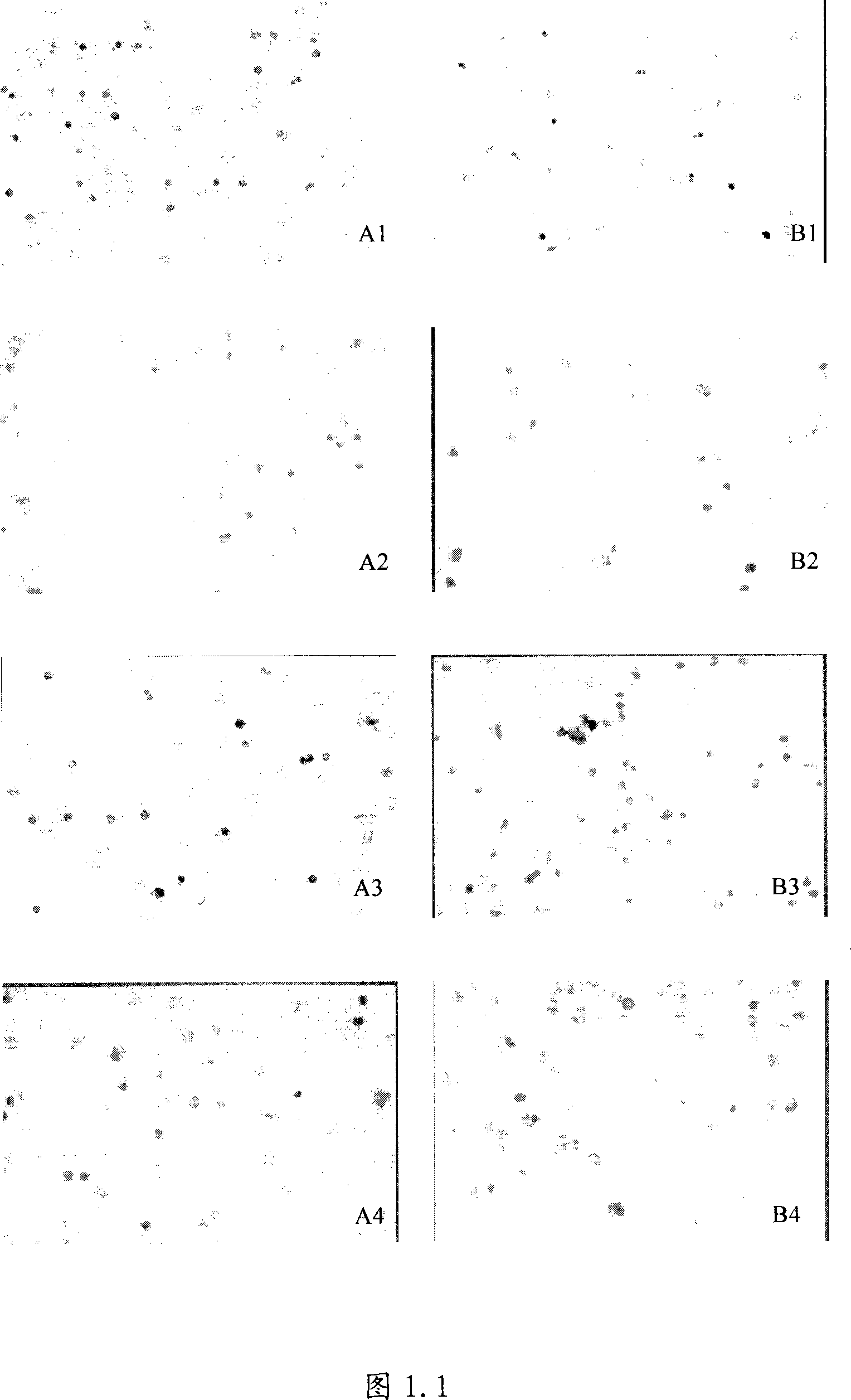

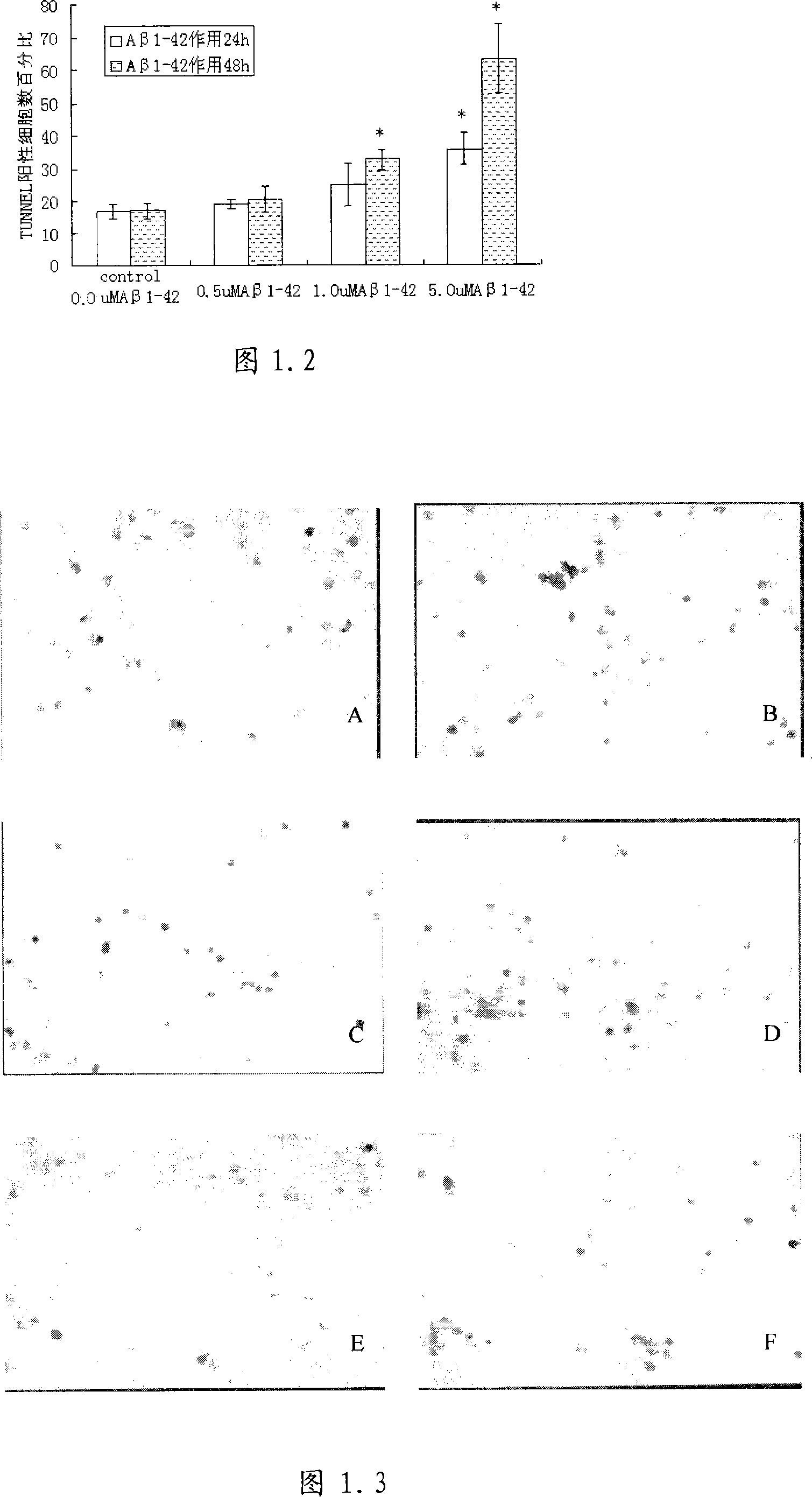

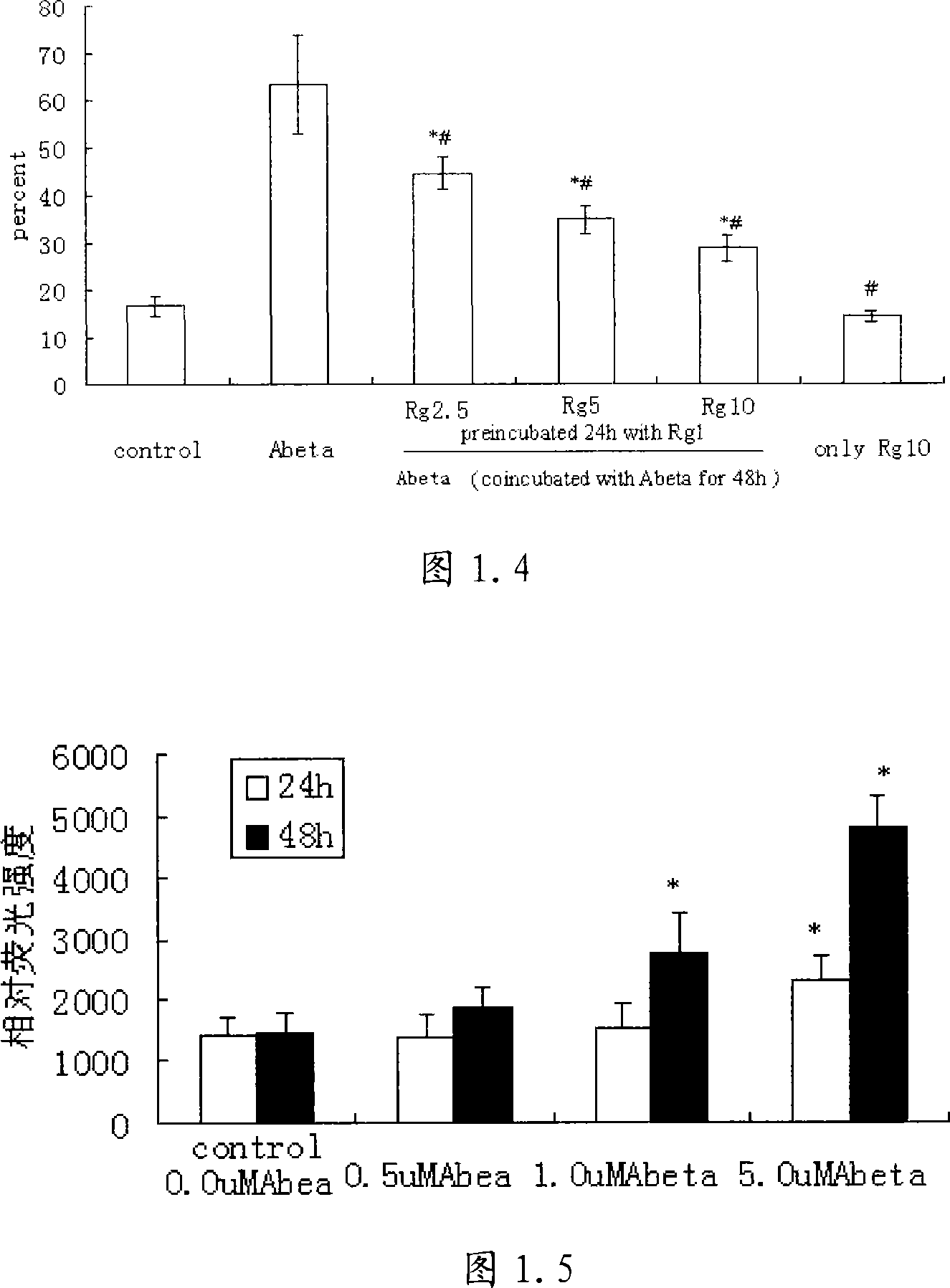

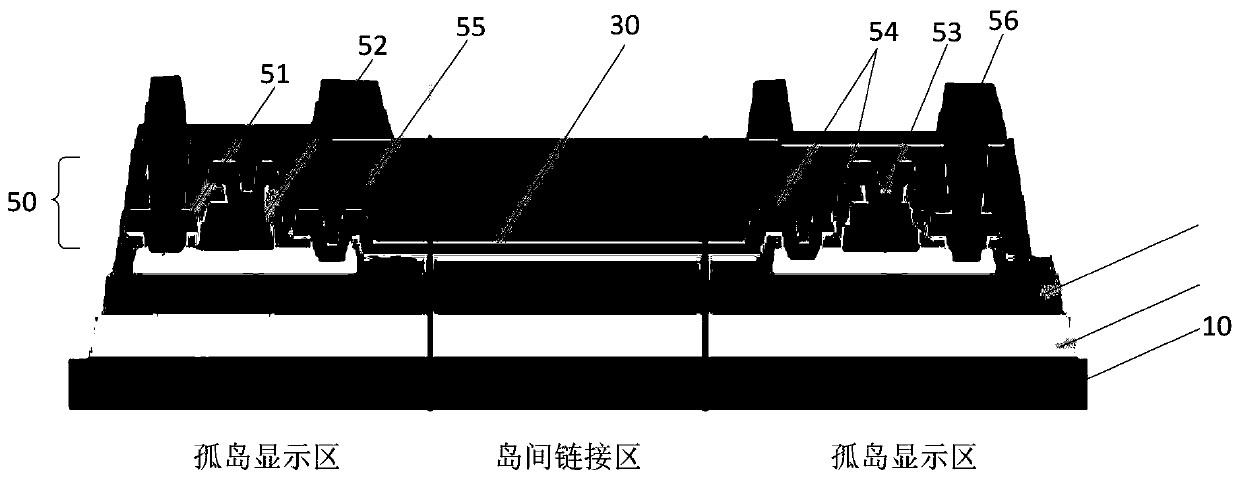

New use of ginsenoside Rg1

InactiveCN101084909AReduce stress damageReduce inhibitionOrganic active ingredientsNervous disorderLong-term potentiationNeurotoxic effect

The invention relates to an application of ginsenoside Rg 1 for treating / preventing Alzheimer disease, and provides new use of ginsenoside Rg 1 in treating / preventing Alzheimer disease caused by A beta 1-42 induced neurotoxic effect. This provided Chinese medicinal monomer of ginsenoside Rg 1 has the following functions: protecting cytochondriome and reducing neuron apoptosis through relieving oligo-A beta 1-42 induced neuron stress injury, relieving inhibiting effect of A beta 1-42 on PKA-CREB signal passage, contributing to form long-term potentiation, and improving memory, thereby providing direct powerful experimental foundation and theoretical basis for ginsenoside Rg 1 in treating Alzheimer disease, and has high scientific and originality, and application value.

Owner:FUJIAN MEDICAL UNIV UNION HOSPITAL

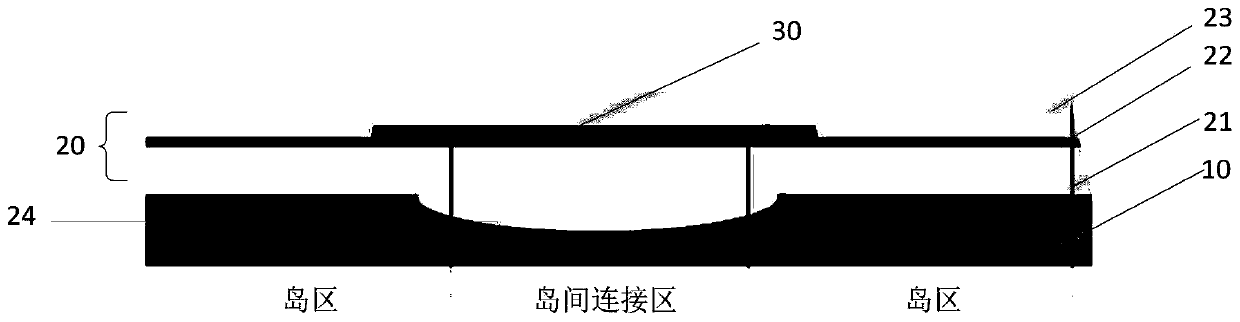

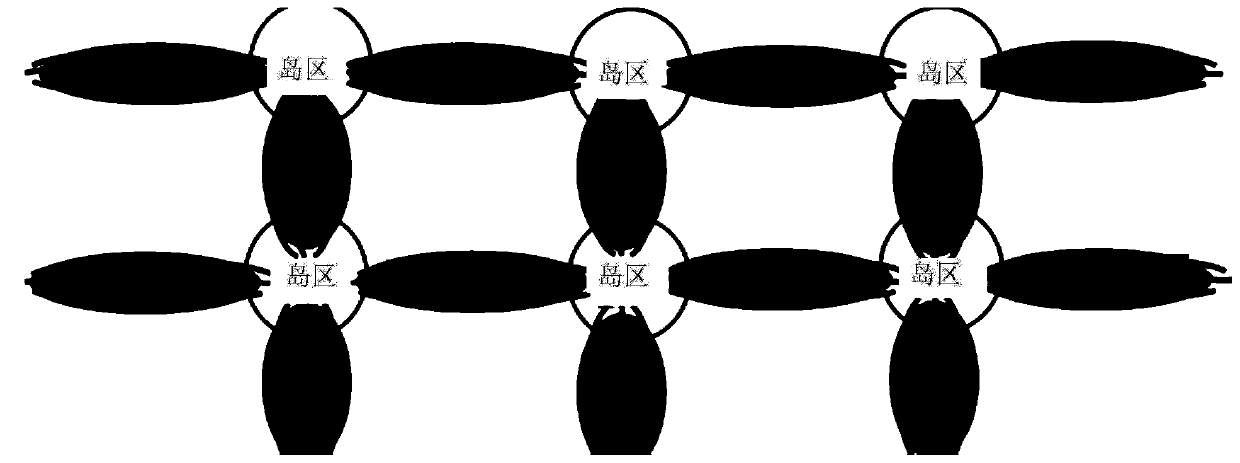

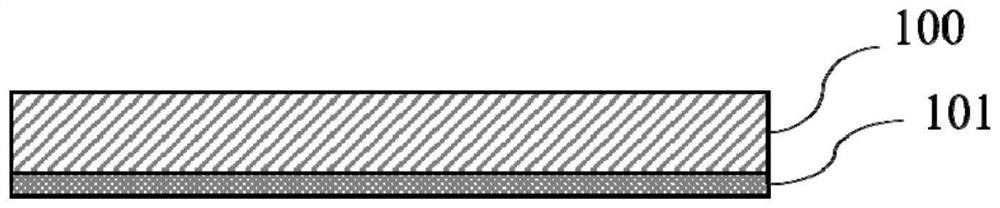

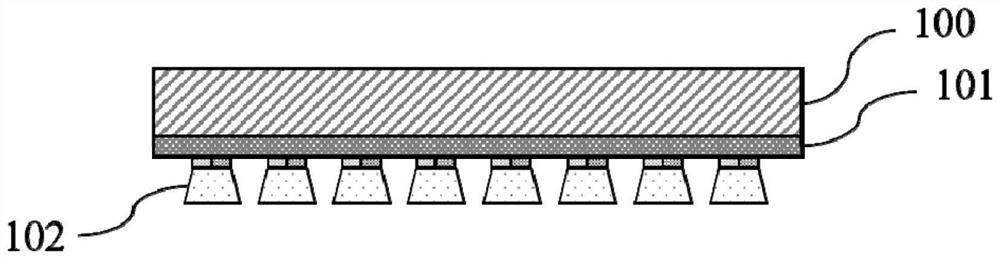

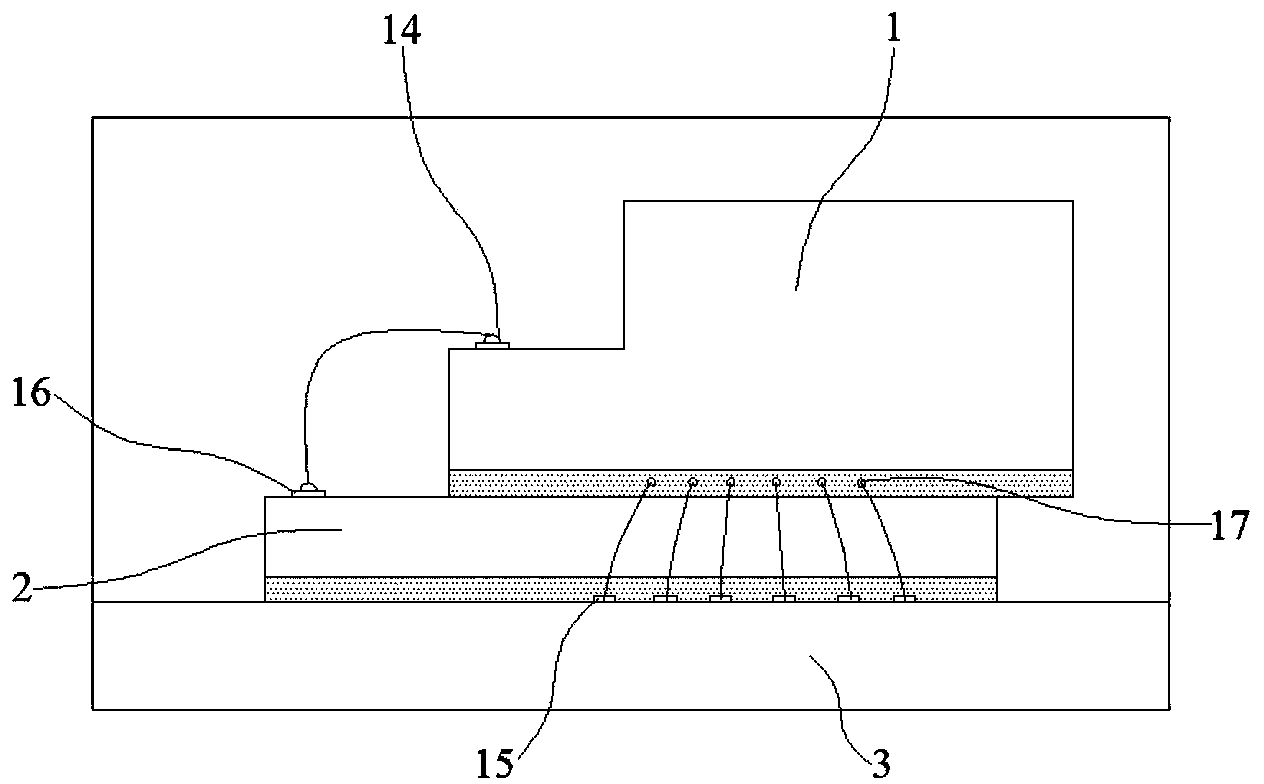

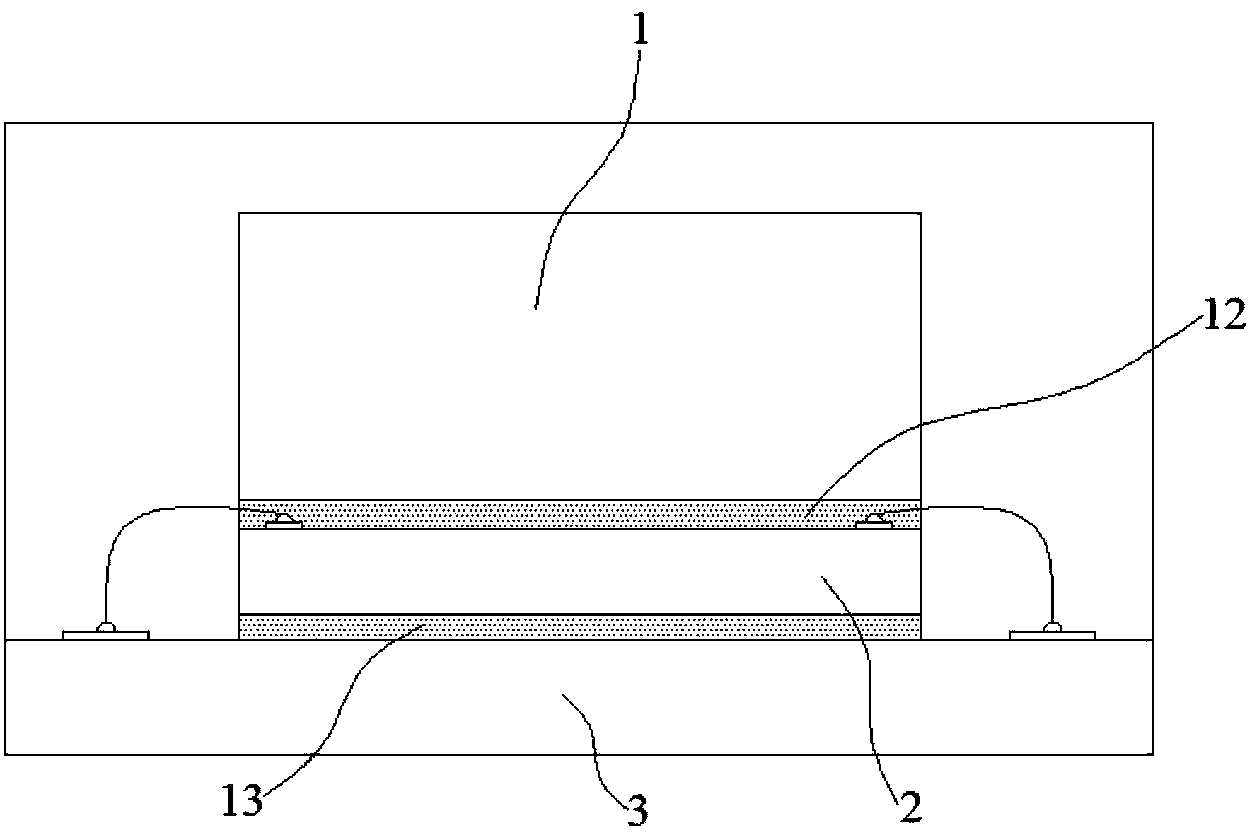

Flexible substrate, production method, flexible display device and electronic device

ActiveCN109755412AReduce shear stressImprove toleranceSolid-state devicesSemiconductor/solid-state device manufacturingCrazingEngineering

The invention discloses a flexible substrate, a production method, a flexible display device and an electronic device. The flexible substrate comprises a substrate body, a first flexible material layer arranged on the substrate body, a metal wire arranged on the first flexible material layer and a second flexible material layer covering the first flexible material layer and the metal wire. The flexible substrate also comprises multiple island regions and island connection regions, wherein the metal wire is arranged in the island connection regions and extend into the island regions. Accordingto the flexible substrate, the metal wire is arranged in the flexible substrate body with better tensile properties to relieve cracking or fracturing in the prior art, meanwhile, shear stress generated during warping deformation of the flexible substrate is reduced, and stress damage of the metal wire in the multidirectional folding and stretching process is reduced. Therefore, the tolerance of the flexible display device or the electronic device to device deformation is improved, and accordingly the yield of a product is increased.

Owner:BOE TECH GRP CO LTD

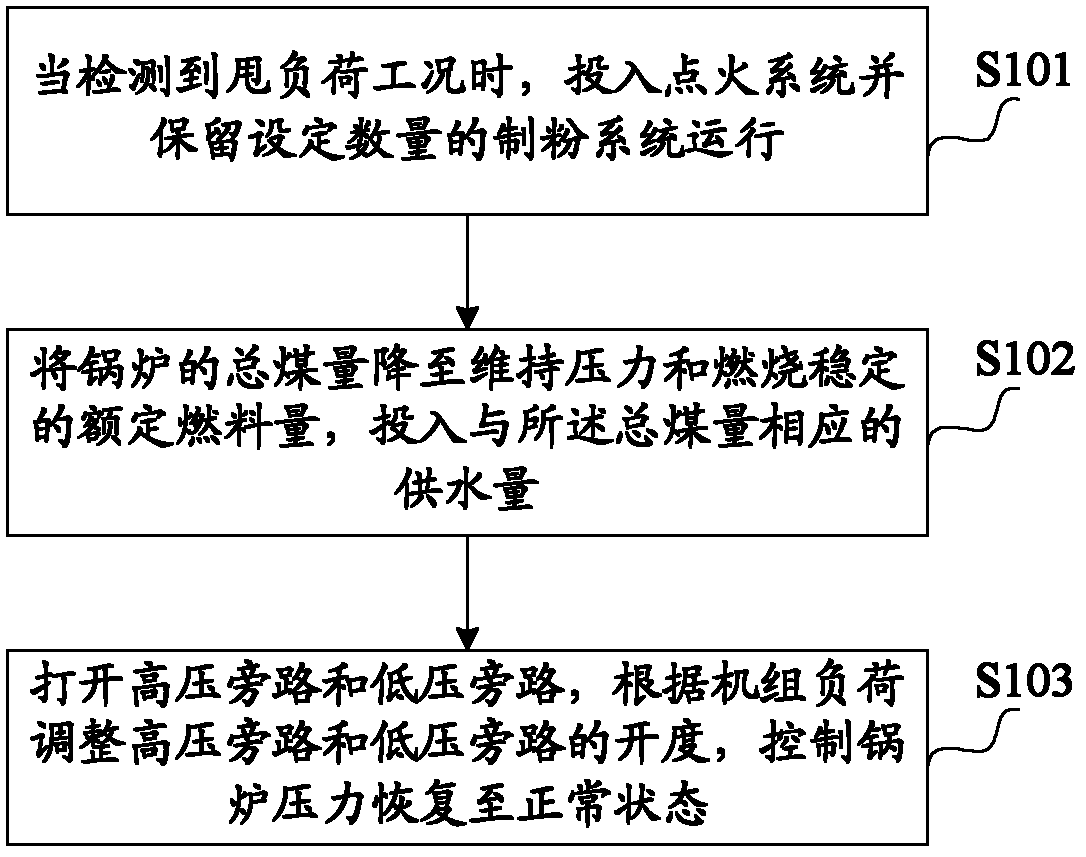

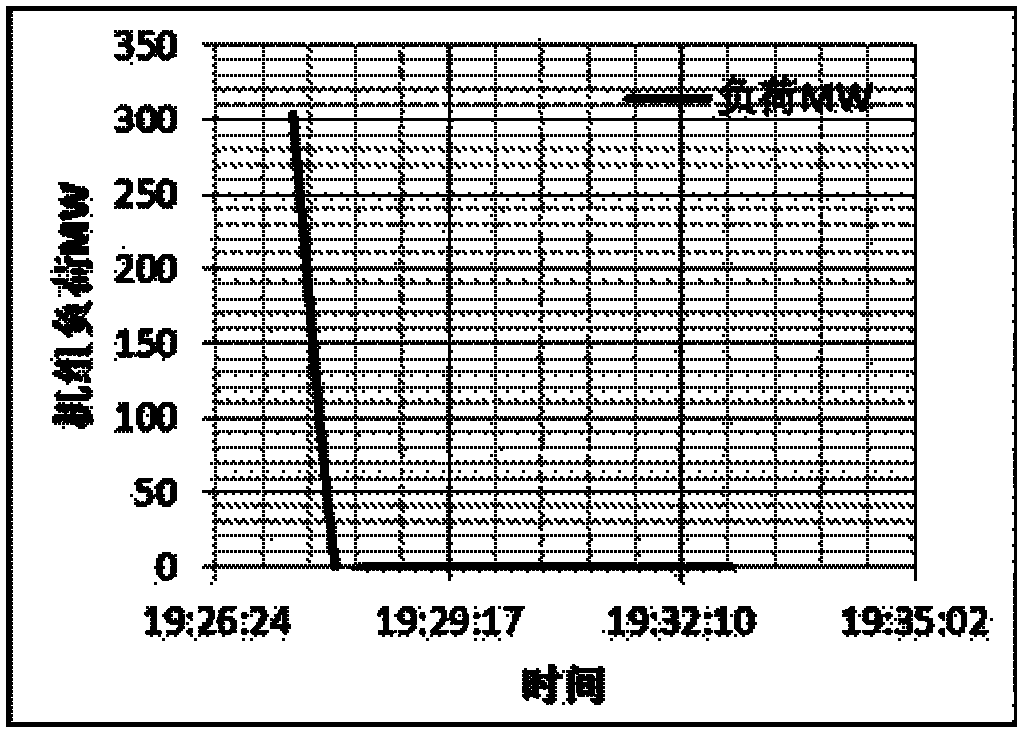

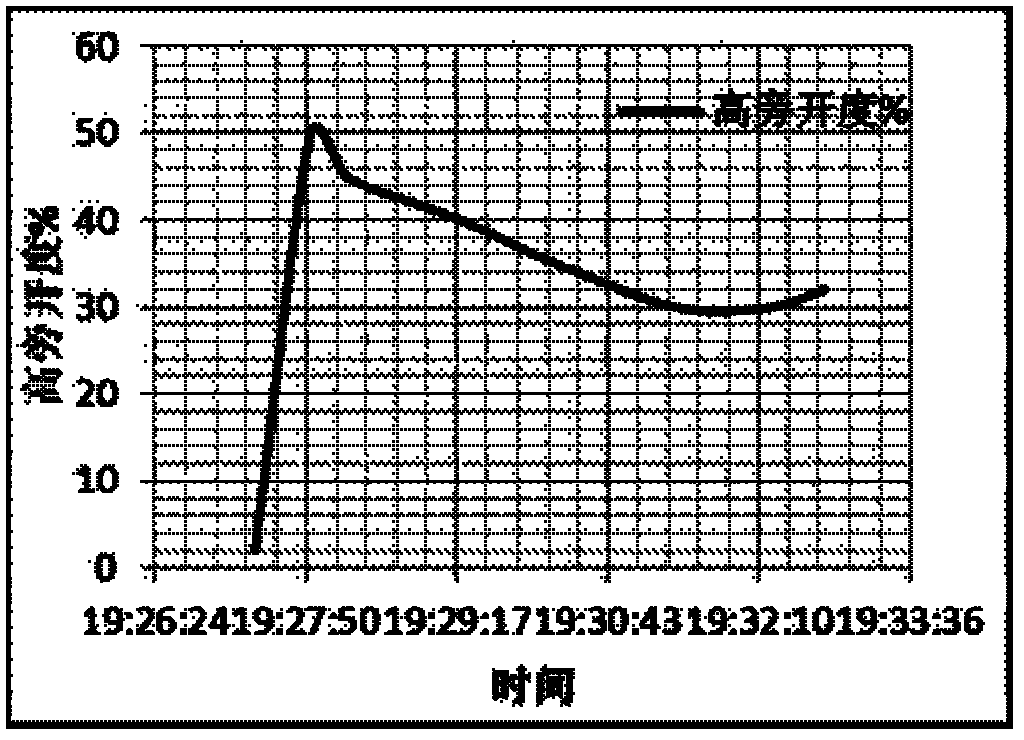

Method and system for controlling load-shedding working condition of supercritical unit

The invention provides a method for controlling a load-shedding working condition of a supercritical unit. The method comprises the following steps of: when the load-shedding working condition is detected, starting an ignition system and operating a set quantity of powdering systems; reducing the total coal quantity of a boiler to rated fuel quantity for maintaining pressure and combustion stability, and supplying water of which the quantity corresponds to the total coal quantity; and opening a high-pressure bypass and a low-pressure bypass, adjusting the openness of the high-pressure bypass and the openness of the low-pressure bypass according to a unit load, and controlling the pressure of the boiler to return to a normal state. Moreover, the invention also provides a system corresponding to the method. By the method and the system for controlling the load-shedding working condition of the supercritical unit, when the load-shedding working condition of a generator unit occurs, steam in the boiler is scientifically and reasonably discharged by bypass control, the boiler can safely and stably operate, stress damage to the metal of the unit is reduced, and safety in power supplying of a power grid is ensured.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Animal brain extract and food component composition for enhancing psycological stress adaptation

InactiveCN1596733AReduce riskImprove mental stress resilienceFood preservationUnknown materialsDiseaseVitamin C

An extract of animal's brain is prepared by use of composite enzyme and can play the role of increasing the adaptive capacity to mental stress. A food for increasing the adptive capacity to mental stress contains said extract and 20 other components including VA, VE, folic acid, glutamine, etc.

Owner:INST OF HYGIENE & ENVIRONMENTAL MEDICINE PLA ACAD OF MILITARY MEDICAL

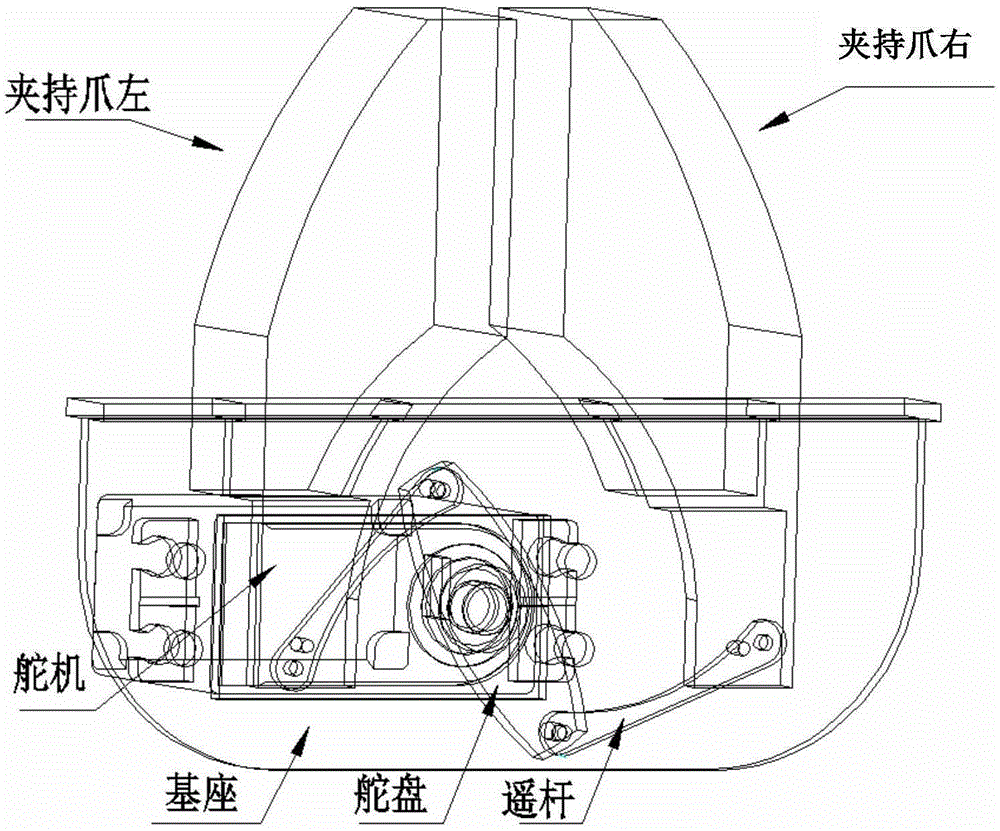

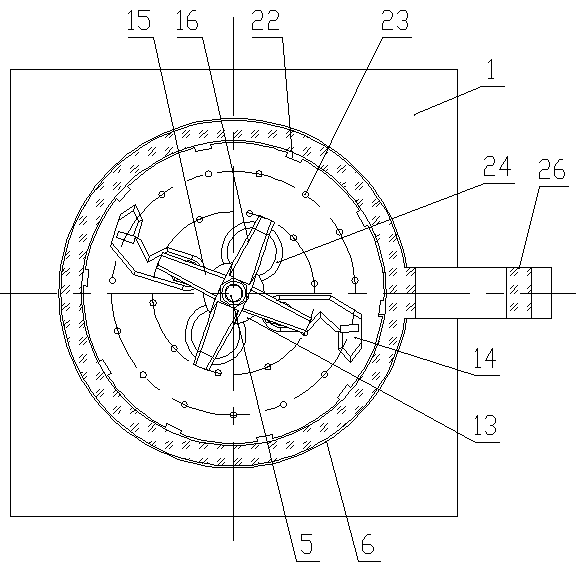

Mechanical gripper

The invention discloses a mechanical gripper. The mechanical gripper comprises a base, gripper jaws, a steering engine, a steering wheel, a helm disc and a rocking bar, wherein the gripper jaws are mounted on slideways of the base; the steering engine drives the helm disc to rotate; the helm disc drives the rocking bar, and then the rocking bar drives the gripper jaws, so that the gripper jaws slide on the slideways and an object can be clamped or released. The mechanical gripper disclosed by the invention can work in a narrow operation space; the mechanical gripper is light in overall weight, simple and reliable in structure, and high in stability, so that the mechanical gripper is particularly suitable for being used in aircrafts or other special industry.

Owner:湖南哈工机器人研究院有限公司

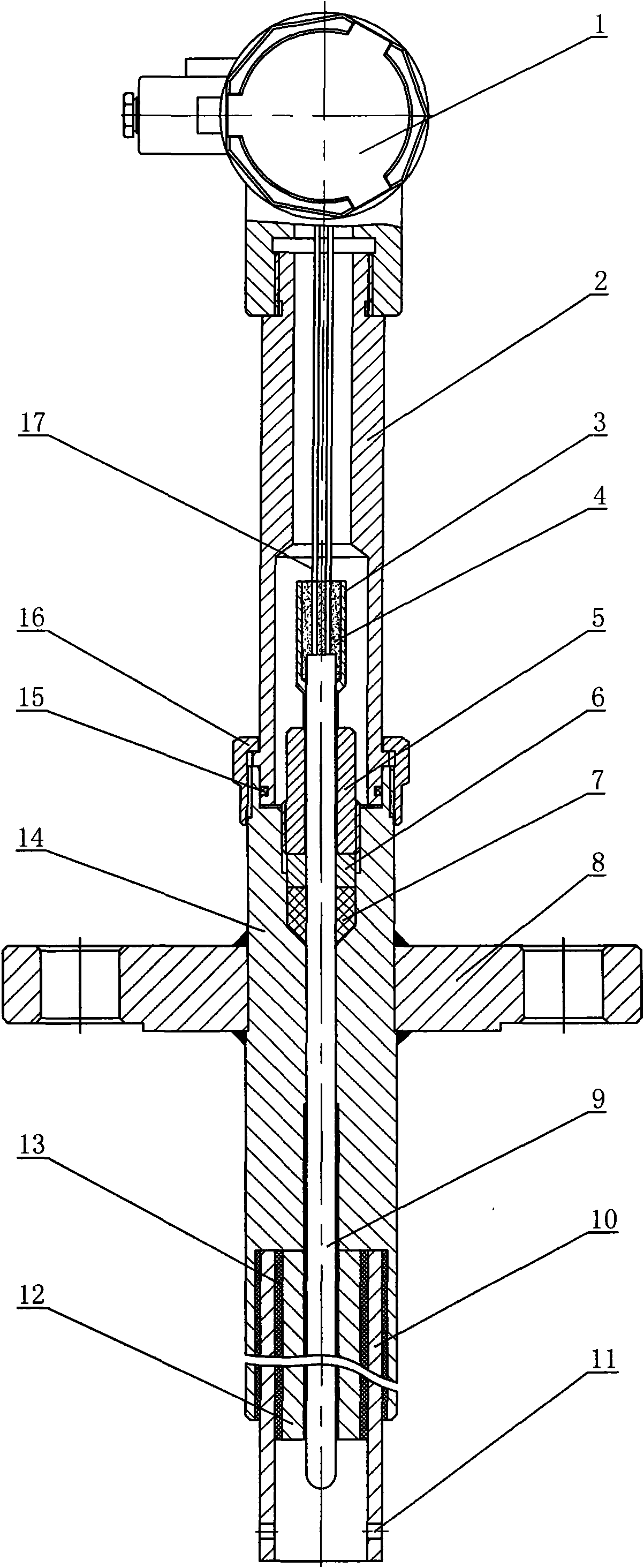

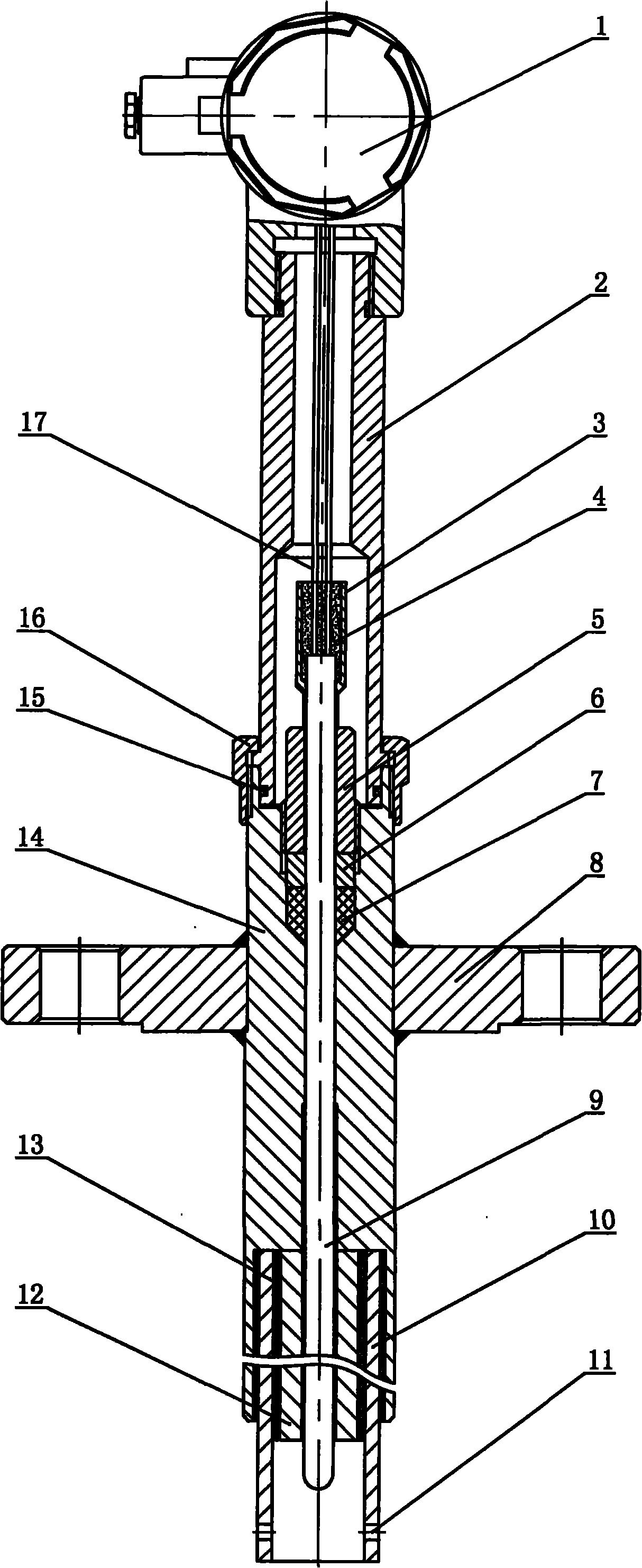

Quick-response leakproof high-temperature thermocouple

ActiveCN101806638AReduced impact strengthShort measurement response timeThermometers using electric/magnetic elementsUsing electrical meansEngineeringThermocouple

The invention belongs to a quick-response leakproof high-temperature thermocouple, which consists of a junction box, a protective casing and a temperature measurement element. The protective casing consists of an upper protective casing and a lower protective casing in coaxial arrangement; the upper end of the upper protective casing is fixedly arranged on the junction box; and the temperature measurement element is arranged in the protective casing coaxially, and a software wire at the upper end of the temperature measurement element is fixed on the junction box. The quick-response leakproof high-temperature thermocouple is characterized in that: an open reinforced tube is fixedly arranged at the lower end of the lower protective casing coaxially; and the lower end of the temperature measurement element is arranged in the reinforced tube out of the protective casing. The quick-response leakproof high-temperature thermocouple has simple structure, scientific and reasonable design, short response time in measurement, convenient replacement of a measurement core, high measurement accuracy and relatively high safety.

Owner:TIANJINSHI ZHONGHUAN TEMPERATURE METERS

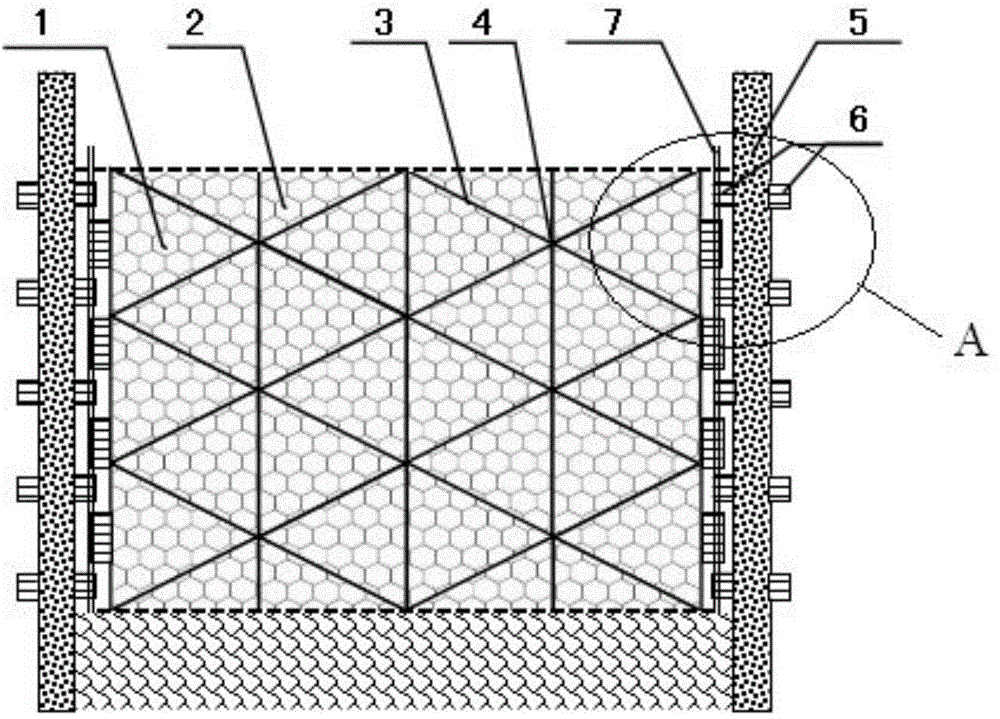

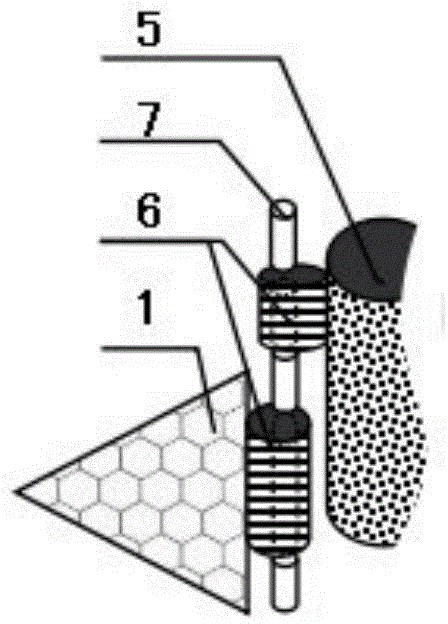

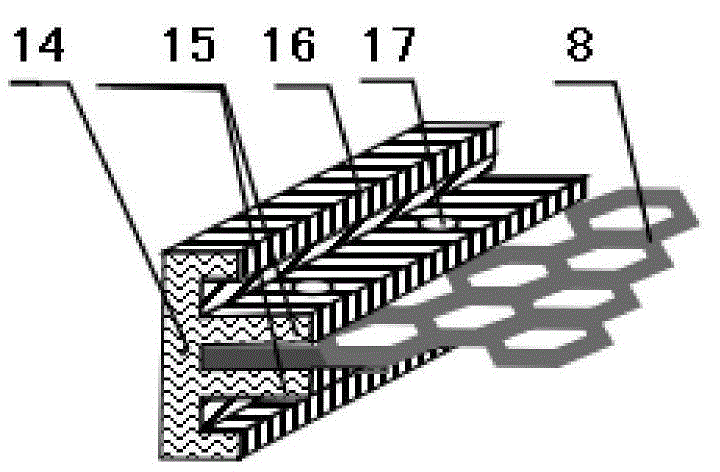

Method for assembling underwater copper alloy perforated mesh of pasture type shallow sea fence farming facility

ActiveCN104813966AStable structureExtended service lifeClimate change adaptationPisciculture and aquariaIsoetes triquetraRight triangle

The invention relates to a method for assembling an underwater copper alloy perforated mesh of a pasture type shallow sea fence farming facility. Basic components include standard assemblies of copper alloy perforated mesh plates with equilateral triangular profile and standard assemblies of copper alloy perforated mesh plates with right angled triangular profile. Assembly of standard assemblies of copper alloy perforated mesh plates is completed through ultrahigh molecular weight polyethylene extruded profiled lath connecting pieces and ultrahigh molecular weight polyethylene injection moulded corner-end connecting pieces. After the copper alloy perforated mesh plates are assembled, the copper alloy perforated mesh plates are hinged to reinforced concrete piles via endless tube section assembly parts prefabricated on the reinforced concrete pillar and ultrahigh molecular weight polyethylene bars. The method prevents adhesion of marine fouling organisms and retains excellent seawater flowing.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

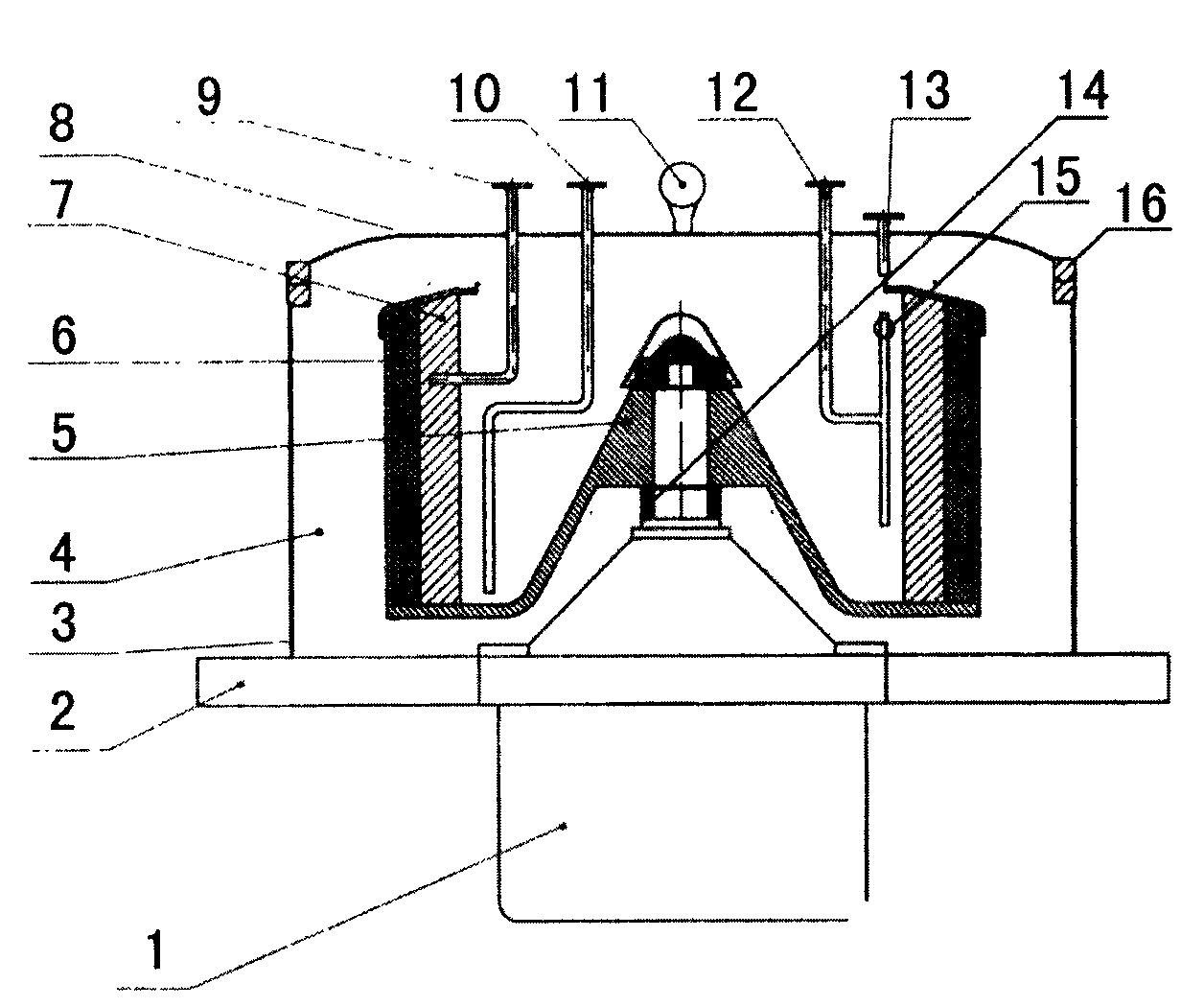

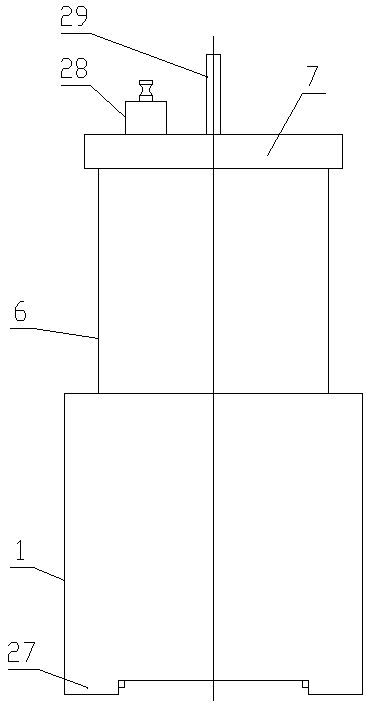

Plate-type settling centrifuge for perfusion

InactiveCN101653749AHigh recovery rateSufficient precipitationRotary centrifugesEngineeringPerfusion

The invention discloses a plate-type settling centrifuge for perfusion, which is used for recycling cultured cells suspended in a bioreactor. A cover of the centrifuge is provided with a material inlet / recycling pipe, a liquid casting pipe, a culture medium conveying pipe and a spraying hole, all of which extend into a rotary drum and are respectively connected with a bioreactor, a supernate storage tank and a culture medium storage tank through a T-shaped valve set. A transmission principal shaft is connected with a rotary drum cavity through four in-series sealing connections comprising framework seal, mechanical sealing, water sealing and mechanical sealing. The rotary drum cavity and the connecting pipes can be sterilized by steam. The cultured material in the bioreactor is sent into the rotary drum through the material inlet / recycling pipe, the centrifugated cells settle on the rotary drum wall, supernate is absorbed out through the liquid casting pipe, the culture medium is sprayed on the settled cells on the rotary drum wall rotating slowly through the culture medium conveying pipe and the spraying hole, and the suspended cells are conveyed back into the bioreactor through the recycling / material inlet pipe.

Owner:BEIJING MABWORKS BIOTECH

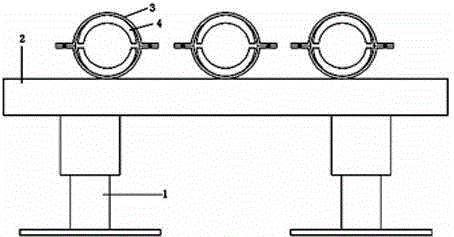

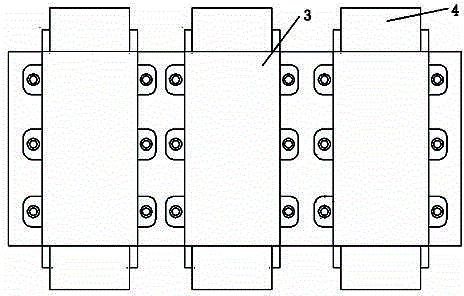

Cable bearer used for cable channel

InactiveCN103062504AImprove corrosion resistanceKeep awayPipe supportsWorking environmentUltimate tensile strength

The invention discloses a cable bearer used for a cable channel. The cable bearer used for the cable channel comprises a bearer and cable grooves. The bearer is formed by bearing legs and a bearing beam, and the bearing legs and the bearing beam are connected through bolts. Each cable groove comprises a fixed groove, a fastening groove and a net-shaped spacer. Each fastening groove and each fixed groove are connected through bolts. The net-shaped spacers are respectively arranged inside the fixed grooves and the fastening grooves. The fixed grooves are tightly connected with the bearing beam through bolts. The cable bearer used for the cable channel is high in mechanical strength and corrosion resistance, the shape and the size can be customized according to actual using needs, distance between a cable and a channel bottom of the cable channel and distance between the cable and a cable wall are short, using is flexible, application range is wide, and working environment of the cable is relatively good.

Owner:QINYANG POWER INTEGRATED CORP

Four-level food grinding smashing high speed blender

The invention discloses a four-level food grinding smashing high speed blender. The blender comprises a base, an electric heater, a dry burning resistance electrode, a temperature sensor, a rotary shaft, a cup body, a cup cover, a motor and a four-level grinding smashing assembly, and the bottom of the cup body is arranged on the base; an up-down through ladder hole is formed in the center which is located at a placing groove and is of the base, a main shaft is in transmission connection with the lower end of the rotary shaft through a coupler, the ladder hole extends upward and is located atthe upper portion of the ladder hole, the rotary shaft is rotatably connected with the inner wall of the ladder hole through a bearing assembly, a sealing disc sleeves the rotary shaft and is arrangedon the upper portion of the ladder hole, and an end cover used for limiting the axial position of the bearing assembly is arranged at the bottom of the ladder hole; the electric heater, the dry burning resistance electrode and the temperature sensor are all arranged at the bottom of the cup body, and the four-level grinding smashing assembly is fixedly arranged on the upper end portion of the rotary shaft. The four-level food grinding smashing high speed blender has the advantages that the blender is reasonable in design and compact in structure, the grinding and smashing effect is good through four-level high speed rotating cutters, better damping effect is achieved, the stability is strong, and the noise is low.

Owner:刘建秀

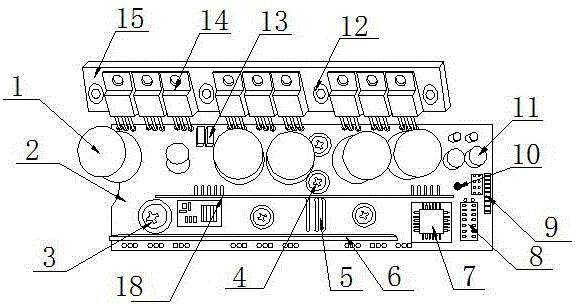

Power controller based on die-casting mould structure

InactiveCN106659038AImprove cooling effectImprove performanceCircuit arrangements on support structuresHermetically-sealed casingsPower controllerBridge type

The invention discloses a power controller based on a die-casting mould structure. The power controller comprises a large-current filtering element, a main PCB, a three-phase motor output terminal, a power input terminal, a current detection element, a bus bar, a master control MCU, a signal input filtering module, a wiring terminal, an indicating lamp, an auxiliary power supply discrete element, an elliptical positioning hole, an upper and lower bridge separation driver, a power switch tube, an aluminum substrate, an aluminum housing, heat dissipation teeth and a bridging type crossover auxiliary PCB. According to the technical scheme of the power controller in the invention, a double-row aluminum substrate and an aluminum shell are connected to improve heat dissipation effect, so that the thermal damage to the switch tube is reduced. Based on the bridging manner of PCBs, the current uniformity of power switch tubes connected in parallel is guaranteed to the greatest extent. Meanwhile, the large-current impact resistance of the entire circuit is improved. The power input terminal and three output terminals (U, V and W) are led out in the casting mode by using a copper column and the aluminum shell of a die-casting mould. Therefore, the problem that water flows into the incoming and outgoing lines and the structure of a common controller in the prior art can be solved.

Owner:刘军

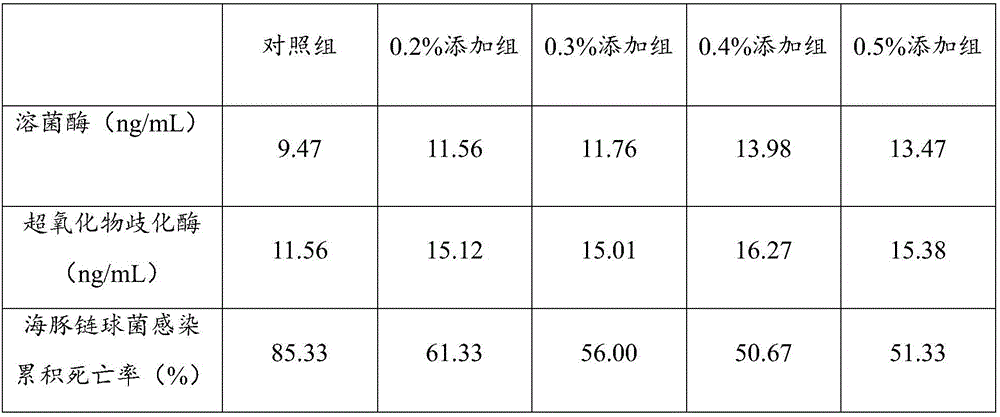

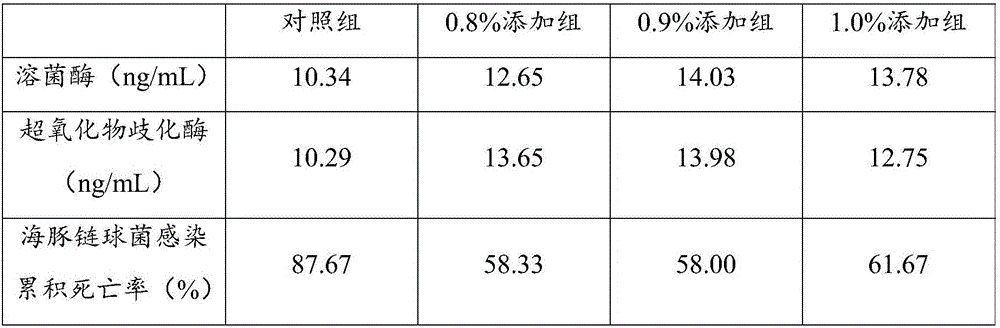

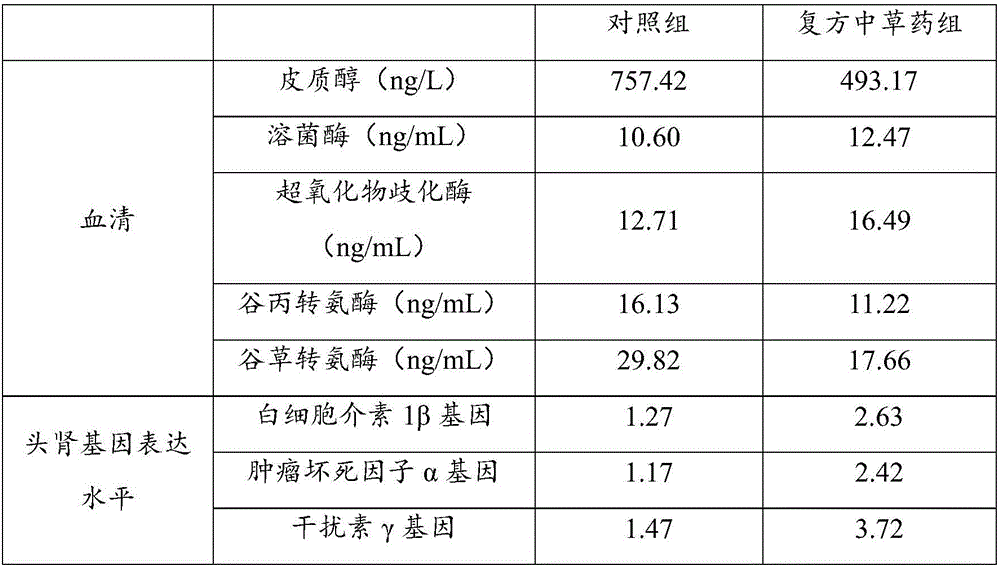

Method for improving streptococcus iniae infection resisting capability of GIFT tilapia in high-density culture

ActiveCN106172145AImprove survival rateLow priceAntibacterial agentsFood processingTilapiaHigh density

The invention discloses a method for improving the streptococcus iniae infection resisting capability of GIFT tilapia in high-density culture. The method comprises the steps of preparing of compound Chinese herbal medicine, adding, feeding and breeding management. Compared with the prior art, the method has the following advantages: (1) the immunological protection of the GIFT tilapia in high-density culture can be effectively improved, and the survival rate of GIFT tilapia infected with streptococcus iniae is improved; (2) the compound Chinese herbal medicine added in a feed belongs to environment-friendly feed additives, and has less negative effect on fish and water; (3) the blood and head-kidney immunological stress response can be effectively enhanced, and the liver stress injury is reduced; (4) the adopted technological steps of the method are simple, the Chinese herbal medicine is low, and easy to obtain and preserve, and can be well absorbed and utilized by a fish body, and excrement of the GIFT tilapia does not impact the water quality.

Owner:江苏恒泰环保科技发展有限公司

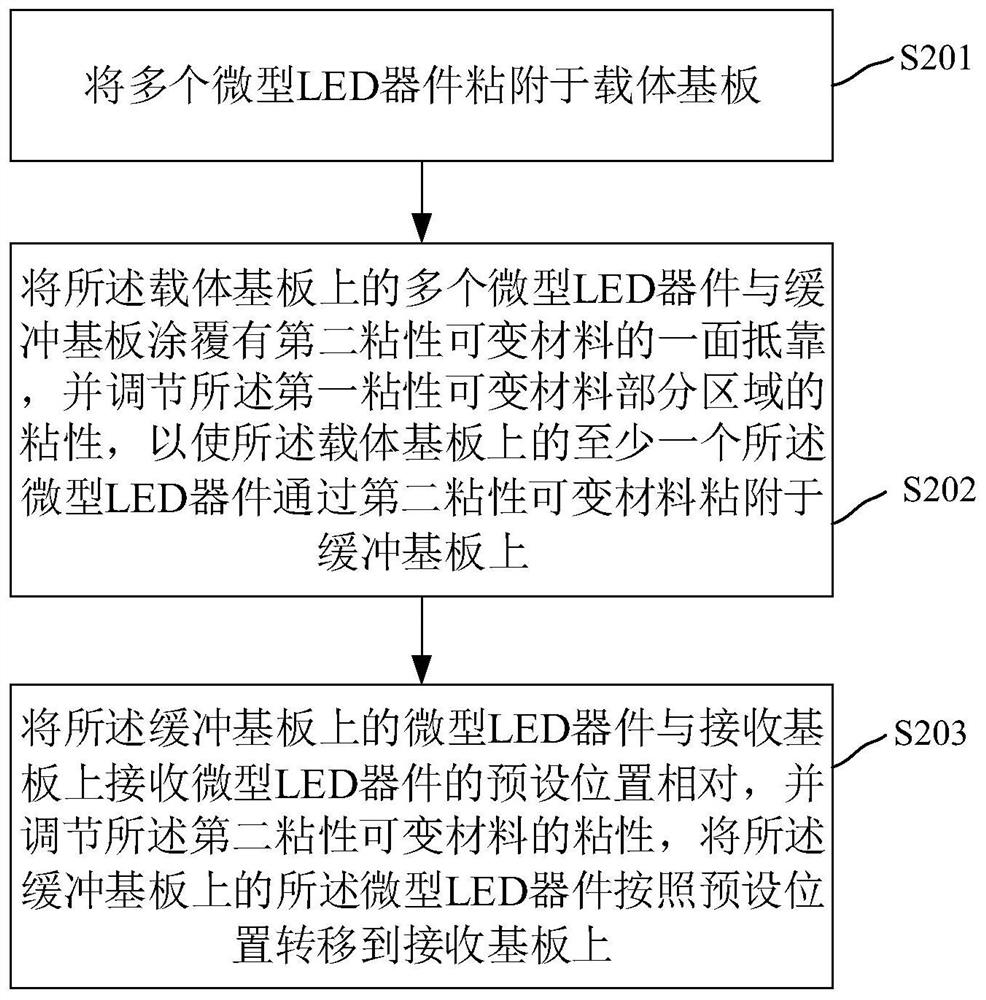

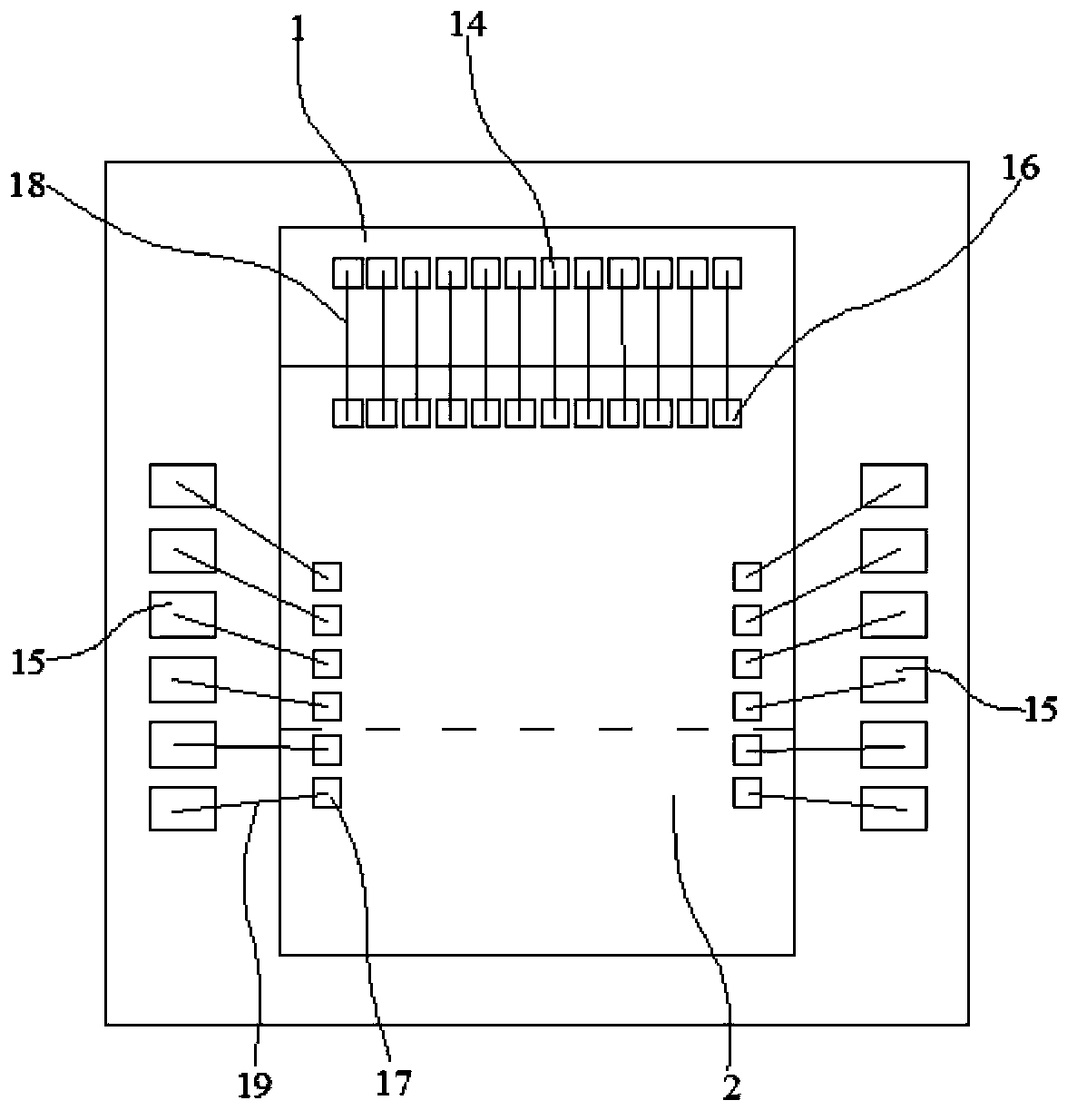

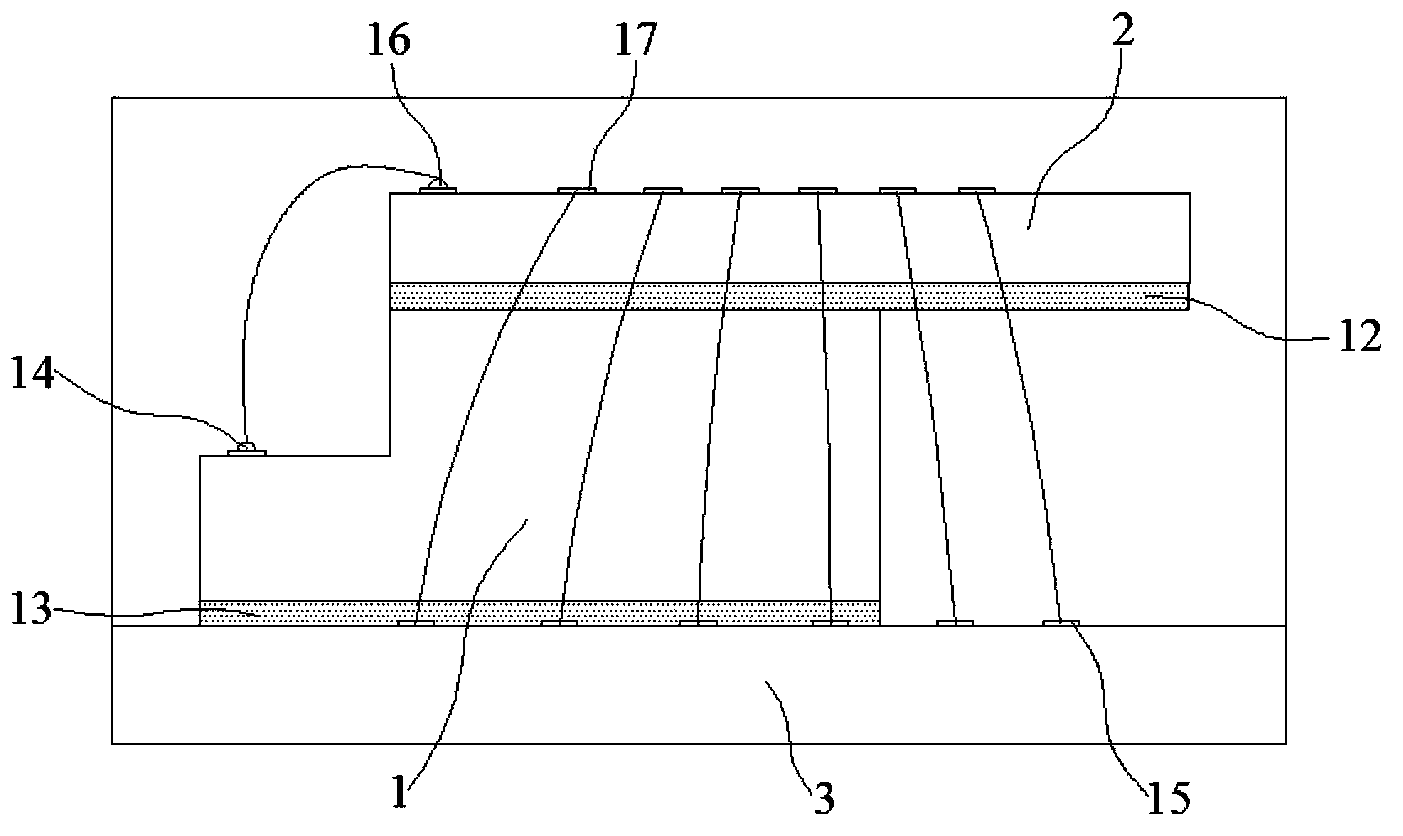

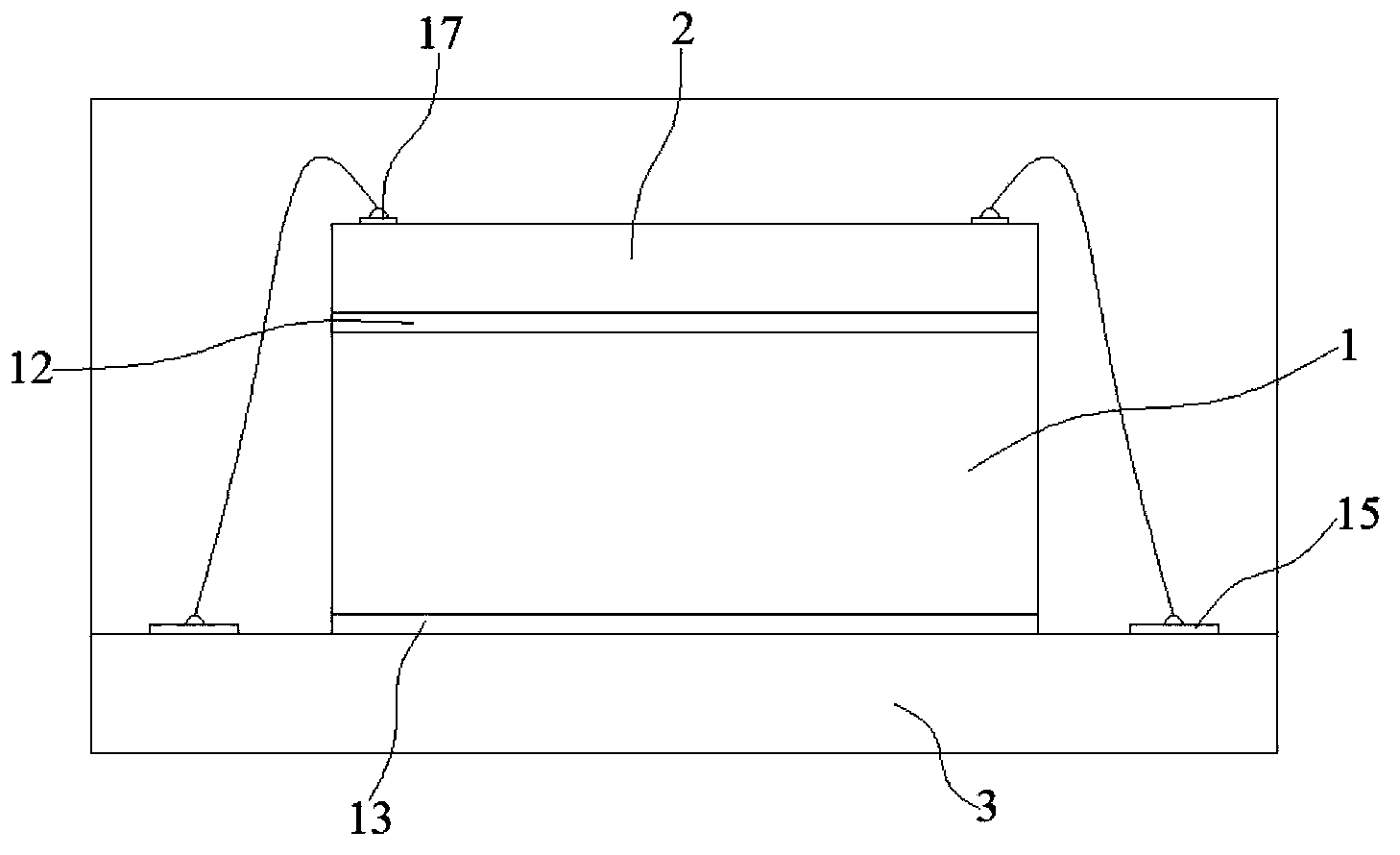

Mass transfer method and device for micro LED devices

PendingCN112366168AAvoid breakingReduce stress damageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention relates to a mass transfer method and device for micro LED devices. The mass transfer method method for the micro LED devices comprises the steps of adhering a plurality of micro LED devices to a carrier substrate; abutting the plurality of micro LED devices on the carrier substrate against the face, which is coated with a second viscosity variable material, of the buffer substrate,and adjusting the viscosity of part of the area of the first viscosity variable material so as to enable the micro LED devices on the carrier substrate to be adhered to the buffer substrate; and transferring the micro LED devices on the buffer substrate to a receiving substrate according to preset positions. According to the mass transfer method and device for the micro LED devices, the carrier substrate, the buffer substrate and the receiving substrate are provided, the second viscosity variable material is used for efficiently and selectively transferring the micro LEDs in batches, stress damage generated in the transfer process is absorbed through the buffer substrate, stress loss generated by attachment is reduced, the micro LED devices are prevented from being broken in mass transfer,the transfer difficulty is reduced, and the transfer effect is good.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG

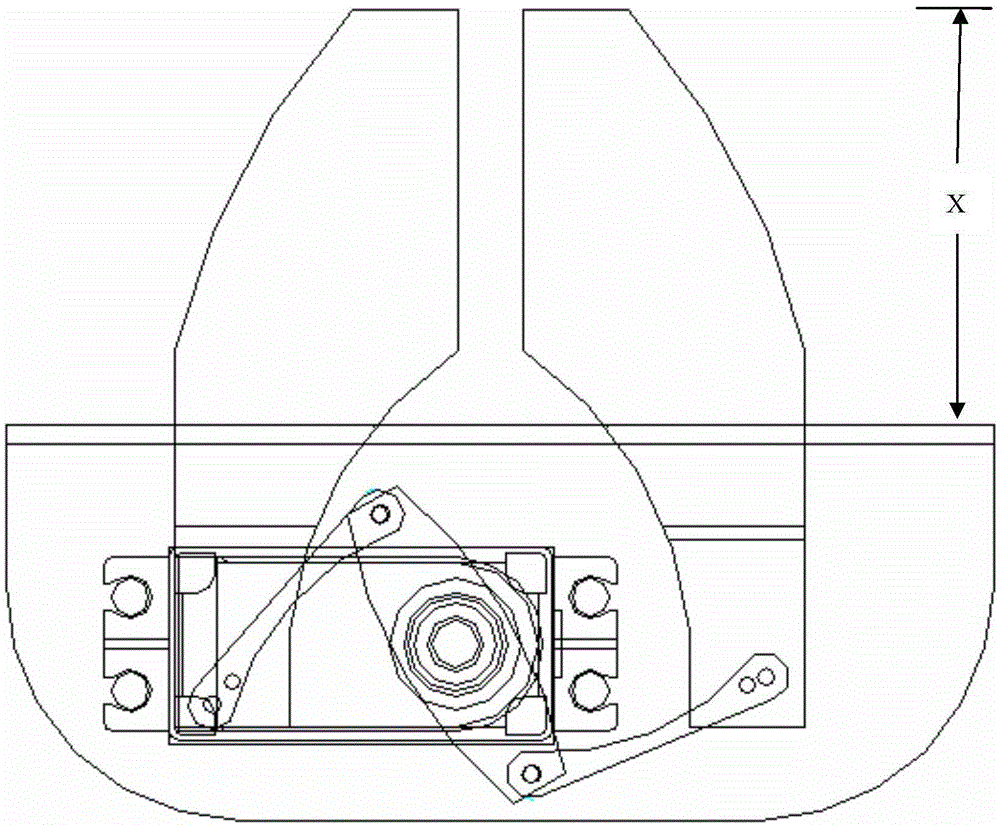

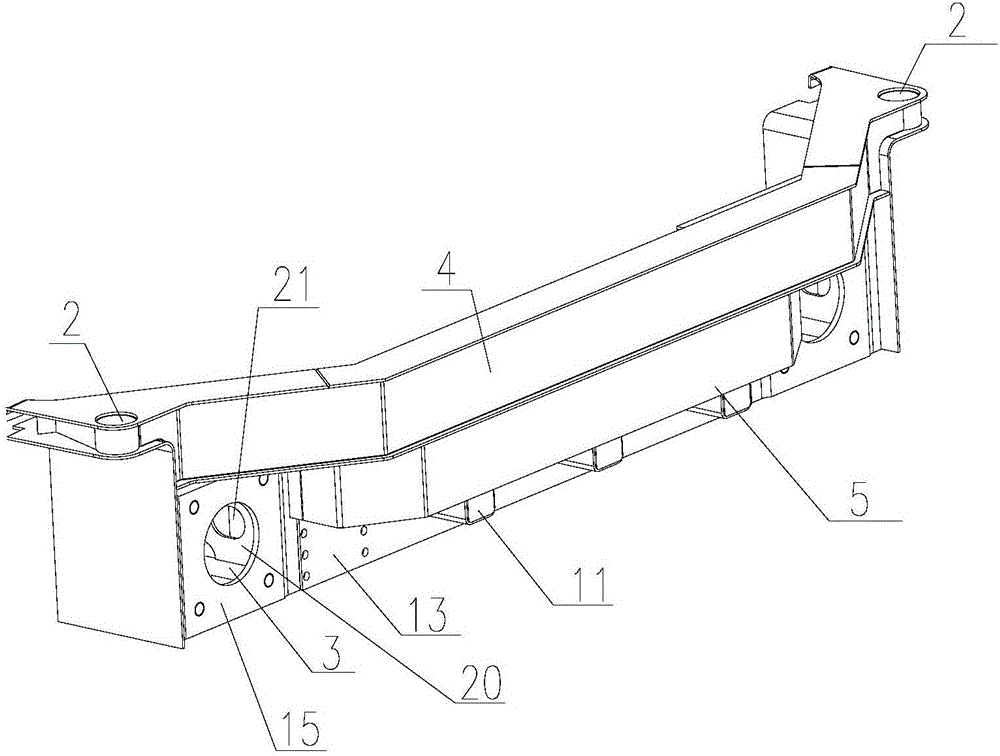

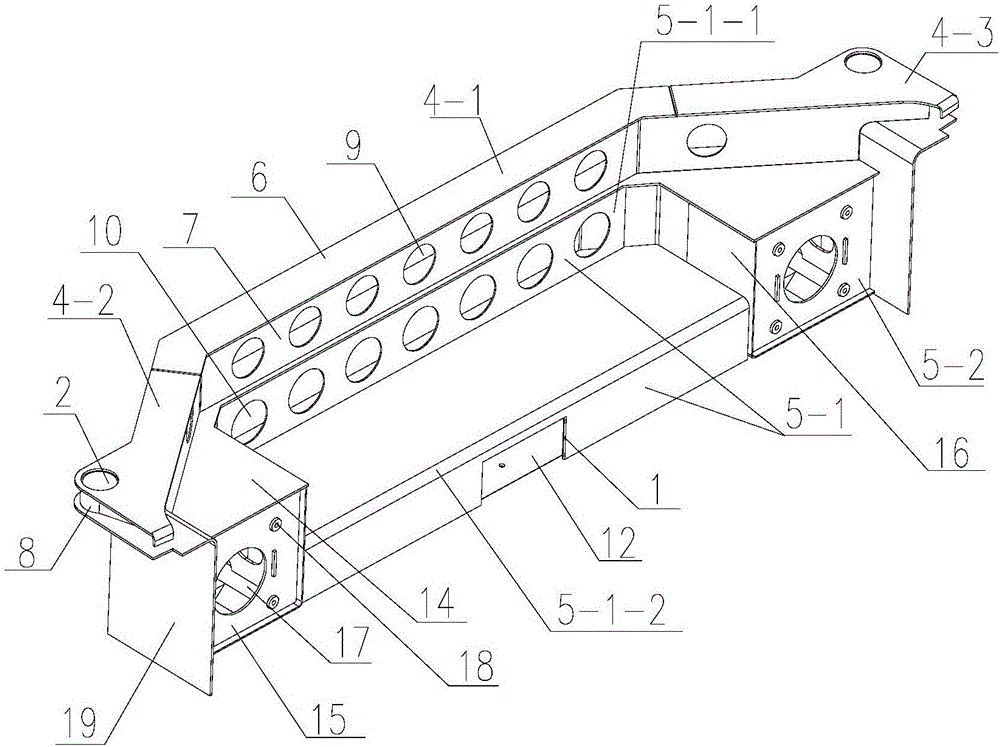

Anticreeper mounting base for low-floor rail vehicle

ActiveCN106347405ASmall footprintGuaranteed structural rigidityRailway wheel guards/bumpersEngineeringUltimate tensile strength

The invention relates to an anticreeper mounting base for a low-floor rail vehicle. The anticreeper mounting base is of a box structure; a vehicle hook mounting joint and / or a driver cab mounting port and / or an anticreeper mounting port is arranged on the mounting base, the vehicle hook mounting joint is fixedly connected with a vehicle hook mounting base, the driver cab mounting port is fixedly connected with a driver cab vehicle body, and the anticreeper mounting port is used for mounting an anticreeping energy absorbing element. The anticreeper mounting base has the advantages that the structure is simple, the occupation space of the whole mounting base is small, and the installation requirement of the narrow space of a chassis of the low-floor rail vehicle is met; at the premises of guaranteeing the structure rigidity and connecting strength of the mounting base, the maximum light-weight design is realized, and the higher light-weight requirement of the vehicle is met.

Owner:CRRC QINGDAO SIFANG CO LTD

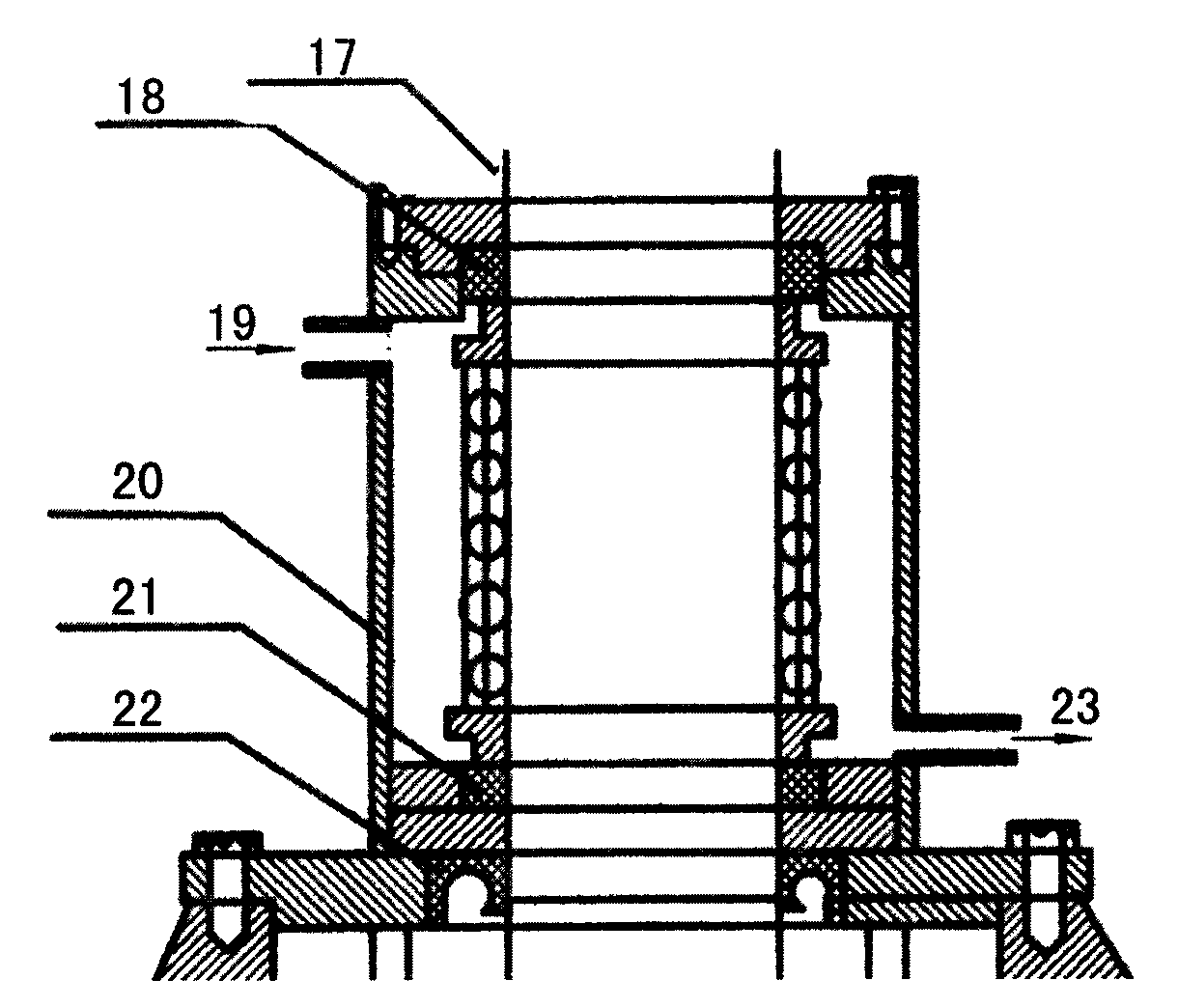

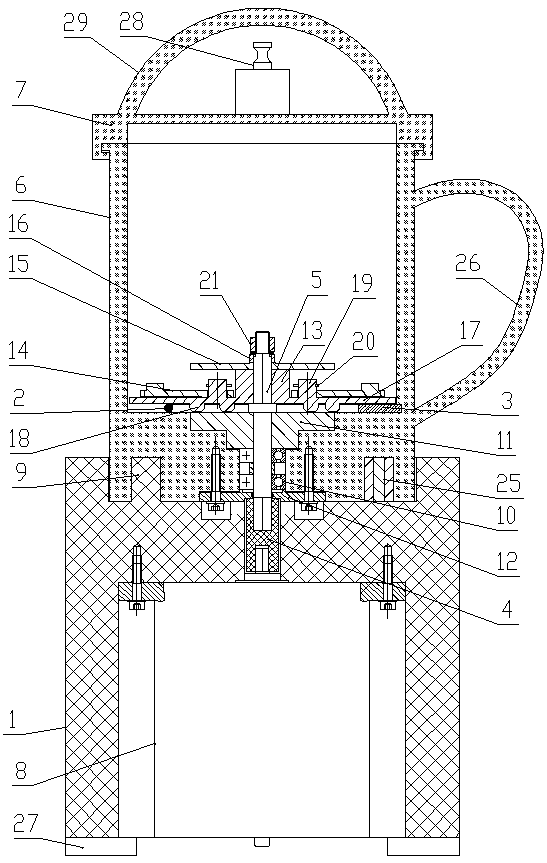

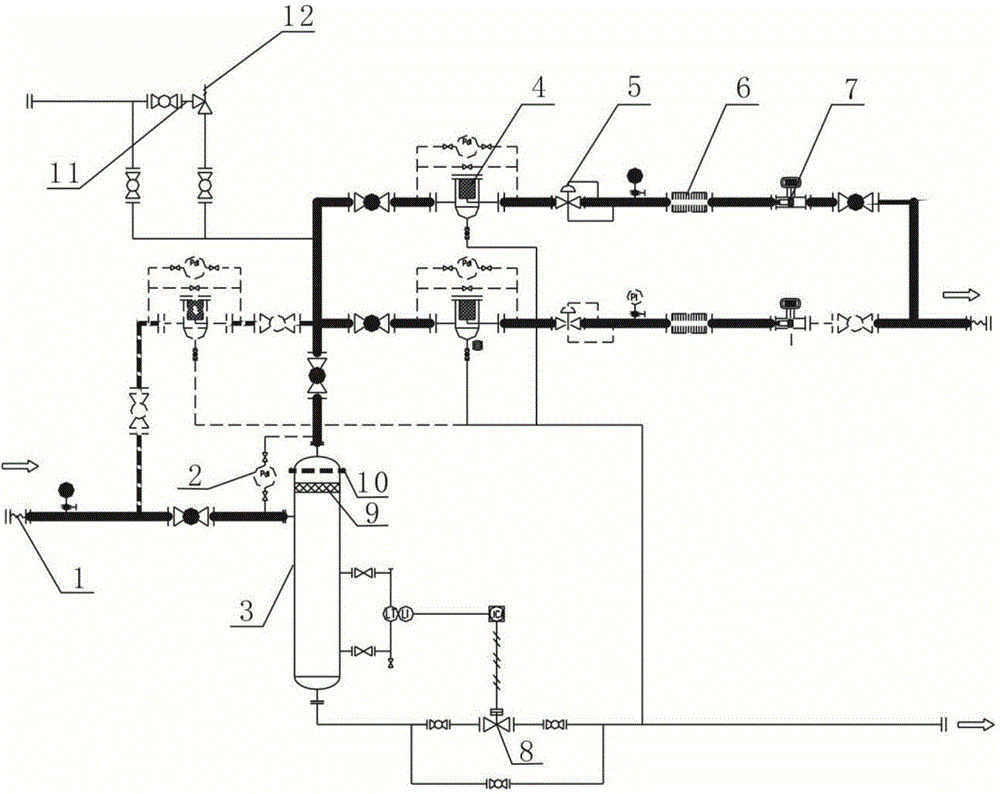

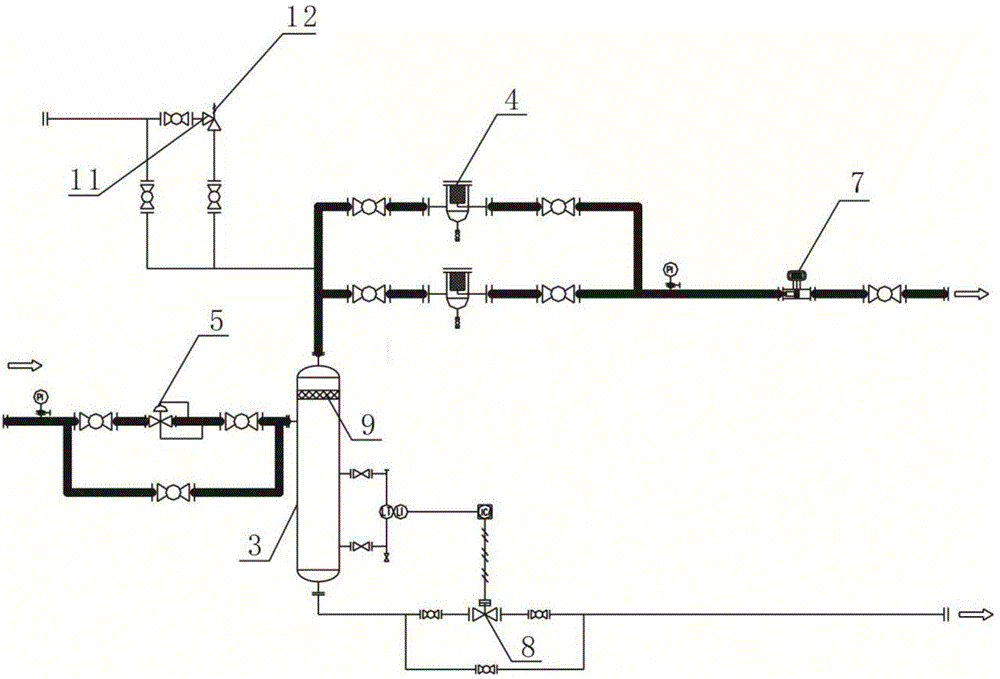

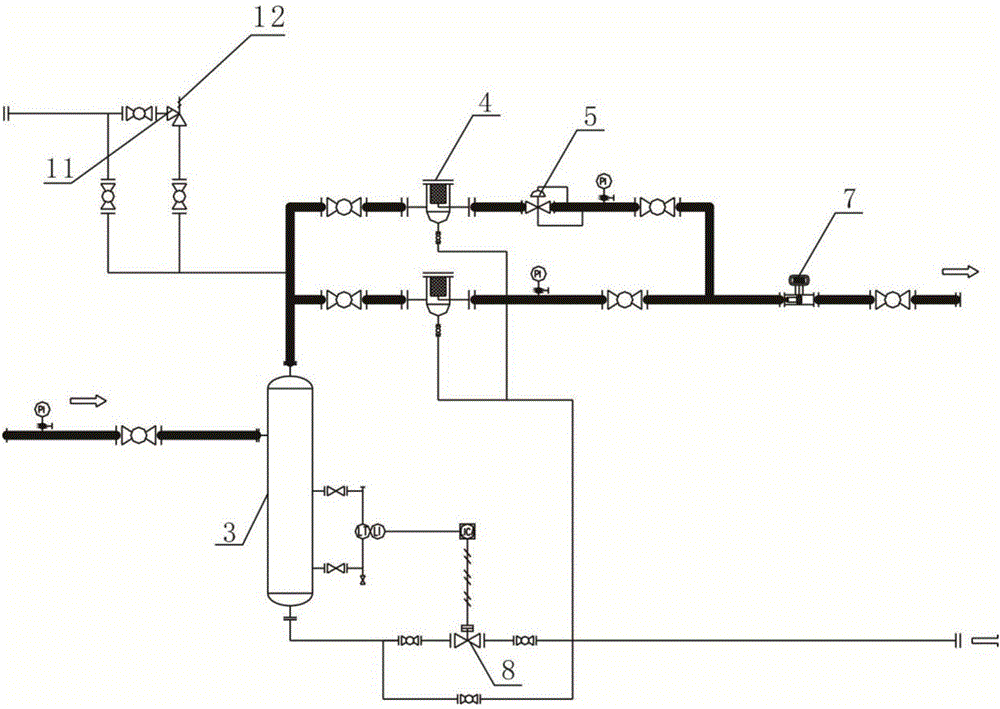

Pressure-regulating and metering pry for liquefied natural gas device

ActiveCN104654018AReduce stress damageExtended service lifePipeline systemsVapor–liquid separatorProcess engineering

The invention discloses a pressure-regulating and metering pry for a liquefied natural gas device. The pressure-regulating and metering pry comprises a prizing base and further comprises a gas-liquid separator which is arranged on the prizing base in a natural gas flow direction and two branches which are successively connected with the top of the gas-liquid separator, wherein each branch comprises a basket type filer, a pressure-regulating valve, a rectifier and a flow rate meter which are connected in sequence; ripple compensators which are used for preventing prizing blocks from being damaged by stress due to extremely high natural gas pressure are respectively arranged at a gas inlet end and a gas discharge end of the metering pry; a bypass which is used for replacing during maintenance of the gas-liquid separator is further arranged between a natural gas inlet end and a natural gas outlet end of the gas-liquid separator. The metering pry disclosed by the invention is relatively optimized and reasonable in design, effectively prolonged in service life, and can truly realize continuous pressure-regulating and metering to raw material natural gas; moreover, two loops are arranged to truly realize the pressure-regulating function and the metering function of double loops, so that the production operation cost and the equipment maintenance cost are effectively reduced.

Owner:SICHUAN HONGDA PETROLEUM & NATURAL GAS

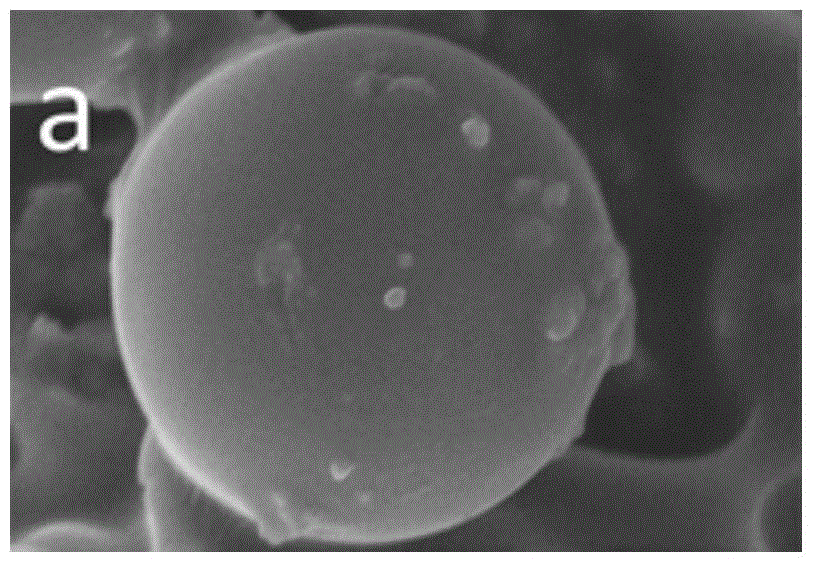

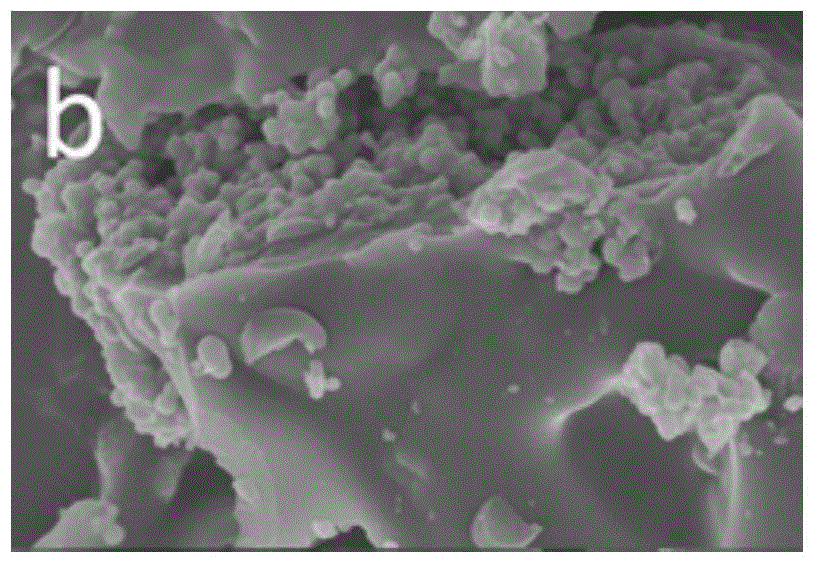

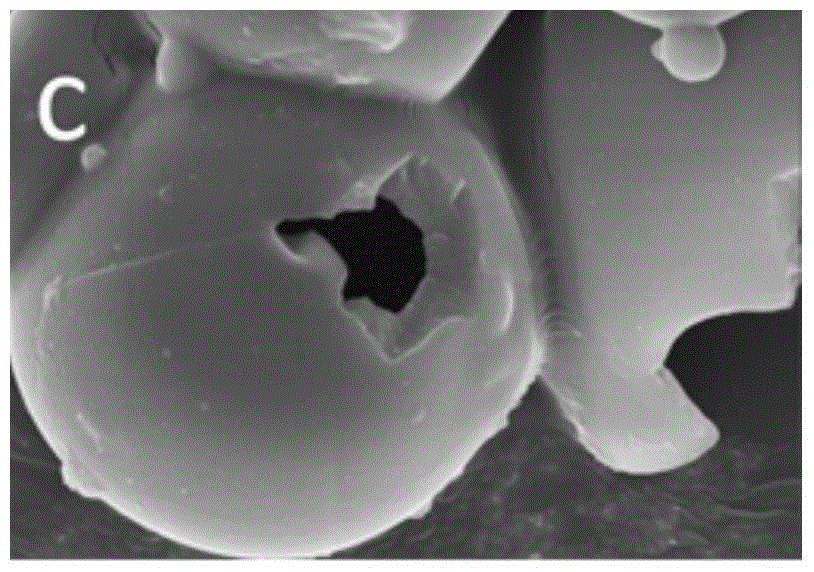

A kind of silicon-carbon composite microsphere negative electrode material and preparation method thereof

ActiveCN104362311BImprove lithium storage performanceReduce stress damageSecondary cellsNegative electrodesCarbon compositesMicrosphere

The invention discloses a silicon-carbon composite microsphere anode material and its preparation method. the preparation method comprises the following steps: firstly, nano-silicon particles and a first macromolecular solution are mixed, and first composite microspheres are formed after spray drying; then, the first composite microspheres and a second macromolecular solution are mixed to carry out surface coating on the first composite microspheres, and second composite microspheres with a core-shell structure are formed after solvent evaporation; and finally, the second composite microspheres undergo oxidation and carbonization treatments to form the silicon-carbon composite microsphere anode material. By the preparation method which has a simple technology, is low-cost and is easy to operate, the silicon-carbon composite microsphere anode material is prepared. In addition, no etching operation for pore-forming is required by the preparation method. Raw materials used in the preparation method can be selected from a number of sources. According to the silicon-carbon composite microsphere anode material obtained, advantages of nano-silicon and a carbon substrate are combined effectively. Thus, electrochemical performance of the silicon-carbon composite microsphere anode material used as a negative electrode of a lithium ion battery is enhanced.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

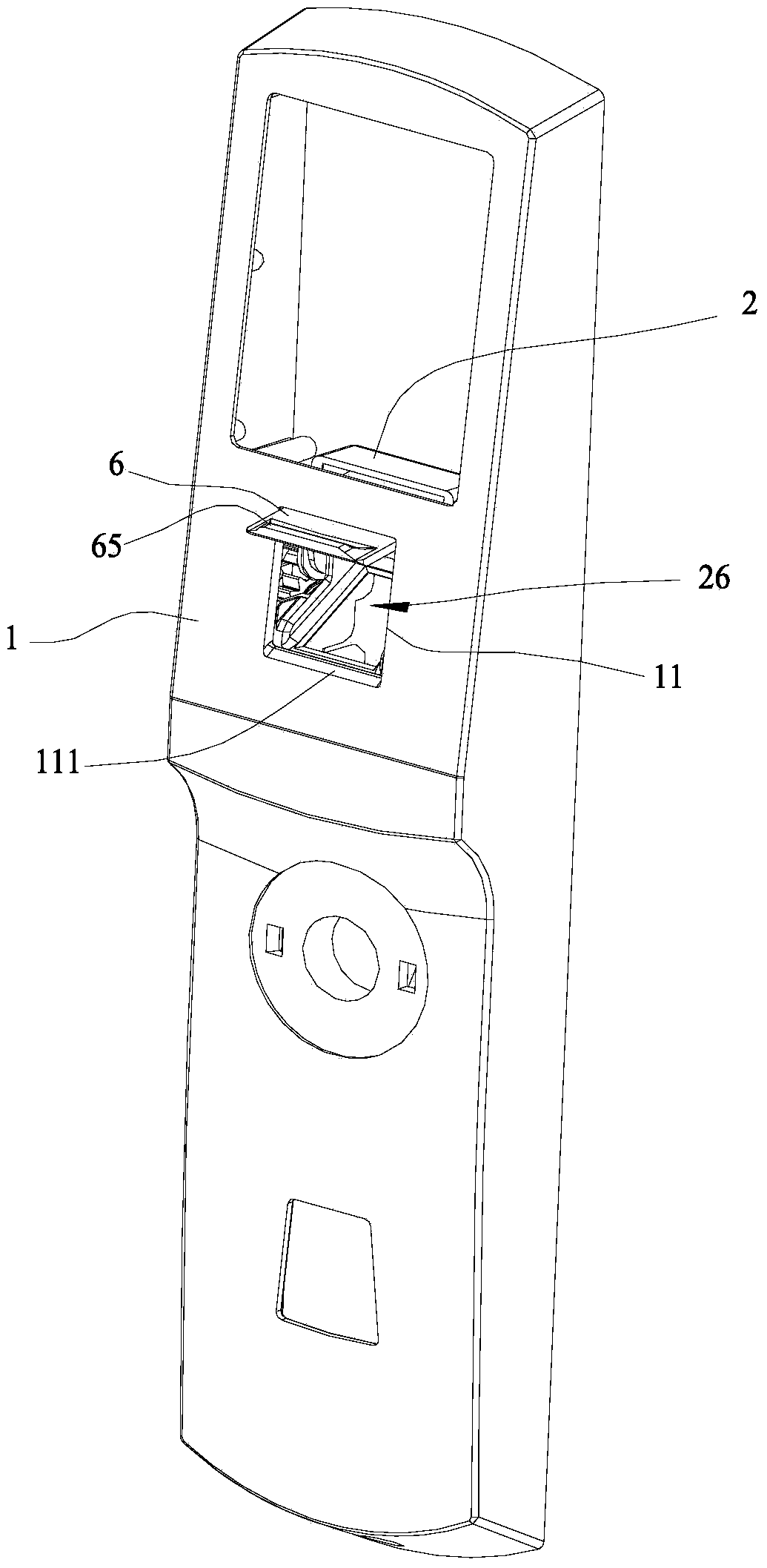

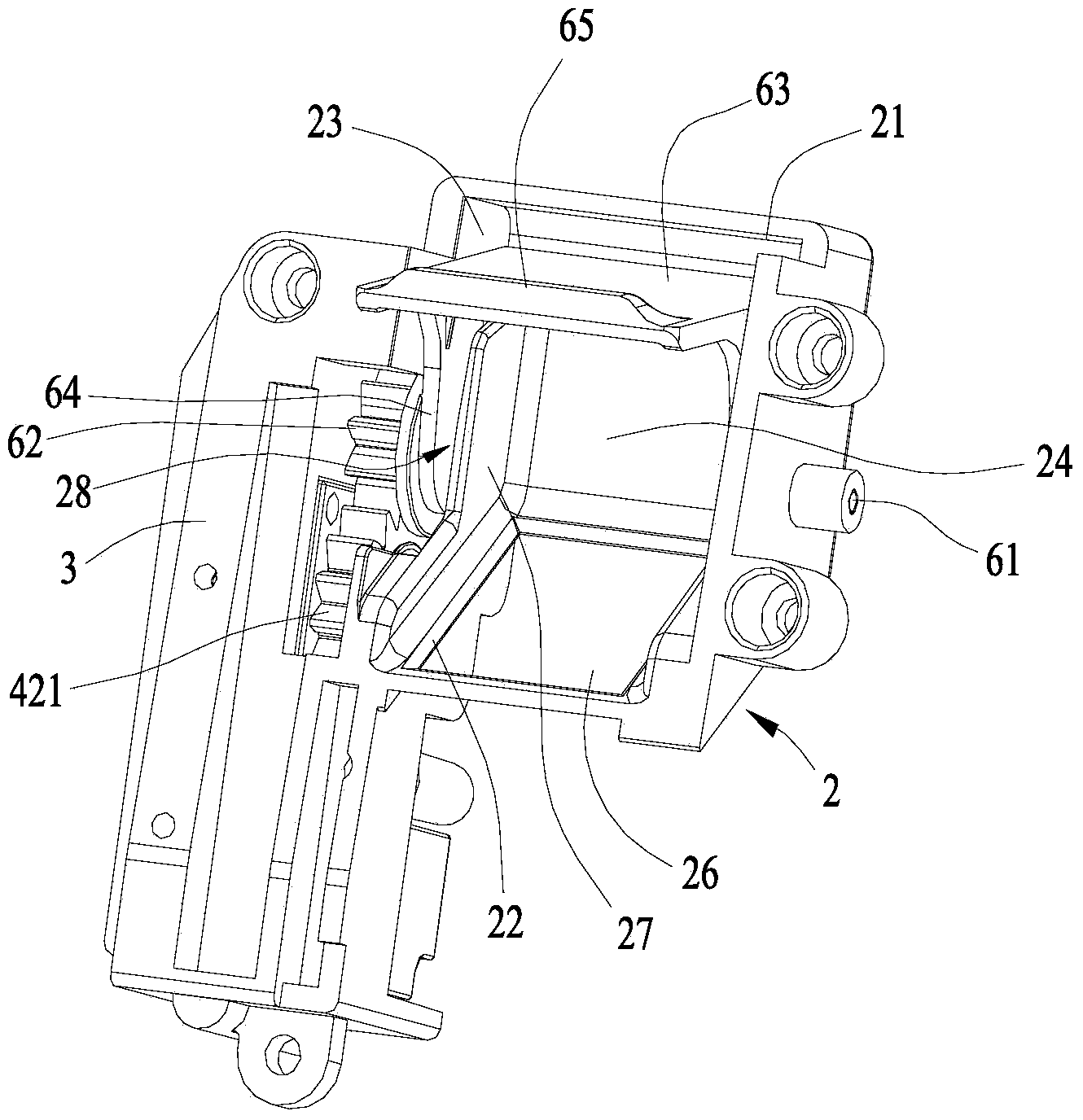

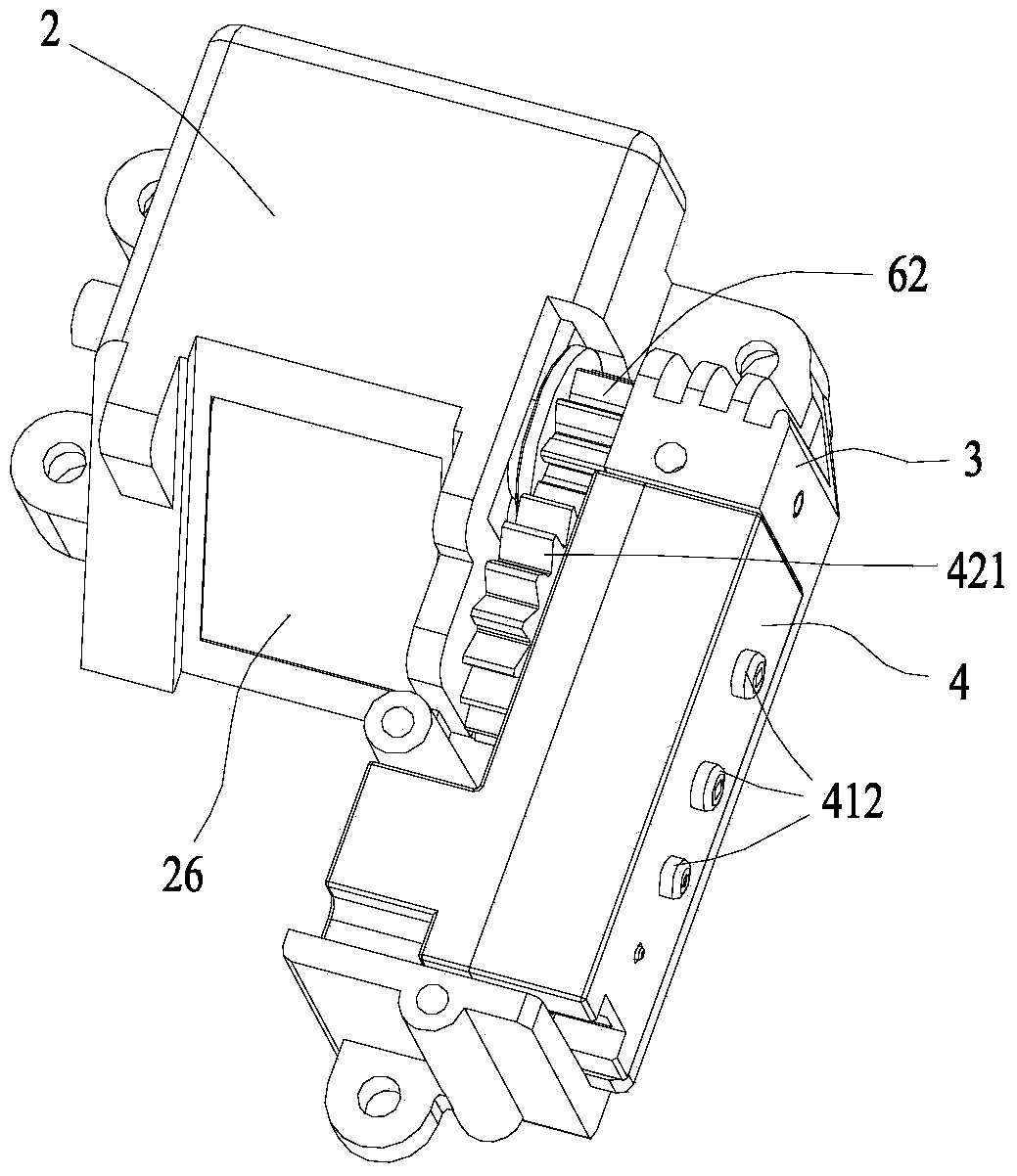

Surface cover of door fingerprint lock of manager room

ActiveCN103510749AReduce stress damagePlay the role of anti-overload bufferPower-operated mechanismLock casingsGear wheelGear train

The invention discloses a surface cover of a door fingerprint lock of a manager room. The surface cover of the door fingerprint lock of the manager room comprises a lock cover body, wherein a window is formed in the outer surface of the lock cover body, and fingerprints can penetrate through the window. The surface cover of the door fingerprint lock of the manager room further comprises a gear reducer and a cover plate which is used for covering the window in an overturned mode, wherein the gear reducer comprises a box body and a gear train installed in the box body, the output end of the gear train is connected with the cover plate, a driving gear which extends out of the box body is arranged at the output end of the gear train, and is installed on an output shaft of the gear train, a blind hole is formed in the output shaft, a notch is formed in an inner hole, corresponding to the blind hole, of the driving gear, a spring is arranged in the blind hole, a clamping ball is clamped between the spring and the notch, one end of the clamping ball extends into the blind hole, and the other end of the clamping ball extends into the notch. The surface cover of the door fingerprint lock of the manager room is simple in structure, capable of preventing overload, small in size, low in cost and beneficial to installation and use.

Owner:AP TENON INFORMATION IDENTIFICATION TECH GUANGZHOU

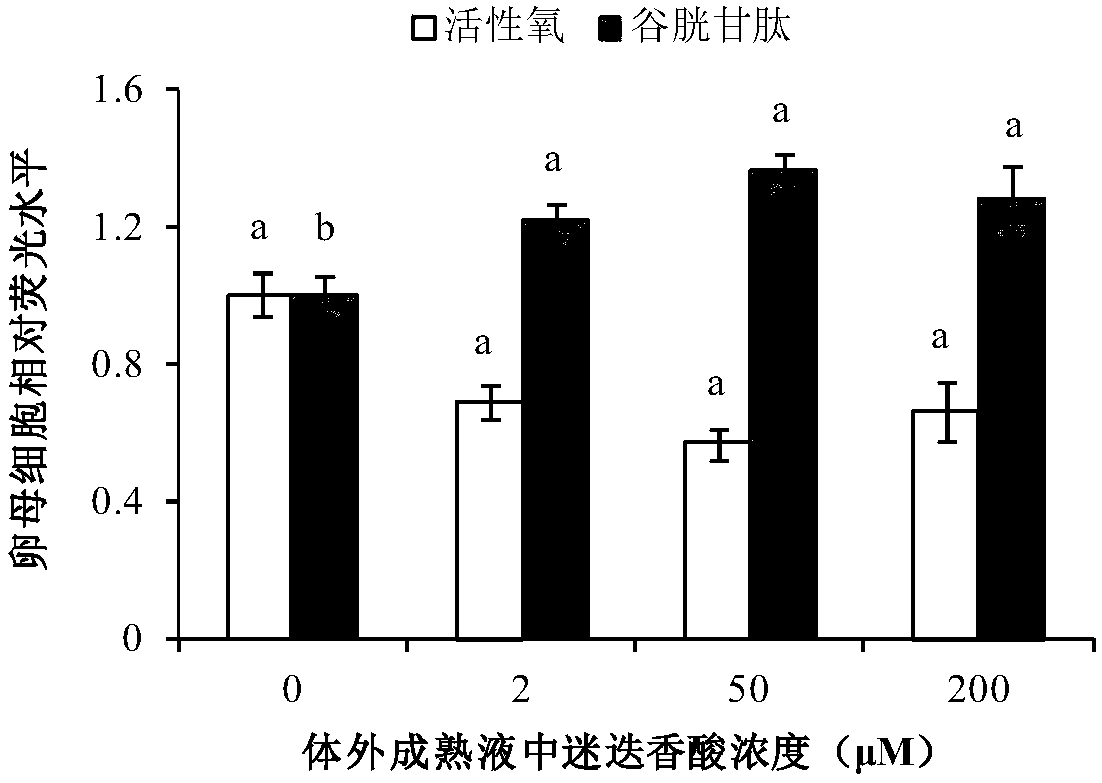

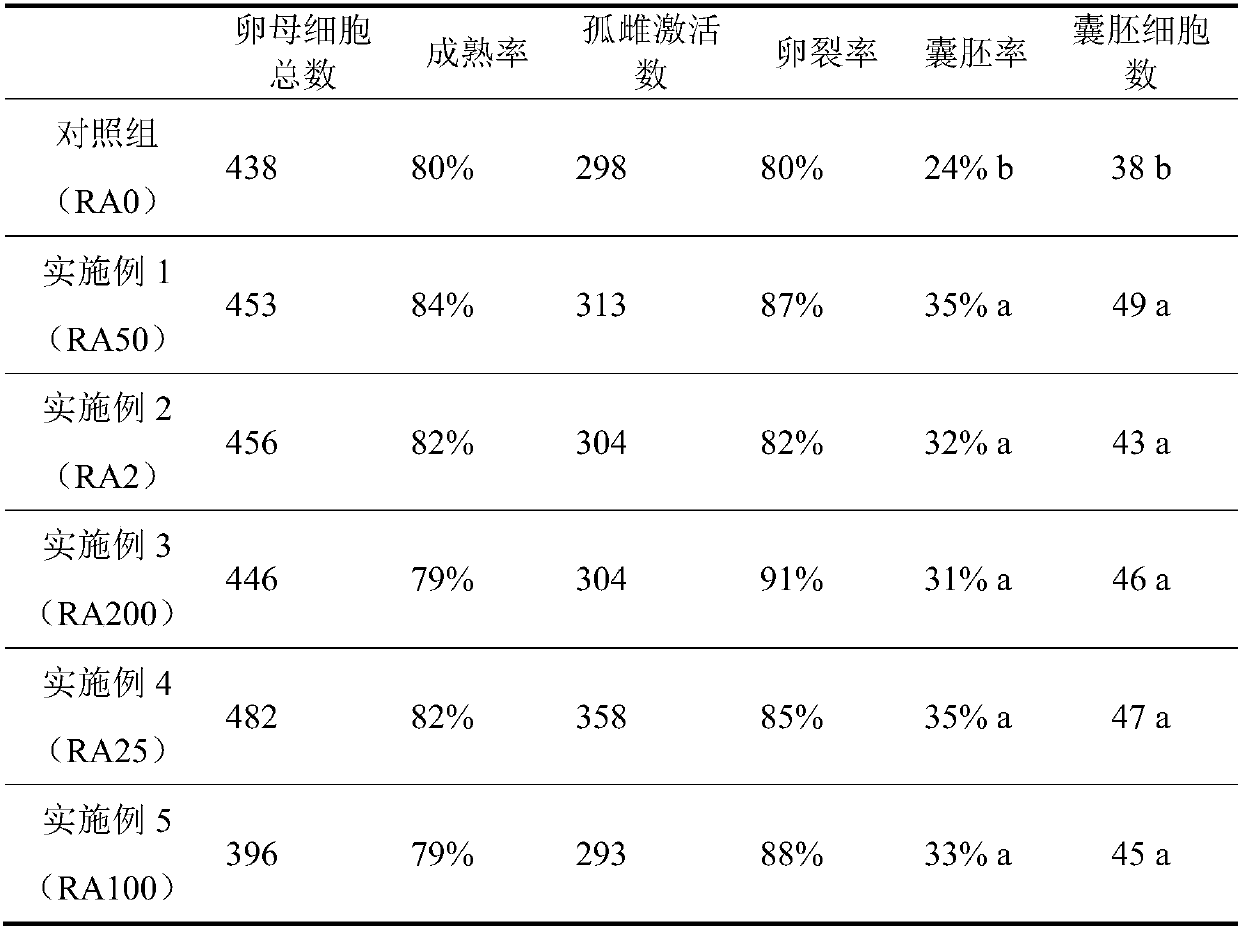

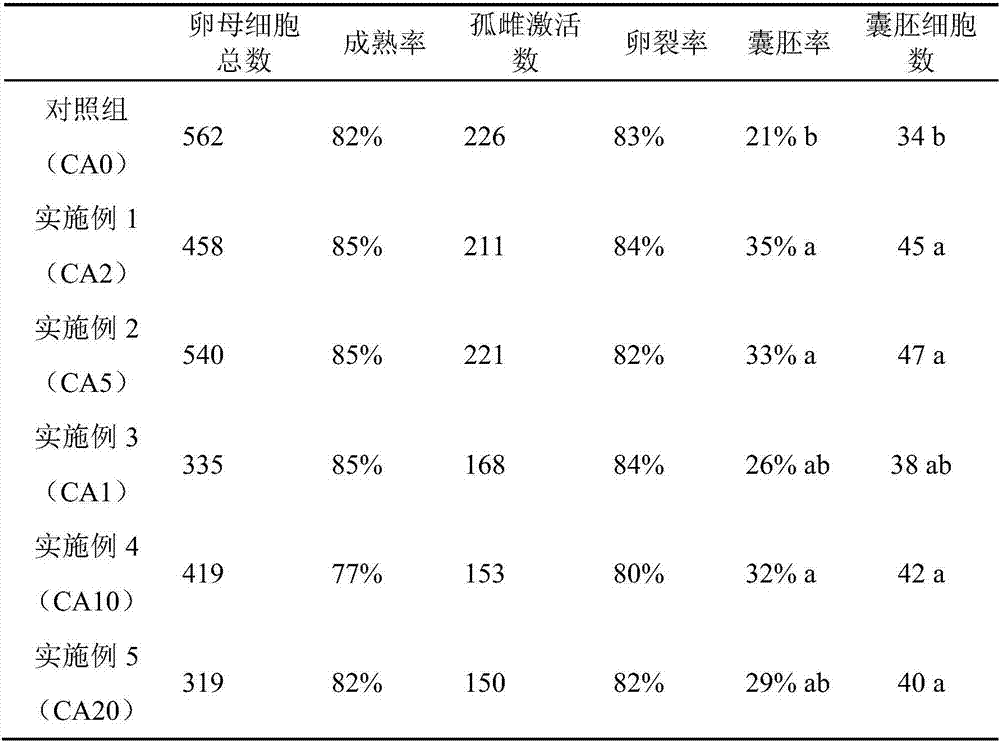

Oocyte in-vitro maturation culture solution added with rosmarinic acid and application thereof

The invention relates to the technical field of cell culture and in particular relates to an oocyte in-vitro maturation culture solution added with rosmarinic acid and application thereof. The in-vitro maturation culture solution is characterized by being prepared from a component rosmarinic acid; the concentration range of the rosmarinic acid is 2muM to 200muM. According to the oocyte in-vitro maturation culture solution provided by the invention, the rosmarinic acid is added into a pig oocyte maturation culture solution and is matched with the synergistic effect of other components, so thatthe maturation quality of pig oocytes is improved and the oocyte in-vitro maturation culture solution has a good promotion effect on pig embryo development. A result shows that the in-vitro maturationculture solution provided by the invention can be used for improving the anti-oxidization capability of the oocytes and the rosmarinic acid with the suitable concentration can be used for effectivelyimproving the oocyte maturation quality, so that the in-vitro development potential of the pig oocytes is improved. The in-vitro maturation culture solution is simple to prepare and convenient to operate and has a relatively great application prospect.

Owner:CHINA AGRI UNIV

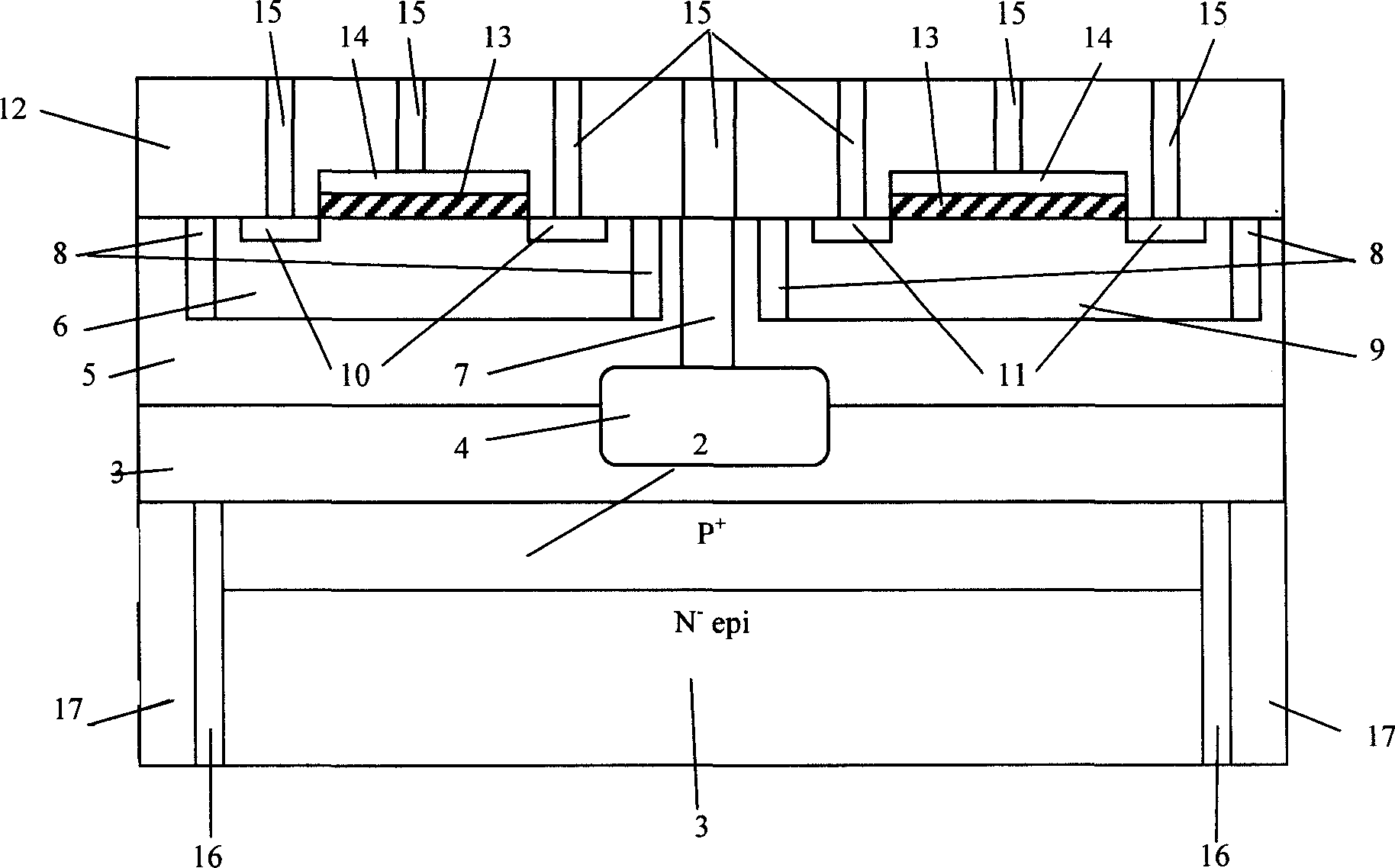

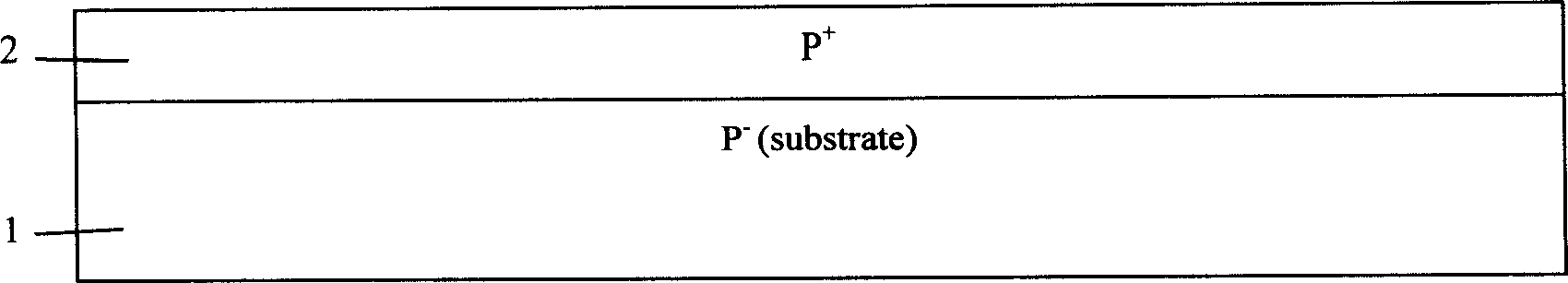

High-activity coefficient active picture element image sensor structure and producing method threof

InactiveCN1889270AEasy to readReduce crosstalkSemiconductor/solid-state device manufacturingRadiation controlled devicesCMOSQuantum efficiency

The present invention relates to high block coefficient active pixel picture sensor structure and manufacturing method. It contains making signal processing circuit on one diode of silica-based support, making photodiode circuit on another side, thereby making block coefficient approaching 100 per cent and maximal raising photodiode structure quantum efficiency. Compared with traditional CMOS picture sensor structure, invented CIS picture sensor has smaller dark current and pixel interference; adopting wet method automatic stop erosion to finely control silicon wafer thinning down thickeness, capable of effectively reducing stress damage, raising sensitivity and block coefficient, and basically solving block coefficient low shortage.

Owner:BEIJING SUPERPIX MICRO TECHNOLOGY CO LTD

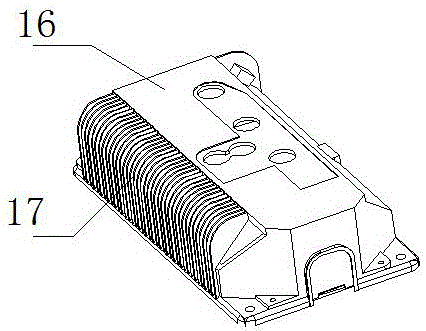

Process for manufacturing photovoltaic bypass Schottky diode

InactiveCN102142371AImprove performanceImprove impact resistanceSemiconductor/solid-state device detailsSolid-state devicesPower flowHeat conducting

The invention belongs to the production process for diodes, particularly relates to a process for manufacturing a photovoltaic bypass Schottky diode. The process is characterized in that through improving the compositions of a black-filled compound adopted in the process of casting and mould pressing, improving the production process for schottky diodes, carrying out tempering and diameter increase on leads and carrying out upsetting processing on the ends of the leads, the stress in the lead is reduced, the heat dissipation capacity of the lead is improved, and the surge current impact resistant capacity of the diode is improved; and because the black-filled compound with a high heat conductivity and a low stress is adopted, the heat-conducting property of the schottky diode is improved, and the surface temperature of the diode is reduced, so that the schottky diode can meet the requirements for being used in junction boxes.

Owner:CHANGZHOUSR SEA ELECTRONICS

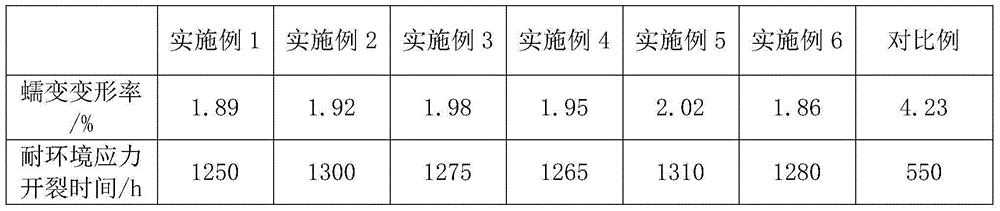

HDPE composite material for snowboard and preparation method thereof

The invention provides an HDPE composite material for a snowboard. The HDPE composite material for the snowboard comprises, by weight, 50-65 parts of HDPE, 10-15 parts of silicon carbide fibers, 8-12 parts of CPE, 8-10 parts of fire retardant, 0.5-1 part of antioxygen, 0.5-1 part of ultraviolet light absorber, 0.9-1.4 parts of antistatic agent, 1-2 parts of light screener, 3-8 parts of flexibilizer, 0.7-1.2 parts of dispersing agent, 0.1-0.6 part of stabilizer and 0.1-0.3 part of coupling agent. The invention further provides a preparation method of the HDPE composite material. The HDPE composite material for the snowboard has good creep resistance and environmental cracking resistance.

Owner:SUZHOU HONGHENG CHEM

Three-axis acceleration sensor

ActiveCN103412147AAvoid damageProtection against mechanical damageAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsSignal processingMetal

The invention discloses a three-axis acceleration sensor which comprises an MEMS accelerated speed chip, a signal processing chip and a substrate. The MEMS accelerated speed chip comprises a cover body, a micro mechanical system and a circuit substrate, and the micro mechanical system is composed of an X axis accelerated speed induction area, a Y axis accelerated speed induction area and a Z axis accelerated speed induction area; the Y axis accelerated speed induction area comprises an H-shaped motion piece with two through holes in the Y direction, two motion electrodes in the Y direction and two fixed electrodes in the Y direction; the Z axis accelerated speed induction area comprises quality strip bars and a supporting shaft; the lower surface of the signal processing chip is pasted with the surface of the cover body of the MEMS accelerated speed chip through a first insulated adhesive layer, the circuit substrate of the MEMS accelerated speed chip is pasted with part of the substrate area through a second insulated adhesive layer, a first metal wire is arranged between a chip welding point and a signal inputting welding point in a spanning mode, and a second metal wire is arranged between a signal output welding point and a substrate welding point in a spanning mode. The three-axis acceleration sensor improves the reliability of appliances and effectively reduces stress damage to the chip by external force.

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

Porcine oocyte in vitro mature culture solution added with carnosic acid and application thereof

The invention relates to the technical field of cell culture and particularly relates to a porcine oocyte in vitro mature culture solution added with carnosic acid and application thereof. The in vitro mature culture solution is characterized in that the component includes carnosic acid, wherein the concentration range of the carnosic acid is 1-20 microns. According to the invention, the carnosicacid is added into the porcine oocyte mature culture solution and has a synergistic effect with the other components, so that the mature quality of the porcine oocyte is promoted and the excellent promoting effect for the early development of the pig embryo is achieved. A result proves that the carnosic acid in proper concentration is capable of effectively improving the mature quality of the porcine oocyte, so that the in vitro development potential of the porcine oocyte is promoted. The in vitro mature culture solution is simple to prepare and convenient to operate and has wide application prospect.

Owner:CHINA AGRI UNIV

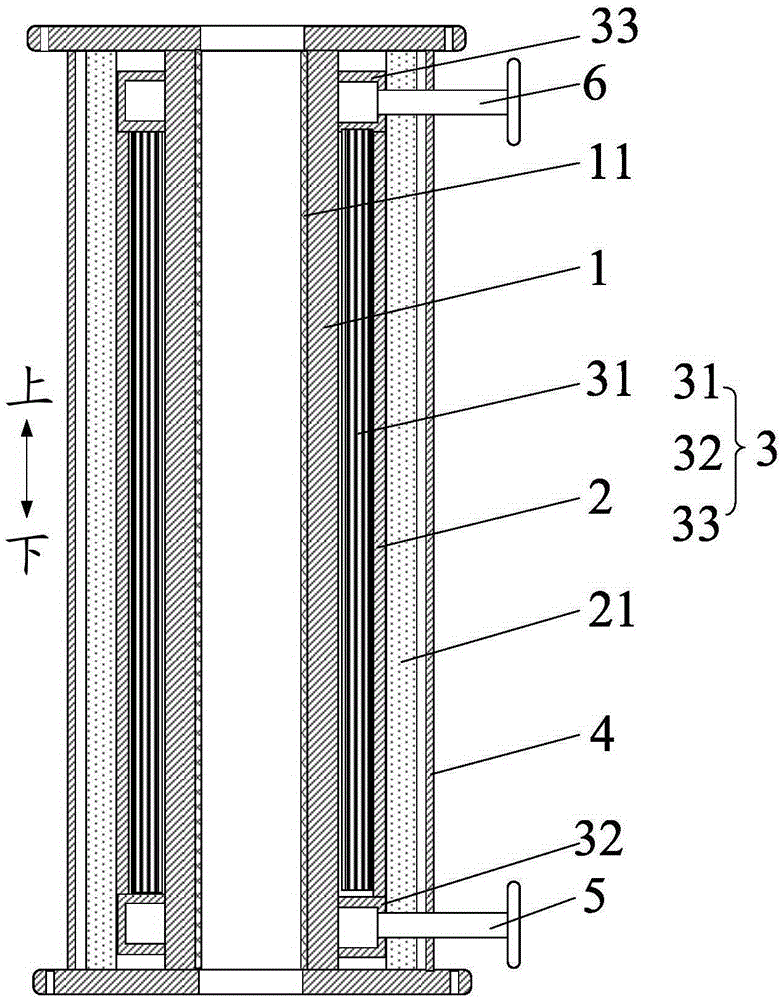

Raw gas riser pipe heat exchange device for coking furnace

InactiveCN105273728AReduce the impactAvoid getting lostStationary tubular conduit assembliesDistillation gas withdrawalEngineeringCoke oven

The invention provides a raw gas riser pipe heat exchange device for a coking furnace. The device comprises an inner barrel, a middle barrel, a heat exchange assembly, an outer barrel and a heat insulation piece, wherein the inner barrel is provided with a smoke flue penetrating through the inner barrel, and the smoke flue is provided with an inlet located in the lower end of the inner barrel and an outlet located in the upper end of the inner barrel; the heat exchange assembly is arranged between the inner barrel and the middle barrel, gaps are reserved between the heat exchange assembly and the inner barrel as well as between the heat exchange assembly and the middle barrel, and a fluid outlet and a fluid inlet are formed in the upper end and the lower end respectively; the heat insulation piece is arranged between the middle barrel and the outer barrel. According to the raw gas riser pipe heat exchange device for the coking furnace, the heat exchange assembly is arranged between the inner barrel and the middle barrel, and the gaps are reserved between the heat exchange assembly and the inner barrel as well as between the heat exchange assembly and the middle barrel, that is, the heat insulation assembly is independent of the inner barrel and the middle barrel, is suspended between the inner barrel and the middle barrel and is not contacted with the inner barrel and the middle barrel, so that the influence of stress change of the barrels under various thermal-state working conditions on the heat exchange assembly is reduced; the heat insulation piece has a heat insulation effect on the device, the heat exchange efficiency of the device is improved, and the environmental influence of heat produced by the raw gas is reduced.

Owner:LIAONING Z H &X METALLURGICAL TECH

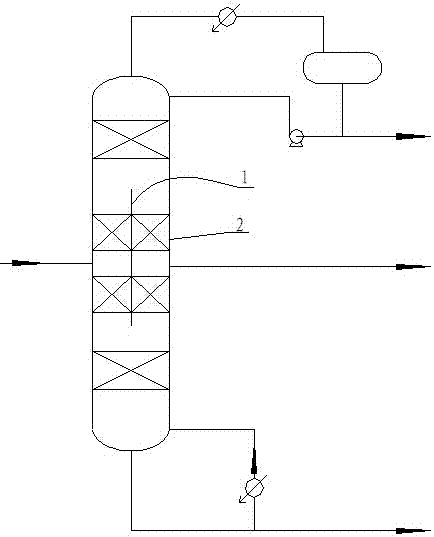

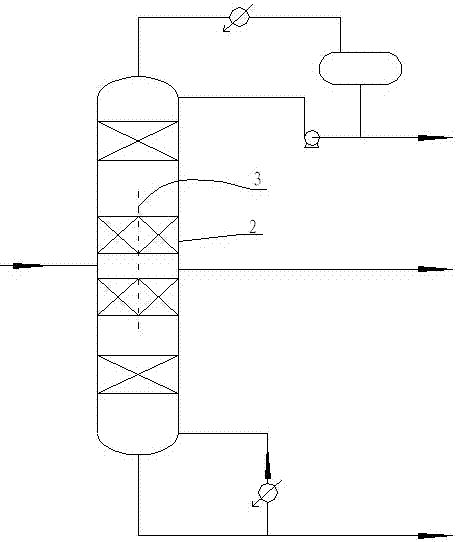

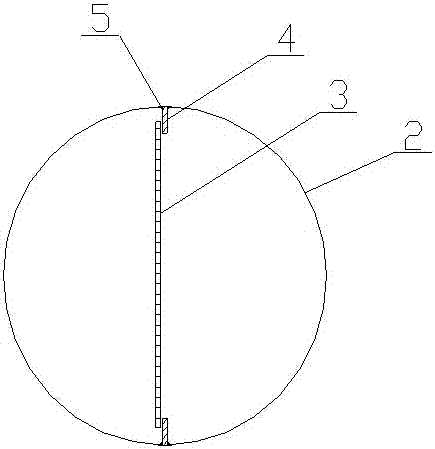

Spliced middle partition plate and method for transforming traditional rectifying tower

The invention discloses a spliced middle partition plate and a method for transforming a traditional rectifying tower. The spliced middle partition plate has the following properties that: the middle partition plate is formed by splicing a plurality of sections of partition plates from top to bottom, wherein the spliced surface of two sections of the partition plates spliced from top to bottom is a concave surface or a convex surface with a certain inclination angle. The transformation method comprises the following steps: canceling the original column plate or packing structure in the traditional rectifying tower, mounting the previous spliced middle partition plate at a middle position of the traditional rectifying tower, and partitioning the tower into four parts, namely a tower top common rectifying section, a tower middle feeding section, a tower middle discharging section and a tower bottom common stripping section. According to the method disclosed by the invention, mutual leakage of gas-liquid phase flow on two sides of the partition plate is effectively avoided, the partition plate is convenient to mount and detach, the utilization rate of old equipment is improved, and the cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Capacitive MEMS acceleration sensor

ActiveCN103412146AProtection against mechanical damageIncreased sensitivity of inductionAcceleration measurement in multiple dimensionsPhysicsAdhesive

The invention discloses a capacitive MEMS acceleration sensor which comprises an MEMS acceleration chip, a signal processing chip and a substrate. The MEMS acceleration chip comprises a cover body, a micromechanical system and a circuit substrate. The micromechanical system is composed of an X-axis acceleration induction area, a Y-axis acceleration induction area and a Z-axis acceleration induction area. The Y-axis acceleration induction area comprises a Y-direction 'H'-shaped moving sheet provided with two through holes, two Y-direction moving electrodes and two Y-direction fixed electrodes. The Z-axis acceleration induction area comprises a mass block and a supporting shaft used for supporting the center of the mass block. The lower surface of the circuit substrate is bonded with a partial area on the upper surface of the signal processing chip through a first insulation adhesive layer. The upper surface of the circuit substrate is provided with a plurality of chip welding points. The upper surface of the substrate is provided with a plurality of substrate welding points which are distributed in the edge areas on the two sides of the substrate. The upper surface of the signal processing chip is provided with signal input welding points and signal output welding points respectively. The capacitive MEMS acceleration sensor improves the reliability of a device and effectively reduces stress damage to the chips by external force.

Owner:苏州明皜传感科技股份有限公司

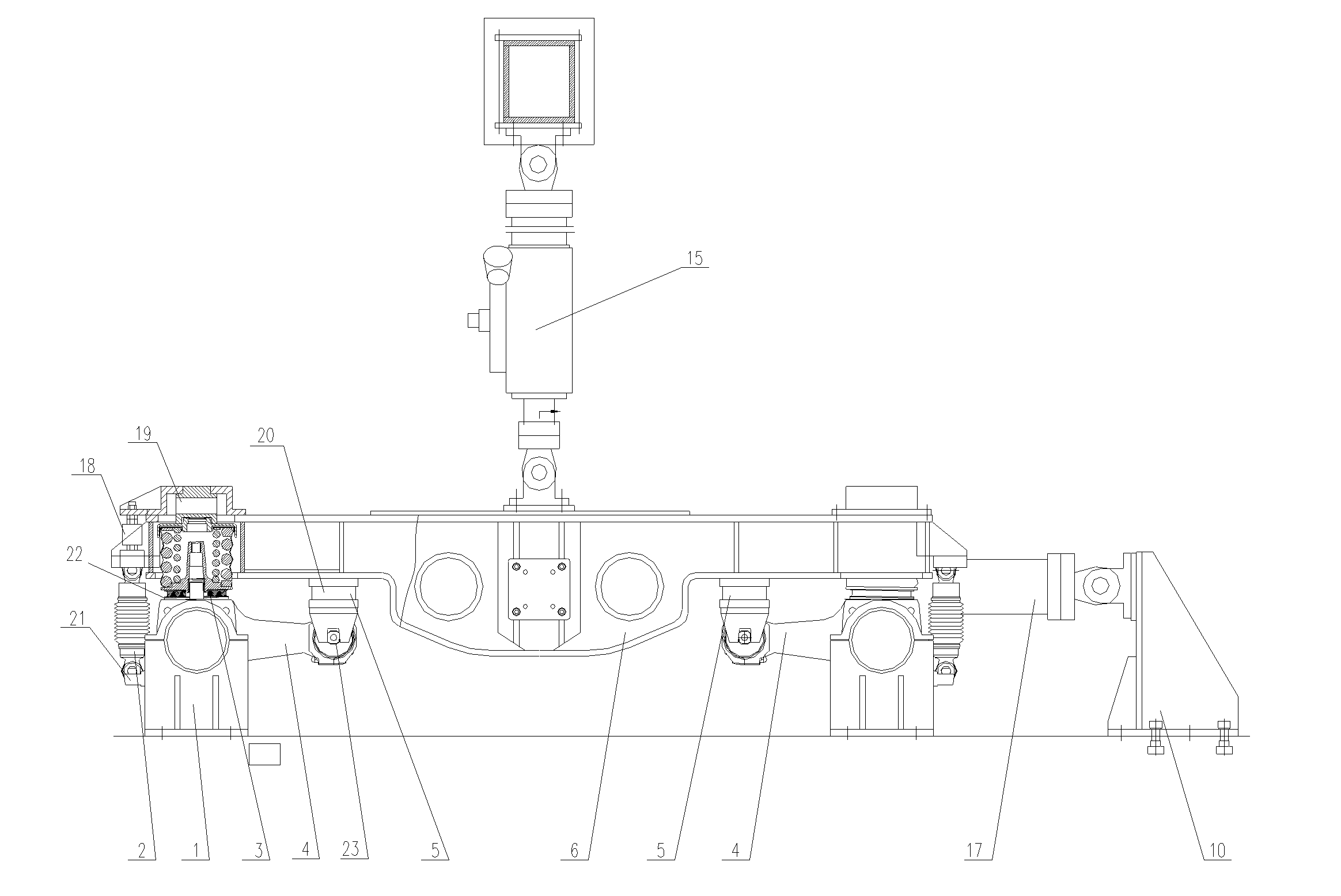

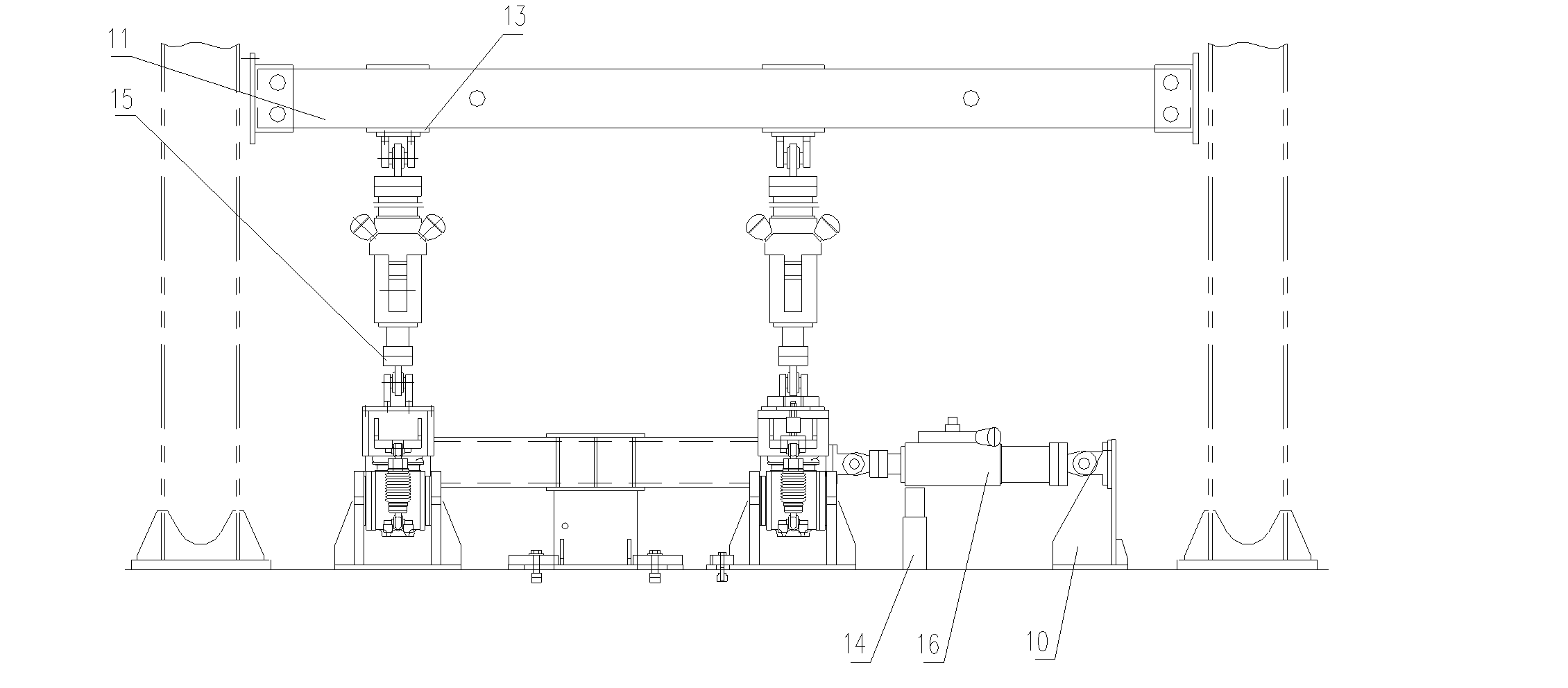

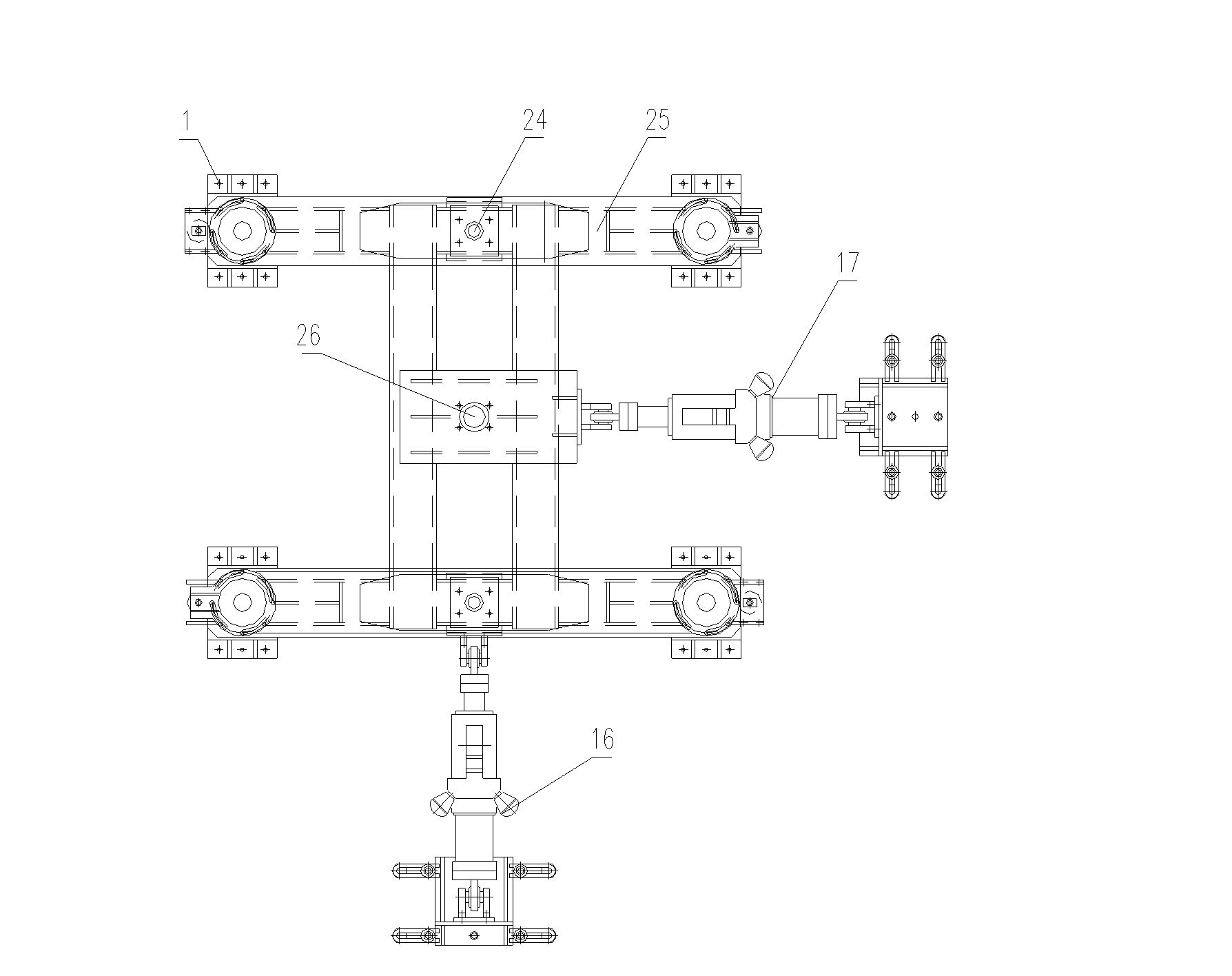

Rotating arm type axle box force measuring device and method thereof

ActiveCN103175642AReduce stress damageReal experimental parametersMeasurement of force componentsEngineeringVertical load

The invention discloses a rotating arm type axle box force measuring device and a method thereof. According to distribution positions of loads exerted on rotating arm type axle boxes, the normative testing method is specified for vertical loads exerted on shock absorber bases and spring bases and vertical, transverse and longitudinal loads exerted on elastic nodes, so that actual and reliable testing parameters are provided for scientific judgment and measurement of the magnitude and directions of loads exerted on rotating arm type axle boxes. The rotating arm type axle box force measuring method comprises the steps of adopting the force measuring device comprising a loading cross beam and a simulation structure to install four rotating arm type axle boxes on the simulation structure according to actual usage positions; connecting a pair of vertical actuating cylinders between the simulation structure and the loading cross beam in the vertical direction, and connecting a transverse actuating cylinder and a longitudinal actuating cylinder respectively on horizontal side portions of the simulation structure; and connecting a first sensor between a vertical shock absorber and the simulation structure, connecting a second sensor between an axle box spring and the simulation structure, and connecting a third sensor between a node base and the simulation structure.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com