HDPE composite material for snowboard and preparation method thereof

A composite material and snowboard technology, applied in the field of composite materials, can solve the problems of inability to directly apply snowboards, creep resistance, poor environmental cracking resistance, etc., achieve excellent fatigue resistance and creep resistance, and improve creep resistance. performance, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

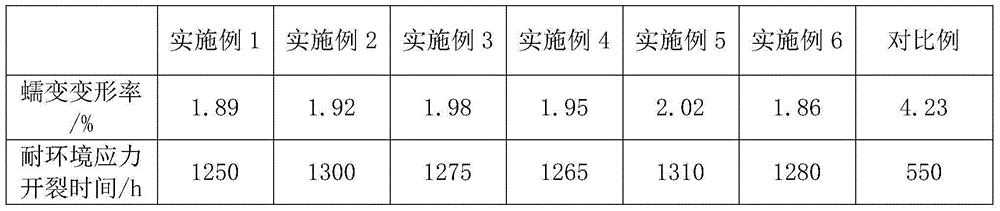

Examples

Embodiment 1

[0025] A HDPE composite material for skis, its components and parts by weight are: 55 parts of HDPE, 14 parts of silicon carbide fiber, 8 parts of CPE, 9.5 parts of superfine magnesium hydroxide, 0.8 parts of antioxidant 1076, and 0.9 parts of UV-531 1 part, 1 part of antistatic agent 1800, 1.5 parts of nano zinc oxide, 4 parts of ABS, 0.7 part of PE wax, 0.2 part of zinc stearate, 0.2 part of coupling agent.

[0026] The steps of its preparation method are as follows:

[0027] (1) Dissolve the rare earth in water and disperse evenly to prepare a rare earth solution with a mass fraction of 1%, immerse the silicon carbide fiber in the rare earth solution, move it to a constant temperature water bath at 80°C and stir for 1 hour, take it out and place it in a vacuum drying oven Dry at 100°C for 5 hours, and cut into short fibers with a length of 10 μm after cooling for later use;

[0028] (2) Put the short fiber and HDPE powder obtained in step (1) into a mortar and grind for 1 ...

Embodiment 2

[0030] A HDPE composite material for skis, its components and parts by weight are: 50 parts of HDPE, 12 parts of silicon carbide fiber, 9.5 parts of CPE, 9 parts of superfine magnesium hydroxide, 0.7 part of antioxidant 1076, 0.5 part of UV-531 1.2 parts of antistatic agent 1800, 1.4 parts of nano zinc oxide, 7 parts of ABS, 0.9 parts of PE wax, 0.5 parts of zinc stearate, and 0.2 parts of coupling agent.

[0031] Its preparation method is the same as Example 1.

Embodiment 3

[0033] A HDPE composite material for skis, its components and parts by weight are: 65 parts of HDPE, 15 parts of silicon carbide fiber, 11 parts of CPE, 8 parts of superfine magnesium hydroxide, 0.9 parts of antioxidant 1076, and 1 part of UV-531 1.1 parts of antistatic agent 1800, 2 parts of nano-zinc oxide, 3 parts of ABS, 1.2 parts of PE wax, 0.1 part of zinc stearate, and 0.1 part of coupling agent.

[0034] Its preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com