Patents

Literature

33results about How to "Increase the construction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

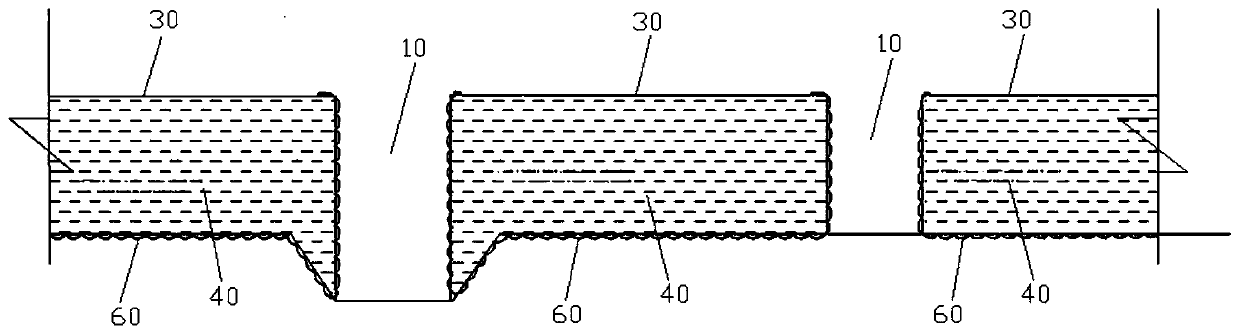

Grouped second liner construction method for large cross-section tunnel

ActiveCN103016029AIncrease the construction processLong construction periodUnderground chambersTunnel liningSocial benefitsArchitectural engineering

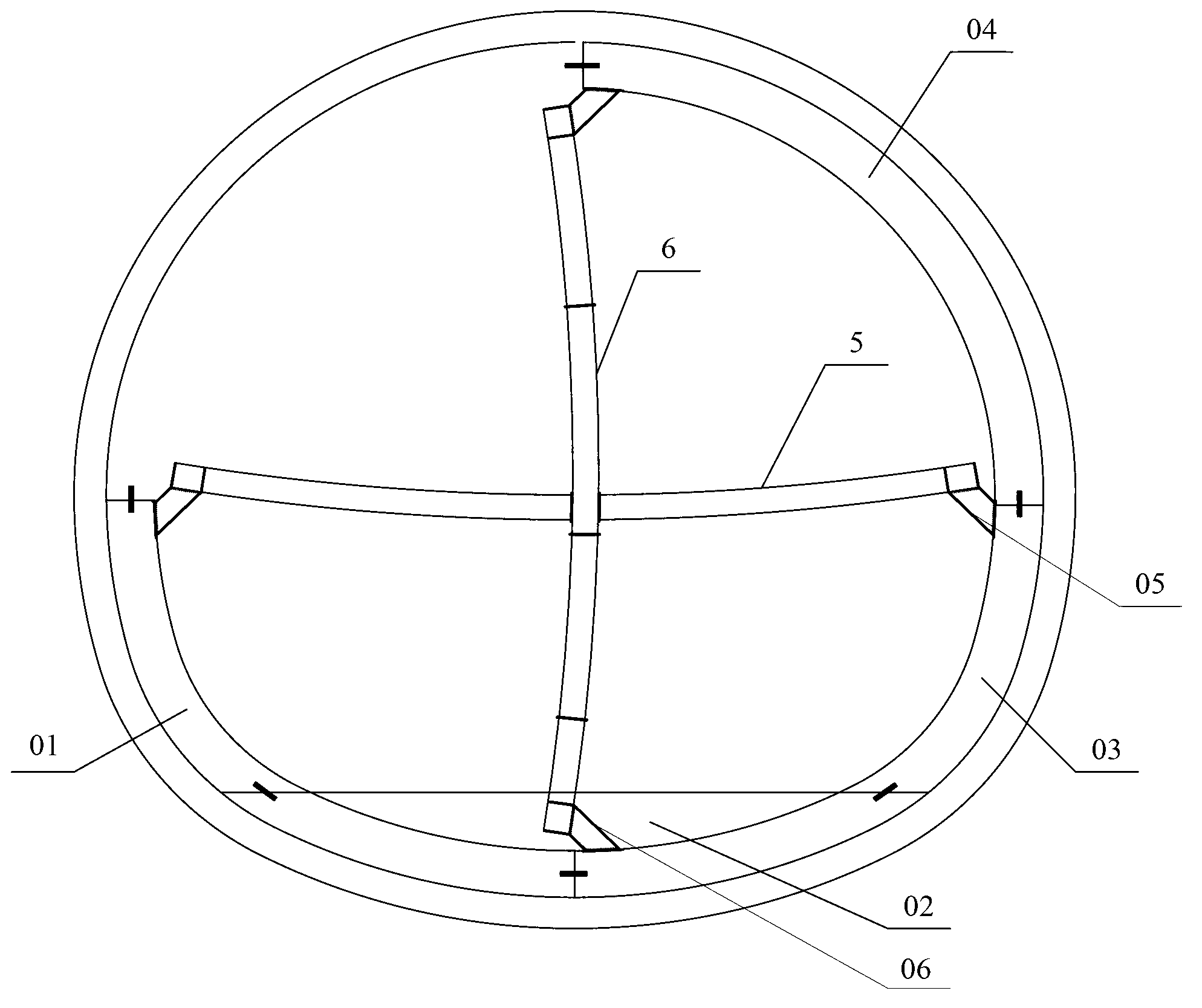

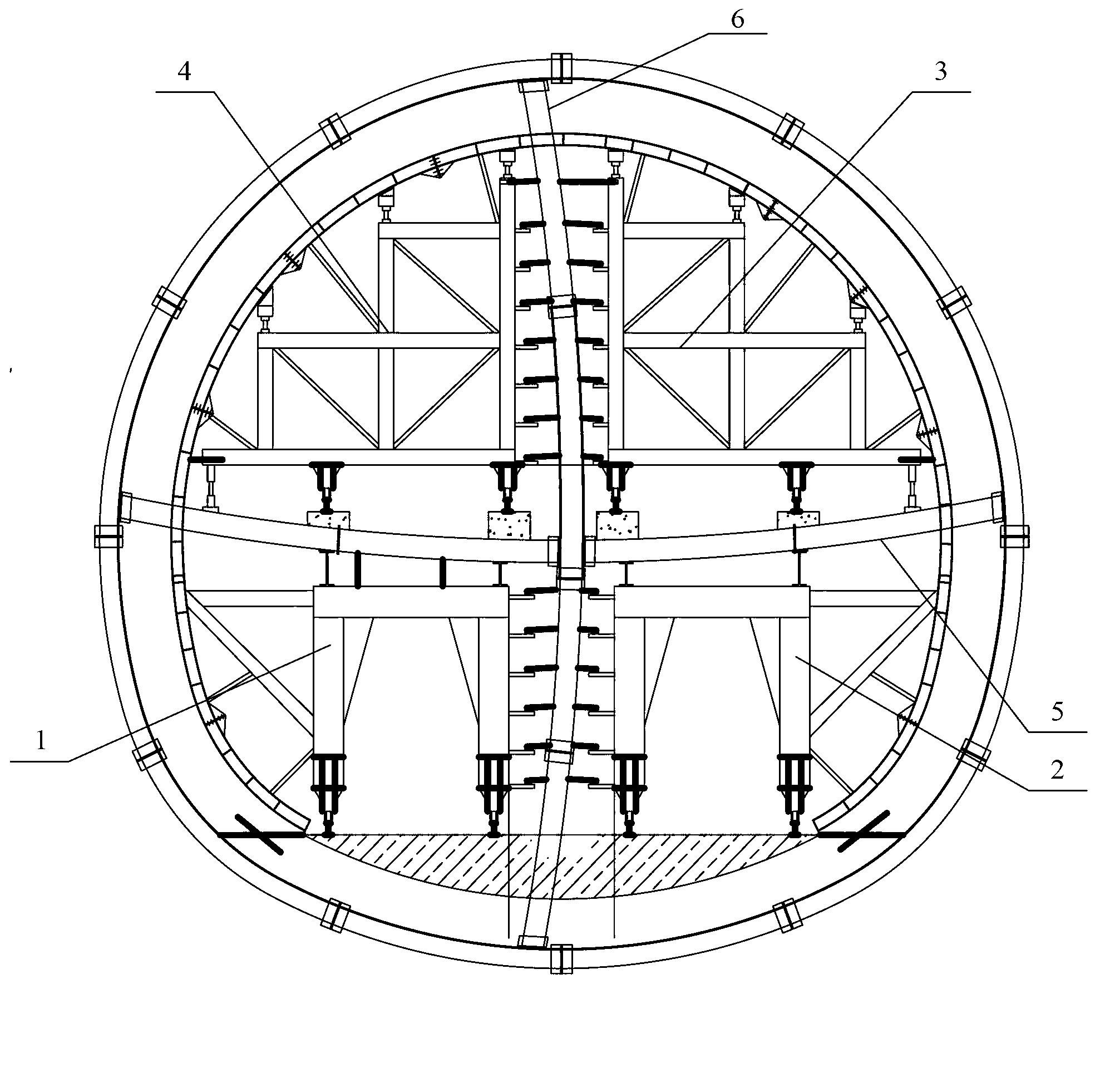

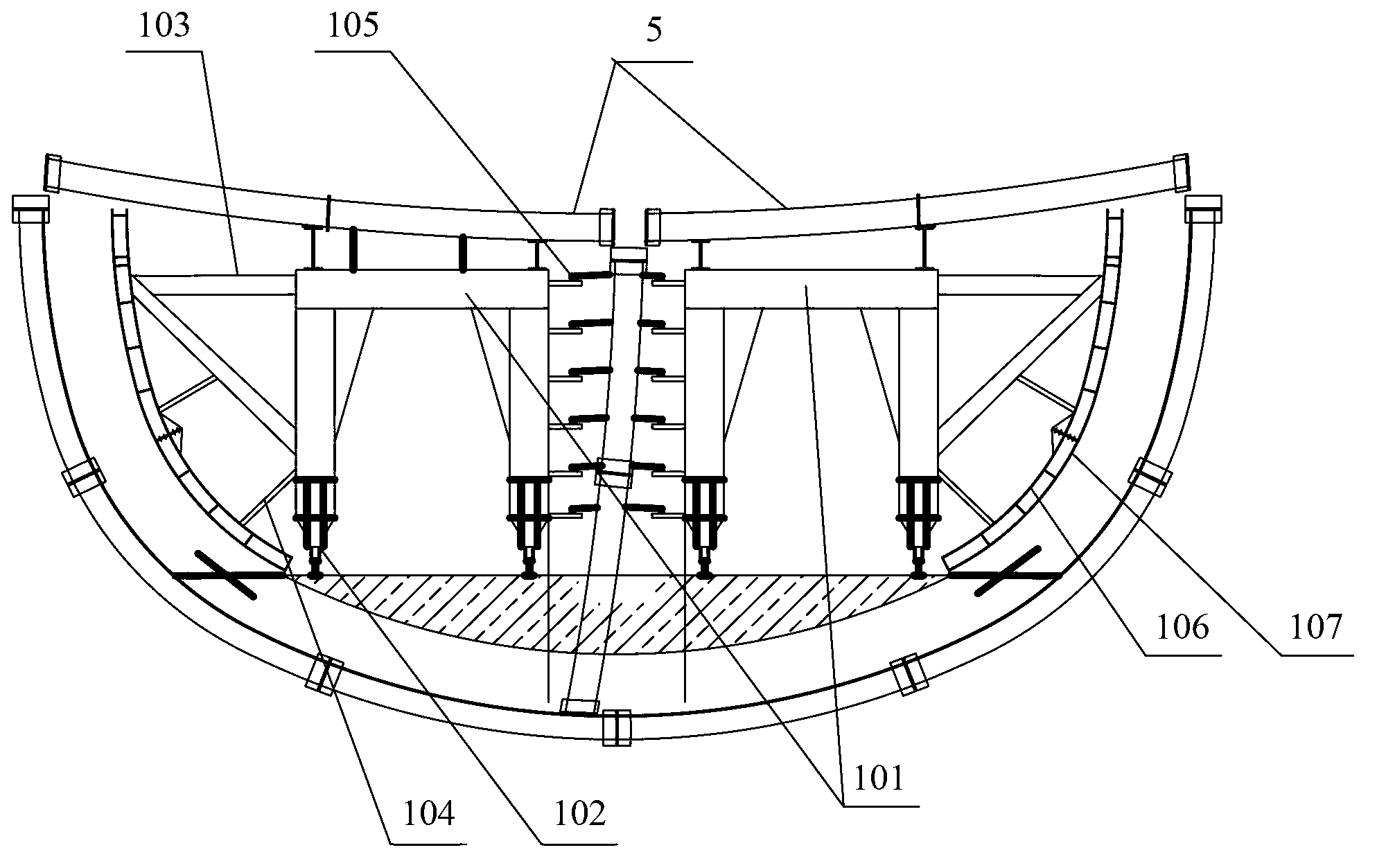

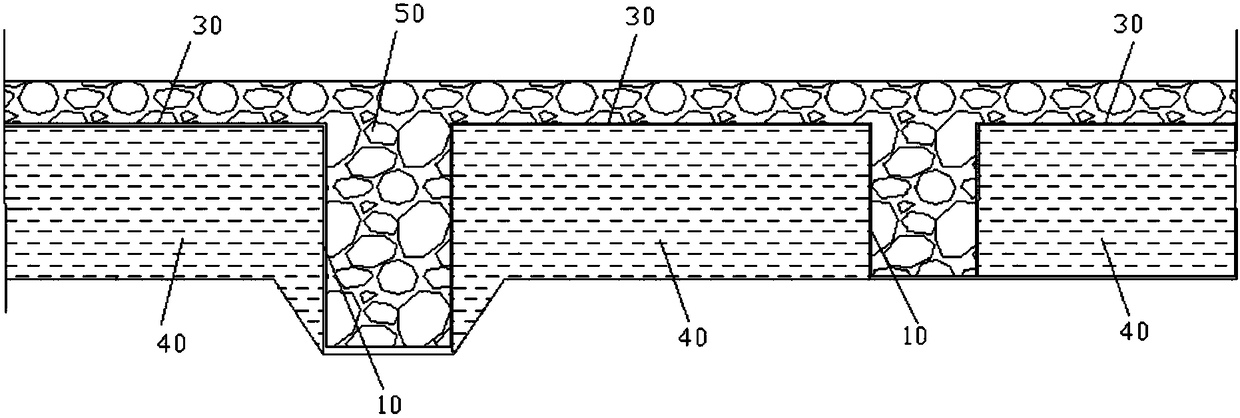

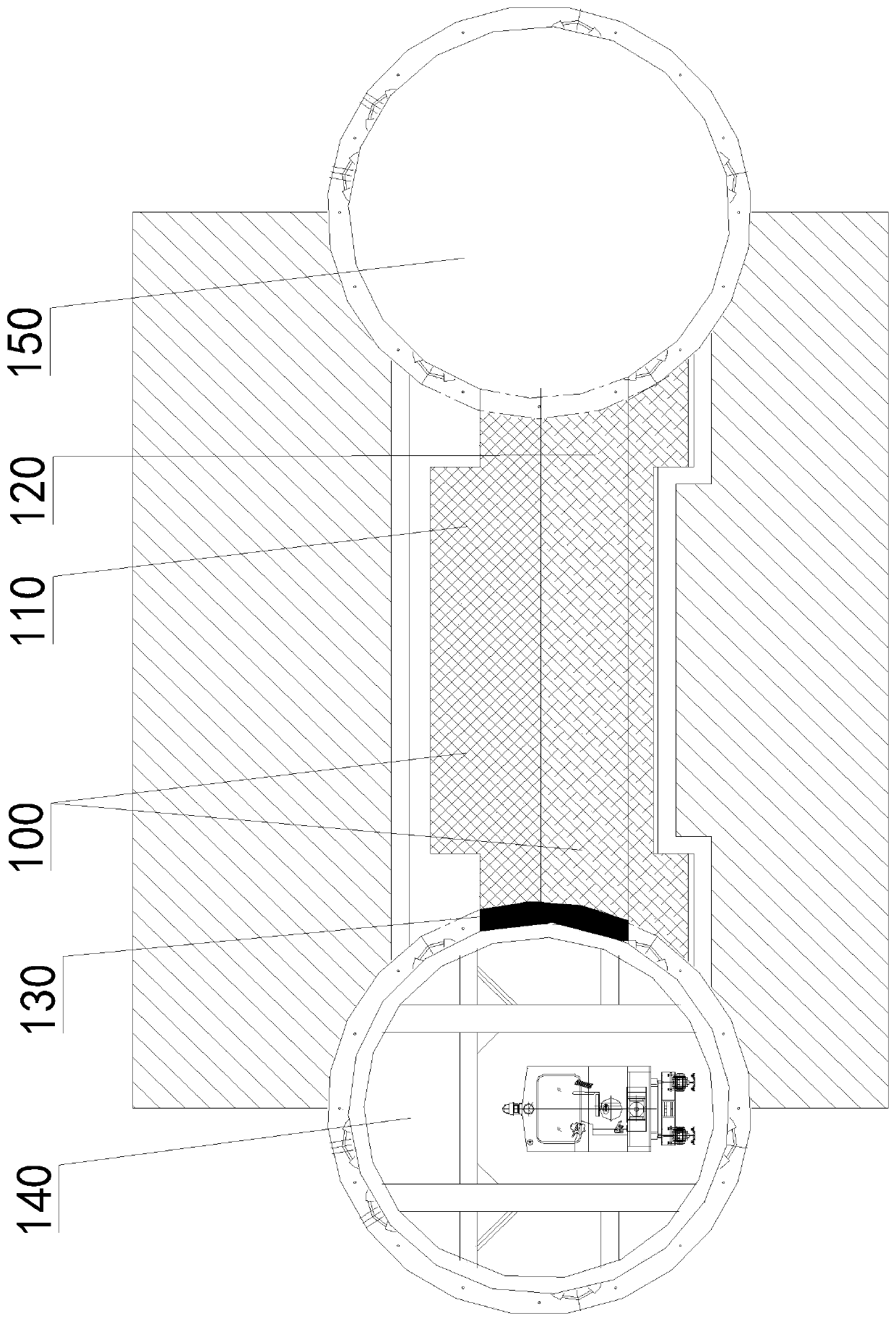

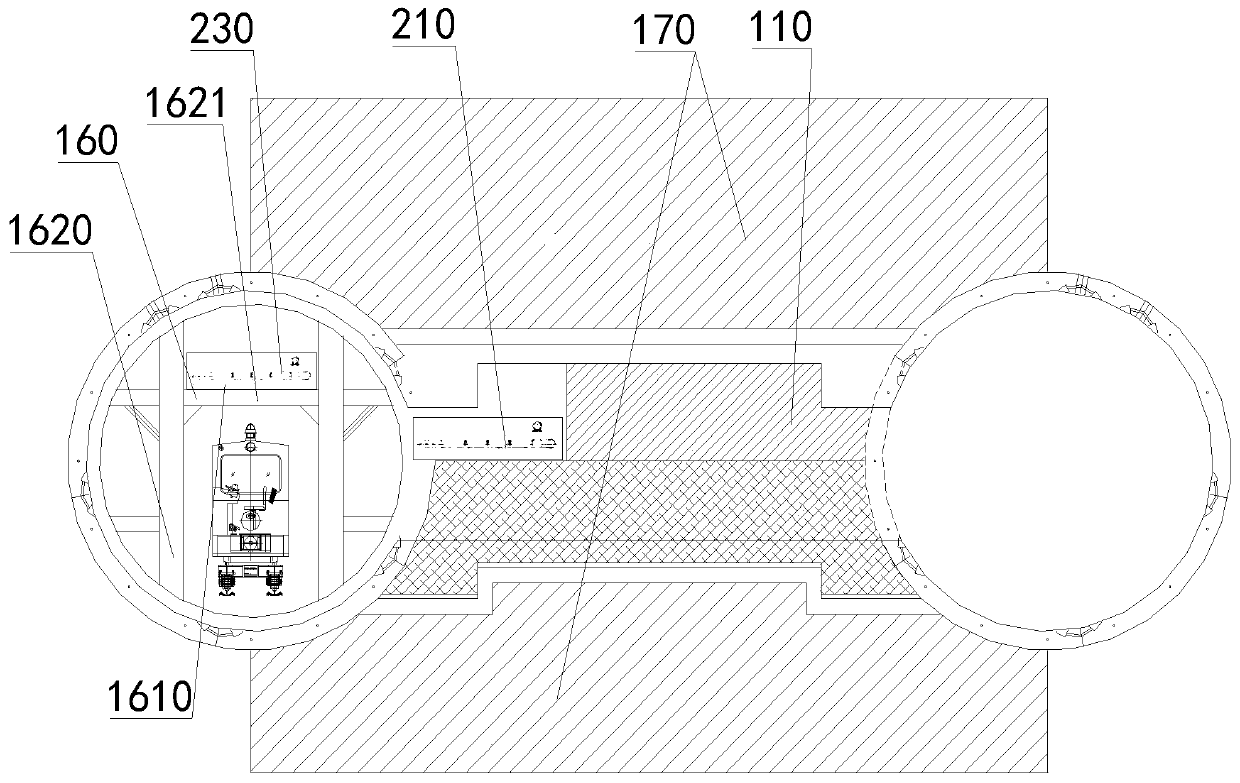

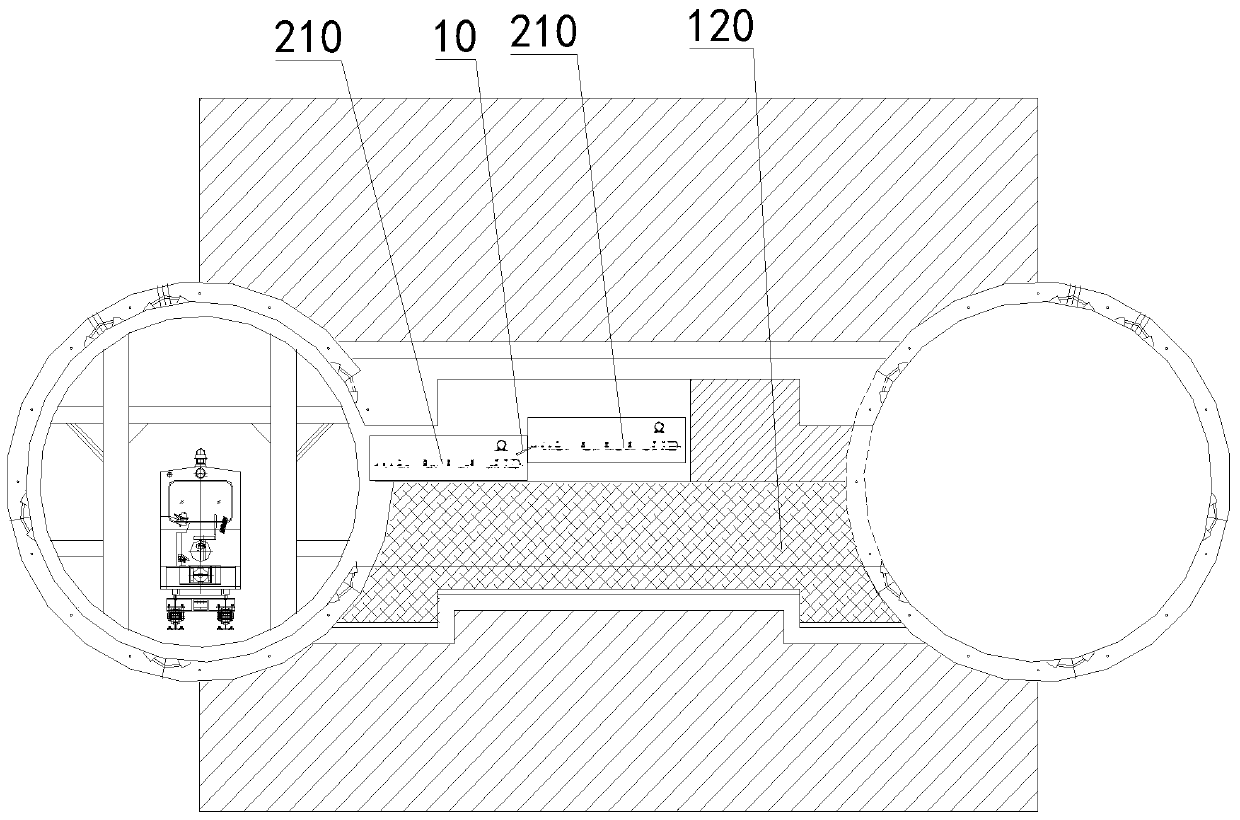

The invention discloses a grouped second liner construction method for a large cross-section tunnel. A whole toroidal second liner is constructed after being divided into 6 parts. The method comprises the following steps: 1), pouring and backfilling an inverted arch of a left lower hole; 2), pouring and backfilling an inverted arch of a right lower hole; 3), pouring a side wall second liner of the left lower hole through a lower hole trolley; 4), moving the lower hole trolley to the right lower hole to pour a side wall second liner of the right lower hole; 5), erecting a bracket in the right lower hole, assembling a right upper hole trolley, and pouring a right upper arch second liner; 6), erecting a bracket in the left lower hole, assembling a left upper hole trolley, and pouring a left upper arch second liner. According to the grouped second liner construction method, a relatively large cross section is divided into a plurality of small cross sections to carry out construction, although the construction procedures the time limit for a product are slightly increased in comparison with those of a traditional two-step construction method, the construction risk is yet reduced to a great extent, the construction safety guarantee coefficient is increased, an extremely important guide value is provided for the tunnel constructed with a CRD (center cross diaphragm) method in certain special urban environment conditions, the construction is smoothly completed on the premise of guaranteeing safety, and remarkable social benefits are achieved.

Owner:RANKEN RAILWAY CONSTR GROUP

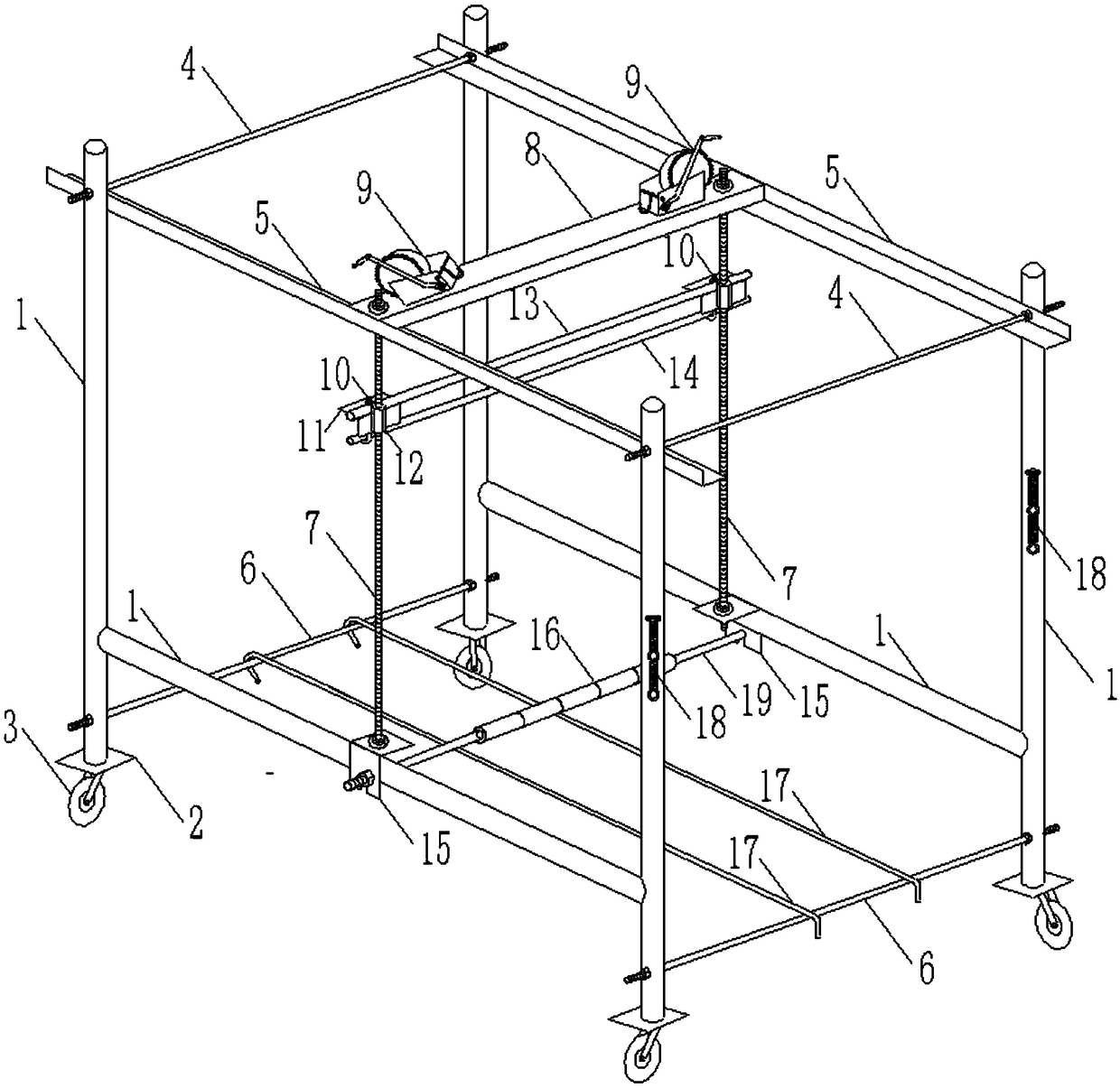

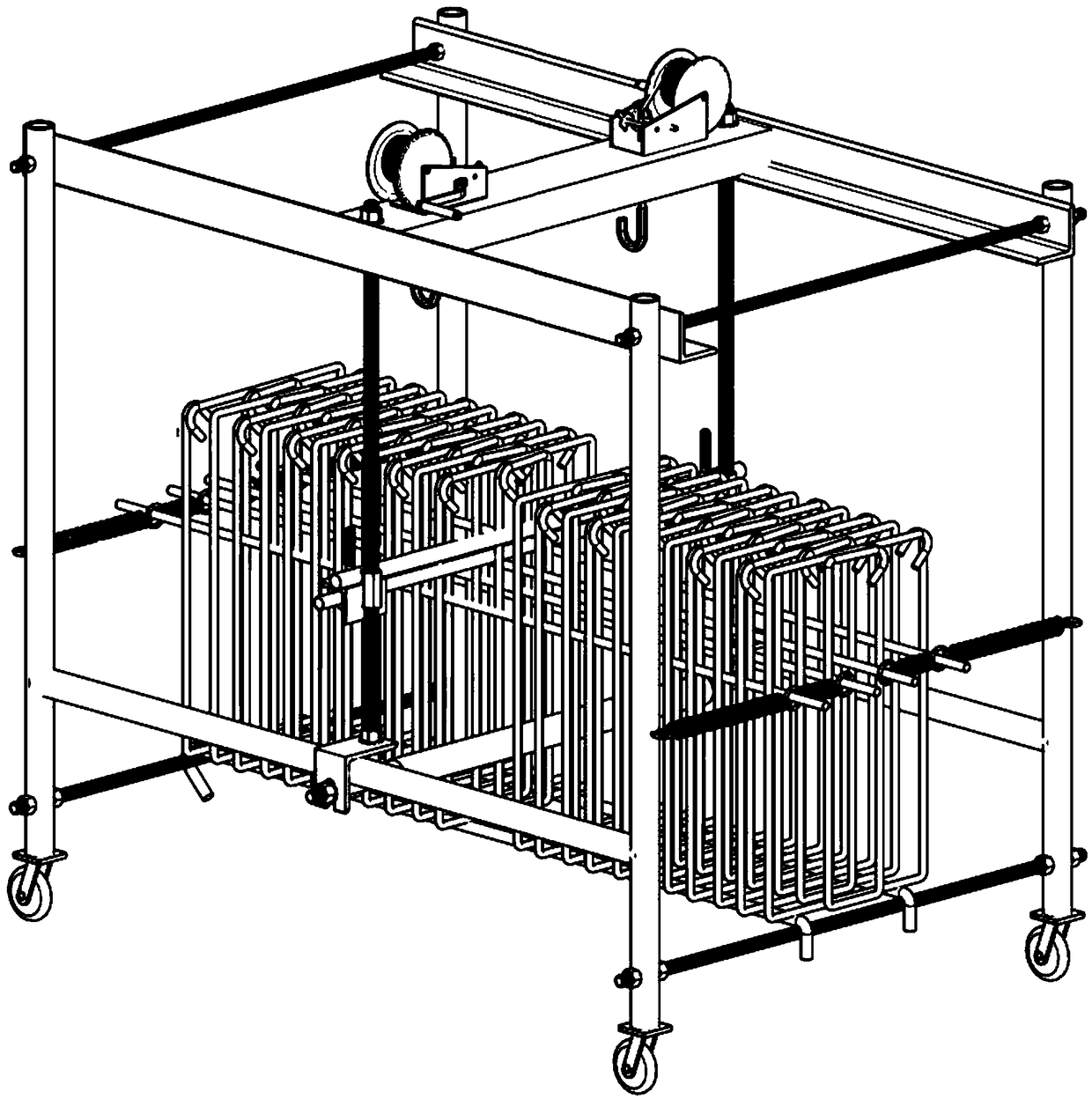

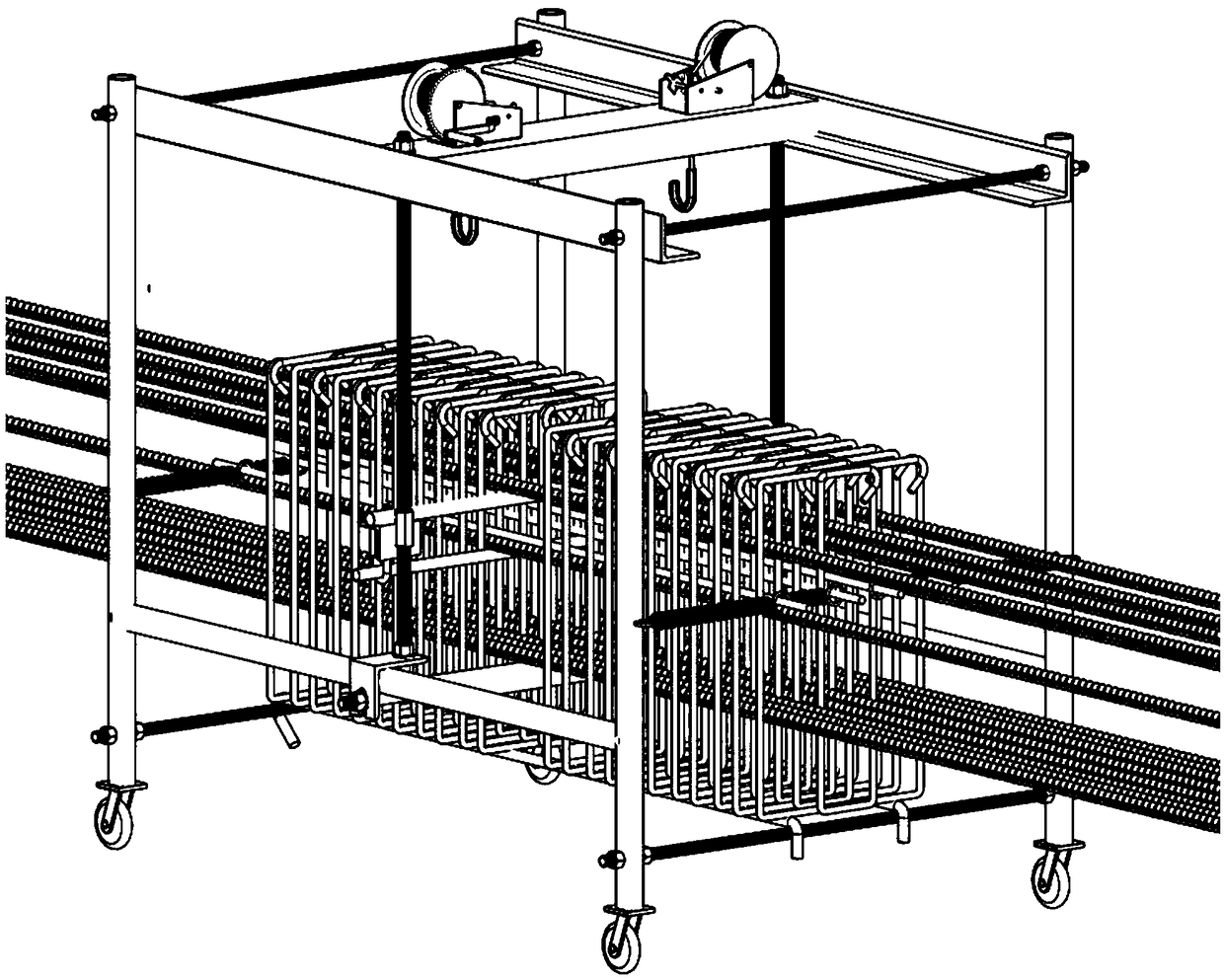

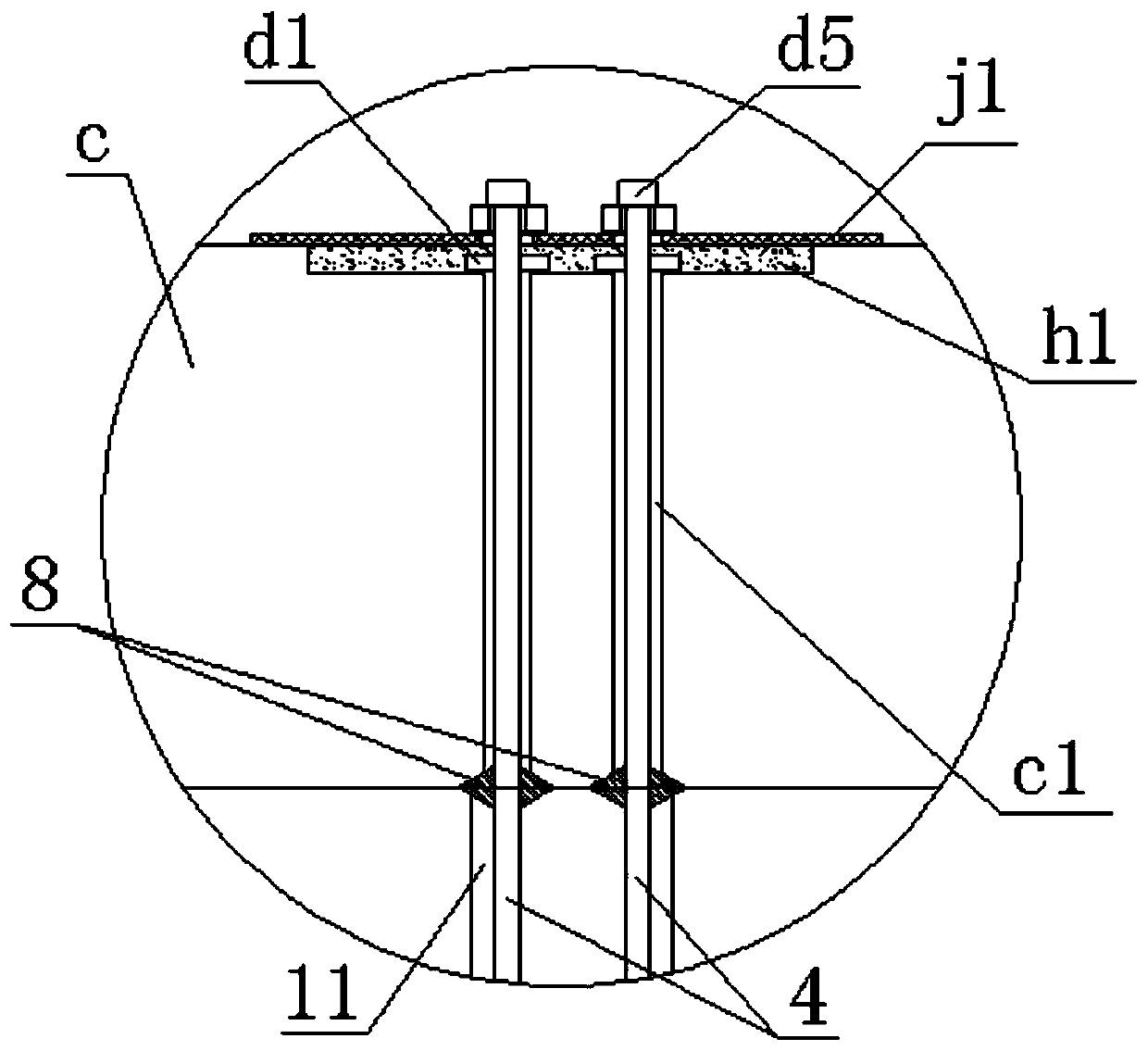

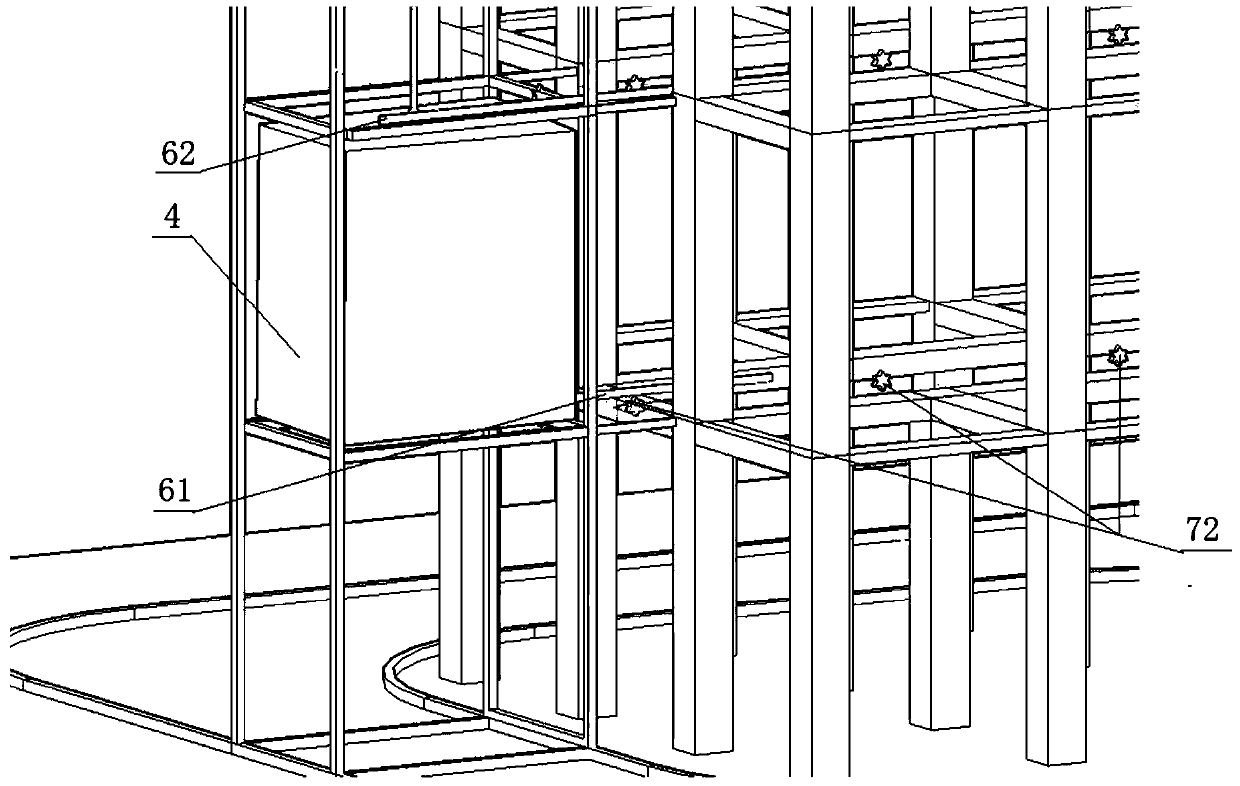

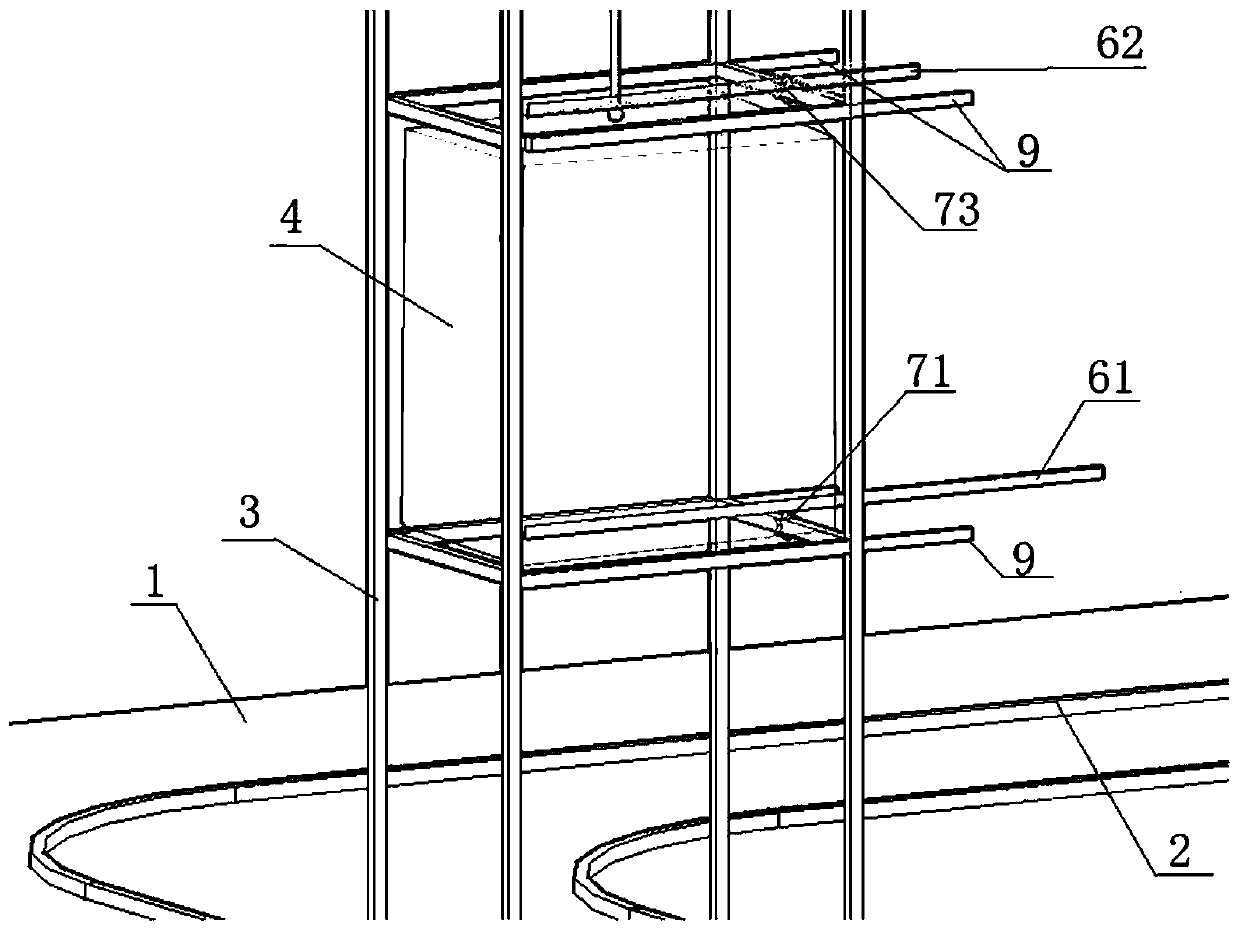

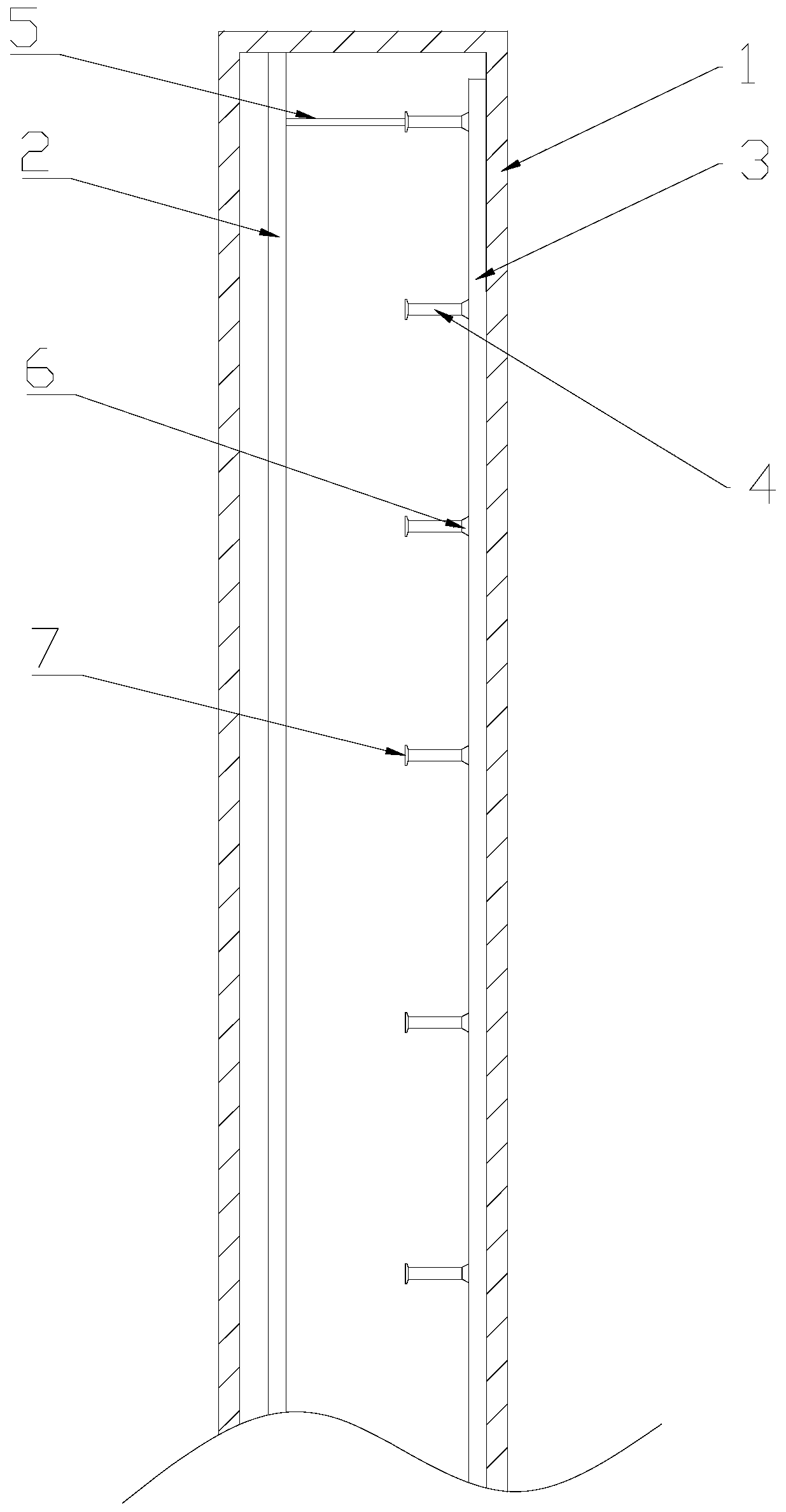

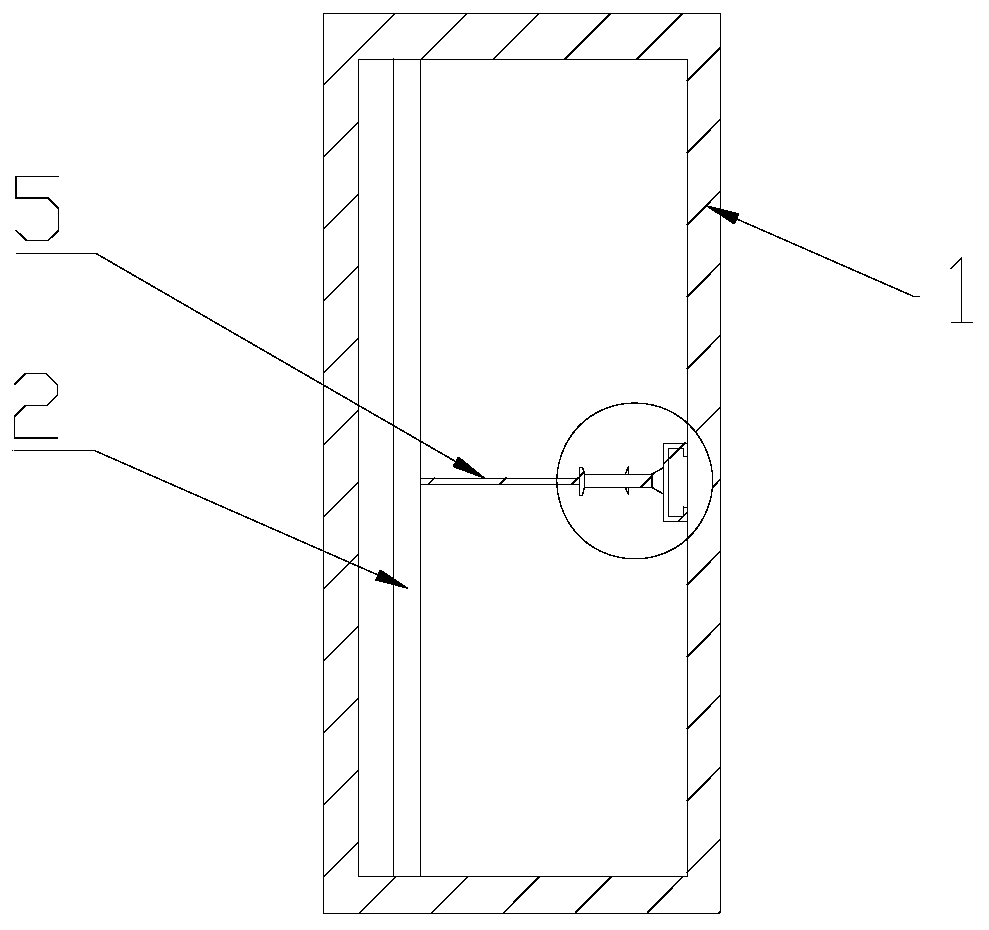

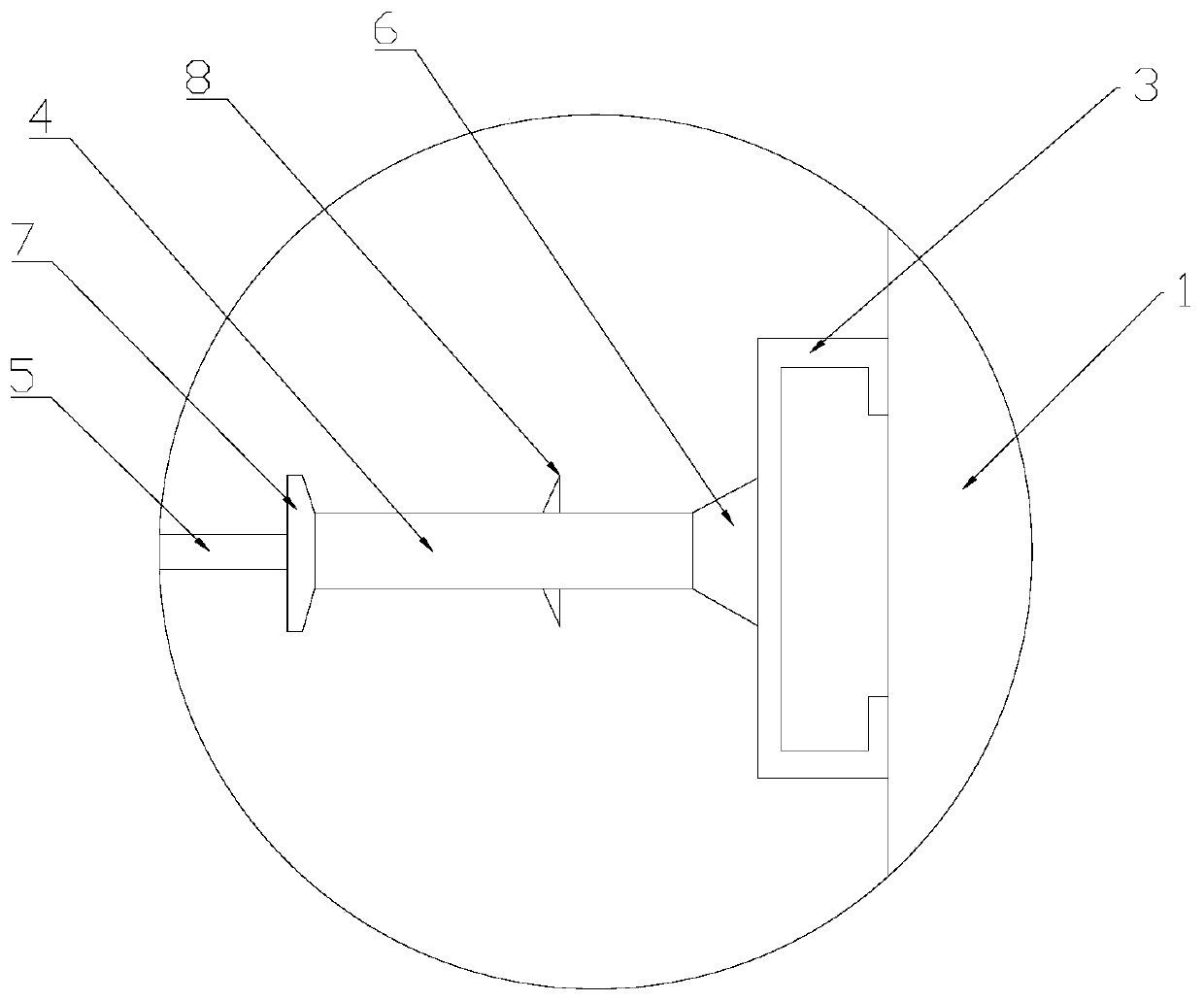

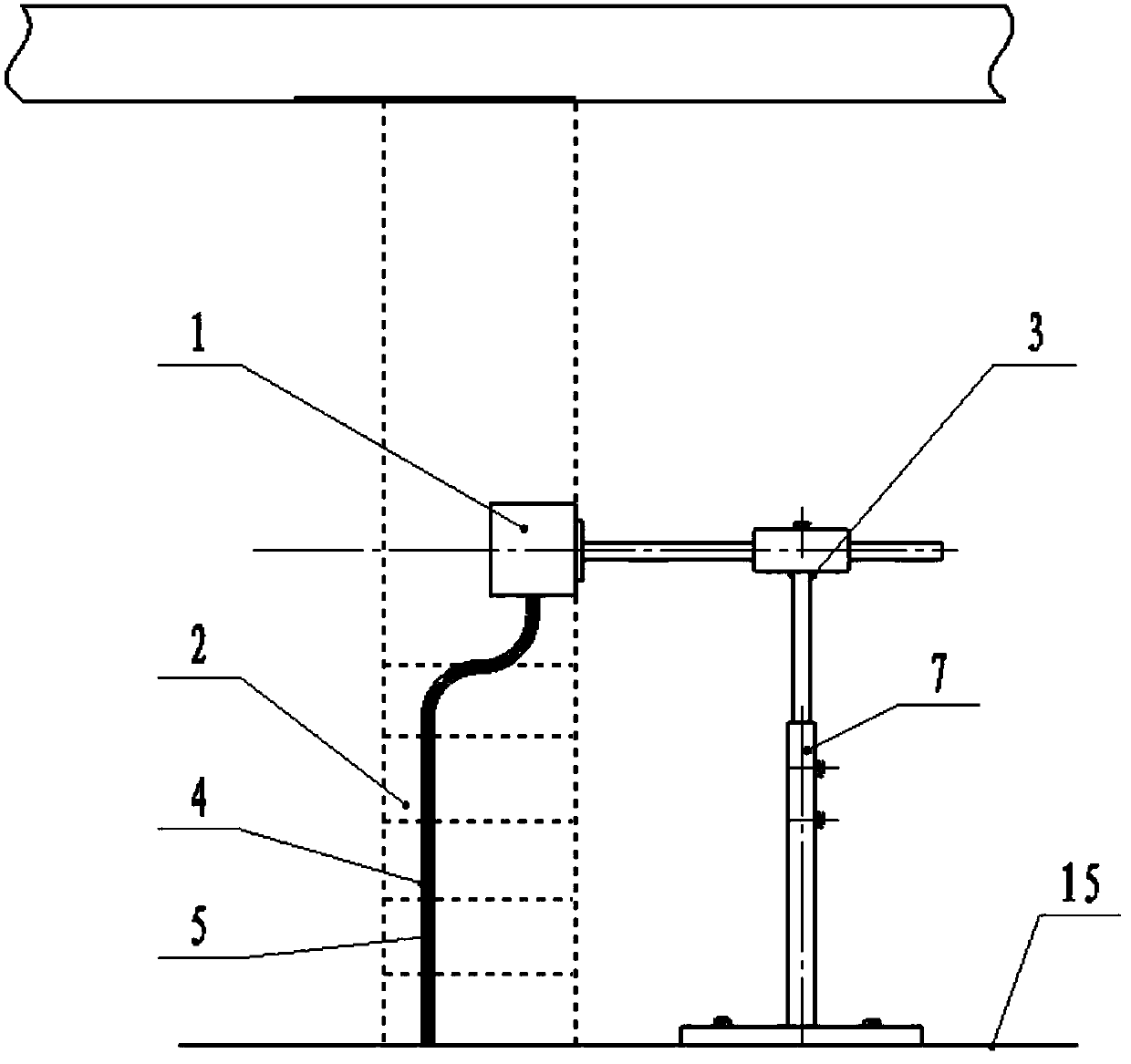

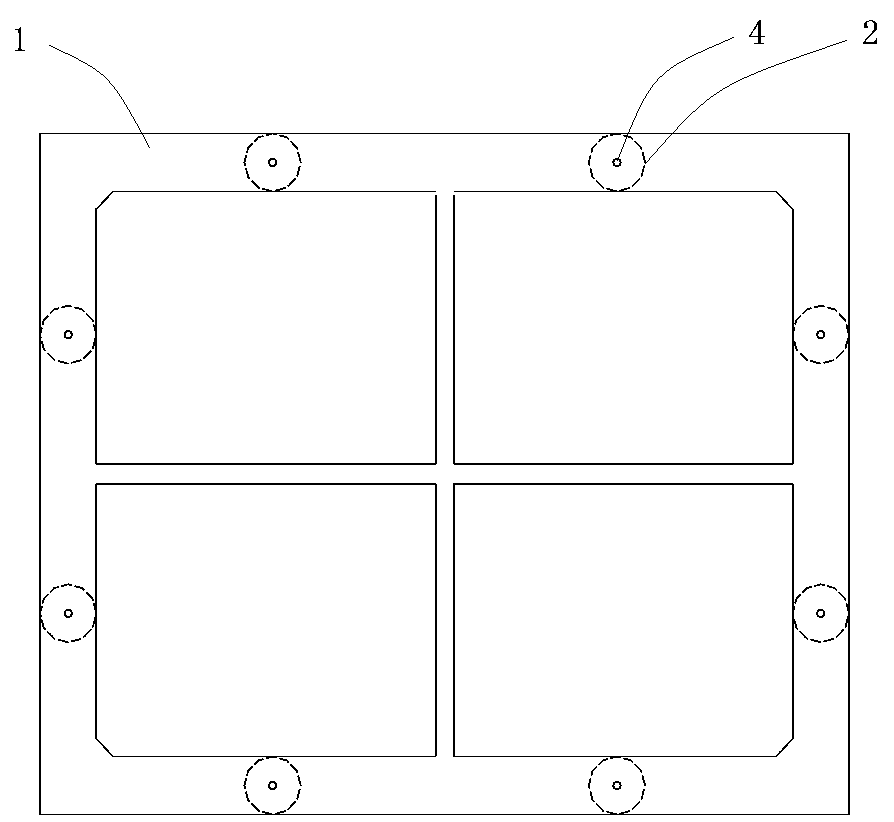

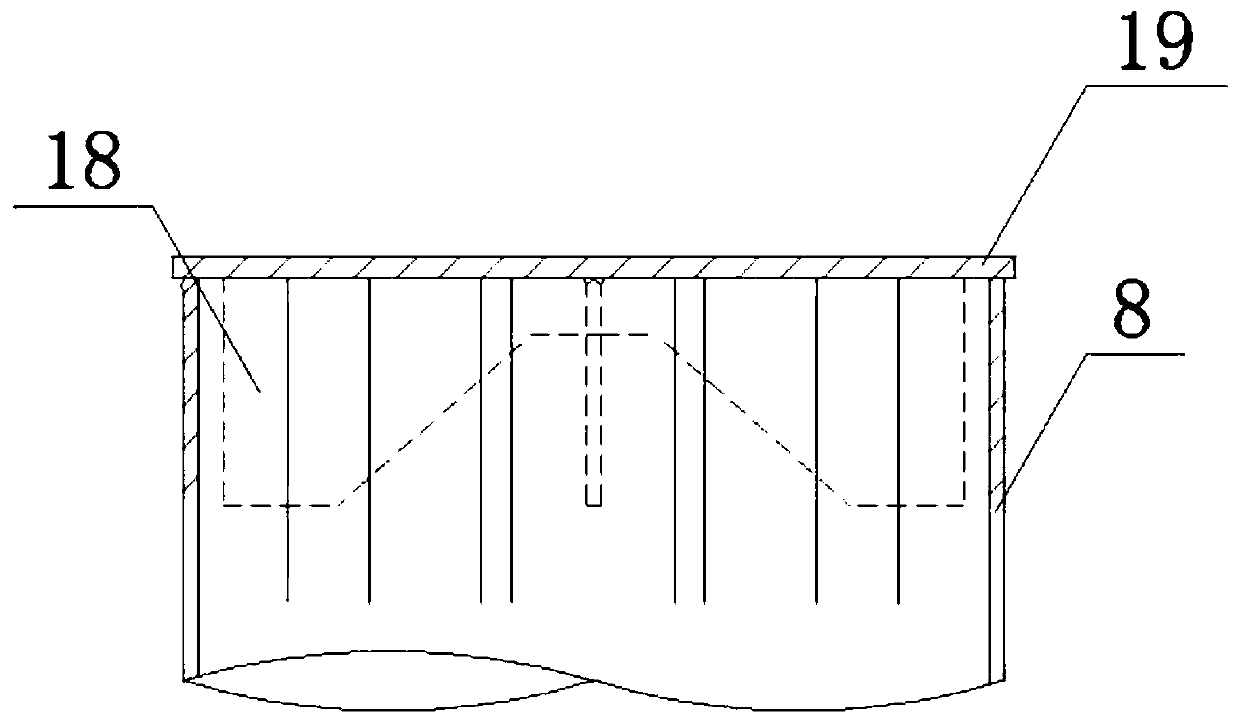

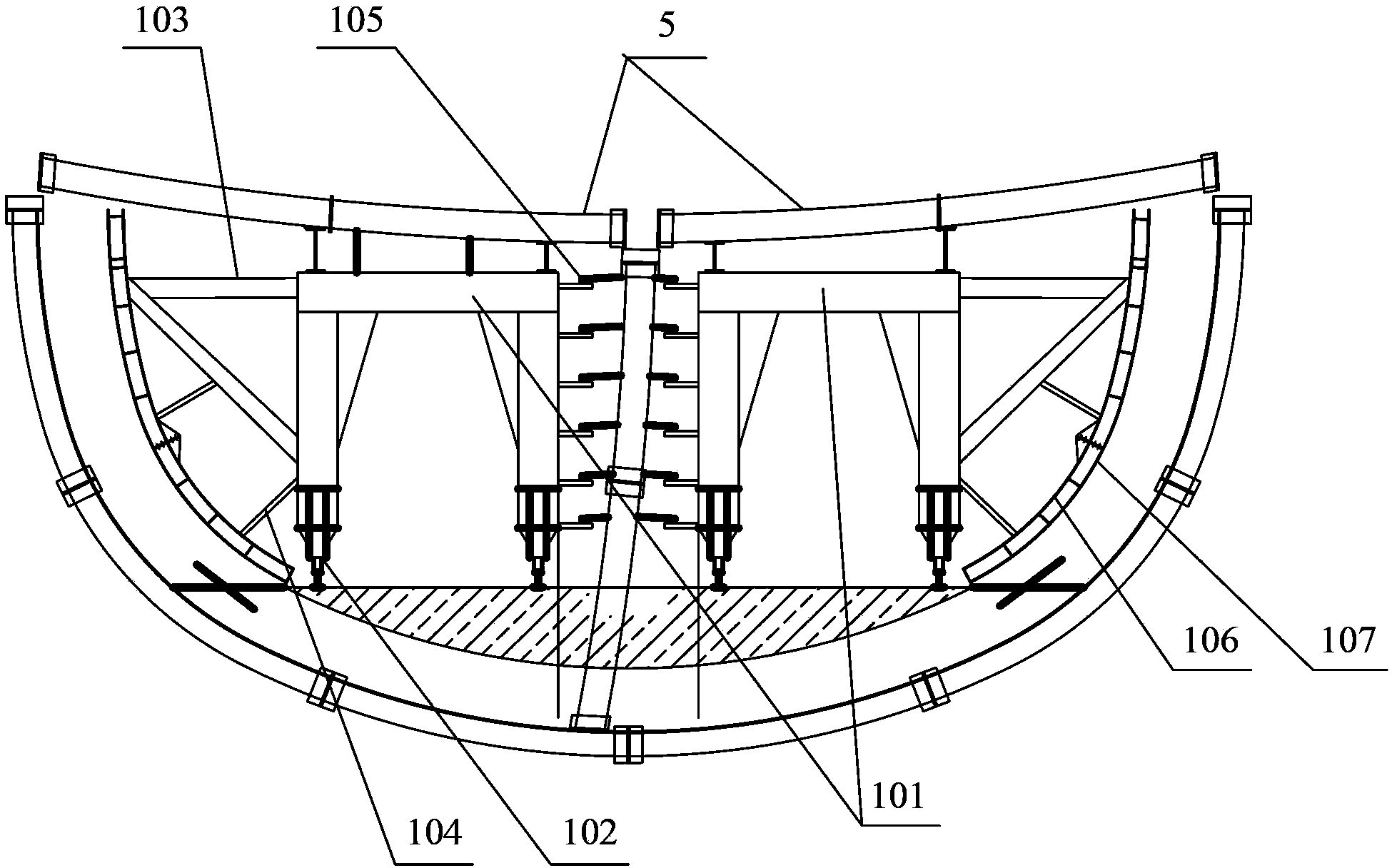

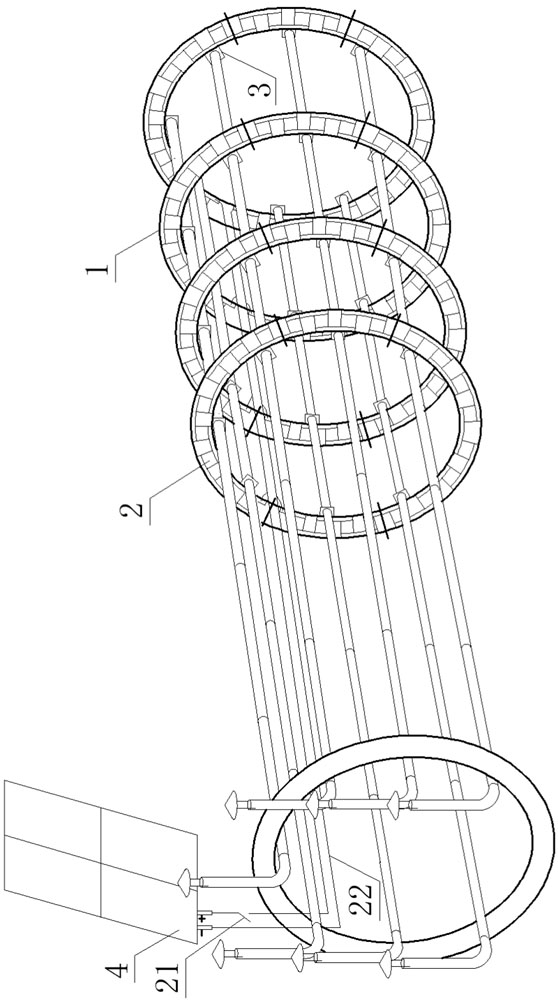

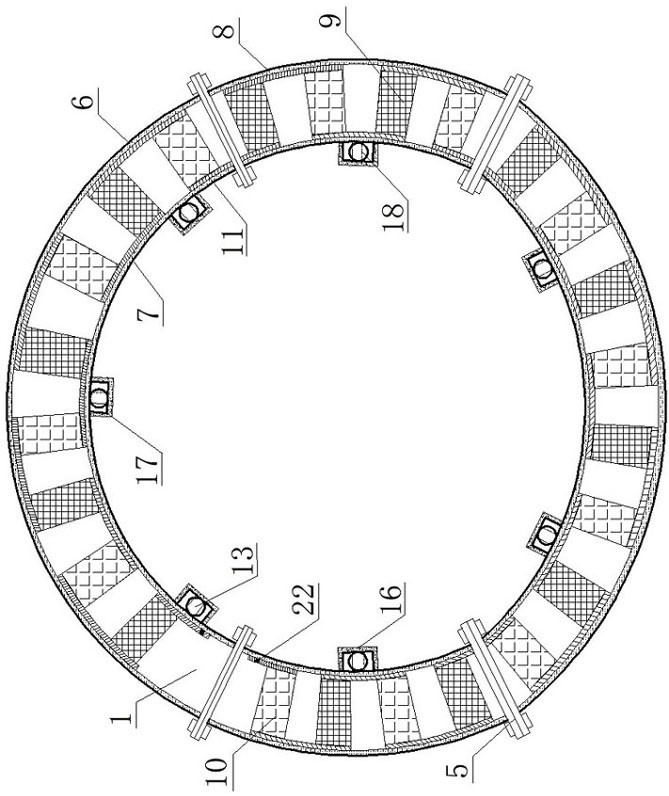

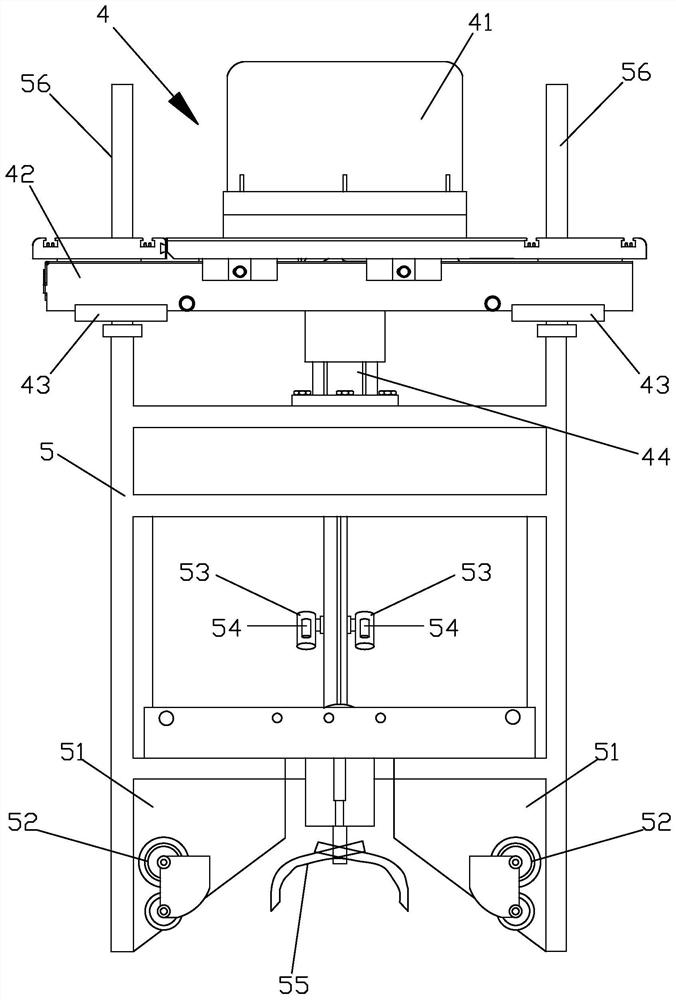

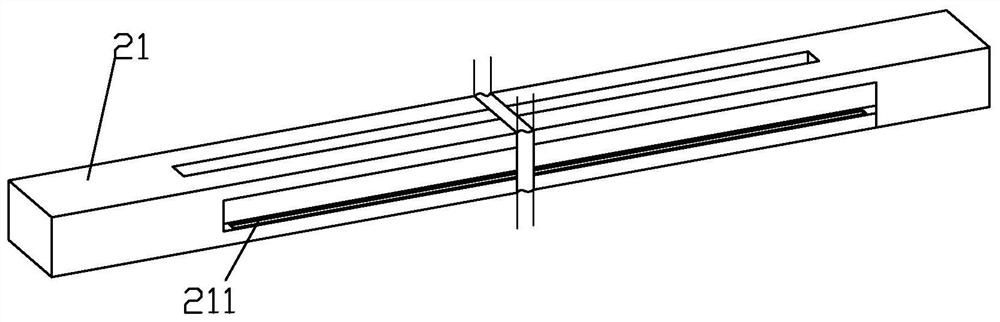

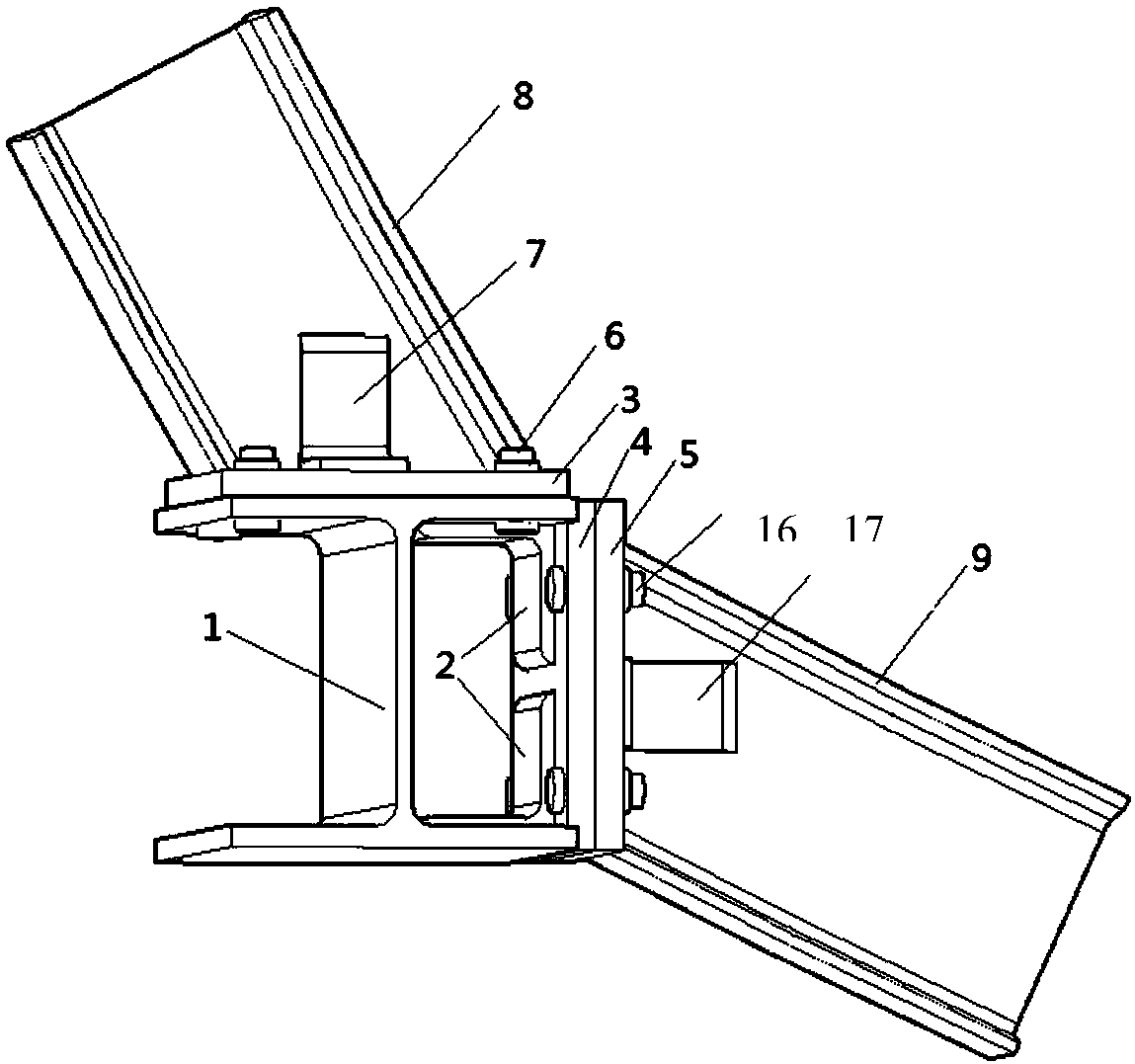

Cast-in-place beam reinforcement cage binding installation multi-function trolley

PendingCN109339458AGuaranteed installation qualityReduce labor intensityBuilding material handlingEngineeringRebar

The invention discloses a cast-in-place beam reinforcement cage binding installation multi-function trolley. The cast-in-place beam reinforcement cage binding installation multi-function trolley comprises a rectangular tubular trolley body frame extending in the front-rear direction, and openings at the front and rear ends of the trolley body frame correspond to reinforcement cage stirrups. A first transverse support, a second transverse support and a third transverse support are detachably arranged in the trolley body frame from top to bottom. The first transverse support, the second transverse support and the third transverse support separately extend in the left and right direction, and the first transverse support and the second transverse support can slide up and down synchronously. The trolley body frame is further internally provided with limiting screws corresponding to the reinforcement cage stirrups in a penetrating mode, and the limiting screws extend in the front-rear direction. A plurality of tension springs are arranged at the front and the rear ends of the trolley body frame, and the limiting screws and the tension springs are detachably connected. The cast-in-placebeam reinforcement cage binding installation multi-function trolley has the characteristics and functions of loading and transporting, stirrup pre-penetrating, skeleton binding, vertical lifting and lowering, adjustable size, flexible movement and the like and replaces traditional cumbersome processes of temporary bracket building, on-site secondary transportation, multiple times of replacing andsupporting, manual or mechanical lifting of the reinforcement cage into a mold.

Owner:JIANGSU NANTONG NO 6 CONSTR GRP

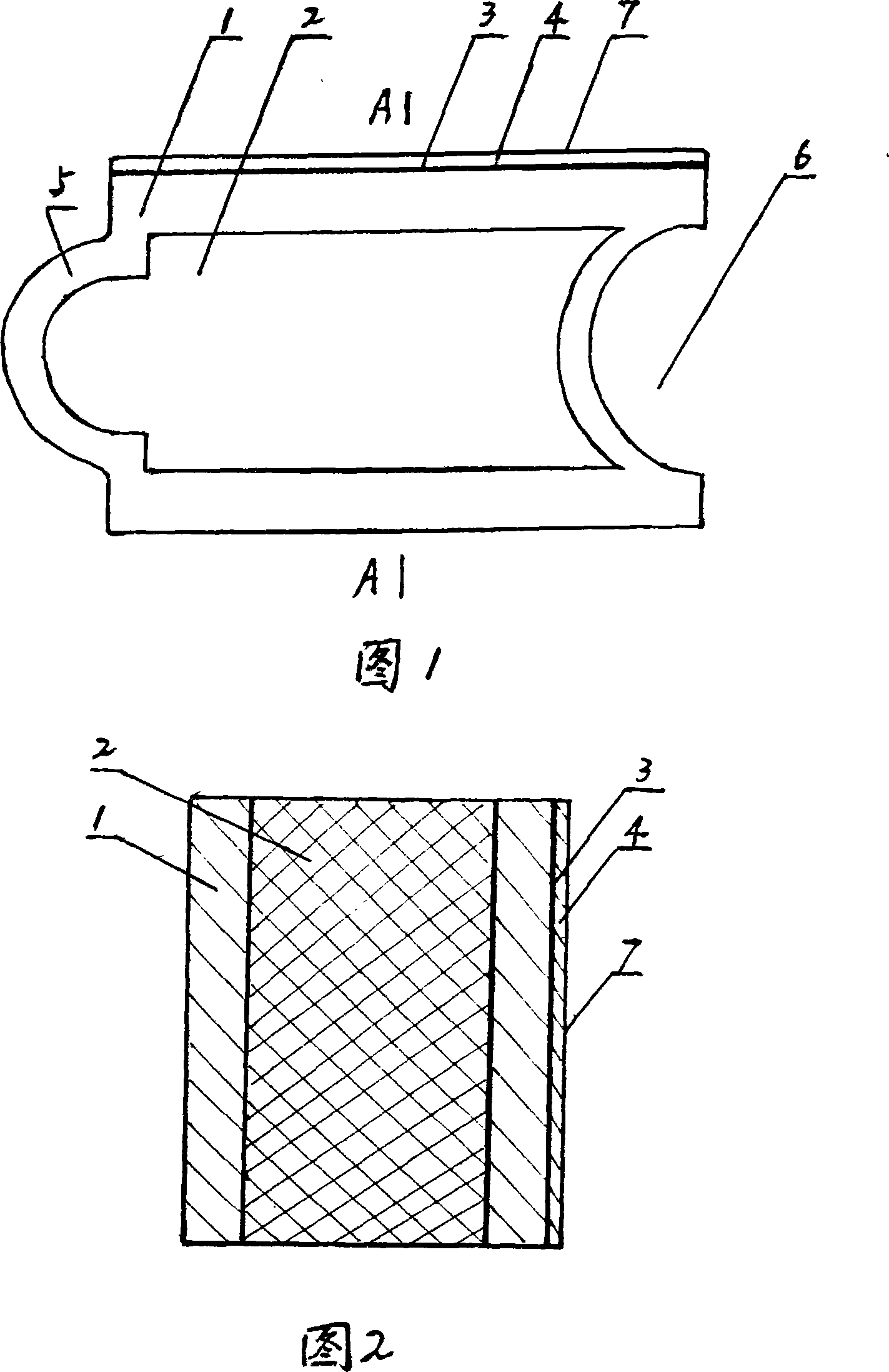

Thermal insulation decorative brick and producing method thereof

InactiveCN101168983AGood heat insulationFast constructionConstruction materialCeramic shaping apparatusEngineeringSurface layer

The invention relates to an insulation facing tile, and a production method thereof. The insulation facing tile is characterized in that the hollow tile is made of the low weight insulation material, either the left side or the right side of the hollow tile is produced to be raised head shaped, the other side is produced to be a groove shape which can be put into the raised head, the hollow part of the hollow tile is filled with an insulation body made of the insulation material and tightly combined with the inner surface of the hollow tile, and a colored ornament surface is adhered on an adhesive layer on the outer surface of the hollow tile. The ornament surface of the tile is directed outward, the raised head of another tile is inserted into the groove and leveled, and the joint is filled with insulation mortar, to form an outer wall. The tile integrates three construction processes of a wall enclosure structure, an insulating layer, and the ornament surface layer together, the on-site installation is simple, convenient, and quick, the quality is easy to be ensured, with safety and reliability, and crack, falling off, cold bridge, alkali resistance and molding of the outer wall surface are avoided; the requirements on energy conservation, environmental protection and aesthetic appearance are met, and the insulation effect is good; the invention can replace a hollow tile, an outer wall insulation adhesive ornament surface and an invention ornament plate.

Owner:薛井生

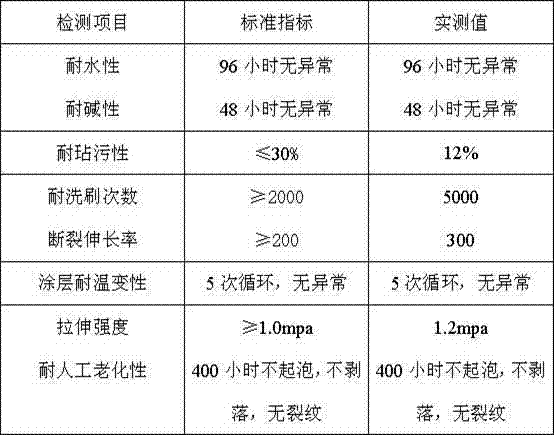

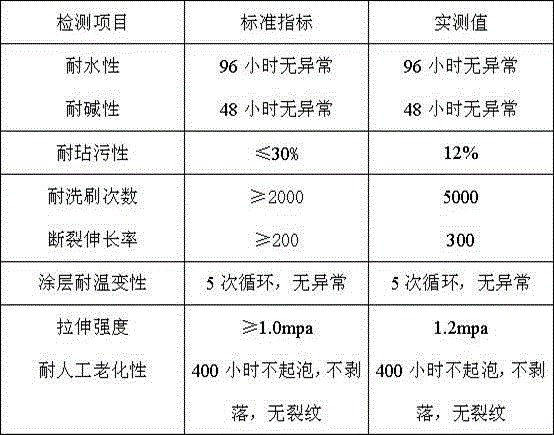

Anti-cracking texture paint preparation method and product thereof

InactiveCN102863898AReasonable formula designHigh tensile strengthCoatingsWeather resistanceCrack resistance

The invention discloses an anti-cracking texture paint preparation method and a product prepared by the method. The product is prepared from the following raw materials: water, ethylene glycol, cellulose, preservative, pH regulator, coarse whiting powder, defoaming agent, elastic emulsion, TEXANOL and thickening agent. The method disclosed by the invention has the advantages of simple preparation technique and high production efficiency, and is easy to implement. The method disclosed by the invention has the advantages of simple preparation technique and high production efficiency, and is easy to implement. The anti-cracking texture paint product disclosed by the invention has reasonable formula design, favorable tensile strength, cracking resistance, water resistance, high adhesive force, excellent weather resistance and excellent decorative effect, can be well bonded on the walling, and ensures the walling to have neat and elegant appearance. The anti-cracking texture paint has the advantages of favorable stereoscopic texture, favorable comprehensive properties, high temperature tolerance, high weather resistance, low cracking tendency and long service life, and effectively lowers the maintenance cost. Besides, the construction process is simple, greatly shortens the construction period, enhances the construction efficiency, requires low cost, and is beneficial to wide popularization.

Owner:黄明杰

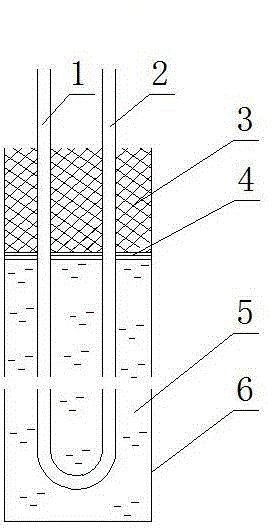

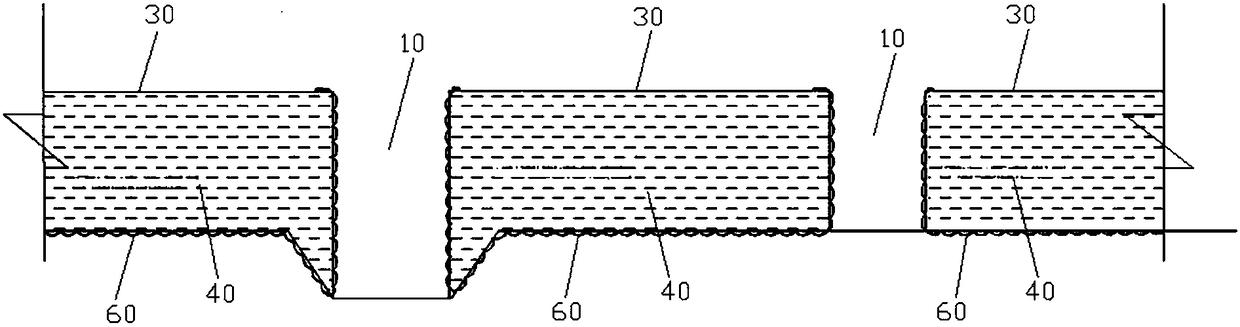

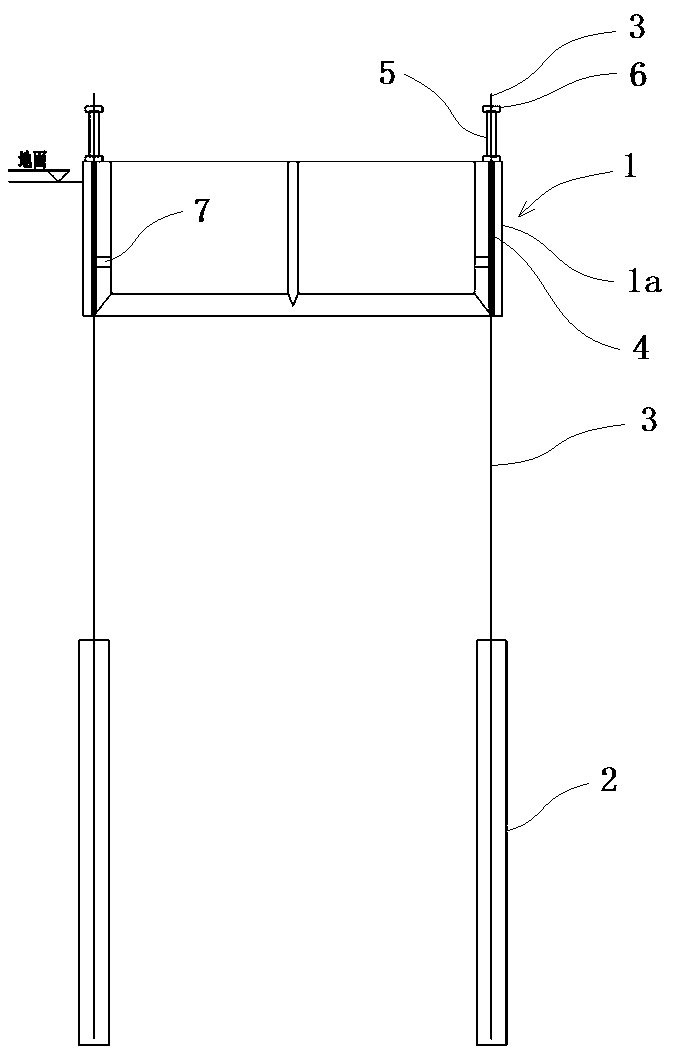

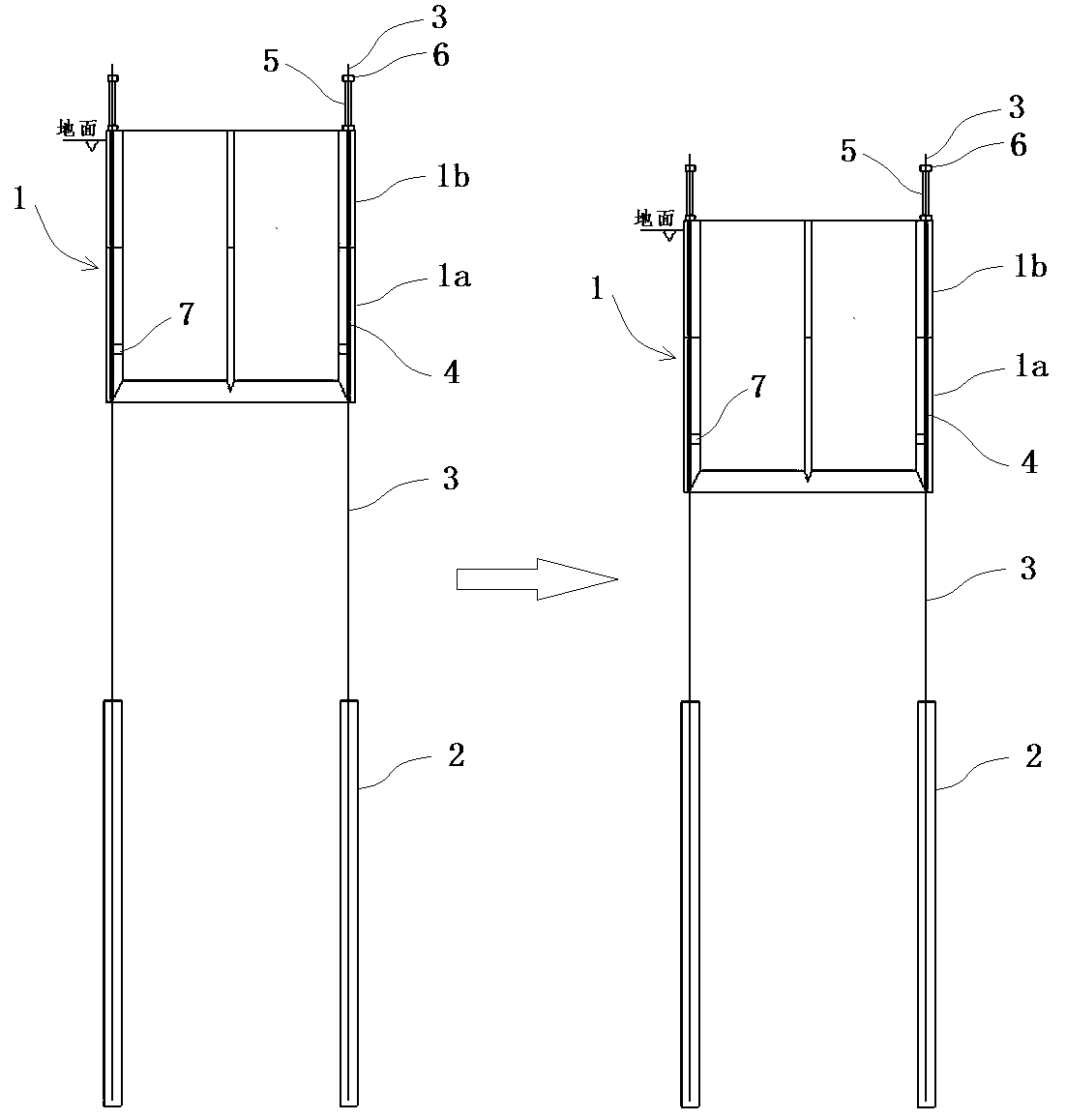

Ground source heat pump buried pipe heat exchanger free of backfilling

ActiveCN104457028AImprove heat transfer performanceReduce the number of drilled holesHeat pumpsOther heat production devicesDrill holeEngineering

The invention provides a ground source heat pump buried pipe heat exchanger free of backfilling to overcome defects in the prior art. The part below the perennial underground water level is reserved in a buried pipe heat exchanging hole, backfilling of sandy soil backfill materials or other special grouting backfill materials is not needed, in other words, backfilling of the backfill materials does not need to be carried out between a water inlet pipeline and a water outlet pipeline of a buried pipe heat exchanging pipe under the perennial underground water level and between the heat exchanging pipe and the hole wall, the heat exchanging performance of the buried pipe heat exchanger is improved through groundwater runoff water, the number of drill holes is reduced, the construction procedure is simplified, the construction cost is reduced, a large number of backfill materials and cost for backfill grouting and compacting are saved, and the social benefits and the economical benefits are very obvious.

Owner:湖南凌天科技有限公司

Prefabricated rail top air duct of subway station and hoisting installation method thereof

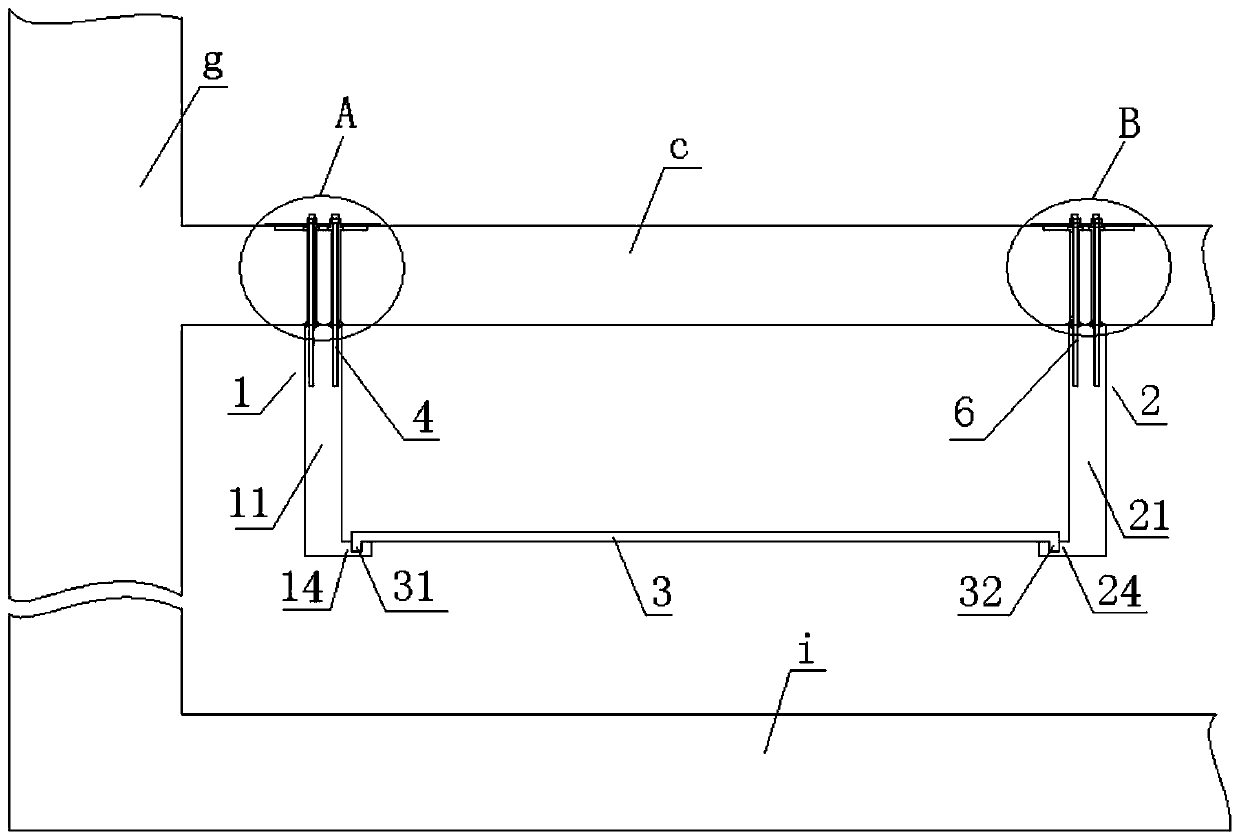

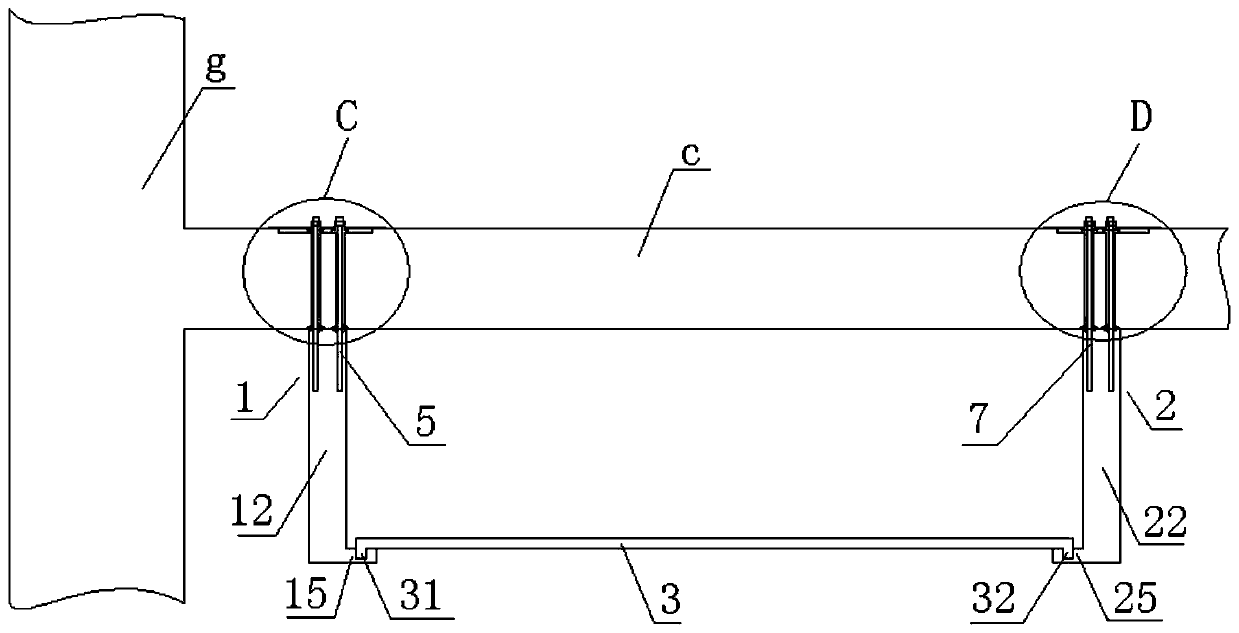

PendingCN110984224AReduce consumptionPrevent leakageDucting arrangementsArtificial islandsRubber ringArchitectural engineering

The invention discloses a prefabricated rail top air duct of a subway station. The prefabricated rail top air duct of the subway station comprises a first prefabricated side plate, a second prefabricated side plate, an air duct bottom plate, a first screw rod, a second screw rod, a third screw rod, a fourth screw rod, a first waterproof rubber ring, a second waterproof rubber ring, a third waterproof rubber ring and a fourth waterproof rubber ring, wherein the first prefabricated side plate comprises a first upright post, a second upright post, a first panel, a first side foot plate and a second side foot plate; the second prefabricated side plate comprises a third upright post, a fourth upright post, a second panel, a third side foot plate and a fourth side foot plate; and the air duct bottom plate is lapped on the first side foot plate, the second side foot plate, the third side foot plate and the fourth side foot plate. The invention also discloses a hoisting installation method ofthe prefabricated rail top air duct of the subway station. According to the prefabricated rail top air duct of the subway station and the hoisting installation method thereof, the construction periodcan be shortened, the construction quality can be improved, the construction cost can be reduced, the safe and civilized construction degree can be improved, the water can be prevented from leaking from a middle plate of the station to a rail top air duct, the normal use of a shielding door of the subway station can be ensured, and the problem that the service life of the prefabricated rail top air duct is influenced due to heavy weight of components can be solved.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

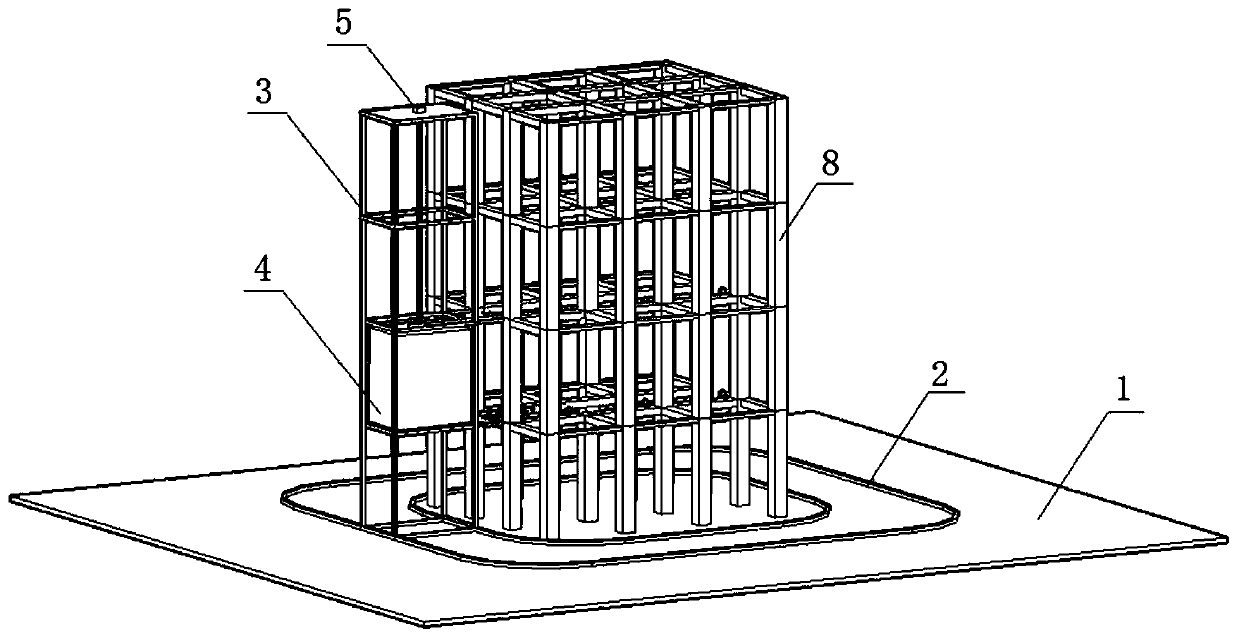

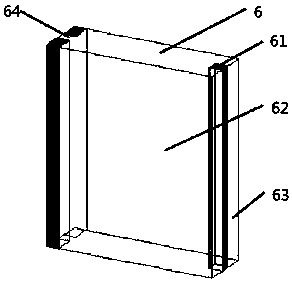

Fabricated building

ActiveCN107620402ALow costGuaranteed construction speedWallsClimate change adaptationWall plateBuilding construction

The invention relates to the technical field of buildings, in particular to a fabricated building. The fabricated building comprises a steel structure frame and prefabricated external wall plates. Themultiple layers of external wall plates are arranged from top to bottom, and each layer of external wall plate is fixed to the outer side of the steel structure frame through a connection part. By fixing the prefabricated external wall plates to the steel structure frame to form the building, the problems that an in-situ concrete pouring method is large in transporting amount and high in construction cost, the construction quality cannot be ensured, environmental pollution is serious, the cost is high, energy waste is prone to being generated can be solved. The external wall plates are transported to a construction site after being prefabricated in a factory, and mounted by adopting hoisting in the construction site to assemble an overall building, thus achievement of housing industrialization is facilitated, and the defects of in-situ formwork building, reinforcement assembling and concrete pouring of a traditional construction method are overcome. Mounting of windows and doors and construction of heat preservation layers and decoration layers are not needed after the main structure of the building is completed, and thus the construction procedures are simplified.

Owner:柏秋

Anti-cracking water-resistant intermediate paint preparation method and product thereof

The invention discloses an anti-cracking water-resistant intermediate paint preparation method and a product prepared by the method. The elastic emulsion used in the product is Tianba 2000, which has excellent water resistance, flexibility, alkali resistance and percentage of elongation. Assistants are common assistants for construction paints; and fillers are barium sulfate, talcum powder and coarse whiting powder, and the coarse fillers can enhance the physical and chemical properties of the coated film and lower the cost. The method disclosed by the invention has the advantages of simple preparation technique and high production efficiency, and is easy to implement. The anti-cracking water-resistant intermediate paint product disclosed by the invention has the advantages of favorable flexibility, strong cracking resistance (can bridge a 0.5-3mm crack), favorable water resistance, high binding firmness, favorable comprehensive properties, high temperature tolerance and high weather resistance, effectively solves the phenomena of cracking and water leakage in the walling, and ensures the walling to have neat and elegant appearance; and besides, the construction process is simple, greatly shortens the construction period, enhances the construction efficiency, requires low cost, and is beneficial to wide popularization.

Owner:黄明杰

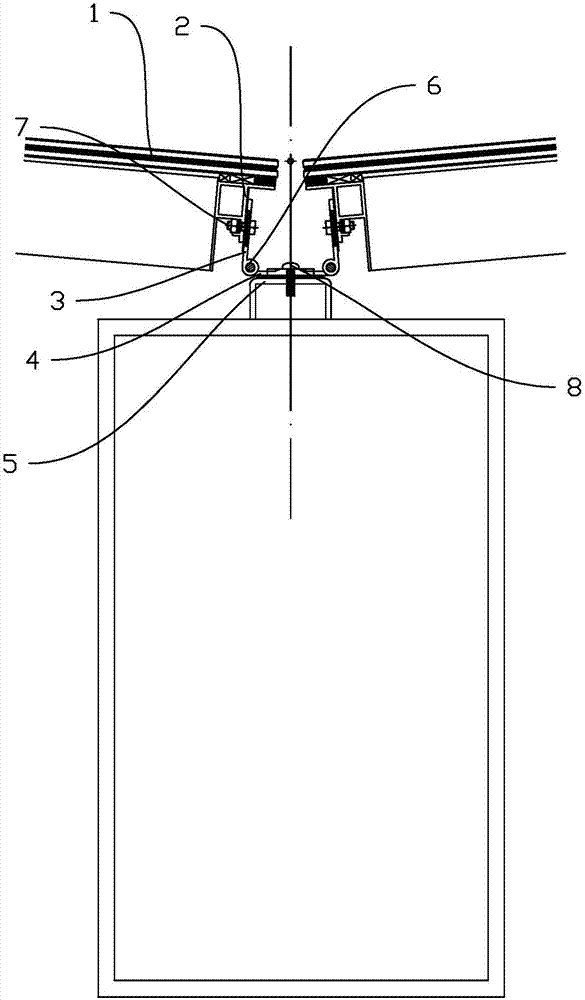

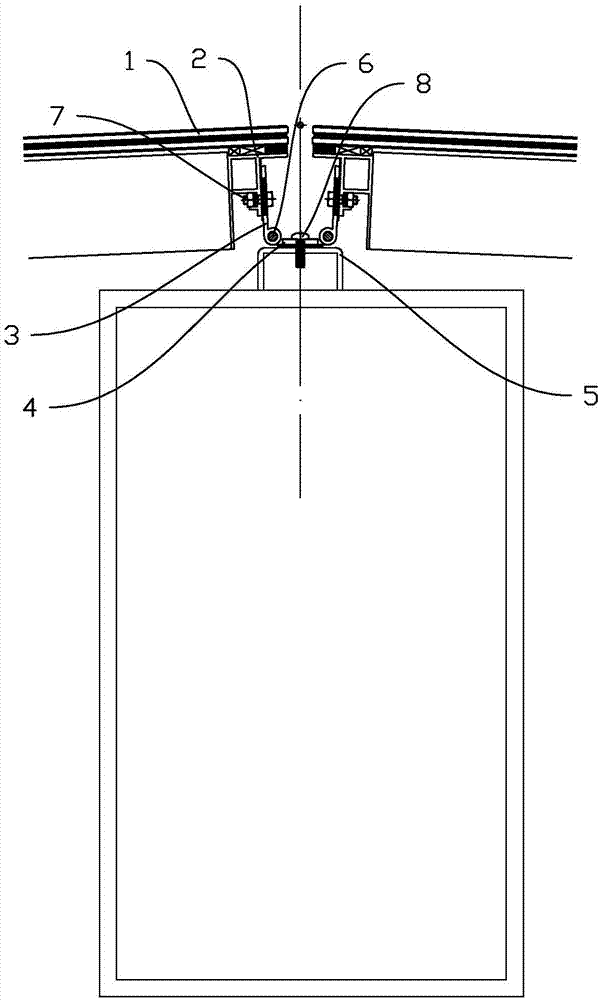

Maneuvering type modular building structure and construction method

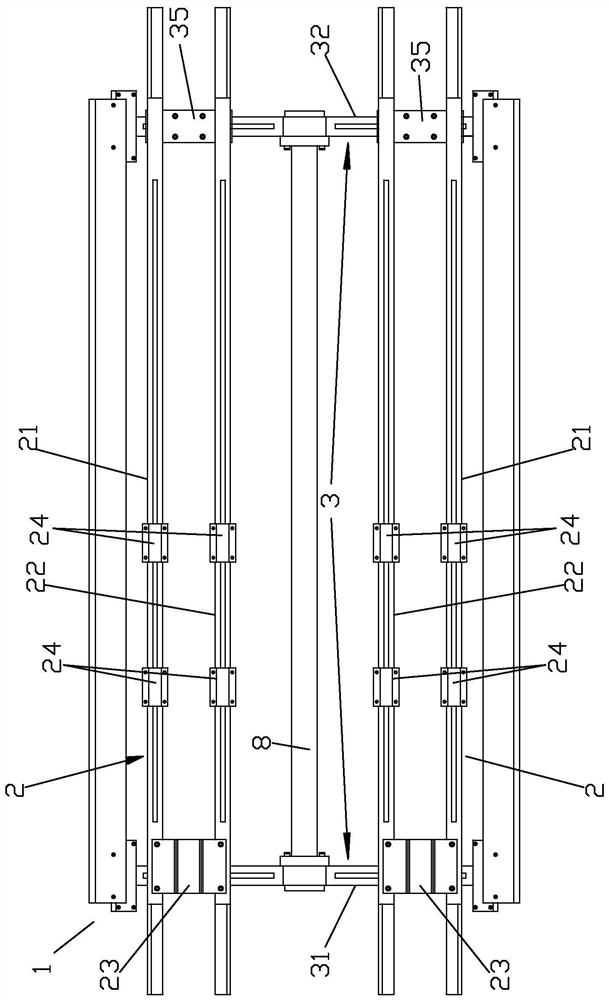

PendingCN110424543AQuick installation and removalSave land resourcesBuilding constructionsElevatorsModular constructionModularity

The invention provides a maneuvering type modular building structure comprising a modular building, a lifting frame module, a lifting unit module and a rail. The rail is arranged on the peripheral ground of the modular building. The lifting frame module comprises a lifting cage of a steel frame structure. The lower end of the lifting cage is provided with a walking device adapted to the rails, andthe walking device drives the lifting frame module to move on the rail. A winch is arranged at the bottom of the lifting cage. A pulley assembly is arranged on the top of the lifting cage. The face,opposite to the modular building, of the lifting cage is provided with telescopic attachment devices. The modular building is provided with a fixing device adaptive to the telescopic attachment device. The telescopic attachment device is connected with the fixing device through hoops. The lifting unit module comprises a lifting box of a box type structure. The upper end of the lifting box is connected with the winch through the pulley assembly by means of a rope. The maneuvering type modular building structure can achieve rapid assembly and disassembly, saves the land resource occupied by a crane, occupies small construction space, saves construction time, lowers labor intensity, shortens work period, lowers cost and has high safety.

Owner:MCC TIANGONG GROUP

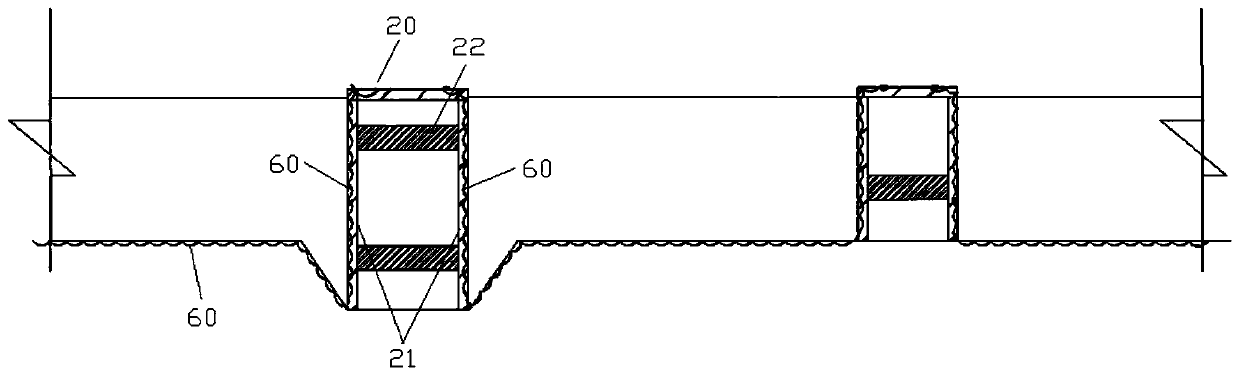

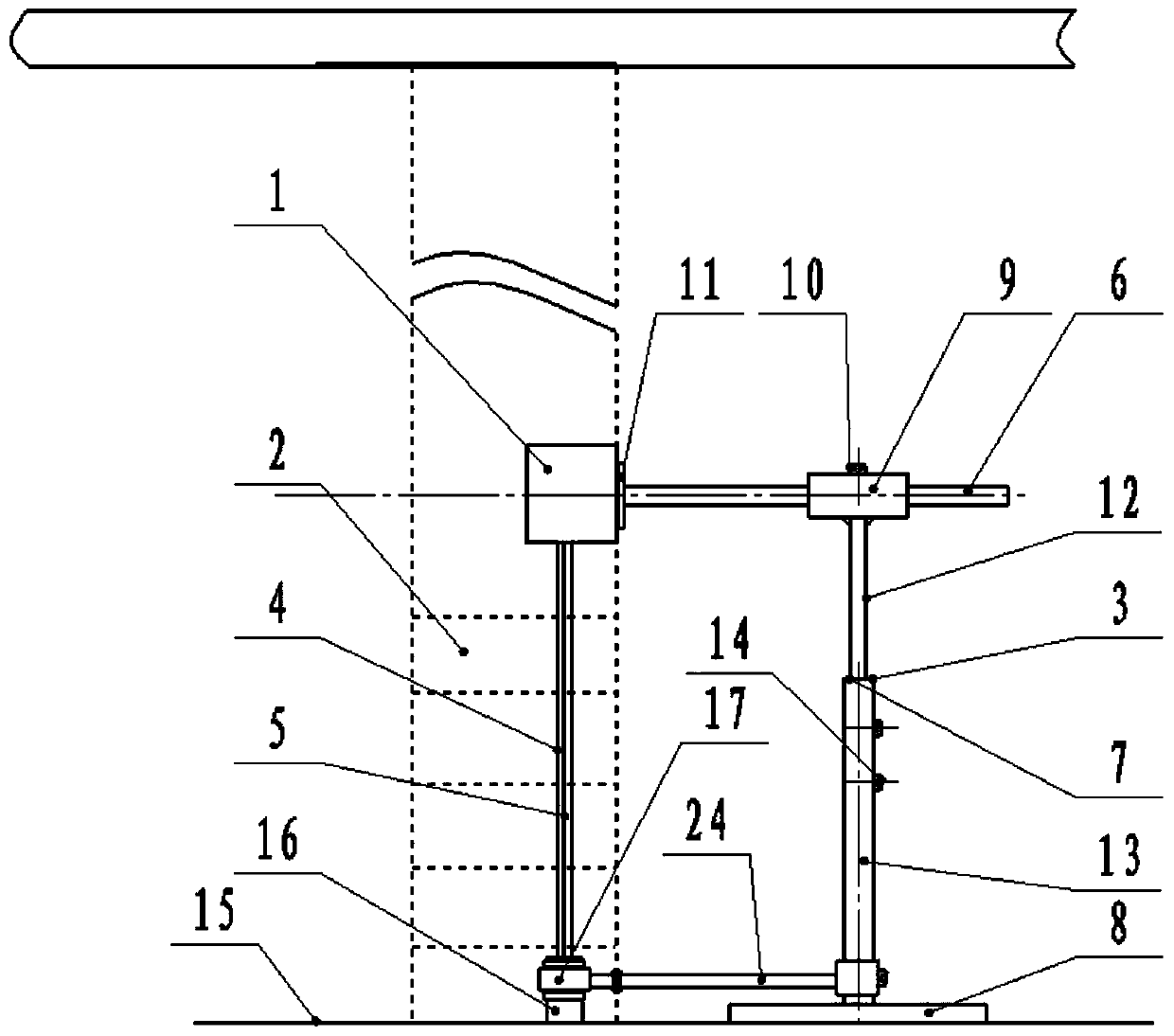

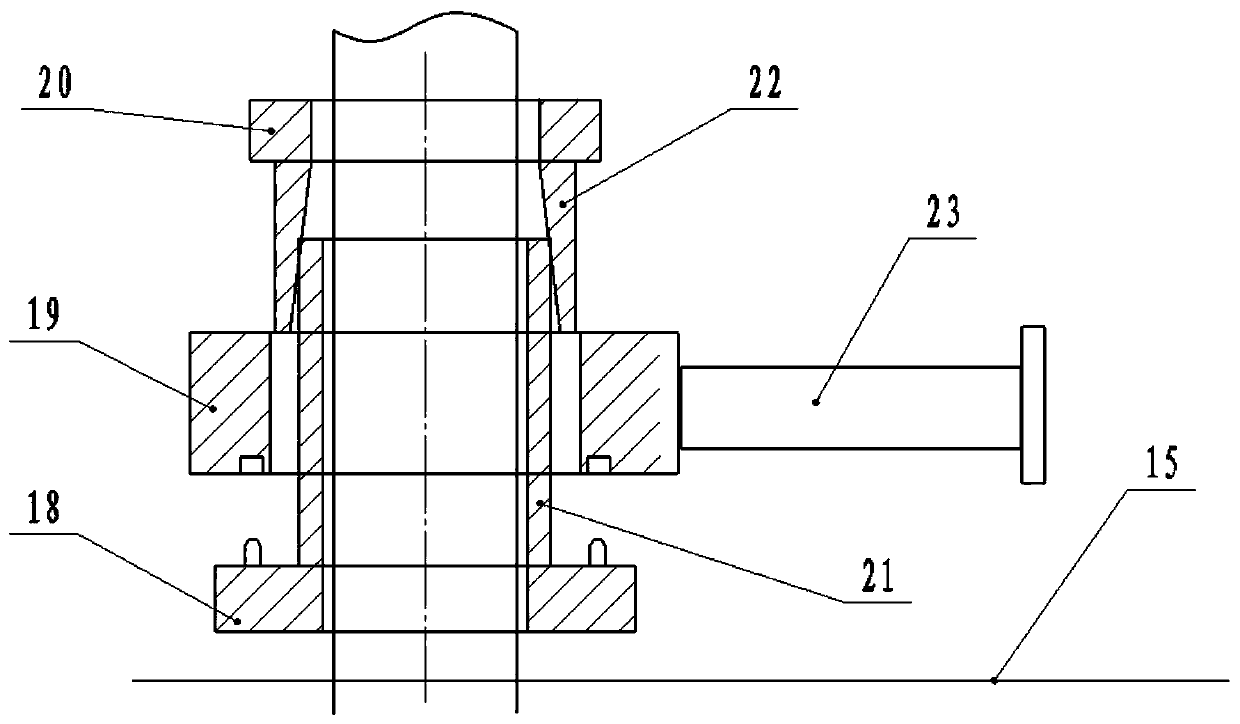

Installing device and method of embedded halfen groove

PendingCN109930628AAccurateMeet repeatabilityArtificial islandsUnderwater structuresArchitectural engineeringRebar

The invention relates to an installing device and method of an embedded halfen groove. The installing device of the embedded halfen groove is suitable for positioning and installation of the halfen groove in a concrete member, and comprises a building template internally provided with a cavity as well as a reinforcing steel bar and the halfen groove in the building template; the halfen groove extends along the length direction of the building template; a plurality of bolt anchors are arranged at the back side of the halfen groove; one or more of the bolt anchors is fixedly connected with the reinforcing steel bar through positioning bars; and the position of an opening in the front side of the halfen groove is tightly attached to one side of the building template. According to the installing device and method of the embedded halfen groove, provided by the embodiment of the invention, the design is reasonable; the precision of the pre-burying, installation and positioning of the halfengroove and the simplification of construction are realized; and the needs of repeatability and generalizability of site construction are met.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

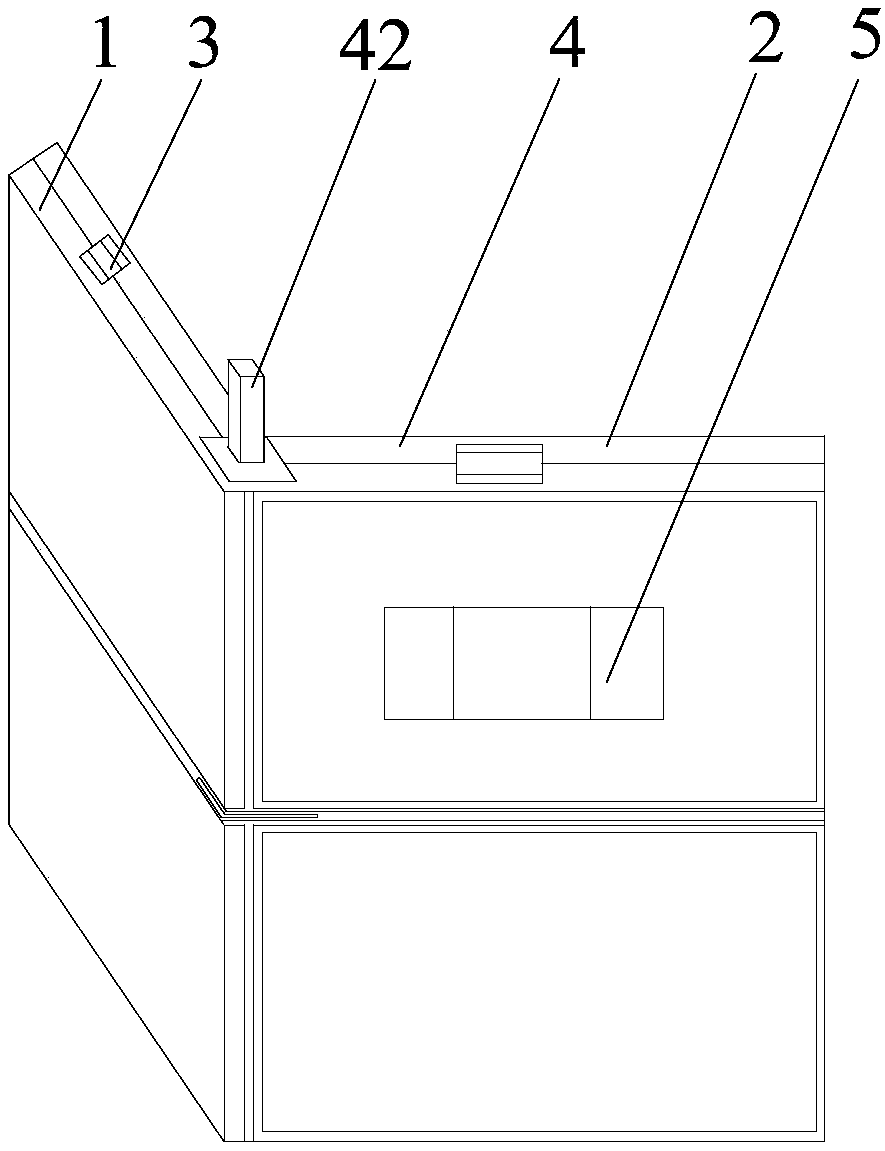

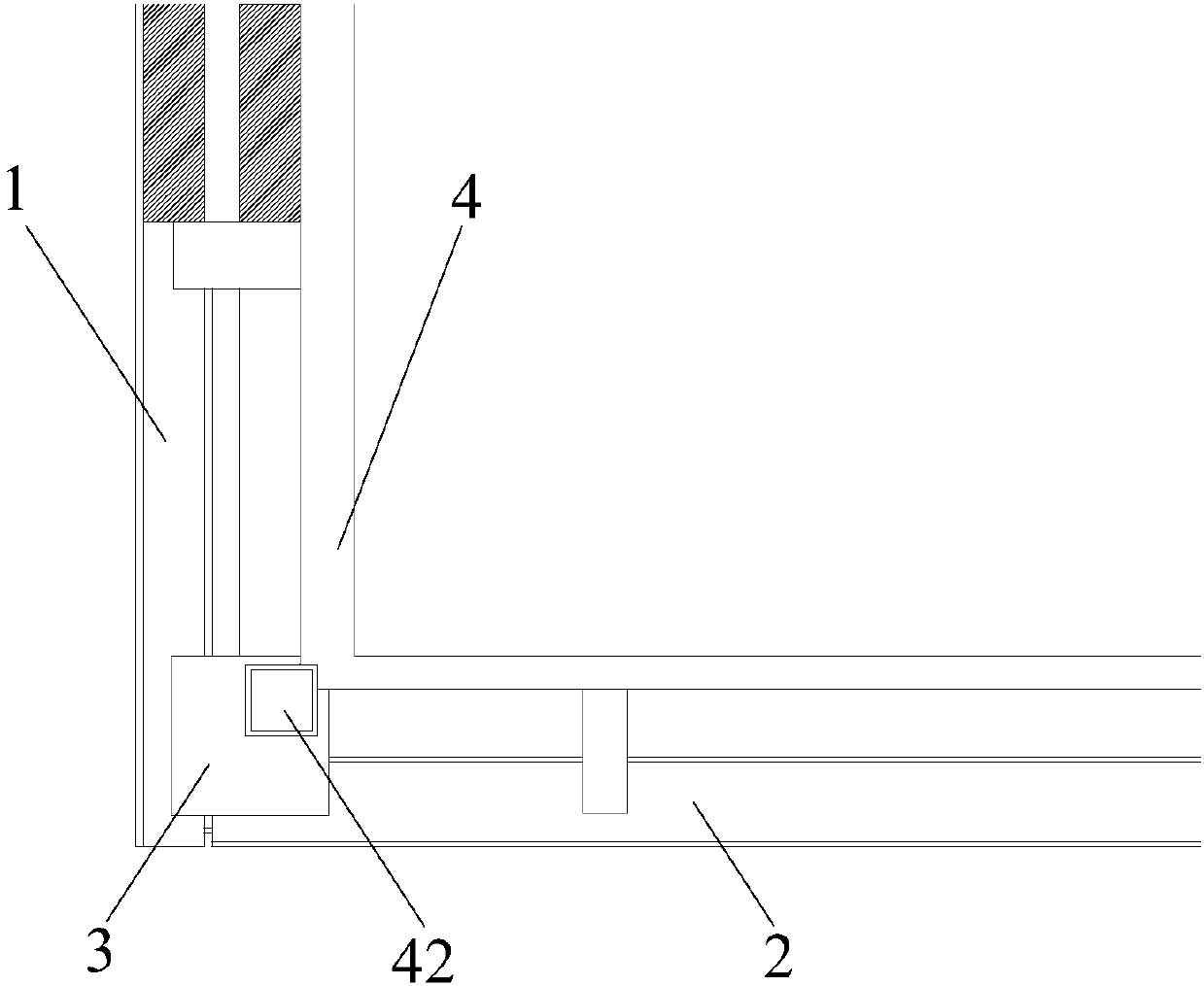

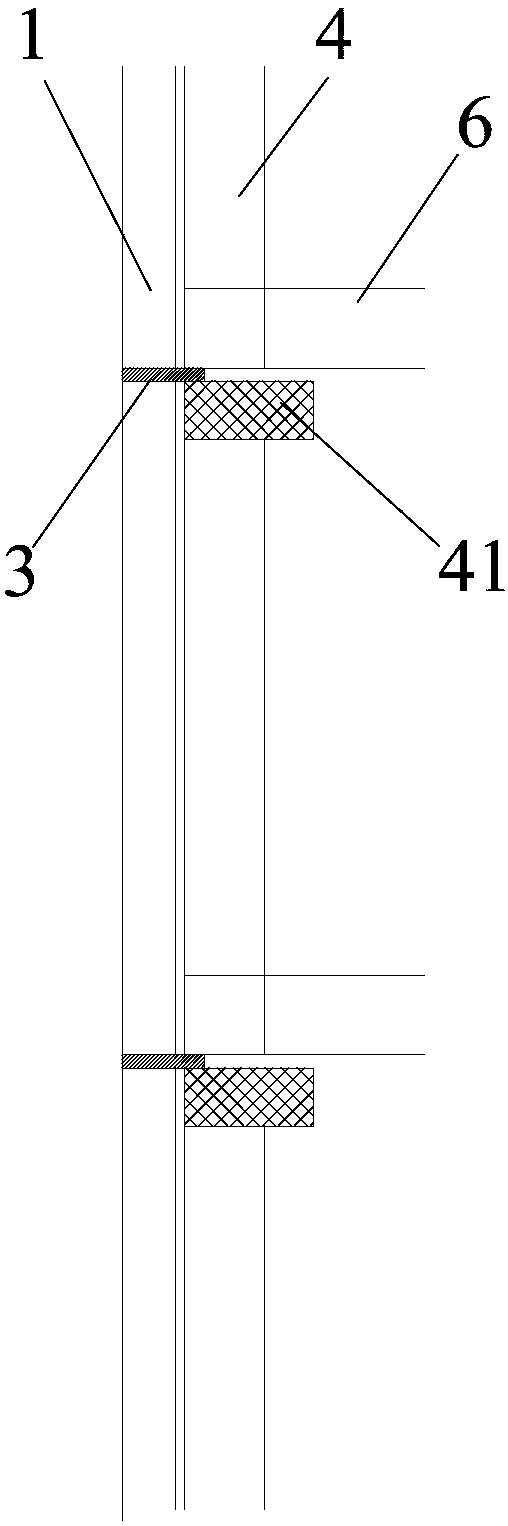

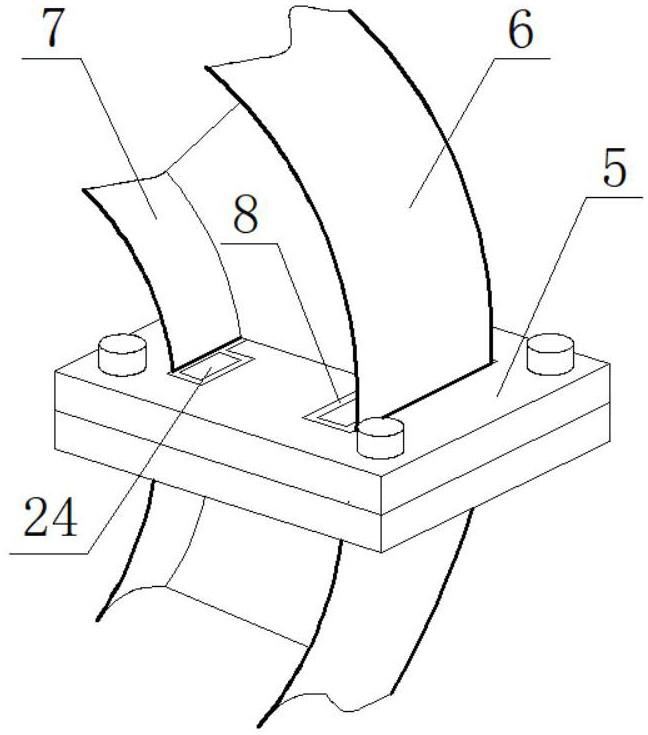

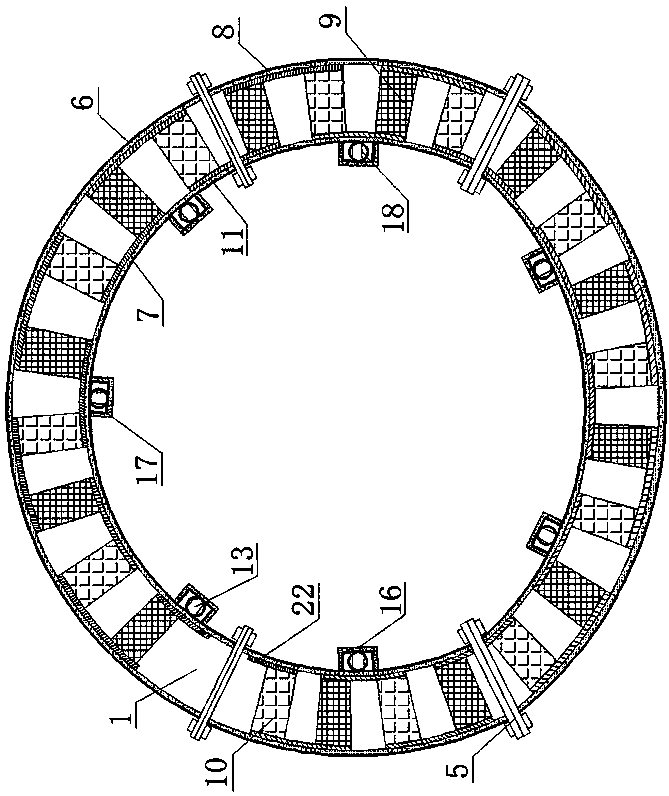

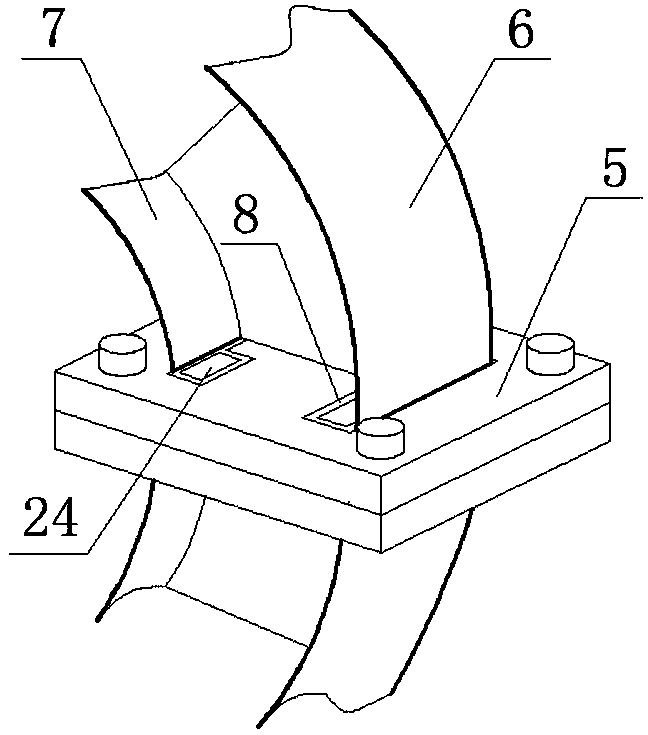

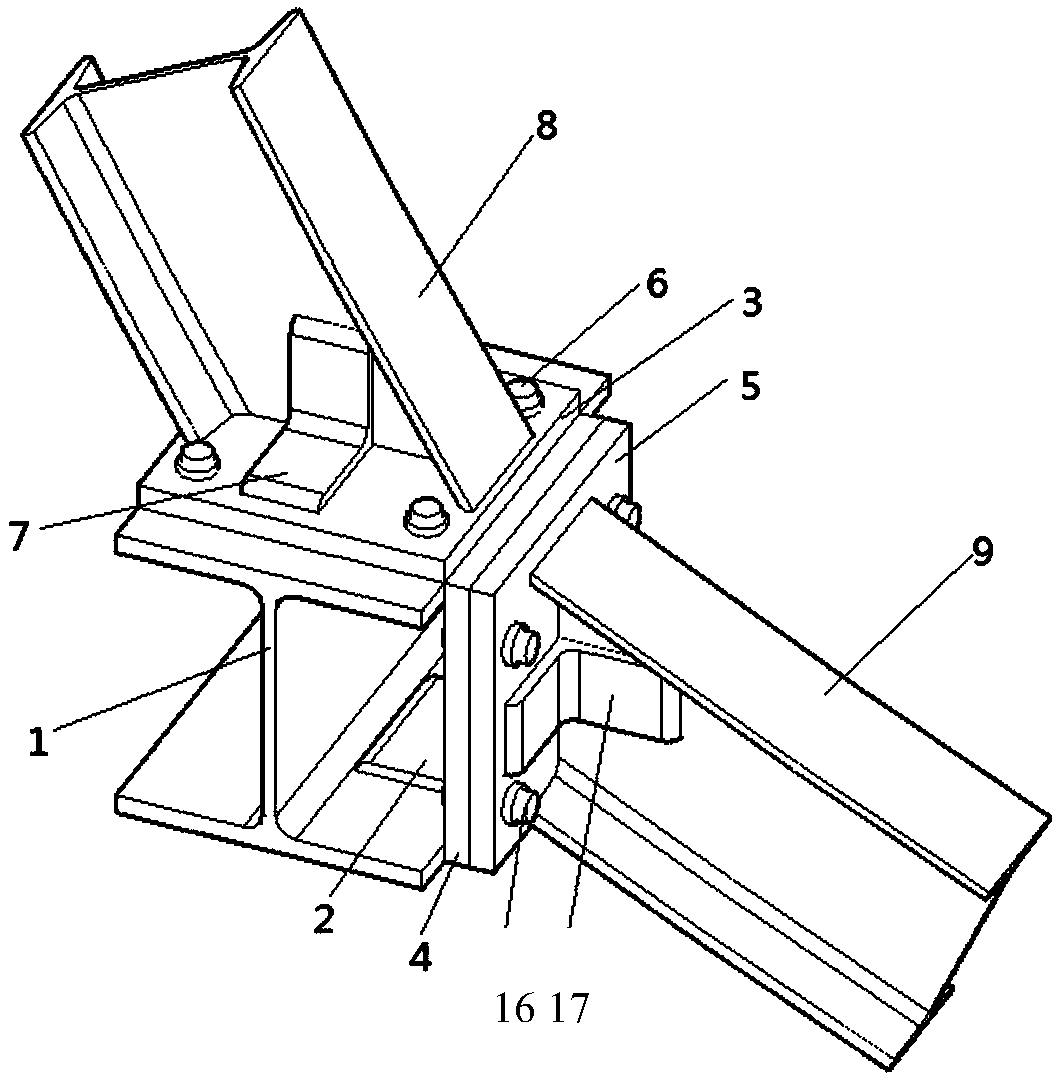

Curtain wall support adjusting system

InactiveCN107035034AIncrease the construction processAvoid increasing the construction processWallsSurface plateIrregular shape

The invention discloses a curtain wall support adjustment system, which comprises at least one curtain wall panel, a plurality of adjustment units with hinged shafts are respectively arranged on two adjacent sides of the curtain wall panel, and one end of each adjustment unit It is directly or indirectly fixed on the curtain wall panel, and the other end of the adjustment unit is fixed on the keel through the first bolt. After positioning the curtain wall panel according to the installation requirements, adjust the placement angle between the curtain wall panel and the keel through the hinge shaft in the adjustment unit. The adjustment unit is fixed on the keel, and the above-mentioned installation process is repeated when installing multiple curtain wall panels, and then the relative angle between two adjacent curtain wall panels is adjusted, so that the curtain wall support system with irregular shapes can be used while using the simplest components. The purpose of flexible and multi-purpose can be achieved, and the construction process is avoided due to cumbersome components, which is not conducive to reducing the construction cost.

Owner:GUANGDONG GOLDEN CURTAIN WALL ENGINEERING CO LTD

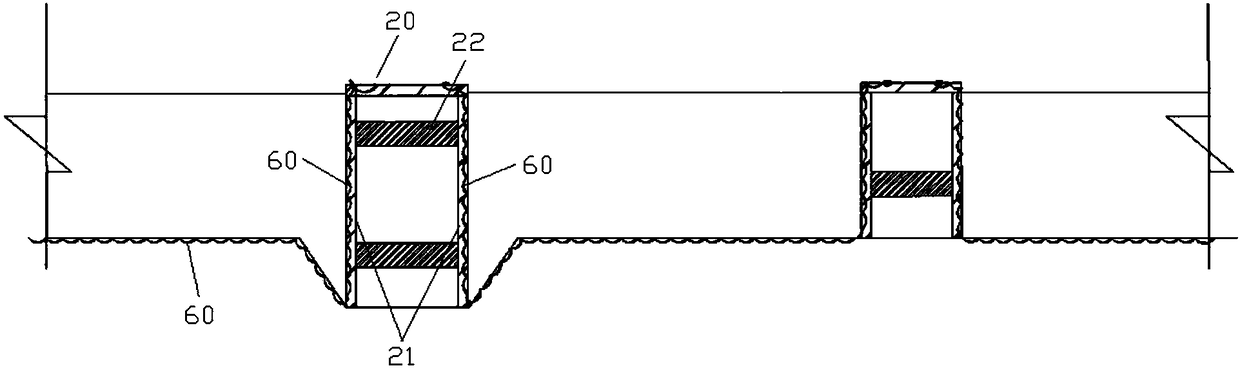

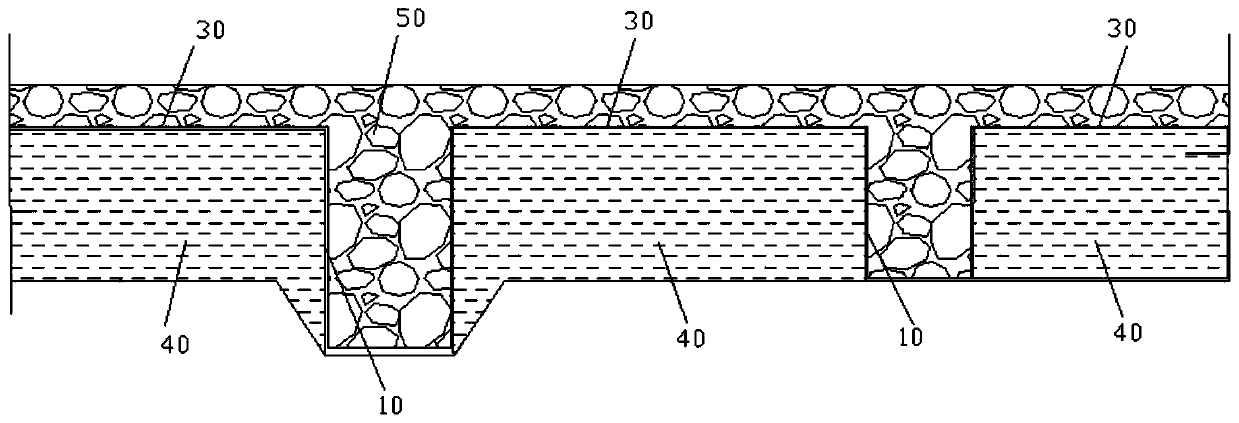

Foundation beam-slab construction method

ActiveCN108532985AReduce plasteringReduce investmentShaping building partsFoam concreteReinforced concrete

The invention discloses a foundation beam-slab construction method. The methods comprises the following steps that a plain soil backfilling method or a foundation excavation method is used for constructing to obtain a foundation soil layer; a cushion layer is constructed on the foundation soil layer, and leveling is carried out; a waterproof layer is constructed on the cushion layer after the leveling; a plurality of crisscross waterproof protective layers extending along the strike of a foundation beam are constructed on the position, where the foundation beam needs to be constructed, of thewaterproof layer; beam mould forming strip groups which extend in the length direction of the waterproof protective layers and are used for forming a foundation beam mould are arranged on waterproof protective layers; geotechnical cloth is laid in each filling grid formed by surrounding of the beam mould forming strip groups, and the periphery of the geotechnical cloth in each filling grid extendsto the top portions of beam mould forming strips which surround the filling grids and is fixed; foamed concrete is poured in the geotechnical cloth of each filling grid to form a base plate mould; the beam mould forming strip groups are removed; and the reinforced concrete is poured on the surface of the formed foundation beam mould and the upper surface of the foundation plate to obtain the foundation beam-slab.

Owner:CCFEB CIVIL ENG

Preparation method of crack-resistant waterproof glazed putty and products thereof

The invention discloses a preparation method of anti-cracking waterproof glaze-surface putty and further discloses a product prepared by implementing the method. Rohm and Haas TM2000 or BATF 300S waterproof emulsion is adopted, and the emulsion has excellent water resistance, flexibility and alkali-resistant elongation. Used auxiliaries are common auxiliaries for building coating, used filling materials are of barium sulfate, talcum powder and calcium carbonate powder preferably, the physical and chemical properties of a coated film can be enhanced by using the filling materials, and the cost can be simultaneously reduced. The preparation process of the method provided by the invention is simple and easy to implement, and the production efficiency is high; and the anti-cracking waterproof glaze-surface putty product provided by the invention has the advantages of good tensile strength, anti-cracking property, water resistance, strong adhesion, smooth and fine surface impression, excellent weather-resistant decoration effect, capability of ensuring the tidy, aesthetic and elegant appearance of a wall body, firmness in binding, good comprehensive performance, better temperature tolerance and weather resistance and simple construction process steps, can greatly shorten the construction period, improve the construction efficiency and realize low cost, and is conductive to extensive popularization and application.

Owner:黄明杰

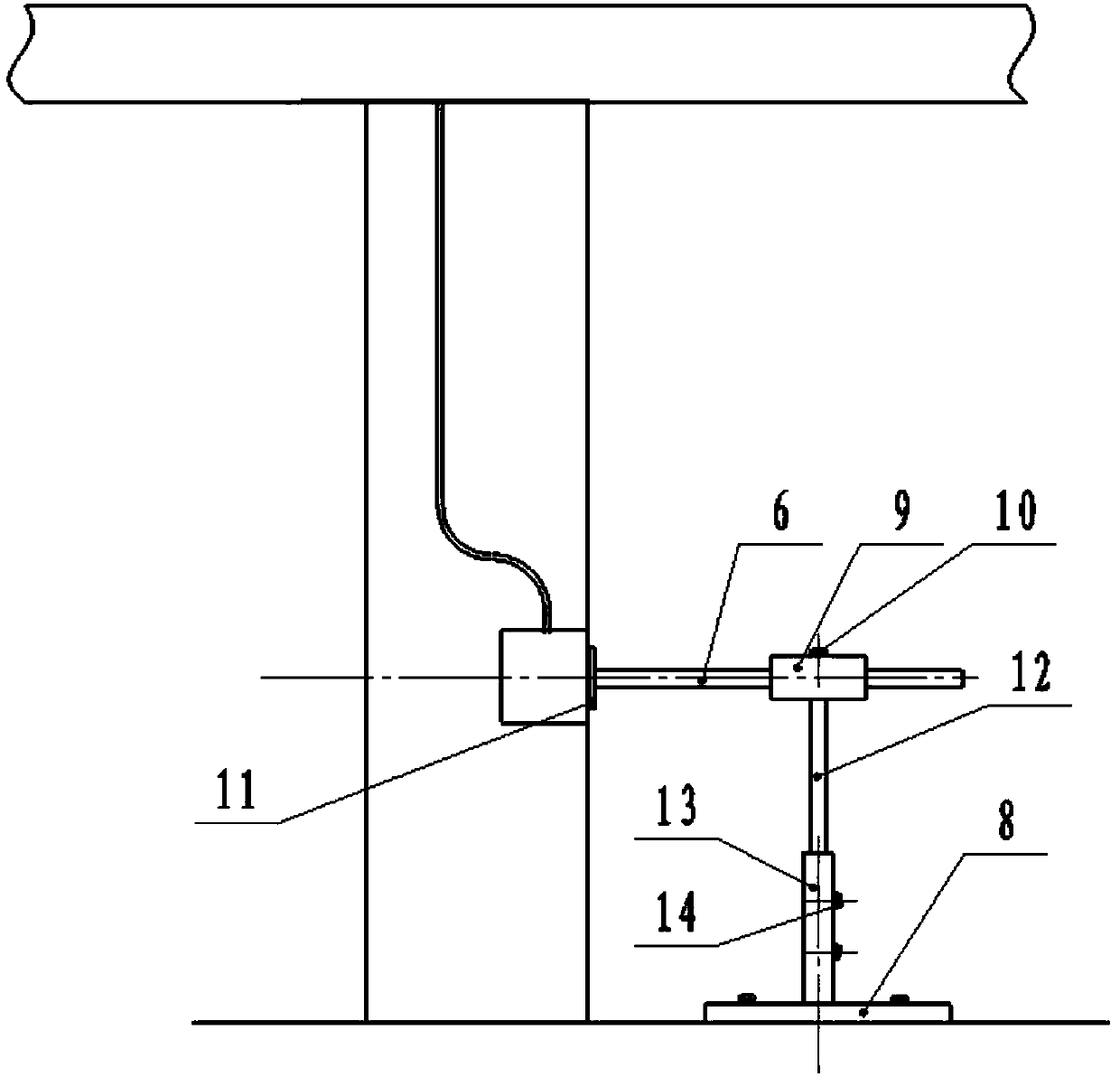

Construction method for building wire box mounting point construction frame

InactiveCN110323703AIncrease construction costsIncrease the construction processElectrical apparatusEngineeringSupport plane

The invention discloses a construction method for a building wire box installation point position construction frame. The construction method comprises the steps: (1) determining the space position ofa wire box on a pre-built wall body; 2) installing a wire box support frame according to the spatial position of the wire box, wherein the wire box support frame comprises a transverse supporting rodand a longitudinal telescopic rod, a mounting base is arranged at the bottom end of the longitudinal telescopic rod, a transverse adjusting sleeve is arranged at the upper end of the longitudinal telescopic rod, a transverse adjusting locking bolt is arranged on the transverse adjusting sleeve, and the transverse supporting rod is inserted into the transverse adjusting sleeve to adjust the telescopic length; the end, connected with the wire box, of the transverse supporting rod is provided with a wire box connecting plate; (3) fixedly installing the wire box on a wire box support frame; (4) cutting out a wire pipe with the matched length, and connecting a wire head in the wire pipe with the wire box; (5) building a wall body according to the position of the pre-built wall body.

Owner:曾敏偲

Construction method for pile-anchor press-in caisson sinking

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

A tidal current power generation cast-in-place pile with a pile core steel pipe and its construction method

ActiveCN107975032BSmall diameterStrong bending and shear resistanceBulkheads/pilesSocial benefitsExtreme weather

The invention discloses a tidal flow electricity generation cast-in-place pile provided with a pile core steel pipe, and a construction method of the tidal flow electricity generation cast-in-place pile. The cast-in-place pile has the advantages of relatively small diameter, high bending and shear resistance and simple and convenient construction procedures; the cast-in-place pile also solves theproblems that an existing common-diameter cast-in-place pile cannot bear overlarge load generated by a large tidal flow speed in a tidal-flow-energy-rich region and a large-diameter cast-in-place pileoccupies too much of an effective tidal flow cross section, so utilization of tidal flow energy is affected and the construction cost of the large-diameter cast-in-place pile is too high. According to the tidal flow electricity generation cast-in-place pile disclosed by the invention, a pile core steel pipe with a certain length is hit into a rock-socketed cast-in-place pile with a common diameter; a pile foundation of the cast-in-place pile is ensured to be embedded in a depth which is 6 m below a seabed bed rock layer; under the reciprocating load effects of wave, tidal flow and the like, and especially under an extreme weather condition, the pile core steel pipe and a steel reinforcement cage can together play relatively high bending resistance and shear resistance of the cast-in-placepile; so the cast-in-place pile is especially applicable to an offshore area engineering foundation such as the foundation of a tidal flow electricity generation pile which bears a relatively large horizontal load, is high in flexibility and has relatively good economic benefits and social benefits.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

A kind of soil transfer method of tunnel communication channel

ActiveCN109915164BImprove excavation efficiencyIncrease the construction processTunnelsBelt conveyorWater resource management

The embodiment of the invention provides a soil body transfer method for a tunnel connection channel. A belt conveyor is adopted for operation, and the belt conveyor comprises a first belt conveyor. the soil body transfer method for the tunnel connection channel comprises the following steps that an upper step of the tunnel connection channel is excavated; the first belt conveyor is placed on theupper step formed by the tunnel connection channel; the soil body of the upper step is placed on the first belt conveyor; and the first belt conveyor is started, and newly excavated soil of the upperstep is conveyed out of an opening of the tunnel connection channel. A constructor places the soil body generated by excavating the upper step on the first belt conveyor, and conveys the soil body outof the opening of the tunnel connection channel by operating the first belt conveyor. Along with excavation of the upper step of the tunnel connection channel, the generated soil body is directly transported out of the opening of the tunnel connection channel, the soil body cannot remain in the tunnel connection channel, the transfer speed is high, and thus the excavation efficiency of the tunnelconnection channel is improved.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +1

Grouped second liner construction method for large cross-section tunnel

ActiveCN103016029BIncrease the construction processLong construction periodUnderground chambersTunnel liningSocial benefitsArchitectural engineering

The invention discloses a grouped second liner construction method for a large cross-section tunnel. A whole toroidal second liner is constructed after being divided into 6 parts. The method comprises the following steps: 1), pouring and backfilling an inverted arch of a left lower hole; 2), pouring and backfilling an inverted arch of a right lower hole; 3), pouring a side wall second liner of the left lower hole through a lower hole trolley; 4), moving the lower hole trolley to the right lower hole to pour a side wall second liner of the right lower hole; 5), erecting a bracket in the right lower hole, assembling a right upper hole trolley, and pouring a right upper arch second liner; 6), erecting a bracket in the left lower hole, assembling a left upper hole trolley, and pouring a left upper arch second liner. According to the grouped second liner construction method, a relatively large cross section is divided into a plurality of small cross sections to carry out construction, although the construction procedures the time limit for a product are slightly increased in comparison with those of a traditional two-step construction method, the construction risk is yet reduced to a great extent, the construction safety guarantee coefficient is increased, an extremely important guide value is provided for the tunnel constructed with a CRD (center cross diaphragm) method in certain special urban environment conditions, the construction is smoothly completed on the premise of guaranteeing safety, and remarkable social benefits are achieved.

Owner:RANKEN RAILWAY CONSTR GROUP

Preparation method and product of anti-crack texture paint

InactiveCN102863898BReasonable formula designHigh tensile strengthCoatingsCrack resistanceWeather resistance

The invention discloses an anti-cracking texture paint preparation method and a product prepared by the method. The product is prepared from the following raw materials: water, ethylene glycol, cellulose, preservative, pH regulator, coarse whiting powder, defoaming agent, elastic emulsion, TEXANOL and thickening agent. The method disclosed by the invention has the advantages of simple preparation technique and high production efficiency, and is easy to implement. The method disclosed by the invention has the advantages of simple preparation technique and high production efficiency, and is easy to implement. The anti-cracking texture paint product disclosed by the invention has reasonable formula design, favorable tensile strength, cracking resistance, water resistance, high adhesive force, excellent weather resistance and excellent decorative effect, can be well bonded on the walling, and ensures the walling to have neat and elegant appearance. The anti-cracking texture paint has the advantages of favorable stereoscopic texture, favorable comprehensive properties, high temperature tolerance, high weather resistance, low cracking tendency and long service life, and effectively lowers the maintenance cost. Besides, the construction process is simple, greatly shortens the construction period, enhances the construction efficiency, requires low cost, and is beneficial to wide popularization.

Owner:黄明杰

Foundation beam and slab construction method

ActiveCN108532985BReduce investmentReduce plasteringShaping building partsFoam concreteReinforced concrete

The invention discloses a foundation beam-slab construction method. The methods comprises the following steps that a plain soil backfilling method or a foundation excavation method is used for constructing to obtain a foundation soil layer; a cushion layer is constructed on the foundation soil layer, and leveling is carried out; a waterproof layer is constructed on the cushion layer after the leveling; a plurality of crisscross waterproof protective layers extending along the strike of a foundation beam are constructed on the position, where the foundation beam needs to be constructed, of thewaterproof layer; beam mould forming strip groups which extend in the length direction of the waterproof protective layers and are used for forming a foundation beam mould are arranged on waterproof protective layers; geotechnical cloth is laid in each filling grid formed by surrounding of the beam mould forming strip groups, and the periphery of the geotechnical cloth in each filling grid extendsto the top portions of beam mould forming strips which surround the filling grids and is fixed; foamed concrete is poured in the geotechnical cloth of each filling grid to form a base plate mould; the beam mould forming strip groups are removed; and the reinforced concrete is poured on the surface of the formed foundation beam mould and the upper surface of the foundation plate to obtain the foundation beam-slab.

Owner:CCFEB CIVIL ENG

Preparation method of anti-cracking waterproof middle paint and products thereof

The invention discloses an anti-cracking water-resistant intermediate paint preparation method and a product prepared by the method. The elastic emulsion used in the product is Tianba 2000, which has excellent water resistance, flexibility, alkali resistance and percentage of elongation. Assistants are common assistants for construction paints; and fillers are barium sulfate, talcum powder and coarse whiting powder, and the coarse fillers can enhance the physical and chemical properties of the coated film and lower the cost. The method disclosed by the invention has the advantages of simple preparation technique and high production efficiency, and is easy to implement. The anti-cracking water-resistant intermediate paint product disclosed by the invention has the advantages of favorable flexibility, strong cracking resistance (can bridge a 0.5-3mm crack), favorable water resistance, high binding firmness, favorable comprehensive properties, high temperature tolerance and high weather resistance, effectively solves the phenomena of cracking and water leakage in the walling, and ensures the walling to have neat and elegant appearance; and besides, the construction process is simple, greatly shortens the construction period, enhances the construction efficiency, requires low cost, and is beneficial to wide popularization.

Owner:黄明杰

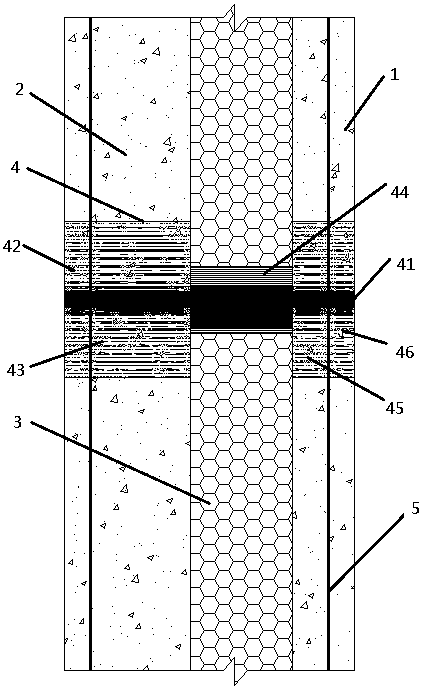

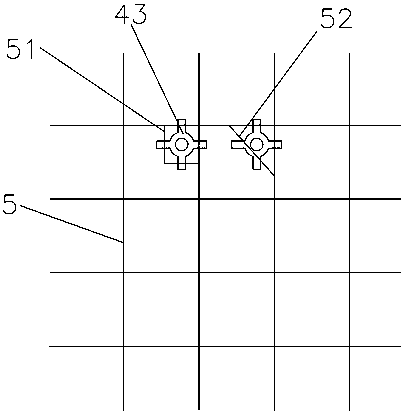

Preparation method of lightweight self-insulating composite wallboard

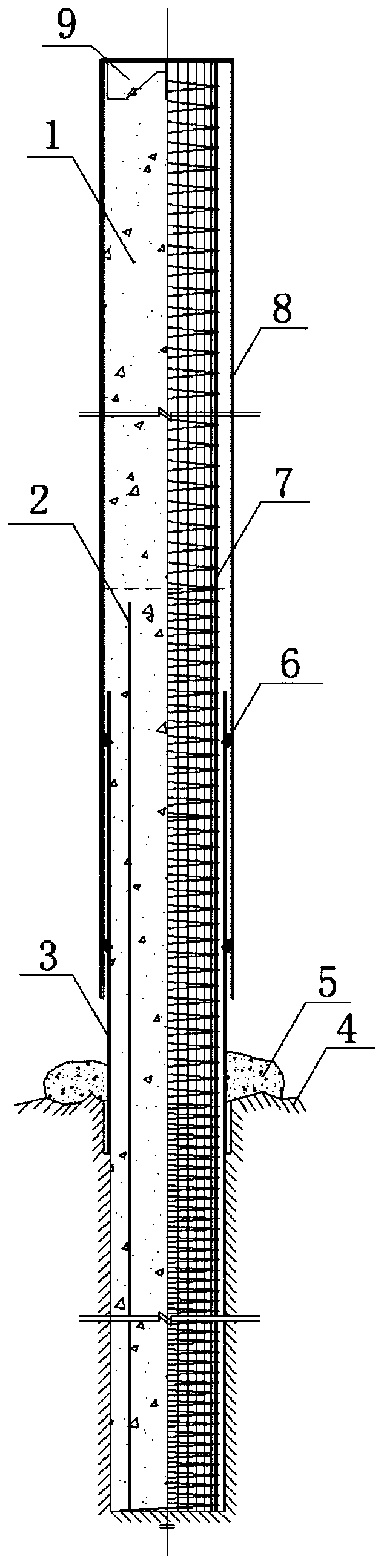

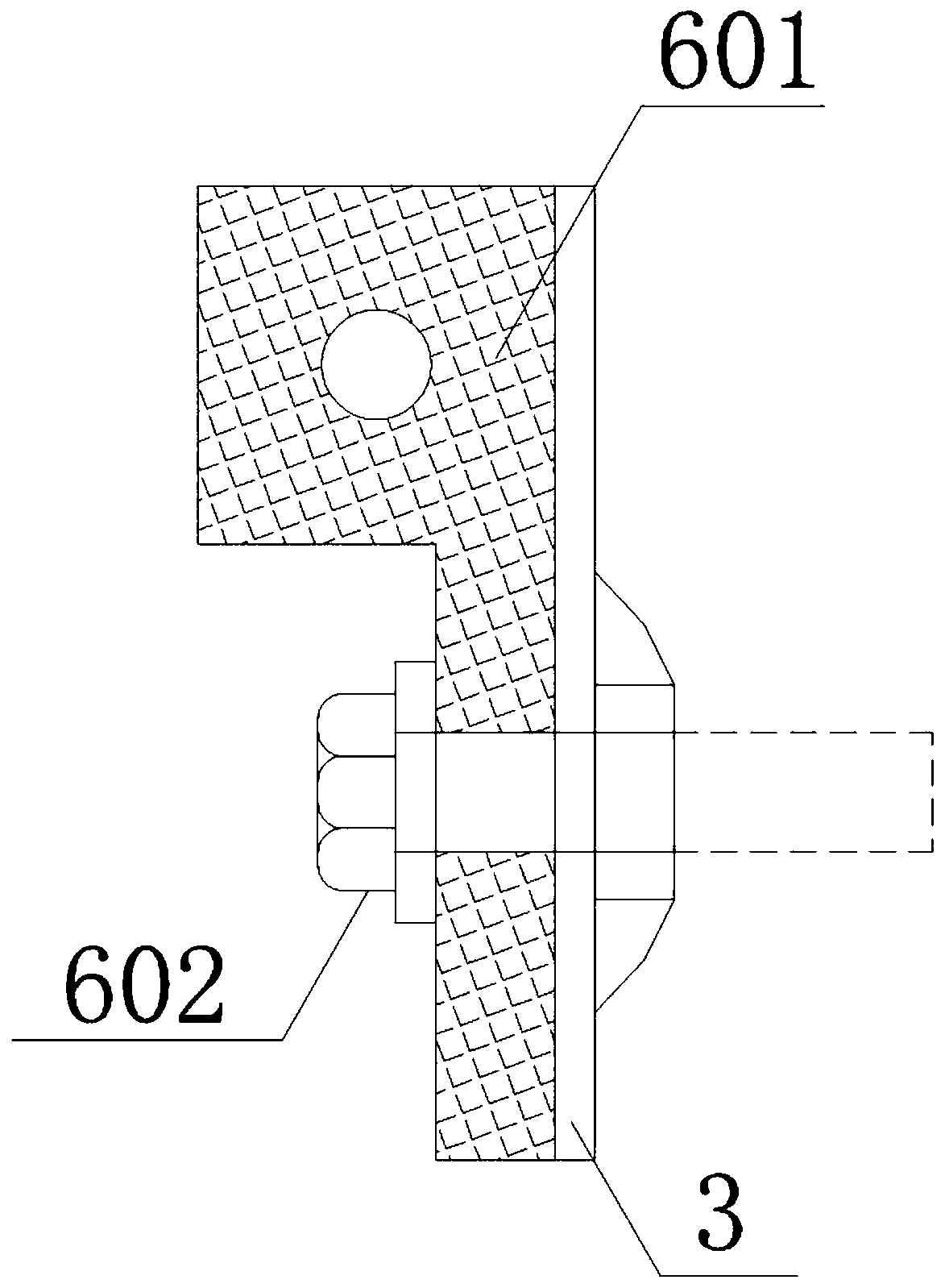

ActiveCN105587073BGuaranteed integrityImprove integrityBuilding componentsInsulation layerArchitectural engineering

The invention belongs to the technical field of architectural engineering and particularly relates to a light self-insulation composite wallboard for architectural engineering such as frames, framed bents and shear walls and a manufacturing method thereof. The light self-insulation composite wallboard comprises an insulation board, ceramsite concrete sheets are arranged on both sides of the insulation board, and the ceramsite concrete sheets on the two sides are fixedly connected with each other through a shear-resisting and compression-resisting connecting part which penetrates through the insulation board. Steel wire meshes are arranged in the ceramsite concrete sheets, the left end and the upper end of the insulation board are concave inside the ceramsite concrete sheets on the two sides so as to form a groove, and the right end and the lower end of the insulation board protrude out of the ceramsite concrete sheets on the two sides so as to form a rib. A wall body is carried to a construction site after being prefabricated in a factory, hoisting installation is adopted on the construction site, components are assembled into a whole in a reliable connection mode, and therefore housing industrialization is facilitated. Construction of an insulation layer is not needed after a building main structure is completed, so that the construction procedure is simplified, the construction progress is accelerated, and construction cost is reduced.

Owner:ZHEJIANG BADA CONSTR GRP

A kind of construction method of wire box installation point

ActiveCN108390307BIncrease construction costsIncrease the construction processCable installation apparatusSlagSupport plane

The invention discloses a wire box installation point position construction method. The method comprises steps: 1) a wire tube head reserved on a floor is sleeved with a support frame connector; 2) the space position of the wire box on a prefabricated wall body is determined; 3) a wire box support frame is installed according to the space position of the wire box, the wire box support frame and the support frame connector are connected and positioned, and a panel part of the wire box is fixedly installed on the wire box support frame; 4) a wire tube with a matched length is cut out, the lowerend of the wire tube is connected with the wire tube head, and a wire joint in the wire tube is connected with the wire box; and 5) the wall body is fabricated according to the position of the prefabricated wall body, and the wire box is embedded in the wall body. The wire box point position is well adjusted when the support is fixed in advance, for example, elevation, an out-wall size and whetherto be stable are adjusted. Collection of construction slag for multiple times is not needed, and later chiseling is not needed, and the wire box support frame can be fixed without drilling in the bottom plate.

Owner:CHINA MCC5 GROUP CORP

Initial supporting structure and construction method of frozen tunnel in weak surrounding rock

ActiveCN110905561BImprove self-supporting capacityImprove water barrier effectMining devicesUnderground chambersVentilation tubeStructural engineering

The initial support structure and construction method of tunnel freezing in weak surrounding rocks belong to the technical field of tunnel support structures. The upper and lower flanges of the arch frame are coated with insulating layers inside; the refrigeration device is composed of N-type semiconductors, P-type semiconductors and metal gaskets. The metal gaskets are pasted on the arch at random, and N-type semiconductors and P-type semiconductors are alternately welded at the intersection positions of the metal gaskets to form a galvanic pair; the heat dissipation device is composed of a connecting pipe, a radiator, a ventilation pipe and an exhaust pipe. After the excavation of the tunnel, the arch frame with refrigeration device is installed, the radiator is arranged inside the arch frame, and the adjacent arch frames are connected by connecting pipes; the ventilation pipe is inserted into the arch frame and led to the tunnel opening, and the exhaust pipe is inserted into the ventilation pipe. The DC power supply is connected with the refrigeration device; the present invention can not only form a frozen soil shell on the surrounding rock around the weak section of the tunnel, prevent water and control the deformation of the tunnel, but also increase tunnel Ventilation improves the construction environment.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

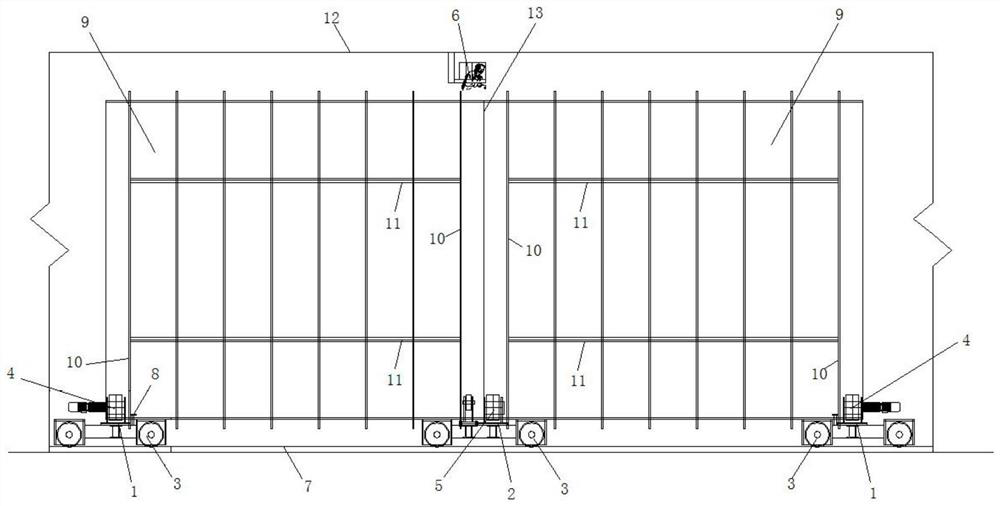

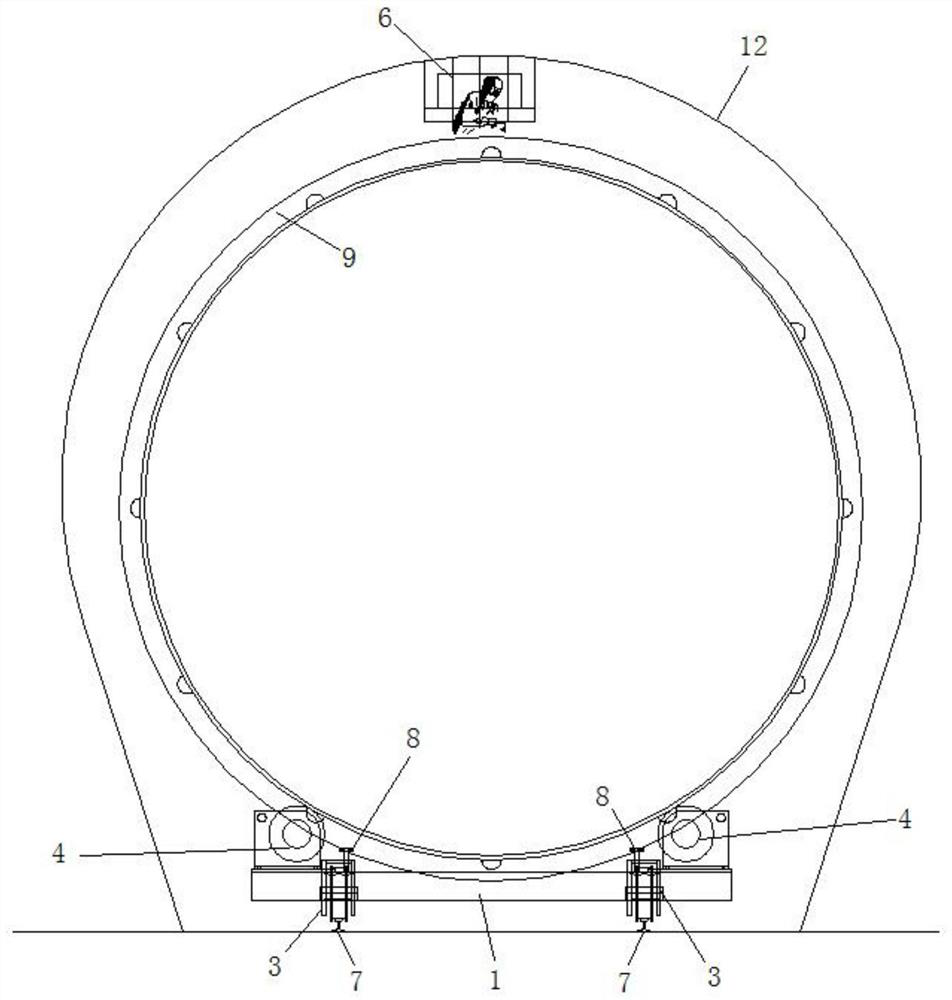

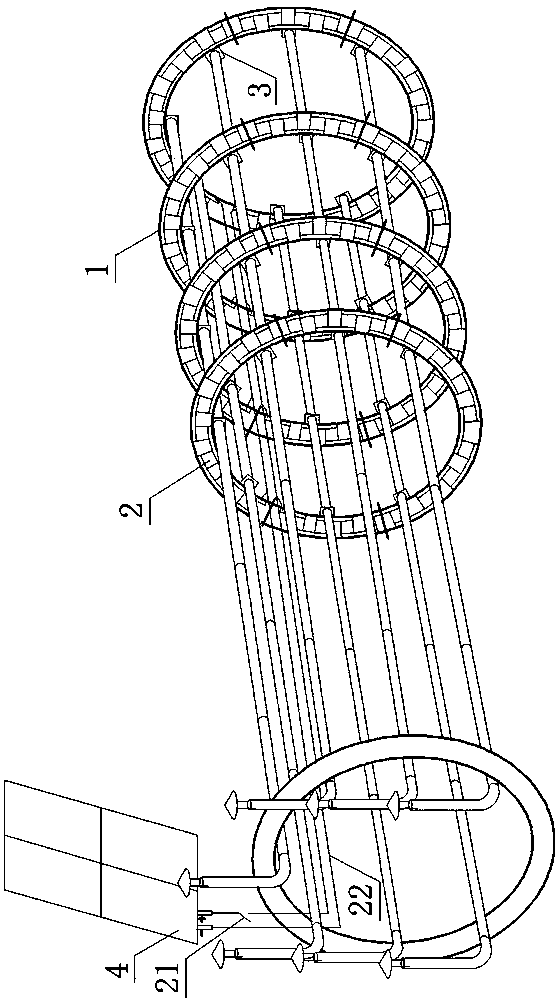

Automatic welding auxiliary device for in-hole pressure steel pipe pile joints

PendingCN112809308ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesSocial benefitsEconomic benefits

The invention discloses an automatic welding auxiliary device for in-tunnel pressure steel pipe pile joints. The device comprises a trolley group used for bearing two pressure steel pipes subjected to circular seam assembly and driving the two pressure steel pipes to do circular motion, wherein the trolley group comprises two first trolleys and a second trolley; each first trolley is provided with a walking wheel and a rolling driving assembly; and the second trolley is provided with a walking wheel and a rolling driven assembly. According to the device, two sections of pressure steel pipes can be changed into one section of pressure steel pipe, so that although construction procedures are increased, the installation work amount is reduced by half, time and labor cost can be reduced, and good social benefits and economic benefits are generated. Automatic submerged arc welding is used for replacing manual welding, so that weld joints are attractive in appearance, the first-pass yield is improved, and the welding cost is reduced. The automatic welding auxiliary device for the in-tunnel pressure steel pipe pile joints also has the characteristics of low cost, simple manufacturing method, safety and simplicity in use, easy mastering and the like.

Owner:SINOHYDRO ENG BUREAU 4

Supporting structure in initial stage of freezing for tunnel in soft surrounding rock, and construction method

ActiveCN110905561AImprove self-supporting capacityImprove water barrier effectMining devicesUnderground chambersInsulation layerClassical mechanics

The invention discloses a supporting structure in the initial stage of freezing for a tunnel in soft surrounding rock, and a construction method, and belongs to the technical field of tunnel supporting structures. Insulation layers are coated in an upper flange and a lower flange of an arch frame; a refrigeration device is composed of N-type semiconductors, P-type semiconductors and metal gaskets,the metal gaskets are bonded onto the arch frame in a staggered manner, and the N-type semiconductors and the P-type semiconductors are alternately welded onto the intersection positions of the metalgaskets and connected into couple pairs; a heat dissipation device is composed of a communication pipe, heat dissipators, a ventilation pipe and an exhaust pipe, the arch frame with the refrigerationdevice is installed after tunnel excavation, the heat dissipators are distributed at the inner side of the arch frame, and the adjacent arch frames are connected by the communication pipe; and the ventilation pipe is inserted into the arch frame and led to the hole of the tunnel, the exhaust pipe sleeves into the ventilation pipe, and a direct-current power supply is connected with the refrigeration device. According to the supporting structure in the initial stage of freezing for the tunnel in the soft surrounding rock, and the construction method, in the case that a refrigeration system isnot constructed independently and the action of the arch frame is not influenced, a frozen soil shell can be formed on the peripheral surrounding rock of a soft section of the tunnel, water isolationis carried out, the deformation of the tunnel is controlled, the ventilation of the tunnel is improved, and the construction environment is improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Powdered layer reinforcement paint preparation method and products thereof

The invention discloses a preparation method of a pulverization layer reinforcing paint and a product prepared by implementing the method. All components comprise water, ethylene glycol, a PH (Potential of Hydrogen) regulator, a preservative, an antifoaming agent, alkali-resistant closing emulsion and Texanol. The method provided by the invention has the advantages of simple preparation process, easiness in implementation and high production efficiency; a pulverization layer reinforcing paint product provided by the invention has the advantages of high tensile strength, crack resistance, water resistance, high permeability, superior closure, superior alkali resistance, high adhesion force, convenience for renovating and adhering new ceramic tiles or mosaic, superior decoration effect, capability of guaranteeing a tidy wall appearance, attractive and elegant appearance, firmness in adhesion, good comprehensive performance, better temperature resistance and weather resistance, simple construction processes, capabilities of greatly shortening construction period and increasing the construction efficiency, low cost and contribution to wide promotion and application.

Owner:黄明杰

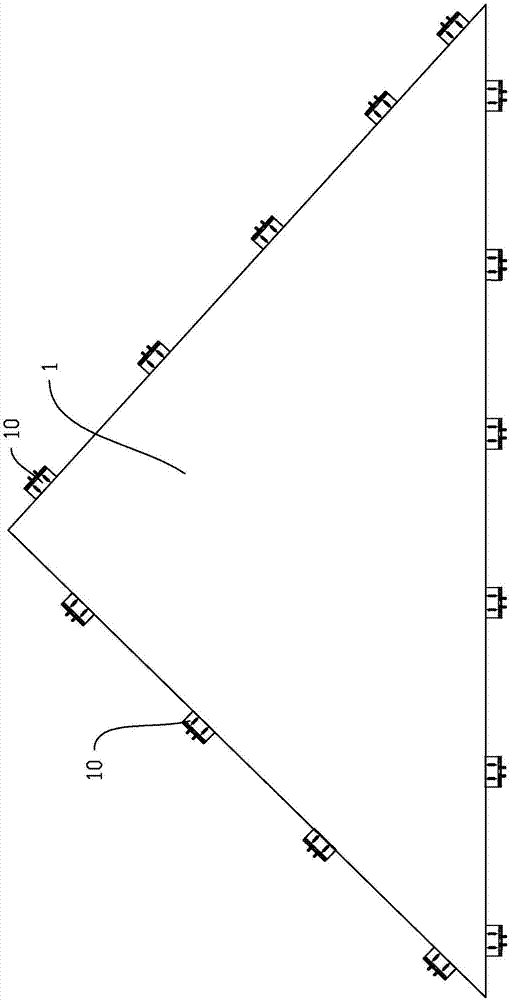

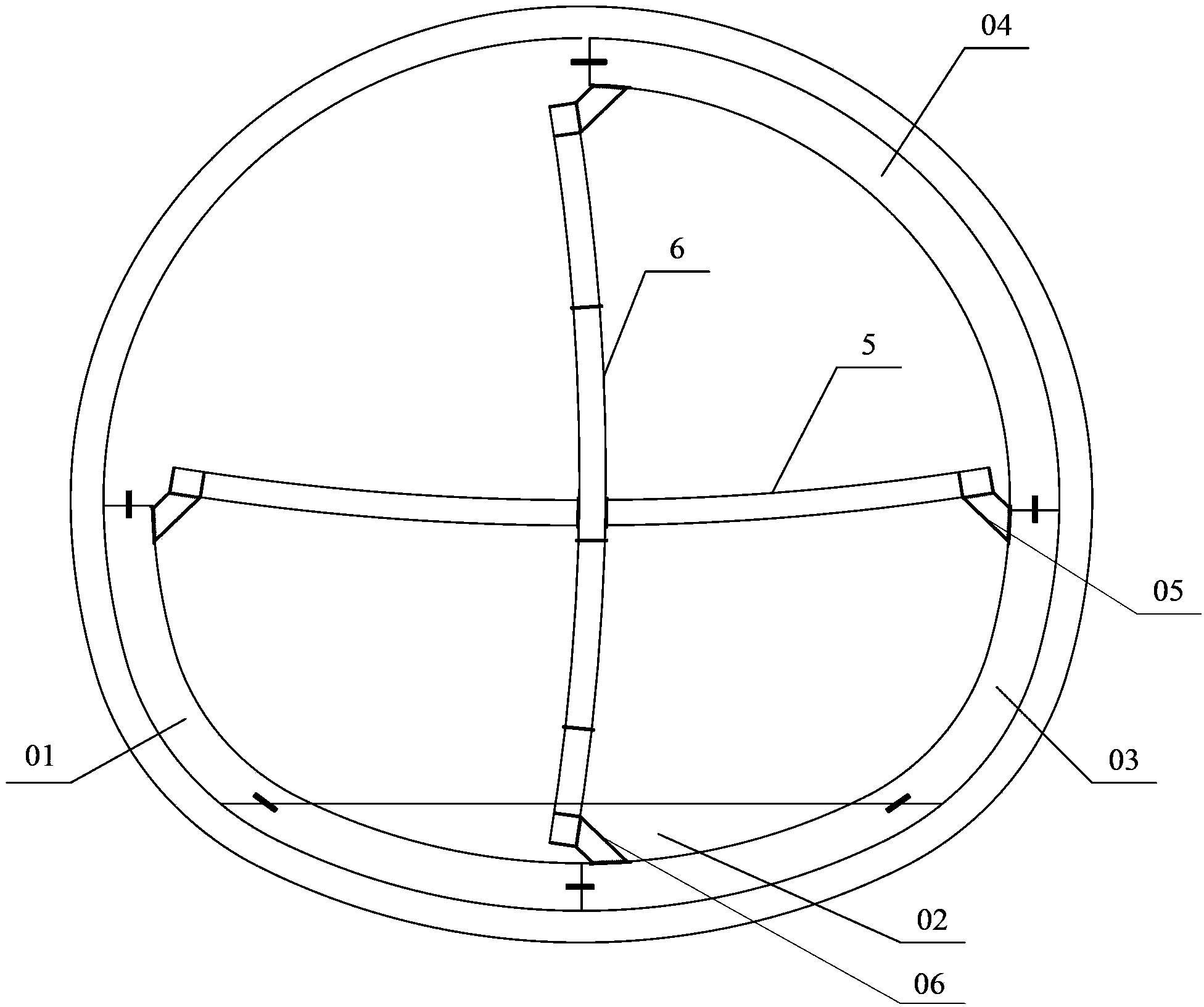

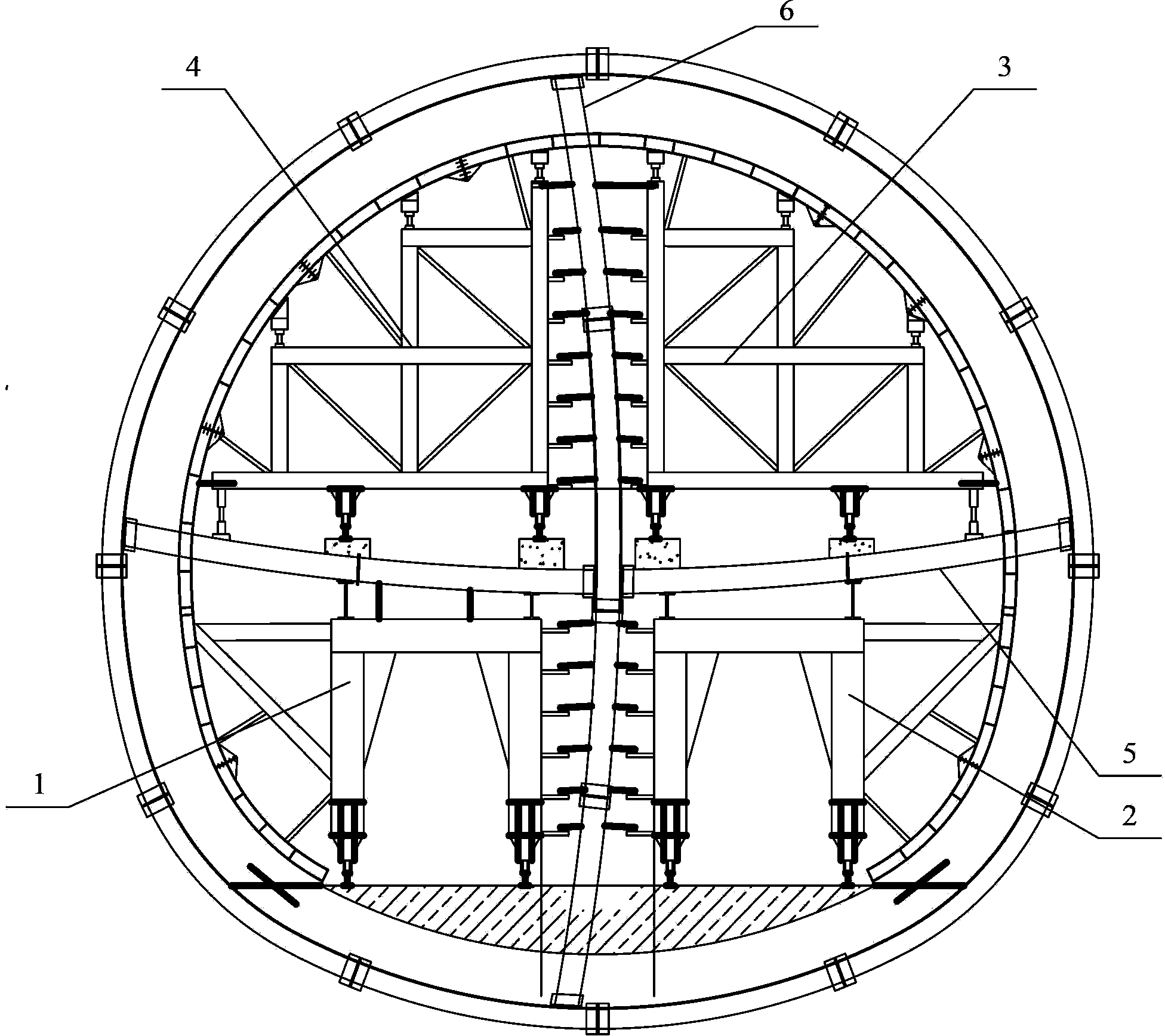

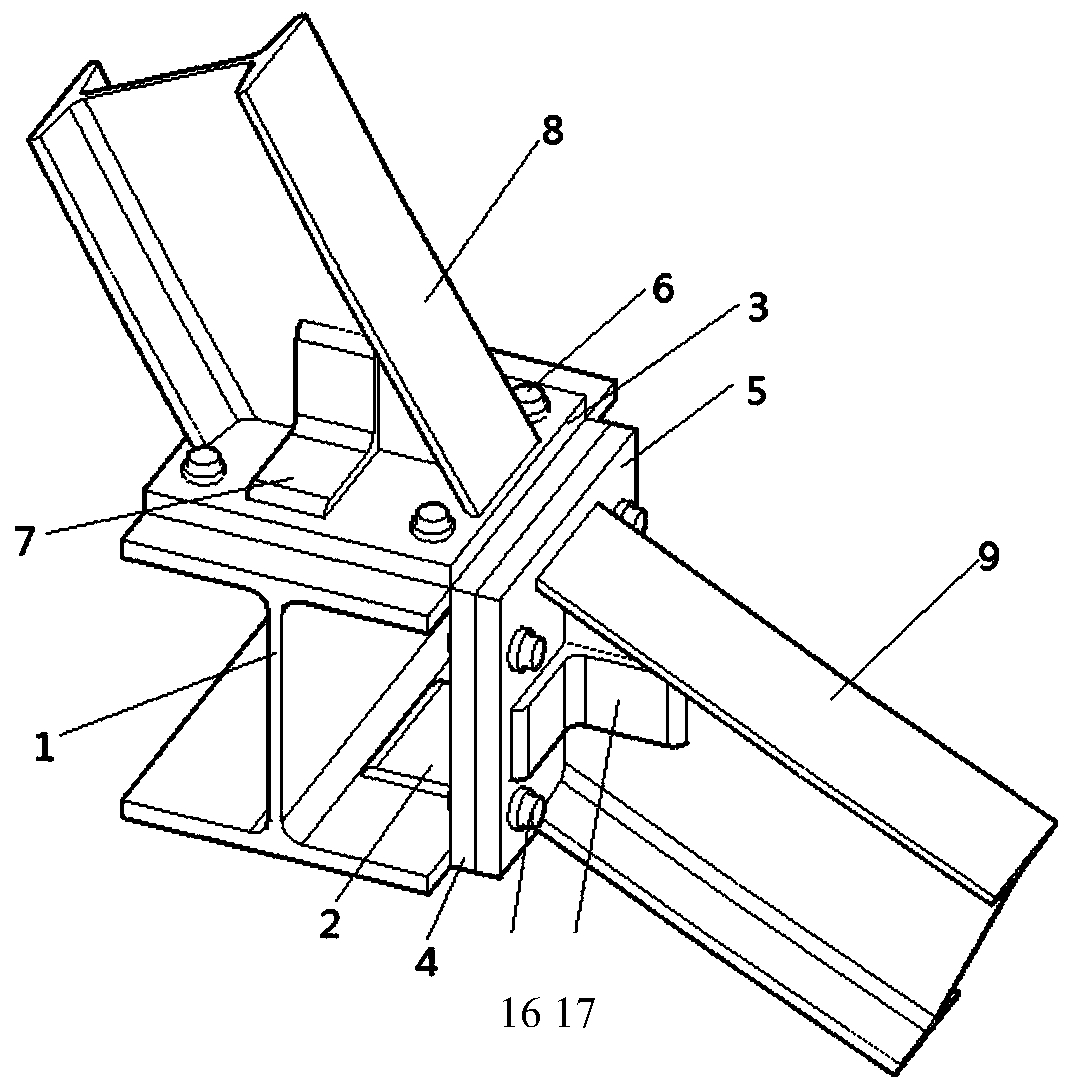

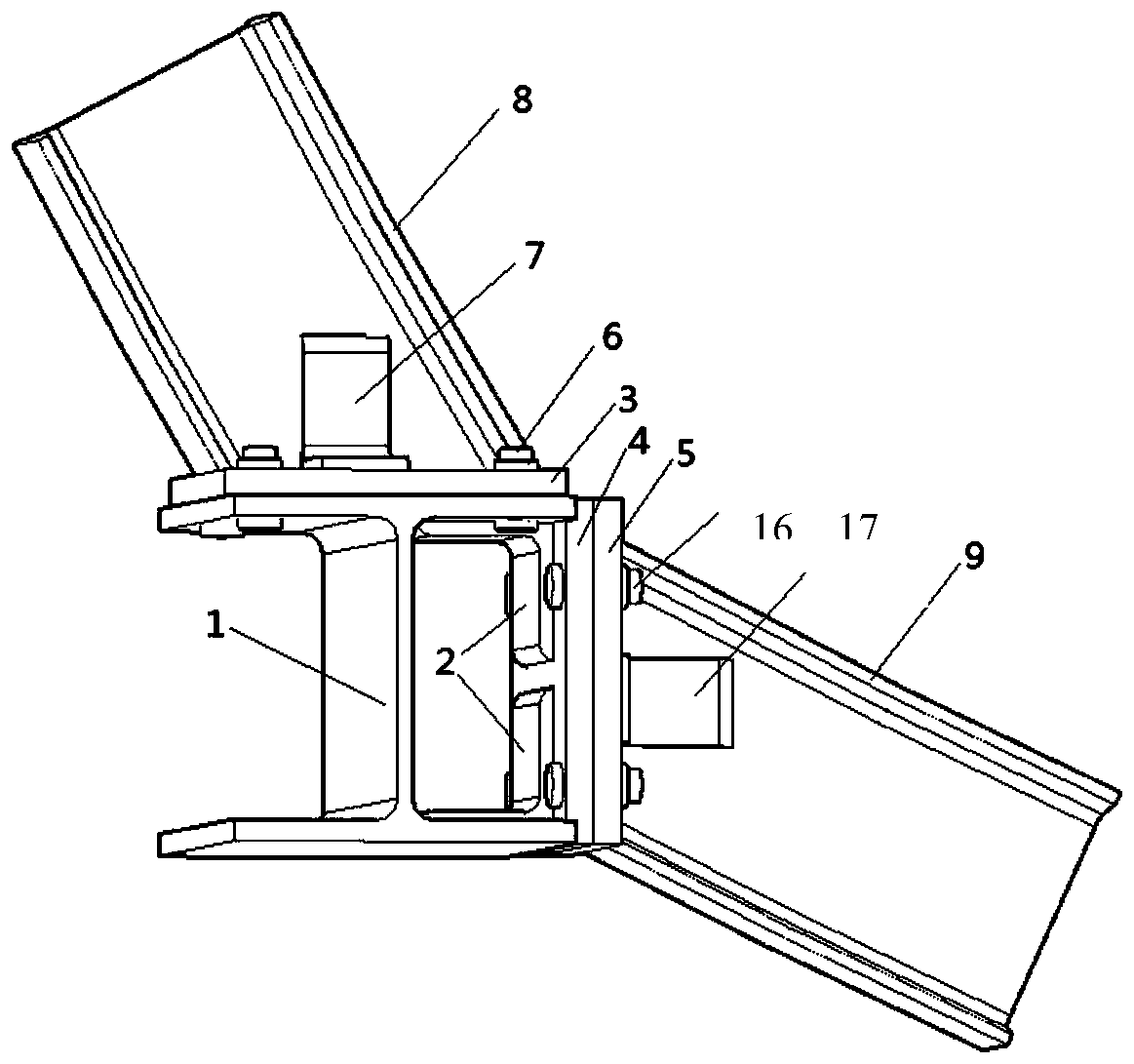

Connection method between steel arch units for tunnel support

ActiveCN108386212BEasy to installPlay a supporting role in timeUnderground chambersTunnel liningArchitectural engineeringJoist

The invention discloses a connecting method of steel arch units for tunnel supporting. Longitudinal section steel joists are arranged at connecting parts of the steel arch units of a tunnel along a tunnel axis; the arch units are connected onto the joists, so that the connection of the arch units is not limited by types and curvatures of the arch units; and during construction, a temporary supporting effect of arches at the upper parts of the joists constructed can be exerted without mounting of the arches at the side parts of the joists. The method solves the problems that the reliable connection between the arch units is difficult due to type and curvature factors of the arches and the supporting effect of the mounted arches is difficult to exert prior to closing of the annular arches; and the method achieves quick mounting of the steel arches without increase of construction procedures and timely exertion of the supporting effect, ensures tunnel safely in a construction process andaccelerates a construction progress.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

Structure and processing method for cutting off existing anchor cable invading range of station foundation pit

PendingCN113152455AIncrease the construction processImprove cutting efficiencySoil-shifting machines/dredgersLoad-engaging elementsDiamond wire sawSteel frame

The invention discloses a structure and a processing method for cutting off an existing anchor cable invading the range of a station foundation pit. Plane movement and lifting movement of a clamping tool are achieved through a hydraulic lifter and a movable steel frame, so that the clamping tool can accurately find the position of an anchor cable through mechanical movement, the clamping effect on the anchor cable is achieved, and a crane or manual alignment and clamping are not needed; in addition, anchor cables in the same groove section can be accurately found and clamped one by one through movement, continuous cutting of the anchor cables in the same groove section is achieved, the cutting construction procedure is greatly accelerated, the cutting efficiency is improved, frequent disassembly and assembly are not needed, multiple clamping tools do not need to be installed, the structure is quite ingenious, and the equipment cost is saved; a diamond wire saw cut the anchor cable, that is, the diamond wire saw is driven by a hydraulic motor to move around the cutting face of the anchor cable at a high speed to grind the anchor cable, and cutting work is completed; due to the fact that diamond particles are used as grinding materials, hard objects such as the anchor cables can be cut.

Owner:中铁十局集团城市轨道交通工程有限公司 +1

Connecting method of steel arch units for tunnel supporting

ActiveCN108386212AEasy to installPlay a supporting role in timeUnderground chambersTunnel liningJoistArchitectural engineering

The invention discloses a connecting method of steel arch units for tunnel supporting. Longitudinal section steel joists are arranged at connecting parts of the steel arch units of a tunnel along a tunnel axis; the arch units are connected onto the joists, so that the connection of the arch units is not limited by types and curvatures of the arch units; and during construction, a temporary supporting effect of arches at the upper parts of the joists constructed can be exerted without mounting of the arches at the side parts of the joists. The method solves the problems that the reliable connection between the arch units is difficult due to type and curvature factors of the arches and the supporting effect of the mounted arches is difficult to exert prior to closing of the annular arches; and the method achieves quick mounting of the steel arches without increase of construction procedures and timely exertion of the supporting effect, ensures tunnel safely in a construction process andaccelerates a construction progress.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com