Ground source heat pump buried pipe heat exchanger free of backfilling

A technology of buried pipe heat exchanger and ground source heat pump, which is applied to geothermal collectors, heat pumps, geothermal energy, etc., can solve problems such as no or little consideration of impact, save construction work time, simplify construction procedures, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

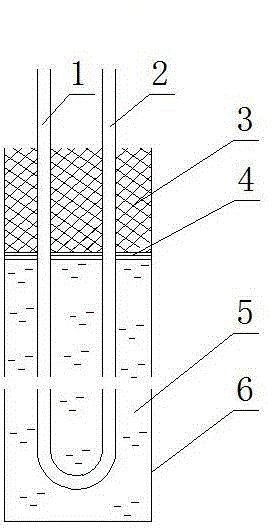

[0022] Specific implementation mode 1: The buried pipe heat exchanger of ground source heat pump without backfilling is composed of multiple heat exchange holes of buried pipes, as shown in Fig. Heat pipes 1 and 2, and fill the heat exchange pipes 1 and 2 with water, carry out pressurization and leak detection, and use PE at the appropriate position 4 of the heat exchange pipes 1 and 2 (at the perennial static water level of the groundwater 5). The waste material of the pipe is folded and wound into a netted rock-soil retaining device 4 and fixed on the heat exchange pipe. After the drilling and cleaning process is completed, the buried pipe heat exchange tubes 1 and 2 that have passed the pressure leak test in advance are placed in the borehole, and the pressure leak test is passed again. Then the sand backfill material 3 is poured into the test hole, and due to the effect of the rock-soil retaining device 4, the backfill material 3 will not sink below the rock-soil retaining...

specific Embodiment approach 2

[0023] Specific implementation mode 2: The ground source heat pump buried pipe heat exchanger without backfilling is composed of multiple buried pipe heat exchange holes, as shown in Figure 1, when the buried pipe is constructed, the buried pipe of the ground source heat pump is welded in advance Heat pipes 1 and 2, and fill the heat exchange pipes 1 and 2 with water, carry out pressurization and leak detection, and use 1 at the appropriate position 4 of the heat exchange pipes 1 and 2 (at the perennial static water level of the groundwater 5). - The short waste of 2 PE pipes is fixed on the heat exchange pipes as rock retaining device 4. After the drilling and cleaning process is completed, the buried pipe heat exchange tubes 1 and 2 that have passed the pressure leak test in advance are placed in the borehole, and the pressure leak test is passed again. Then the sand backfill material 3 is poured into the test hole, and due to the effect of the rock-soil retaining device 4, ...

specific Embodiment approach 3

[0024]Specific implementation mode 3: As an imprecise construction method, the ground source heat pump buried pipe heat exchanger without backfilling is composed of multiple buried pipe heat exchange holes, and there is no rock-soil retaining device 4 on the heat exchange pipe. After the drilling and cleaning process is completed, the buried pipe heat exchange tubes 1 and 2 that have passed the pressure leak test in advance are placed in the borehole, and the pressure leak test is passed again. Throw mud balls or soil clods into the heat exchange holes to block the heat exchange pipes and hole walls, and then pour the sand backfill material 3 into the test hole. Due to the blocking effect of the mud balls or soil clods, the backfill material 3 will not sink Below the rock and earth retaining device. In the heat exchange hole, the part above the mud mass or soil block has the water inlet pipe 1 of the buried pipe heat exchange pipe, the water outlet pipe 2 of the buried pipe he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com