Patents

Literature

72results about How to "Reduce construction work time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-molecular environmentally-friendly fracturing fluid and use of recovery liquid thereof

The invention relates to a low-molecular environmentally-friendly fracturing fluid and use of recovery liquid, wherein the fracturing fluid comprises low molecular thickening agent, cross linking agent, water, pH regulator, crude oil demulsification agent, surface active agent, clay stabilizer and bactericidal agent, thus no glue-breaking agent is needed, and very good rheological property can be achieved.

Owner:CHANGQING GASOLINEEUM EXPLORATION BUREAU

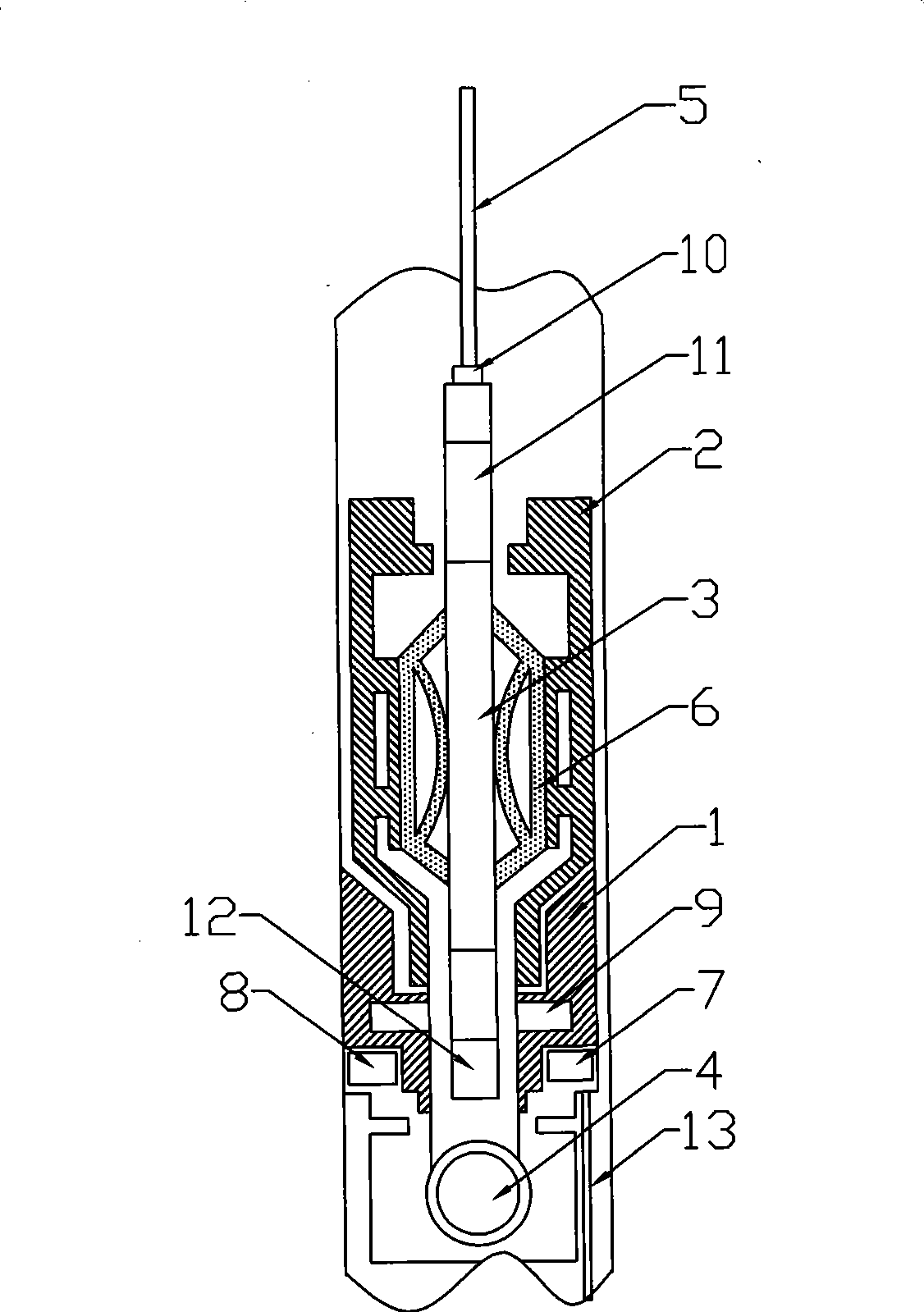

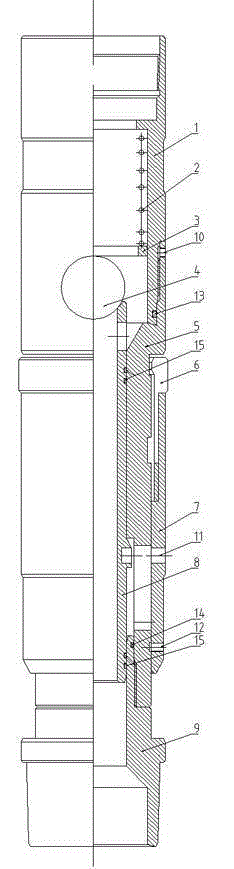

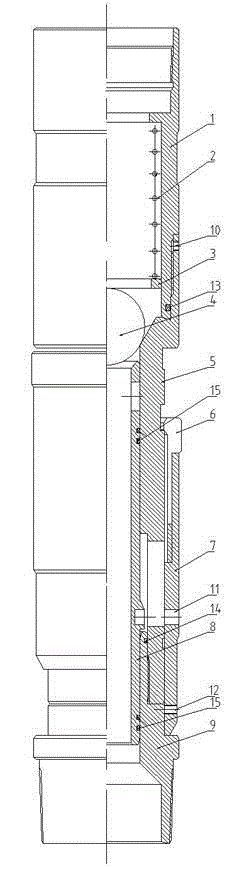

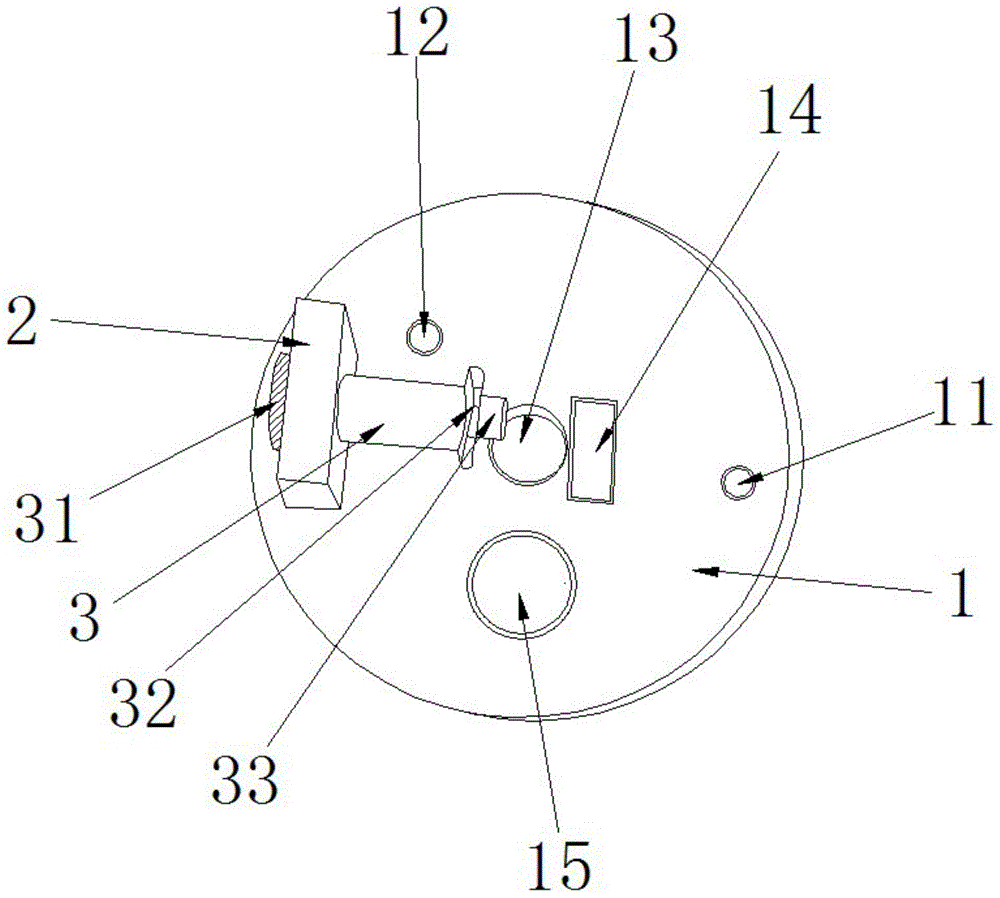

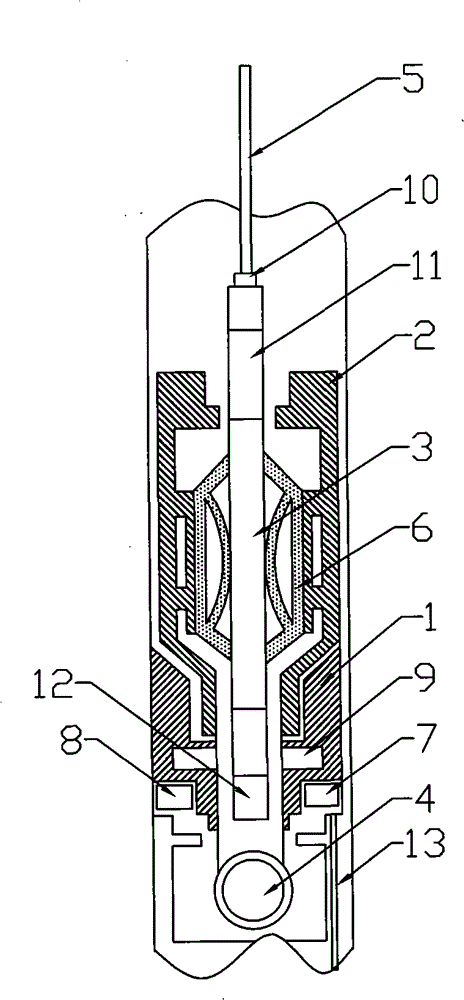

Super-deep well wireless transmission well testing system

ActiveCN101440705AAvoid the effects of accumulationImprove accuracySurveyMicrocontrollerPressure transmission

The invention discloses a wireless transmission well testing system of an ultra-deep well and relates to the filed of dynamic monitoring of an oil reservoir, in particular to a device for a pressure buildup test for an oil gas production well. The proposal utilizes a ground receiving device, a cable, a supporting cylinder, a sensing system and a ball valve; the supporting cylinder is connected with the upper part of the ball valve; the outer wall of the supporting cylinder is provided with a groove; the inside of a tube is provided with a pressure transmission passage from the lower part of the ball valve to a groove of a direct-reading manometer; the sensing system comprises the direct-reading type manometer, a cell and a receiver; the direct-reading type manometer and the cell are arranged inside the groove of the outer wall of the supporting cylinder respectively; the direct-reading type manometer consists of a sensor, an A / D module, a microcontroller, a signal emitter and a transmitting coil which are sequentially connected; the receiver consists of a receiving coil, a signal receiver, a microcontroller and a signal transmitter which are sequentially connected; and the receiver is arranged inside the supporting cylinder and is connected with the ground receiving device through the cable. The proposal realizes well shutdown underground, avoids accumulation in a well cylinder, shortens the well testing period, can fully avoid causing incomplete underground pressure buildup curve by insufficient time for well shutdown, can set sampling density at any moment through a ground computer, avoids causing the loss of wire section in early stage and meets the testing requirement of well testing of the oil gas well.

Owner:XINJIANG SINOGASOLINEEUM ENG

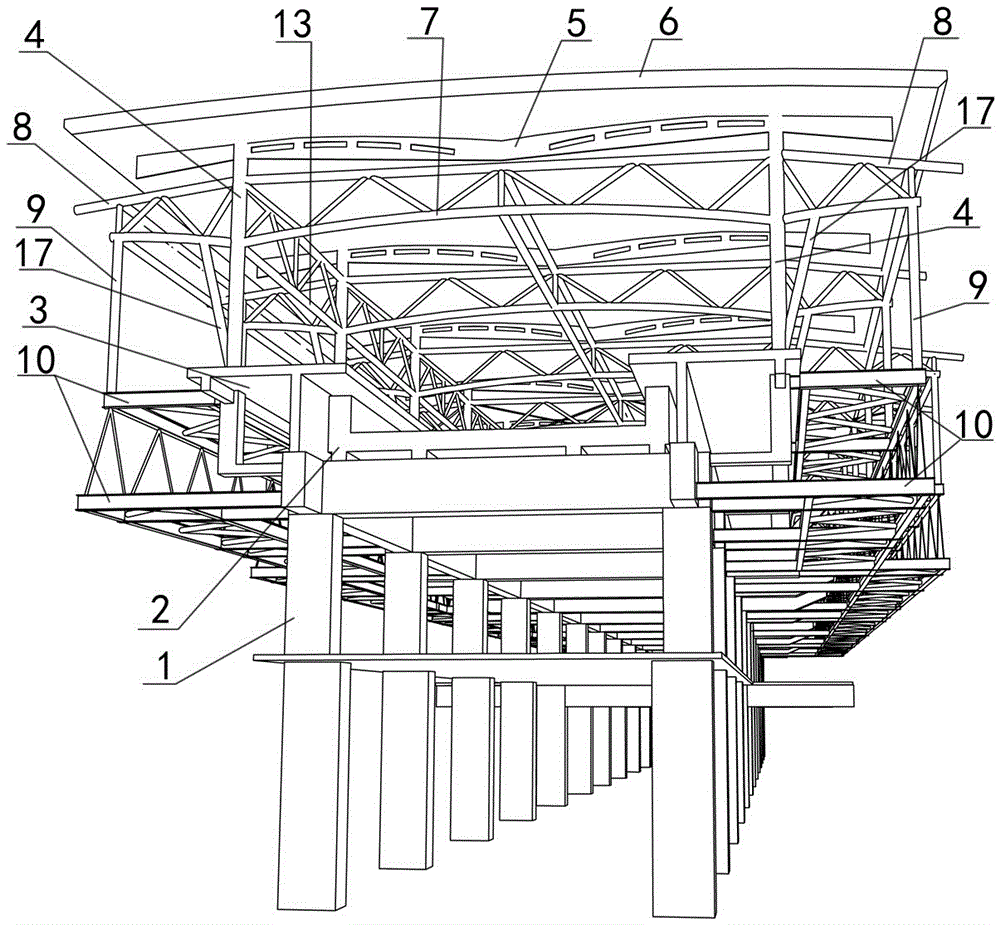

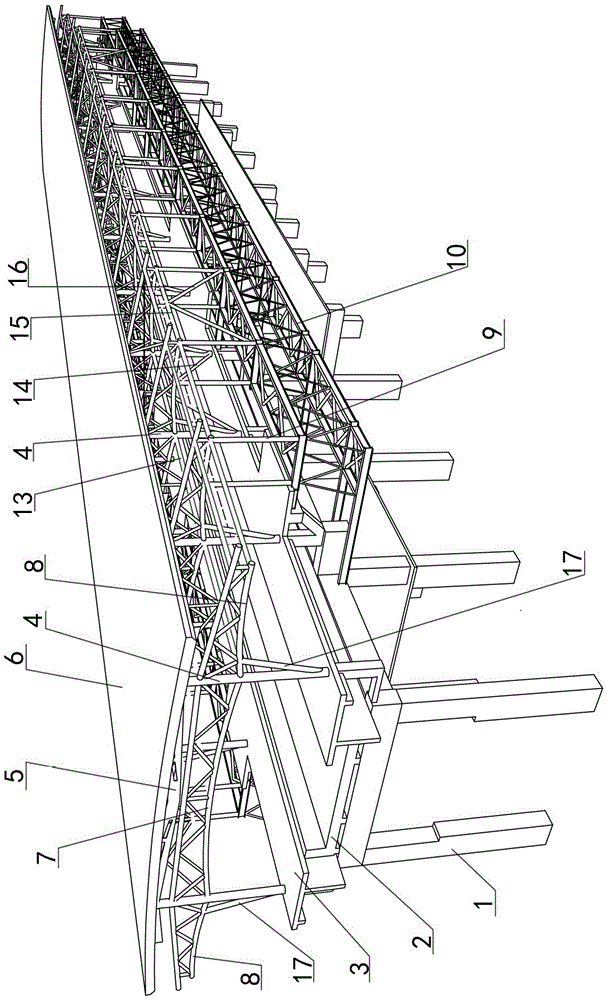

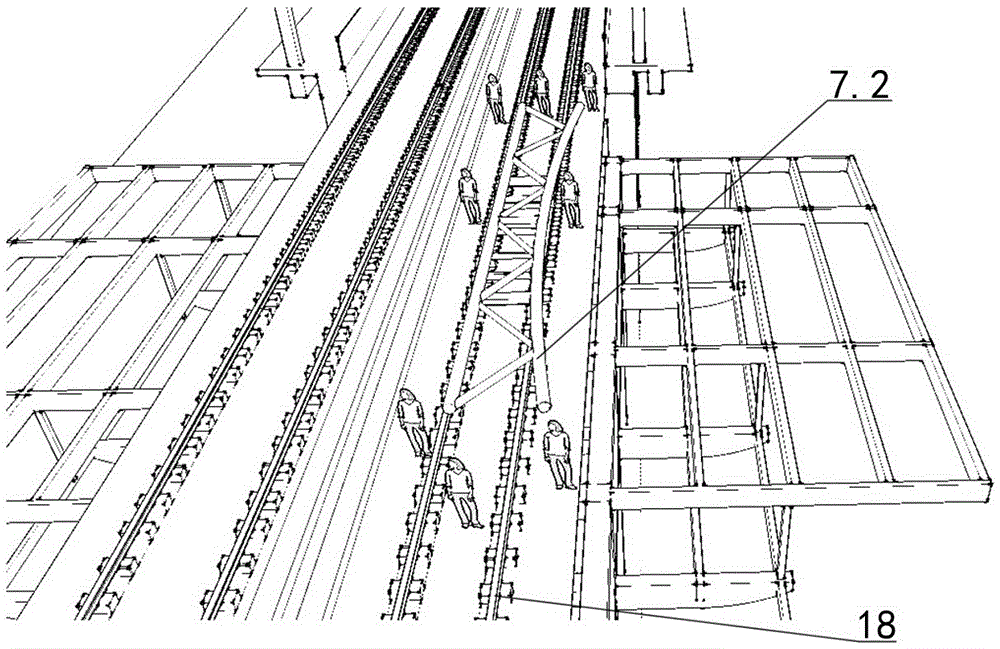

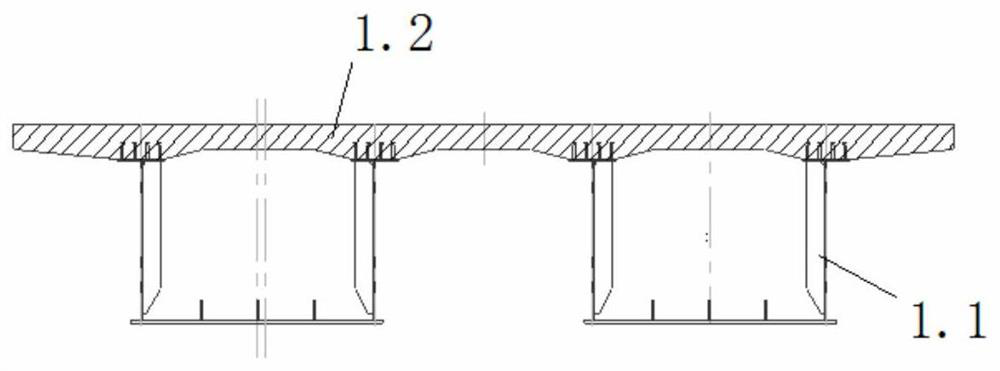

Construction method of widened and improved structure system for existing station platform

ActiveCN106088660AGuaranteed Node DurationSmall size errorBuilding repairsGirdersSubway stationSteel columns

The invention provides a construction method of a widened and improved structure system for an existing station platform, which comprises the following steps: pre-processing steel members of a widened steel structure of a station; reinforcing frame columns of an original frame structure; reinforcing bent steel columns; mounting middle beams; mounting side beams; and mounting a structure widened platform. According to the invention, the steel members of the widened and improved part of the station are divided into middle beams, cantilever side beams and a steel structure widened platform to be respectively constructed, so that the processes are reasonable, the construction time is accurate, and the construction period is ensured; and the early subway station which can not meet the existing passenger flow is widened and improved, thereby summarizing construction experience for a new trend of the future subway industry, filling up the blank of the track traffic industry and providing reference for future improved construction.

Owner:北京住总集团有限责任公司 +1

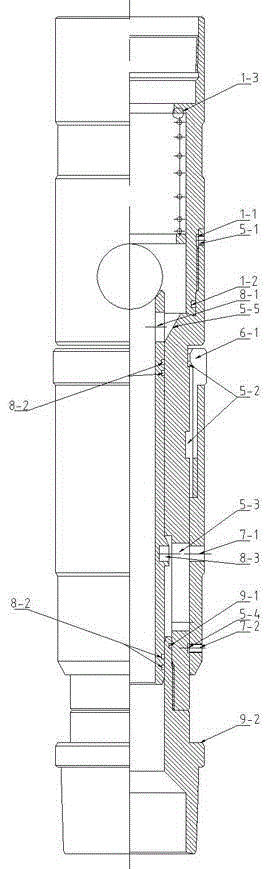

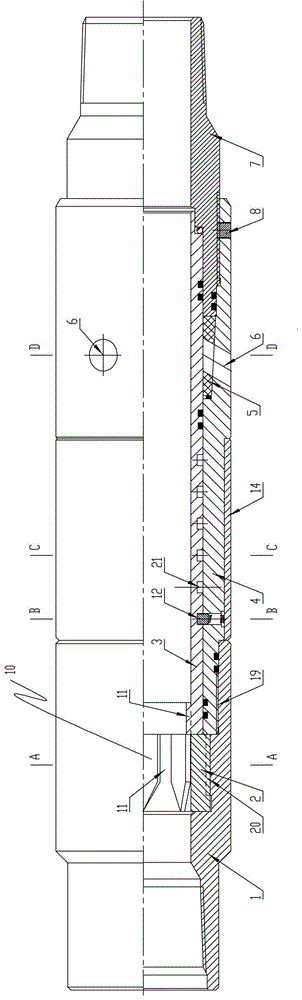

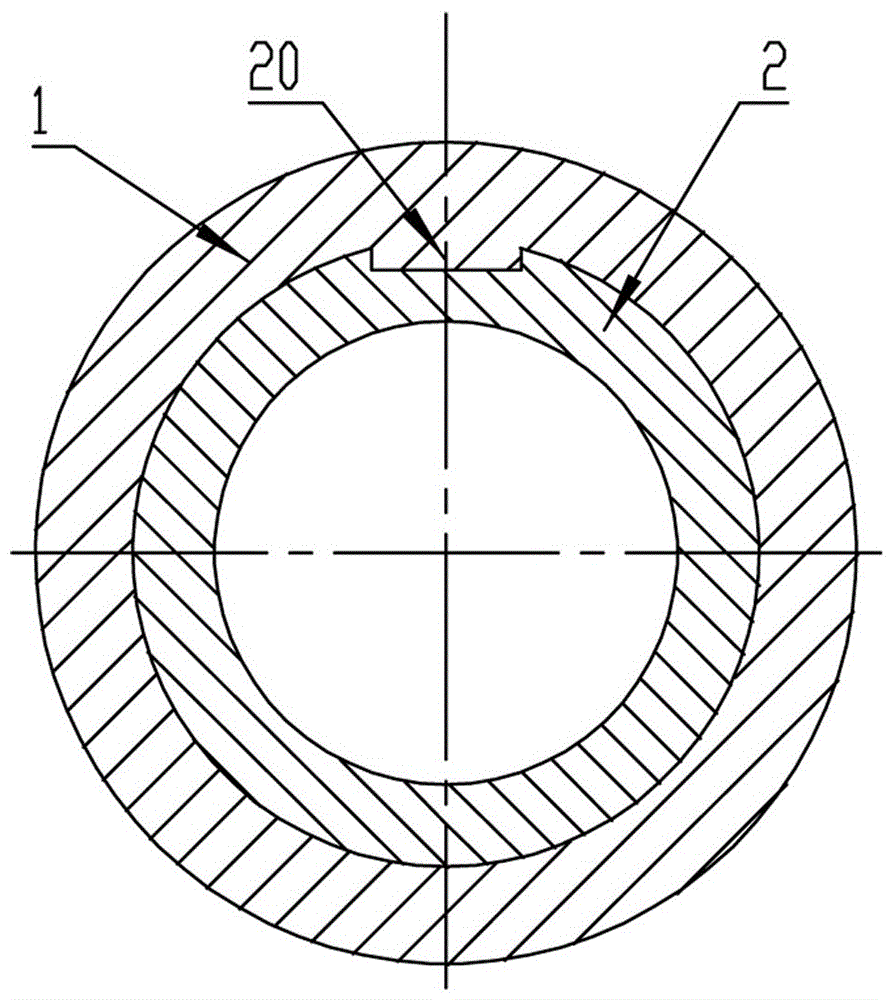

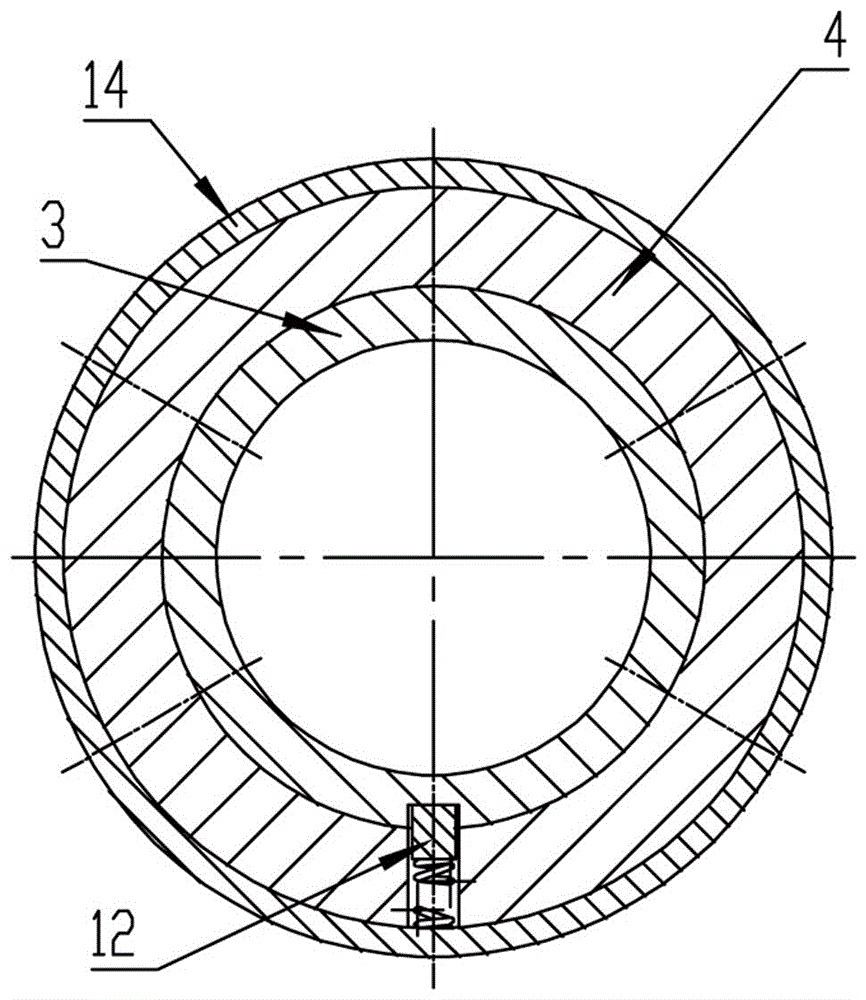

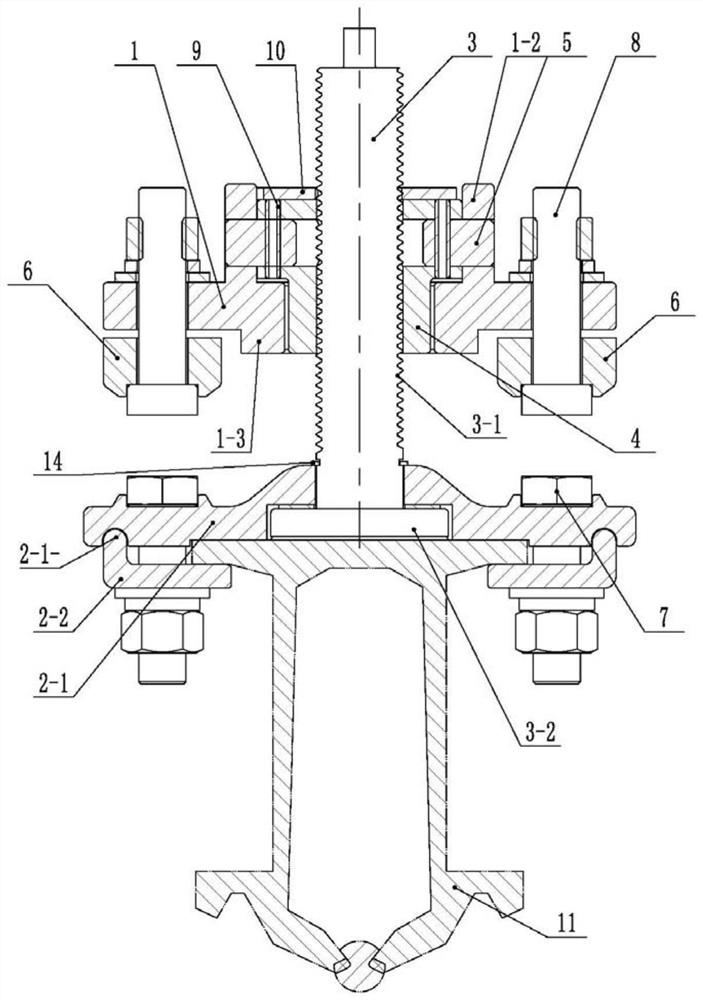

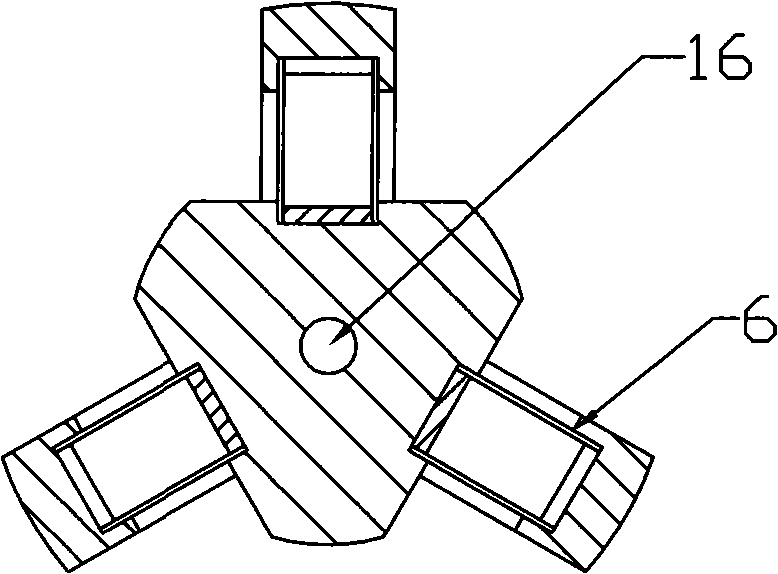

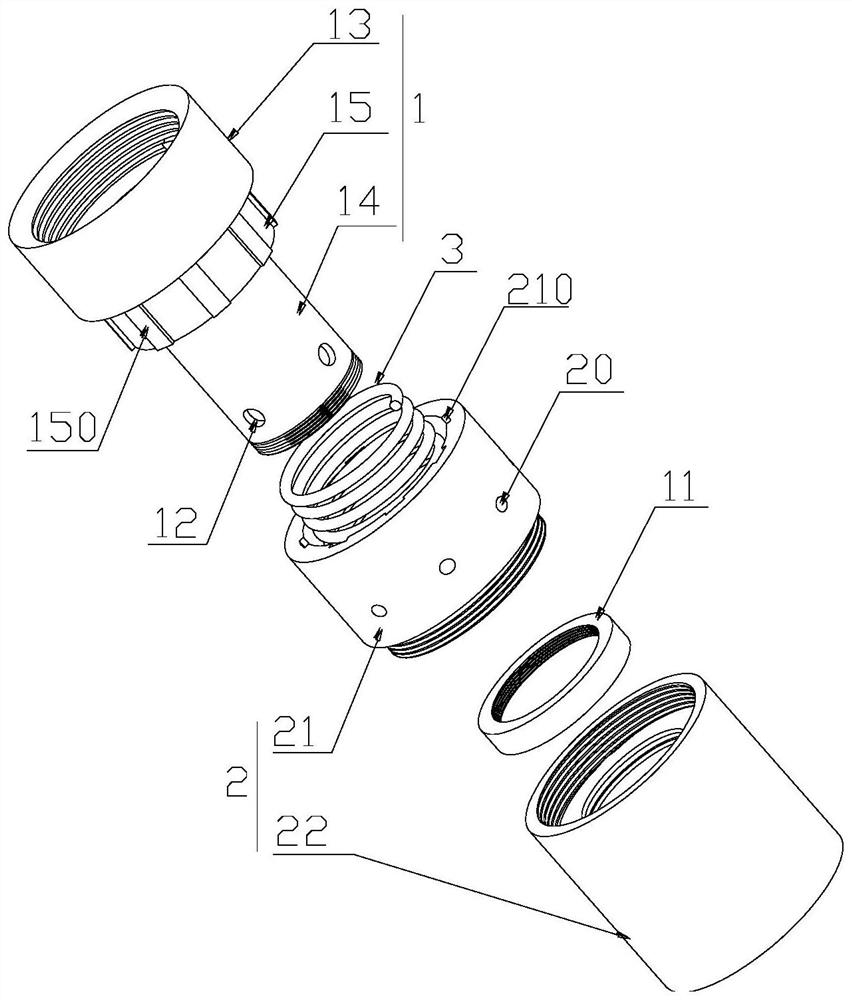

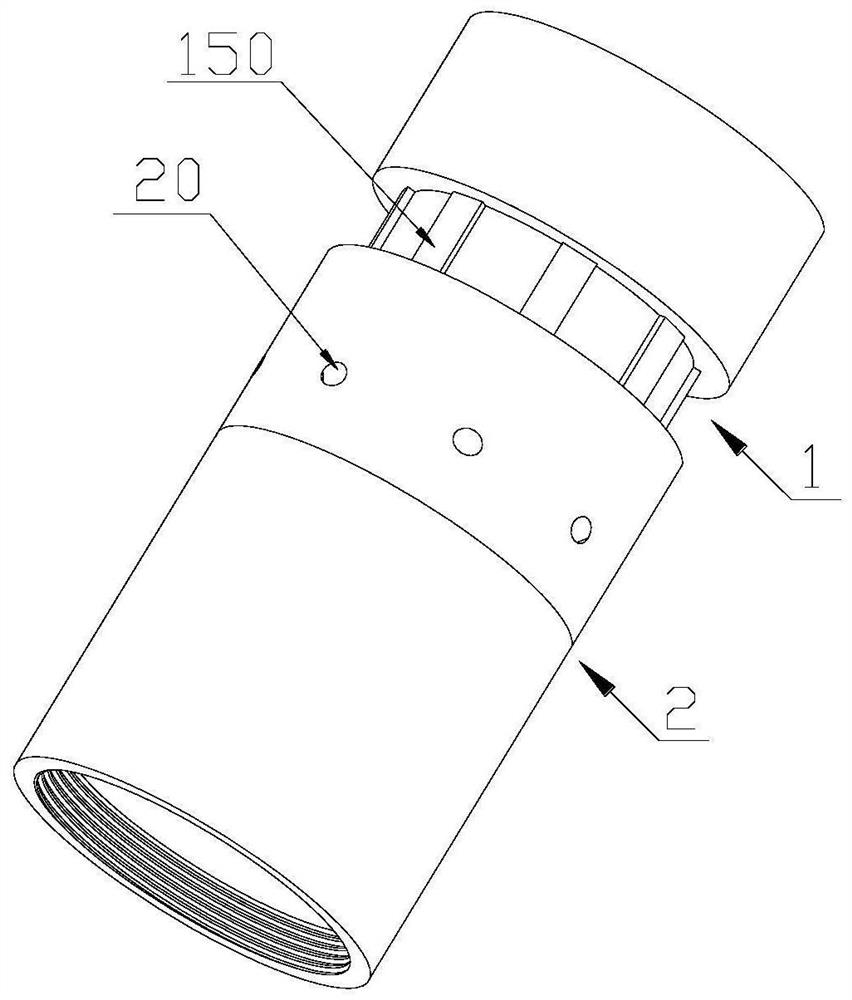

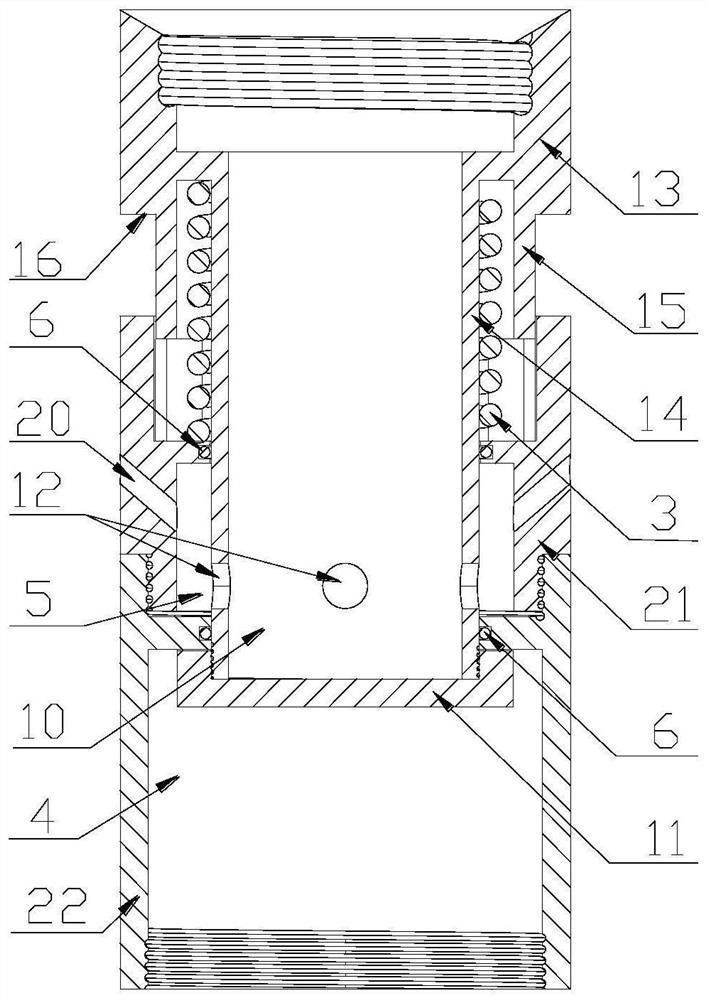

Deep sea oil well one or two direction well washing conversion tool

ActiveCN104389539ANo throttling differential pressureChange the direction of circulationFlushingPressure differenceHigh pressure

The invention provides a deep sea oil well one or two-way well washing conversion tool which includes an upper connection joint. The lower end of the upper connection joint is connected to a hanging cover, and an elastic locking claw is placed at the outside of the hanging cover, and a sliding sleeve is connected below the elastic locking claw. A lower connection joint is connected to the lower end of the hanging cover. The hanging cover and the lower connection joint are provided with well washing conversion sleeves, and the sliding sleeve can drive the well washing conversion sleeves to synchronously move up and down through the hanging cover. A median septum with circulation holes thereon can ensure that the liquid in the operation tube can not form throttle pressure difference. The disclosure can change the flow direction of the liquid in the conversion tool, and ensure the mud cakes and gravel in the operation tube flow into the wellbore again after the well washing finishes. In addition, the conversion tool can realize the connections of oil sleeves, and can realize positive and negative well washing operation, and can further realize well control operation under high pressure in the pit.

Owner:杜学新

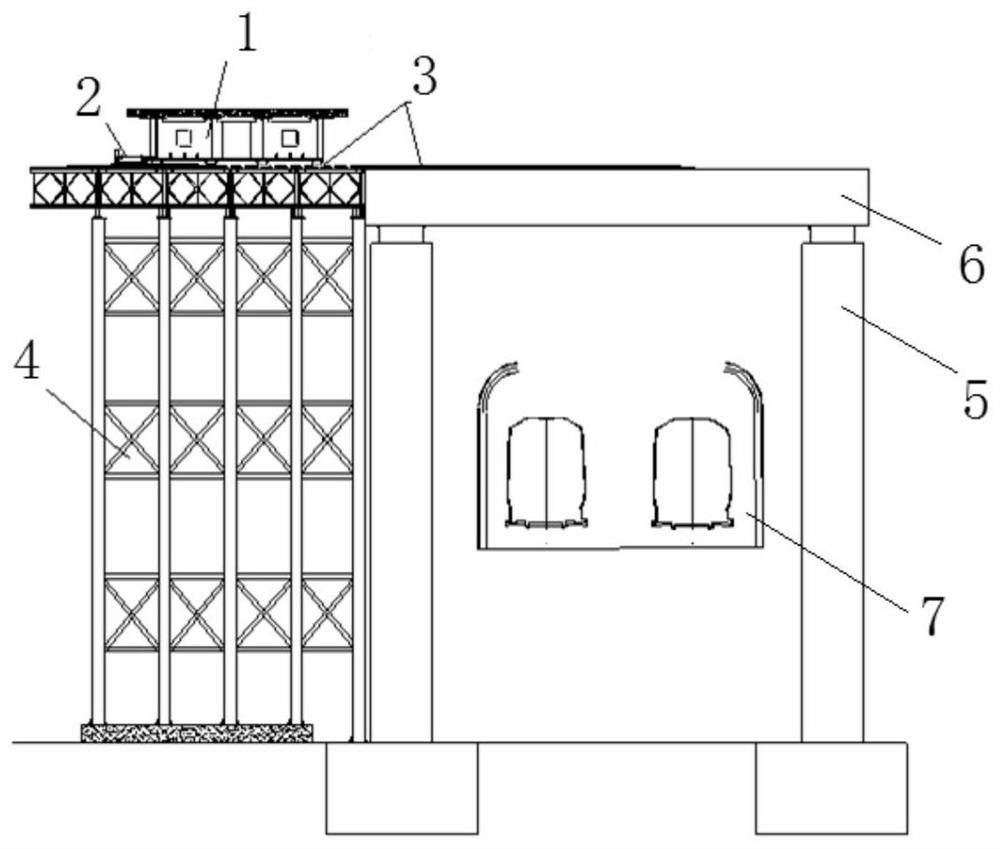

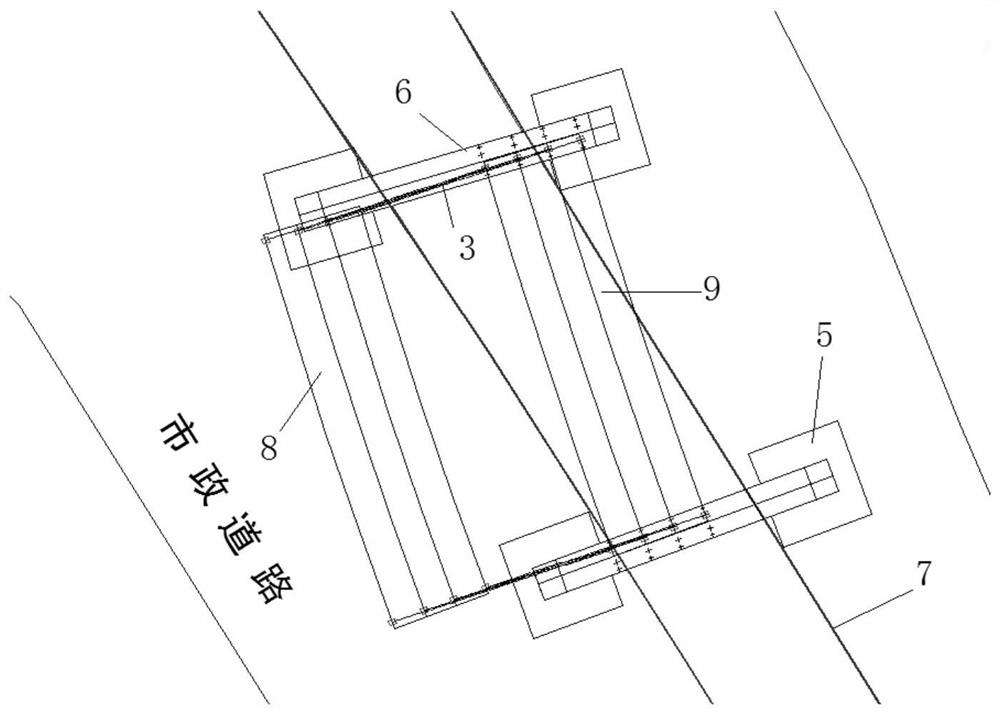

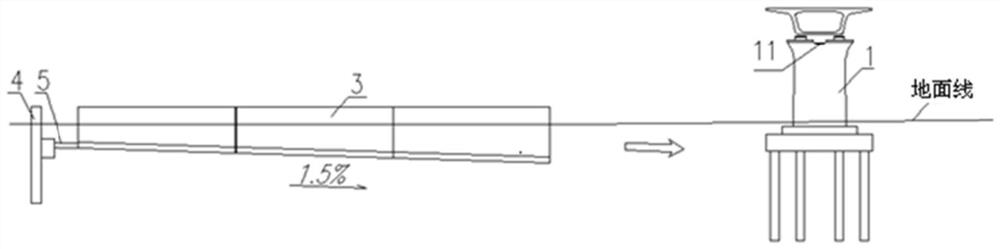

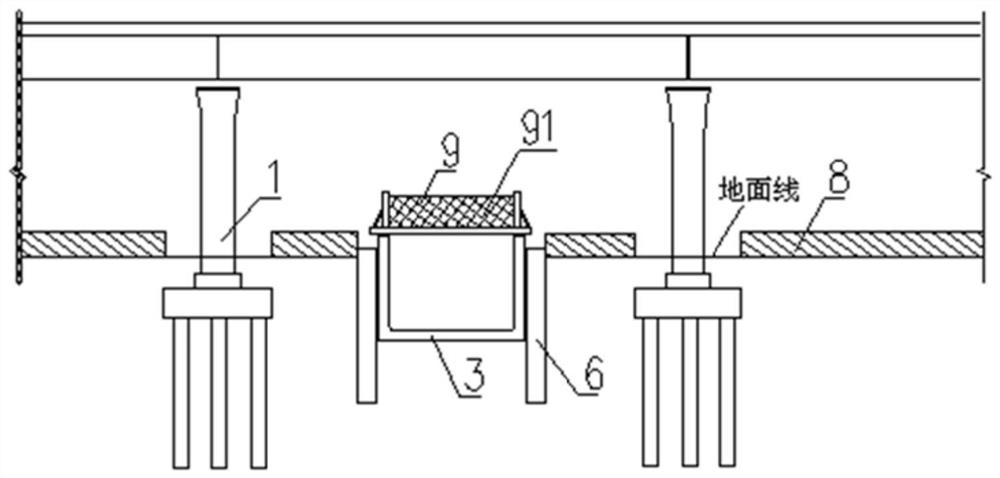

Lateral flat top construction structure and method for reinforced concrete superposed beam

PendingCN111608086AOperations cannot be affectedLow costBridge erection/assemblyButtressReinforced concrete

The invention relates to a lateral flat top construction structure and method for a reinforced concrete superposed beam. The structure comprises a temporary buttress system arranged on the side of a pier column beside an existing line, a sliding way is arranged at the top of the temporary buttress system and on a steel cross beam stretching across the upper portion of the existing line, a reinforced concrete superposed beam is erected on the sliding way on one side of the temporary buttress system firstly, and the reinforced concrete superposed beam is in place through a lateral flat top at the skylight point time. The construction working time of the operation line is greatly reduced, the interference of the construction process to the existing operation line under the bridge is minimum,and the construction cost is economical and safest.

Owner:KUNMING SURVEY DESIGN & RES INST OF CREEC

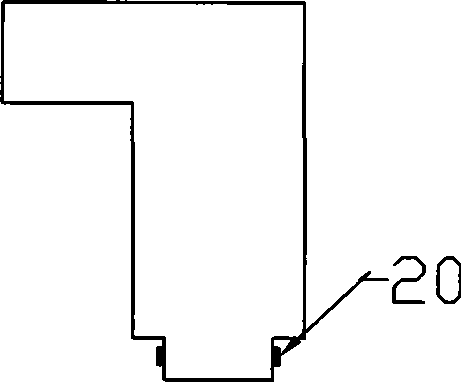

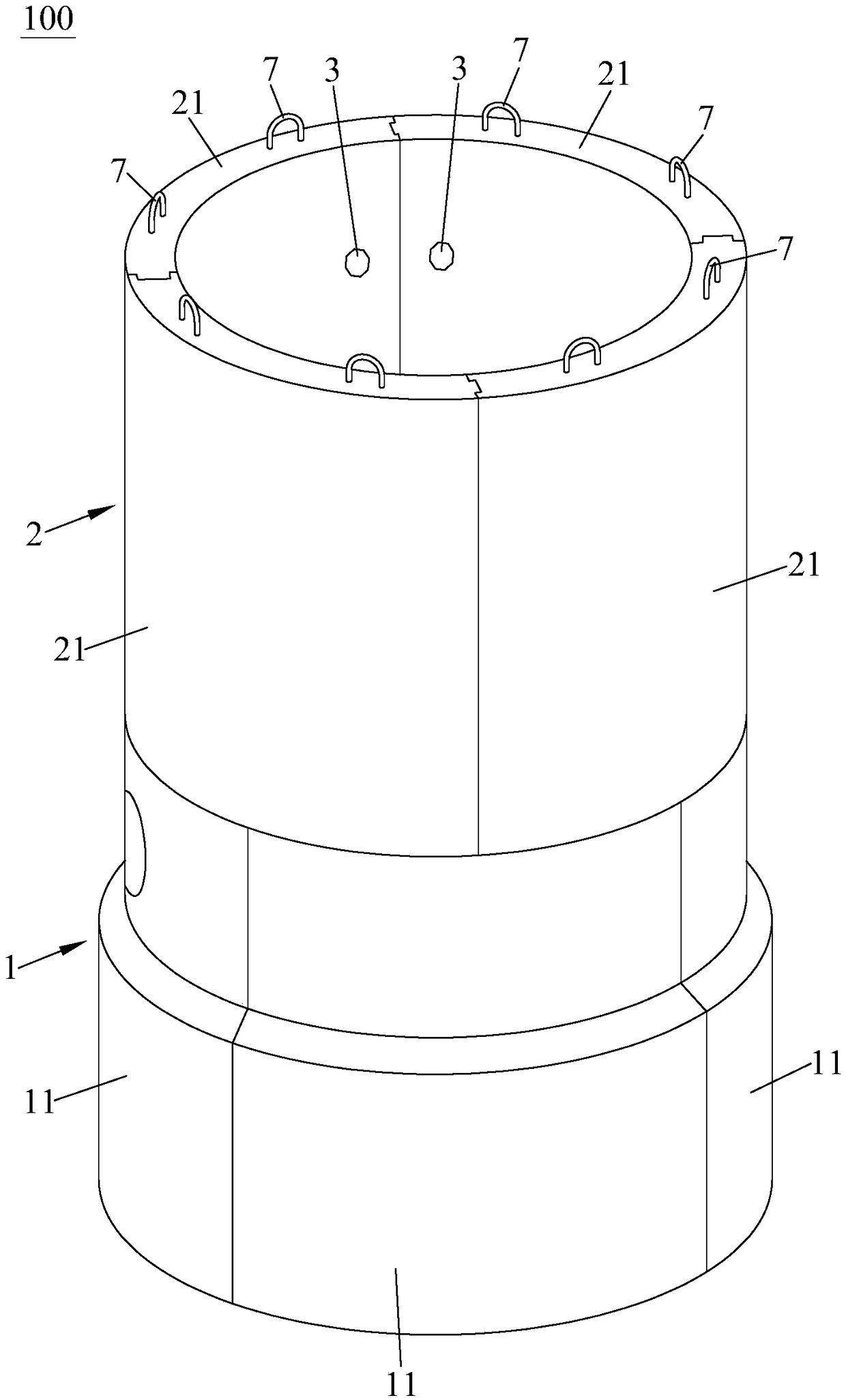

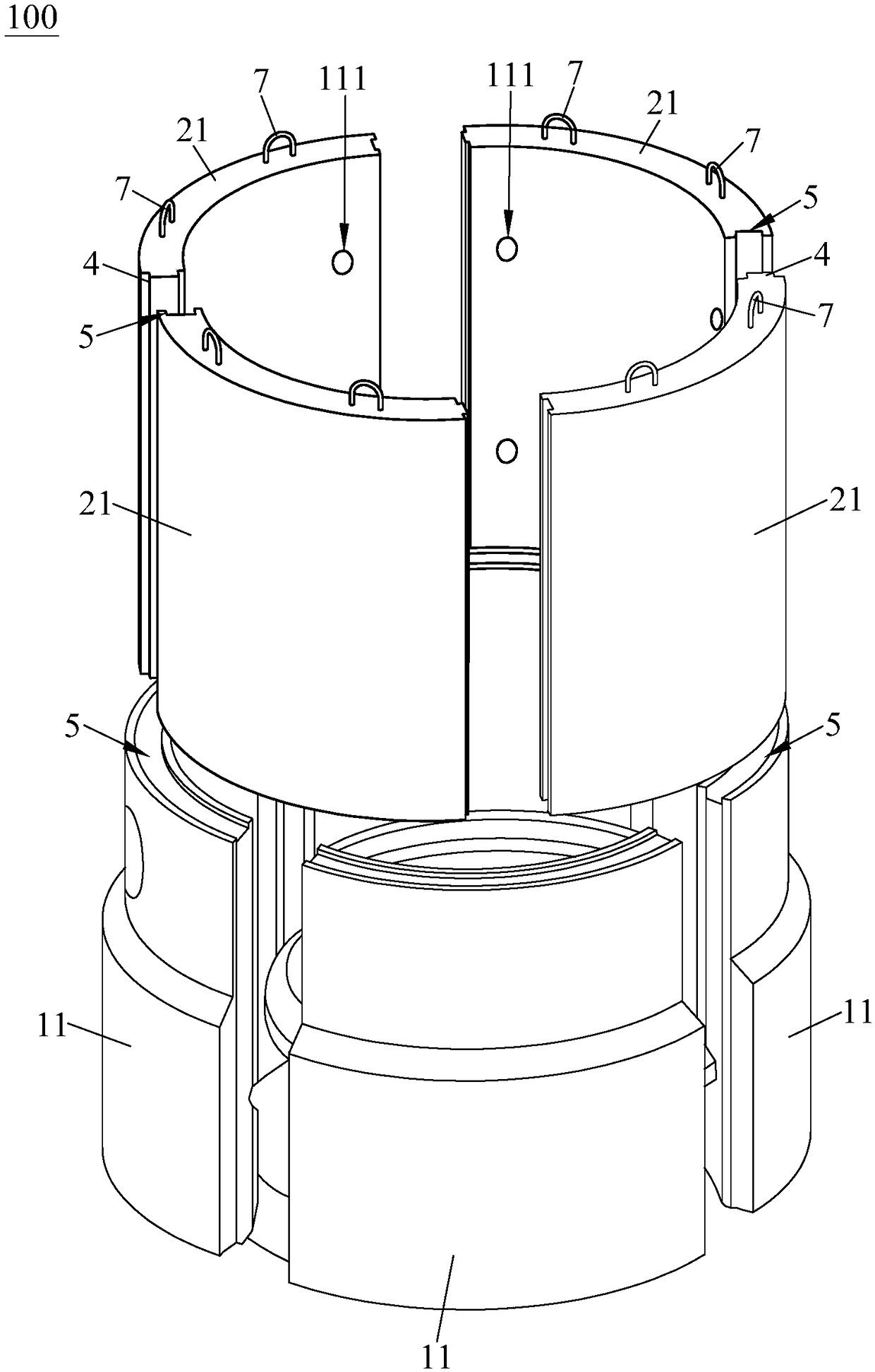

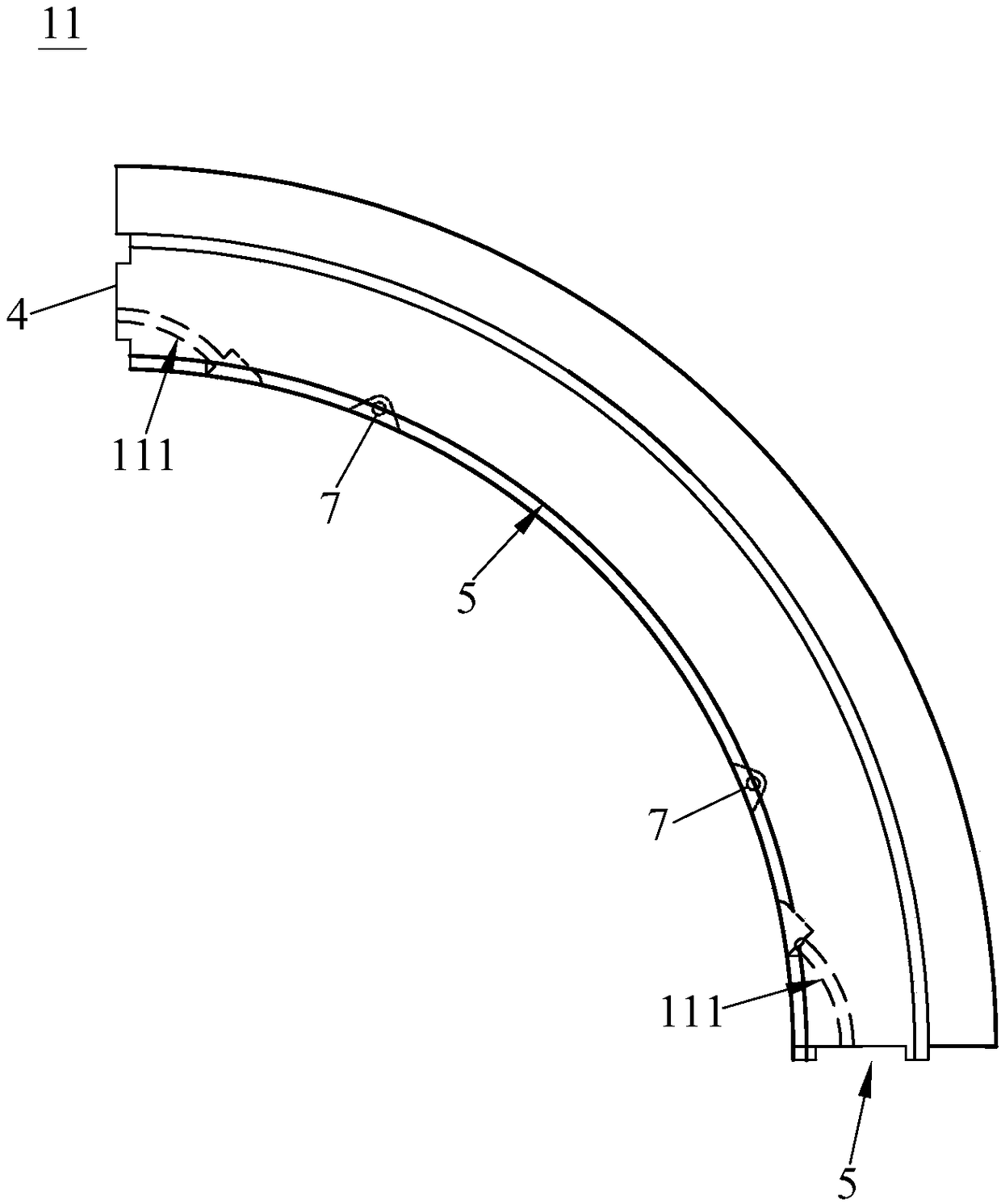

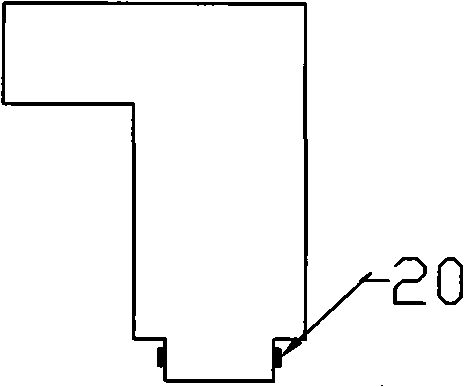

Well piece, prefabricated assembled caisson and caisson construction method

The invention provides a prefabricated assembled caisson. The prefabricated assembled caisson comprises a ring well body and a plurality of tubing bolts, the ring well body comprises at least two arc-shaped well pieces, first arc round holes are formed in the two opposite sides of the well pieces, the first arc round holes in the two adjacent well pieces in the circumference direction communicatewith each other, and the tubing bolts penetrate through the first arc round holes to fix and connect the two adjacent well pieces. When the prefabricated assembled caisson is transported, the tubing bolts can be loosened in a screwed mode to remove the two adjacent well pieces, the transporting space occupied by the prefabricated assembled caisson is reduced so as to transport more prefabricated assembled caissons to reduce the transporting cost; when the transported well pieces reach to a designated location, the two adjacent well pieces can be quickly assembled and connected through the tubing bolts, and then the ring well body is installed in the caisson construction place and sunken; and compared with the site pouring concrete, the construction is simple and convenient, the construction efficiency is improved, in addition, the invention further provides a caisson construction method.

Owner:SINOHYDRO BUREAU 7 CO LTD

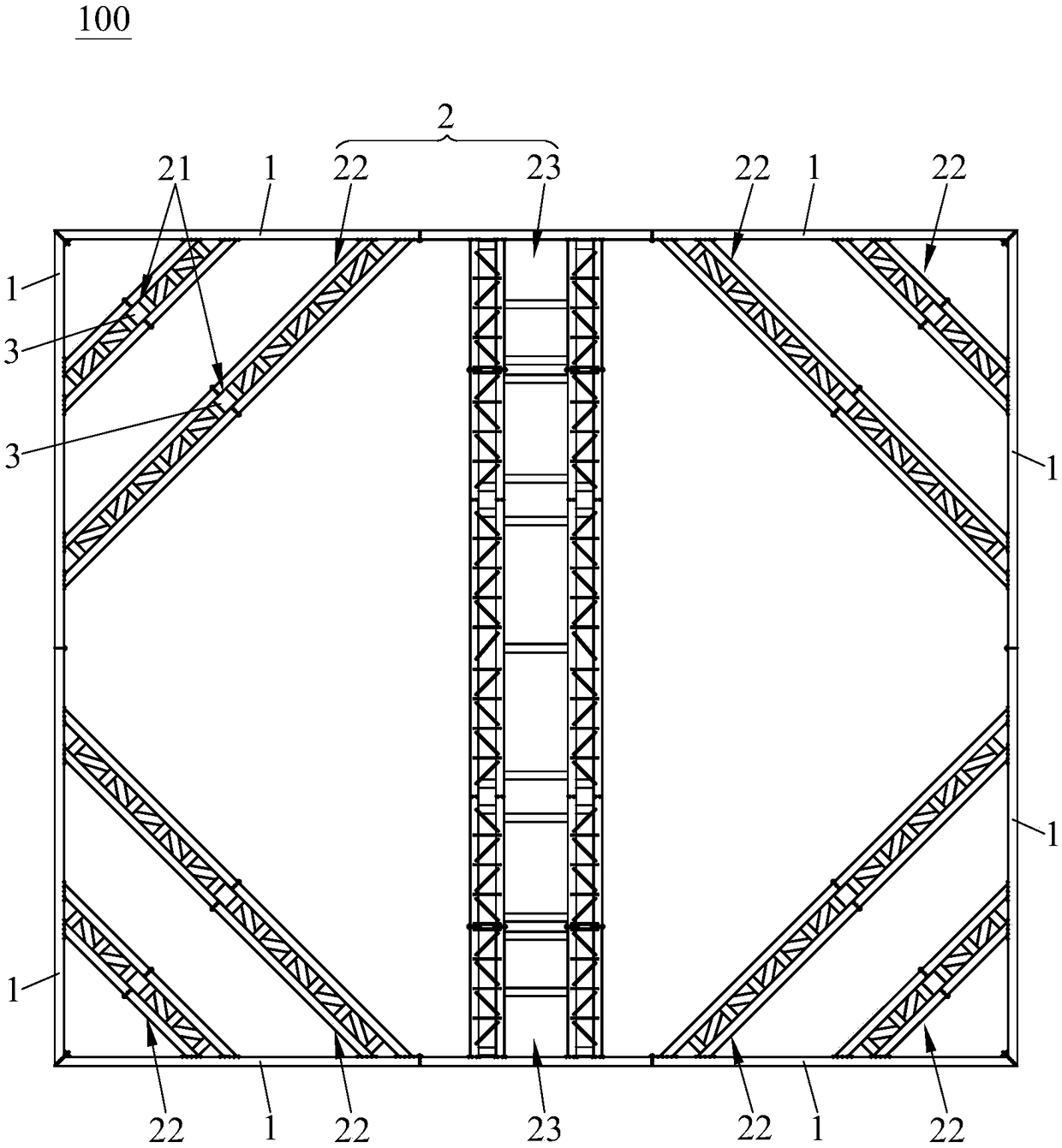

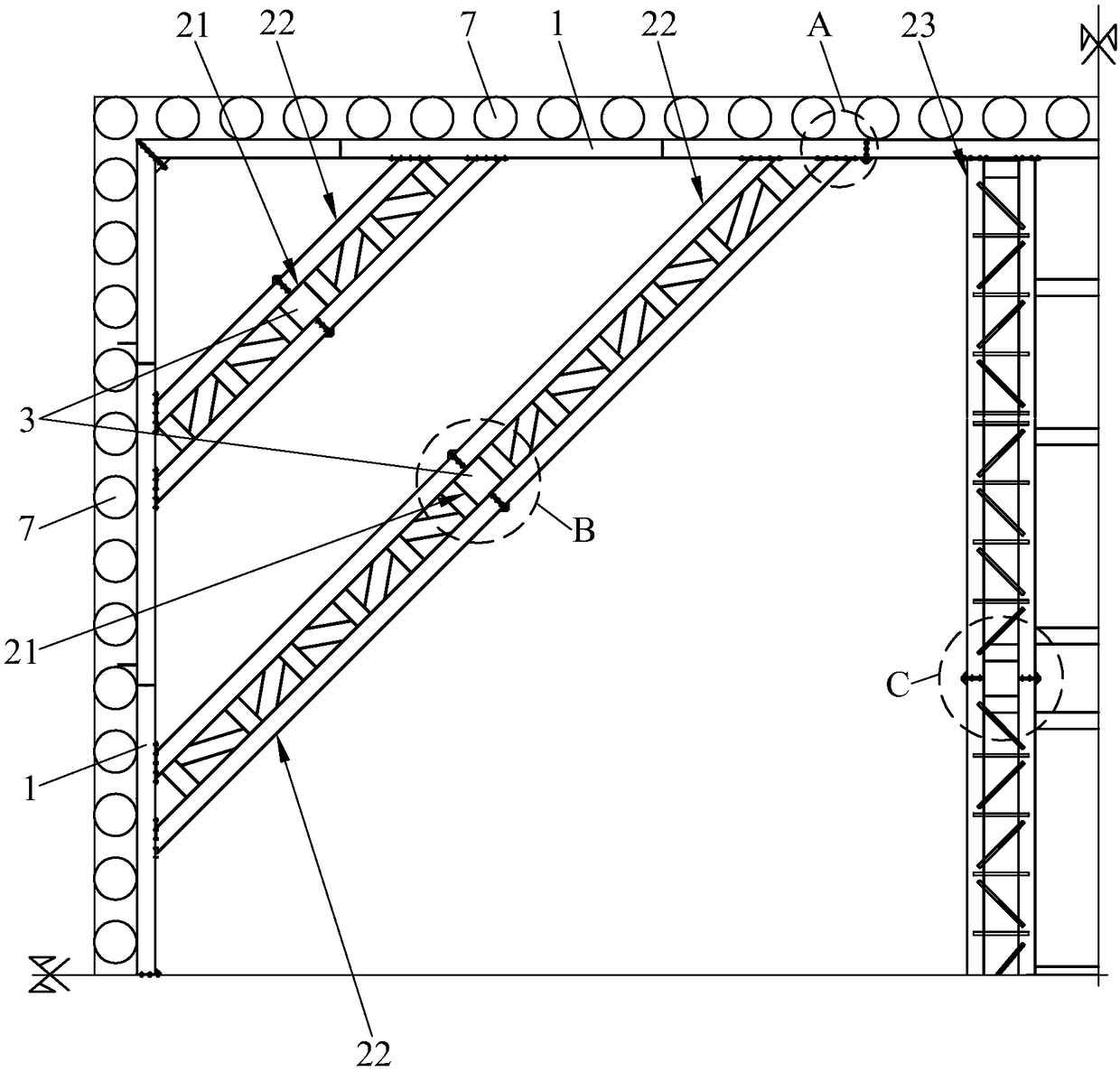

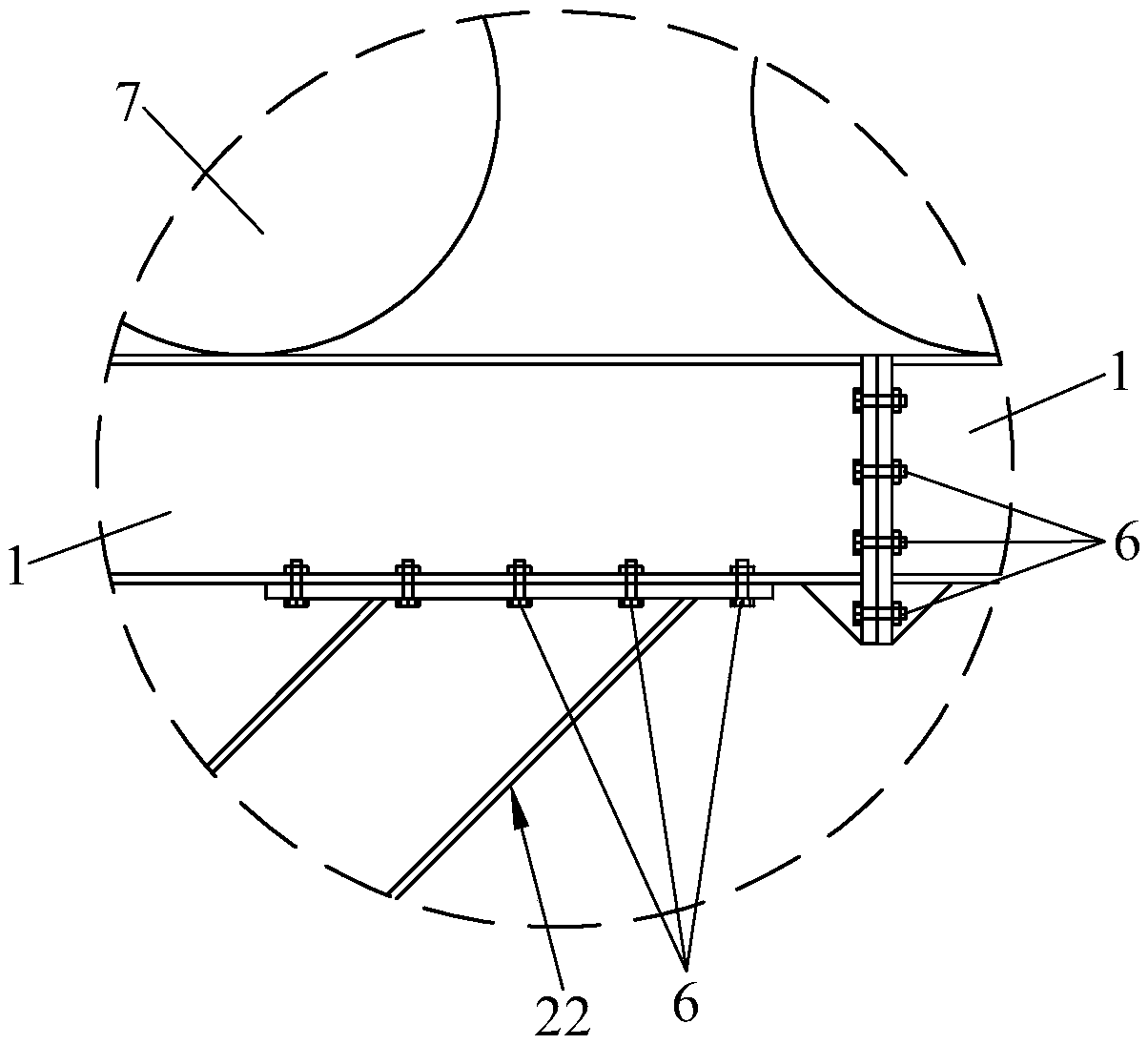

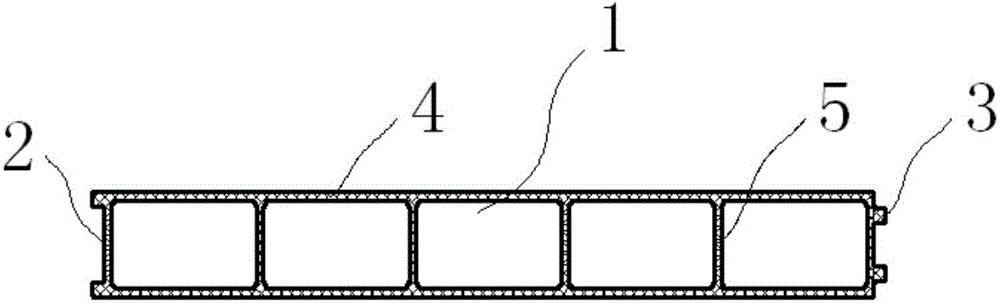

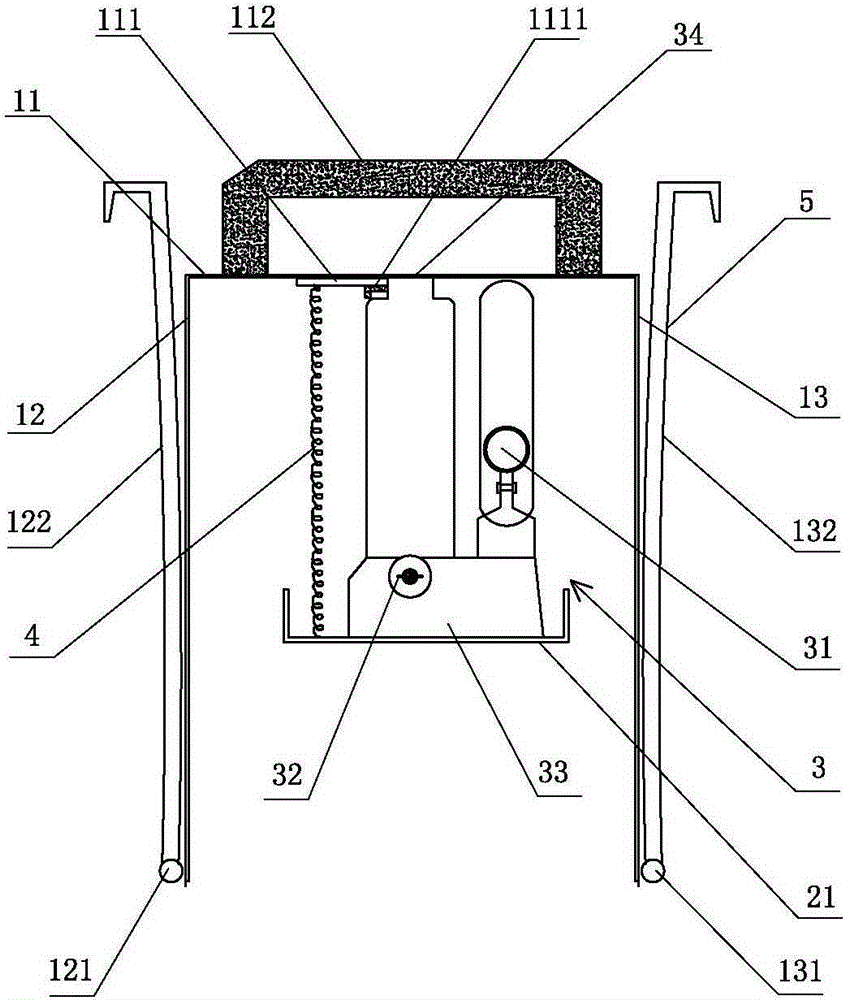

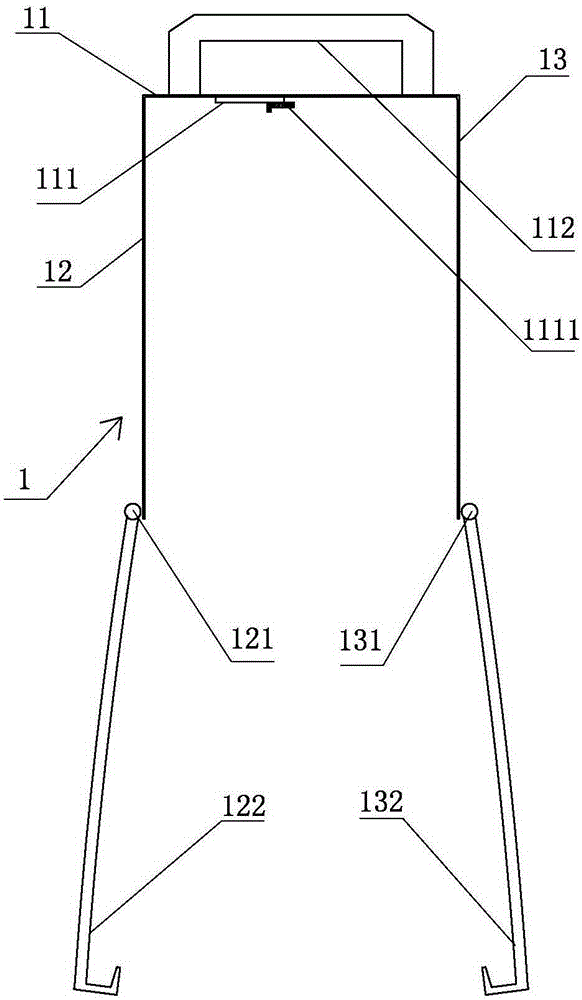

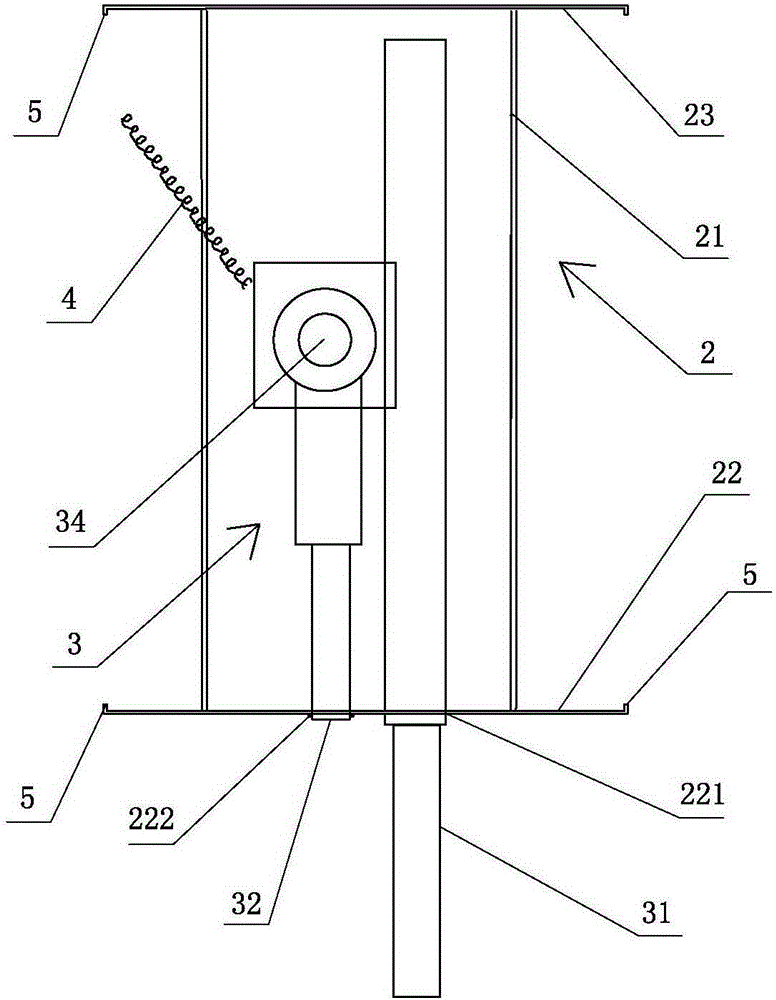

Movable foundation pit internal supporting system and foundation pit construction method

PendingCN108755706AGuaranteed safety and reliabilityEasy to assemble and disassembleExcavationsPurlinSupporting system

The invention provides a movable foundation pit internal supporting system. The movable foundation pit internal supporting system comprises enclosure purlins, supporting assemblies, lattice columns, pushing devices and a hoisting device. The enclosure purlins are arranged on the inner wall of a foundation pit, and every two adjacent enclosure purlins are detachably connected. The enclosure purlinsare driven by the hoisting device to move up and down along the inner wall of the foundation pit. Each supporting assembly is detachably connected between the two corresponding enclosure purlins andis provided with an accommodating opening. The lattice columns are vertically arranged in the foundation pit and are inserted into the accommodating openings. The supporting assemblies can be driven by the pushing devices to move in the axial direction of the lattice columns. According to the movable foundation pit internal supporting system, the enclosure purlins are driven by the hoisting deviceto move downwards along the inner wall of the foundation pit, and the supporting assemblies are driven by the pushing device to move downwards in the axial direction of the lattice columns, so that the enclosure purlins and the supporting assemblies are positioned and mounted again in the excavation layer so as to support the excavation layer, and accordingly, the safety and reliability of the foundation pit in the excavation process are ensured; and the movable foundation pit internal supporting system can be recycled, low in work amount and low in engineering cost. The invention further provides a foundation pit construction method.

Owner:东莞市建筑科学研究所

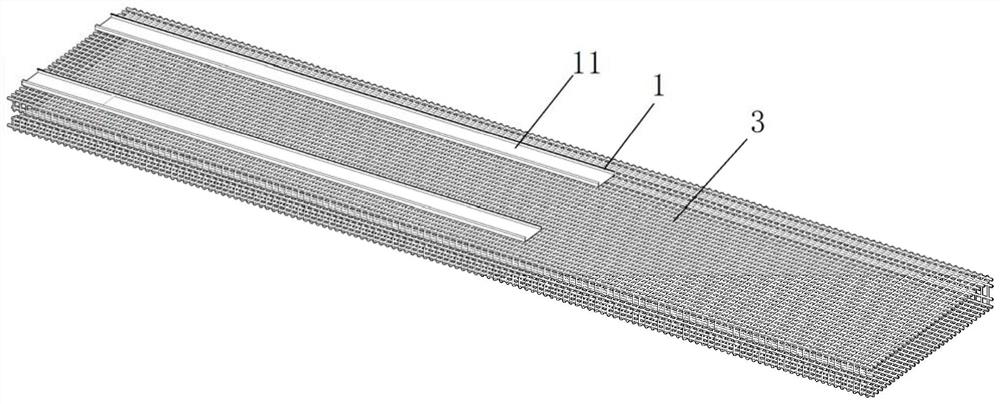

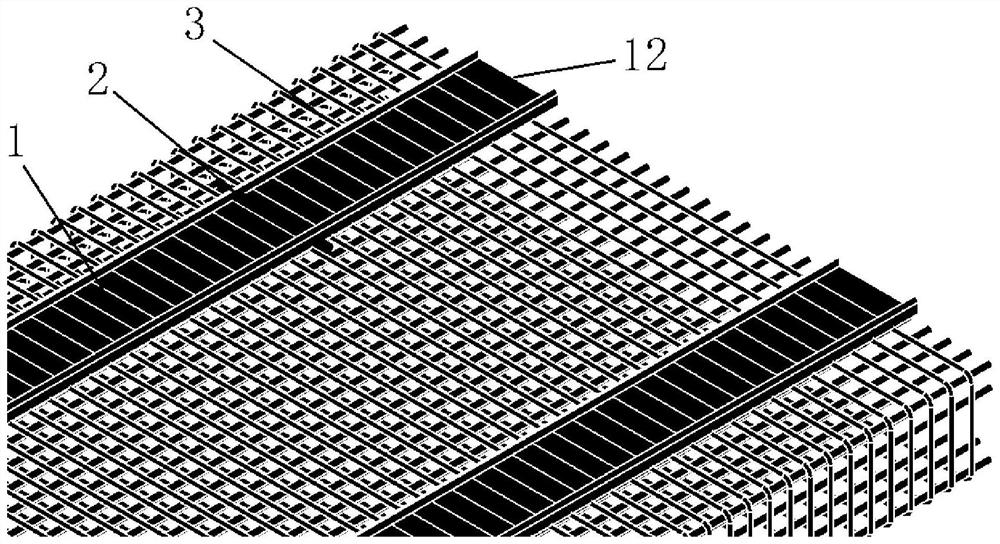

Railway bridge walking plate, installation structure and installation method

The invention provides a railway bridge walking plate, an installation structure and an installation method. The railway bridge walking plate is a walking plate made of composite materials and is of a hollow multi-cavity structure, the railway bridge walking plate can be set at any length, the railway bridge walking plates can be installed in a manner of paving two spans or more than two spans longitudinally, the longitudinal walking plates are buckled and pressed by T-shaped section steel, and the T-shaped section steel and installation brackets are welded together. Z-shaped necks are formed in the bottom surfaces of the walking plates and matched with the installation brackets; concave-convex grooves are formed in the sides of the walking plates, and thus the transverse walking plates are inlayed better; an anti-skidding layer of resin and quartz sand mixture is arranged on the surface of the walking plate. Compared with the ordinary concrete walking plate, the defect that the length of the walking plate is not matched with the spacing between the installation brackets is overcome, limitation of single-span installation is also overcome, and thus the problems that the overlapped length of the walking plates is insufficient and thus the walking plates drop due to the great error of the adjacent installation brackets on site, and dropping is caused due to handling faults in the installation process are solved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Construction method for preventing erection of crossing frame by using overhead ground wire to perform pulley block hanging operation

ActiveCN104393524AAvoid red tapeReduce construction work timeApparatus for overhead lines/cablesElectricityEarth anchor

The invention discloses a construction method for preventing erection of a crossing frame by using an overhead ground wire to perform pulley block hanging operation. The method is simple in construction and safe to operate, can shorten the construction time and power failure time, is time-saving and labor-saving, and reduces the construction cost. The method comprises the following steps: first of all, arranging work personnel to climb a tower near a position in need of crossing to hang the triaxial pulley block on an overhead ground wire; making the two ends of each insulation rope vertical down to the ground, and the ground work personnel sliding the pulley block from the overhead wire to a crossover object by use of the insulation ropes vertical down to the ground; the ground work personnel binding a wire holder wheel, leading the two ends of each of the two insulation ropes out respectively from collars at the two sides of the wire holder wheel, lifting the wire holder wheel to a position distanced 100mm to 200mm away below a lead, encircling the lead, and at the same time, by use of a temporary ground anchor, binding the two ends of each of the two insulation ropes so as to maintain a certain height from the ground to reach a safety distance when the lead descends; and then, controlling the lead to swing from left to right and bounce by use of the insulation ropes so as to prevent contact with a lead at a same-tower parallel live-line side.

Owner:STATE GRID CORP OF CHINA +1

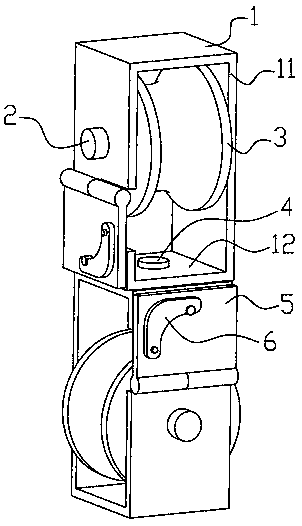

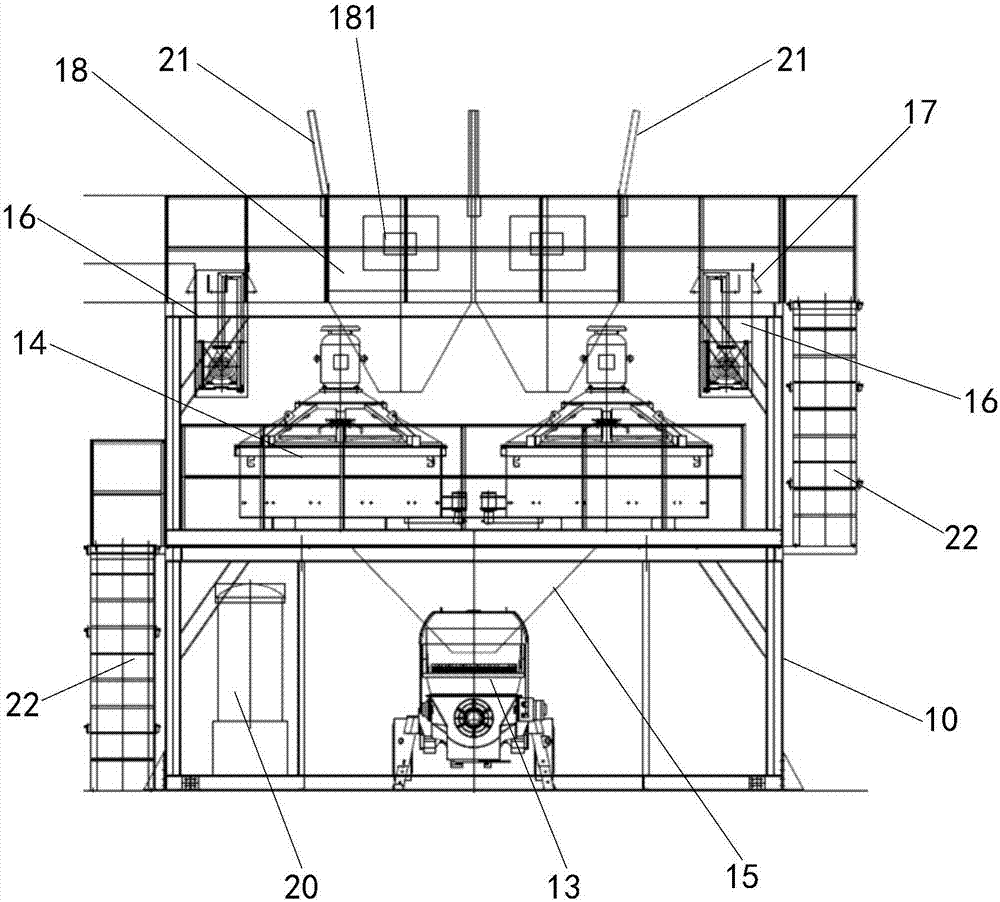

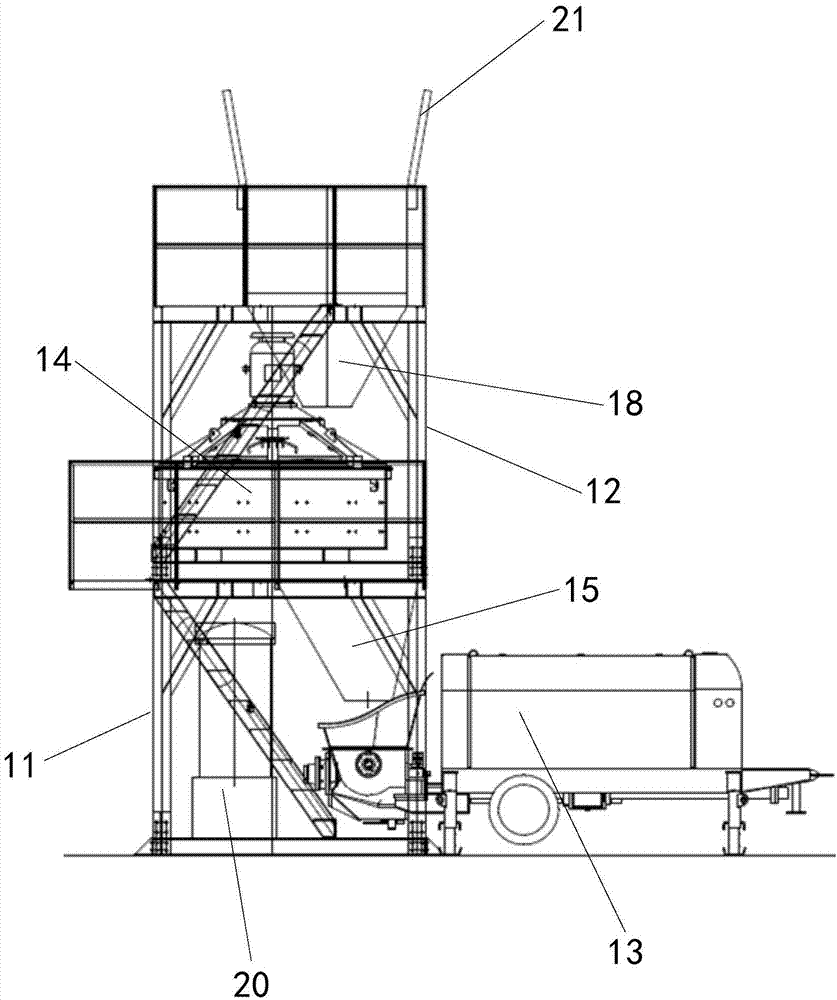

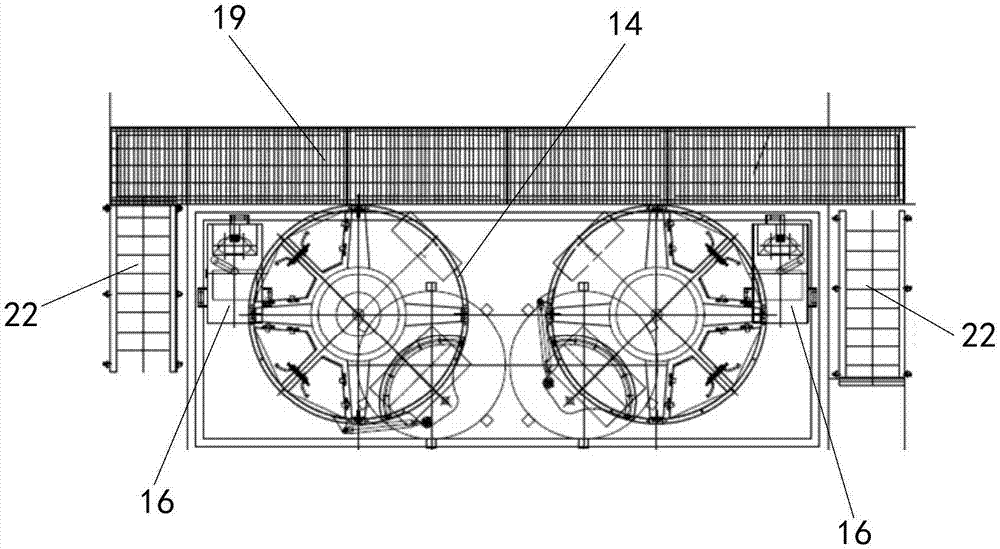

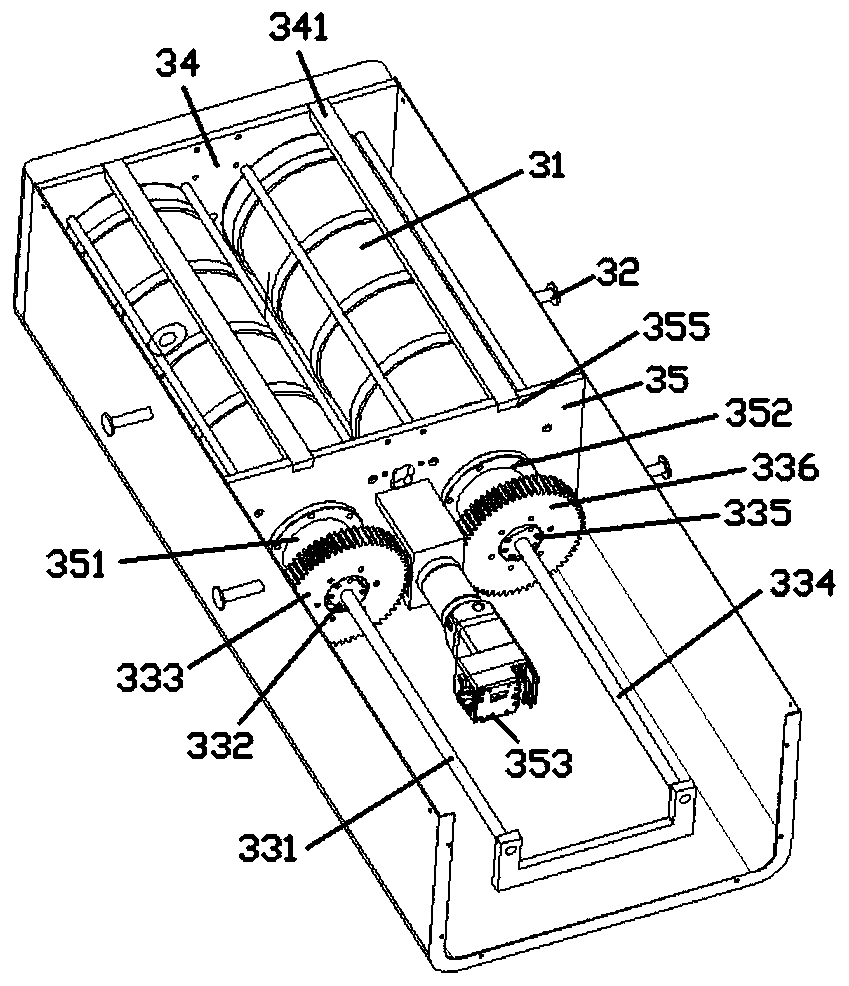

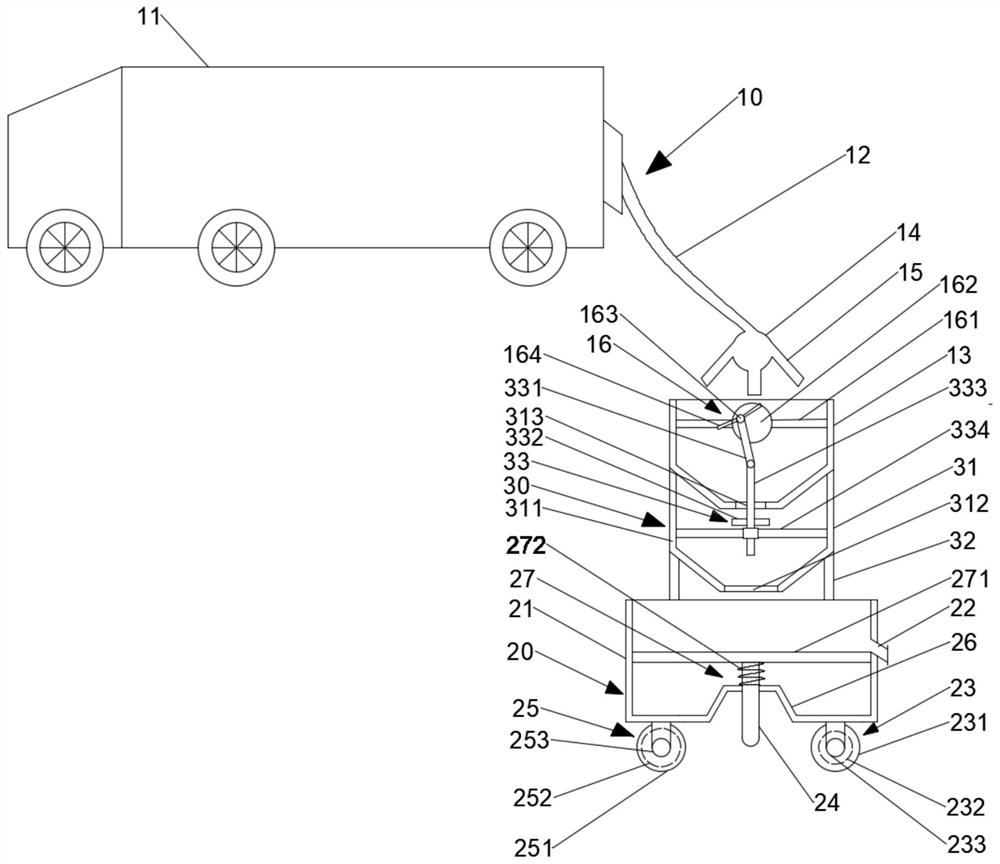

Whole concrete stirring and conveying work platform

PendingCN107498714AStir wellShort mixing timeDischarging apparatusMixing operation control apparatusWater useControl system

The invention relates to the technical field of concrete stirring and conveying, in particular to a whole concrete stirring and conveying work platform. The whole concrete stirring and conveying work platform comprises a rack, at least one conveying pump, at least one stirring device and a control system; the rack is provided with a first layer support and a second layer support; the stirring device is arranged on the second layer support, a feeding cylinder and a water supply system are arranged at the position corresponding to an inlet of the stirring device, and the water supply system can convey stirring water to the stirring device; a discharging hopper is arranged at the top of the first layer support, an inlet of the discharging hopper corresponds to a discharging opening of the stirring device, the conveying pump is arranged below the discharging hopper, and therefore concrete in the discharging hopper can flow into the conveying pump; the control system is connected with the stirring device, the conveying pump and the water supply system. According to the scheme, modular integration design is adopted, whole lifting can be achieved, grouting construction can be continuously achieved for a long time, smooth construction can be effectively ensured, manpower is saved, and construction efficiency is improved.

Owner:ZHEJIANG HUA YUN OFFSHORE ENG & TECH SERVICE CO LTD

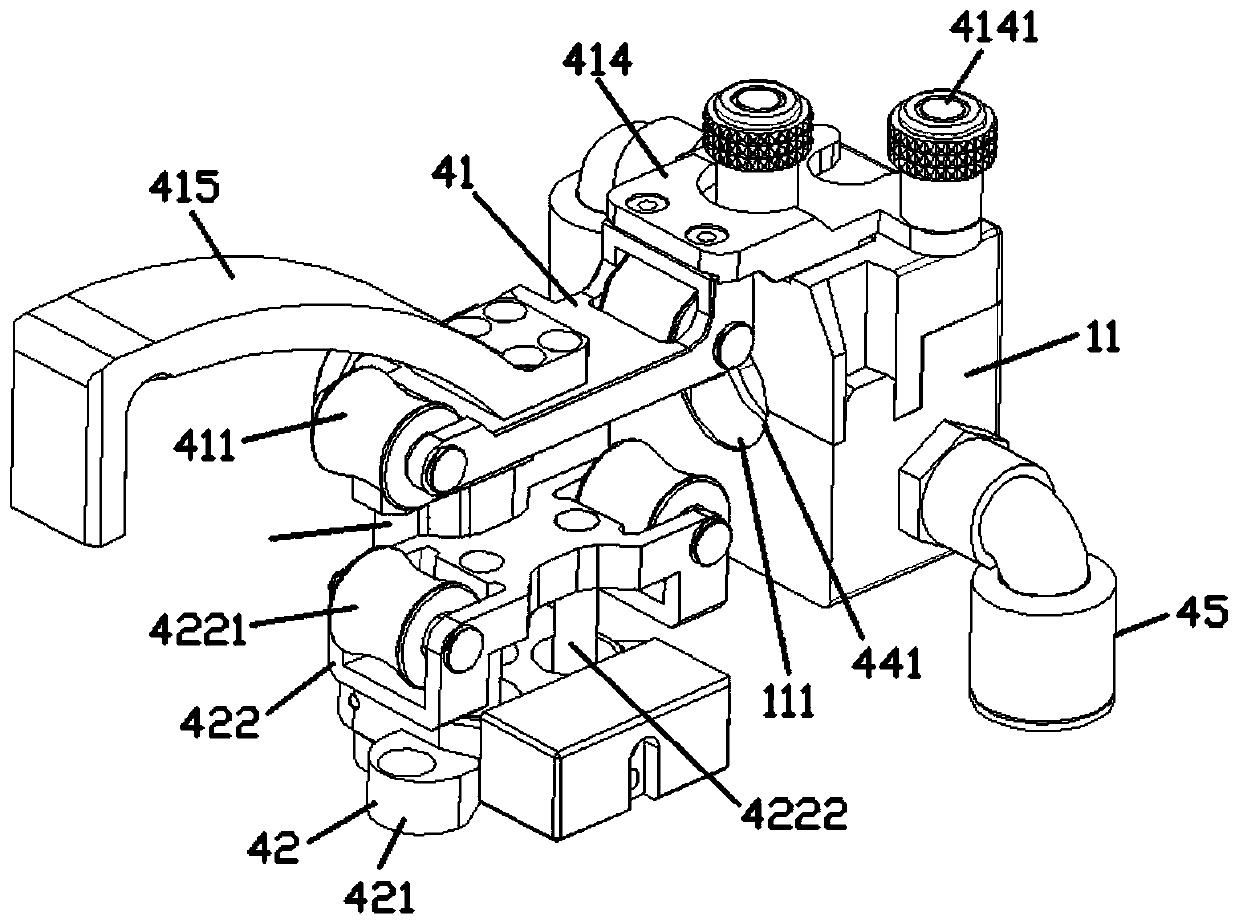

Overhead bare conducting wire insulating coating robot

PendingCN111463723AGuaranteed operating efficiencyGuaranteed benefitsApparatus for repairing insulation/armouring cablesMaterial resourcesElectrical and Electronics engineering

The invention discloses an overhead bare conducting wire insulating coating robot, which comprises an insulating coating module, an active driving assembly and a gluing module, wherein the active driving assembly comprises an active driving rack, winding shafts are hinged to the left side and the right side of the active driving rack respectively, the winding shafts are driven by a winding shaft driving device to rotate, gluing connecting parts are arranged on the left side and the right side of the gluing module correspondingly, and the winding shafts on the left side and the right side of the active driving rack are connected with the gluing connecting parts on the left side and the right side of the gluing module through connecting ropes correspondingly. In the embodiment of the invention, the whole overhead bare conducting wire insulating coating robot can be lifted to the height of the overhead bare conducting wire without other lifting equipment, so that the lifting process is simple and convenient, a large amount of manpower and material resources do not need to be consumed, the construction operation time is shortened, the construction cost is reduced, and the operation efficiency and economic benefits of overhead bare conducting wire insulating transformation are guaranteed.

Owner:安捷电维智能科技研究院(广州)有限公司

Simple punching device and construction method thereof

PendingCN108746760AEasy to operateImprove construction safetyWork benchesPortable drilling machinesPunchingFloor slab

The invention relates to a simple punching device and a construction method thereof. The simple punching device and the construction method thereof are used for solving the problems that during structural construction, the top of a floor slab needs to be drilled to allow steel bars to be buried or expansion bolts to be mounted, when the floor is high, operation can be conducted with the help of ascending equipment, and consequently the operation difficulty is increased. The simple punching device provided by the invention comprises a longitudinal supporting rod and a rotating lever movably connected with the middle of the longitudinal supporting rod through rotating buttons; the rotating lever can radially rotate with the rotating buttons of the longitudinal supporting rod as a pivot; a mounting component is arranged at one end of the rotating lever, and a handle is arranged at the other end of the rotating lever; and a base is arranged at the bottom end of the longitudinal supportingrod, and the mounting component is used for being fixedly connected with drilling equipment. The construction method comprises the steps that first, the simple punching device provided with the drilling equipment is moved to a construction site and powered on; and second, the construction site is determine, a power switch of the drilling equipment is turned on, the rotating lever is rotated to slowly lift the drilling equipment to the construction site, and drilling operation can be conducted.

Owner:SHANGHAI NO 7 CONSTR

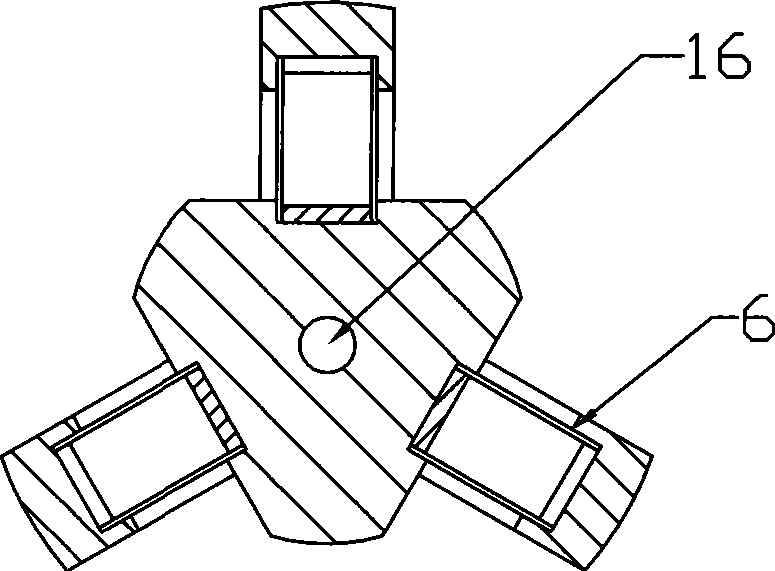

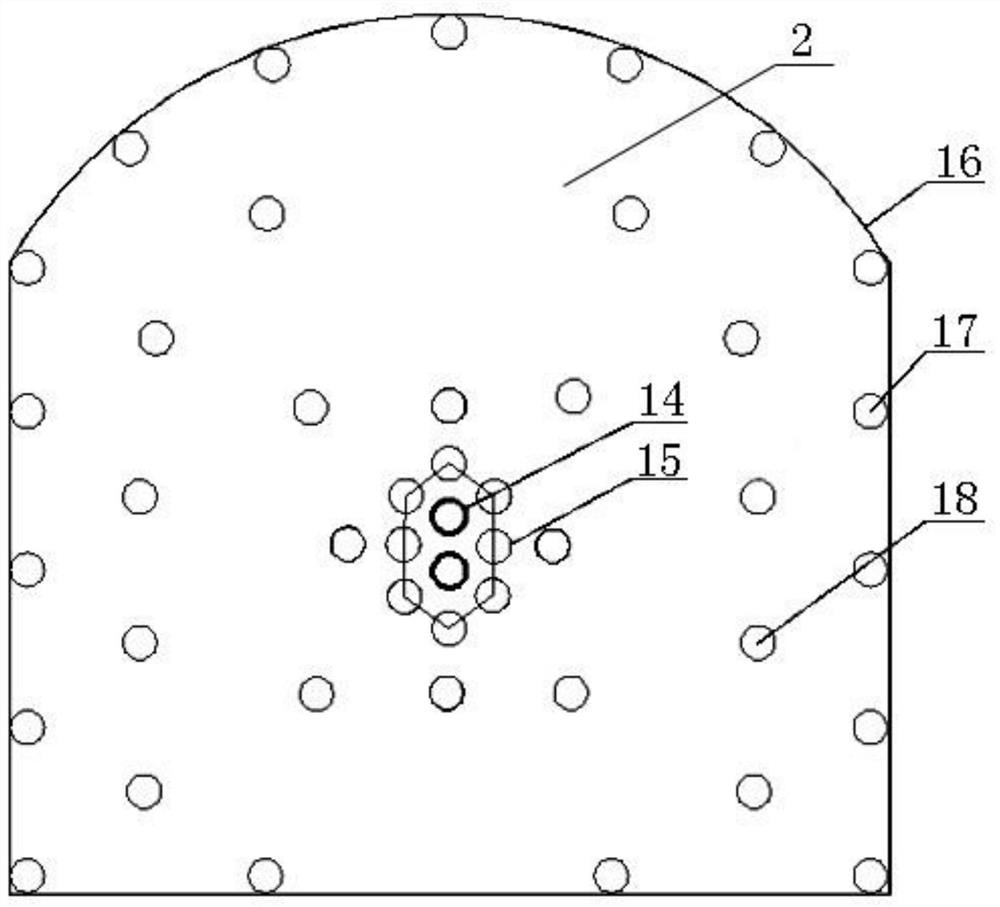

Rotary type fracture sand jet and multistage sand jetting and fracturing process

ActiveCN106121610AThe rotation angle is easy to controlGuaranteed hierarchical managementFluid removalType fractureAbrasive blasting

The invention relates to a rotary type fracture sand jet and a multistage sand jetting and fracturing process. The rotary type fracture sand jet is structurally characterized in that an upper connector and a lower connector are connected with the two ends of the fracture sand jet; a rotary type slide sleeve inner core is arranged on the inner circumference of the fracture sand jet; a plurality of shear pin grooves are formed in the middle of the surface of the outer circumference of the rotary type slide sleeve inner core; a plurality of spring type extensible shear pin assemblies are arranged on a fracture sand jet body, and one spring type extensible shear pin assembly falls into the corresponding shear pin groove; a rotary control mechanism is arranged at the end, close to the upper connector, of the rotary type slide sleeve inner core; rotary sand jetting holes distributed evenly and circumferentially are formed in the end, close to the lower connector, of the rotary type slide sleeve inner core; outer sand jetting holes distributed evenly and circumferentially are formed in the fracture sand jet body; and the outer sand jetting holes correspond to the rotary sand jetting holes in position. A rotary opening type is adopted for the fracture sand jet. In the construction process, the opening process is stable and reliable, and construction can be conducted independently for a layer section; and after construction, a slide sleeve of the constructed layer section can be closed, and layered sand jetting management can be effectively conducted for the stratum.

Owner:铁岭曲氏石油技术开发服务有限公司

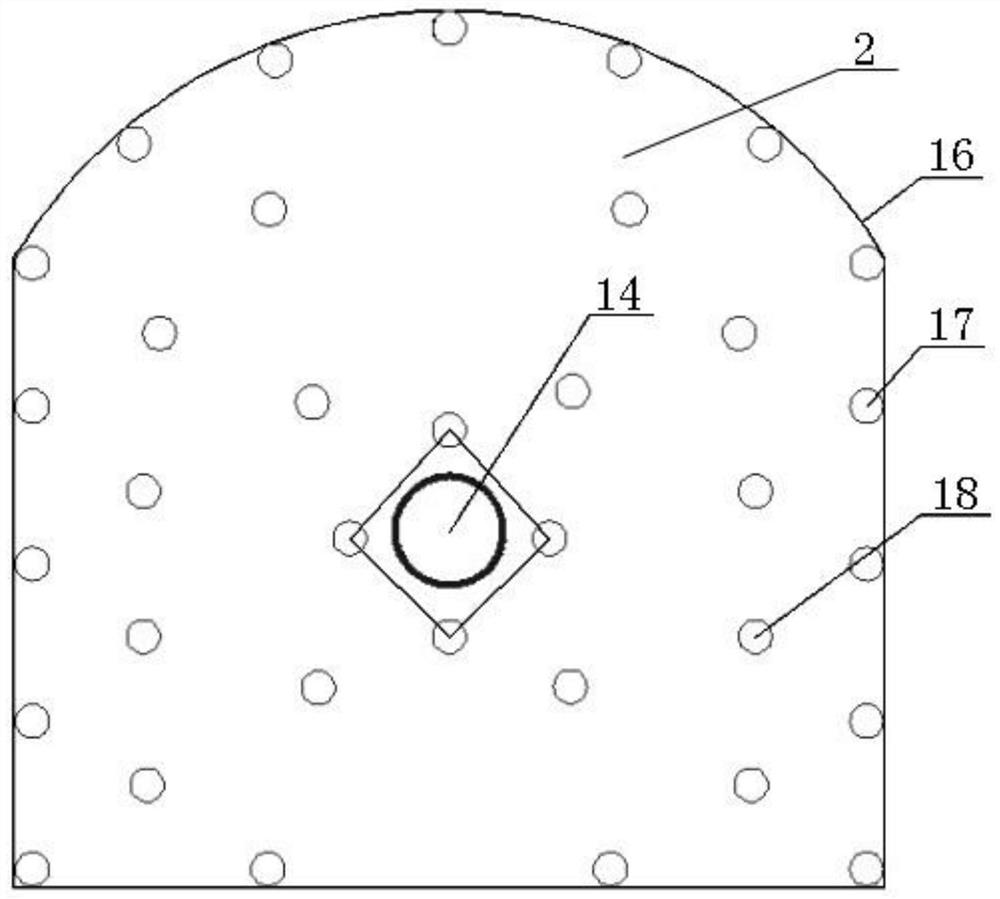

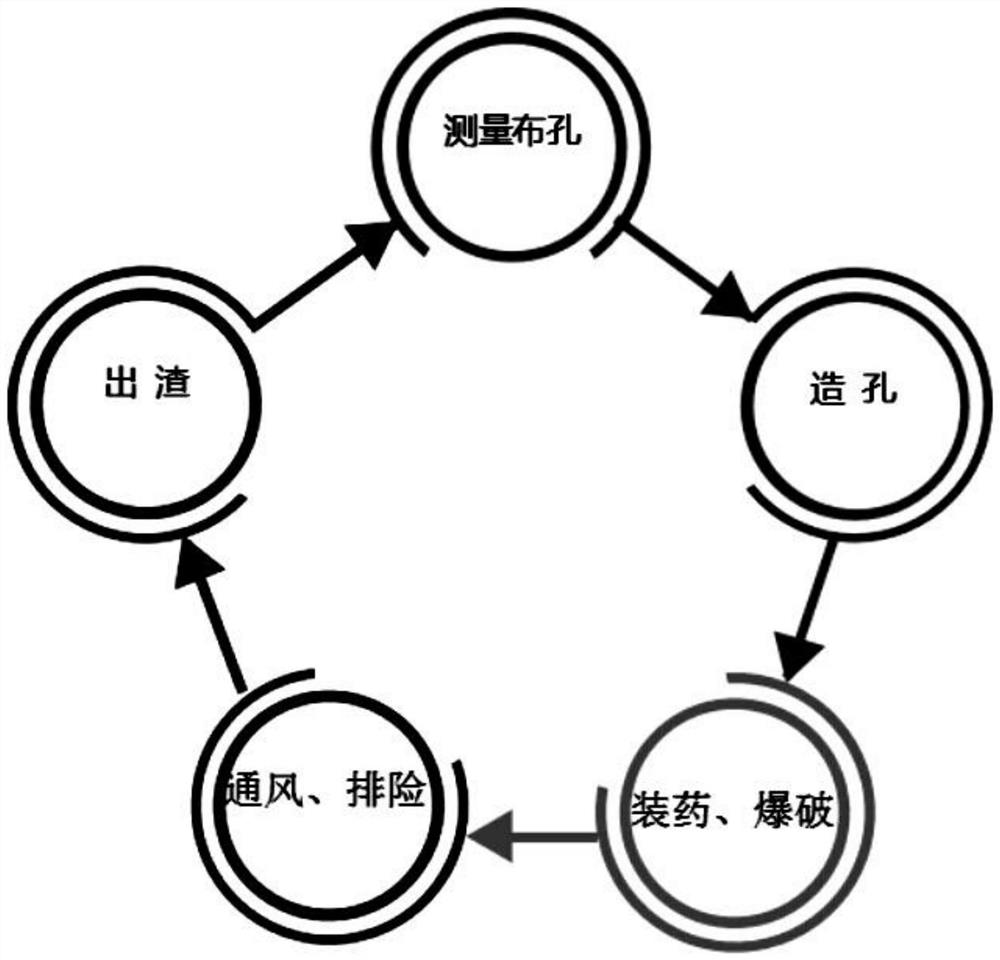

Hydraulic tunnel drilling trolley excavation construction method and device

PendingCN113338979ASolving the problem of complex look-ahead detectionSolve the problem of complex and advanced detection of tunnel geological conditionsTunnelsDrilling machinesDrill hole

The invention discloses a hydraulic tunnel drilling trolley excavation construction method and device. According to the method, a simple down-the-hole drill trolley combining a down-the-hole drill and a vehicle is used for drilling advanced geological forecast holes, and the advanced geological forecast holes are used as central cut holes. The device comprises the vehicle and the down-the-hole drill installed at the position of a container of the vehicle, and the down-the-hole drill is connected to the vehicle through a drilling machine platform; the drilling machine platform is provided with a supporting base used for supporting and controlling the drilling direction of a drill rod of the down-the-hole drill; and the down-the-hole drill is connected with the drilling machine platform through a connecting plate and a fastening bolt. The tunnel drilling trolley (the simple down-the-hole drill trolley) combining the down-the-hole drill and the vehicle is used for drilling the advanced geological forecast holes, the problem of complex tunnel geological conditions for advanced detection is solved, the advanced geological forecast holes are used as the central cut holes, drilling and chemical use of the cut holes are reduced, and the tunnel single-wheel circulation footage length is increased.

Owner:贵州水利实业有限公司

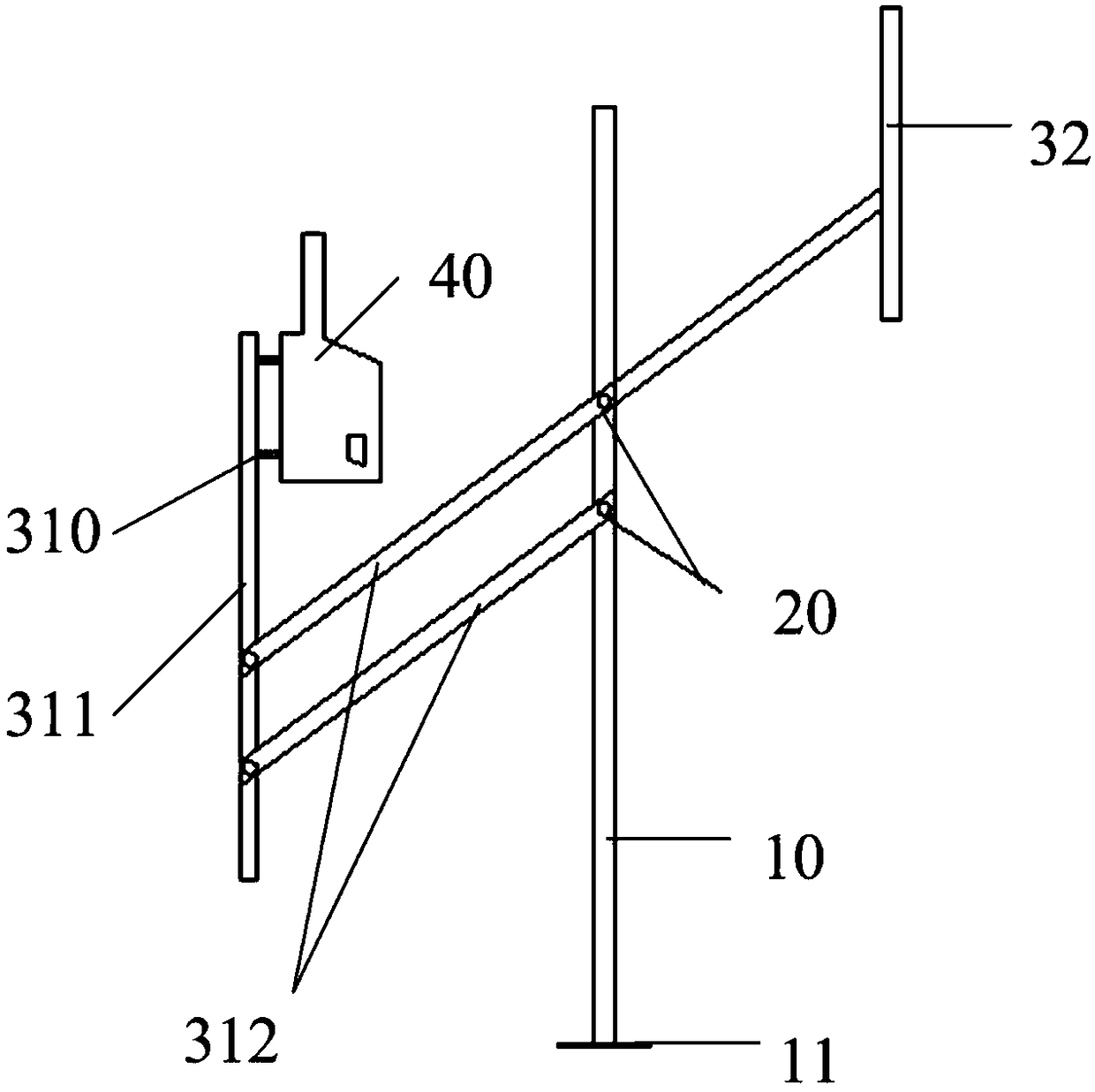

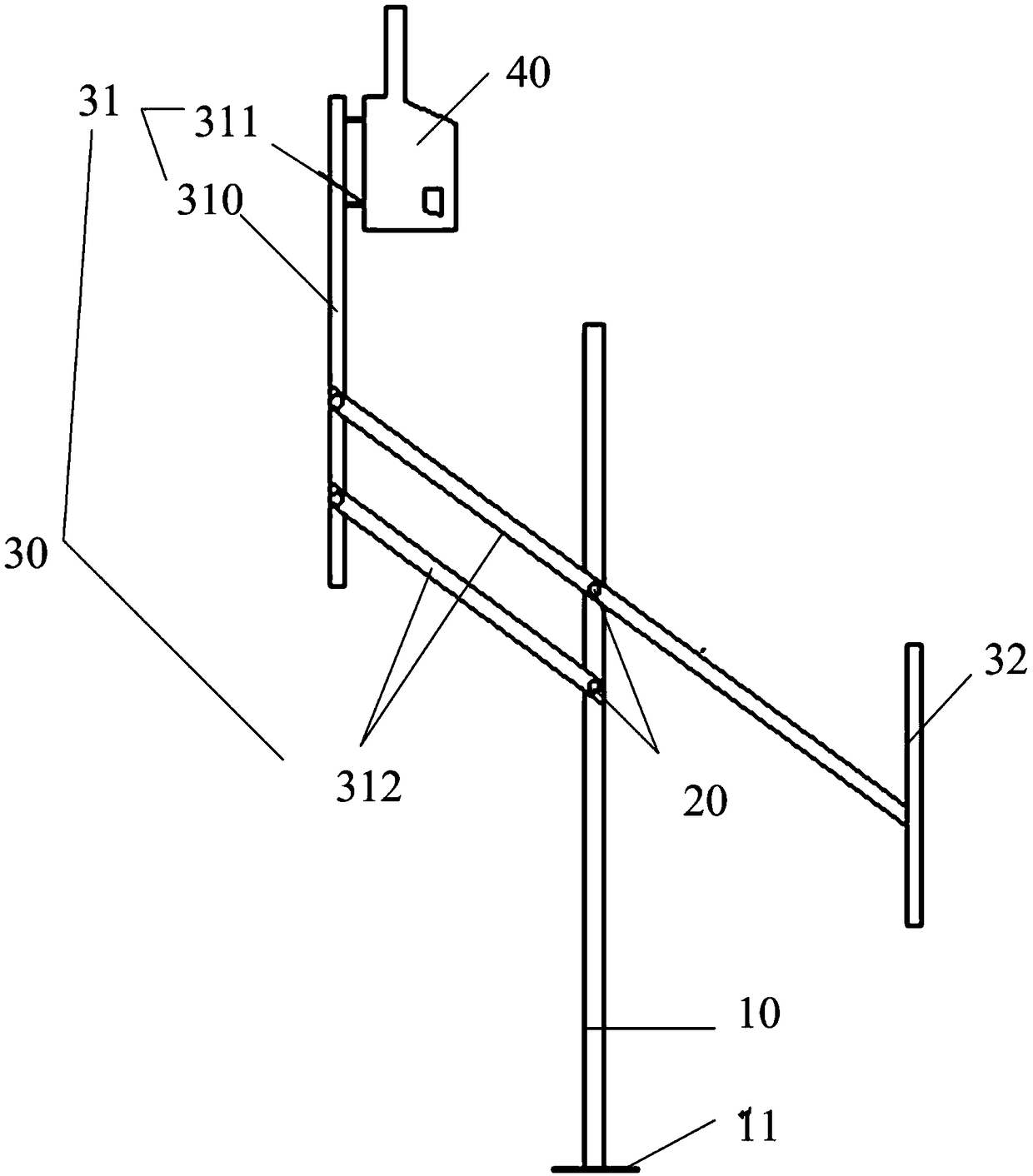

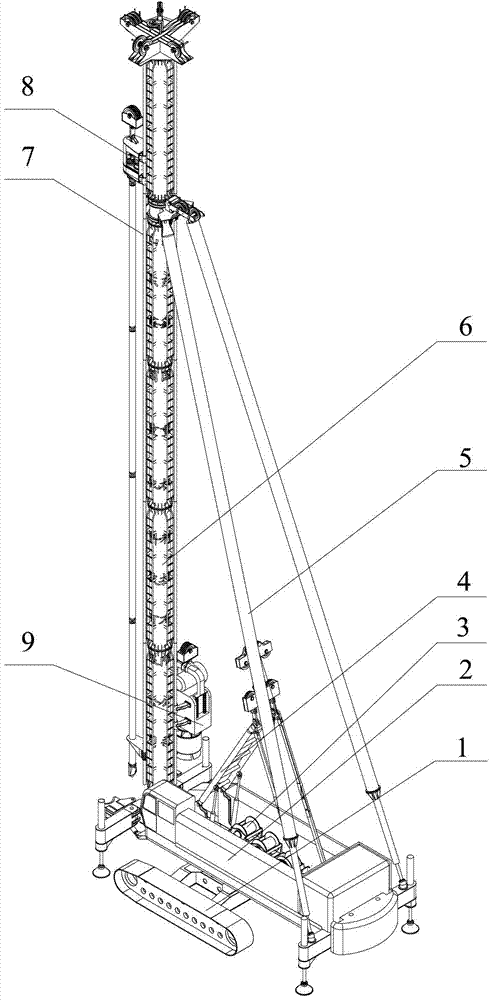

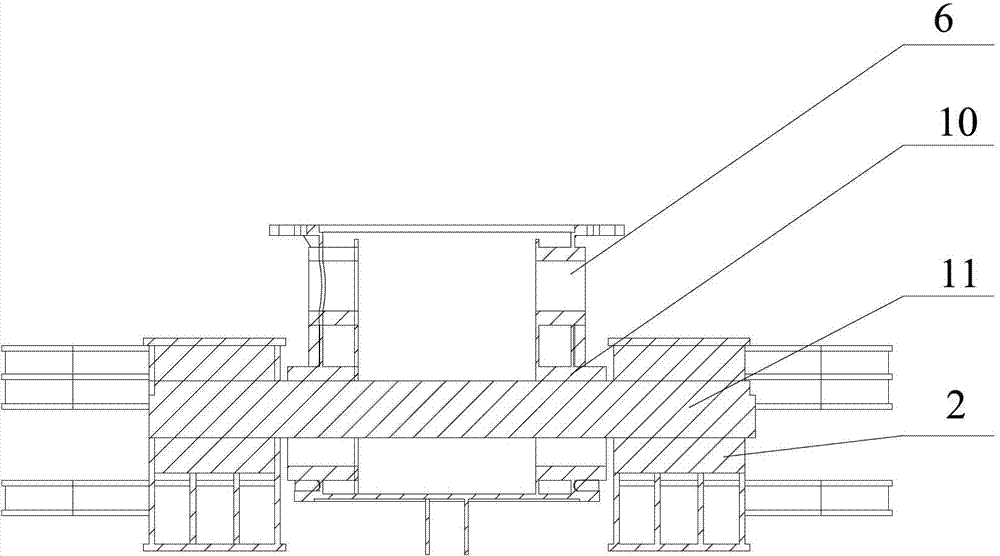

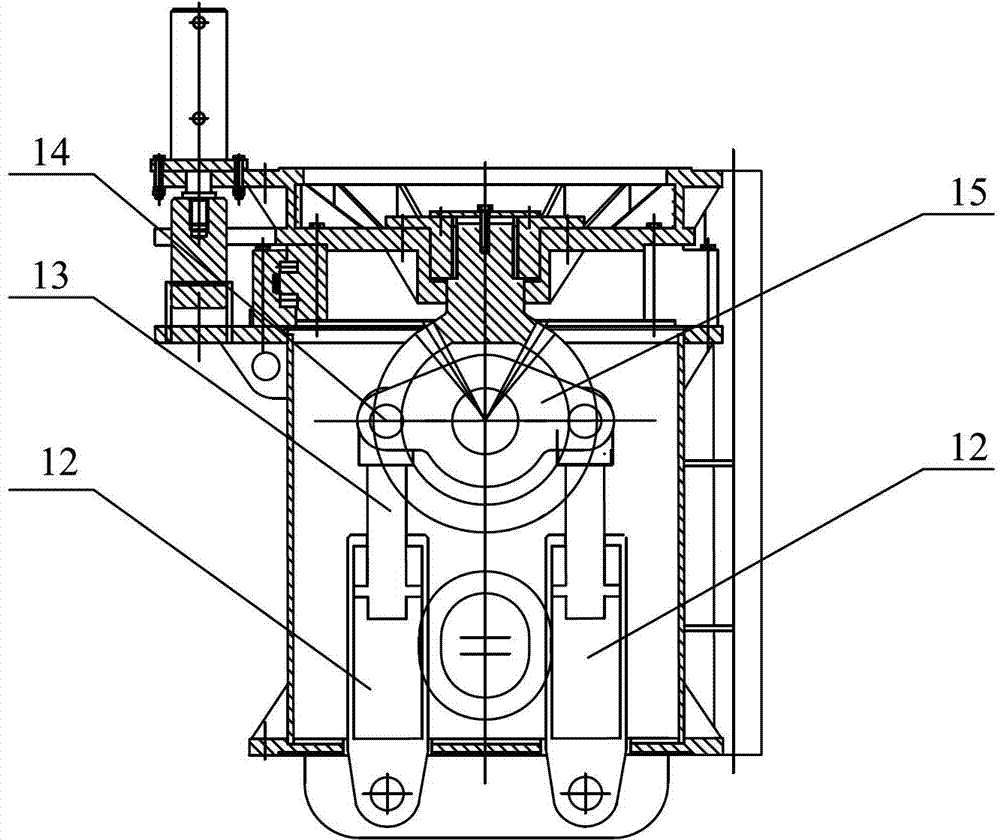

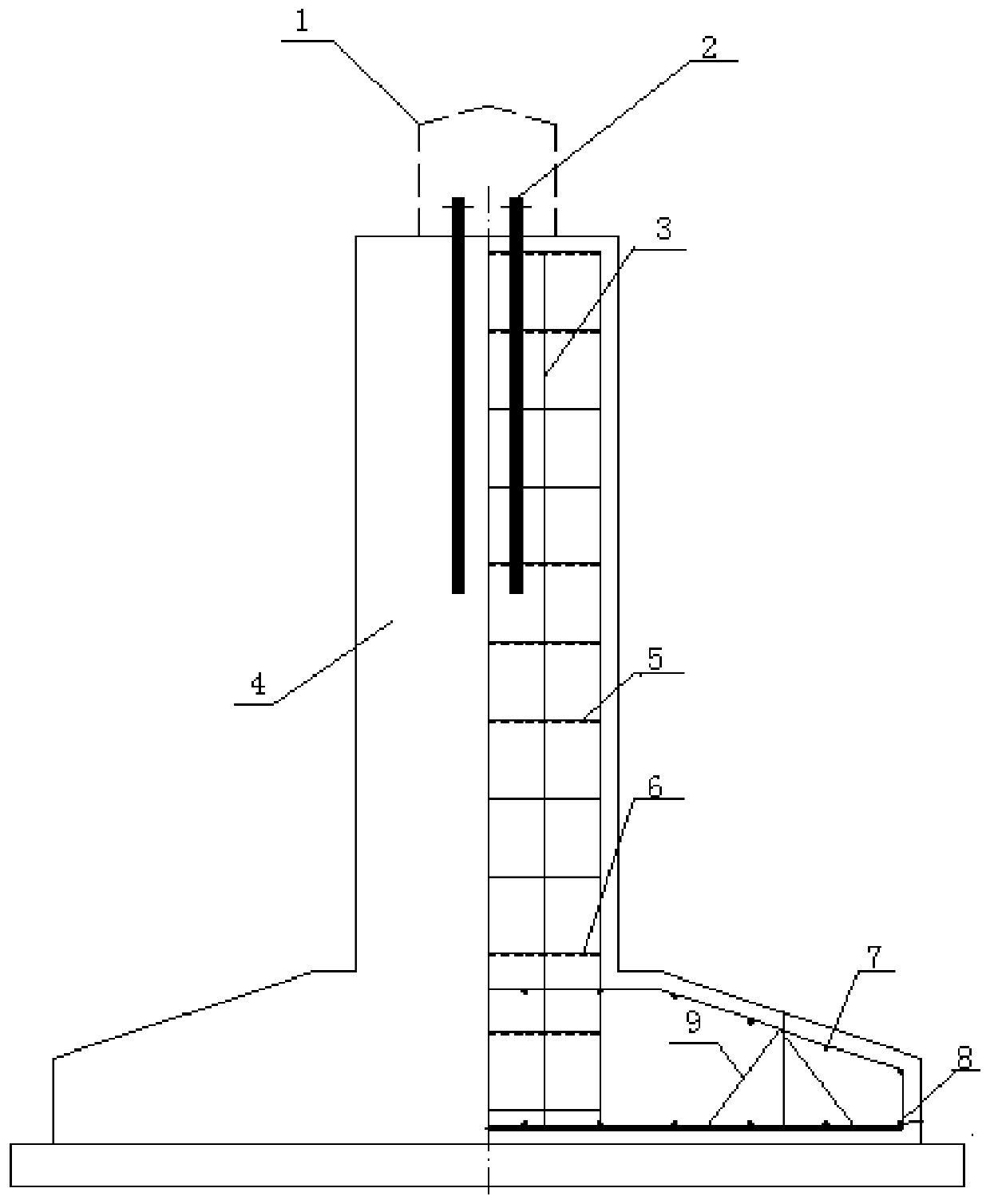

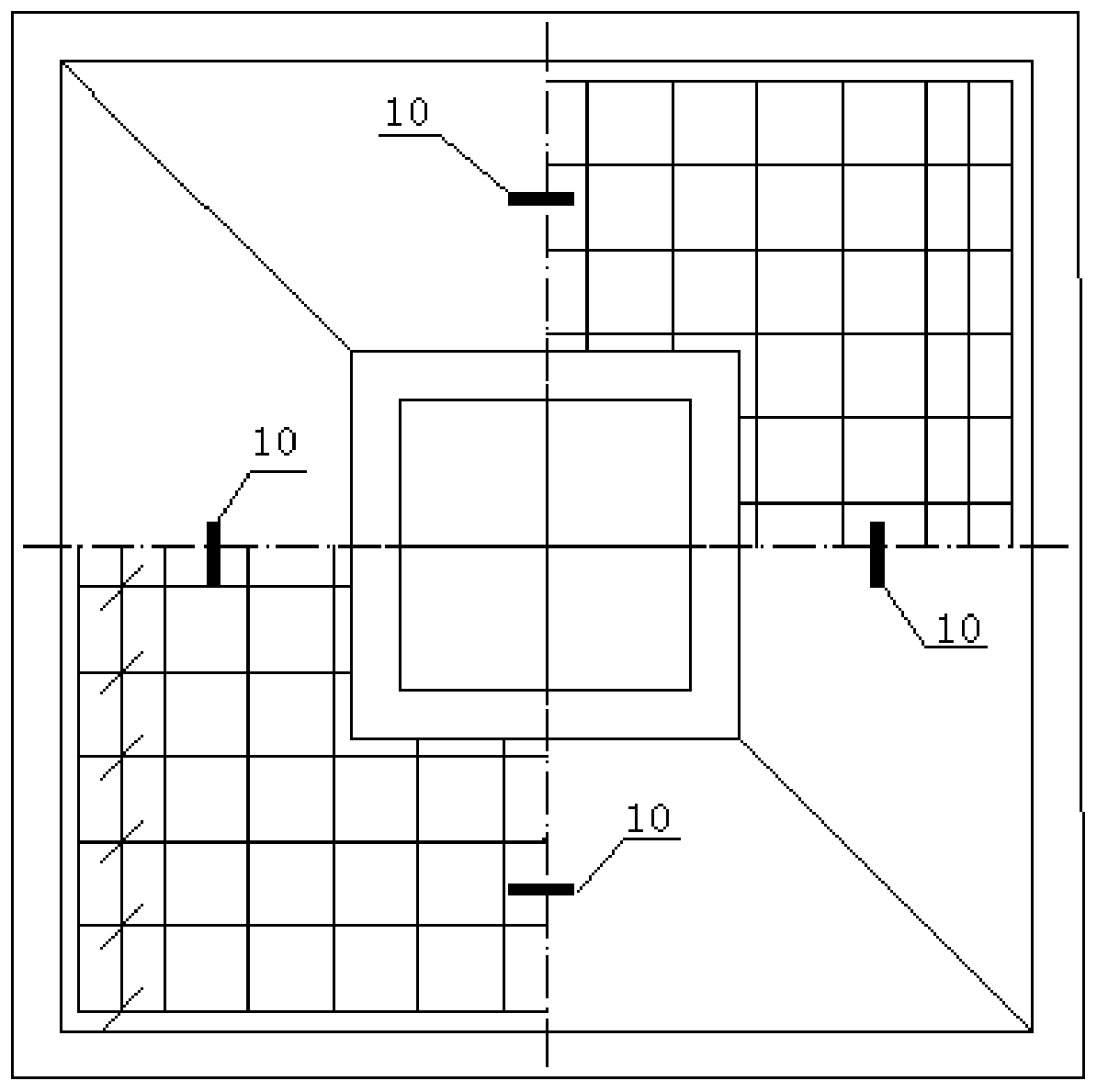

Multifunctional piling machine with rotary vertical shaft

InactiveCN102787598AReduce construction work timeAchieve multi-functionBulkheads/pilesFoundation engineeringEngineering

The invention relates to a multifunctional piling machine with a rotary vertical shaft and belongs to the field of foundation engineering construction equipment. The multifunctional piling machine with the rotary vertical shaft comprises a travelling mechanism, a piling machine underpan, a hydraulic work station, a lifting frame mechanism, an inclined strut, an upright post and two different working devices; the piling machine underpan is arranged on the travelling mechanism; the hydraulic work station, the lifting frame mechanism and the inclined strut on the piling machine underpan are connected with the upright post; and the multifunctional piling machine is characterized in that the upright post is a rotary upright post connected with the piling machine underpan. The upright post is the rotary upright post and provided with two vertical slide ways with a horizontal included angle of 90 DEG, and different pile work machine tools are hung on the two vertical slide ways so that the piling machine has multiple functions. The piling machine can perform two engineering construction works simultaneously after being located just in one time. The centers of the two construction works are kept to coincide, the time spent on the two construction works is greatly shortened, and meanwhile, the problems of single function, poor compatibility and interchangeability, poor working stability of a pile frame, low working efficiency and inconvenience for transportation in the traditional piling machines are solved.

Owner:山东鑫国重机科技有限公司

Low-clearance adjustable suspension wire clamp

PendingCN112193128AMeet the installation requirementsReduce the height of the structureTrolley linesEngineeringScrew thread

A low-clearance adjustable suspension wire clamp comprises a connecting base and a busbar wire clamp. Double lugs are arranged on the upper end face of the connecting base, and a strip-shaped hole inthe line direction is formed between the double lugs; the upper end of an internal thread bushing is hinged between the two lugs, the lower end of the internal thread bushing is inserted into the strip-shaped hole, and the internal thread bushing can swing back and forth in the strip-shaped hole around a hinge point; the upper end of an external thread adjusting shaft is in threaded connection with the internal thread sleeve, the lower end of the external thread adjusting shaft is hinged to the busbar wire clamp, and the busbar wire clamp is hung below the connecting base and can horizontallyrotate around the external thread adjusting shaft. The swinging hinge point is moved upwards, the height of the whole structure is reduced, the use requirement of low-clearance tunnel installation ismet, and installation and adjustment are convenient.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD +1

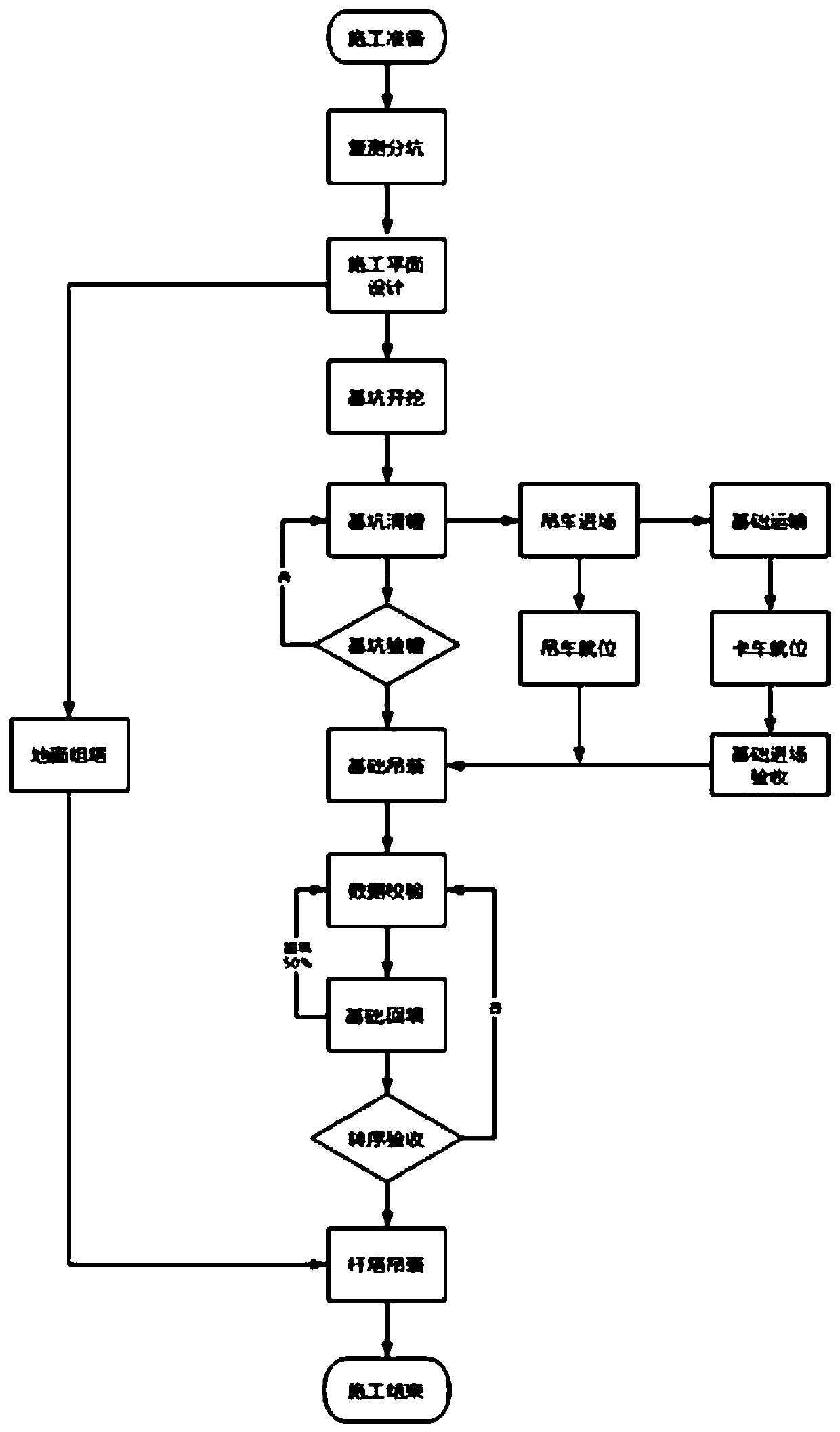

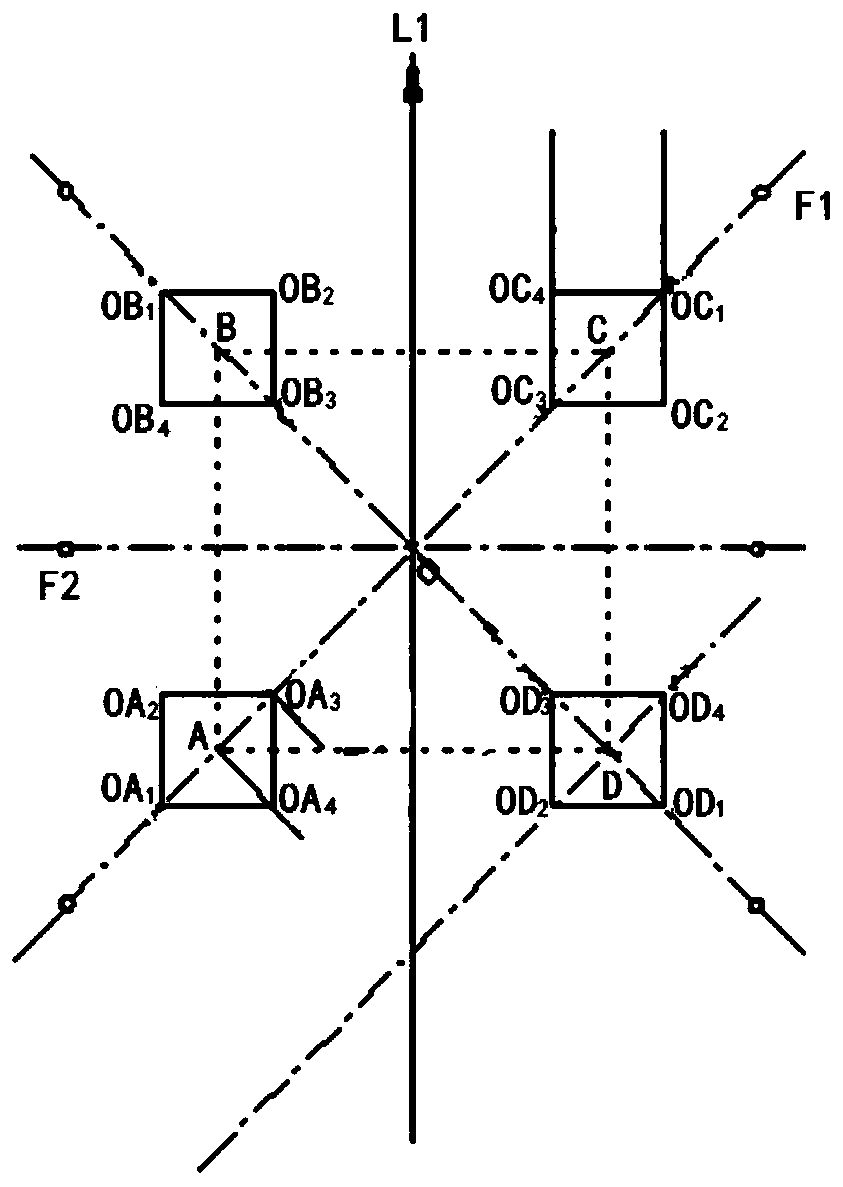

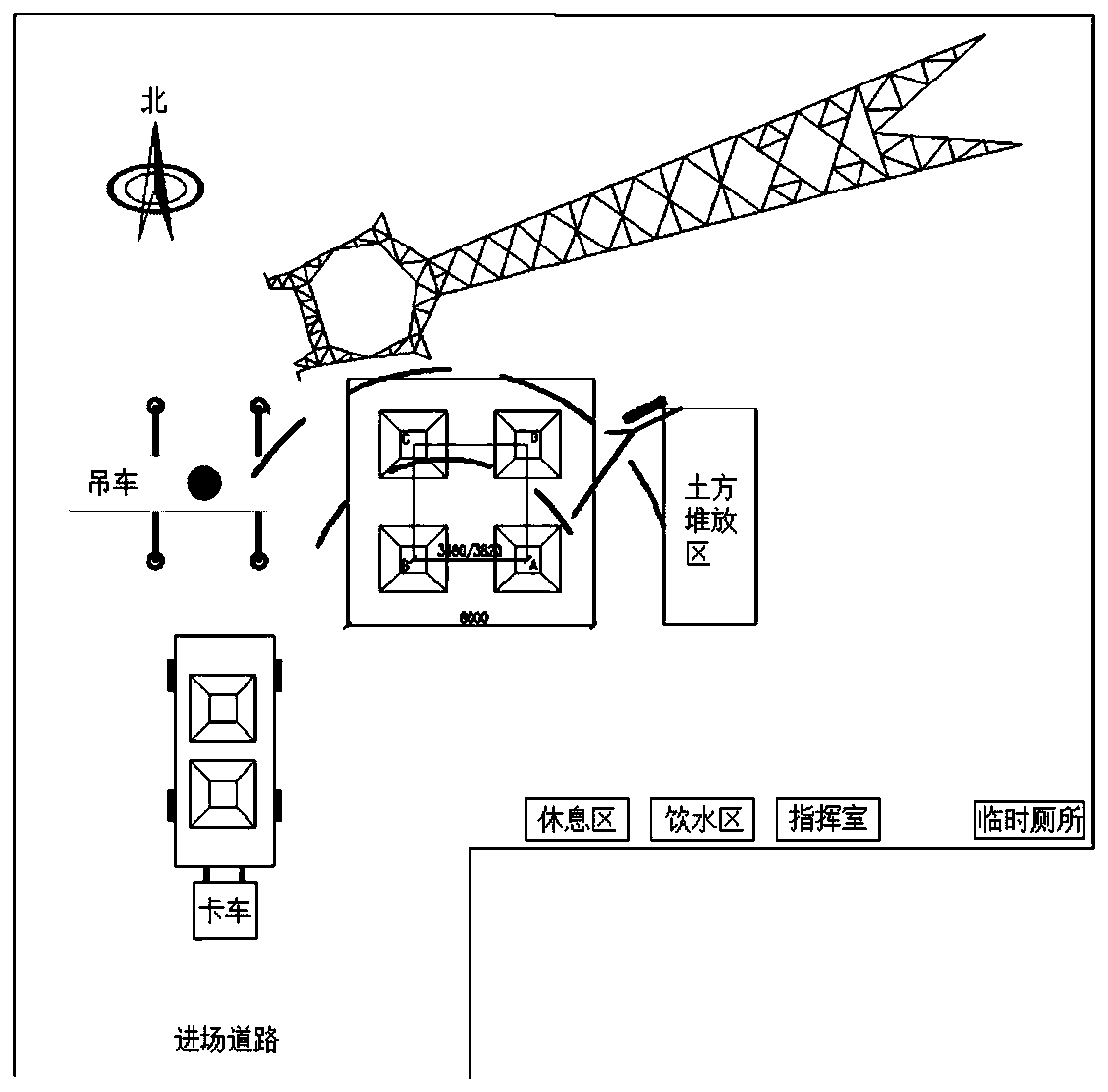

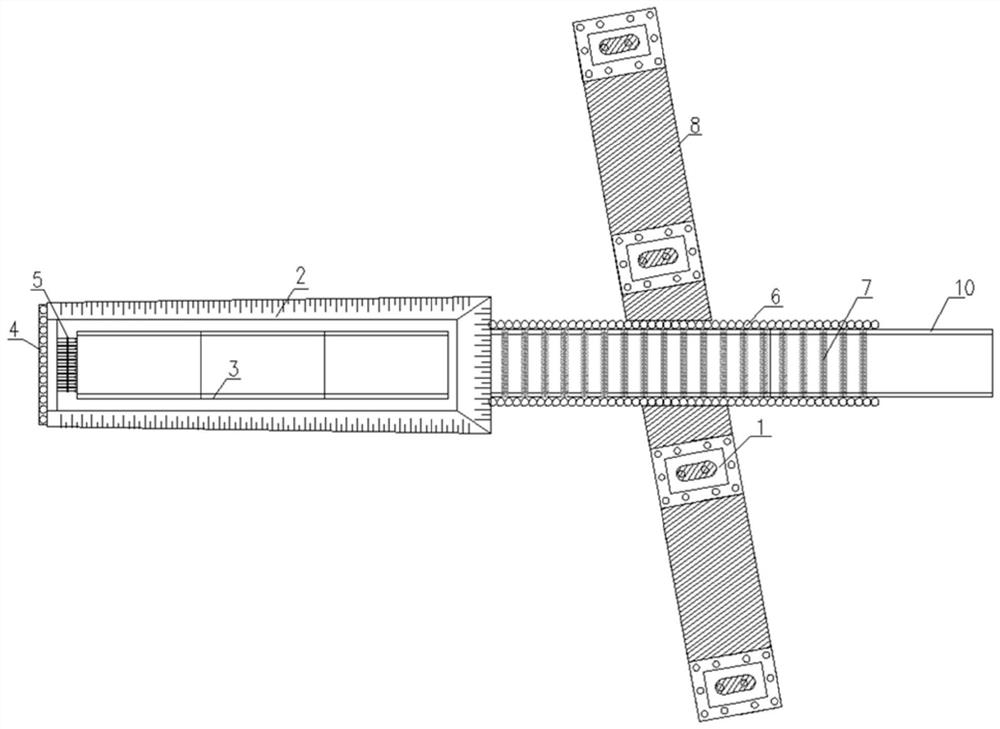

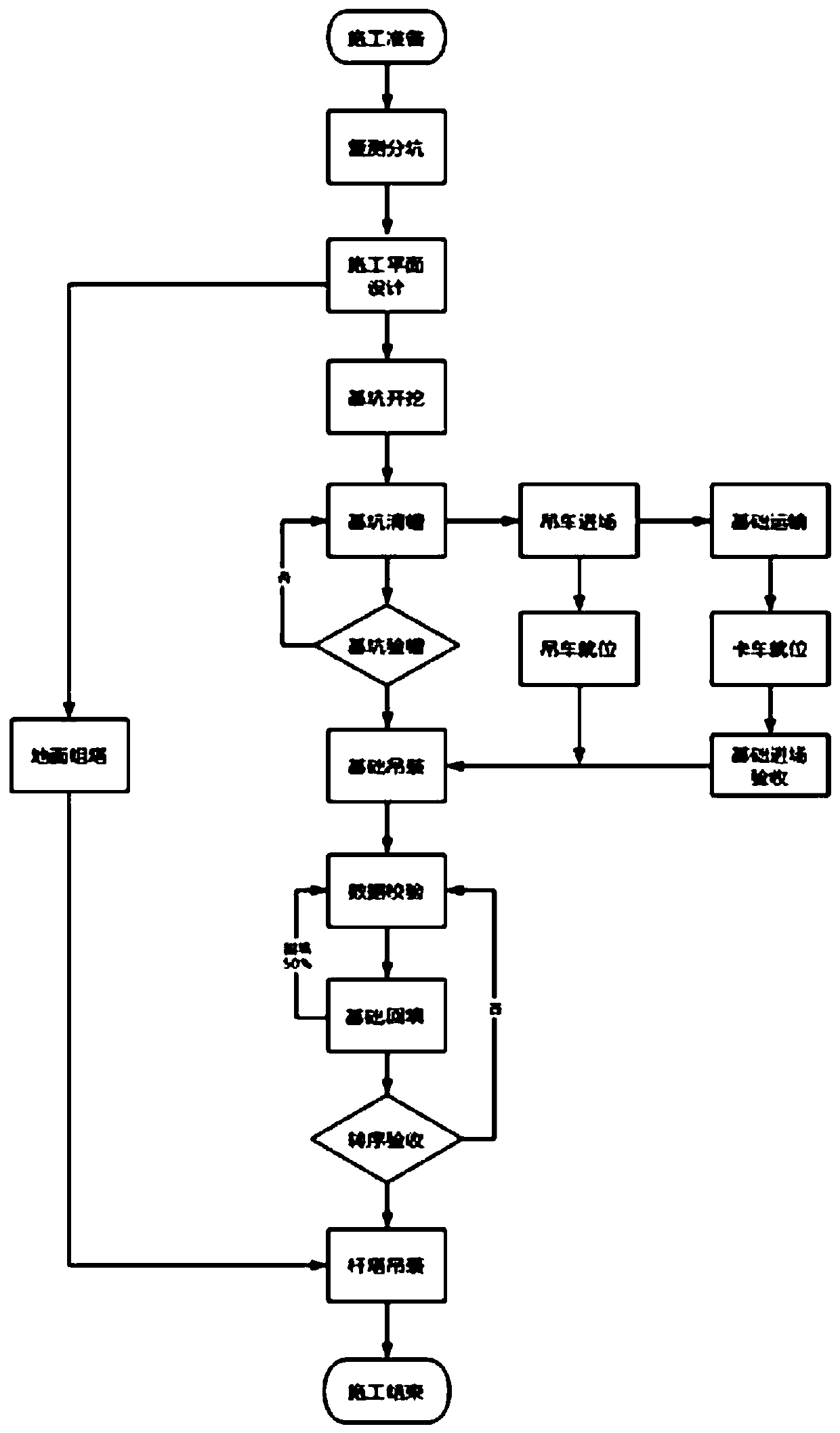

Power transmission project prefabricated foundation installation and iron tower assembly coherent construction method

InactiveCN111485573AImprove construction efficiencyShort construction periodFoundation testingTowersArchitectural engineeringEconomic benefits

The invention discloses a power transmission project prefabricated foundation installation and iron tower assembly coherent construction method which includes the following steps of re-measurement andpit dividing, construction plane design, ground tower assembly, foundation pit excavation, foundation backfill, process changing acceptance and overall tower erection. Through the technical scheme, aconstruction process of "foundation construction first, then tower assembly on the ground" in the prior art is adjusted to " tower assembly first, then foundation construction", the on-site development of a flow process mode of "personnel flow with machinery, continuous machinery operation and process close connection" is facilitated, the close connection of ten processes of "on-site re-measurement, pit dividing positioning, construction plane design, ground tower assembly, foundation pit excavation, prefabricated foundation transportation and installation, grounding installation, foundationbackfilling and compaction, process changing acceptance and overall tower erection" can be realized, the overall construction efficiency of the line foundation and the iron group assembly is improved,the construction period is shortened and controllable, the fully mechanized construction of the line engineering is realized, the economic benefits are significant, and the safety risks are reduced.

Owner:衡水衡源电力建设有限责任公司

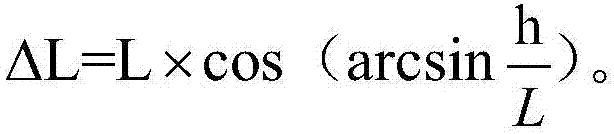

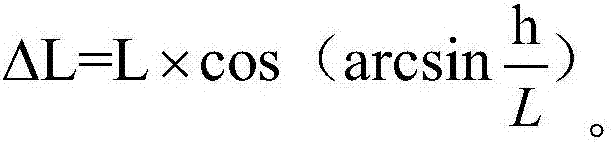

Method for controlling bridge deformation in engineering of underneath passing high-speed railway bridge on road

PendingCN113089464AControl deformation valueEffective control of deformation valueBridge structural detailsBridge erection/assemblyArchitectural engineeringJackscrew

The invention provides a method for controlling bridge deformation in a road underneath pass high-speed rail bridge project. The method comprises the steps: calculating the lengths of U-shaped grooves in a lower jacking section and a cast-in-place section of an existing high-speed rail bridge, the distance between a foundation pit and the existing high-speed rail bridge and the number and length of underground road protection piles on the two sides of the U-shaped grooves in the underneath pass range of the existing high-speed rail bridge; excavating a foundation pit in a layered mode, prefabricating a jacking section U-shaped groove structure, arranging a temporary U-shaped groove jacking rigid frame on the jacking section U-shaped groove structure, constructing a back pile, and installing a jack jacking system; while the foundation pit is excavated, constructing road protection piles; solidifying soil under a bottom plate of the U-shaped groove structure of the jacking section; gradually jacking the jacking section U-shaped groove in the direction of the existing high-speed railway bridge along the designed gradient, and excavating a soil body at the front end of the jacking section U-shaped groove while jacking is conducted; in the jacking process, dynamically controlling the ballasting measures; after the U-shaped groove of the jacking section is in place, constructing the U-shaped groove of the cast-in-place section; and gradually reducing the weight. The bridge pier abutment top deformation can be controlled to meet the new regulation requirement.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

Tool fixture for drilling and tapping

InactiveCN104999300AEasy drilling operationAvoid replacementWork clamping meansPositioning apparatusCircular discQuality of work

The invention relates to a tool fixture for drilling and tapping. The tool fixture comprises a disk, a connecting block, a connecting shaft, a rotary plate and a clamped connector, wherein a first positioning hole and a second positioning hole are formed in the surface of the disk, and a first cutting hole is formed in the center of the disk; a fixing hole is formed in the right side of the first cutting hole, and a second cutting hole is formed behind the first cutting hole; the connecting block is connected with the disk, and a threaded hole is formed in the center of the connecting block; an external thread is arranged on the left side of the connecting shaft, and the connecting shaft is in mesh connection with the threaded hole in the center of the connecting block; the rotary plate is connected with the connecting shaft, and a spring is arranged in the connecting shaft; one end of the spring is connected to the bottom of the connecting shaft, and the other end of the spring is connected with the clamped connector. The tool fixture is convenient for a user to drill or tap, the working efficiency of constructors is effectively improved, the working quality of the constructors is greatly increased, and the working time of the constructors is effectively saved.

Owner:SFAM SCI & TECH JIANGSU

Contact pipeline well used on inclined ore and construction method of contact pipeline well

InactiveCN107461208AReduce construction work timeImprove construction efficiencyTunnelsInternal stressPollution

The invention relates to a contact pipeline well used on an inclined ore and a construction method of the contact pipeline well. The contact pipeline well comprises an upper end driftway, a lower end driftway, a vertical pore channel and a lower end pore channel, one end of the vertical pore channel communicates with the upper end driftway, the other end of the vertical pore channel communicates with one end of the lower end pore channel, and the other end of the lower end pore channel communicates with a lower end driftway; and the construction method comprises the steps that a raise-boring machine is utilized to drill the vertical pore channel and a full-hydraulic trackless drill jambo is utilized to drill horizontal pore channels. By adopting the technical scheme of the contact pipeline well used on the inclined ore and the construction method of contact pipeline well, the pipeline well is not parallel to the side face of a slope of the ore body while being composed of the vertical pore channel and the multiple horizontal pore channels, the work such as explosive filling and blasting do not need to be conducted on the ore body in the construction technology, so that the construction technology is simplified, the damage to internal stress balance of the ore body and pollution to the environment are avoided, and the construction working efficiency of the pipeline well is improved.

Owner:贵州开磷有限责任公司

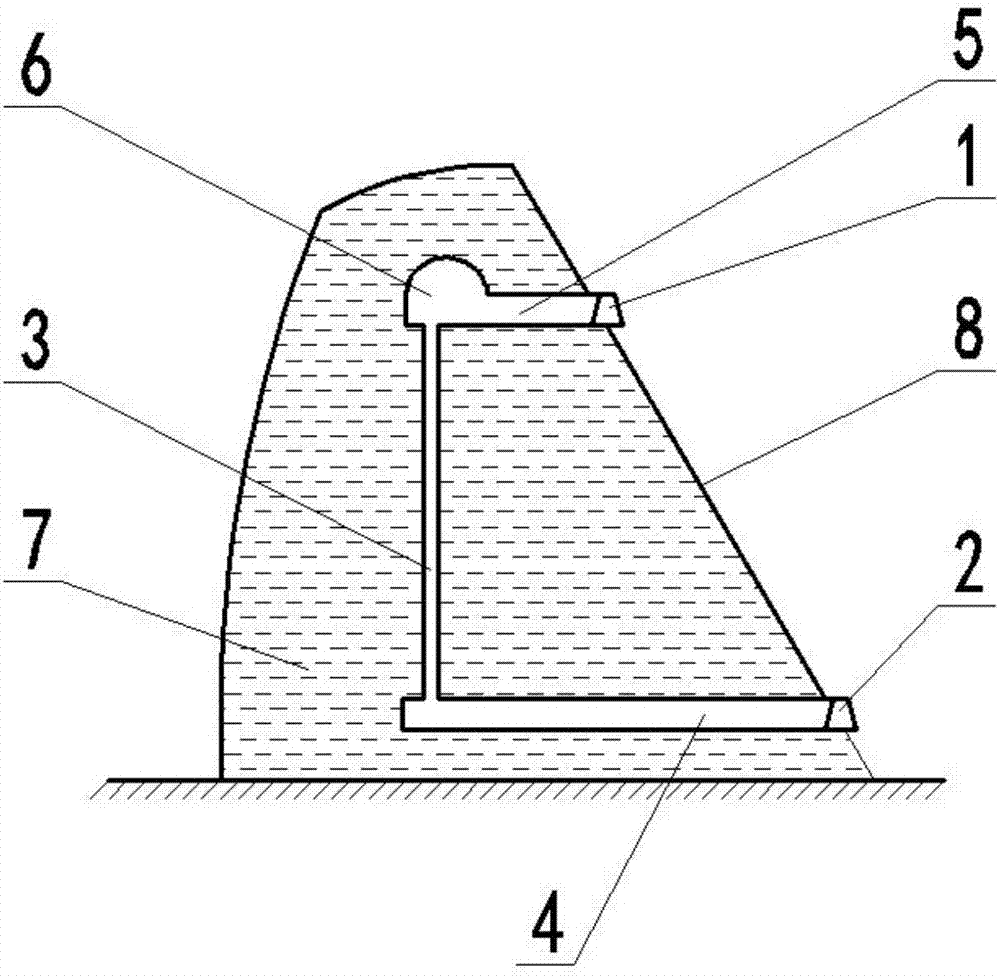

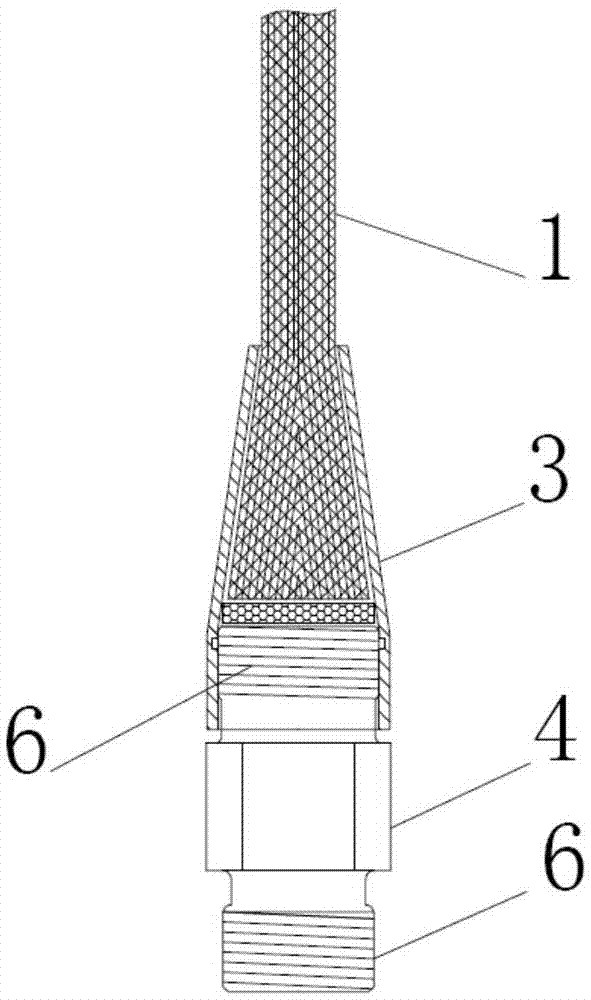

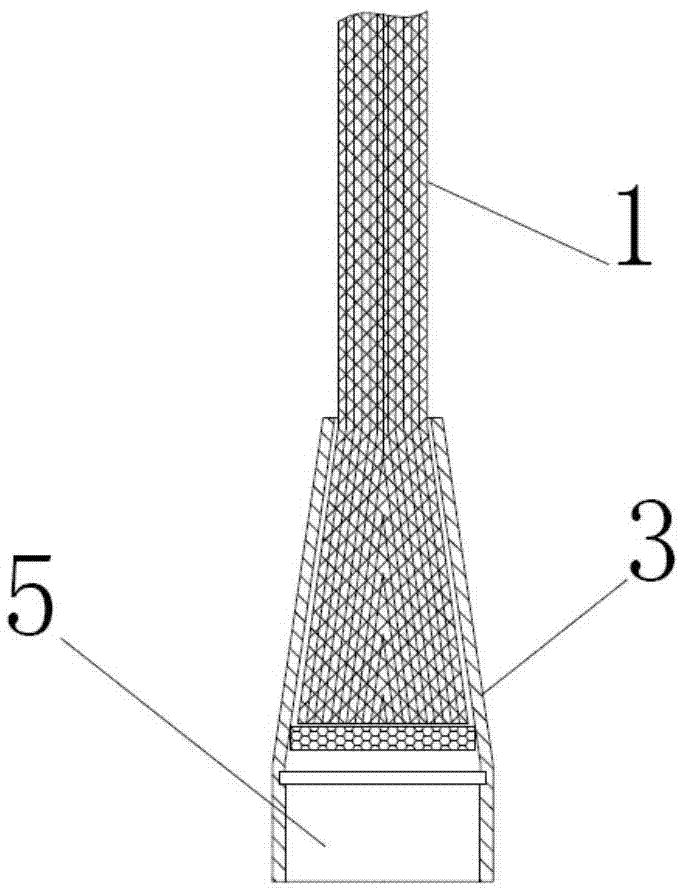

Prefabricated foundation for power transmission engineering

InactiveCN111395382AAvoid pollutionQuality improvementFoundation engineeringArchitectural engineeringTower

The invention discloses a prefabricated foundation for power transmission engineering. The prefabricated foundation comprises a foundation upright post and a foundation base. The foundation upright post is arranged on the foundation base and is provided with a foundation main rib and a foundation bolt, and the upper end of the foundation bolt is exposed out of the upper surface of the foundation upright post and is used for being connected with an iron tower; and the foundation base is provided with a lifting ring, and the ring part of the lifting ring is exposed out of the upper surface of the foundation base to be connected with a crane through a connecting piece. The foundation for power transmission engineering is designed as the prefabricated foundation, so that the manufacture of a concrete foundation is completed in advance in a factory, formwork erection, casting and curing are carried out in a centralized mode, the process control and curing environment can be controlled strictly, the cost can be saved to a great extent, the quality of a foundation finished product can be improved, the curing period can be shortened by 28 days, meanwhile, the construction operation time onsite can be reduced by 80%, and personnel can be prevented from getting up and down a foundation pit; and the safety risk of personnel working in the foundation pit is avoided, the pollution of concrete to the environment is avoided, the mechanization degree of a construction site is improved, and the construction period is controllable. In addition, the prefabricated foundation is convenient totransport and install.

Owner:衡水衡源电力建设有限责任公司

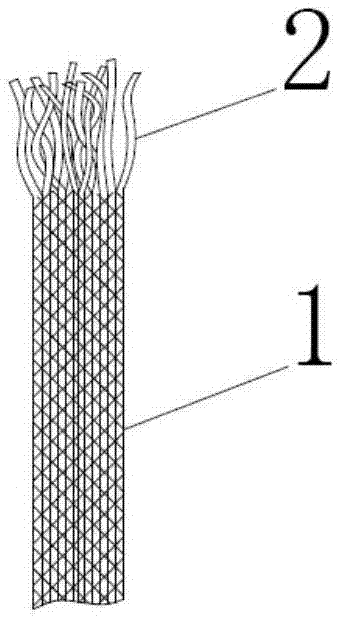

Flexible continuous sucker rod made of synthetic fiber

ActiveCN105443046AHigh tensile strengthHigh elastic modulusDrilling rodsDrilling casingsEngineeringUltimate tensile strength

The invention provides a flexible continuous sucker rod made of synthetic fiber and relates to the technical field of oil exploitation. The flexible continuous sucker rod made of the synthetic fiber comprises a sucker rod body and a connector in sequence from top to bottom. The sucker rod body is connected with an underground oil pumping device through the connector. The sucker rod body is made of the synthetic fiber. The flexible continuous sucker rod is made of the synthetic fiber, and multiple strength and chemical performance tests verify that equipment loads are reduced greatly, and strength, toughness and various chemical properties of the sucker rod body are improved; moreover, the working procedure of manufacturing the sucker rod is simplified, time is saved, and efficiency is improved.

Owner:青岛新胜石油机械有限公司

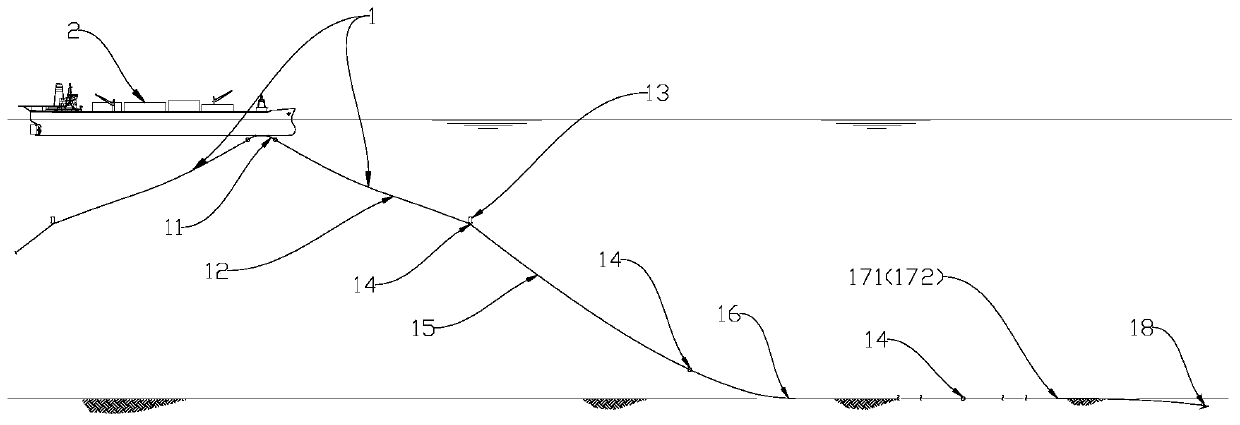

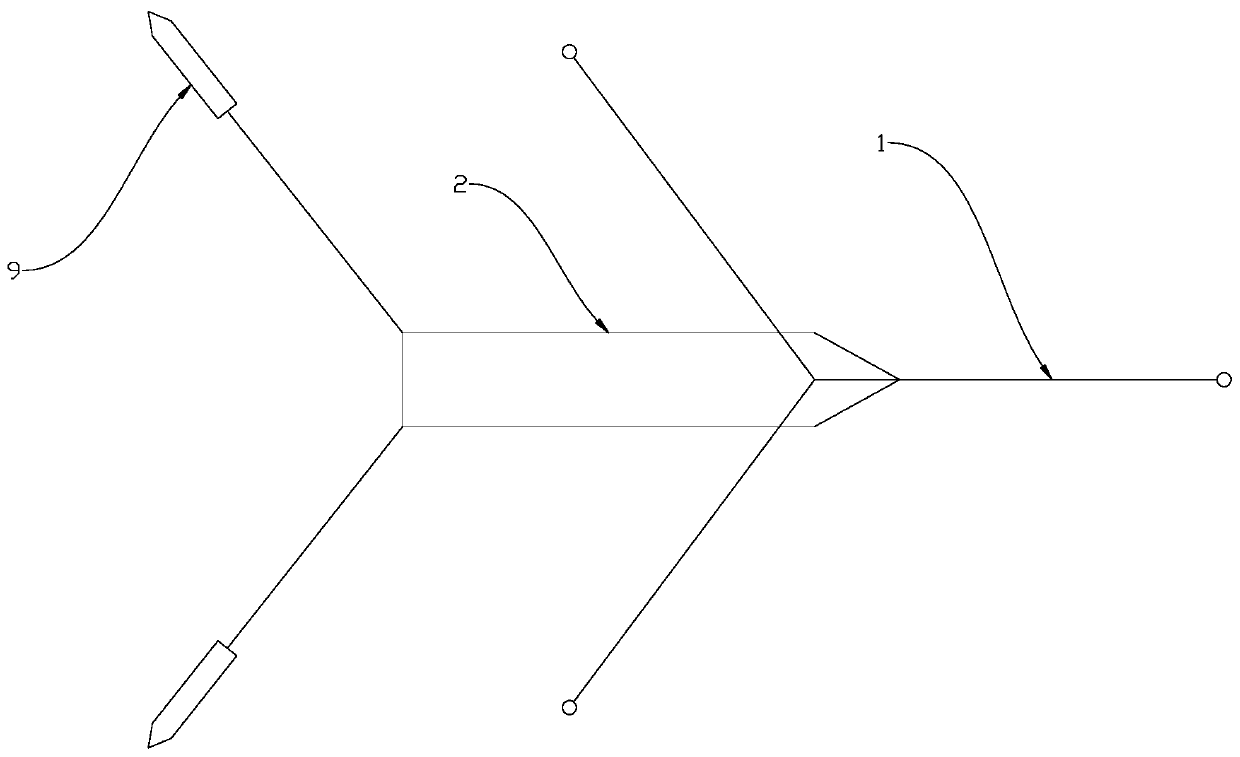

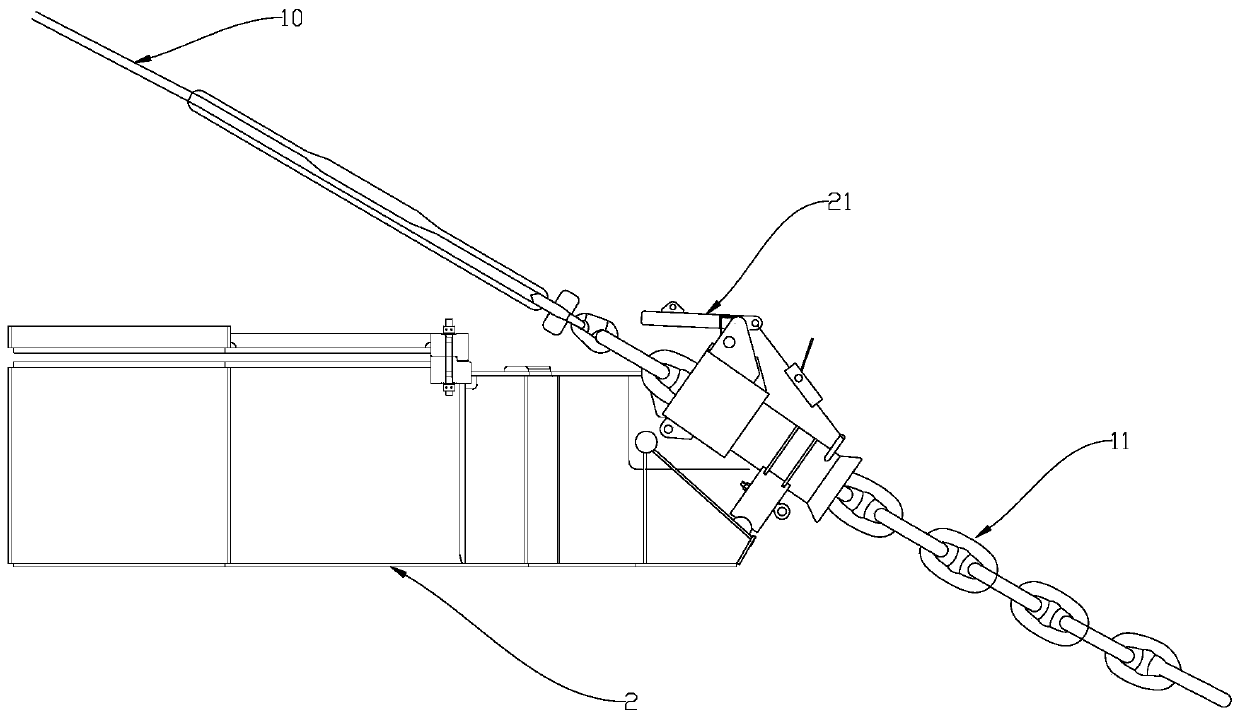

Method of changing mooring anchoring legs of two ships by lifting and pulling

The invention relates to a method of changing mooring anchoring legs of two ships by lifting and pulling. The method comprises the following steps: adjusting heading of an FPSO; loosening the anchoring legs; connecting an auxiliary lifting and pulling ship and a mooring treatment ship to a first preset position and a second preset position on a counterweight chain separately; lifting a recycling winch belt of the auxiliary lifting and pulling ship to an designated depth, and synchronously moving the ship in the reverse direction of the FPSO; adopting the mooring treatment ship to recycle the counterweight chain and a used buried cable until all the damaged section of the used buried cable is recycled on a deck, and adopting the auxiliary lifting and pulling ship to cooperate to move the ship; cutting and recycling the damaged section of the used buried cable; manufacturing a new upper cable joint of the rest section of the used buried cable, connecting the new upper cable joint with the lower cable joint of a new buried cable, and putting the connected joints in water; cooperating the mooring treatment ship and the mooring treatment ship to move the ship and lay along the originaldesign route; and tensioning the anchoring legs. With adoption of the method, the buried cable can be changed on the condition that the FPSO is in place and halt production of the FPSO is avoided, part of buried cable and the counterweight chain need to be recycled and laid only, the workload is greatly reduced, construction operation risk and operation time are reduced, and the yield loss of an oilfield is reduced.

Owner:SHENZHEN OFFSHORE OIL ENG UNDERWATER TECH

Super-deep well wireless transmission well testing system

The invention discloses a wireless transmission well testing system of an ultra-deep well and relates to the filed of dynamic monitoring of an oil reservoir, in particular to a device for a pressure buildup test for an oil gas production well. The proposal utilizes a ground receiving device, a cable, a supporting cylinder, a sensing system and a ball valve; the supporting cylinder is connected with the upper part of the ball valve; the outer wall of the supporting cylinder is provided with a groove; the inside of a tube is provided with a pressure transmission passage from the lower part of the ball valve to a groove of a direct-reading manometer; the sensing system comprises the direct-reading type manometer, a cell and a receiver; the direct-reading type manometer and the cell are arranged inside the groove of the outer wall of the supporting cylinder respectively; the direct-reading type manometer consists of a sensor, an A / D module, a microcontroller, a signal emitter and a transmitting coil which are sequentially connected; the receiver consists of a receiving coil, a signal receiver, a microcontroller and a signal transmitter which are sequentially connected; and the receiver is arranged inside the supporting cylinder and is connected with the ground receiving device through the cable. The proposal realizes well shutdown underground, avoids accumulation in a well cylinder, shortens the well testing period, can fully avoid causing incomplete underground pressure buildup curve by insufficient time for well shutdown, can set sampling density at any moment through a ground computer, avoids causing the loss of wire section in early stage and meets the testing requirement of well testing of the oil gas well.

Owner:XINJIANG SINOGASOLINEEUM ENG

Magnetic steel replacer

ActiveCN105220588AAvoid pollutionSave human effortRailway track constructionRear quarterReciprocating motion

The invention discloses a magnetic steel replacer, and belongs to the technical field of train operation auxiliary equipment. The magnetic steel replacer comprises a II-type sleeve frame and an H-type support, the II-type sleeve frame is formed by connecting a left side plate and a right side plate through a top plate, and the H-type support is formed by connecting a front side plate and a rear side plate through a middle cross plate. The support is sleeved with the sleeve frame. A left rotary shaft is horizontally arranged on the outer surface of the lower portion of the left side plate, and a right rotary shaft is longitudinally arranged on the outer surface of the lower portion of the right side plate. A left pull hook and a right pull hook are arranged on the left rotary shaft and the right rotary shaft respectively, and can vertically rotate around the left rotary shaft and the right rotary shaft. A lifting device is arranged on the middle cross plate of the support. The lifting device can drive the sleeve frame to do vertical reciprocating motion along the support. Compared with the prior art, the magnetic steel replacer has the advantages that construction personnel are greatly reduced, work time is greatly shortened, and work efficiency is improved; replacement is convenient and fast, operation is easy, and meanwhile a sleeper is not damaged, and can continue to be used; magnetic steel is protected, and can be recycled to be reused; resources are greatly saved, and cost is reduced.

Owner:青岛瑞铁电工科技有限公司

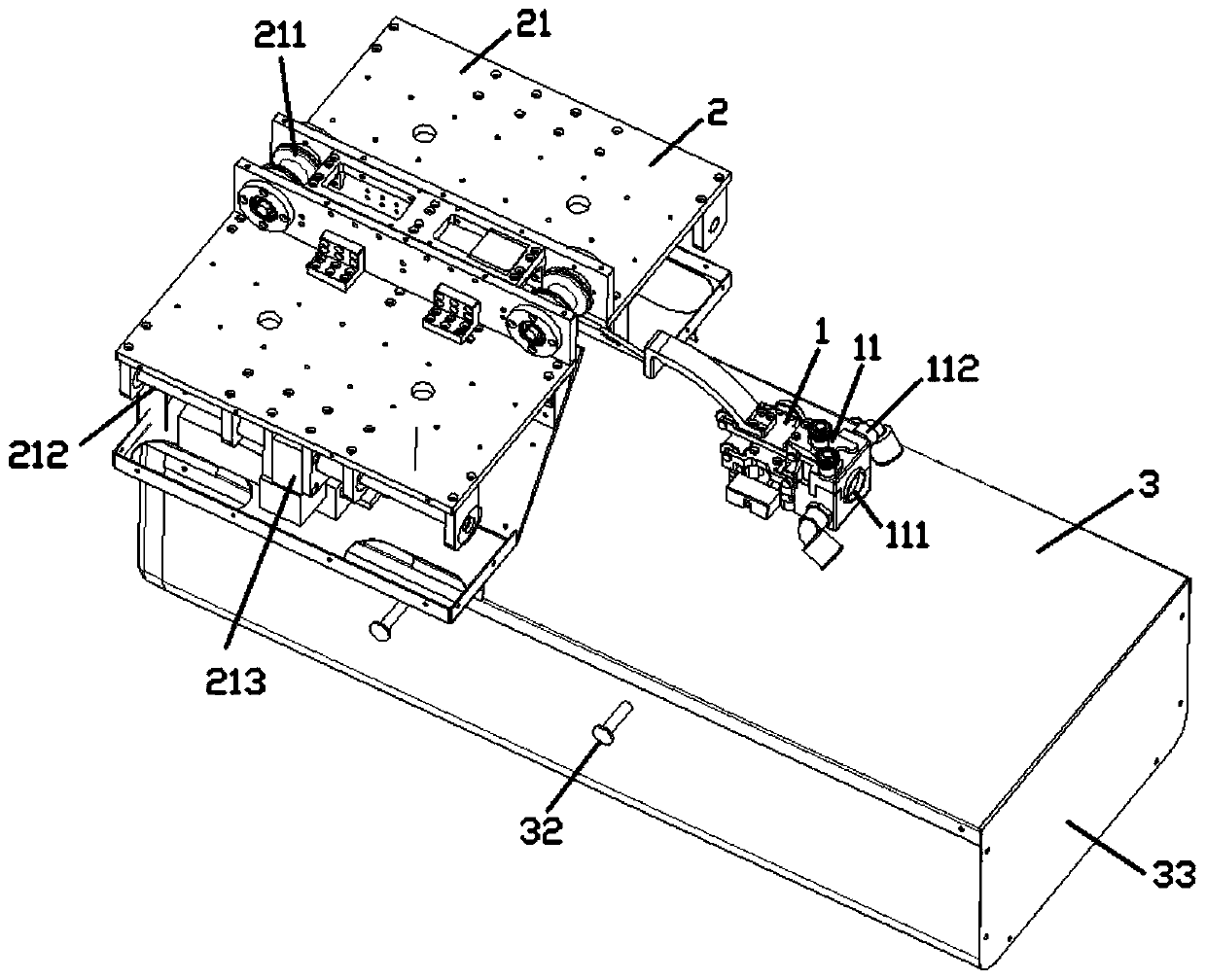

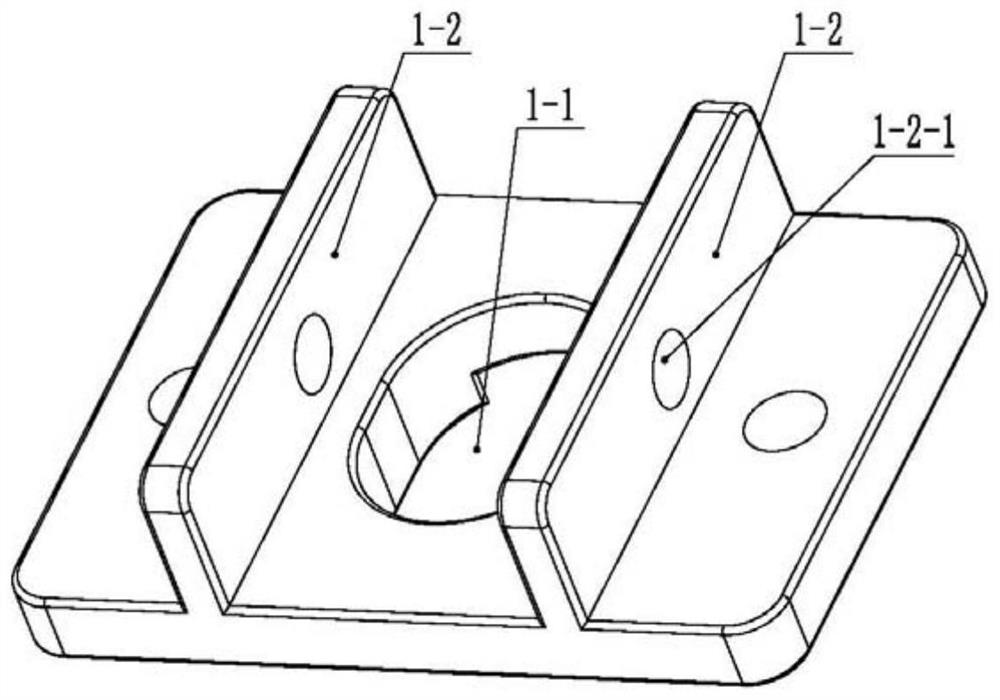

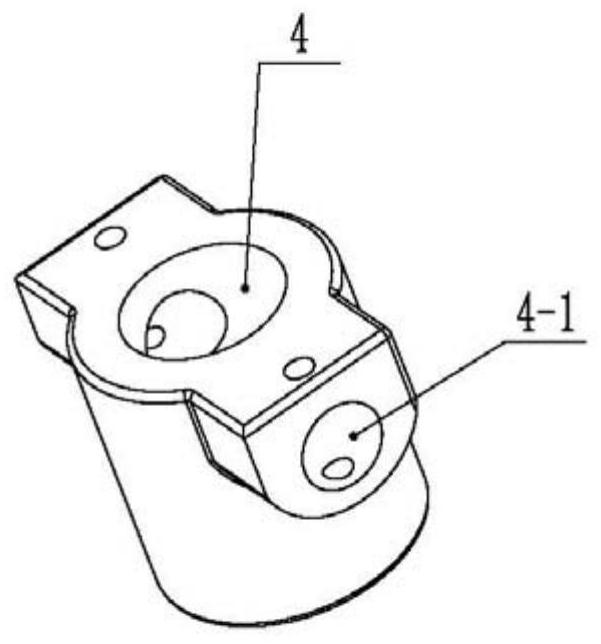

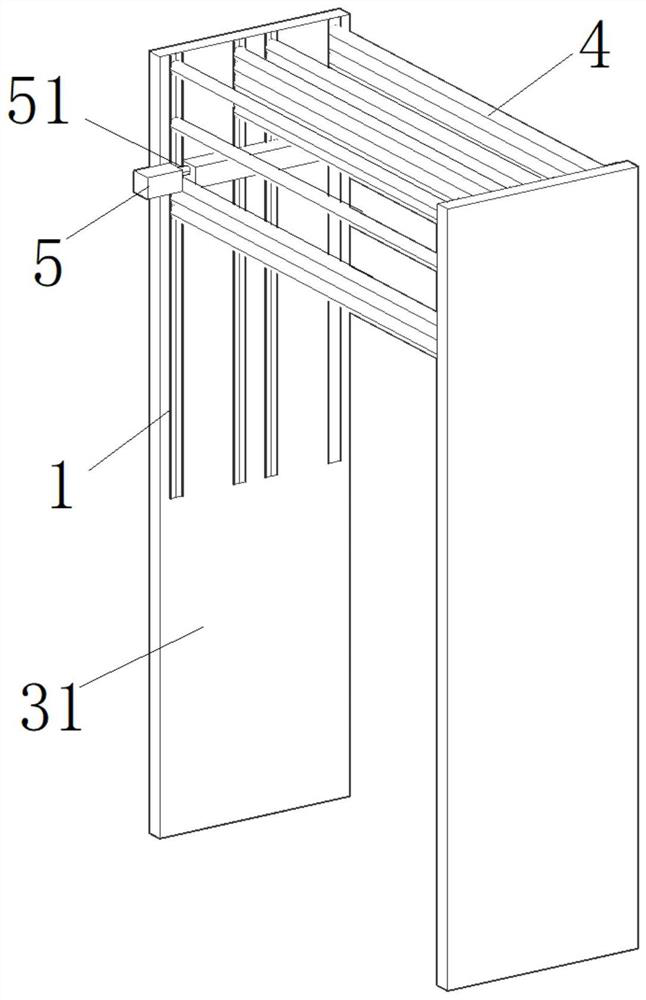

Ground wall embedded slideway type steel support foundation pit supporting system and construction method thereof

PendingCN114411760AAvoid the problem of loadingEasy to installExcavationsBulkheads/pilesSupporting systemArchitectural engineering

The invention discloses a ground wall pre-buried slideway type steel support foundation pit supporting system and a construction method thereof. The supporting system comprises a pre-buried slideway (1), a fixing bolt (2) and a steel support (4). The embedded slide way is installed on a reinforcement cage (3) of a ground wall (31) in an embedded mode, and the embedded slide way is arranged along the supporting position of the steel support; notches of the pre-buried slideways on the ground walls on the two sides of the foundation pit are oppositely arranged, so that the two ends of the steel support can be inserted into the pre-buried slideways through the notches respectively, and the steel support can slide along the pre-buried slideways; a plurality of bolt holes are formed in the pre-buried slide way, bolt holes are formed in the two ends of the steel support, and the fixing bolts penetrate through the pre-buried slide way and the steel support through the bolt holes, so that the end of the steel support is fixed in the pre-buried slide way through the fixing bolts. All the steel supports are placed through the pre-buried sliding ways, and the problem that follow-up support hoisting is affected by cross operation conflicts, steel support stacking and loading and dense supports on a construction site can be effectively solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Bit pressure controlled type downhole circulating pup joint and continuous pipe drilling plug dynamic flushing process

PendingCN111894496AReduce the difficulty of operationSimple structureDrilling rodsFlushingUpper jointEngineering

The invention discloses a bit pressure controlled type downhole circulating pup joint and a continuous pipe drilling plug dynamic flushing process. The circulating pup joint comprises an upper joint body and a lower joint body which are in sliding fit through an elastic element. Flow passing holes are formed in the lower end of the side wall of the upper joint body. A front spraying passageway anda side spraying passageway are arranged between the lower joint body and the upper joint body, and the lower joint body can slide in the axial direction of the upper joint body, so that one of the flow passing holes communicates with the front spraying passageway or the side spraying passageway. Side spraying holes are formed in the side wall of the lower joint body, and the side spraying holes are arranged obliquely upwards. The circulating pup joint is mainly adopted in a drilling and grinding process, and drilling and grinding operation is carried out after reasonable bit pressure parameters are determined; and the speed is increased through an optimized lateral jet flow structure, delivery capacity and tubular columns, dynamic flushing and upward grinding returning are carried out, and finally drilling and grinding circulation is repeated until all work is completed. The pup joint is ingenious in overall structure, long in service life and convenient to operate; and according to the process, the grinding flushing effect can be improved, the continuous pipe drilling plug benefits can be increased, and popularization and application of the technology can be promoted.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Mass concrete pouring system under high-temperature climate condition

ActiveCN112709444AConsistent pouring volumeReduce construction work timeFoundation engineeringBuilding material handlingArchitectural engineeringPre treatment

The invention discloses a mass concrete pouring system under a high-temperature climate condition. The system comprises an integrated pouring machine for pouring concrete on site, a transfer treatment device and a conveying and collecting device, wherein the transfer treatment device is connected to the feeding end of the integrated pouring machine, the transfer treatment device is used for conducting quantitative division treatment on the concrete before the concrete enters the integrated pouring machine so as enable the concrete to sequentially enter the integrated pouring machine according to a preset required amount, the output end of the conveying and collecting device is connected to the feeding end of the transfer treatment device, and the conveying and collecting device is used for collecting the pretreated concrete to the transfer treatment device. According to the system, quantitative pouring of the integrated pouring machine can be realized, a concrete pouring amount of each pouring floor is kept consistent, the integrated pouring machine can finish pouring, flattening, vibrating and flattening of the concrete, the subsequent concrete construction operation time is shortened, and high-quality completion of concrete pouring at a high temperature is guaranteed.

Owner:CITIC CONSTR

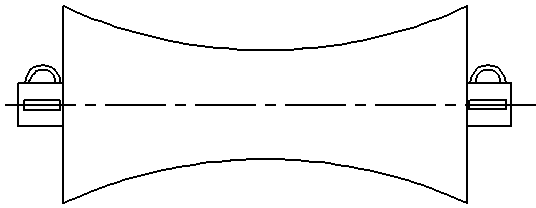

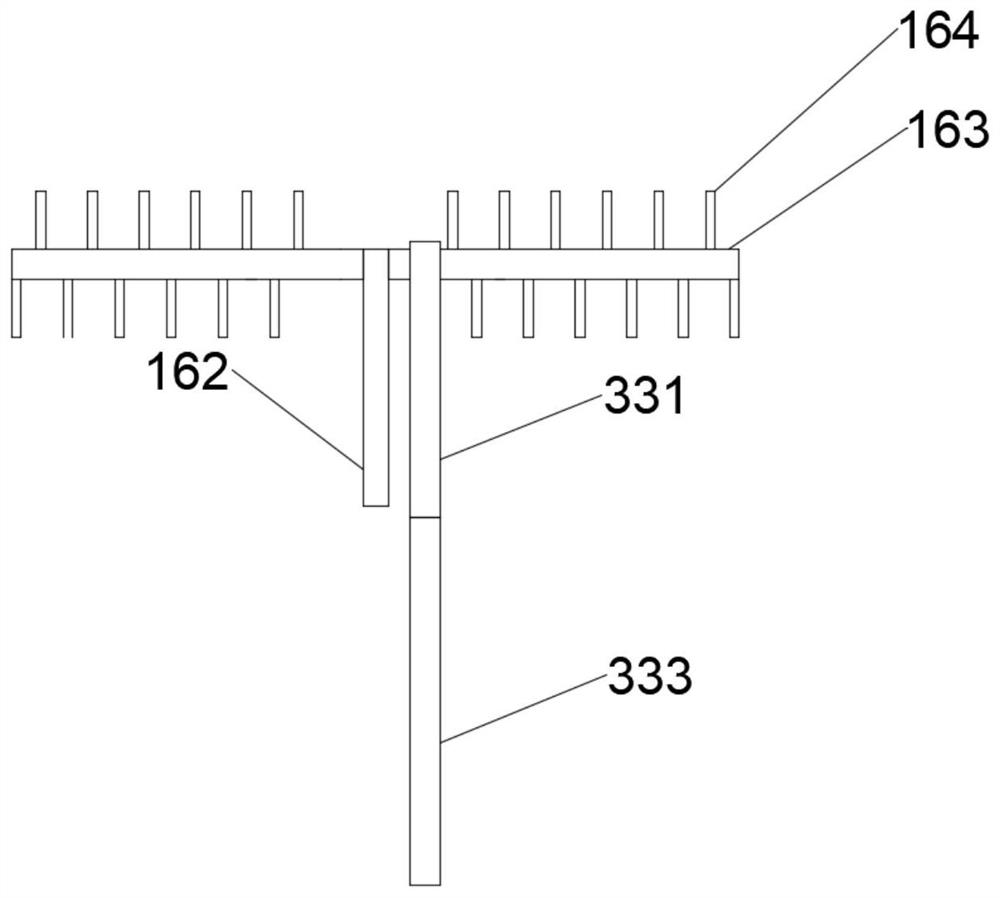

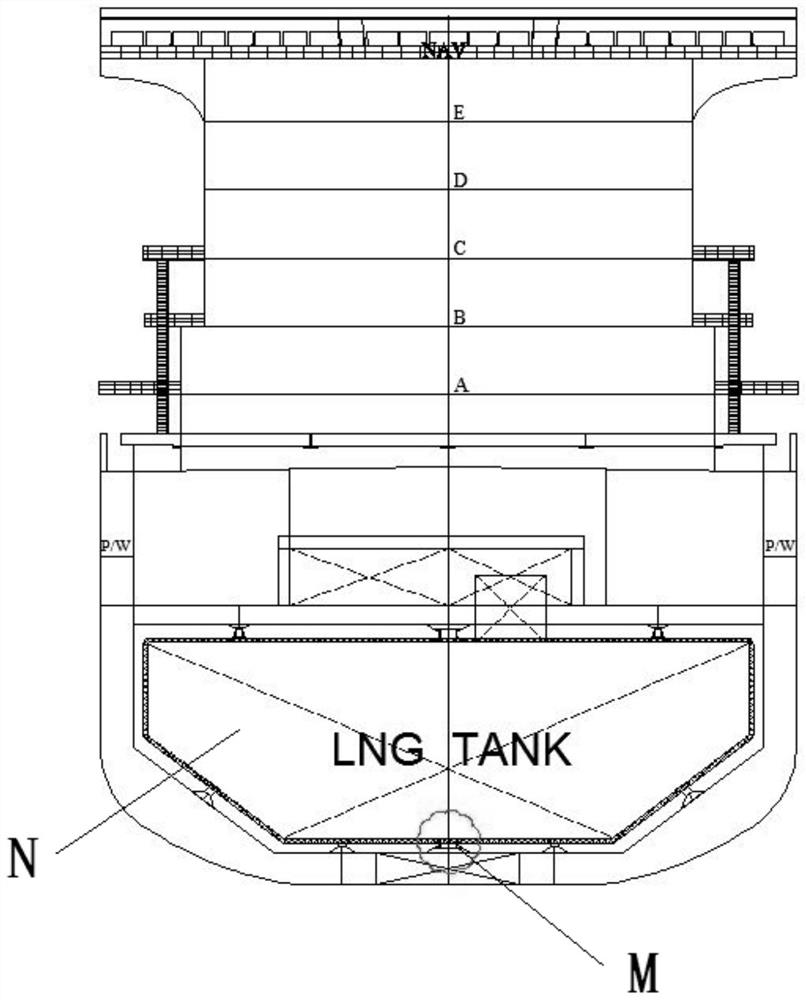

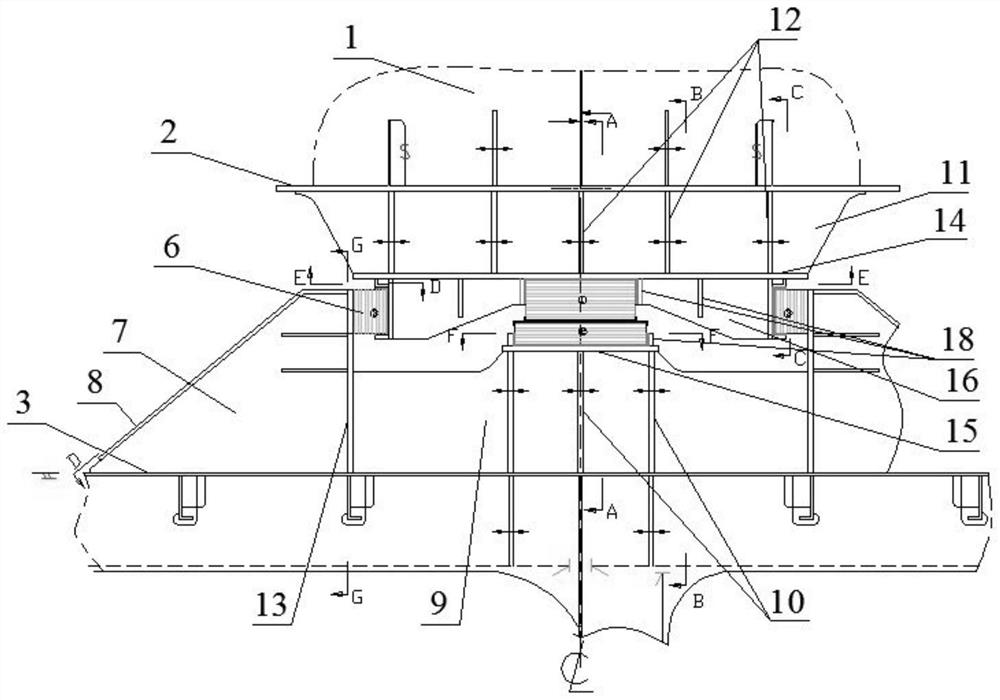

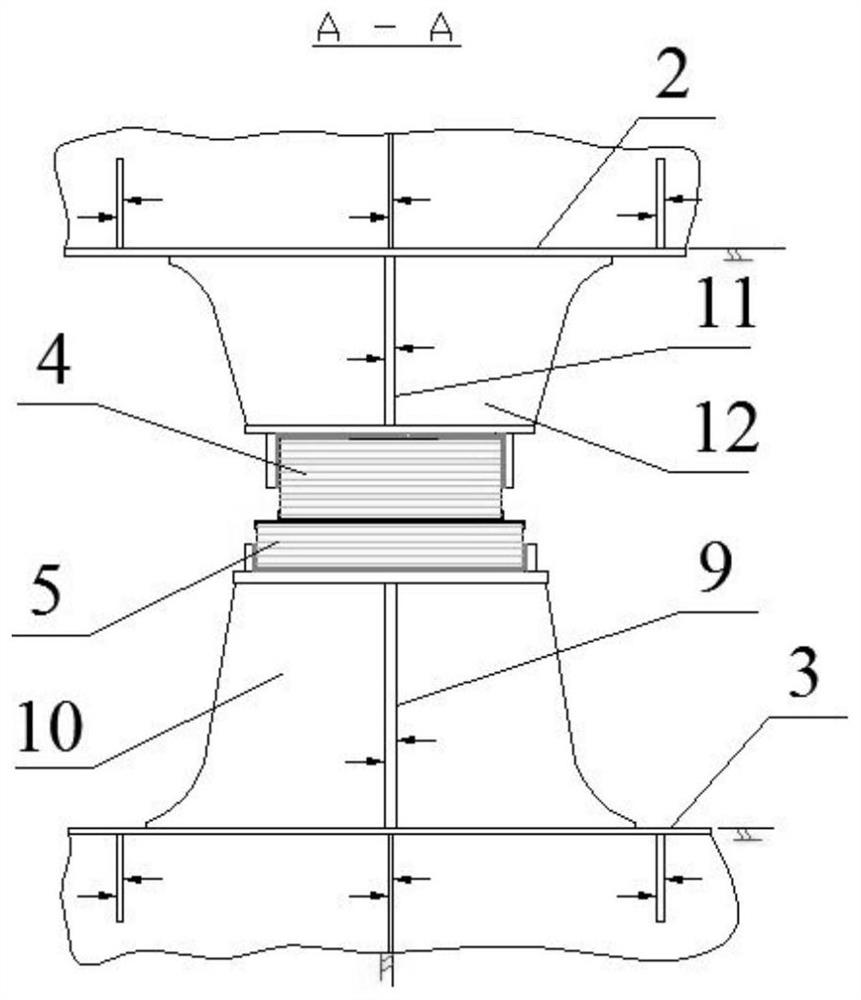

Swing-stopping and vertical-supporting composite device for B-type LNG fuel cabin

PendingCN113978611AReduce in quantityIncrease profitHull interior subdivisionVessel stability improvementMarine engineeringStructural engineering

The invention relates to a swing-stopping and vertical-supporting composite device for a B-type LNG fuel cabin. A plurality of the swing-stopping and vertical-supporting composite devices are arranged between a bottom plate (2) of the B-type LNG fuel cabin (1) and a bottom plate (3) in a ship body, and the plurality of swing-stopping and vertical-supporting composite devices are longitudinally arranged along the center line of the cabin; and each swing-stopping and vertical-supporting composite device structurally comprises an upper support, a lower support and laminated wood between the upper support and the lower support, the upper support is connected with the bottom plate (2) of the B-type LNG fuel cabin in a welded mode, and the lower support is connected with the bottom plate (3) in the ship body in a welded mode, and the laminated wood comprises vertical laminated wood playing a supporting role and transverse laminated wood (6) playing a swing stopping role. The swing-stopping and vertical-supporting composite device has the swing stopping function and the vertical supporting function at the same time, the number of supports of the B-type LNG fuel cabin is greatly reduced, the material utilization rate is increased, and the construction operation time is shortened.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

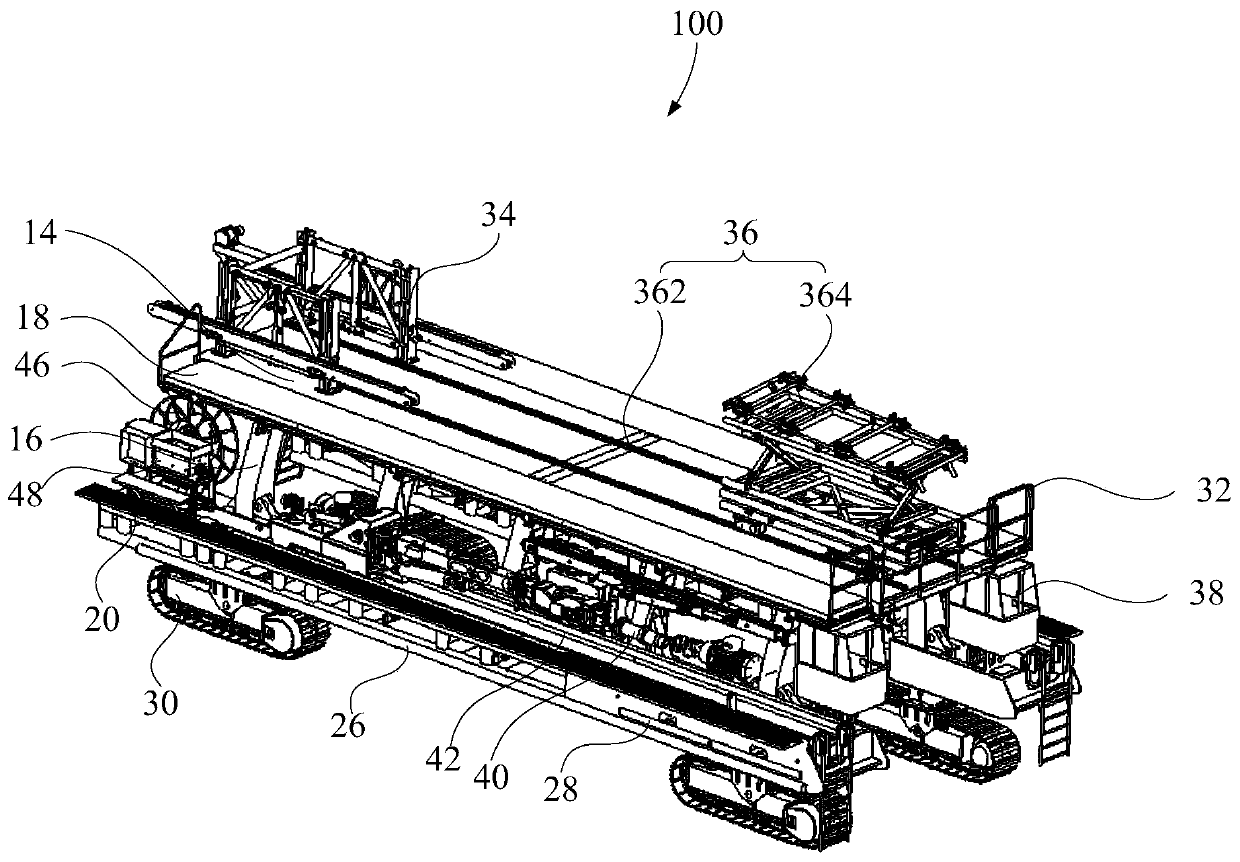

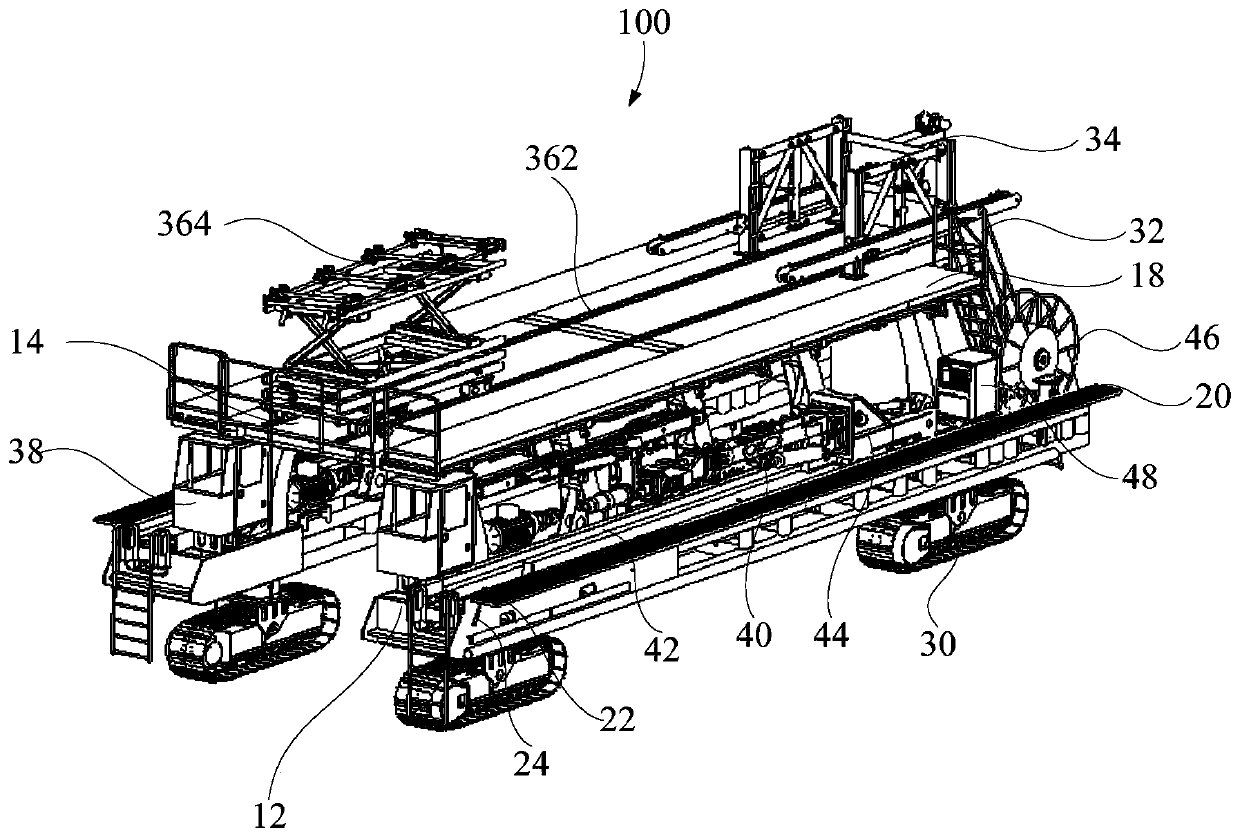

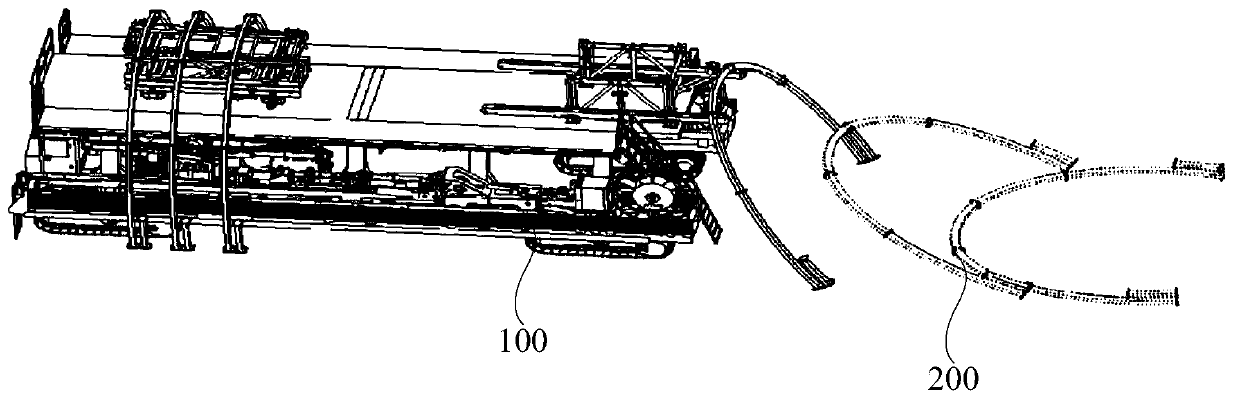

Tunnel operation vehicle

ActiveCN110486020AImprove satisfactionReduce procurement costsUnderground chambersTunnel liningEngineeringIndustrial engineering

The invention provides a tunnel operation vehicle. The tunnel operation vehicle comprises a rack and working parts. The rack comprises a first platform and a second platform. The second platform is connected with the first platform and is located above the first platform. The working parts comprise a first working part and a second working part, wherein the first working part is arranged on the first platform, the second working part is arranged on the second platform, and the first working part and the second working part can work simultaneously. The tunnel operation vehicle has functions ofa plurality of processes like drilling, grouting, arch frame mounting and high-altitude working, so that one machine can be used for a plurality of purposes; compared with working through independentequipment for a plurality of processes, working through the tunnel operation vehicle greatly reduces the procurement cost of equipment and can be shorter in operation time; and meanwhile, the first working part and the second working part can work simultaneously, so that the operation of different processes can be completed at the same time by the tunnel operation vehicle, the construction operation time is greatly shortened, and the construction progress and the construction efficiency are further improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com