Bit pressure controlled type downhole circulating pup joint and continuous pipe drilling plug dynamic flushing process

A control-type, weight-on-bit technology, applied in drill pipe, drilling equipment, flushing wellbore, etc., can solve the problem of increasing the degree of fatigue damage and deformation of the pipe string, the risk of sticking, restricting the application and promotion of coiled tubing drilling and grinding bridge plugs, Increase the operation time and cost to achieve the effect of improving the return speed and bridge plug drilling and grinding efficiency, promoting application and promotion, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

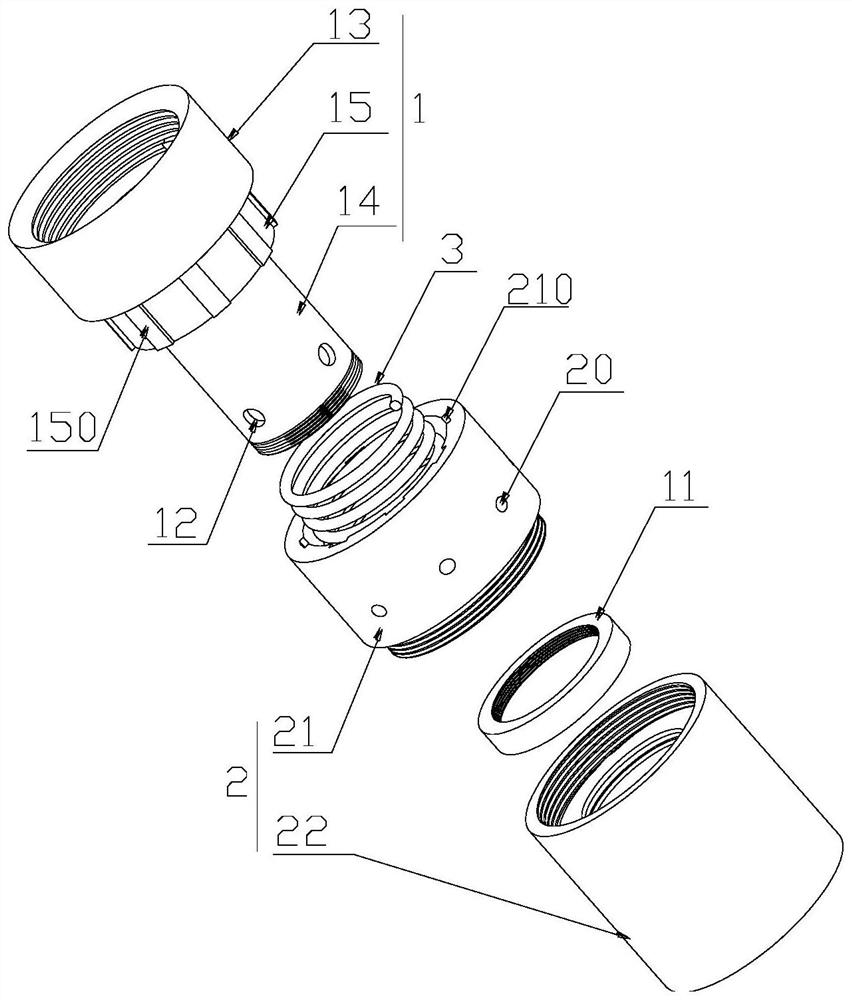

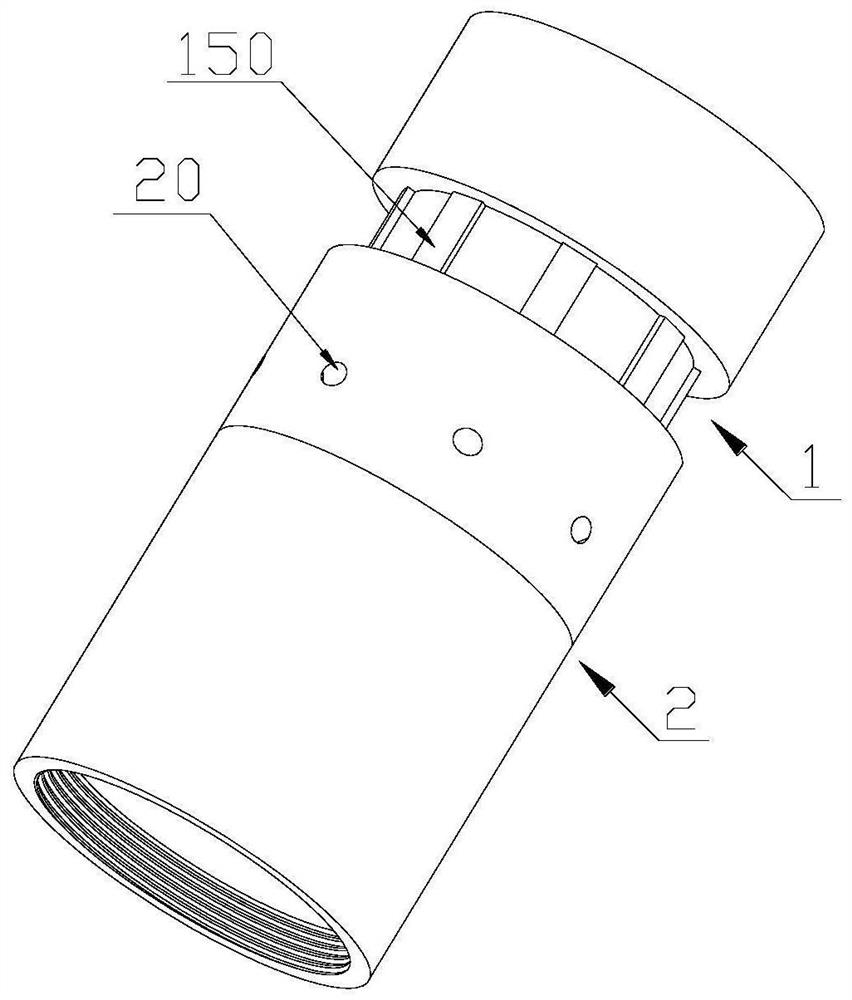

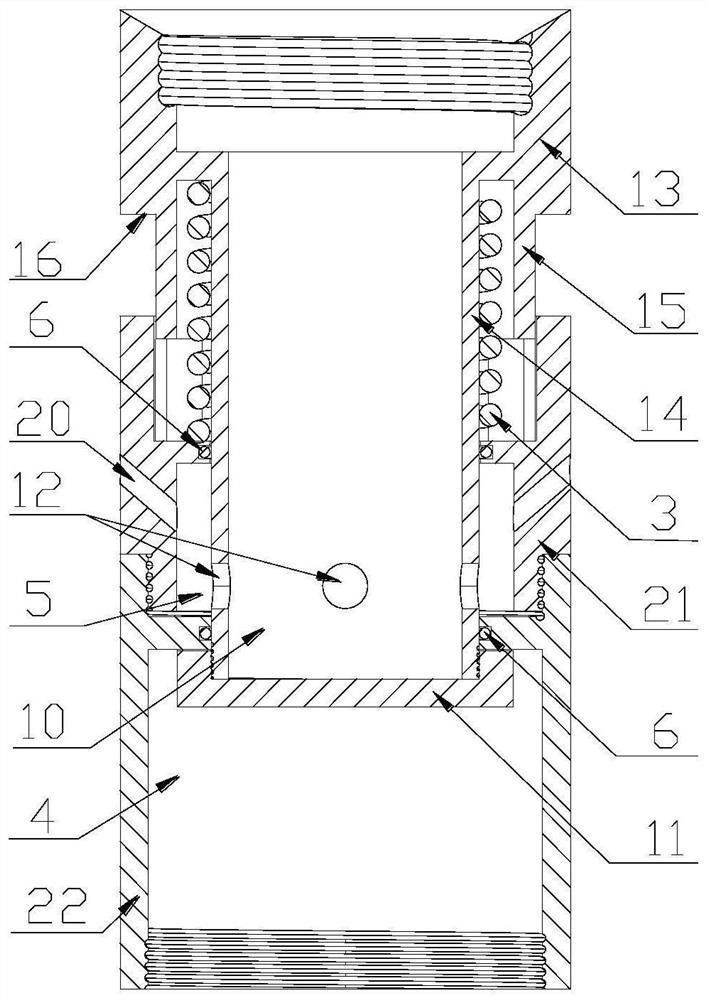

[0038] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0039] refer to Figure 1 to Figure 10 The pressure-on-bit controlled downhole circulation short connection and coiled tubing plug dynamic flushing process are shown, wherein the pressure-on-bit control downhole circulation short connection mainly includes an upper joint body 1 and a lower joint body 2, both of which are generally hollow tubular structures, and the upper joint body The body 1 and the lower joint body 2 are relatively movably connected, that is, the two can slide relative to each other along the axis, and an elastic element 3 is arranged between the two. The elastic element 3 is mainly used to assist the two to return to their original positions when they are not under pressure. , the upper end of the upper joint body 1 and the lower end of the lower joint body 2 both have threaded buckles for connecting with corresponding drilling tools.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com