Well piece, prefabricated assembled caisson and caisson construction method

A construction method and prefabricated assembly technology, applied in caissons, basic structure engineering, construction, etc., can solve the problems that construction operations are greatly affected by weather changes, long construction operation time, and low construction efficiency, so as to shorten construction operation time and improve construction efficiency. Simple and convenient, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

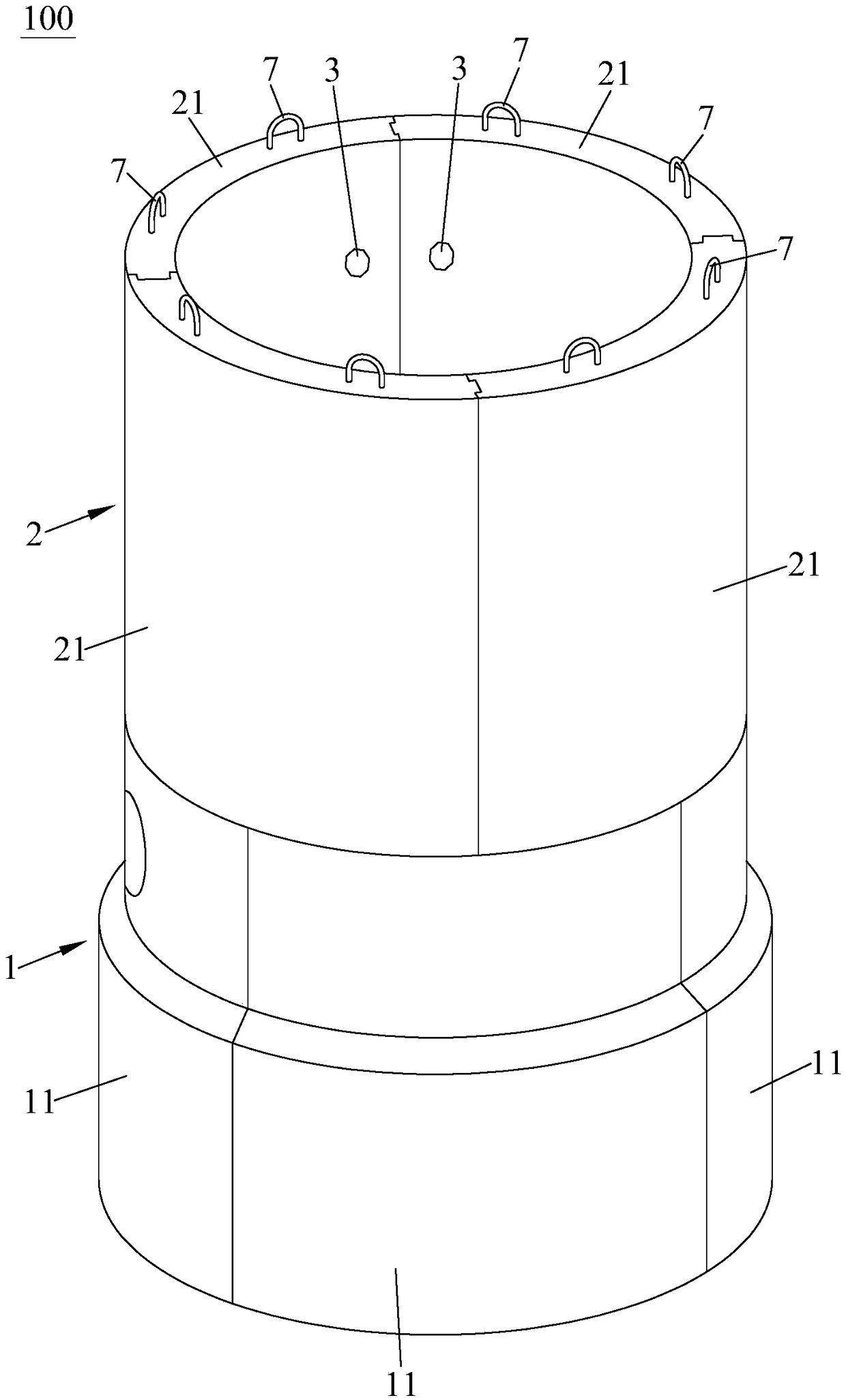

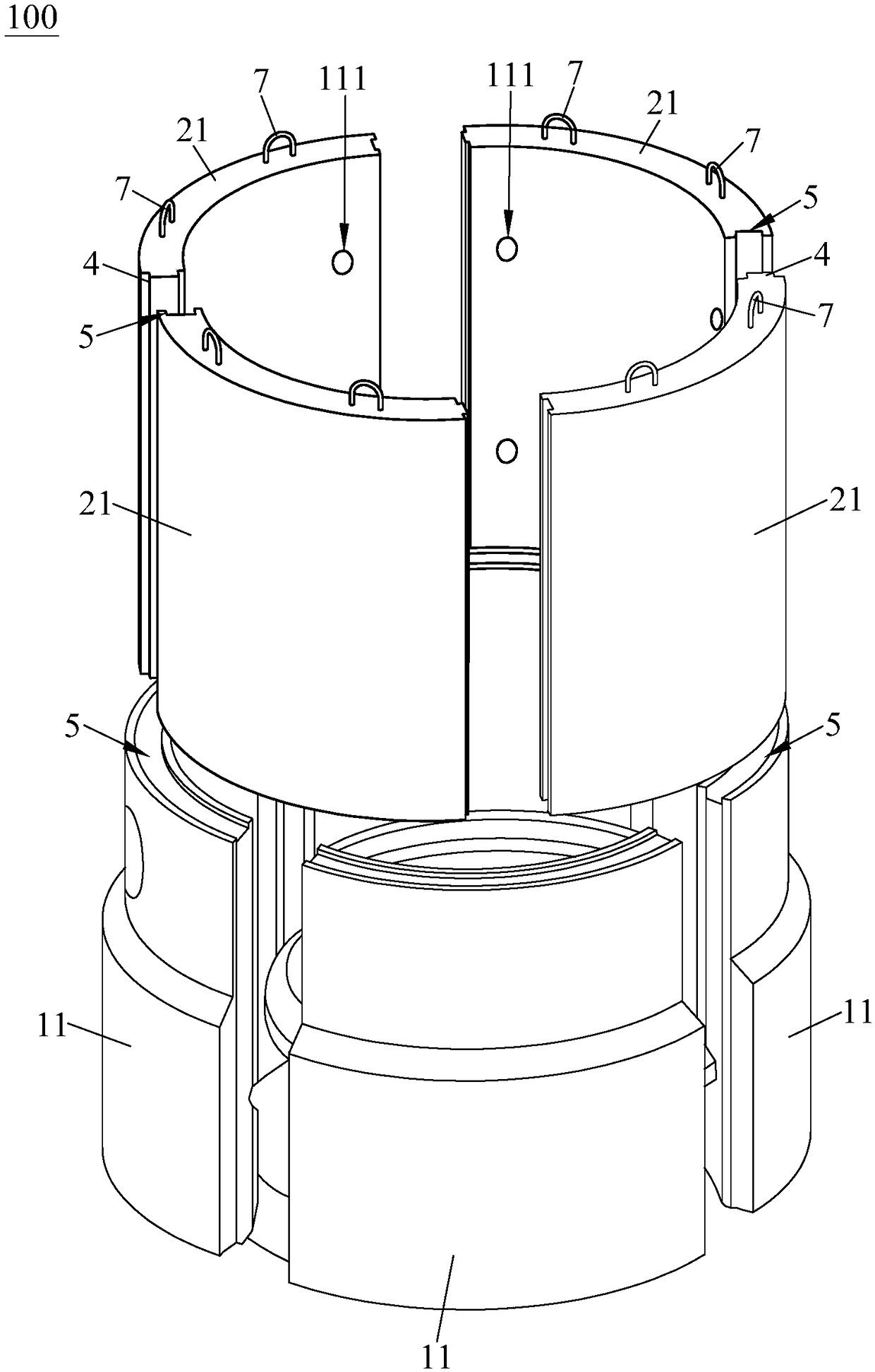

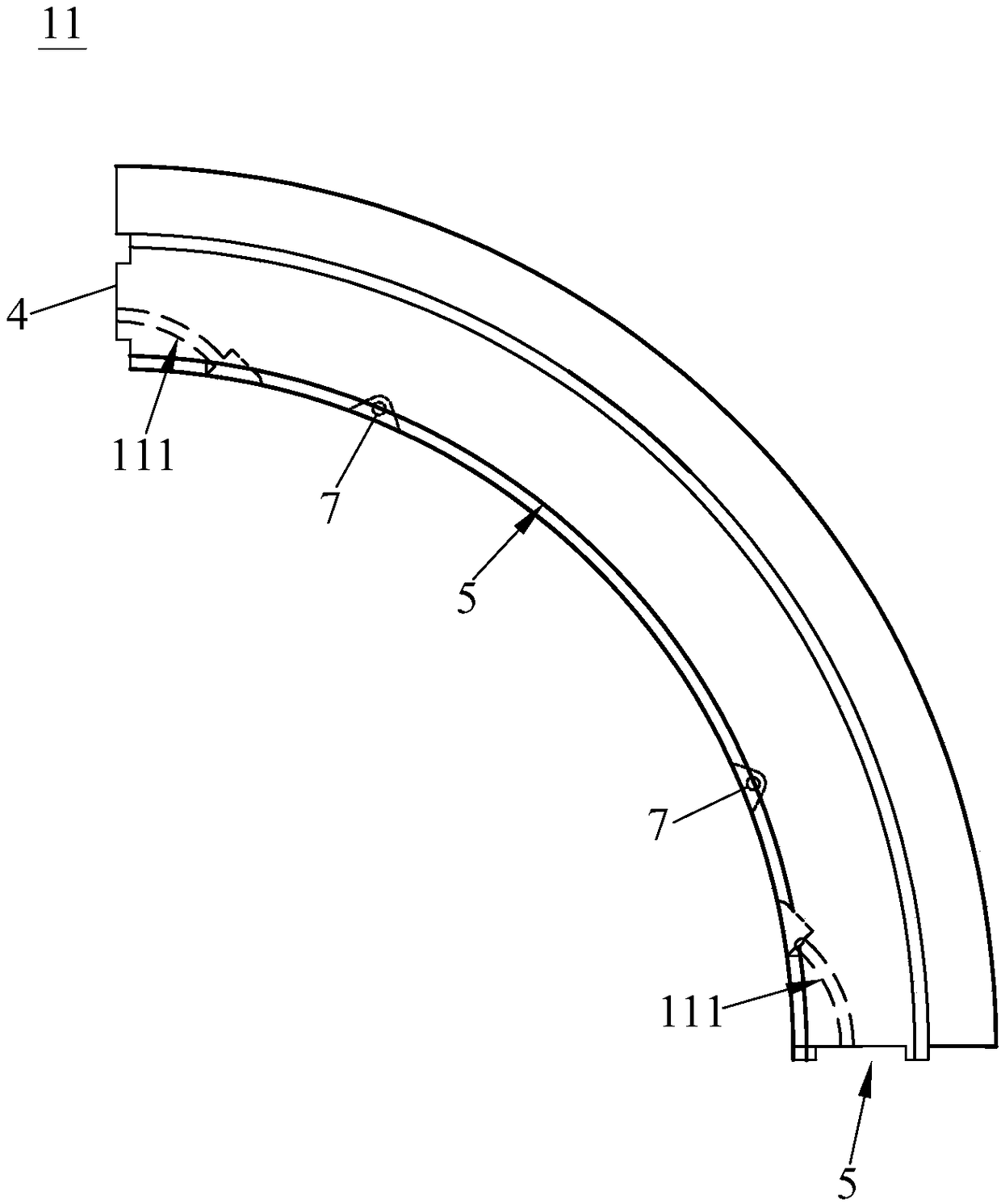

[0031] see Figure 1 to Figure 7 , the prefabricated caisson 100 of the present invention comprises an annular well body and several segment bolts 3, the annular well body comprises at least two arc-shaped well slices, the well slices are arc-shaped, and one of the well slices is opposite Both sides are provided with first arc-shaped circular holes 111, the first arc-shaped circular holes 111 of two adjacent well slices in the circumferential direction are connected, and the segment bolts 3 pass through the first arc-shaped circular holes 111 to connect the two adjacent well slices. Fixed connection. Specifically, at least two annular well bodies are coaxially arranged on the central axis, and at least one side of the other opposite two sides of the well slice o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com