Method for controlling bridge deformation in engineering of underneath passing high-speed railway bridge on road

A bridge engineering and road technology, which is applied in the field of bridge deformation control, can solve problems such as difficult to meet the strict displacement restrictions of the pier abutment top, reduce the difficulty and construction operation risk, reduce the difficulty and time, and control the deformation value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

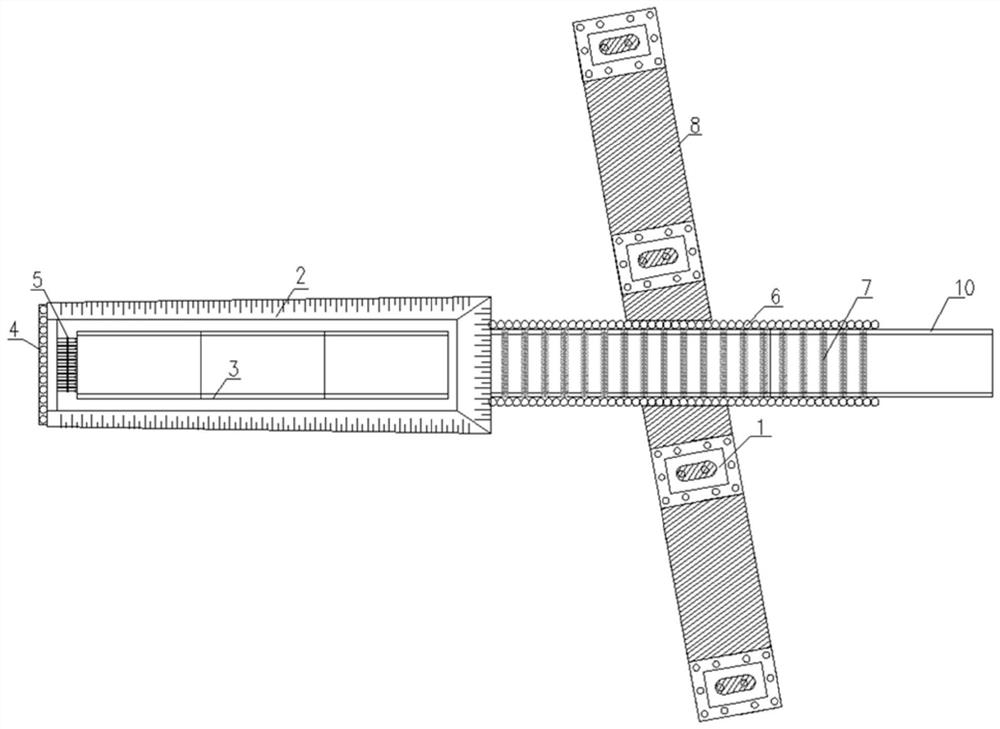

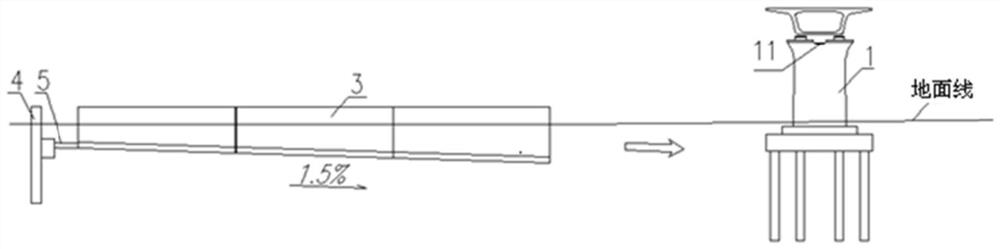

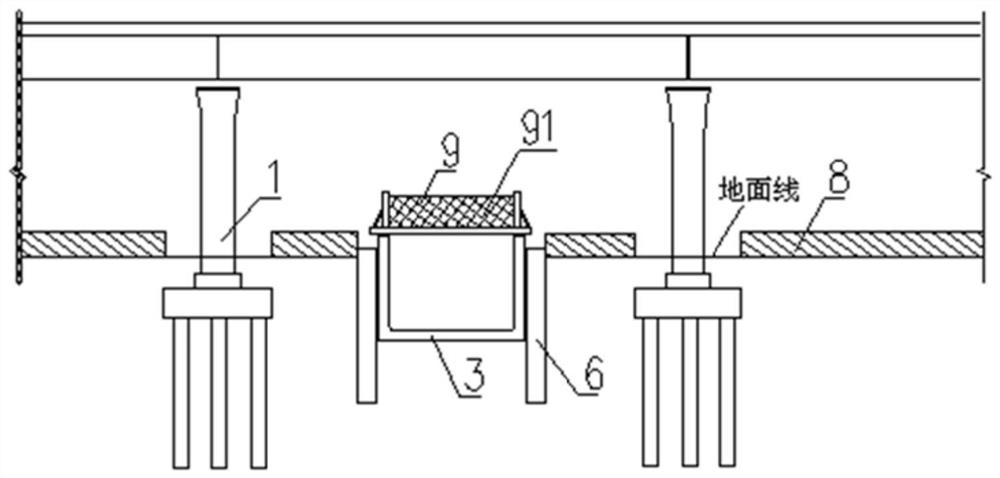

[0032] This embodiment provides a method for controlling the deformation of the bridge in the high-speed rail bridge project under the road, such as Figure 1 to Figure 4 As shown, the method includes the following steps:

[0033] Step S1, taking the deformation of the pier top as the control condition to calculate the lengths of the U-shaped groove 3 of the lower jacking section and the U-shaped groove 10 of the cast-in-place section of the existing high-speed rail bridge 1 . According to the depth and size of the prefabricated foundation pit 2 of the U-shaped groove 3 in the jacking section, calculate and determine the distance between the foundation pit 2 and the existing high-speed rail bridge 1 and the underground road protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com