Construction Method of Composite Foundation Pit Support with Horizontal Jet Grouting Soil Anchor and Cast-in-situ Pile

A technology of horizontal rotary spraying and cast-in-place piles, which is applied in foundation structure engineering, sheet pile wall, excavation, etc., can solve the problems of large consumption of concrete supporting materials, increased dismantling, supporting replacement technology, and increased deformation of foundation pit side walls. , to achieve good social and economic benefits, convenient construction, and little space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

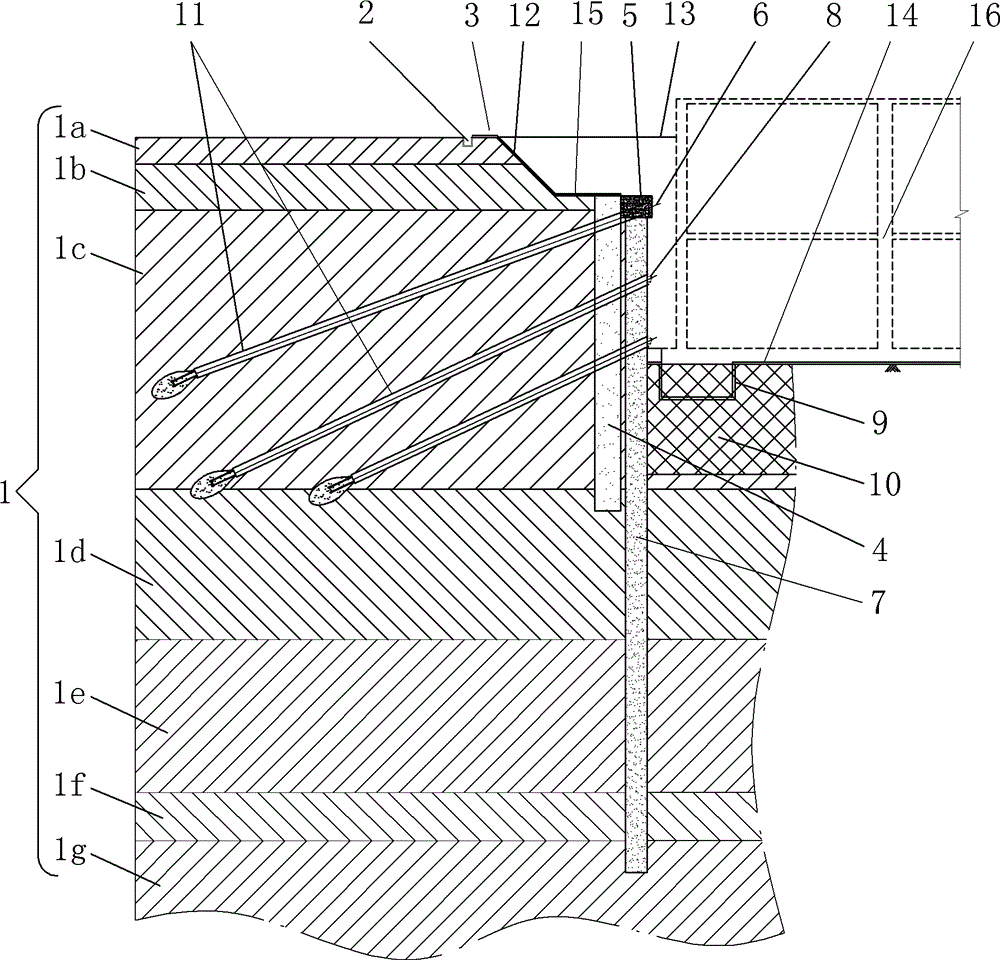

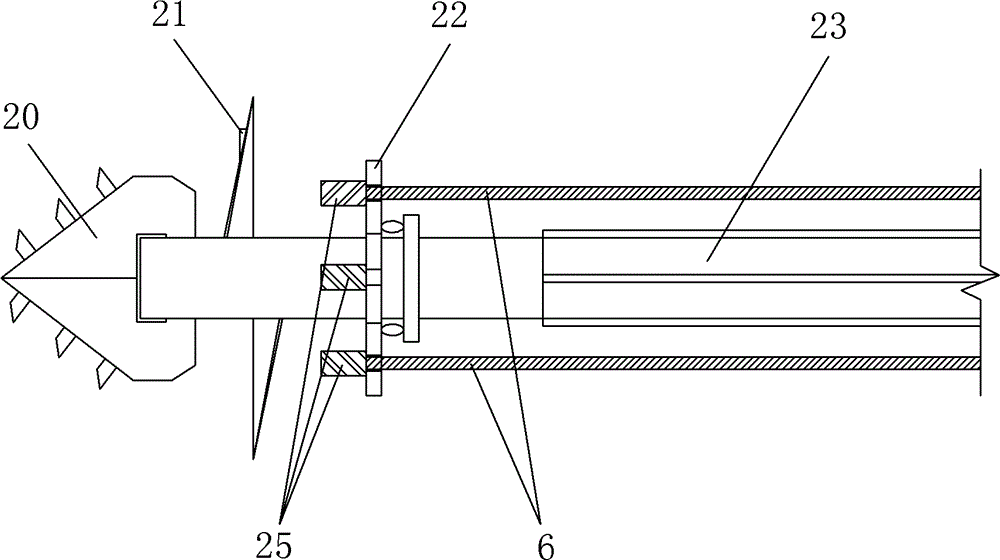

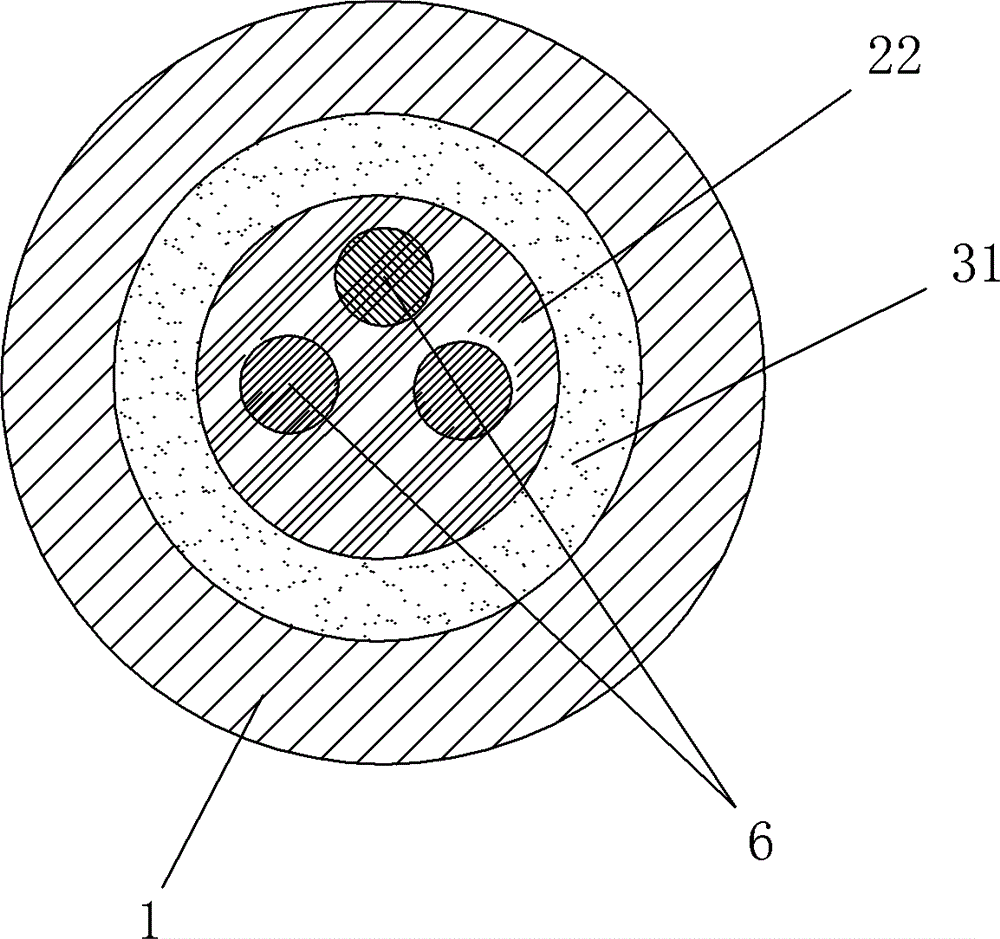

[0026] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-4 ;

[0027] The construction method of horizontal rotary grouting soil anchor and cast-in-situ pile composite foundation pit support includes the following steps:

[0028] (1) According to the preset foundation pit 14, the construction of the water-stop mixing pile (cement mixing pile) 4 is carried out to form a water-stop curtain wall, and the construction of the bored pile 7 is carried out according to the pile position, and the lateral stiffness of the bored pile 7 is Larger, the depth of penetration can be calculated according to the design, which can fully meet the support needs of foundation pits with thick silt layers in coastal areas;

[0029] (2) Carry out earthwork excavation and soil anchor construction according to the principle of layering and segmentation, including the following procedures: ① The earthwork excavation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com