Heave deformation resisting construction method for foundation pit excavation above existing tunnel

A technology with existing tunnels and construction methods, applied in infrastructure engineering, excavation, soil protection, etc., can solve problems such as water leakage at tunnel joints, impact on safe operation of tunnels, and inability to operate safely. The effect of long-term stable operation and preventing formation from floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

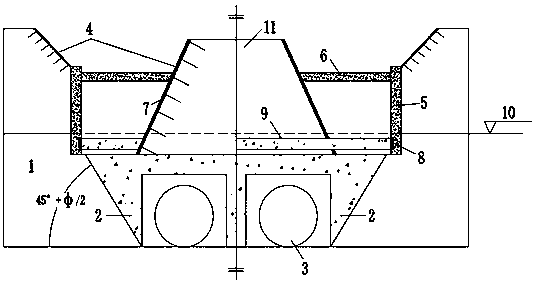

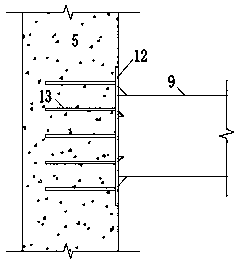

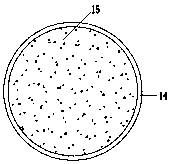

[0047] Such as Figure 1~5 As shown, a construction method for anti-uplift deformation of foundation pit excavation above an existing tunnel includes the following steps:

[0048] ⅰ. Grouting pre-reinforcement of the bottom layer and overlying soil layer around the existing tunnel

[0049] Carry out grouting reinforcement to the surrounding formation 1 of the existing tunnel 3, thereby forming a formation grouting pre-reinforcement zone 2;

[0050] ⅱ. Initial grading and soil nailing and spray anchor support from the vertical top of the existing tunnel

[0051] From the appropriate position vertically above the existing tunnel 3 to the design boundary of the foundation pit, the initial slope and soil nailing and anchor support 4 are performed. The slope and starting position of the initial slope depend on the design range of the foundation pit and the relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com