Method of changing mooring anchoring legs of two ships by lifting and pulling

A mooring anchor and anchor leg technology, applied in the field of mooring systems, can solve the problems of multi-sea operation time, increased construction costs, and increased construction costs, so as to improve construction efficiency and reliability, reduce workload, and reduce construction operations the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

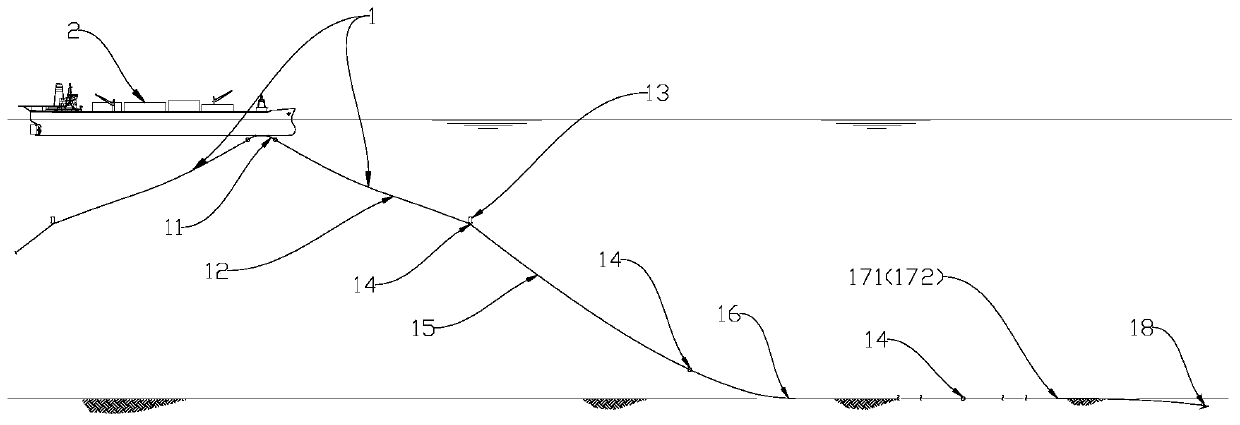

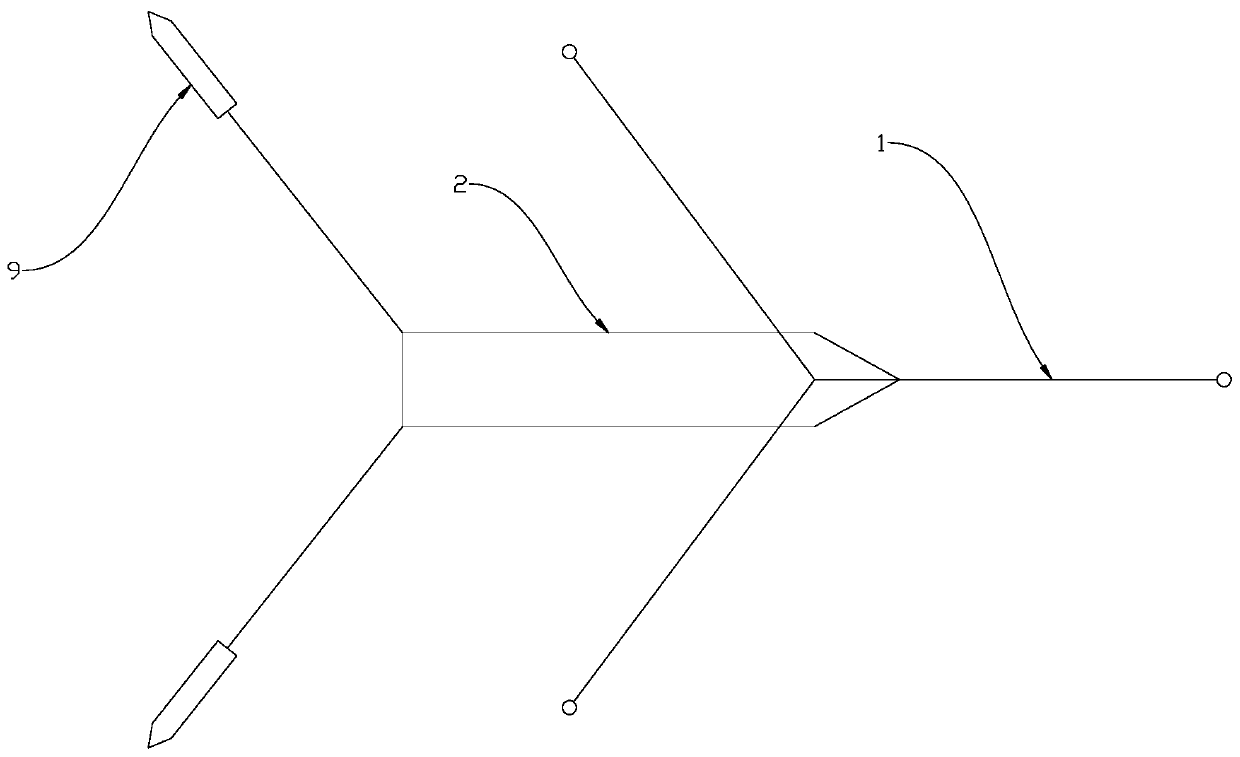

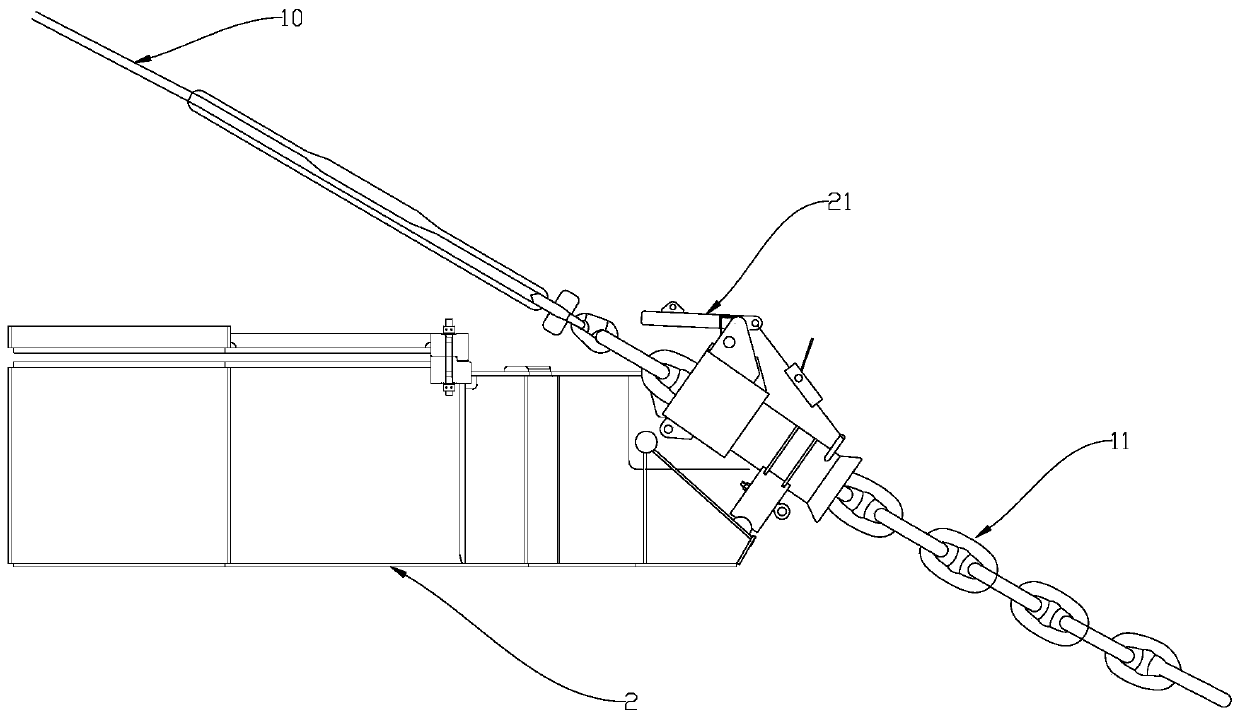

[0060] Such as figure 1 As shown, the anchor leg 1 can generally include an ACT chain (adjustment chain) 11, an upper anchor cable 12, a mid-water buoy 13, a lower anchor cable 15, a counterweight chain 16, a ground cable, an anchor point 18, and several connecting plates 14. Wherein, the ground cable can be composed of one steel cable, or it can also be spliced by several steel cables. Both ends of each steel cable are respectively provided with an upper cable joint and a lower cable joint for connection. The anchor point 18 can be a grasping anchor, a suction anchor, a gravity anchor, an anchor pile, a vertical plate anchor or the like.

[0061] Such as Figure 1-6 As shown, the present invention provides a meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com