Negative pressure toothpaste extrusion apparatus

An extruder and toothpaste technology, applied in brackets or dispensers, household appliances, sanitary equipment, etc., can solve the problems of affecting the toothpaste extrusion effect, cumbersome actions, corrosion of shoulders, etc., to achieve convenient rotation and switching, and reduce toothpaste pollution. , the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

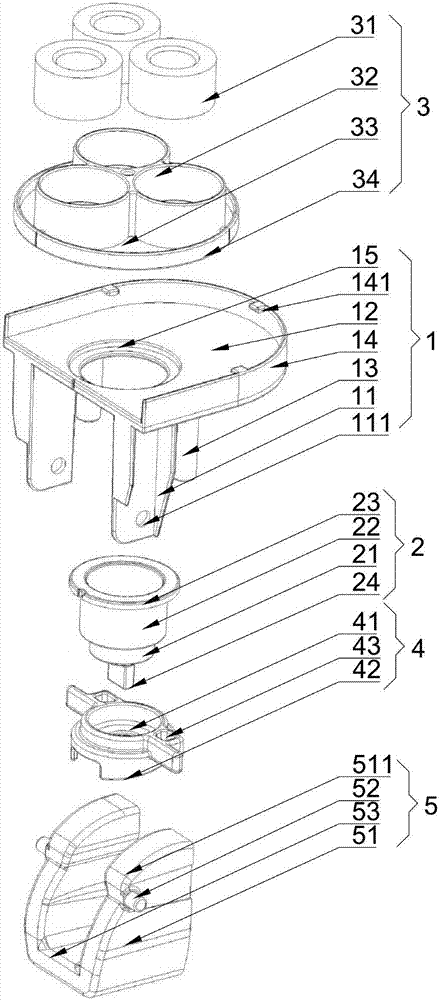

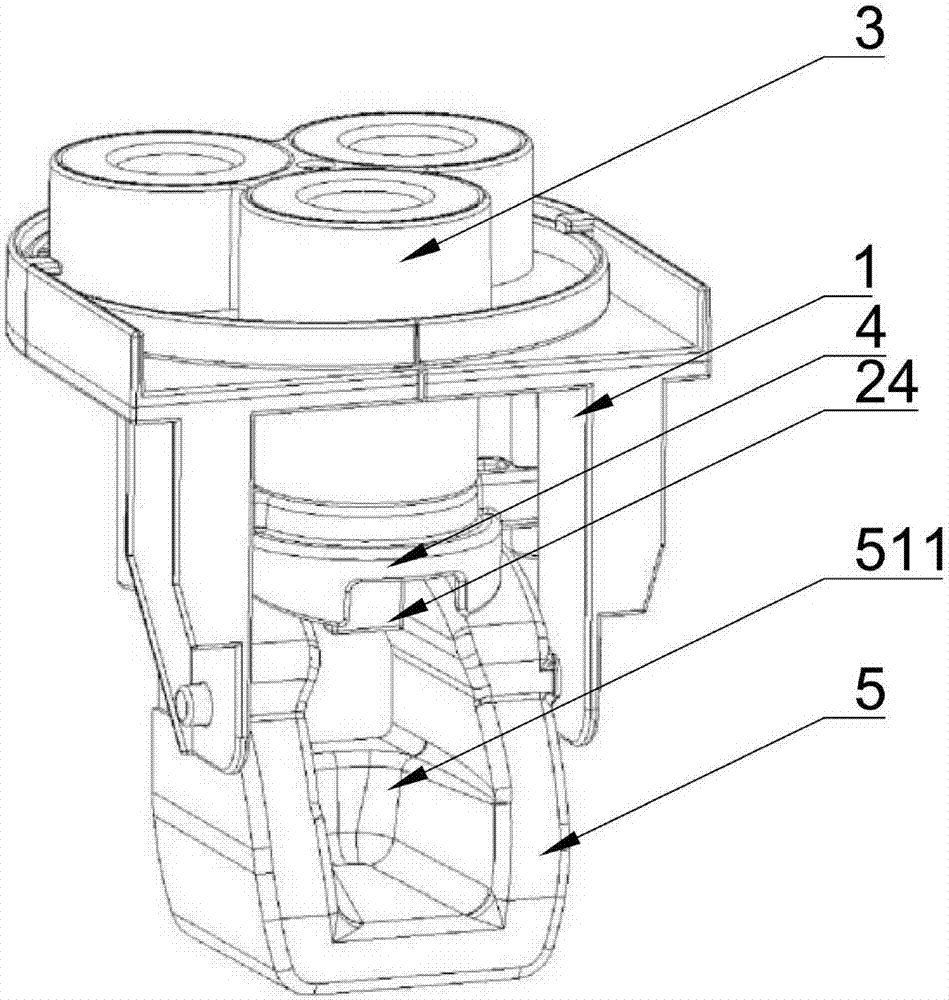

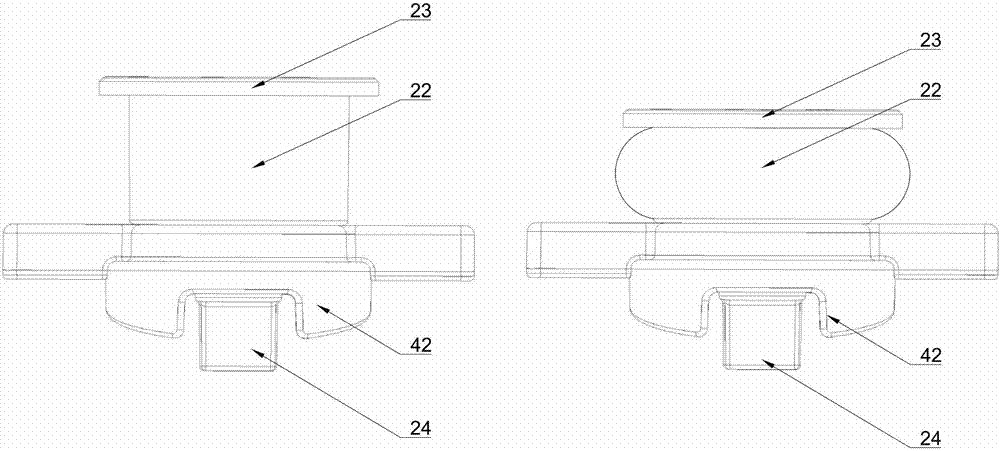

[0032] Such as Figure 1-2 , a toothpaste extruder, comprising a fixed frame 1, a lower lever 5 hinged with the fixed frame 1, a top pressure piece 4, a lower rubber barrel 2 with an extrusion head 24 on the lower edge; the top pressure piece 4 and the fixed frame 1 An upper and lower limit sliding mechanism is arranged between them, and the lower edge 21 of the lower rubber barrel and the top pressure piece 4 are detachably inserted into the top pressure piece fixing hole 41 of the top pressure piece 4, and the toothpaste head holder 3 is arranged on the fixed frame 1 Above and through the detachable locking mechanism and the fixing frame 1 to lock the upper edge of the lower rubber barrel 2, the toothpaste head holder 3 is provided with a rubber fixing head 31 that communicates with the accommodating cavity 22 of the lower rubber barrel 2 and matches with the toothpaste head The upper end surface of the lower lever 5 is an upwardly curved arc-shaped slope 511. When the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com