Optical fiber twisting recovering method and device

A recovery method and optical fiber technology, applied in glass fiber products, other household appliances, applications, etc., can solve problems such as affecting the performance of optical fibers, and achieve the effect of solving the decline of symmetry, improving performance, and quick recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

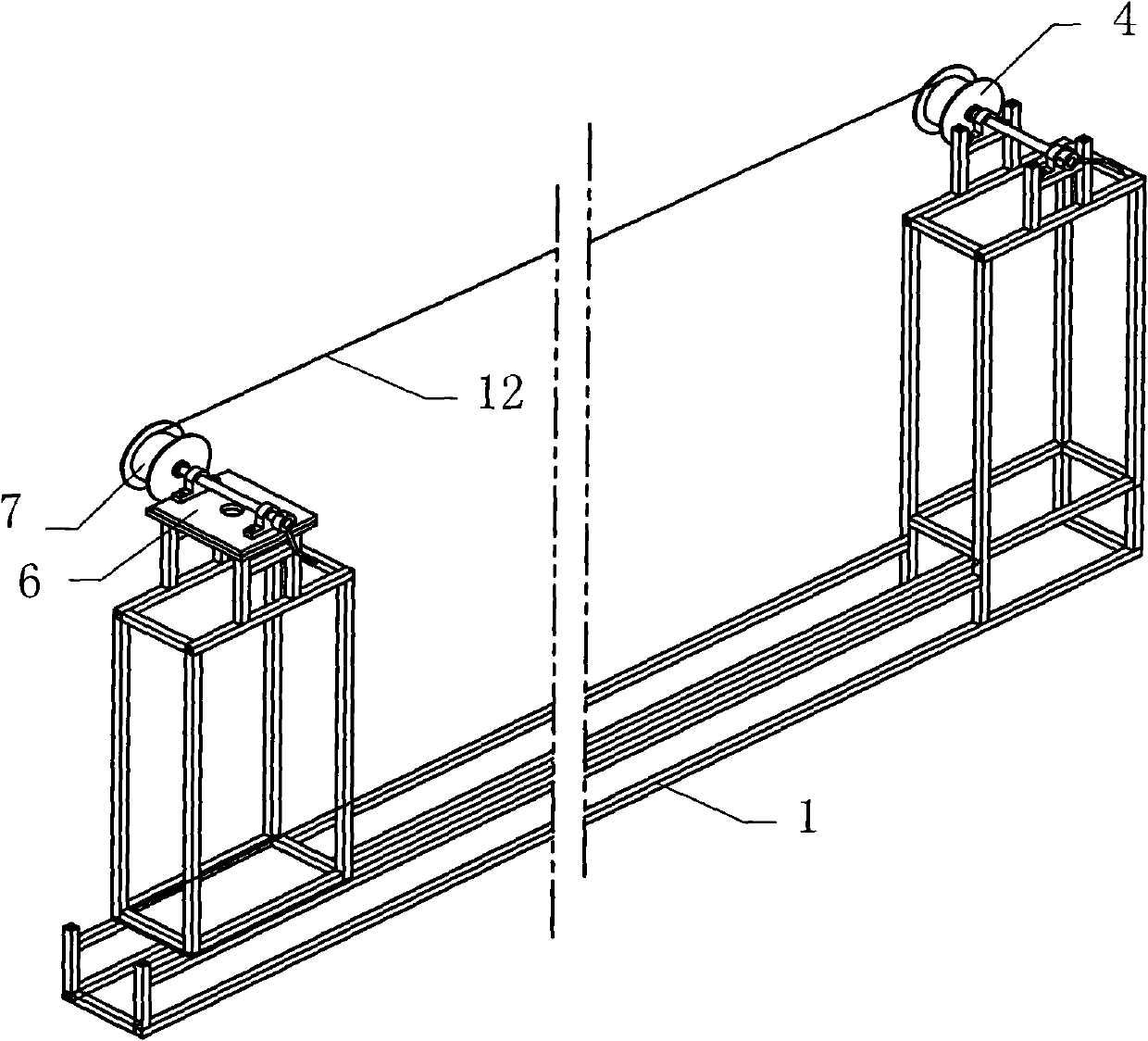

[0036] Such as Figure 1~5 The shown optical fiber torsion recovery method is special in that it includes the following steps:

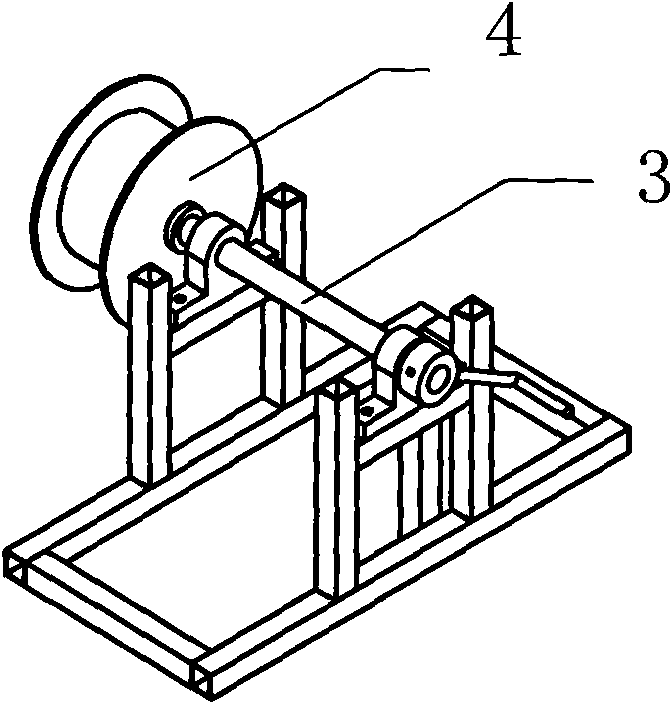

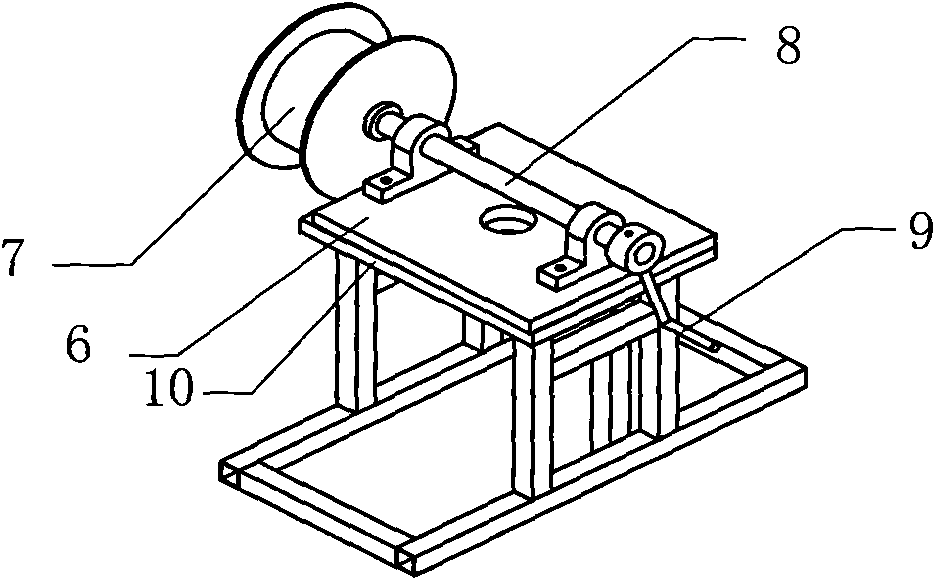

[0037] First, the optical fiber 12 is paid out from the fiber payout reel 4 of the fiber payout device, and the optical fiber 12 is connected to the fiber take-up reel 7 of the fiber take-up device. Then, the fiber payout device and the fiber collection device move toward the middle through the linear guide rail 1 until the optical fiber 12 is twisted due to natural sagging. In other words, along with the winding of the optical fiber 12 , when the fiber pay-off device and the fiber take-up device are close together, the optical fiber 12 will be twisted counterclockwise or the optical fiber 12 will be twisted clockwise.

[0038] In order to continue winding of the fiber, torsional recovery must be performed. Specifically, if the optical fiber 12 is twisted counterclockwise before, the fiber collection reel 7 is rotated clockwise, and the driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com