Power transmission project prefabricated foundation installation and iron tower assembly coherent construction method

A construction method and a technology for erecting steel towers, which are applied in infrastructure engineering, foundation structure tests, towers, etc., can solve problems such as high cost and long period, and achieve the effects of avoiding pollution, saving costs, and shortening the maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments. It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

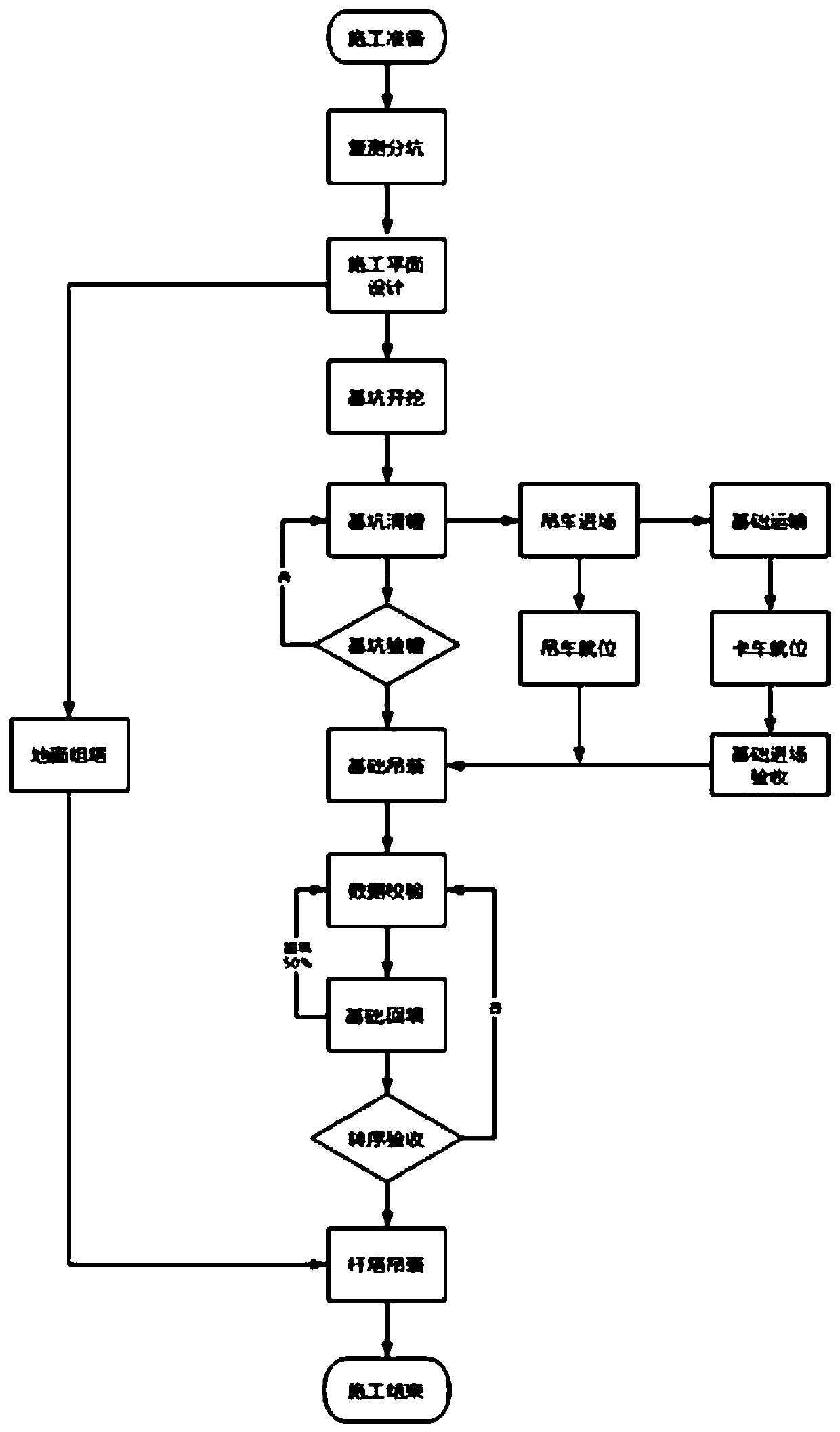

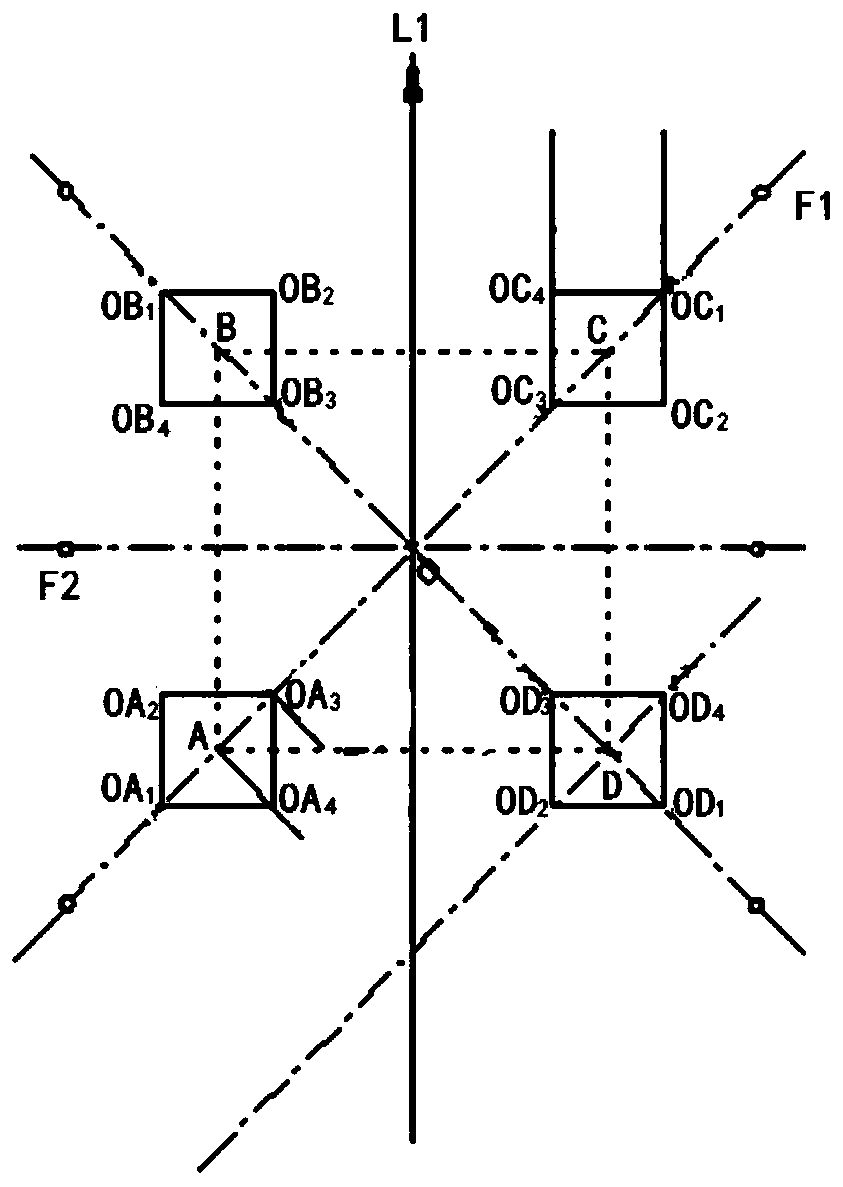

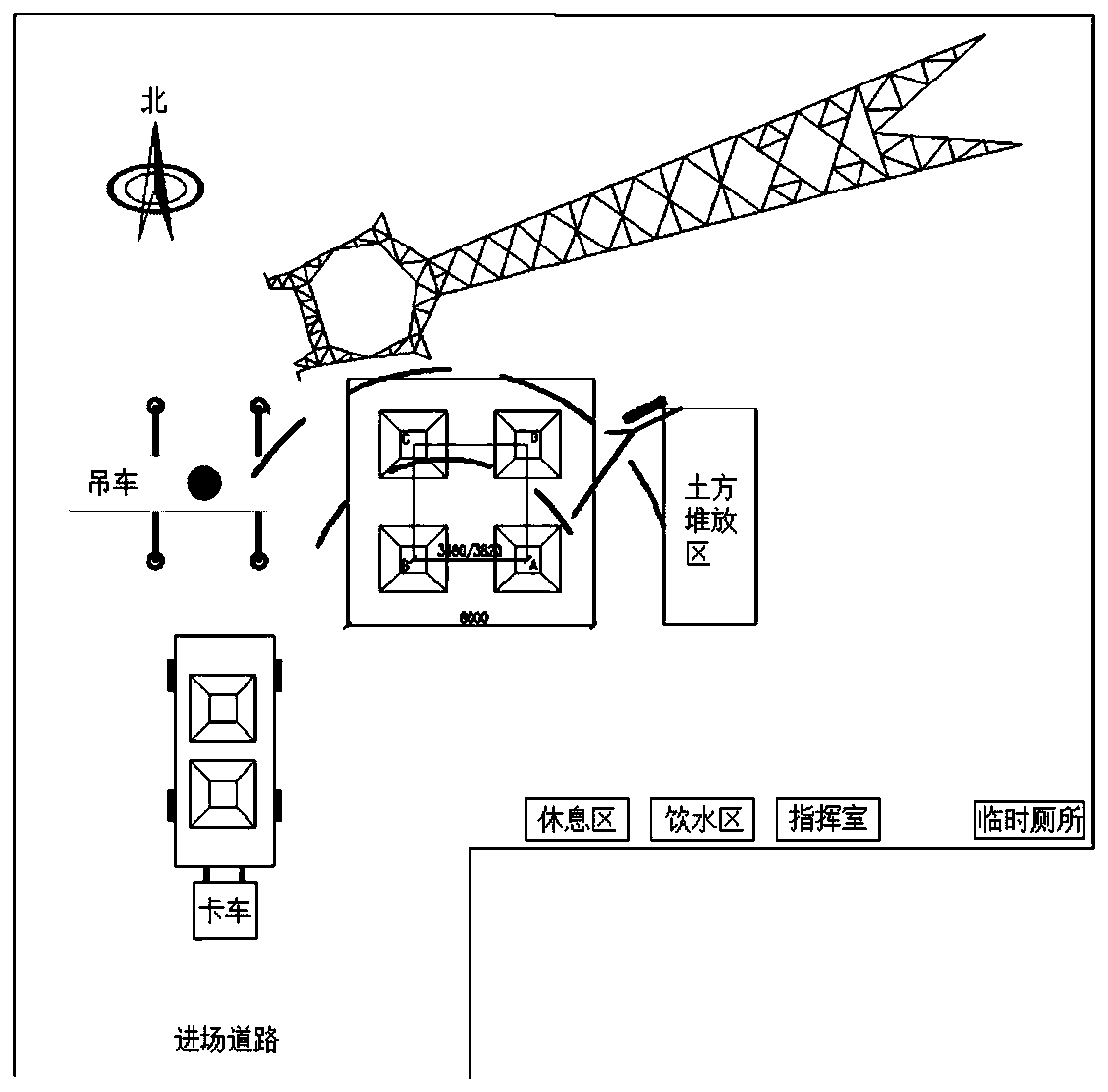

[0028] Such as figure 1 As shown, this embodiment provides a coherent construction method for prefabricated foundation installation and iron tower assembly of a power transmission project, which includes the following steps: step S1, retest sub-pits; step S2, construction plan design; step S3, ground tower assembly; step S4 , Foundation pit excavation; step S5, prefabricated foundation transportation and installation, where the prefabricated foundation is formed is a non-construction site; step S6, foundation backfill; step S7, transfer order acceptance; step S8, overall tower erection.

[0029] Specifically, it is usually necessary to make preparations for the construction of step 1 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com