Whole concrete stirring and conveying work platform

A working platform and concrete technology, which is applied in mixing plants, mixing operation control, clay preparation equipment, etc., can solve the problems of safety accidents, large floor area, and affecting the success of construction, so as to facilitate installation and transportation, improve construction efficiency, Simple and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

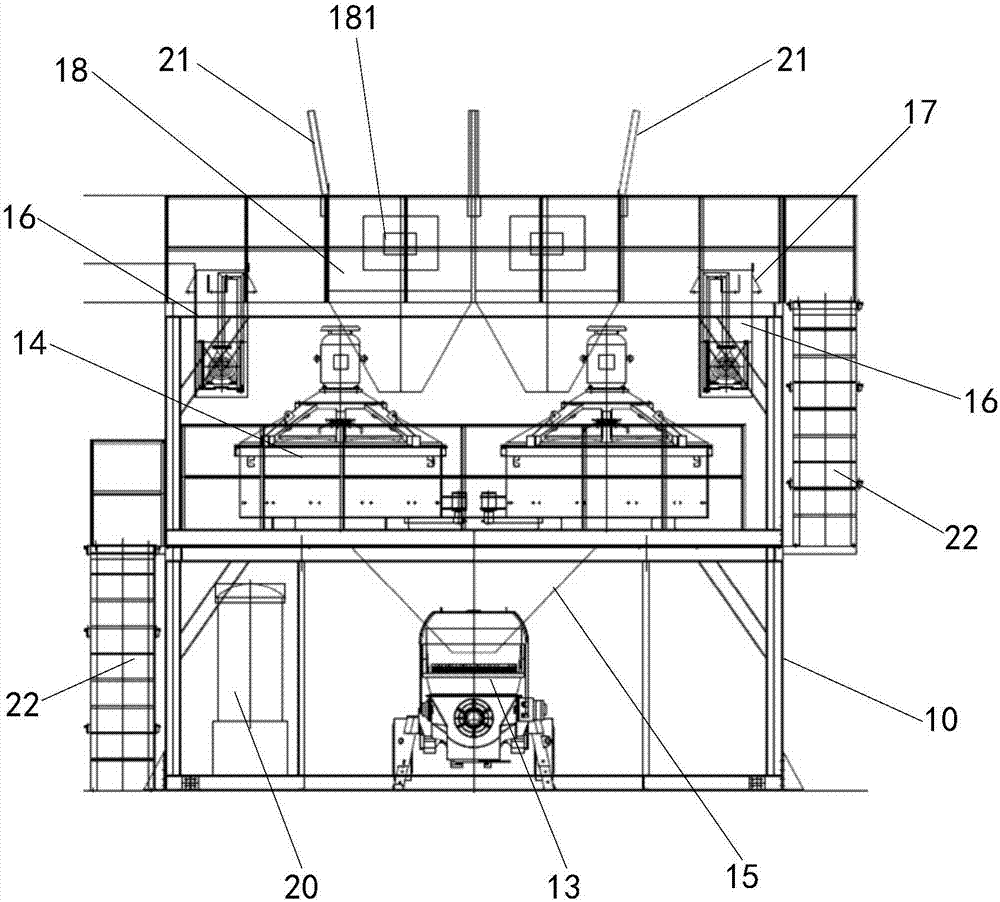

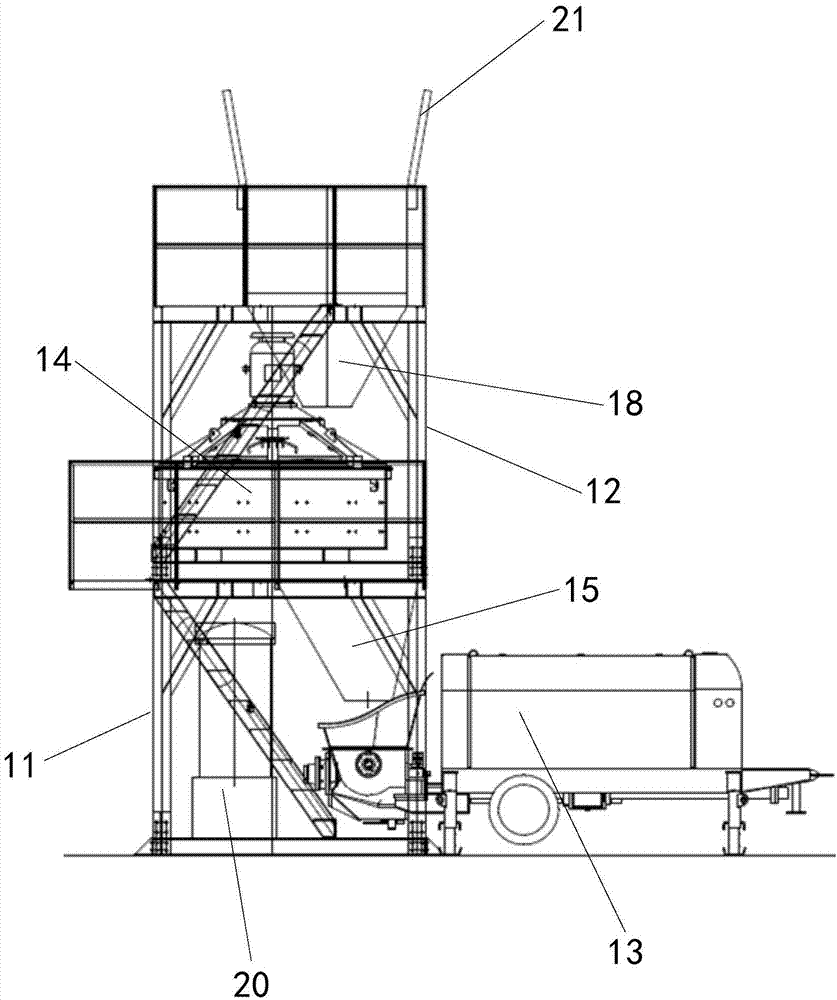

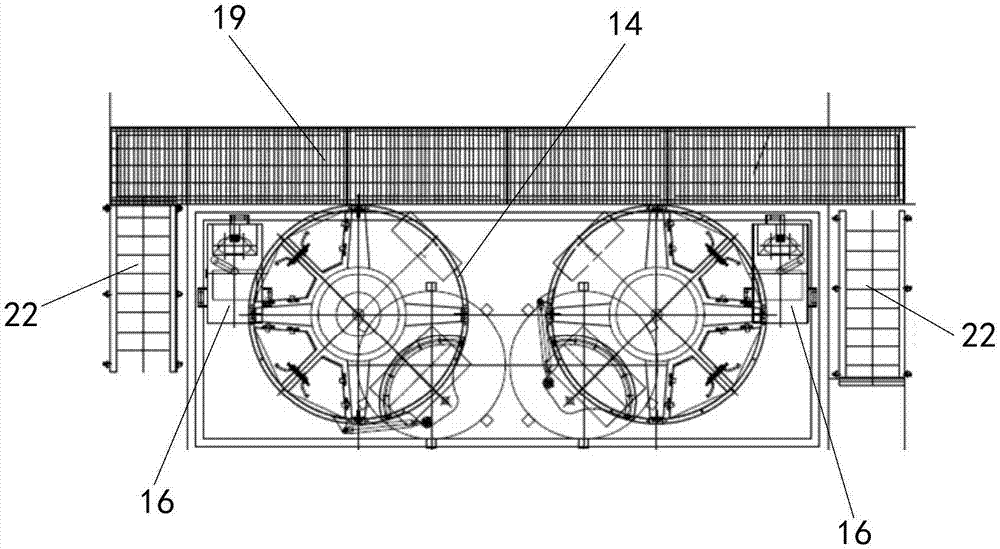

[0044] like Figure 1-7 As shown, the overall working platform for concrete mixing and conveying provided in this embodiment includes a frame 10, at least one conveying pump 13, at least one agitator 14 and a control system;

[0045] like Figure 4-7As shown, the frame 10 includes a first layer of support 11 and a second layer of support 12, the frame 10 is a frame structure, including horizontal members, vertical members and braces welded, such as Figure 6-7 As shown, there are brackets installed around the bottom of the first layer of bracket 11, which are used for temporary fixing by welding during construction, and as shown in Figure 4-5 As shown, the bottom and top of the second layer of support 12 are equipped with detachable railings. The second layer of support 12 is located above the first layer of support 11, and the agitator 14 is arranged on the second layer of support 12. , the agitator 14 is connected to the second layer of support 12 by bolts, and fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com