Ground wall embedded slideway type steel support foundation pit supporting system and construction method thereof

A technology of support system and construction method, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of increased difficulty in the installation of lower steel supports, more upper supports, and influence on the construction period, so as to save construction work time, The effect of reducing construction cost and facilitating subsequent disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

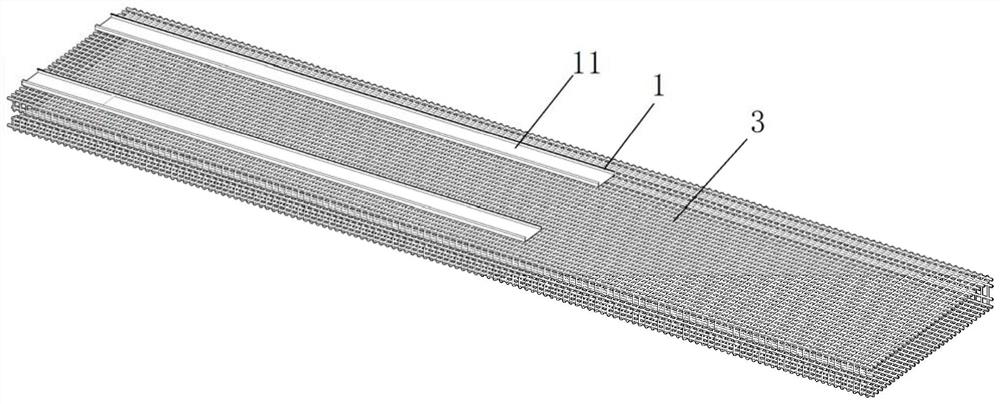

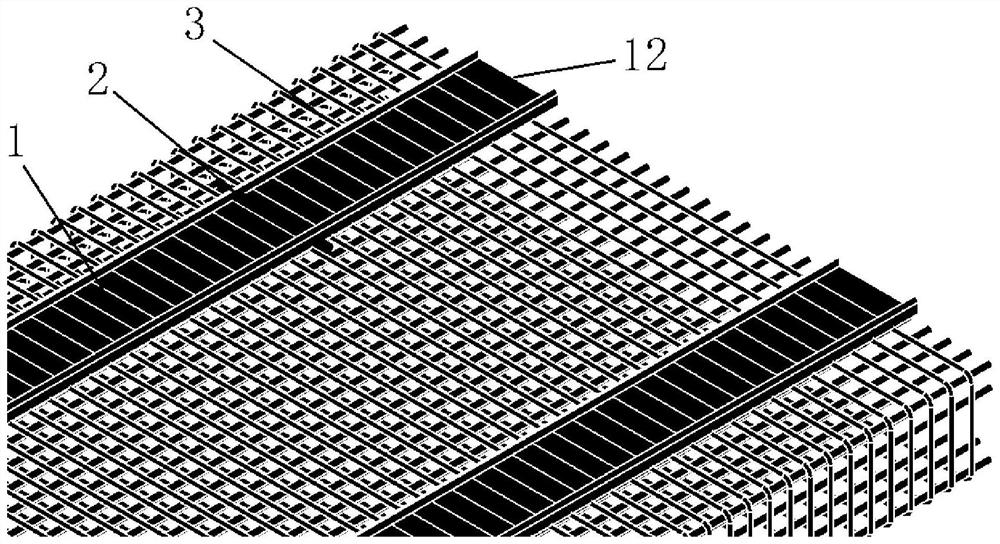

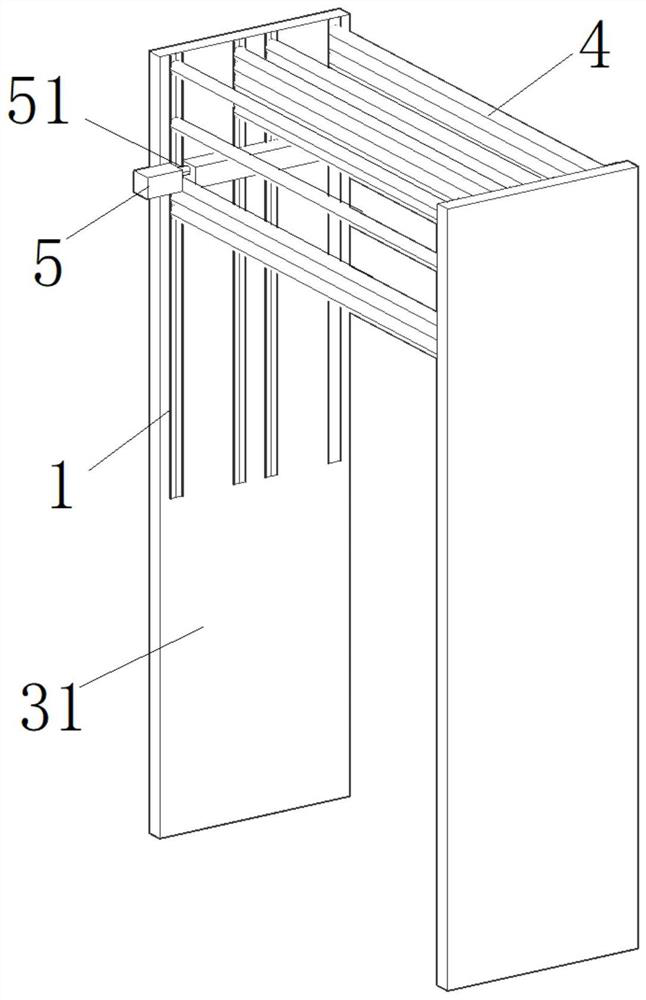

[0028] Please see attached figure 1 to attach image 3 , a ground wall pre-embedded slideway type steel support foundation pit support system, including a pre-embedded slideway 1, a fixed bolt 2 and a steel support 4; , the pre-embedded slideway 1 is set along the supporting position of the steel support 4; the notches of the embedded slideway 1 on the ground walls 31 on both sides of the foundation pit are arranged oppositely, so that the two ends of the steel support 4 can be respectively inserted into the notch through the notch embedded in the slideway 1, and the steel support 4 can slide along the embedded slideway 1; several bolt holes (not shown in the figure) are formed on the embedded slideway 1, and bolt holes are formed at both ends of the steel support 4 The fixed bolt 2 penetrates the embedded slideway 1 and the steel support 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com