Overhead bare conducting wire insulating coating robot

A wire insulation and insulation coating technology, which is applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems of large volume, complicated and inconvenient lifting process, and increased construction work time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

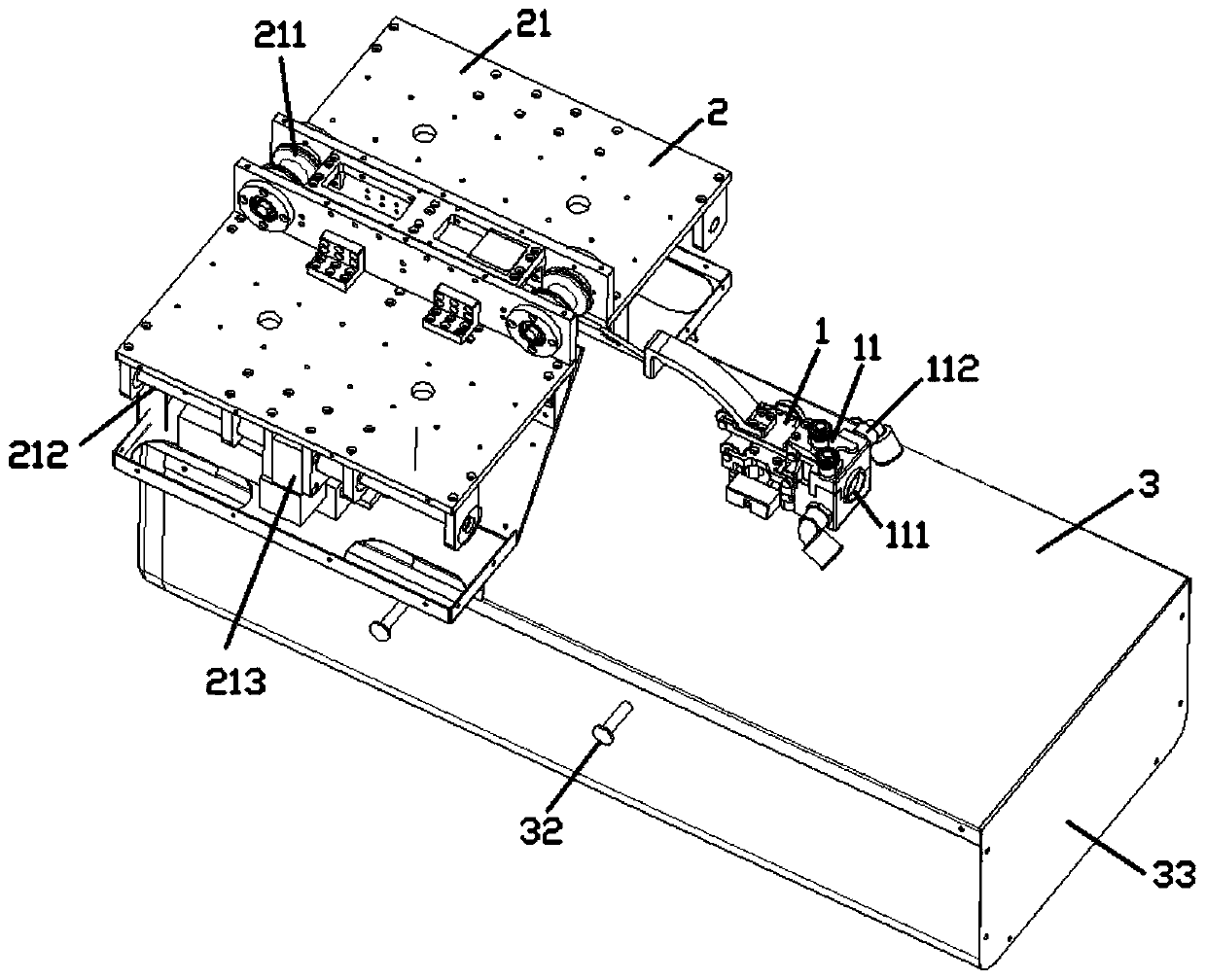

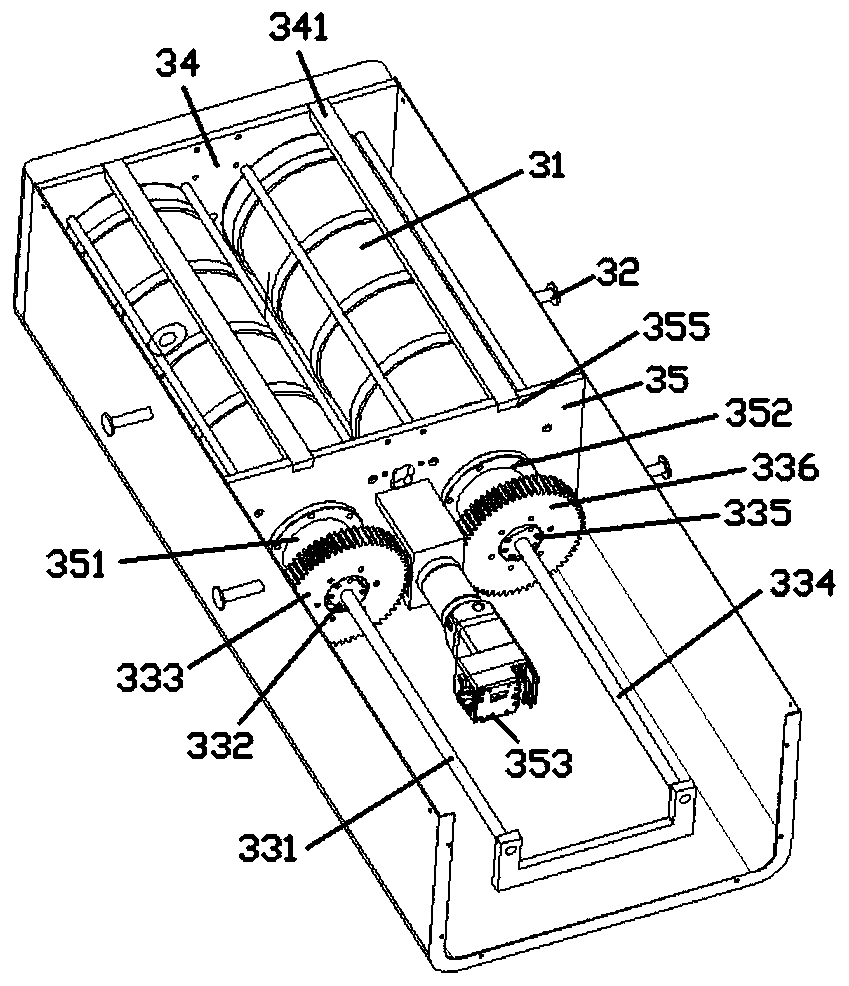

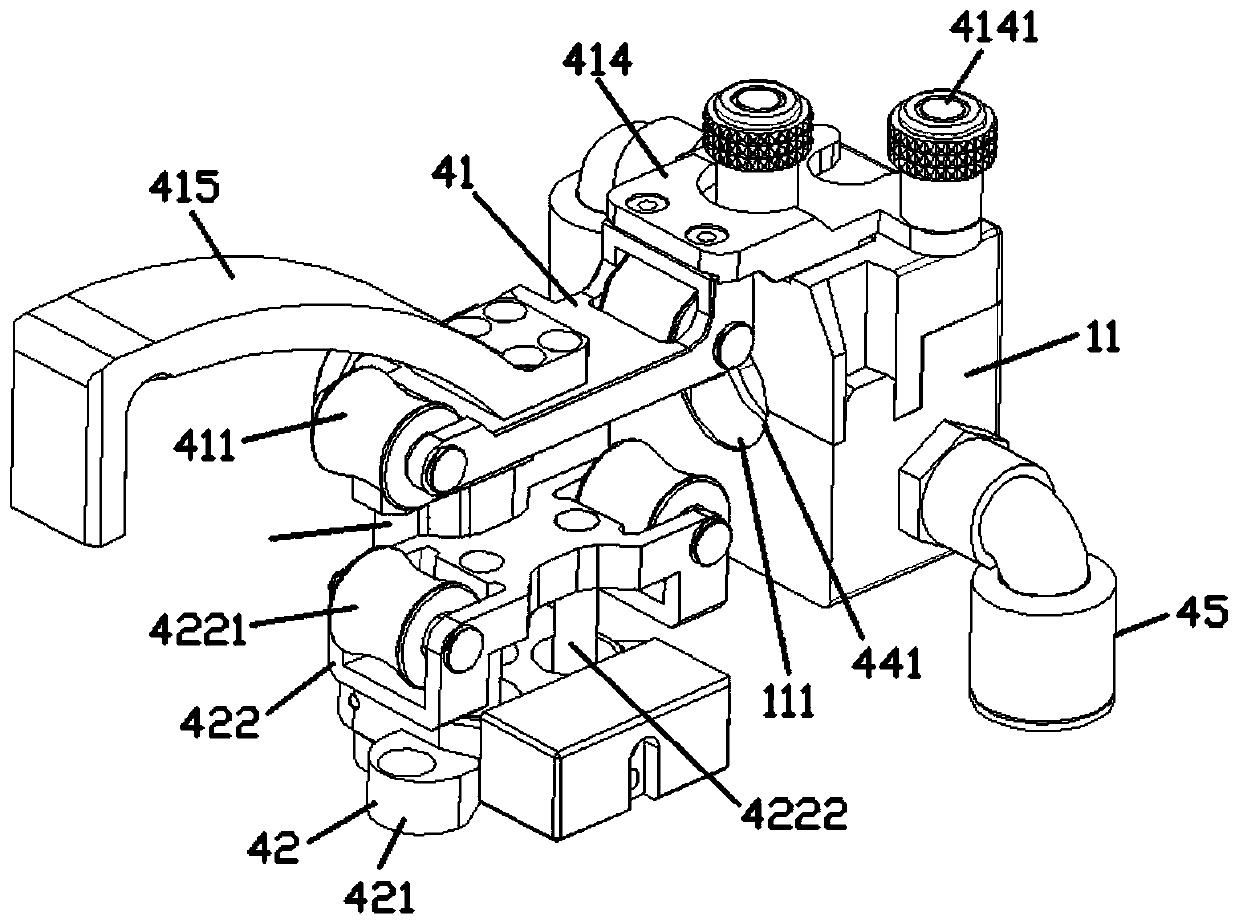

[0060] image 3 It is the first three-dimensional structural schematic diagram of the insulating coating module in the first embodiment of the present invention, Figure 4 It is a schematic diagram of the second three-dimensional structure of the insulating coating module in Embodiment 1 of the present invention, Figure 5 It is a schematic diagram of the three-dimensional structure of the fixed pallet in Embodiment 1 of the present invention.

[0061] In the first embodiment, the insulation coating module 1 further includes a fixed bracket 41 , a sliding assembly 42 and a positioning guide rod 43 .

[0062] The fixed pallet 41 is connected to the front side of the insulating coating die head 11, and a plurality of fixed positioning wheels 411 are sequentially hinged in the fixed pallet 41 along the straight direction of the cable channel 111, and the The fixed pallet 41 is provided with a pallet sliding hole 412 and a plurality of sliding guide rods 413 along the vertical d...

Embodiment 2

[0079] Figure 7 It is the first three-dimensional structural schematic diagram of the insulating coating module in the second embodiment of the present invention, Figure 8 It is a schematic diagram of the second three-dimensional structure of the insulating coating module in the second embodiment of the present invention.

[0080] In the second embodiment, the insulation coating module 1 further includes a support assembly 51 and a first mold driving device 54 , and the insulation coating die head 11 includes a first mold 52 and a second mold 53 .

[0081] The support assembly 51 includes a support mounting plate 511 and a module bottom plate 512, the module bottom plate 512 is connected to one side of the support mounting plate 511, and a plurality of The first positioning wheel 5111, the module bottom plate 512 is provided with a plurality of horizontal guide pins 5121 perpendicular to the first horizontal line.

[0082] The inner surface of the first mold 52 is provided...

Embodiment 3

[0103] Figure 9 It is a schematic diagram of the first three-dimensional structure of the insulating coating module in the third embodiment of the present invention, Figure 10 It is a schematic diagram of the second three-dimensional structure of the insulating coating module in the third embodiment of the present invention.

[0104] In the third embodiment, the insulation coating module 1 further includes a support frame 61 and a second mold driving device 62 , and the insulation coating die head 11 includes a third mold 63 and a fourth mold 64 .

[0105] A plurality of second positioning wheels 611 are sequentially hinged on the top of the support frame 61 along the first straight line.

[0106] The inner surface of the third mold 63 is provided with a third groove 631, and the outer surface of the third mold 63 is provided with a third coating hole 632 communicating with the third groove 631; the fourth mold The inner surface of the mold 64 is provided with a fourth gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com