Patents

Literature

121results about How to "Spread out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mud content inhibitor for concrete doped with polycarboxylic acid type water reducer and preparation method and application method of mud content inhibitor

The invention relates to the field of concrete additives and specifically relates to a mud content inhibitor for concrete doped with a polycarboxylic acid type water reducer and a preparation method and an application method of the mud content inhibitor. The mud content inhibitor is prepared by the following raw materials of, by weight, 20%-30% of mud dispersion components, 0.5%-5% of mud adsorption components, 0.5%-5% of ion complexation exchange components and the balance water. The preparation method includes firstly, uniformly stirring water and the mud dispersion components, and adding and uniformly stirring the mud adsorption components and the ion complexation exchange components. The application method includes that the usage amount of the mud content inhibitor is 2-5 wt. % of that of the polycarboxylic acid type water reducer. By means of the mud content inhibitor, the liquidity and the slump-retaining performance of the concrete can be increased, the viscosity of the concrete is reduced, the work state of the concrete can be improved, the adsorption quantity of high valence metal ions to the polycarboxylic acid type water reducer can be reduced, and the performance of the concrete doped with the polycarboxylic acid type water reducer is guaranteed.

Owner:山东华伟银凯建材科技股份有限公司

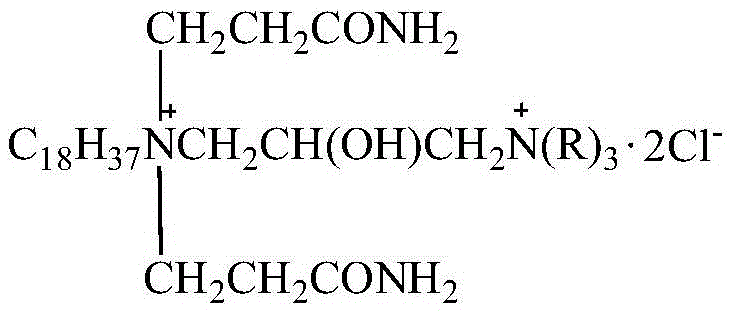

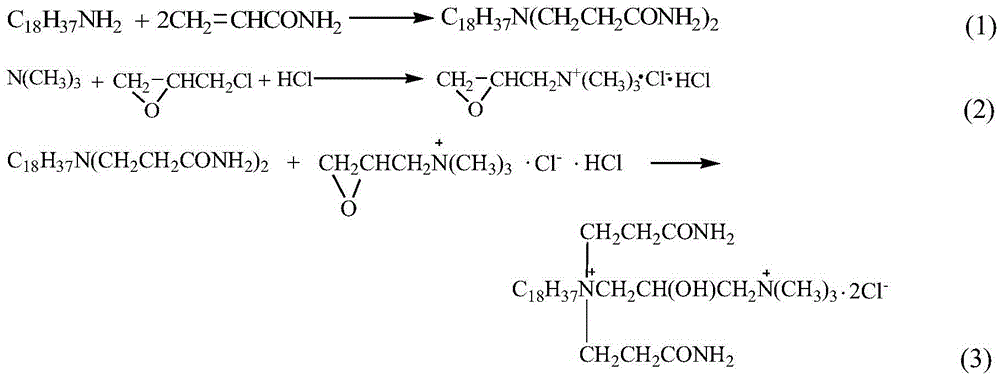

Dicationic amide type asphalt emulsifier and preparation method therefor

InactiveCN105418942AReduce manufacturing costSave raw materialsOrganic compound preparationCarboxylic acid amides preparationCarbon numberEthyl group

The invention discloses a dicationic amide type asphalt emulsifier, the molecular structure of which is represented by a formula, wherein R is a methyl group (-CH3), an ethyl group (-C2H5) or an alcoholic group (-C2H4OH); The emulsifier is prepared from the following raw materials in a following molar ratio: octadecylamine: an alcohol solvent: acrylamide: low carbon number tertiary amine: technical hydrochloric acid: epichlorohydrin=1mol:(4.00-9.00)mol:(2.00-2.10)mol:(1.02-1.10)mol:(1.02-1.10)mol:(1.02-1.08)mol. The dicationic amide type asphalt emulsifier disclosed by the invention is easily available in synthetic raw materials, low in production cost, simple in process and free of high-temperature reactions. The emulsifier can be used for emulsifying asphalt in various different types and the prepared emulsified asphalt is fine and smooth and uniform and good in storage stability. The emulsifier can be used for prepare rapid type cationic emulsified asphalt.

Owner:SHANDONG UNIV

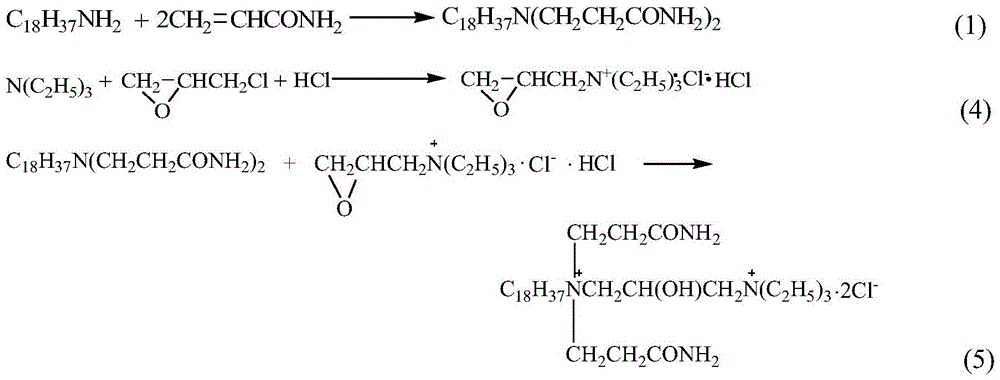

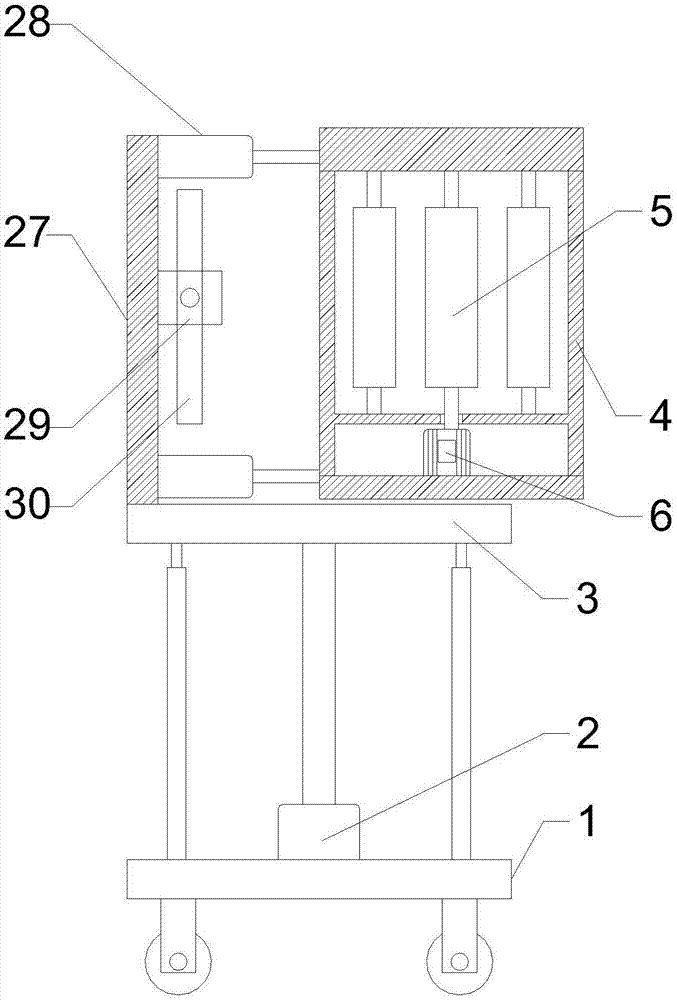

Indoor wallpaper laying device

InactiveCN107344472ASpread outWell laidLiquid surface applicatorsPaperhangingEngineeringMechanical engineering

The invention discloses an indoor wallpaper laying device, which comprises a base plate; a first hydraulic cylinder is fixedly connected to the center of the upper surface of the base plate, and a lifting plate is connected to the first hydraulic cylinder through a piston rod; the upper surface of the lifting plate is slidingly connected to a Moving frame; the moving frame is rotatably connected with a wallpaper roller; behind the wallpaper roller is a glue roller; on the right side of the glue roller is a glue spraying device; between the glue roller and the wallpaper roller there is a wallpaper cut-off device. The present invention realizes the uniform and high-efficiency smearing of wallpaper glue by being provided with a glue hair roller and a glue spraying device, and is convenient for wallpaper laying; On the wall, the air bubbles between the wallpaper and the wall are squeezed out, and the glue is fully spread at the same time, ensuring the sticky quality and flatness of the wallpaper, and improving the work efficiency and quality of wallpaper laying.

Owner:李明超

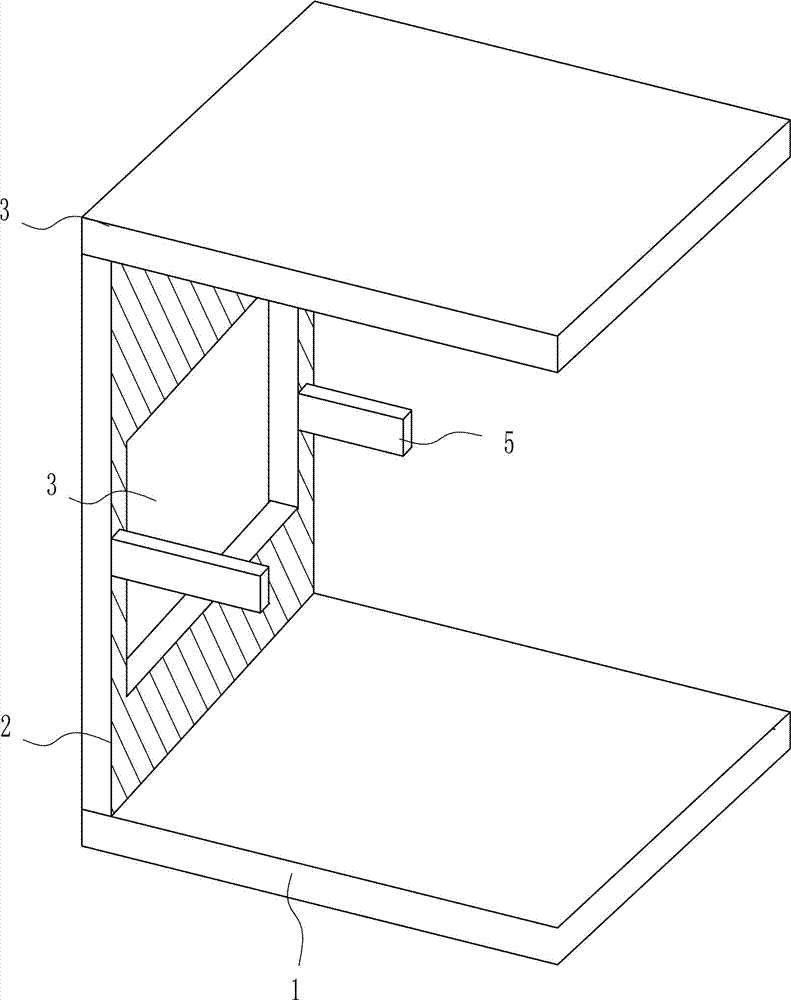

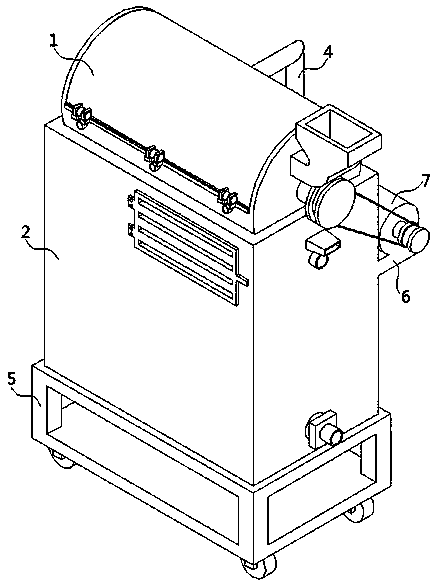

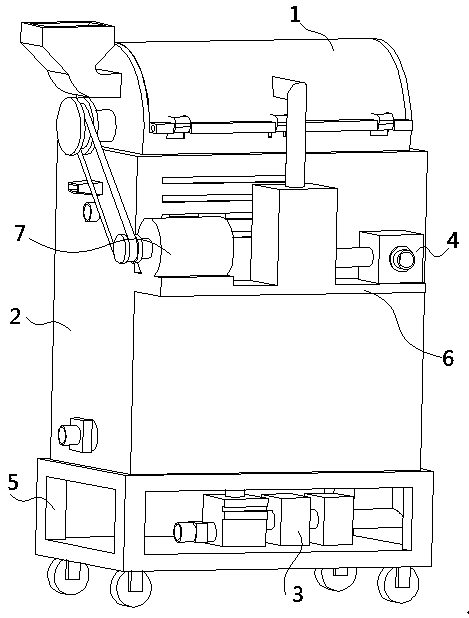

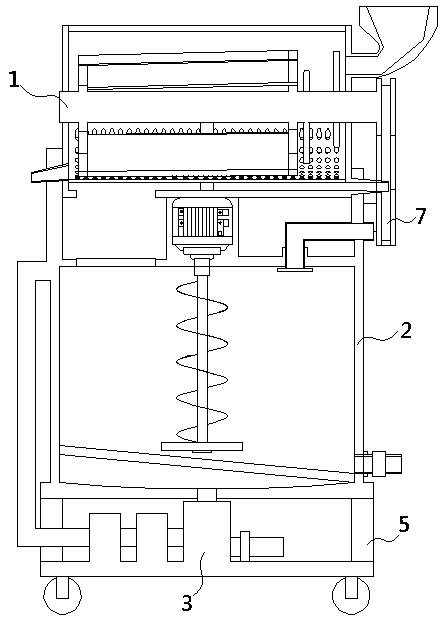

Environmental protection and deodorization equipment for household garbage transfer station

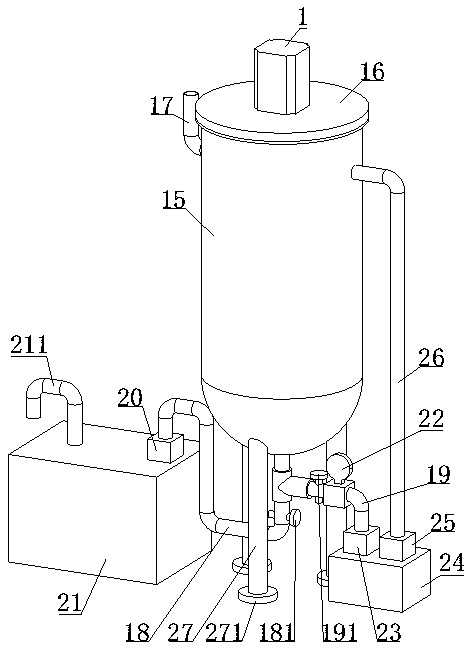

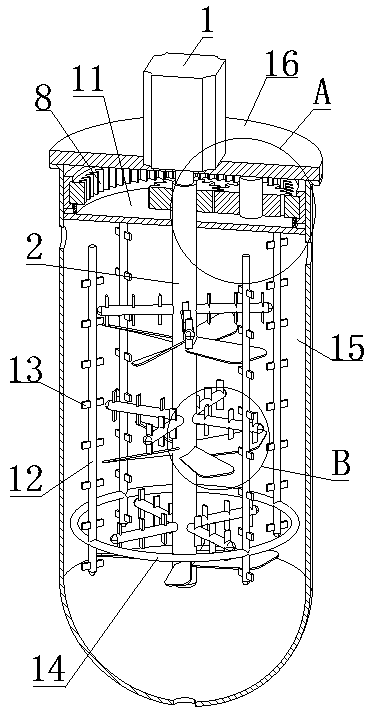

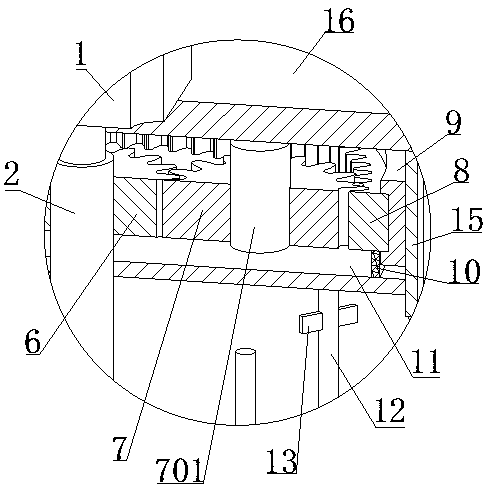

InactiveCN107010347AAchieve liftingSimple structureRefuse receptaclesRefuse cleaningEngineeringPre treatment

The invention belongs to the field of household garbage pre-treatment, and particularly relates to environmental protection and deodorization equipment for a household garbage transfer station. The environmental protection and deodorization equipment for the household garbage transfer station can purify odor, facilitate garbage disposal, and prevent microorganism from breeding, and comprises a base, a fixed plate, a top plate, rotating shafts, fixed links, a garbage can, a lifting device, a gas-collecting hood, an odor treatment device, an exhaust fan, and the like; and the fixed plate is arranged on the left side of the top of the base, a square groove is formed in the middle portion of the fixed plate, the fixed links are arranged on the front side and the back side of the middle portion of the right wall of the fixed plate correspondingly, and the rotating shafts are arranged on the middle portions of the two fixed links correspondingly. The environmental protection and deodorization equipment for the household garbage transfer station achieves the effects of purifying the odor, facilitating garbage disposal, and preventing the microorganism from breeding, and is novel in structure, environment-friendly, and beneficial to the construction of urban and rural garbage transfer stations.

Owner:江西太赫兹环保科技有限公司

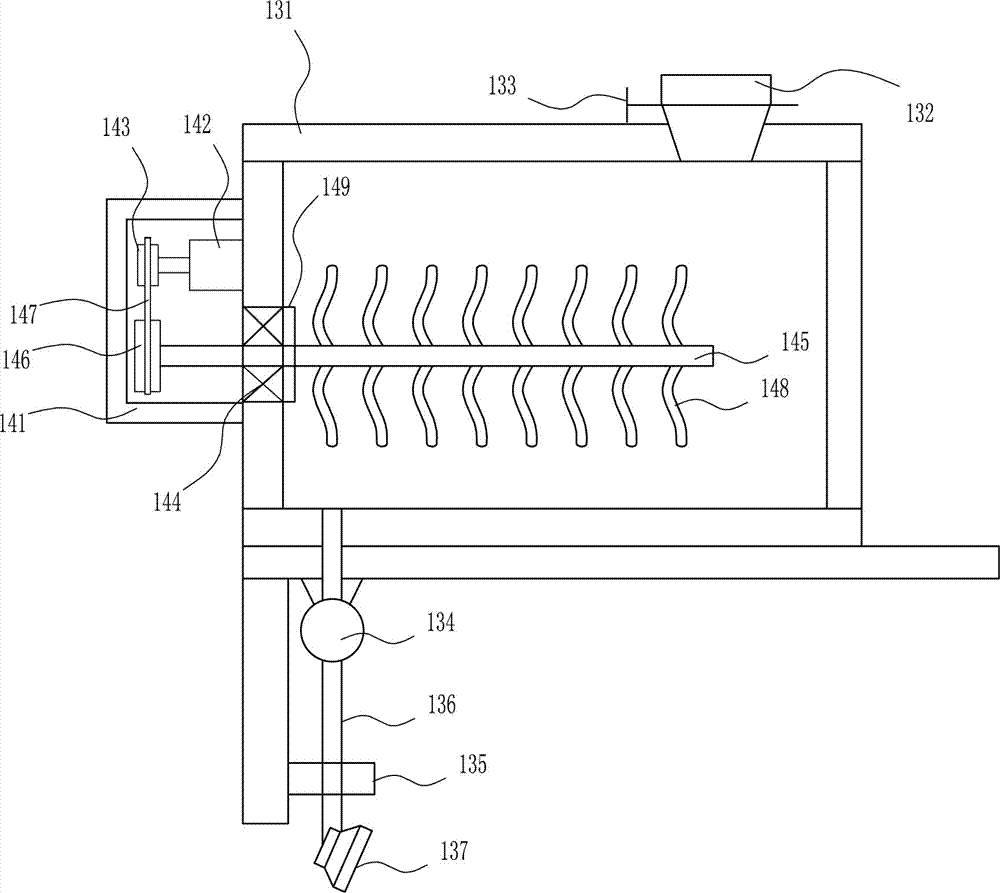

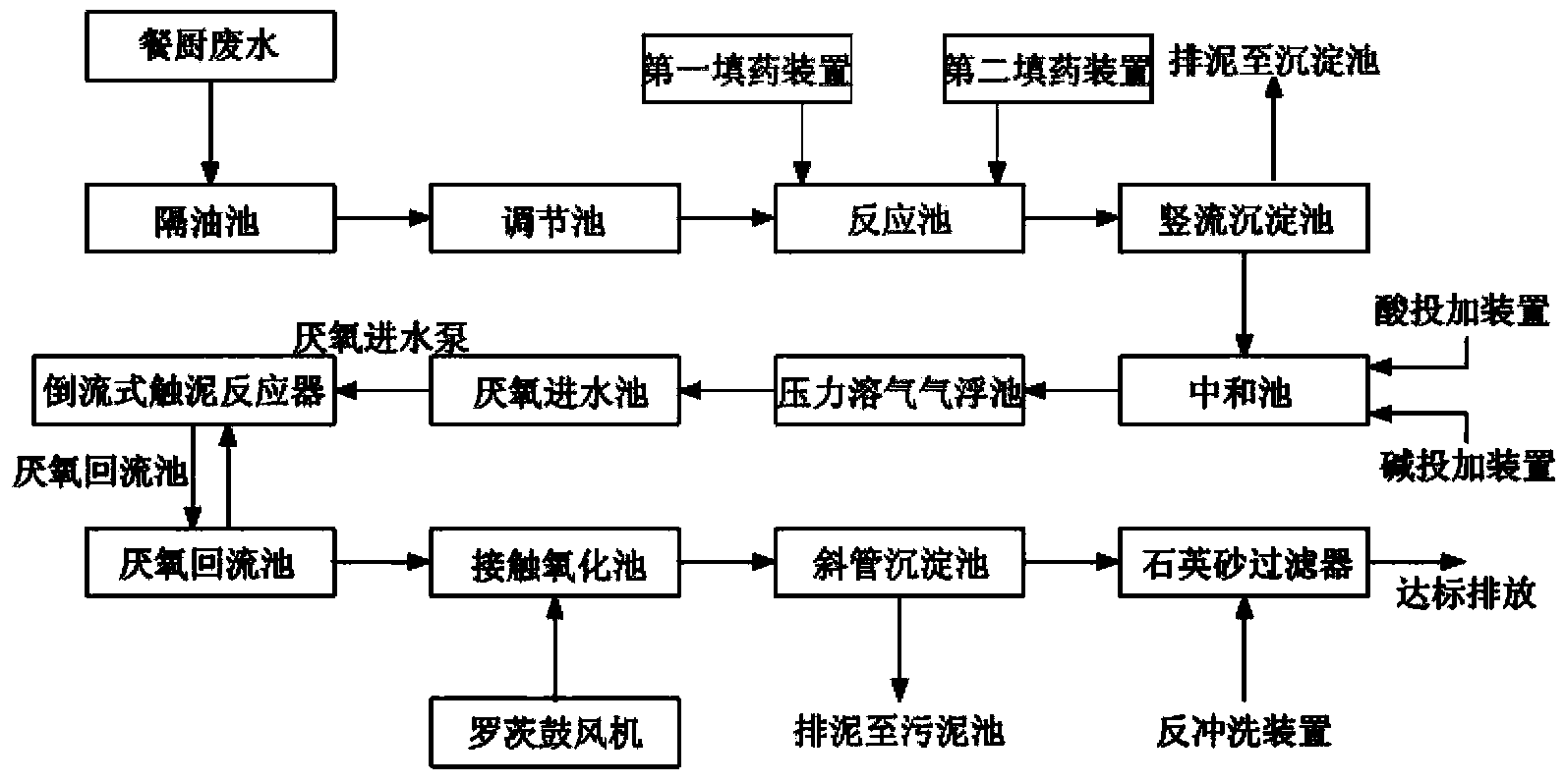

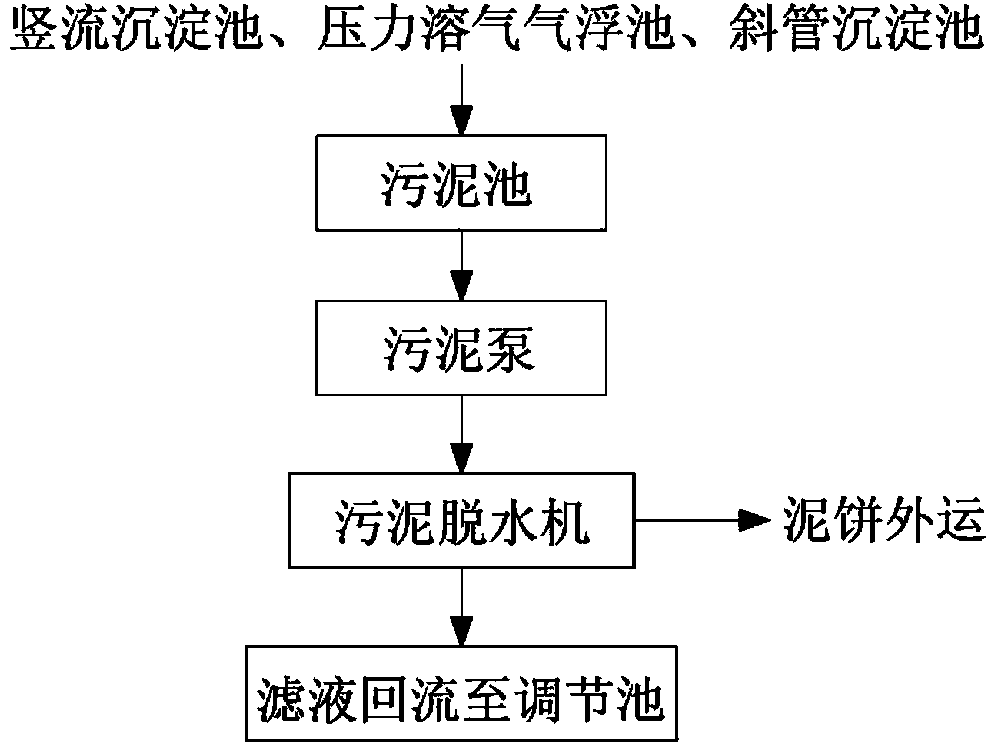

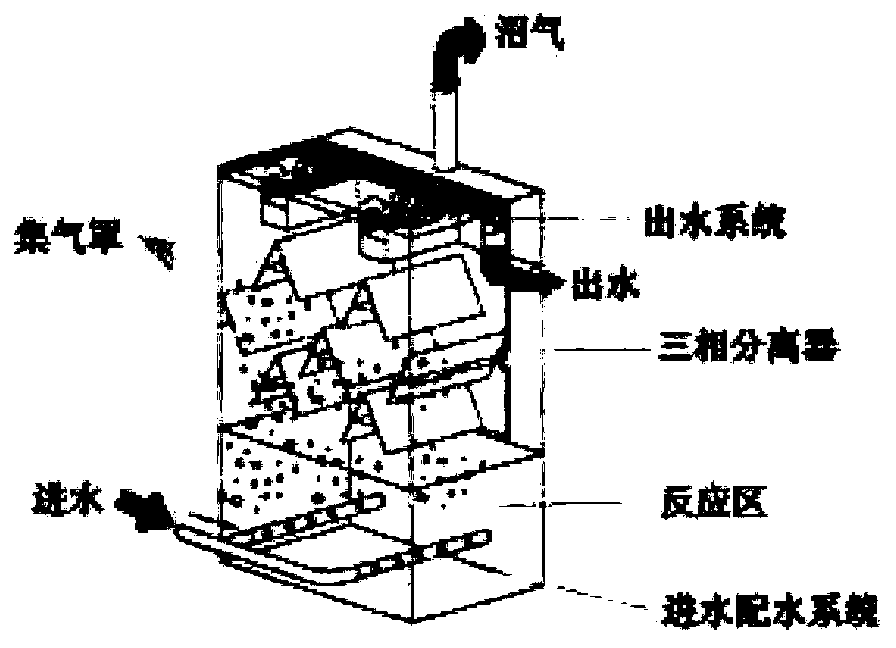

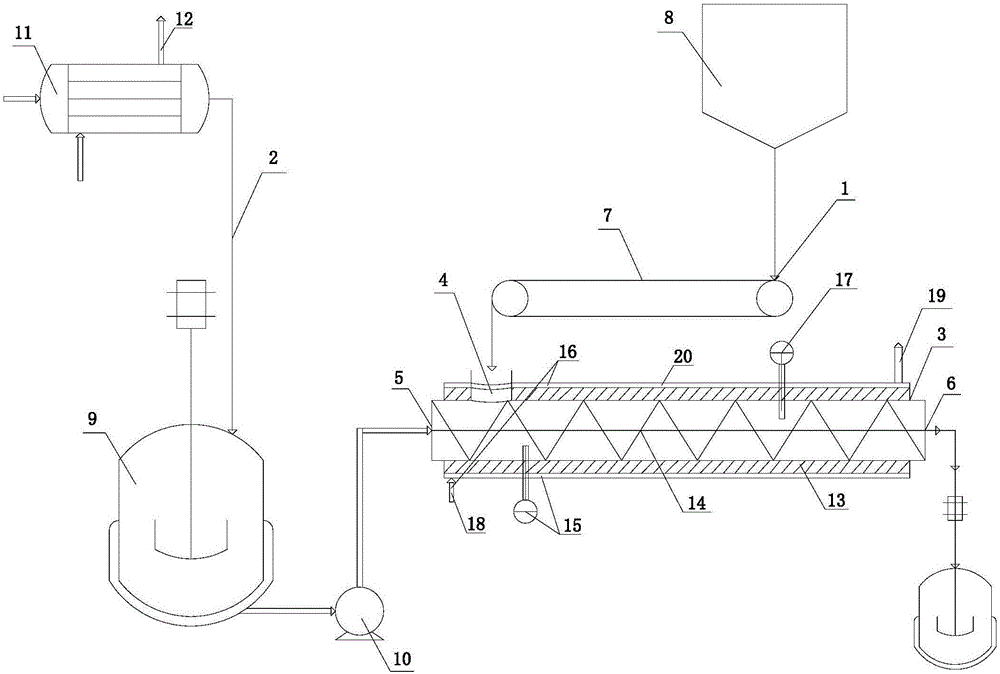

Kitchen waste filtrate treatment equipment and method

ActiveCN103435235AImprove CODHigh oil contentFatty/oily/floating substances removal devicesMultistage water/sewage treatmentSludgeFiltration

The invention discloses kitchen waste filtrate treatment equipment and method. The treatment method comprises the steps that the kitchen filtrate firstly enters an oil separation tank used for separating oil substances from water substances; the water after separation is converged into a regulating tank and the water quality and quantity are regulated; the effluent enters a reaction tank, PAC (polyaluminium chloride) and PAM (polyacrylamide) are added to the effluent, so that fine particles in the water form a plenty of alum flocs, and then the alum flocs precipitate to be separated in a precipitation tank, thus removing most oil and scum; the effluent from the precipitation tank automatically flows into a neutralization tank, the pH value is regulated to neutral and then the effluent enters a pressure dissolved air floatation tank used for removing the scum formed by the flocculated suspended matter particles or oil particles brought on the water surface from the wastewater; then the pollutants such as organic matters, ammonia nitrogen and the like are removed by the pretreatment+anaerobic+aerobic precipitation+sand filtration technology of an exclusively added backflow sludge contact reactor; finally the wastewater reaches discharge standard.

Owner:裕英(北京)生物科技有限公司

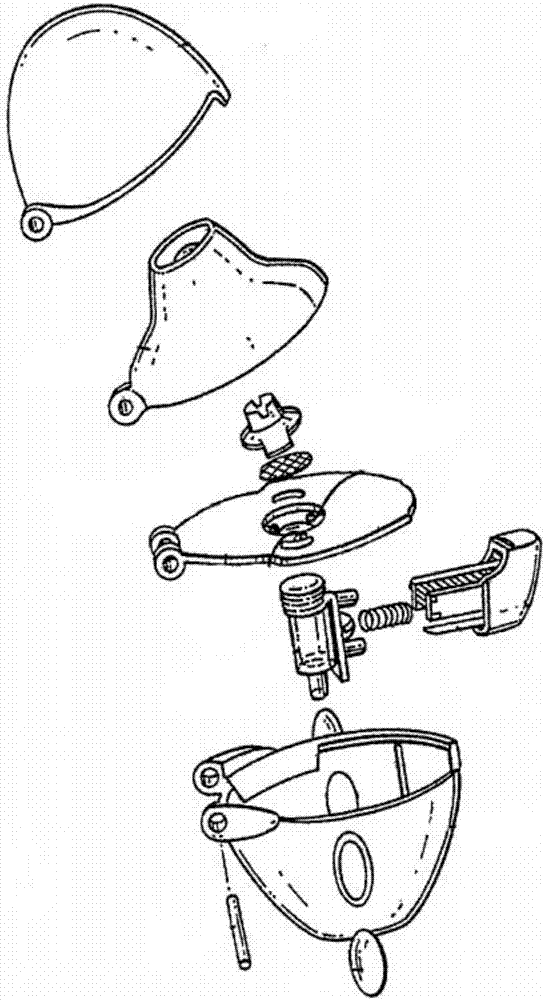

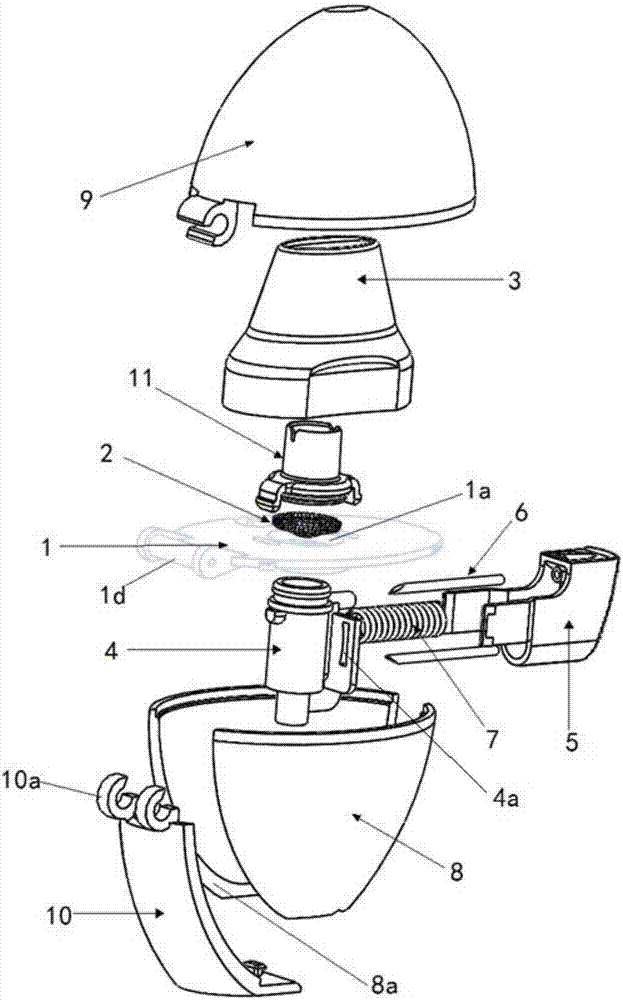

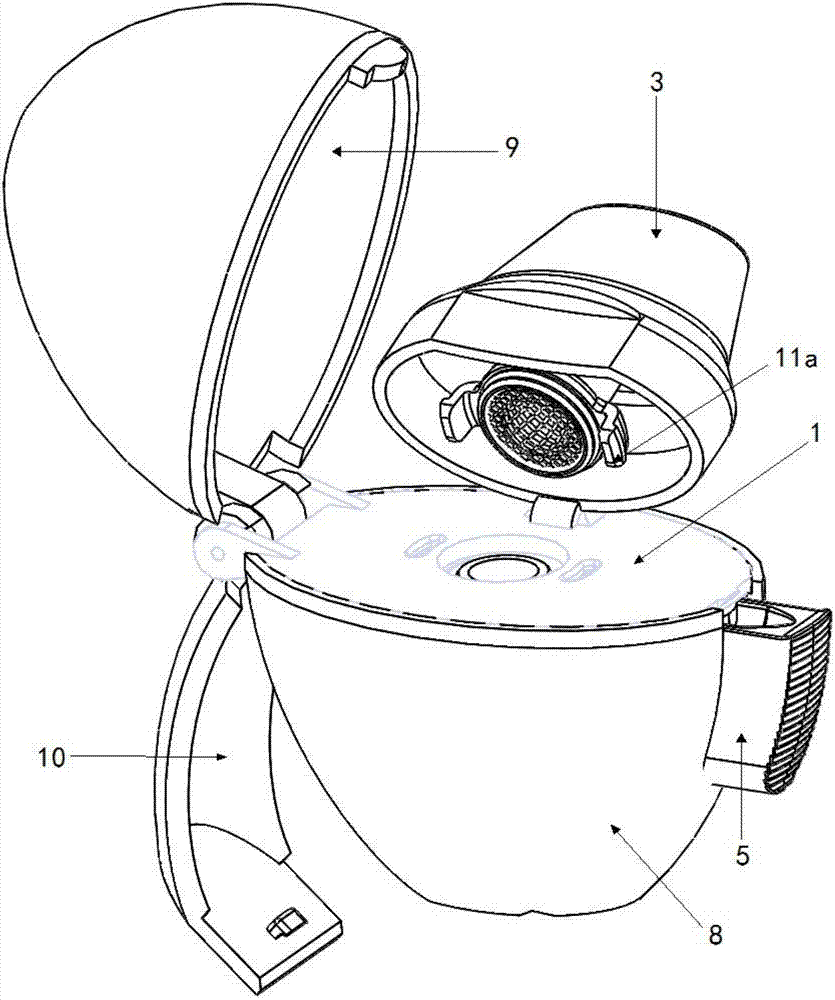

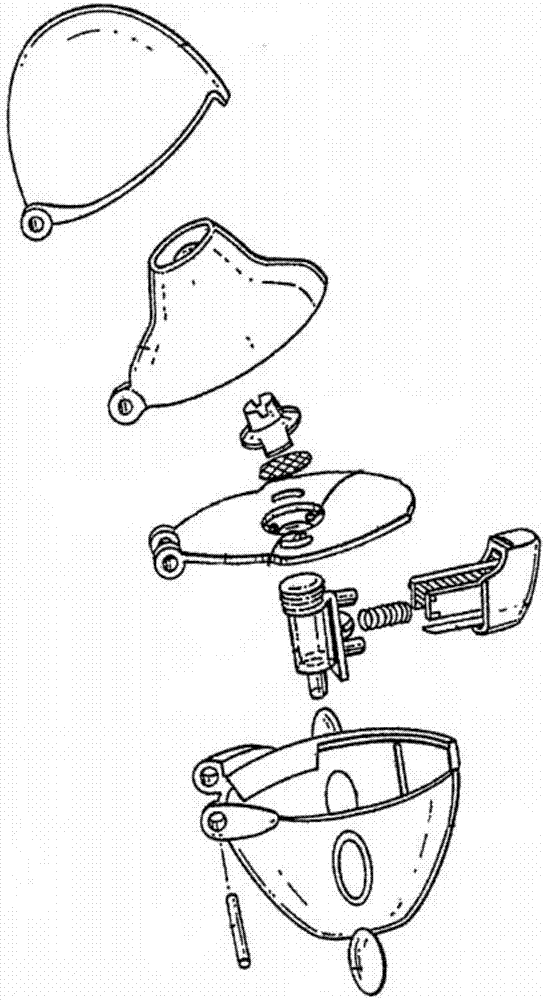

Dry powder inhaler

PendingCN106924845AEasy to assembleReduce manufacturing costMedical devicesInhalatorsBiomedical engineeringDry-powder inhaler

The invention discloses a dry powder inhaler, which comprises a bearing plate, a suction nozzle, a capsule chamber, a button, a spring and a lower shell, wherein through holes are formed in the bearing plate in a going-through mode; the suction nozzle is connected to the upper side of the bearing plate and is arranged on the through holes; the capsule chamber is connected to the lower side of the bearing plate and is located on the through holes; tip pins, which are made from metal, are connected to the button, and the tip pins, through a pressing action of the button, can extend into the capsule chamber; the spring is clamped between the button and the capsule chamber, and by virtue of the spring, elasticity away from the direction of the capsule chamber is exerted; the upper side of the lower shell is of an opening structure; the bearing plate is connected to an opening of the upper side of the lower shell, and meanwhile, the capsule chamber is accommodated within the lower shell; the tip pins are fixedly connected to the button by virtue of a plastic tip pin seat; the tip pins and the tip pin seat are fixed in an injection-molding mode; and the tip pin seat and the button are fixed in a clamping mode. According to the dry powder inhaler, the tip pins, when used, are prevented from getting fallen or displaced easily; and moreover, the capsule chamber can be cleaned by a user more conveniently.

Owner:SUZHOU SINGMED MEDICAL DEVICE SCI & TECH LTD

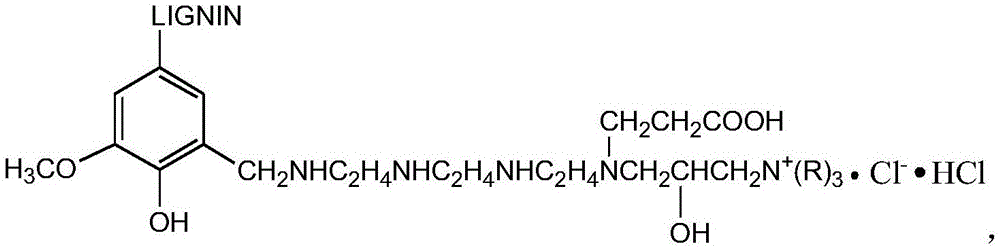

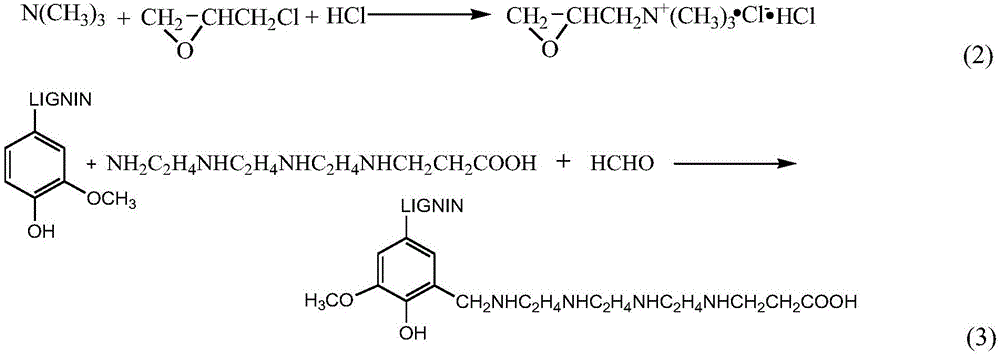

Lignin polyamine cation type asphalt emulsifier as well as preparation method and application thereof

InactiveCN106008996AGood emulsifying effectImprove hydrophilicityBuilding insulationsEpoxyChemical structure

The invention discloses a lignin polyamine cation type asphalt emulsifier as well as a preparation method and an application thereof. The asphalt emulsifier has the molecular structural general formula shown in the specification, wherein R refers to methyl (-CH3), ethyl (-C2H5) or an ethoxy group (-C2H4OH); LIGNIN refers to a lignin molecular chain. Acrylic acid, triethylene tetramine, low-carbon-number tertiary amine and epoxy chloropropane are added to raw materials, so that a prepared asphalt emulsifier molecule adopts the polyamine cation type chemical structure, the charge strength of the asphalt emulsifier molecule is enhanced, and the hydrophilia of the asphalt emulsifier molecule is improved.

Owner:SHANDONG UNIV

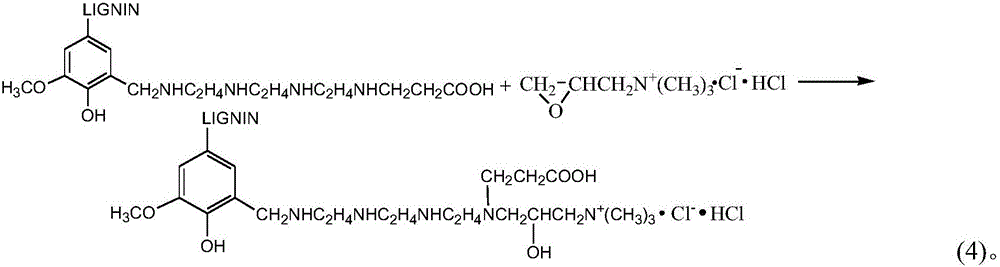

Preparation method of hercynite

InactiveCN102603315AThe reaction is fully and evenlyCompact internal structureBriquetteNeutral atmosphere

The invention provides a preparation method of hercynite, comprising the following steps of: dissolving iron salt and aluminum salt into water or alcohol to prepare a mixed solution in a molar ratio of iron ion to aluminum ion of 1:2; dropwise adding aqueous alkali into the mixed solution to neutralize till the pH value is 7; washing, dispersing and calcining precipitate; adding a binding material and graphite powder to be pressed into a briquette; sintering the briquette at the neutral atmosphere; and cooling to prepare the material. In the method, aluminum hydroxide precipitate and iron hydroxide precipitate, which are evenly mixed with each other, are generated by reaction of aqueous alkali, the aluminum salt and the iron salt react in the solution, and then the precipitate is dispersed by organic alcohol, so that the raw material can be sufficiently dispersed, the reaction is more sufficient and even, and the formed hercynite is more compact in an inner structure; and as the reductive graphite powder is added during sintering, the hercynite can be more preferably generated, so that the reaction time is shortened, and the content is increased.

Owner:HENAN UNIV OF SCI & TECH

Soybean processing device for agricultural product processing

InactiveCN108393258AReduce transportationSmall footprintSievingScreeningMaterial resourcesSmall footprint

The invention discloses a soybean processing device for agricultural product processing, and relates to the technical field of production equipment. The soybean processing device comprises an impurityremoval device and a cleaning device; the top of the cleaning device is fixedly connected with the bottom of the impurity removal device; the bottom of the cleaning device communicates with a water circulation device; a dust removal device is fixed to one surface of the cleaning device; the impurity removal device comprises a storage tank, and a rotating shaft penetrates through the side face ofthe storage tank; and the cleaning device comprises a cleaning box, a supporting frame is fixed to the top of the cleaning box, and a first motor is fixed to the top of the cleaning box. Through combination use of the impurity removal device and the cleaning device, soybeans can immediately enter the cleaning device to be cleaned after being screened, thus the transport process is omitted, screening equipment and cleaning equipment do not need to be purchased correspondingly, the occupied area is small, the cost, manpower, material resources and time are saved, and the work efficiency is improved.

Owner:饶琼仙

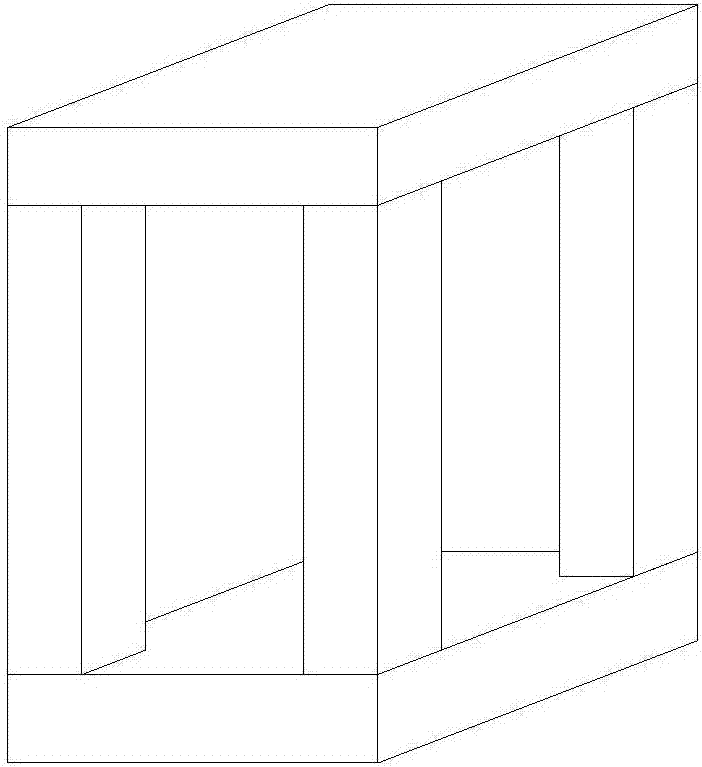

Device with telescopic fixed multifunctional underwear cutting tables

InactiveCN107460715AAchieve multifunctional featuresEasy to operateSevering textilesSortingEngineeringMultiple function

The invention discloses a device with telescopic fixed multifunctional underwear cutting tables. The device comprises a telescopic cutting table, a cloth cutting table and a sorting device. The telescopic cutting table comprises a cutting platform sliding block, a telescopic box and a cabinet box are arranged on the bottom of the cutting platform sliding block, a base is arranged on the bottoms of the telescopic box and the cabinet box, a power switch sliding block is arrange on the top of the cutting platform sliding block, an electromagnetic plate is arranged on one side of the cutting platform sliding block, the power switch sliding block is electrically connected with the electromagnetic plate, and a first support rod is arranged in the telescopic box and connected with a first gear in a rotating mode. The device is provided with the telescopic cutting table, the cloth cutting table and the sorting device, and organic combination and switching are conducted on the telescopic cutting table, the cloth cutting table and the sorting device; compared with the prior art that only a cutting device is arranged, the device with the telescopic fixed multifunctional underwear cutting tables achieves a characteristic of multifunction, operation is simple, and the practical performance is high.

Owner:谢泽波

Processing method for recycling waste packaging paper

InactiveCN112111984AImprove detachment efficiencySpread outWashing/displacing pulp-treating liquorsPaper recyclingFiberWarm water

The invention discloses a processing method for recycling waste packaging paper, and relates to the technical field of waste paper recycling. The processing method comprises the following steps of: 1,conveying waste paper into a cutting machine, and sequentially carrying out twice flattening treatment, cutting treatment and crushing treatment on the waste paper in the cutting machine, 2, pouringa waste paper raw material into a magnetic suction rolling cylinder, rotating the magnetic suction rolling cylinder, supplying power for electromagnet in the magnetic suction rolling cylinder to adsorb metal impurities in the waste paper raw material; and 3, pouring the waste paper raw material into a pulping machine, pouring warm water into the pulping machine, conducting stirring to obtain pulp,pouring a deinking agent, a defoaming agent and a dispersing agent into the pulp, and starting an ultrasonic cleaner in the pulping machine to physically clean the pulp. When paper pulp is stirred, the surfaces of fibers in the paper pulp can be physically cleaned through ultrasonic waves, so that the separation efficiency of the fibers in the paper pulp and ink is improved, ultrasonic cleaning and stirring are mixed and used for 2-3 times, and the deinking quality can be improved.

Owner:界首市鑫华装璜彩印有限公司

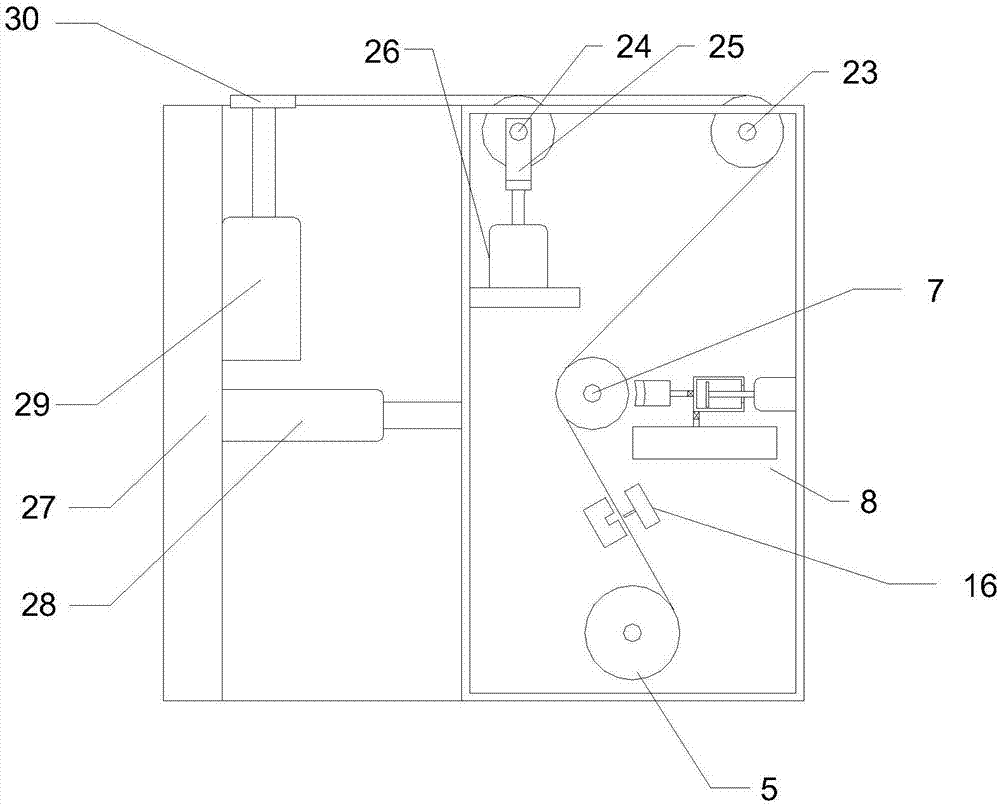

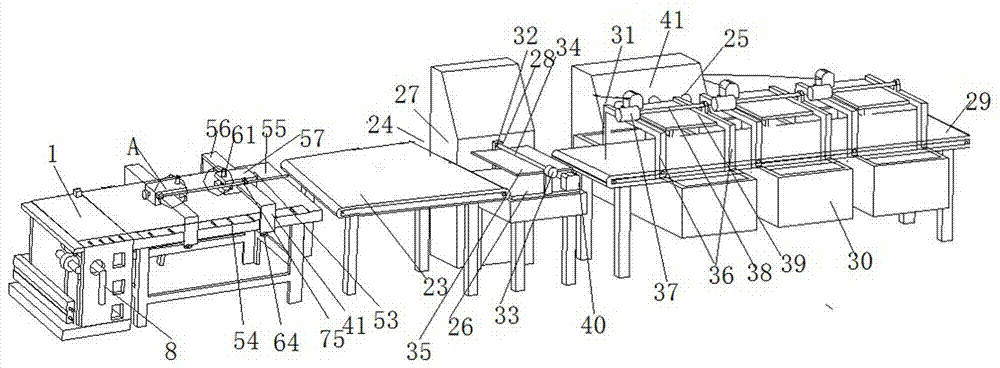

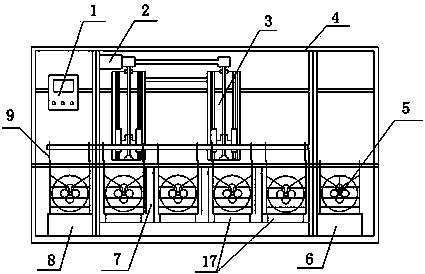

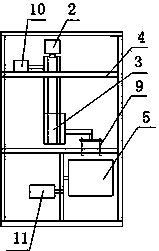

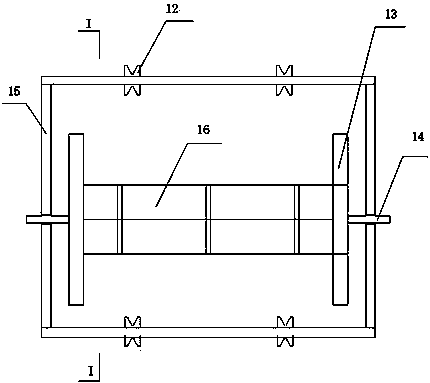

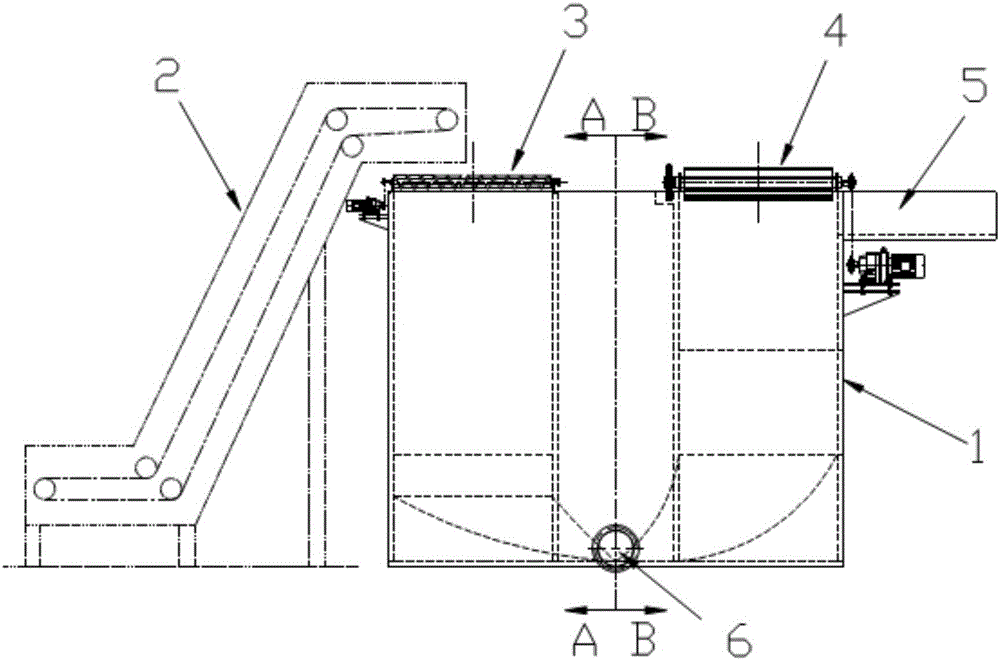

Wafer cleaning machine

ActiveCN103990614AReduce labor costsIncrease production capacityCleaning using liquidsManipulatorEngineering

The invention discloses a wafer cleaning machine which comprises a rack (4). A feeding workbench (6), a cleaning tank (7) and a discharging workbench (8) are arranged on the lower portion of the rack (4) from right to left in sequence, an ultrasonic vibrating plate (17) is arranged at the bottom of the cleaning tank (7), a rotary cleaning device (5) is arranged in the cleaning tank (7), a single-arm multi-hook mechanical arm (3), a gear motor B (10) driving the single-arm multi-hook mechanical arm (3) to horizontally move and a gear motor C (2) driving the single-arm multi-hook mechanical arm (3) to vertically move are arranged on the upper portion of the rack (4), a plurality of hooks (9) are arranged on an arm body of the single-arm multi-hook mechanical arm (3) and are used for lifting the rotary cleaning device (5), and a controller (1) is further arranged on the rack (4). The wafer cleaning machine has the advantages of being high in automation degree, high in product yield, high in product quality and low in manpower cost.

Owner:CHENGDU TIMEMAKER CRYSTAL TECH

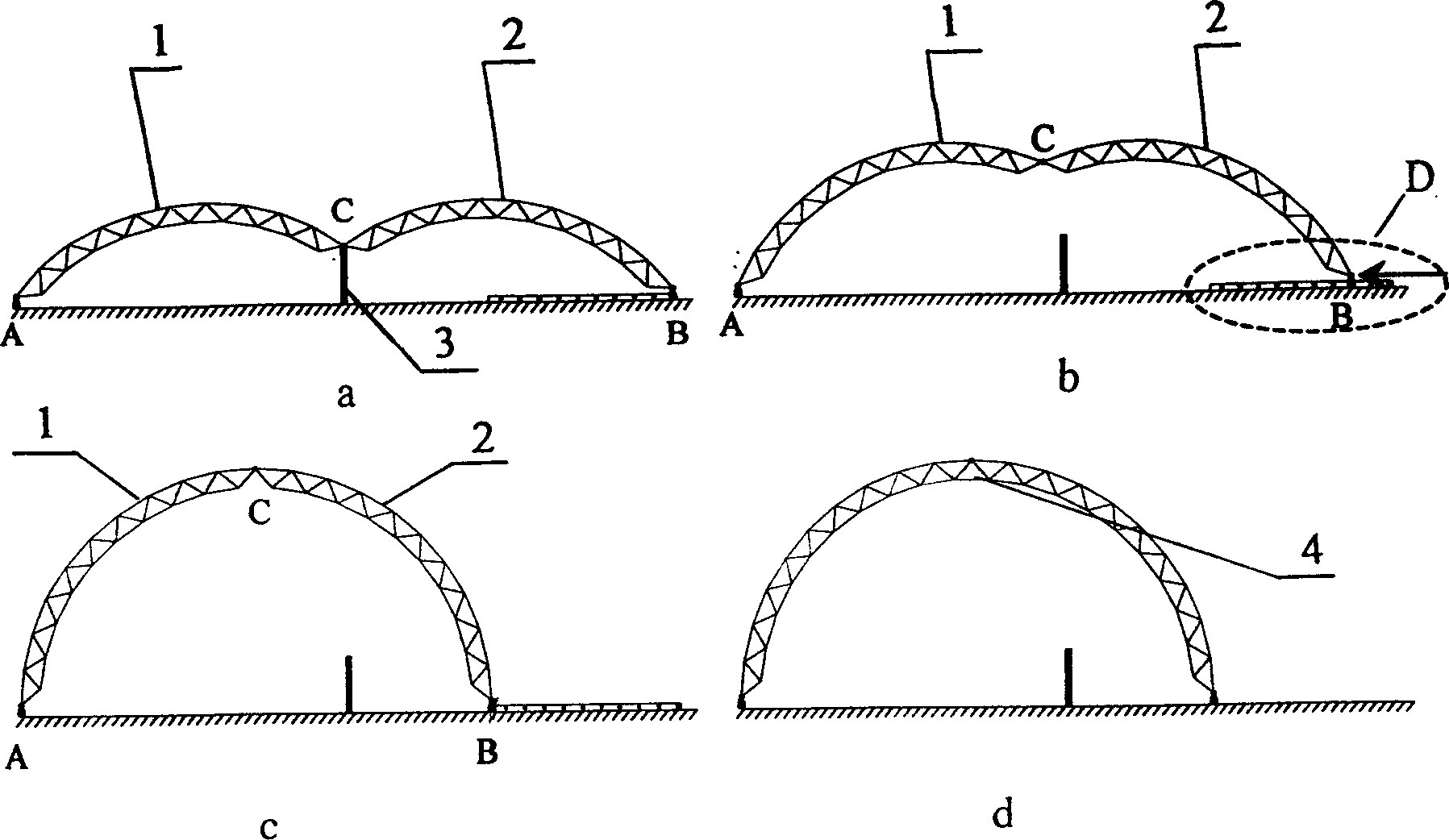

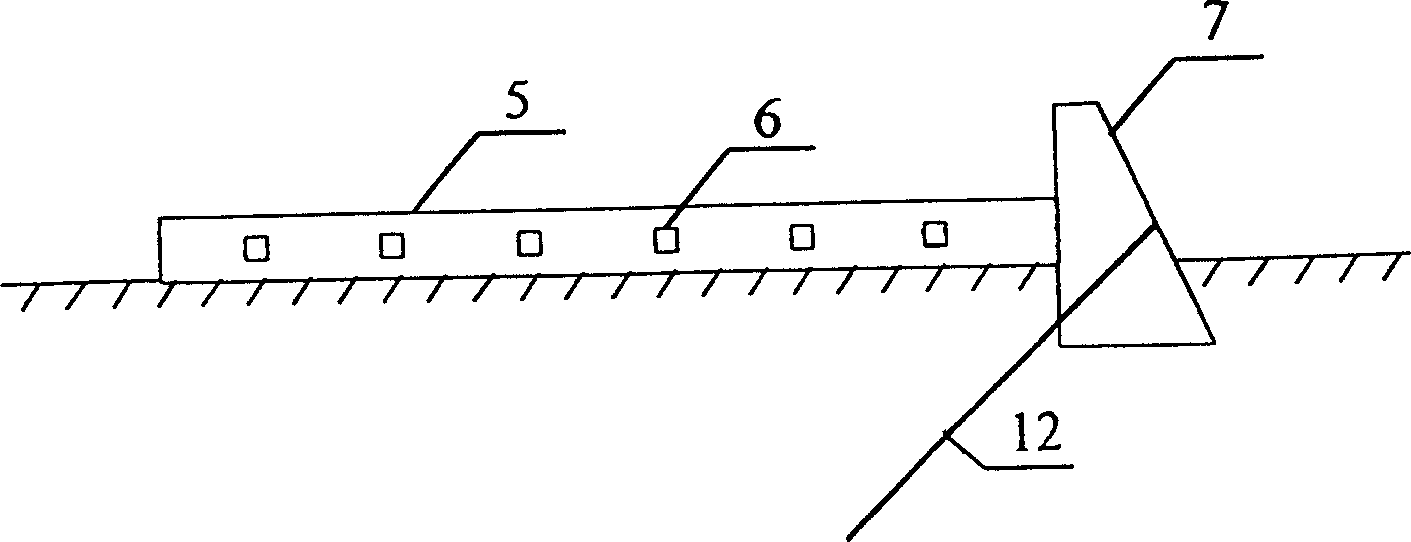

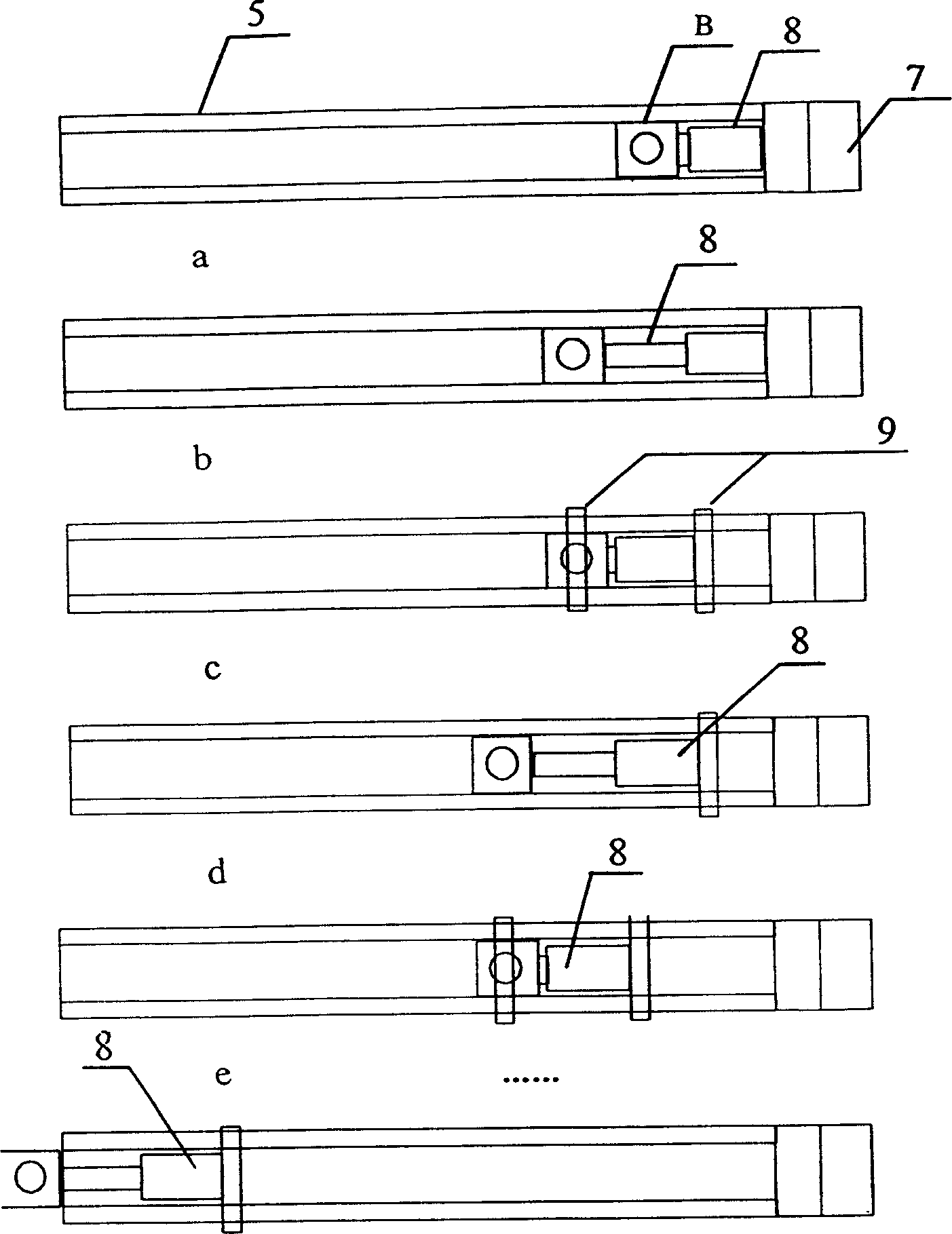

Whole forming method for cylindrical netting support with horizontal sliding structure

InactiveCN1472408AImprove installation accuracyGood construction qualityBuilding constructionsFixed hingeHinge angle

A construction method for integrally formed cylindrical reticulated shell with horizontal slide structure is disclosed. A cylindrical reticulated shell is divided into two segments for individual assembly. Its one end is a fixing hinge and its another end is a slide hinge in slide way. The hinged points between two segments are borne on temporary supporter. Both slide hinges are horizontally moving until they reach designed positions and the slide hinges are fixed to base. When hinged point reached designed height, a horizontal rod is linked to fix the hinged points. Its advantages are short period, and low cost.

Owner:浙江国盛钢结构有限公司

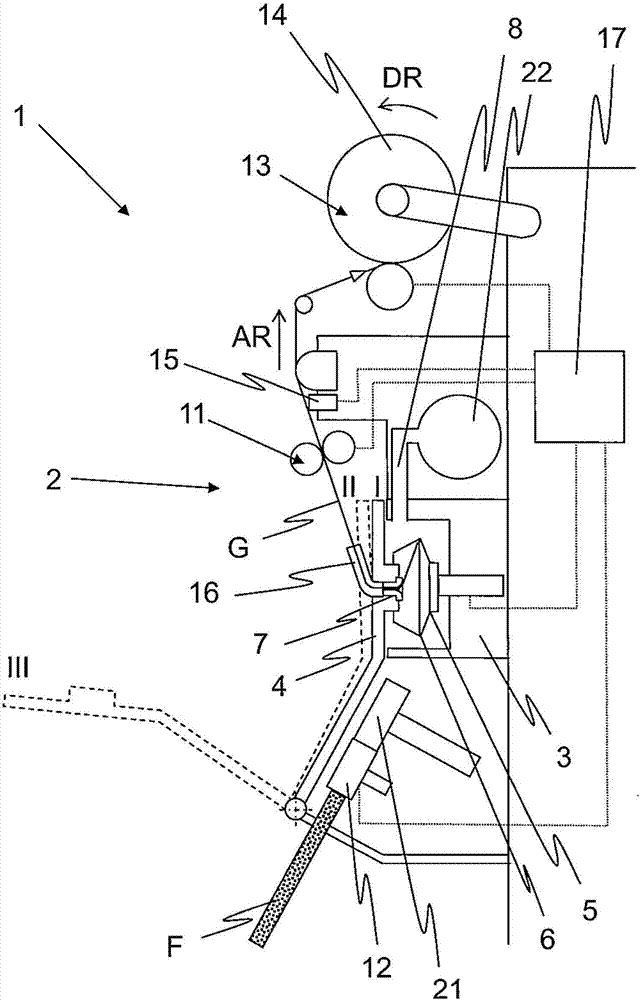

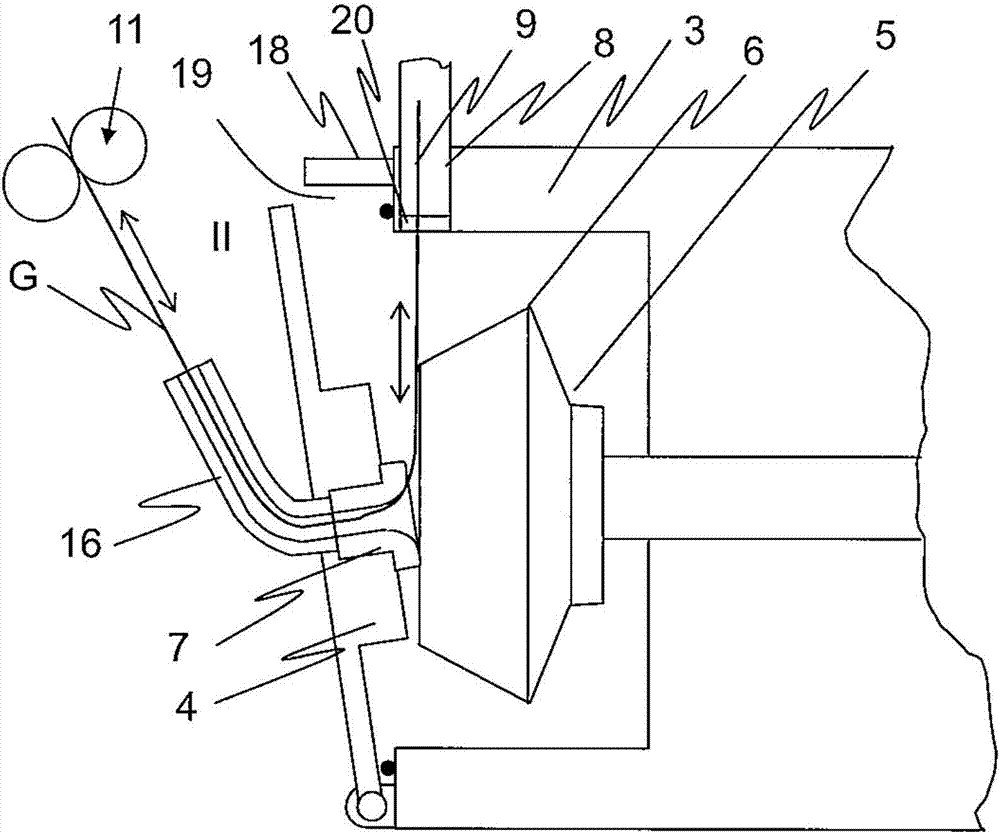

Method for Preparing a Yarn End for Spinning in at a Rotor Spinning Device of a Rotor Spinning Machine along with a Rotor Spinning Machine

ActiveCN106995952AAvoid cutsSpread outContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

With a method for preparing a yarn end (9) for spinning in at a rotor spinning device (2) of a rotor spinning machine (1) with a rotor housing (3) that can be closed with a cover (4) and can be subjected to negative pressure through a negative pressure channel (8), with a spinning rotor (5) that is rotatably mounted in the rotor housing (3) and rotates with an operating rotational speed during the spinning operation along with a draw-off nozzle (7), the yarn end (9) to be prepared is introduced into the negative pressure channel (8), and is interrupted by a severing structure (10) of the open edge of the rotating spinning rotor (5), and is thereby prepared for spinning in. During the interruption of the yarn end (9), the spinning rotor (5) is driven with a defined rotational speed for the preparation of the yarn end, whereas the rotational speed for the preparation of the yarn end is either equal to the operating rotational speed of the spinning rotor (5) or is less than the operating rotational speed of the spinning rotor (5). A corresponding rotor spinning machine (1) features a control unit (17), by means of which the rotor spinning device (2) can be operated in accordance with one of the preceding claims.

Owner:RIETER INGOLSTADT GMBH

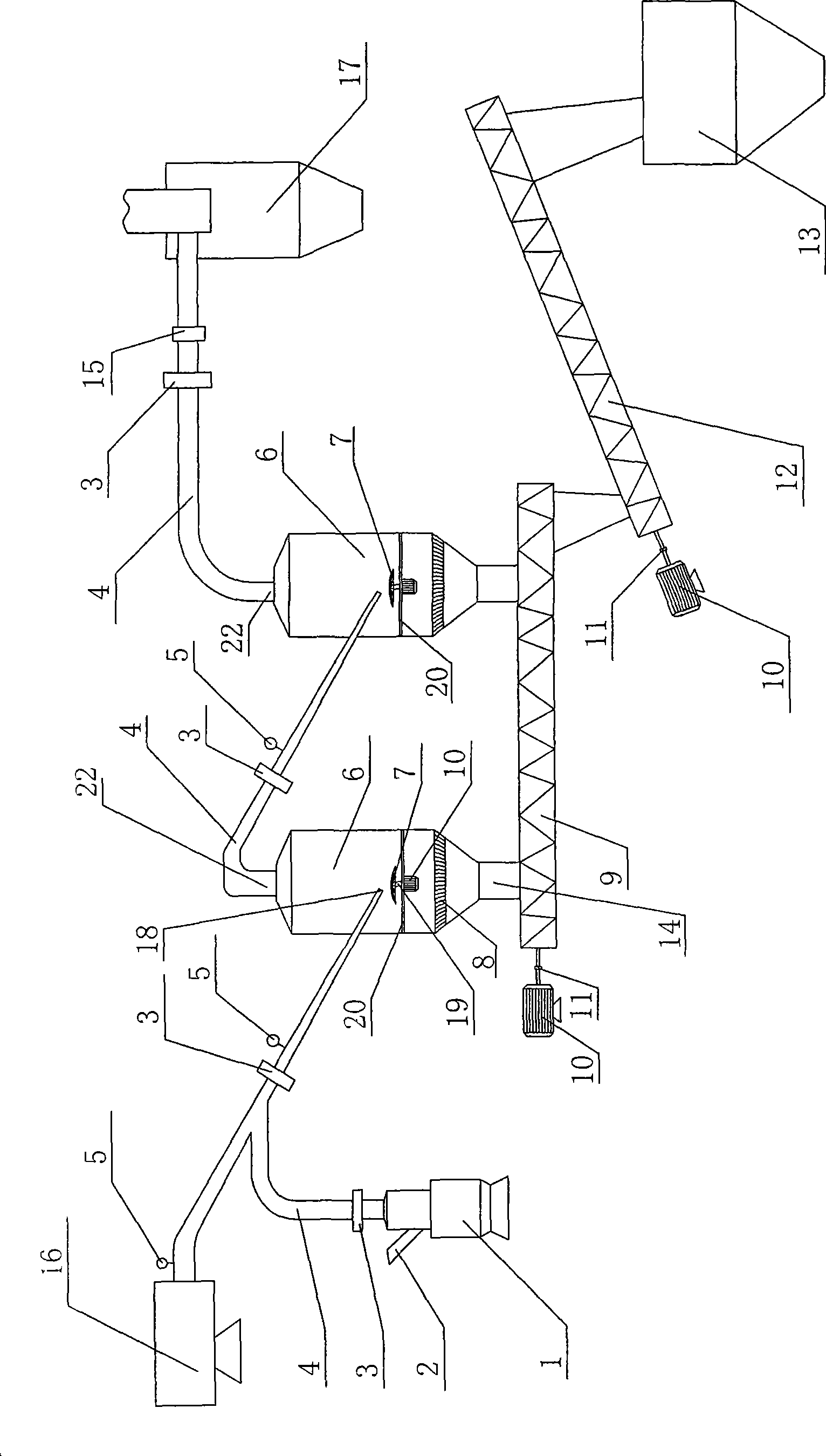

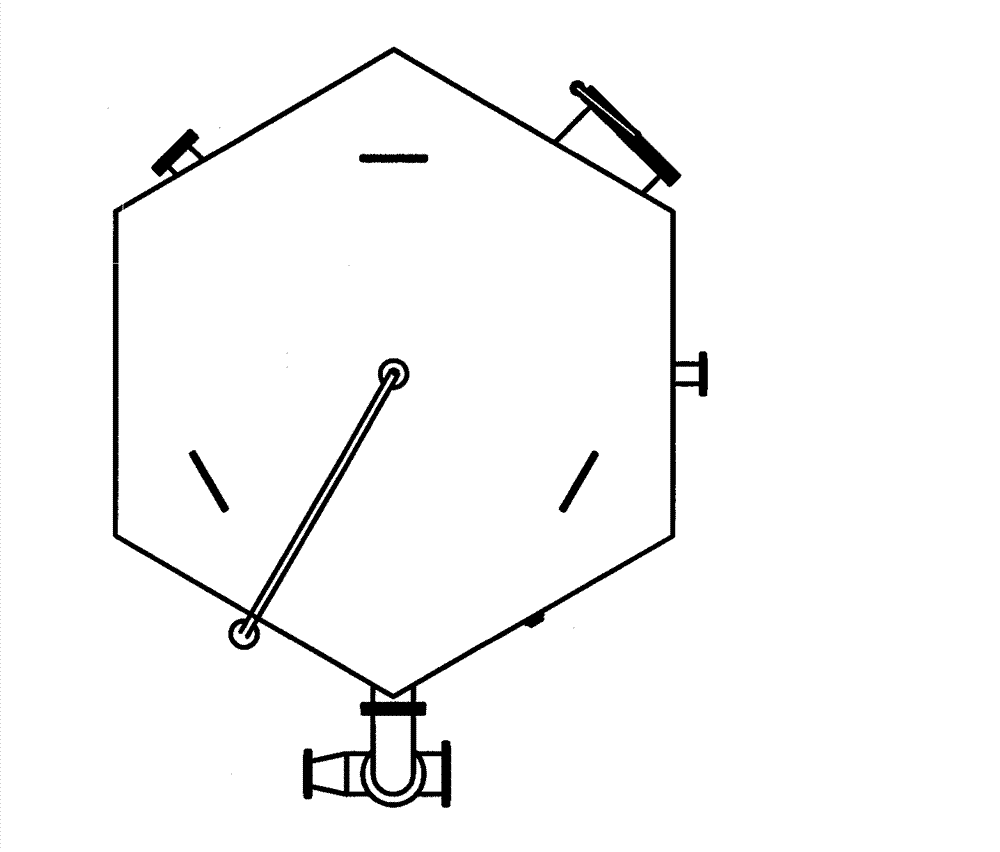

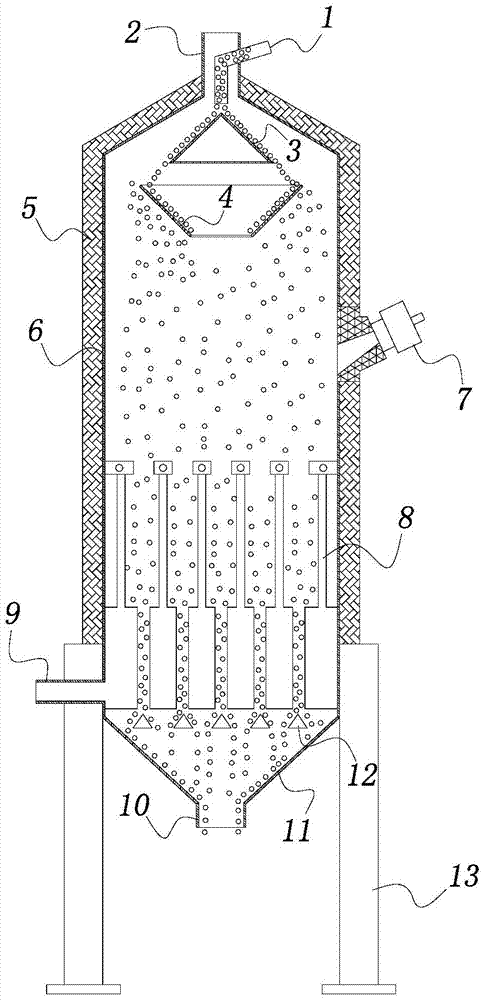

Novel dressing machine

The present invention discloses a novel dressing machine, comprising a milling machine and an ore dressing bunker, wherein, the ore dressing bunker is a hollow container, with feed port and feed pipe on the top, discharge hopper and fresh air inlet on the bottom, and a distributor in the bunker; the milling machine is connected to the ore dressing bunker through feed pipes, and each feed pipe is equipped with an induced fan; the discharge port of the feed pipe on the ore dressing bunker is right above the distributor. The feed pipe on the top of the ore dressing bunker is serially connected to a second ore dressing bunker. The milling machine mill dry ore into ore powder at 250-500 mesh size, and the blast fans and induced fans drive the ore powder to convey in the feed pipes. The distributor agitates the ore powder completely, to disperse the ore powder. Ore with high specific gravity drops to the bottom of the ore dressing bunker directly, while ore or foreign substances with low specific gravity are driven by the induced fan to enter into the next ore dressing bunker for further ore dressing. The dressing machine employs a pneumatic separation method, is free of pollution, can save water resource, and has high ore recovery rate.

Owner:王家听

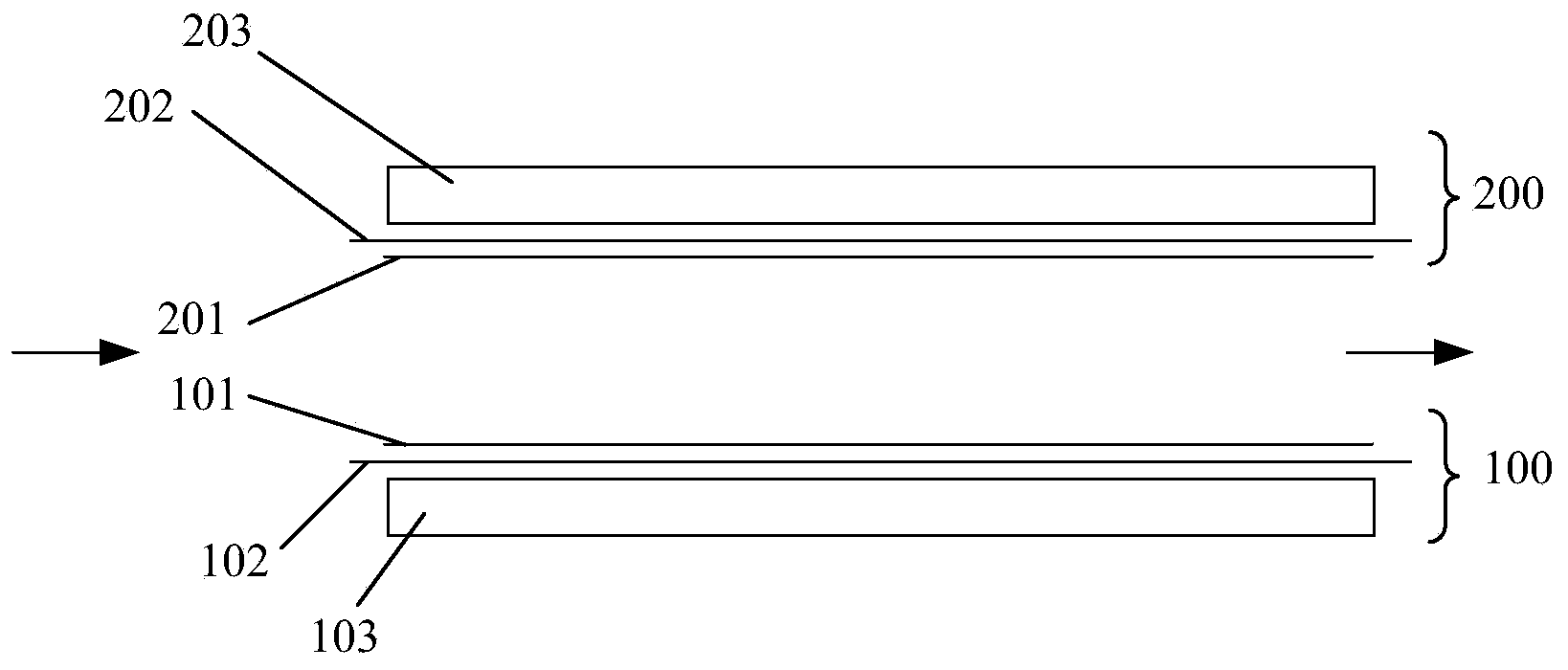

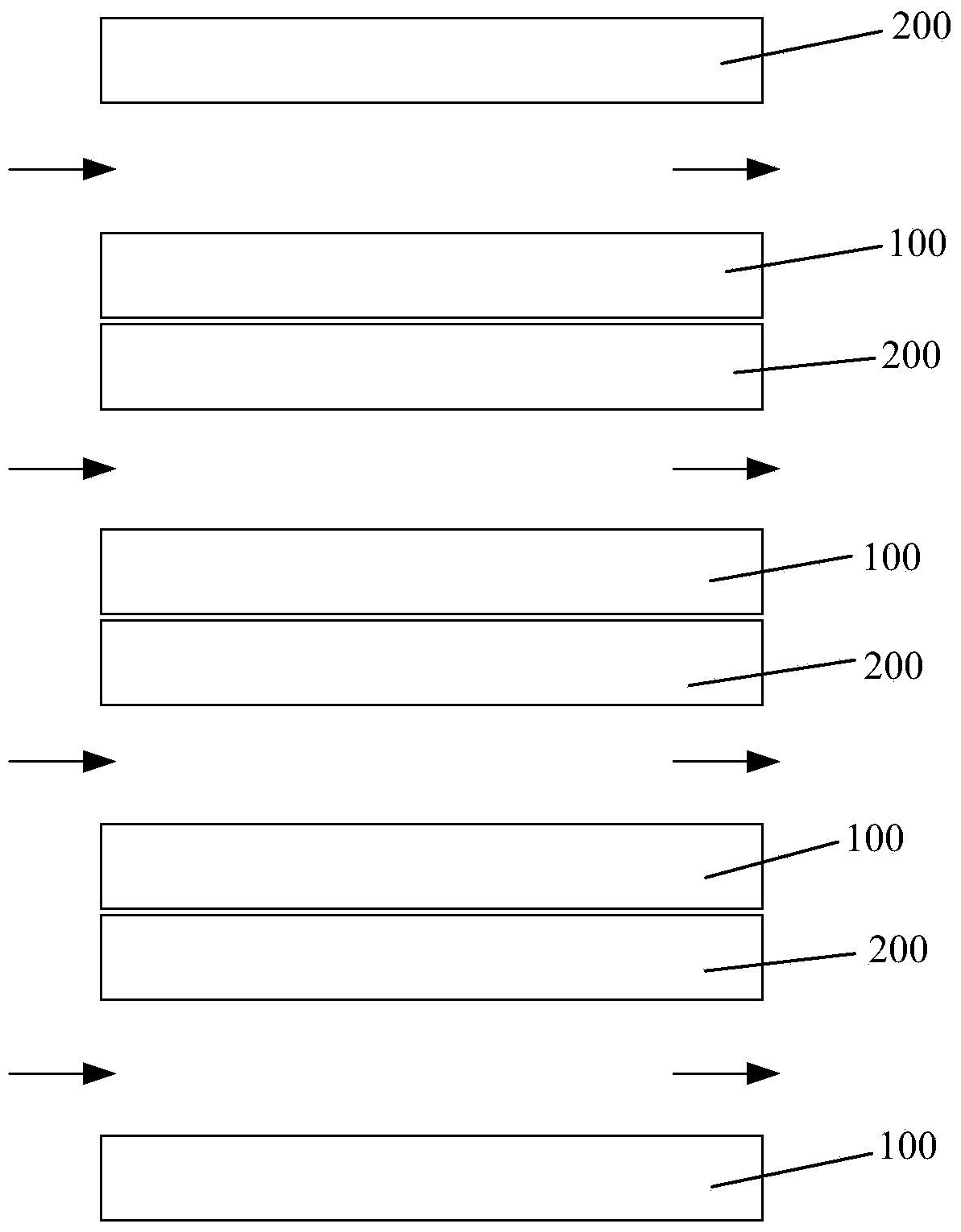

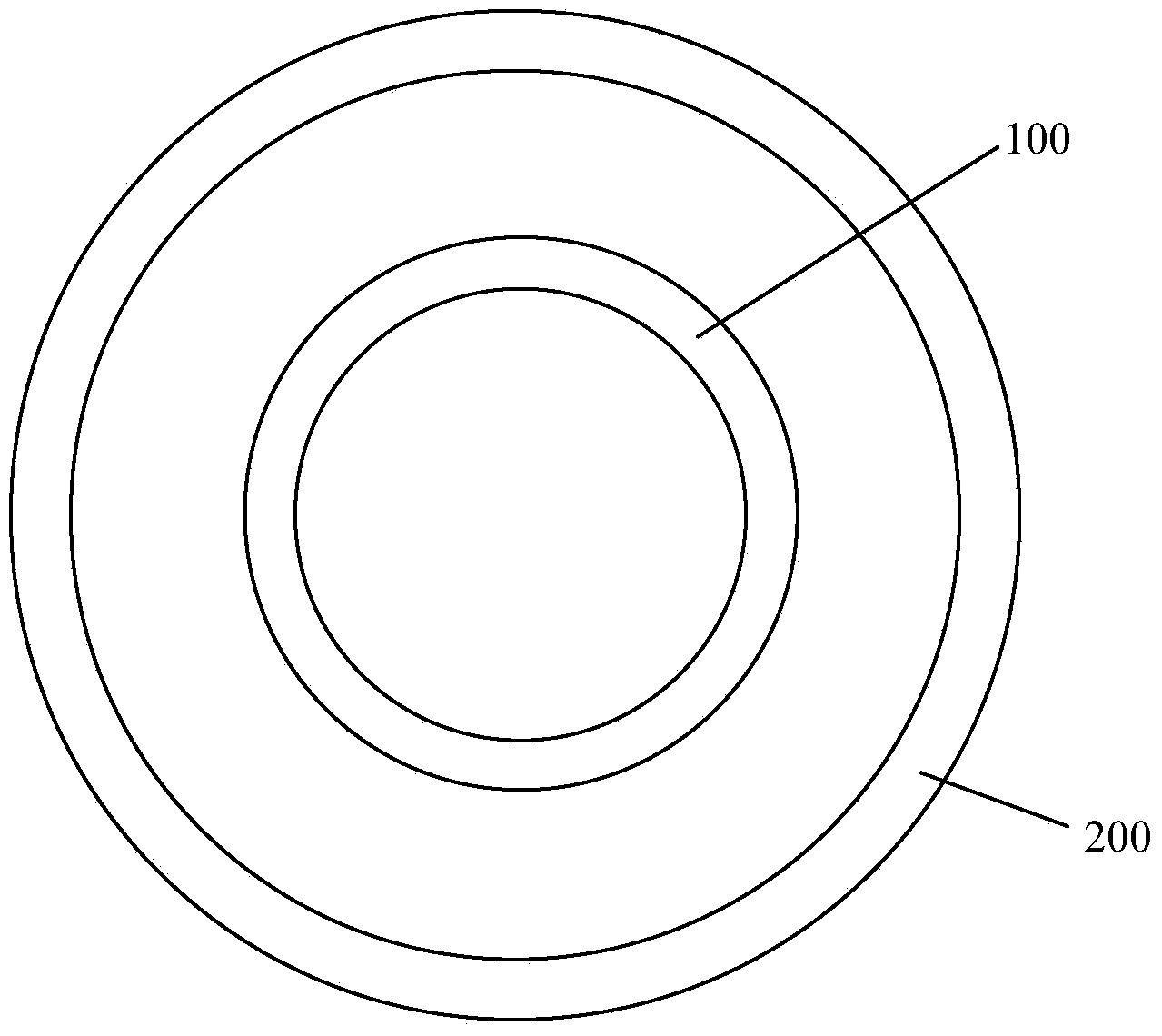

Air purification method and device based on electrostatic deflection

InactiveCN103894289ANo maintenanceLow costDeodrantsExternal electric electrostatic seperatorParticulatesCatalytic oxidation

The invention relates to an air purification method and an air purification device based on electrostatic deflection. The air purification method based on electrostatic deflection comprises the following steps: spacing a positive plate and a negative plate by a certain distance and arranging oppositely, and applying a static electric field between the positive plate and negative plate, wherein the negative plate comprises a catalytic oxidation layer; enabling air to pass through the space between the positive plate and the negative plate so as to enable electrically charged particle matter in air to be deflected to the positive plate and the negative plate in an electrostatic way; carrying out catalytic oxidation on the electrically charged particle matter which are deflected to the catalytic oxidation layer of the negative plate in an electrostatic way. The air purification method and device based on electrostatic deflection, which are provided by the invention, have the beneficial effects that air can be purified efficiently at low cost without generating harmful substances of ozone and the like, are long-acting without maintenance, and especially can effectively remove PM2.5.

Owner:山右环境技术(上海)有限公司

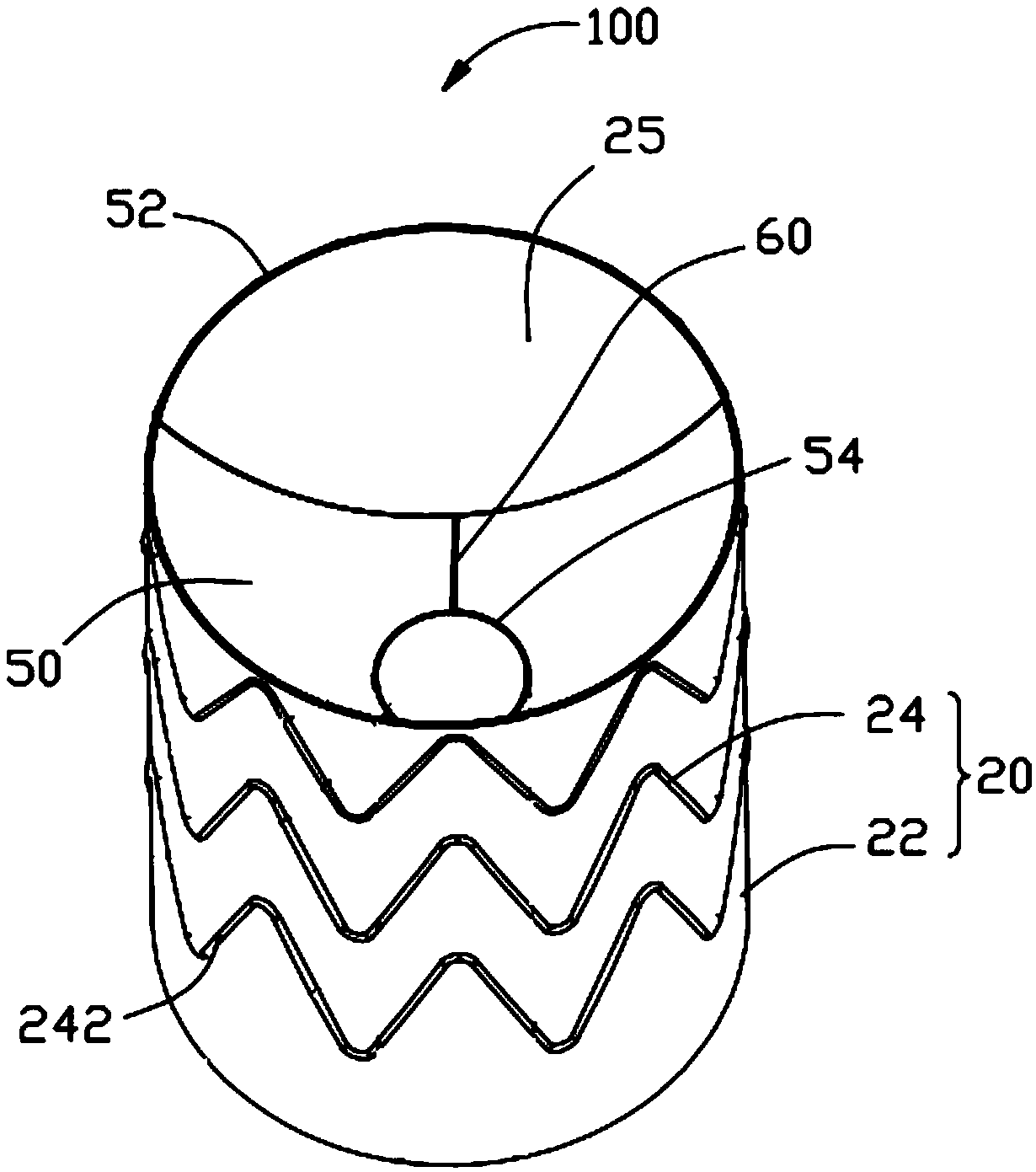

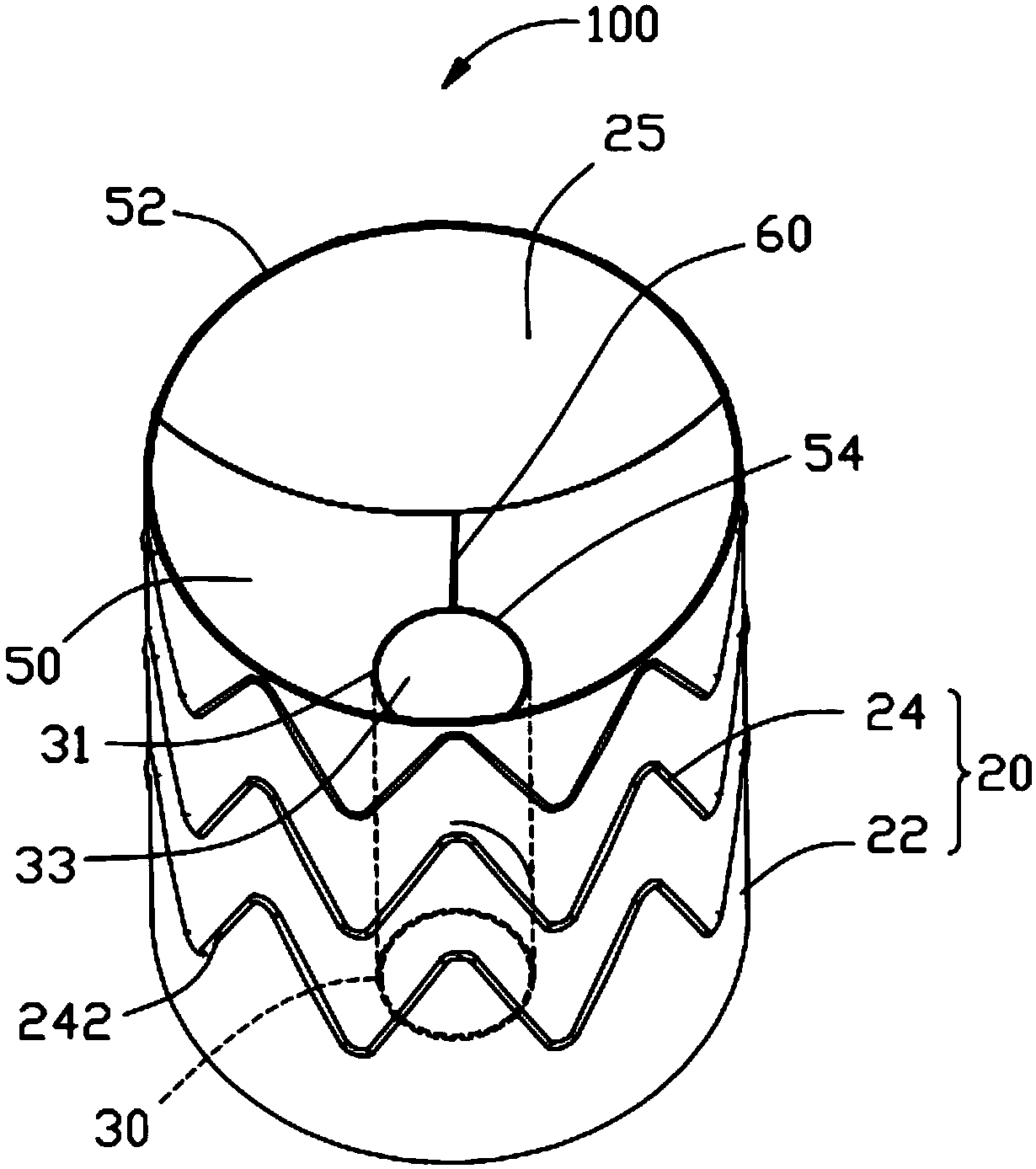

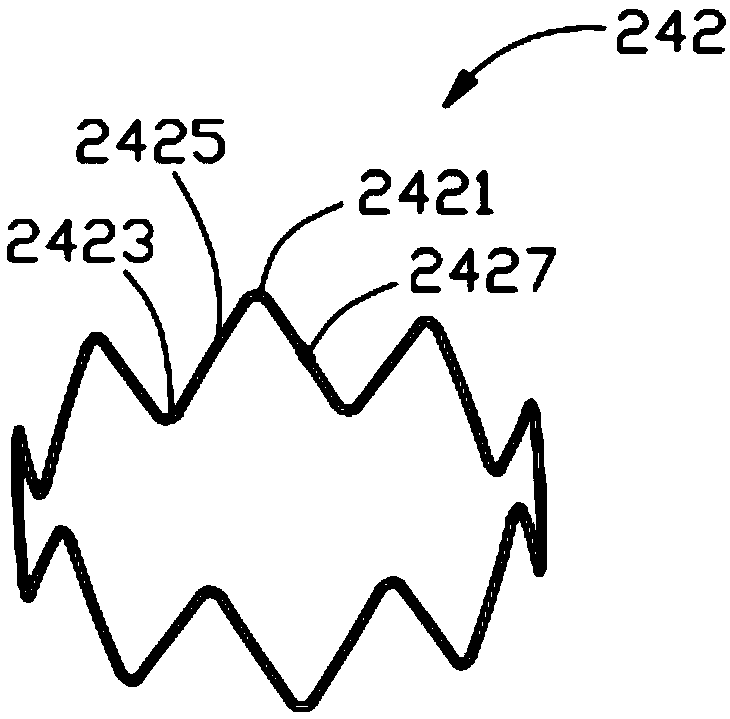

Blood vessel shunting frame capable of reinforcing stability and blood vessel bracket

The invention provides a blood vessel shunting frame capable of reinforcing stability. The blood vessel shunting frame comprises a main body pipe, wherein an airtight overlay film is arranged at one or two ends of the main body pipe, a main blood flow opening and one or more secondary blood flow openings are formed in each airtight overlay film, and one or more supporting members are arranged on the airtight overlay film, and are connected between the two adjacent edges of the main blood flow opening and the secondary blood flow openings. The supporting members can support the airtight overlayfilms, so that the airtight overlay films can be sufficiently spread, the airtight overlay films can be prevented from being folded to move towards the main blood flow opening or the secondary bloodflow opening, and blood in the blood vessel shunting frame can flow smoothly. The invention further provides a blood vessel bracket having the blood vessel shunting frame capable of reinforcing stability.

Owner:HANGZHOU WEIQIANG MEDICAL TECH CO LTD

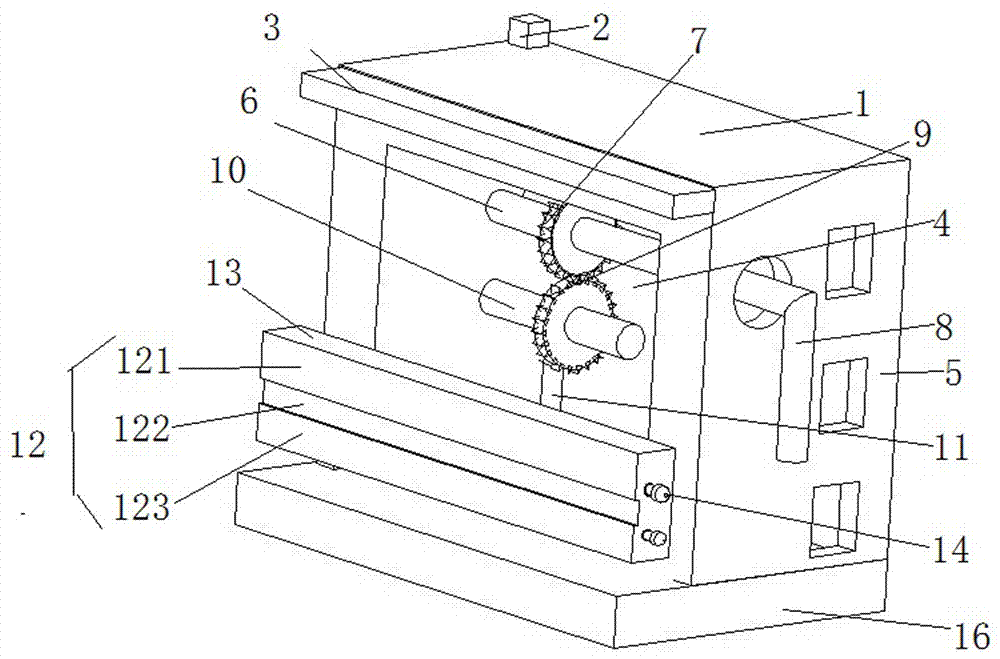

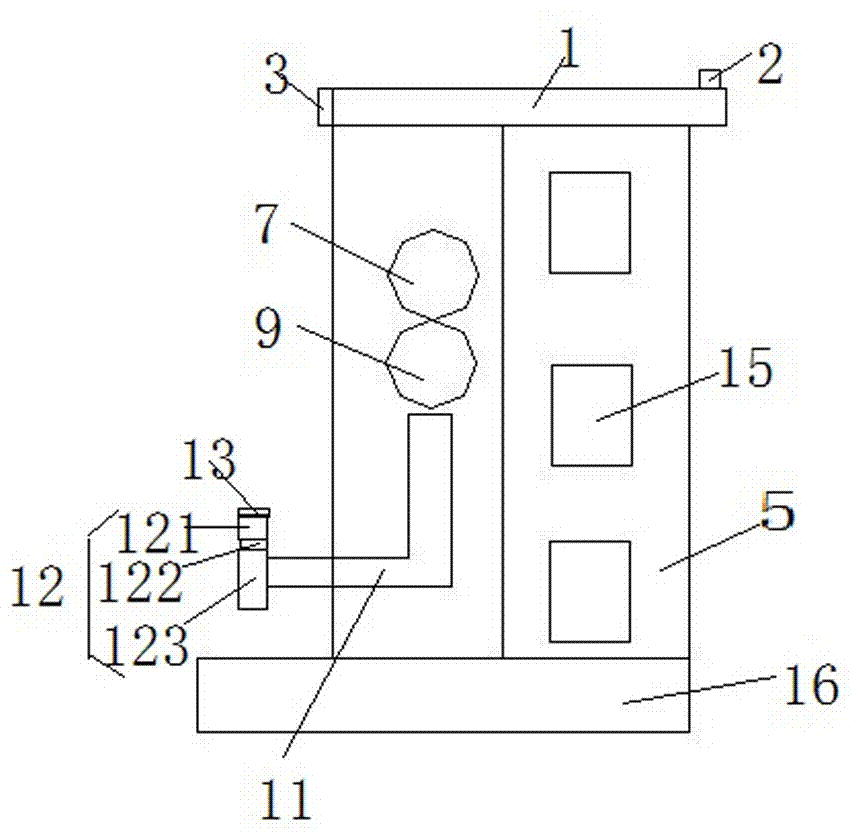

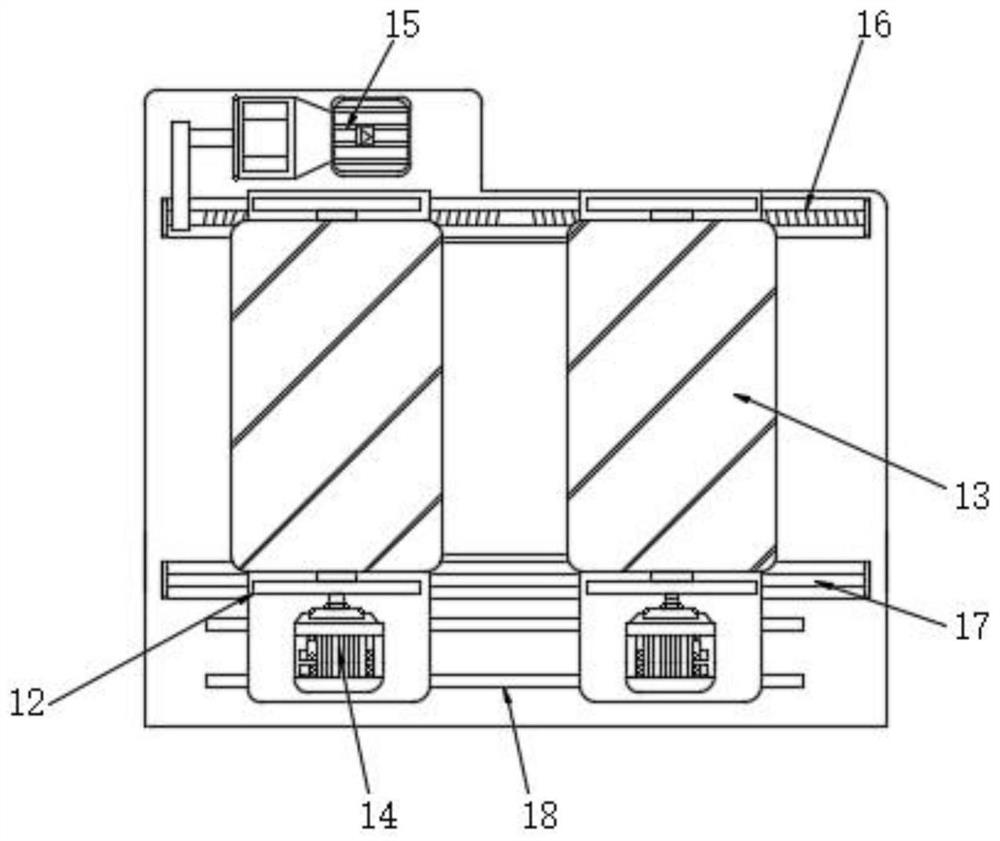

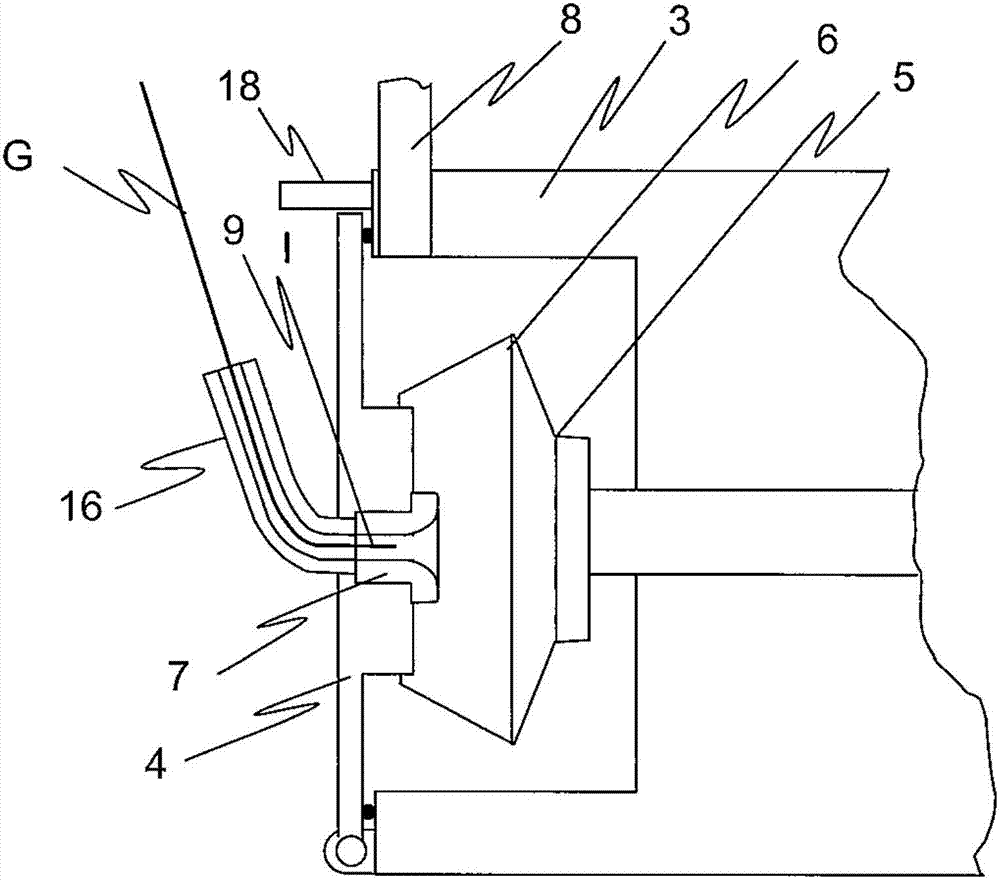

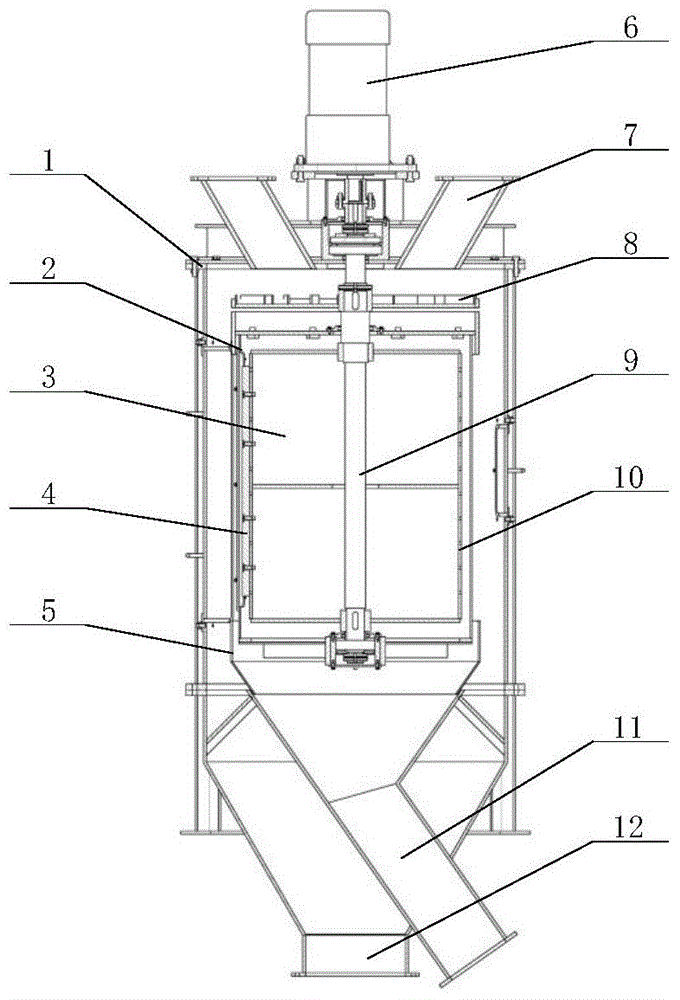

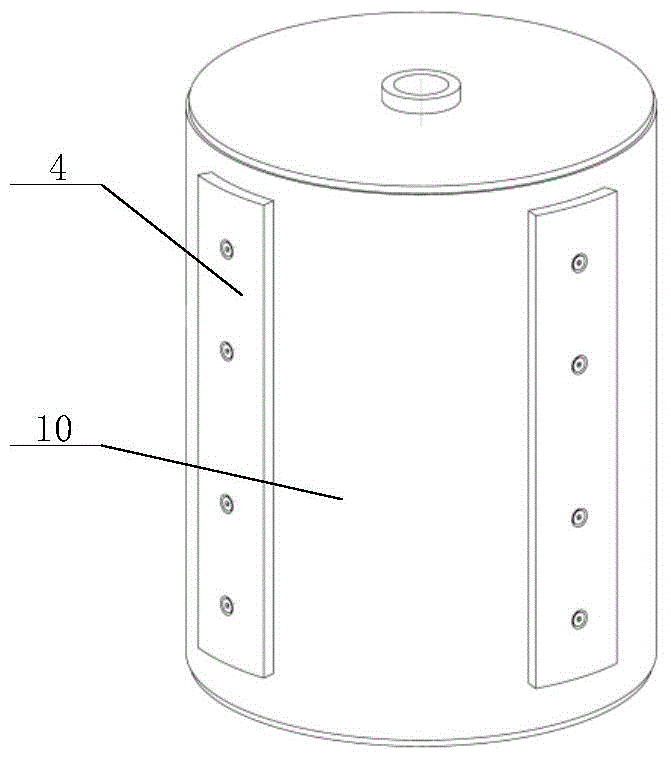

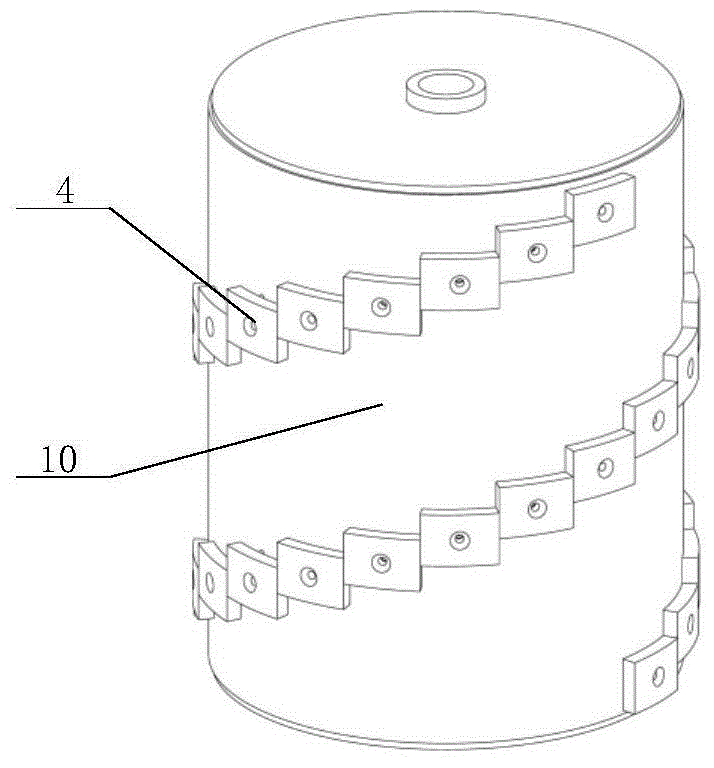

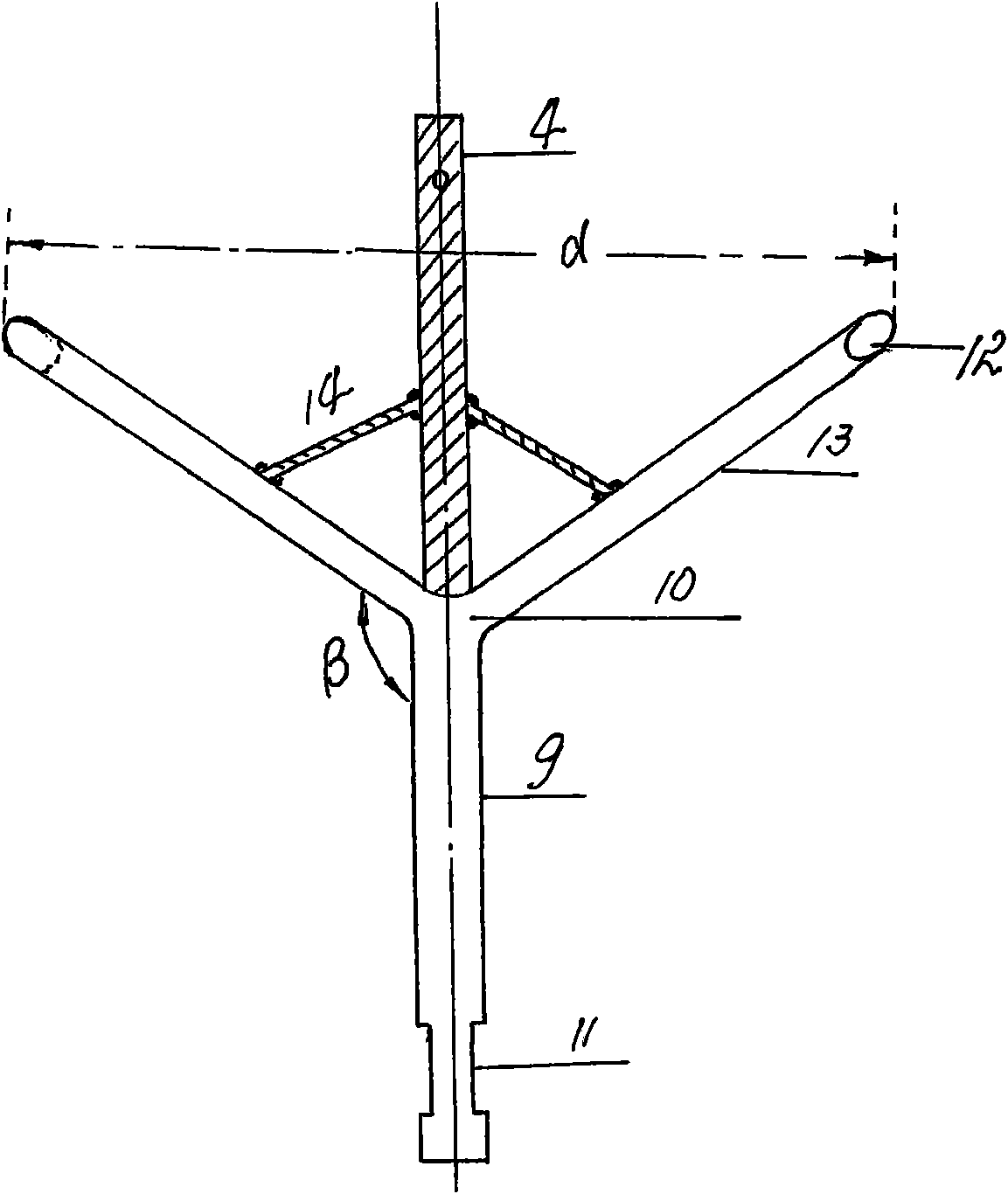

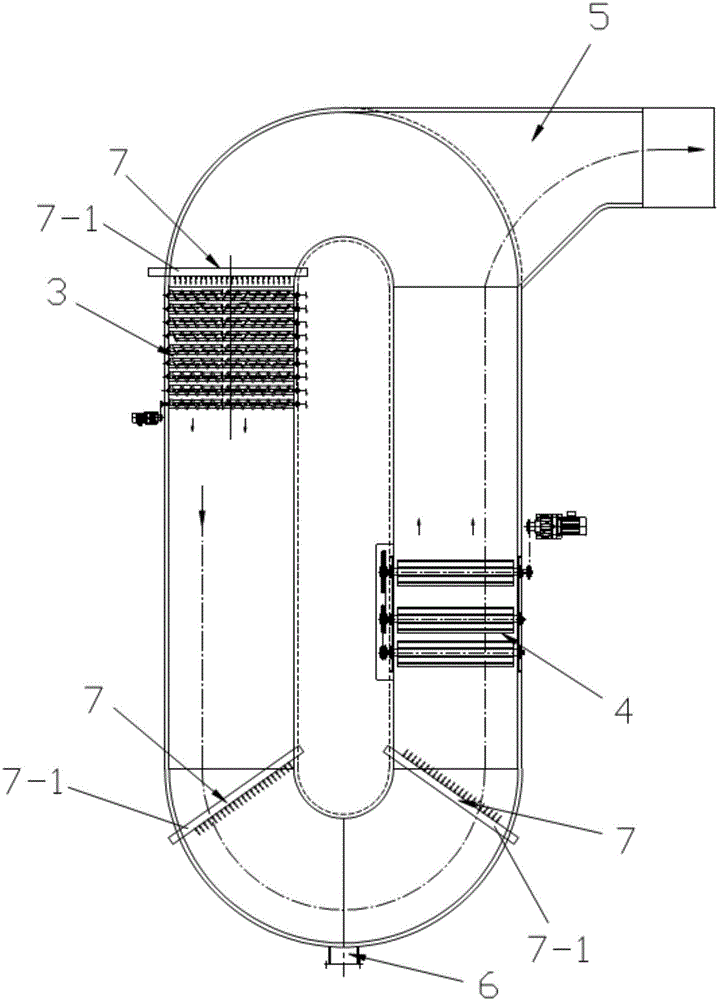

Vertical magnet separator with rotary magnetic system

ActiveCN104984822ASimple structureSpread outMagnetic separationMaterial scatteringMagnetic separator

The invention relates to a vertical magnet separator with a rotary magnetic system. The vertical magnet separator comprises an outer cylinder 1, an inner cylinder 2, the magnetic system 3, a material scattering plate 8 and an isolation cylinder 5; the end cover of the outer cylinder 1 is provided with material inlets 7 and a driving device 6, the magnetic system 3 is arranged in the inner cylinder 2, and the material scattering plate 8 is positioned between the end cover of the outer cylinder and the magnetic system 3; the material scattering plate 8 and the magnetic system 3 are connected with the driving device 6 through a vertical shaft 9; and the isolation cylinder 5 is arranged between the outer cylinder 1 and the inner cylinder 2. The material scattering plate 8 rotates to generate centrifugal force in order to disperse a material along a circumferential direction, and sorting is carried out through rotating the magnetic system 3. The magnet separator has a simple structure, can guarantee full dispersion of the material, allows the layer of the material to be thin as possible, and realizes facilitation of adsorption of magnetic materials to the magnetic system and no generation of magnetic agglomeration.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

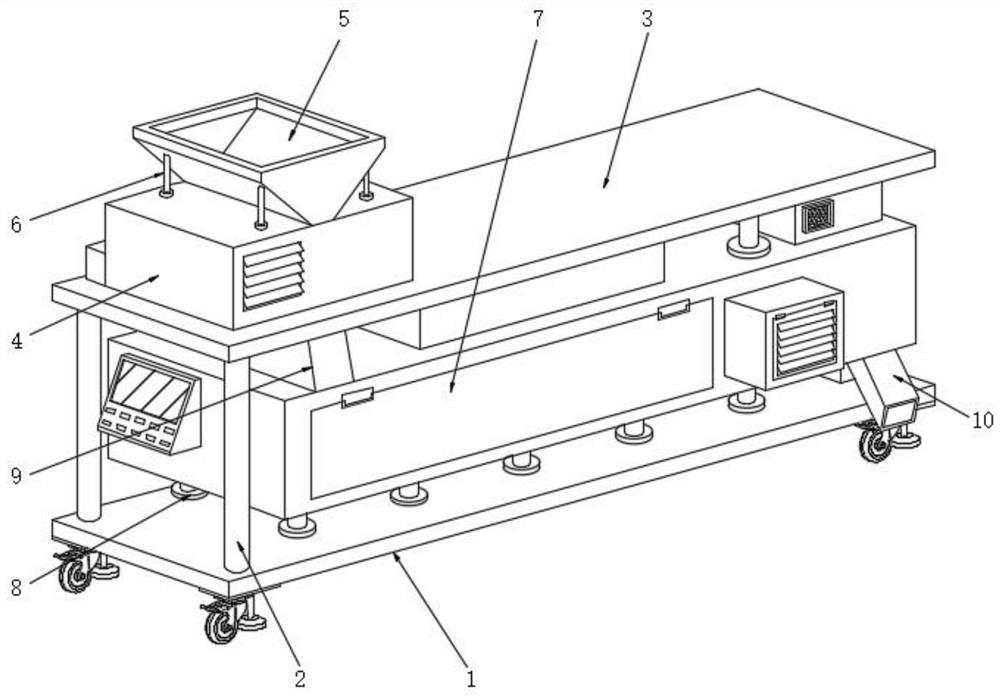

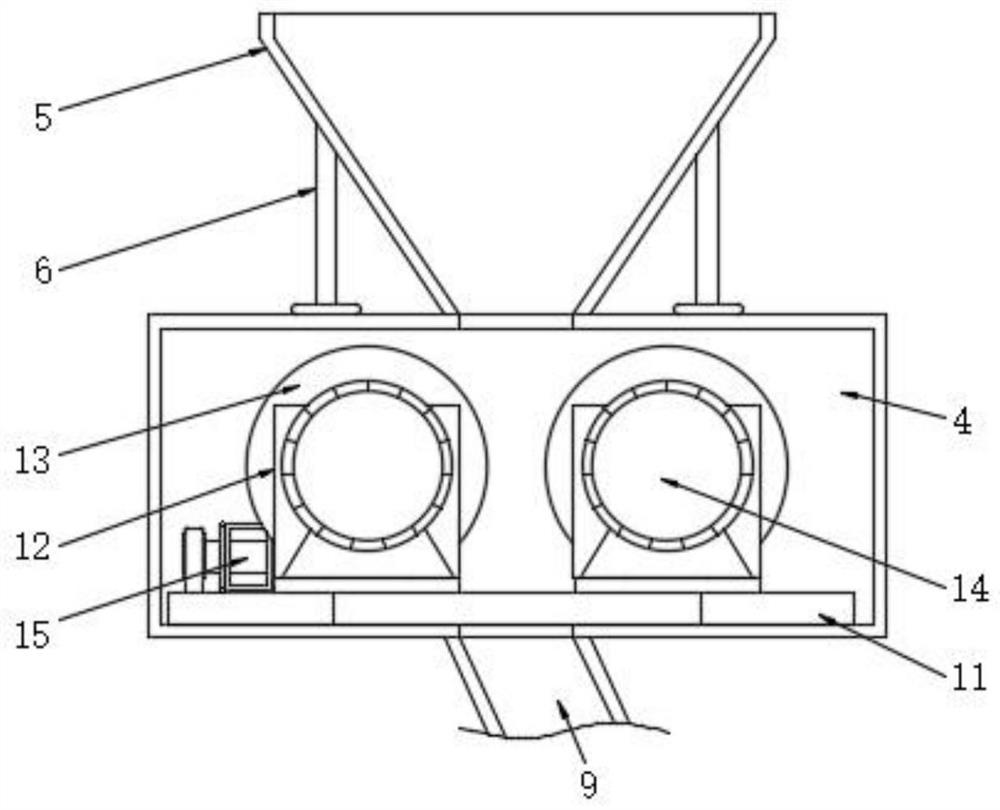

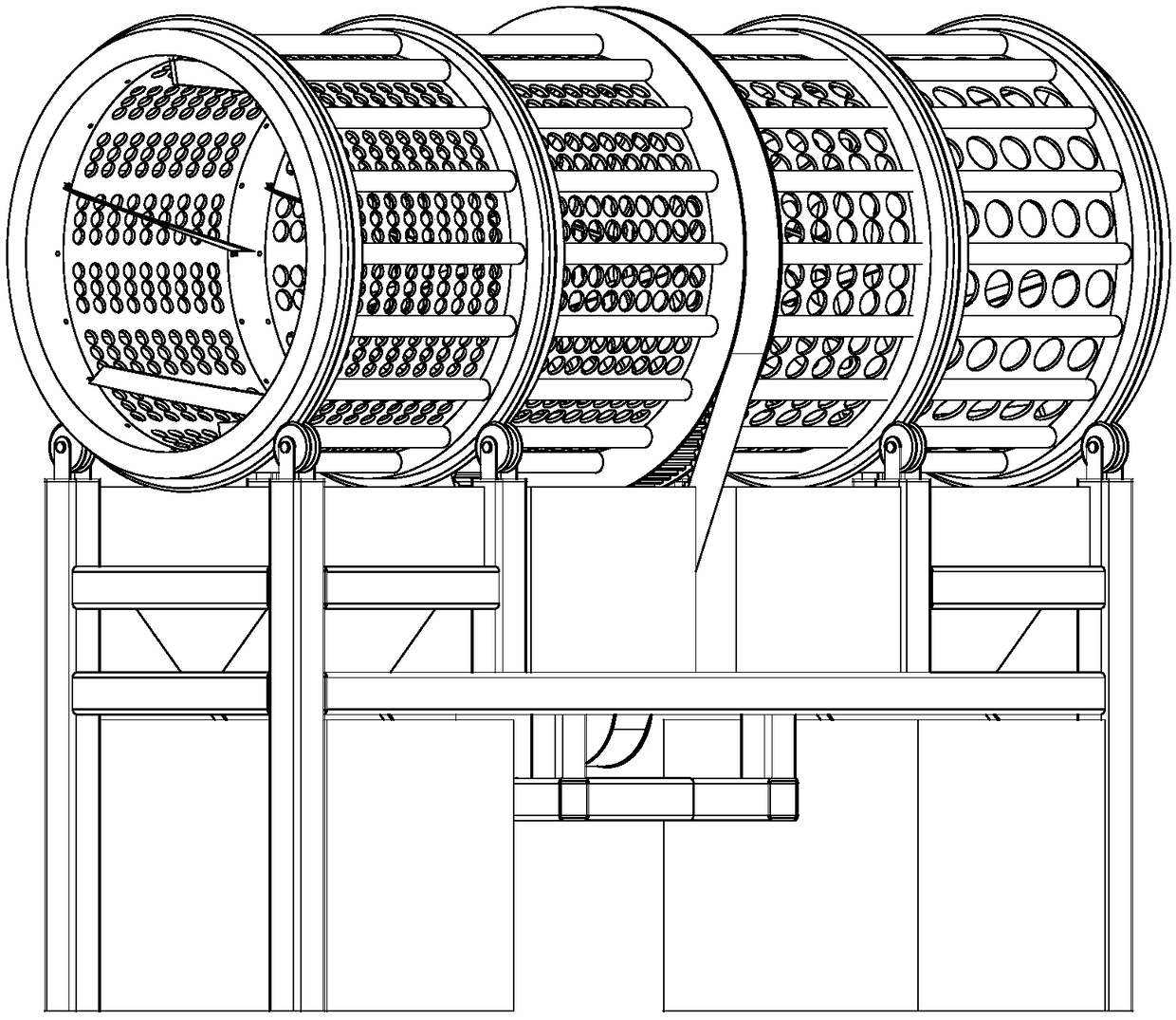

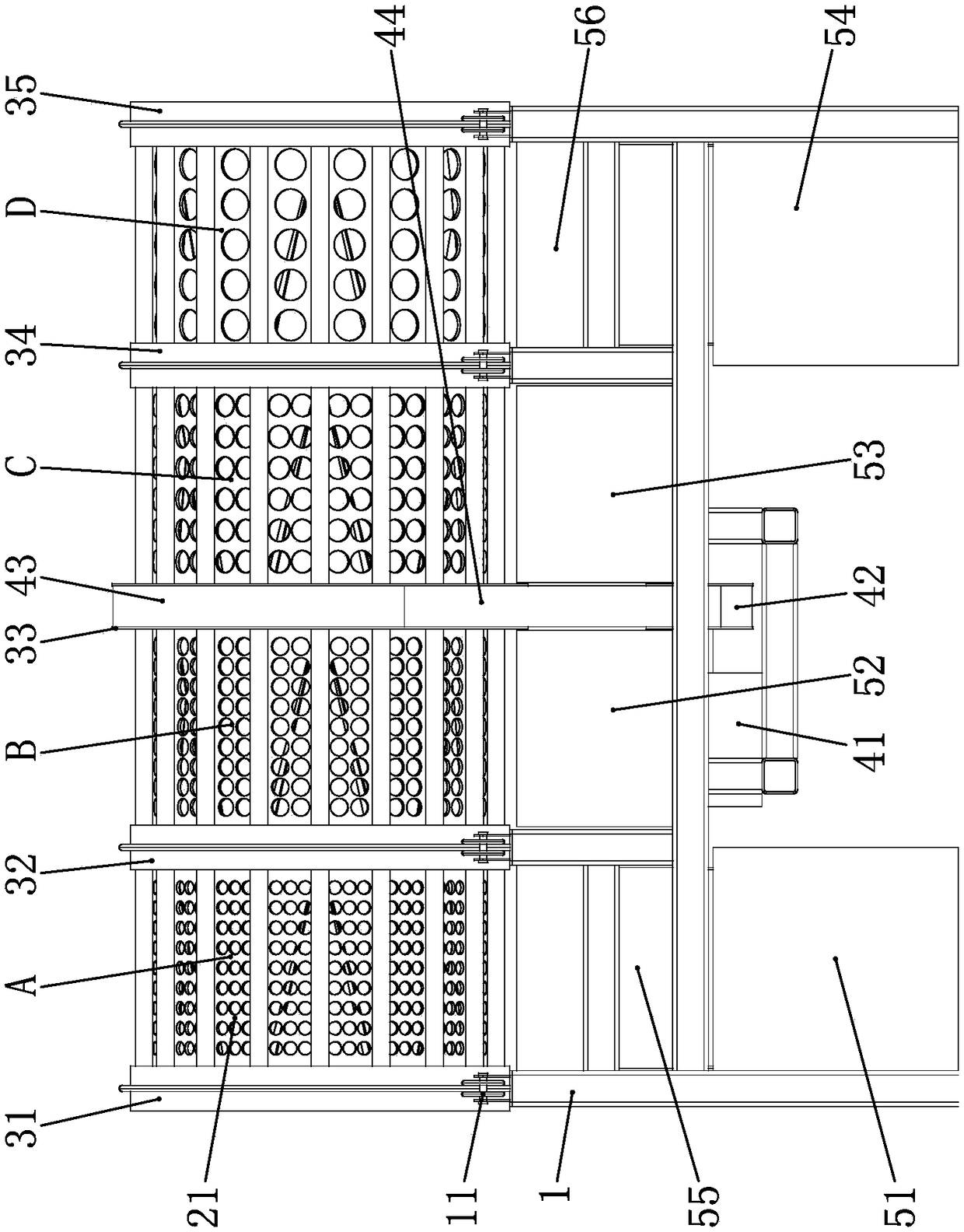

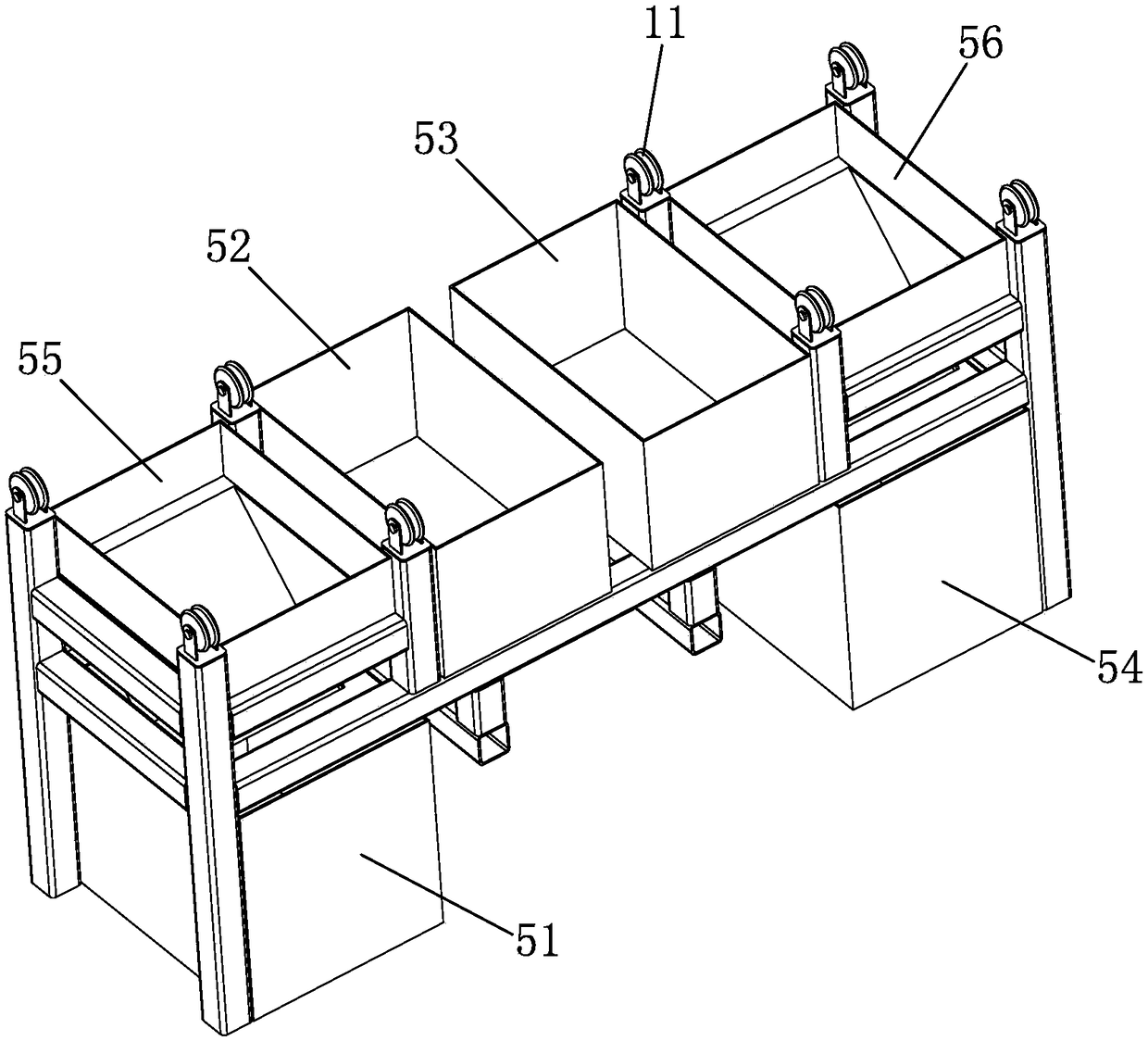

Tea roller sorting device

ActiveCN108499835ASpread outRealize hierarchical screeningSievingScreeningScreening effectHorizontal axis

The invention relates to a sorting device, and aims to provide a tea roller sorting device, which has the advantages of the simple and reliable structure and good screening effect, is capable of effectively improving the sorting efficiency and meets the sorting level requirements of most tea varieties. The tea roller sorting device is characterized by comprising sorting barrels, a power mechanismand a discharging mechanism; and the sorting barrels are respectively arranged on a support table and can rotate around a horizontal axis, the power mechanism is used for driving the sorting barrels to rotate, the discharging mechanism is used for collecting tea, the sorting barrels are formed in a way that a plurality of subsections are axially connected, flexible screening nets are arranged on the barrel walls of the subsections, a plurality of spiral plates are arranged on the inner circumferential surface of the barrel walls, and the aperture of the screening net of the right subsection isgreater than that of the screening net of the left subsection in two adjacent subsections.

Owner:ZHEJIANG SCI-TECH UNIV

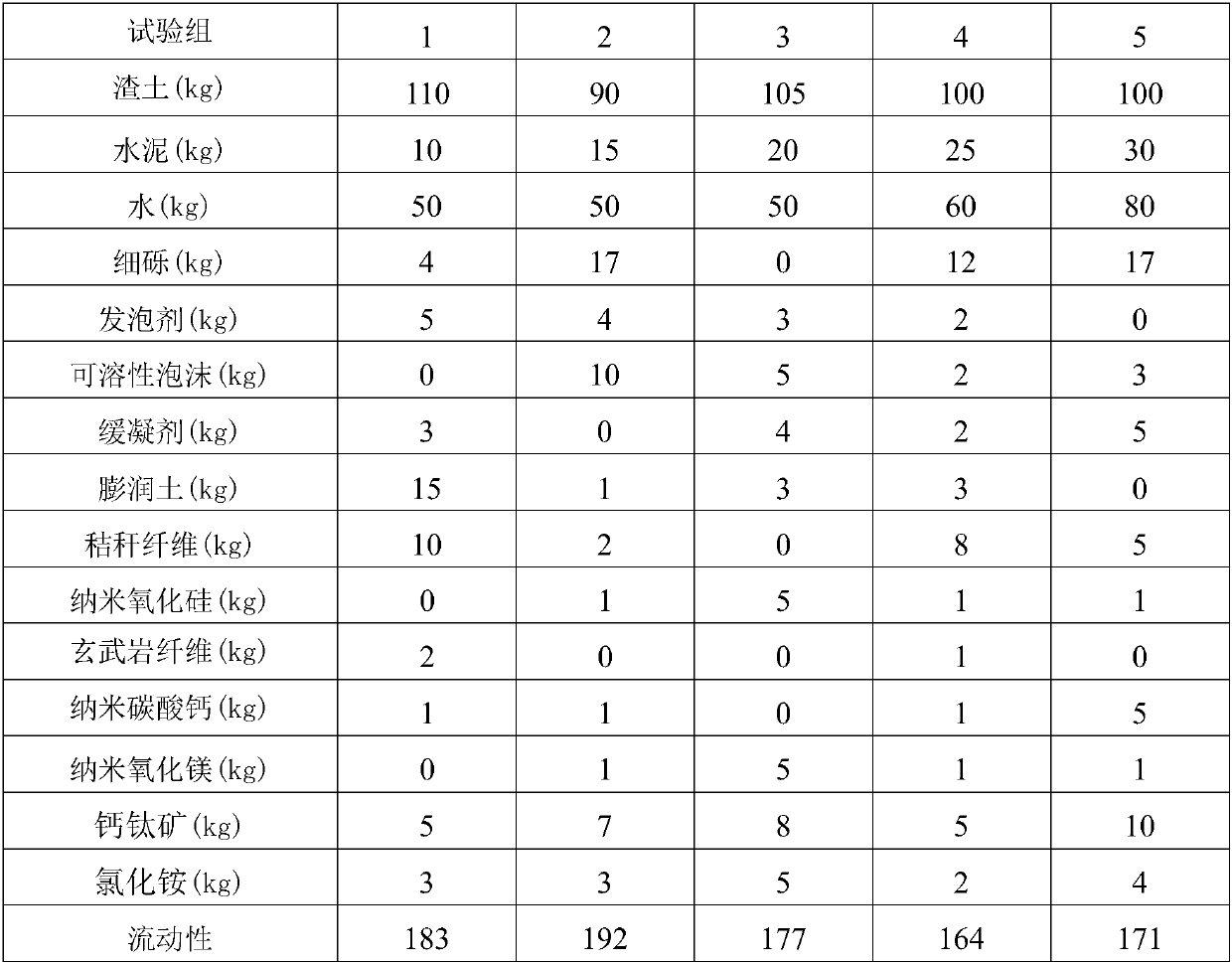

Fluidized roadbed soil and construction method

The invention discloses fluidized roadbed soil and a construction method. The fluidized roadbed soil comprises the following raw materials, in parts by weight: 90-110 parts of residue soil, 10-30 parts of cement, 50-80 parts of water, 0-20 parts of fine gravel, 0-5 parts of a foaming agent, 0-10 parts of soluble foam particles, 0-5 parts of a retarder, 0-15 parts of bentonite, 0-10 parts of straw fibers, 0-5 parts of nano silicon oxide, 0-2 parts of basalt fibers, 0-5 parts of nano calcium carbonate, 0-5 parts of nano magnesium oxide, 5-10 parts of perovskite, and 2-5 parts of ammonium chloride. The fluidized roadbed soil is obtained by the steps of mixing the above raw materials, performing sieving, performing mud scattering and the like. The fluidized roadbed soil provided by the invention has the following advantages: the fluidized roadbed soil has a wide application range: the fluidized roadbed soil is in a flowing state and has no special requirements for formation flatness; the fluidized roadbed soil has good water permeability: the fluidized roadbed soil has good water permeability, the water permeability coefficient can reach 12 m / s<-4>, and a water body can be dispersed more quickly; the fluidized roadbed soil has high strength: the unconfined compressive strength under fluidity of 185 reaches 362 kPa; and the fluidized roadbed soil is convenient for construction and has high economic benefits.

Owner:JIANGSU UNIV OF SCI & TECH

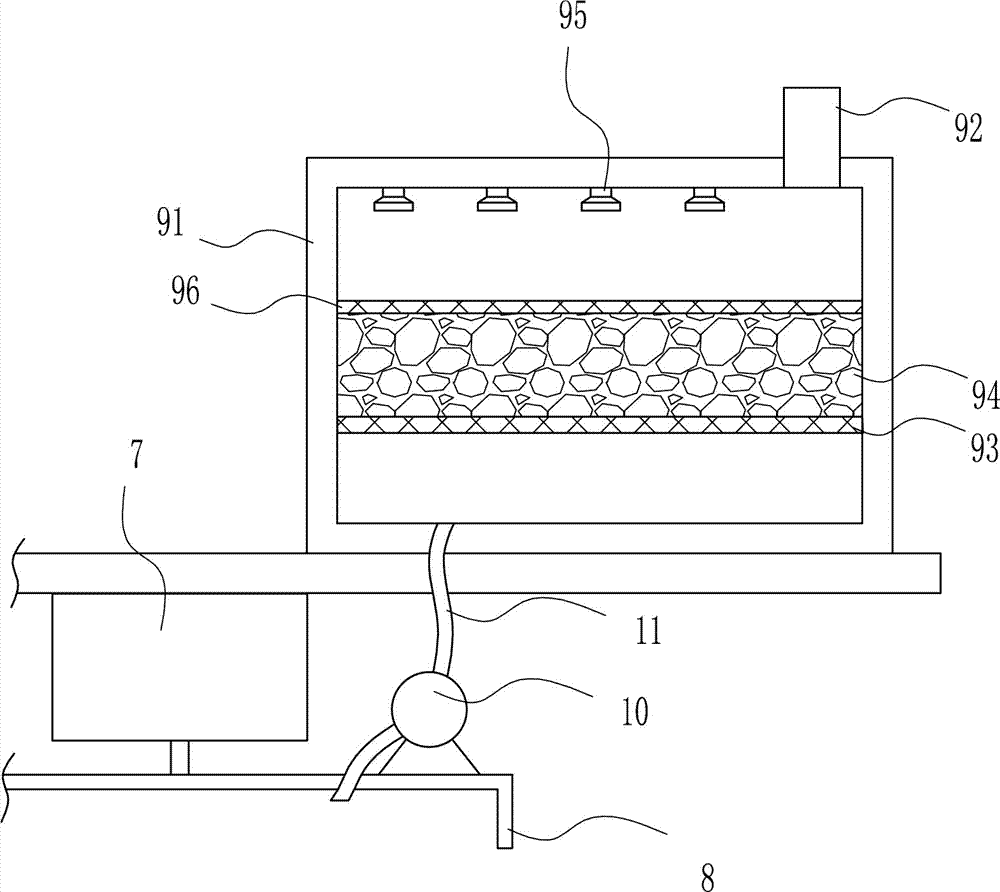

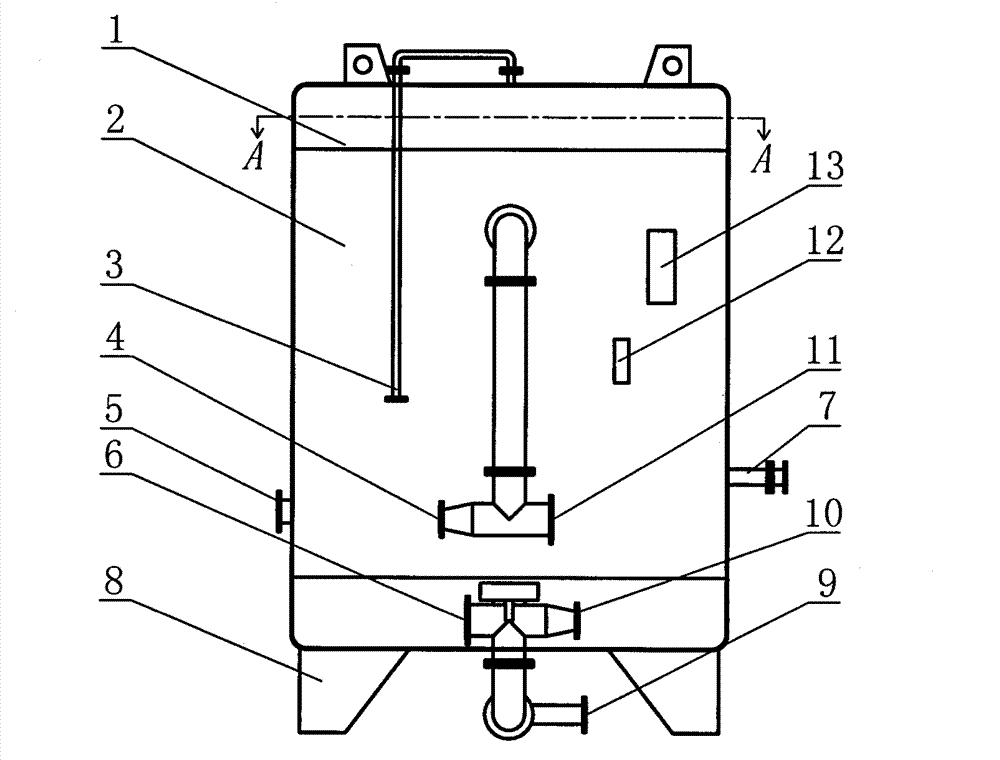

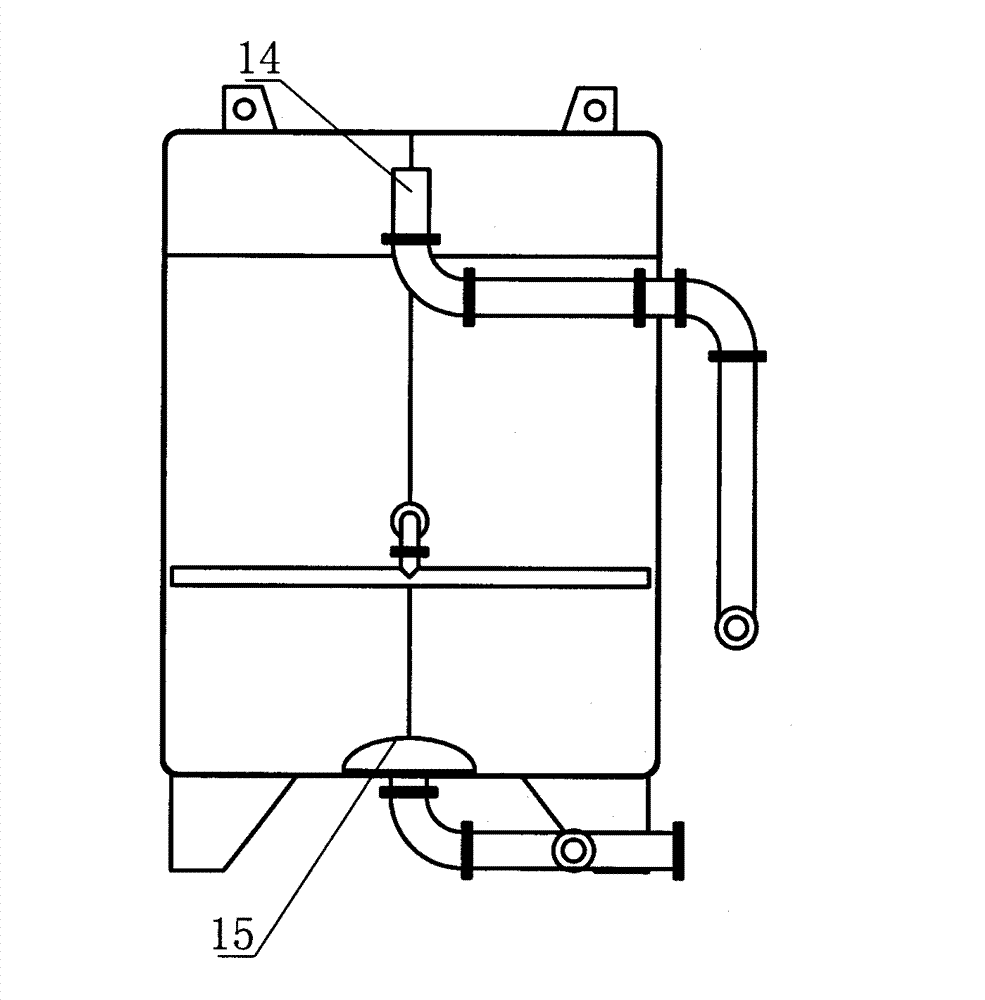

Novel quartz sand filter

InactiveCN102847351ASpread outEfficient removalLoose filtering material filtersGravity filtersWater qualityPapermaking

The invention provides a novel quartz sand filter, which belongs to the technical field of the papermaking industry. A filter layer of the quartz sand filter employs a quartz sand and pebble layer, the quartz sand filter is integrally pressure type filtering purifying equipment, the filter can remove suspended solids in water, silt is intercepted by a sand filter blanket, and thus, raw water is purified. The quartz sand filter is composed of a filter body (2), filter material layers, a feed inlet and an air vent. The upper and lower ends of the filter body (2) are provided with arched perforated plates (15), the outer sides of the arched perforated plates (15) are respectively provided with sealing heads (1) for assembling the filter body (2) and the arched perforated plates together, and the middle parts of the arched perforated plates (15) are filled with the filter material layers; the filter material layer is composed of a pebble layer and a quartz sand layer. The quartz sand filter provided by the invention can effectively remove suspended solids in water and has small filtration resistance, strong acid and alkali resistance and resistance to oxidation, which is beneficial for ensuring the quality of effluent under a variety of operation conditions; a filter material fully disperses during backwashing, and a good cleaning effect is obtained; and the quartz sand filter has the advantages of a wide application scope and a simple structure.

Owner:王天海

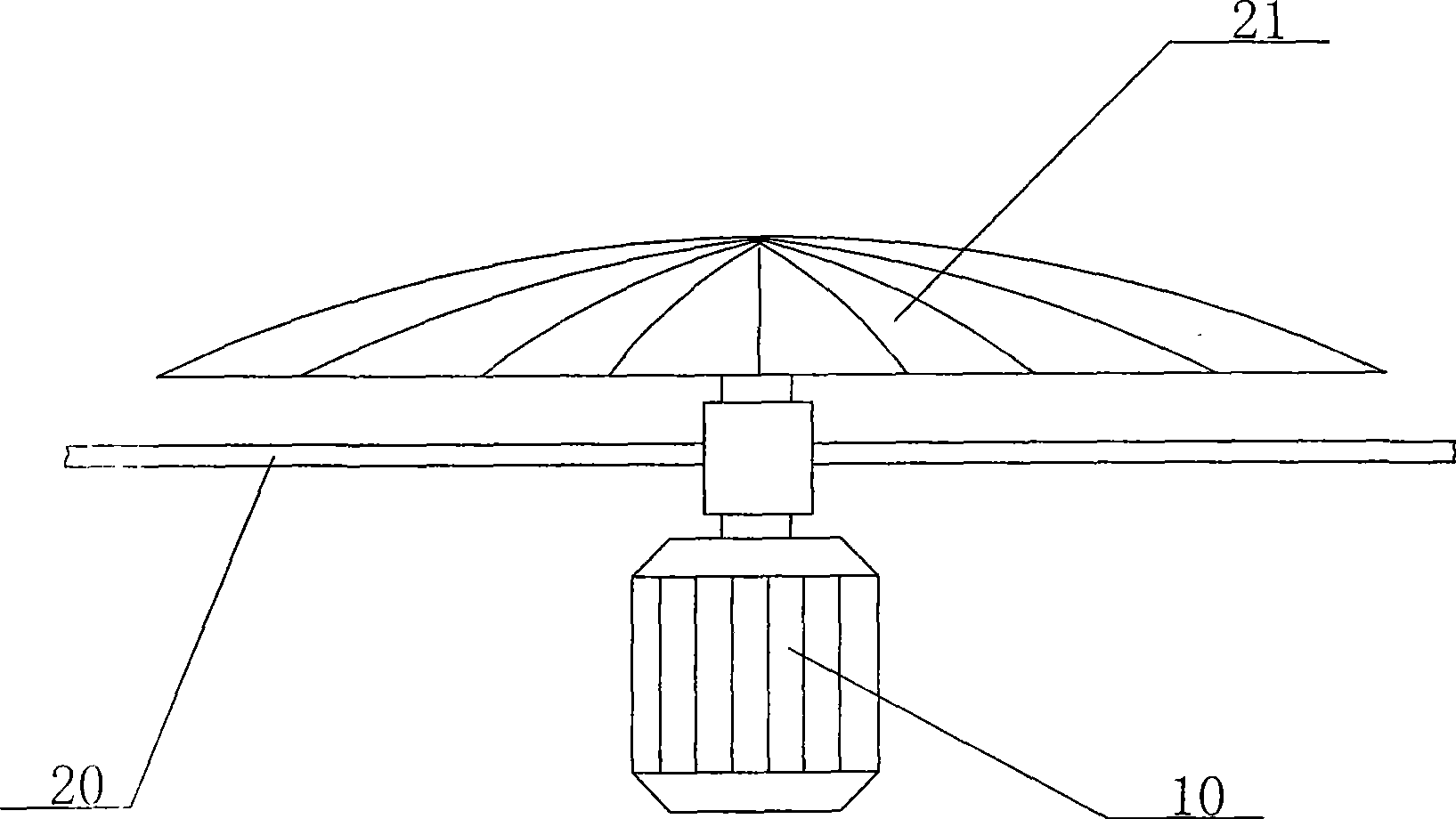

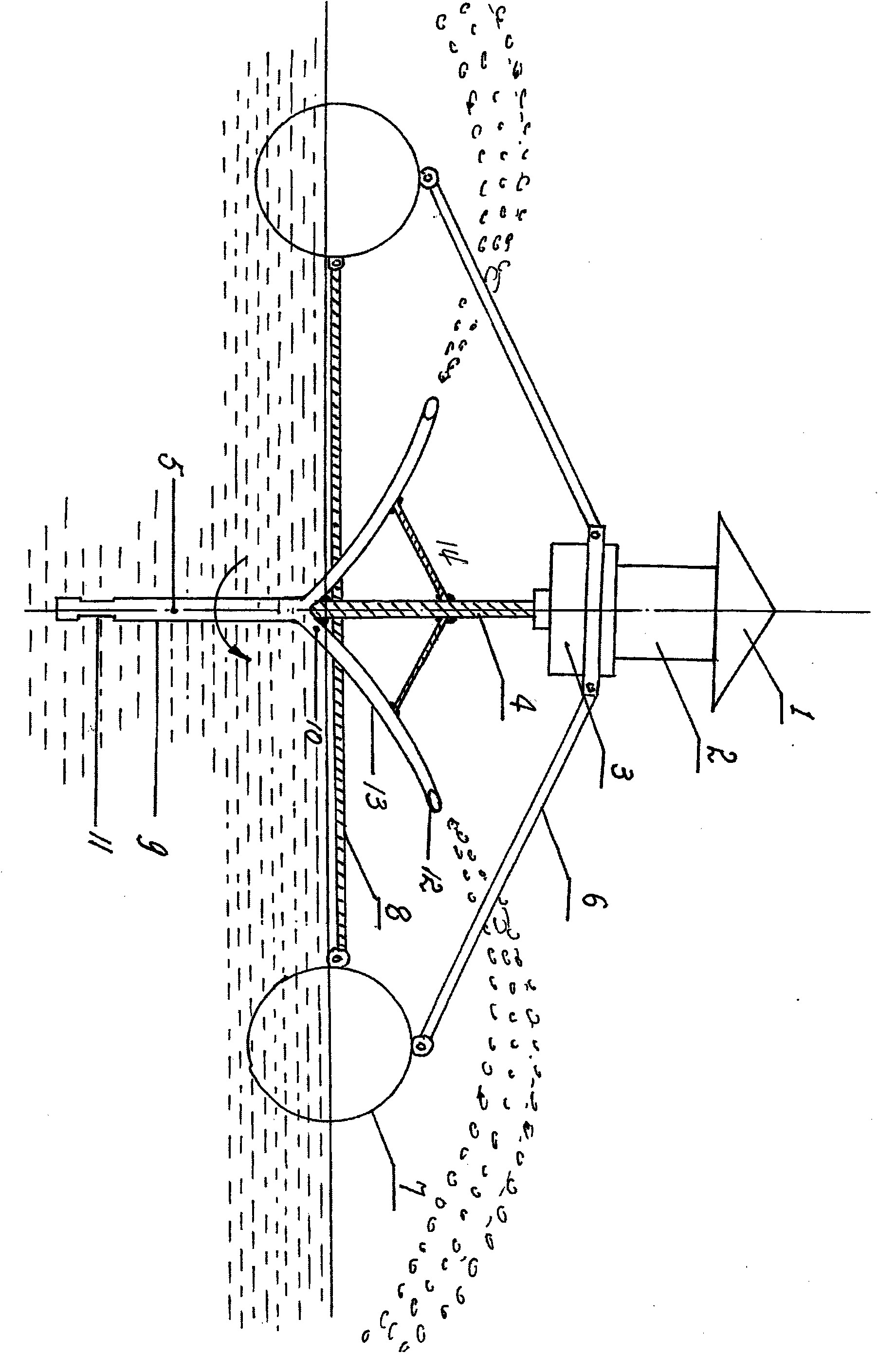

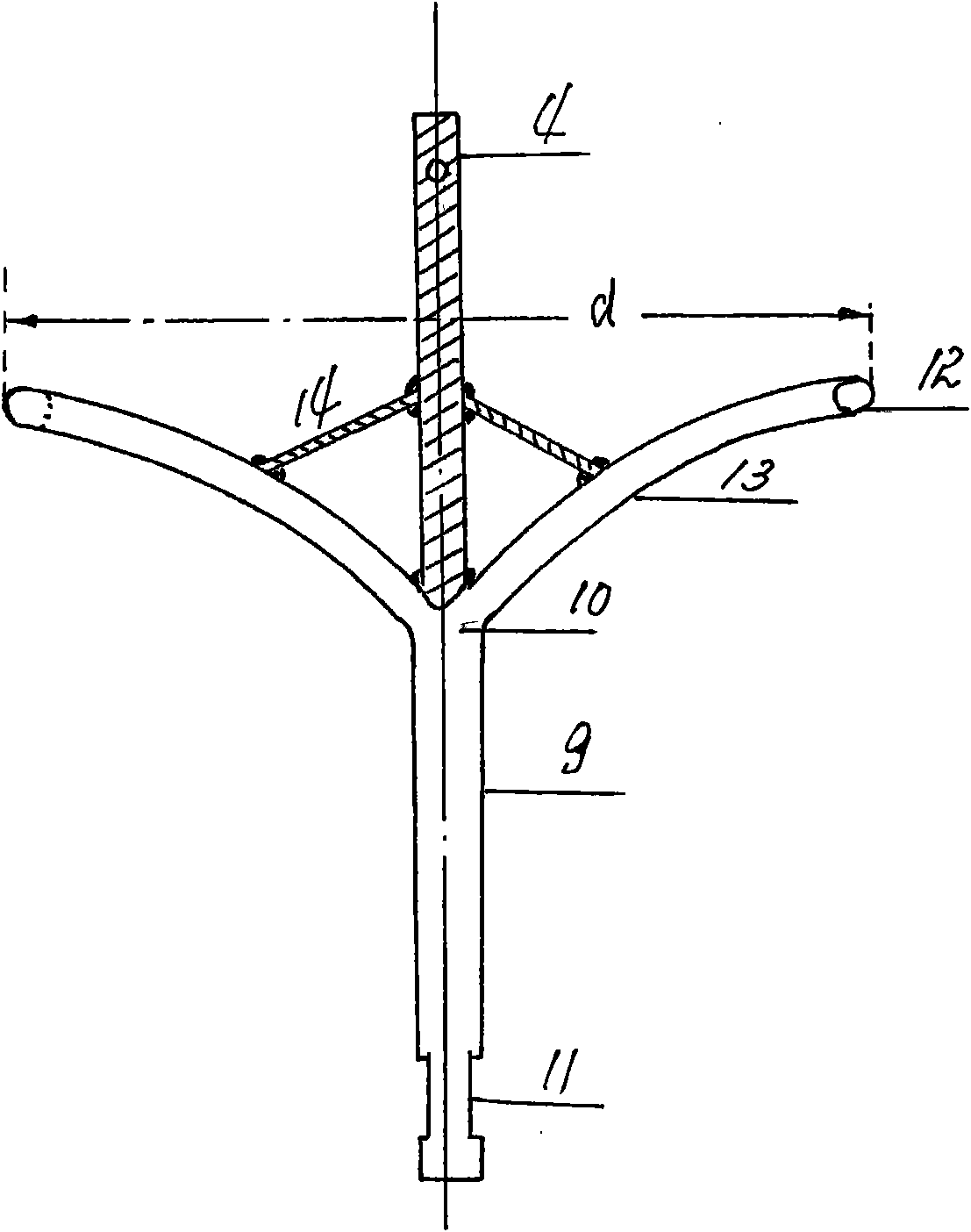

Pond aerator and application

InactiveCN102124987AInnovative designImprove performanceWater aerationPisciculture and aquariaImpellerReducer

The invention discloses a pond aerator, and relates to a pool aerator and application thereof. The aerator solves the problems that the conventional aerator has high impeller resistance, is high in energy consumption, frequently beats fishes and shrimps to death, and can only pump shallow water to the air and has smaller covering surfaces and low oxygen supply effect, and a motor is easy to burn, so that the single-unit oxygen supply coverage area is improved, and the lower watt limit and the cost of an optional motor are reduced. The aerator basically consists of a motor (2), a reducer (3), a tubular fork-shaped water thrower (5), and fixing and connecting components, wherein the tubular fork-shaped water thrower (5) is arranged at the upper end of a vertical hollow round pipe (9), and is connected with a radial hollow round pipe (10). The aerator can throw water in a deeper layer to the air; and the thrown water is fully dispersed, water beads are fully distributed in the air and the coverage area is large, so that the water and the air are fully contacted to fulfill the aim of aeration. A novel variety is provided for pond aerators, the effectiveness of the aerators is improved, and effective guarantee is provided for increasing the density of aquaculture, safely producing and improving benefit.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

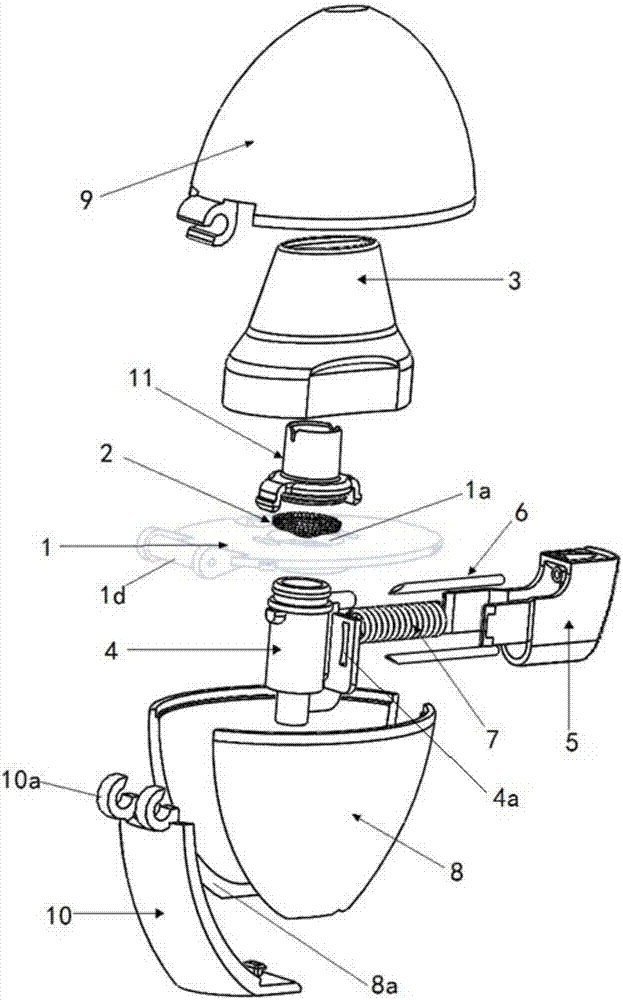

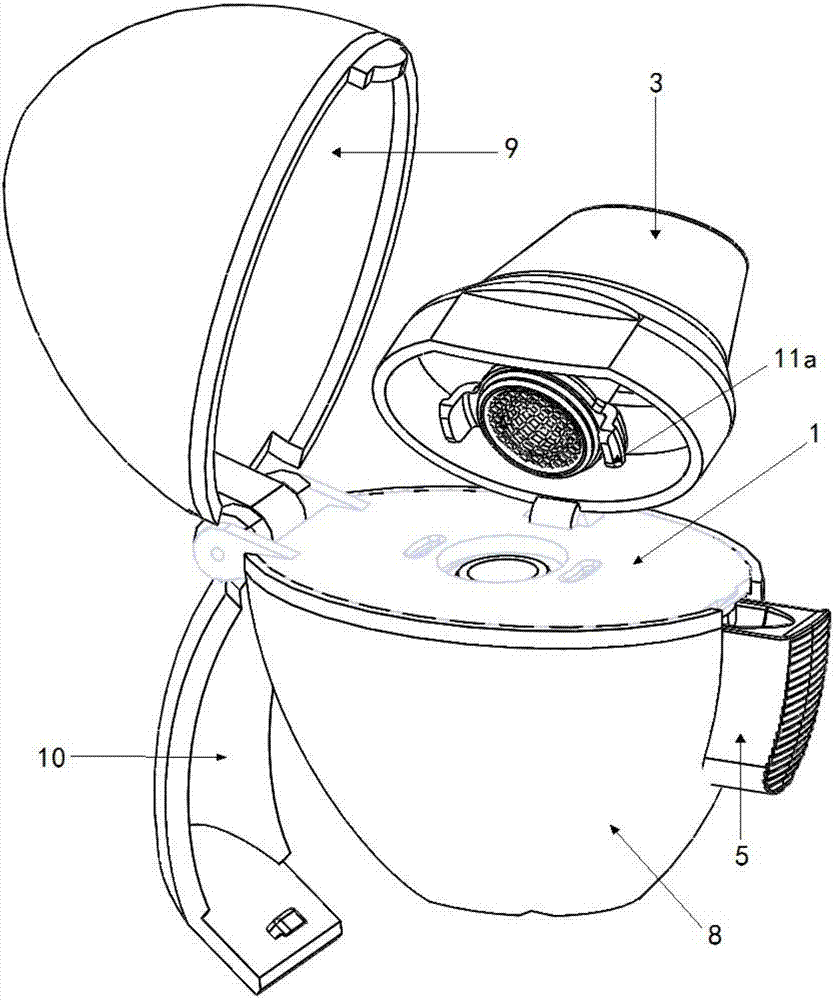

Powder medicine inhaler

InactiveCN107041986AEasy to assembleReduce manufacturing costMedical devicesInhalatorsEngineeringInhaler

The invention discloses a powder medicine inhaler comprising a bearing plate, a suction nozzle, a capsule chamber and an upper housing. Two spaced bearing plate lugs are integrally formed on the side part of the bearing plate; the inner sides of the two bearing plate lugs are close to each other and integrally form internal bosses; the deviated external sides integrally form external bosses; the side part of the suction nozzle integrally forms two suction nozzle lugs spaced to each other; the two suction nozzle lugs are provided with suction nozzle rotary holes matched with the internal bosses; the two suction nozzle rotary holes respectively cover the internal bosses in a rotary way; an upper housing lug is integrally formed on a lower part opening side of the upper housing; the left and right sides of the upper housing lug integrally form a left boss and a right boss; and the left boss and the right boss are respectively disposed in the two suction nozzle rotary holes of the suction nozzle in a rotary way. Pivotal connection between the upper housing, the suction nozzle, the bearing plate and the lower housing requires no specific rotating shaft component, so product production and management cost can be reduced and assembling of the powder medicine inhale can be simplified.

Owner:SUZHOU SINGMED MEDICAL DEVICE SCI & TECH LTD

Heat supply equipment with good heat supply effect

ActiveCN106705093ASpread outBurn fullyLump/pulverulent fuel feeder/distributionDust particlesWater tanks

The invention discloses heat supply equipment with a good heat supply effect. The heat supply equipment comprises a base, a combustion bin, a water tank, a gas cleaning bin and a cleaning device, wherein the top of the combustion bin is connected to an air blower positioned on the outer part through a gas inlet pipeline; the combustion bin is divided into an upper space and a lower space through a combustion plate body which is horizontally blocked in the combustion bin; the lower surface of the combustion plate body is fixedly connected with an air cylinder positioned on the outer part of the combustion bin through a vertically arranged connecting rod; the top of the water tank communicates with a gas outlet tube, and communicates to the outside; and the gas cleaning bin is arranged in the water tank. The heat supply equipment disclosed by the invention can effectively ensure sufficient combustion of raw material particles, the gas cleaning bin is used for removing smoke dust particles in hot gas and absorbing peculiar-smell gas easily dissolved in water, gas is utilized to heat water, and high-temperature waste gas is further prevented from being exhausted, so that the temperature of the exhausted gas is reduced, and pollution is avoided.

Owner:上海上乘新能源科技有限公司

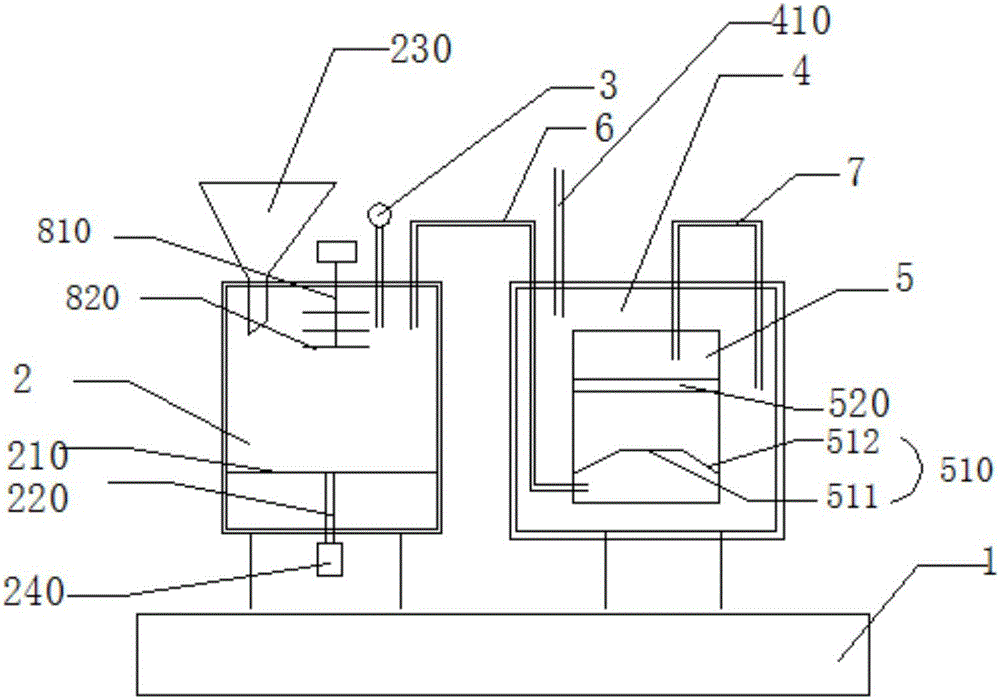

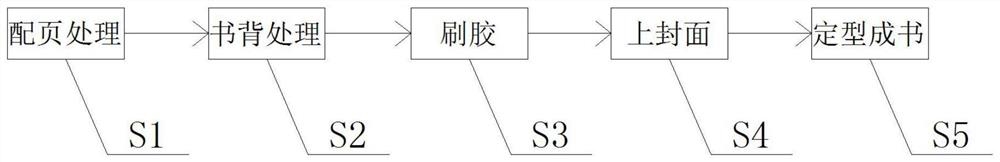

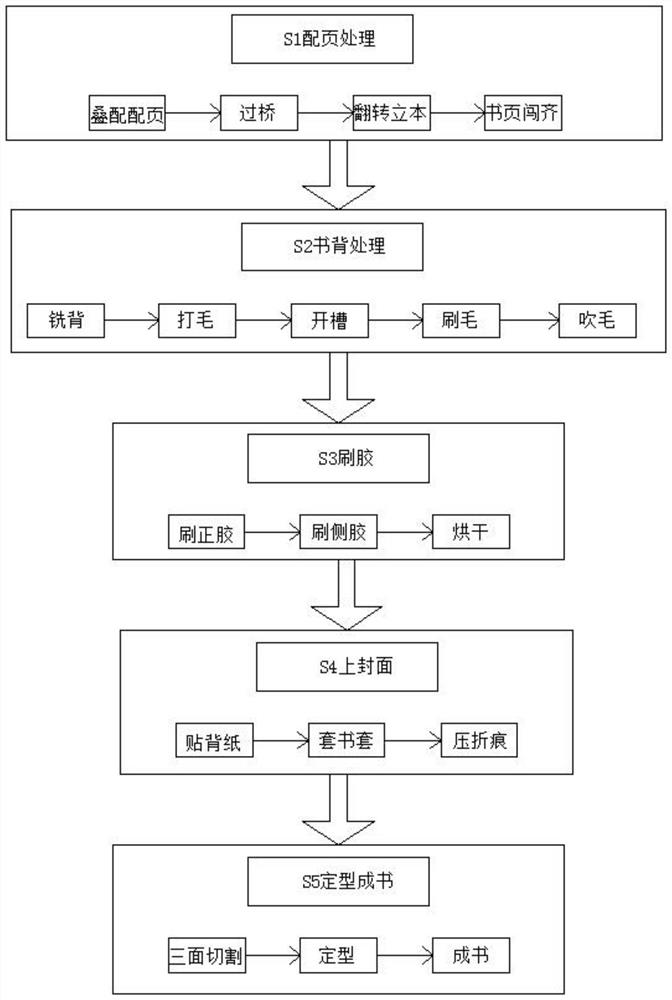

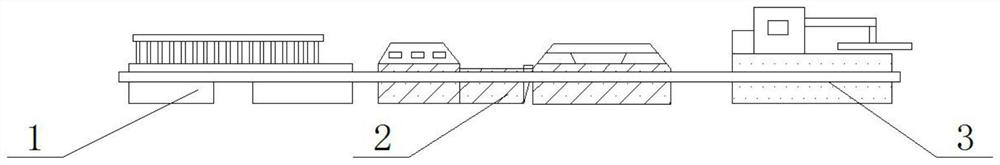

Book gluing and binding method

InactiveCN112572012AInhibit productionSave production raw materialsBook making processesBookbinding adhesivePaper dustAdhesive glue

The invention discloses a book gluing and binding method. The method comprises the steps of book feeding treatment, book back treatment, gluing, covering and book shaping. A page detection device is arranged, so that unqualified pages are prevented from flowing into subsequent procedures, the qualification rate of books is effectively improved, and the waste of raw materials is avoided; a book back treatment mechanism is redesigned, so that paper scraps are prevented from affecting adhesion of glue, strength of the books is improved, meanwhile, the paper scraps on the pages can be prevented from falling into a glue pool, and purity of the glue is guaranteed. A first glue roller, a second glue roller and a distance sensor are arranged, so that gluing of the pages is neither too thick nor too thin, gluing is more uniform, waste of the raw materials can be avoided, and strength and reading experience of the books are not influenced. PUR hot melt adhesive is adopted for book adhesive binding, so that the reading comfort of a reader is improved, and use at high temperature or low temperature can be facilitated. Finally, the cooling time of PUR adhesive coating is shorter, so that the book processing speed is increased.

Owner:储茂东

Artificial intelligence based efficient emulsifying device for defoaming agent production

InactiveCN110743426AImprove processing efficiencyEasy to handleFlow mixersRotary stirring mixersElectric machineryEngineering

The invention relates to an artificial intelligence based efficient emulsifying device for defoaming agent production. The device comprises a motor, a mounting shaft, stirring blades, stirring rods, shearing knives, a stirring barrel, a barrel cover, a feeding tube and a discharging tube, wherein the barrel cover is arranged at the top of the stirring barrel; the motor is arranged on the barrel cover; the output shaft of the motor output is connected with the mounting shaft in a drive manner; the stirring blades are arranged on the mounting shaft; a plurality of stirring blades are uniformly arranged around the central shaft of the mounting shaft; the shearing knife is arranged on the stirring rod; a plurality of shearing knives are arranged side by side along the length direction of the stirring rod; the stirring rod is arranged on the mounting shaft; a plurality of stirring rods are uniformly arranged around the central shaft of the mounting shaft; the feeding tube communicates withthe upper part of the stirring barrel; the discharging tube communicates with the bottom end of the stirring barrel; and a first control valve is arranged on the discharging tube. By adopting the device, stirring and shearing and emulsification treatment on a defoaming agent can be carried out, and the treatment efficiency and effects can be improved.

Owner:九江市美景水处理科技有限公司

Energy-saving type flowing roasting furnace

InactiveCN104275436AReasonable structural designGood energy saving effectMould handling/dressing devicesFlueHeat exchanger

The invention relates to an energy-saving type flowing roasting furnace for regenerating casting waste sand. The energy-saving type flowing roasting furnace comprises a barrel which is provided with a draught flue on the top and a cone bottom at the bottom, wherein the center of the bottom of the cone bottom is provided with a sand outlet; the top of an inner cavity of the barrel is provided with a first sand separating cone; a sand dispersing device for further dispersing the casting waste sand is arranged under the first sand separating cone; the top wall of the barrel is provided with a waste sand inlet pipe, and the bottom end of the barrel just faces to the cone top of the first sand separating cone; a heat preserving layer covers the outer wall of the barrel; a plurality of burners are arranged in the middle of the side wall of the barrel; a heat exchanger is arranged at the bottom of the inner cavity of the barrel and above the cone bottom and comprises a flat cylindrical shell, and the outer wall of the shell is fixedly connected with the inner wall of the barrel; a plurality of vertical tubes which are through along the longitudinal direction are fixedly connected between the top wall and the bottom wall of the shell; a plurality of vertical air pipes are arranged on the top wall of the shell and among the vertical tubes; inner cavities of the air pipes are communicated with the inner cavity of the shell; the outer wall of the shell is also provided with an air inlet.

Owner:JINYING CASTING MATERIAL TIANJIN CO LTD

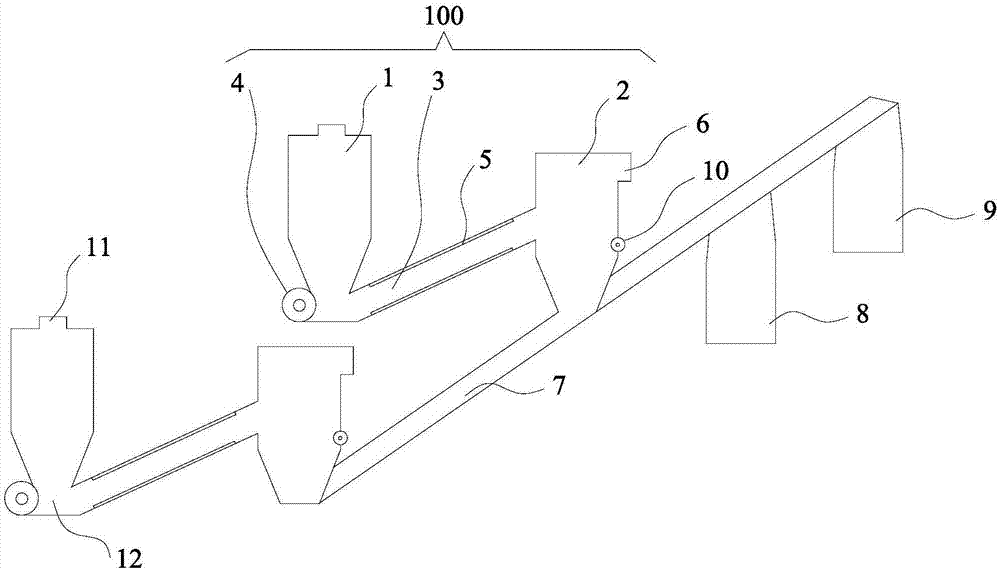

Premixer for acid and ore

ActiveCN106693752AGuaranteed continuous contact timeGuaranteed accuracyRotary stirring mixersMixing methodsMaterials science

The invention discloses a premixer for acid and ore, which belongs to the technical field of the design and manufacturing of metallurgical material production equipment. The provided premixer has the advantages of sufficient premixing and accurate premixing input amount. The premixer comprises a material input system, a concentrated sulphuric acid input system, and a continuous acid-ore premixing and output system, an ore input port and an acid liquor input port are respectively arranged at the head end of the continuous acid-ore premixing and output system, and a premixed material output port is arranged at the tail end of the continuous acid-ore premixing and output system; the material input system and the concentrated sulphuric acid input system respectively communicate with the continuous acid-ore premixing and output system via the ore input port and the acid liquor input port; and ore and concentrated sulphuric acid which need to be premixed are respectively and simultaneously inputted into the continuous acid-ore premixing and output system by the material input system and the concentrated sulphuric acid input system according to set speeds, continuously uniformly mixed and continuously outputted from the premixed material output port.

Owner:CHONGQING TITANIUM IND OF PANGANG GROUP

Rice bran air-drying and separation system

InactiveCN107537772AEfficient separationEfficient deliveryGas current separationBroken riceEngineering

The invention discloses a rice bran air-drying and separation system and relates to the field of separation systems. The rice bran air-drying and separation system comprises a plurality of air-dryingdevices arranged parallelly. Each air-drying device comprises a collection bin, an air-drying barrel, a first feeding guide pipe, a blower and an adjusting fan. The two ends of the first feeding guidepipes are connected with the collection bins and the air-drying barrels. The first feeding guide pipes and the collection bins form included angles, and the first feeding guide pipes and the air-drying barrels form included angles. The blowers are mounted on the sides, away from the first feeding guide pipes, of collection parts. An air outlet is formed in one end of each air-drying barrel, and the other ends of the air-drying barrels are connected with a second feeding guide pipe. The adjusting fans are mounted on the inner walls of the air-drying barrels. The multiple air-drying devices areconnected through the second feeding guide pipe. A broken rice collection device and a rice bran collection device are sequentially connected to the end, away from the air-drying barrels, of the second feeding guide pipe. According to the rice bran air-drying and separation system, broken rice is further separated from rice bran, the separation effect is good, and operation is easy.

Owner:广西贵港市恒桥米业有限公司

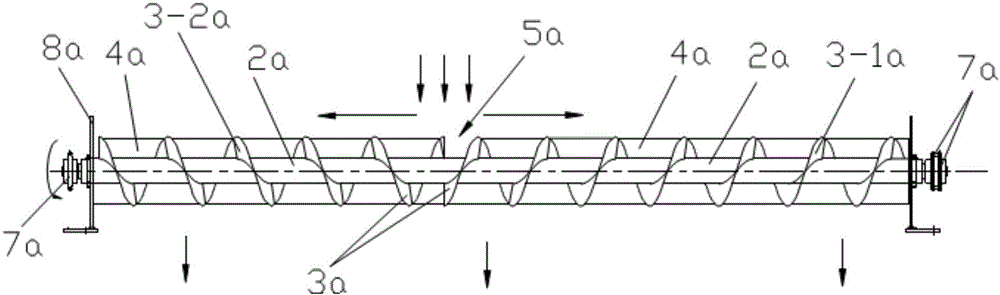

Rinsing tank used in tailing regeneration treatment of regeneration papermaking

ActiveCN106049144ASpread outFully exposedWashing/displacing pulp-treating liquorsPaper recyclingHelical bladePapermaking

The invention discloses a rinsing tank used in tailing regeneration treatment of regeneration papermaking. The rinsing tank includes a tank body, a dispersing device, and a cutting separating cleaning device. The dispersing device includes a plurality of dispersing units which are arranged together, and each dispersing unit includes a dispersing rotation shaft, a screw blade arranged on the dispersing rotation shaft, and a tearing piece arranged on the dispersing rotation shaft; and the screw blade consists of a left blade and a right blade which are arranged at two ends of the dispersing rotation shaft. The cutting separating cleaning device includes a plurality of cutting cleaning mechanisms, and each cutting cleaning mechanism includes a cleaning rotation shaft and a cutting blade; and the liner velocity of the cutting blade of the posterior cutting cleaning mechanism is greater than the linear velocity of the cutting blade of the previous cutting cleaning mechanism in the flowing direction of cleaning liquid. The rinsing tank can allow a material to be treated to be fully dispersed and evenly spread, allow impurities to be fully exposed and separated, can improve the cleaning efficiency and effect, and can improve the separating efficiency between paper pulp and plastic.

Owner:广东致顺化工环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com