Pond aerator and application

A technology for supplying oxygen and ponds, which is applied in the field of pond oxygen supply machines. It can solve the problems of small contact area between water and air, heavy economic burden on farmers, and large starting current of motors. It achieves good oxygenation effect, novel design, and large The effect of coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

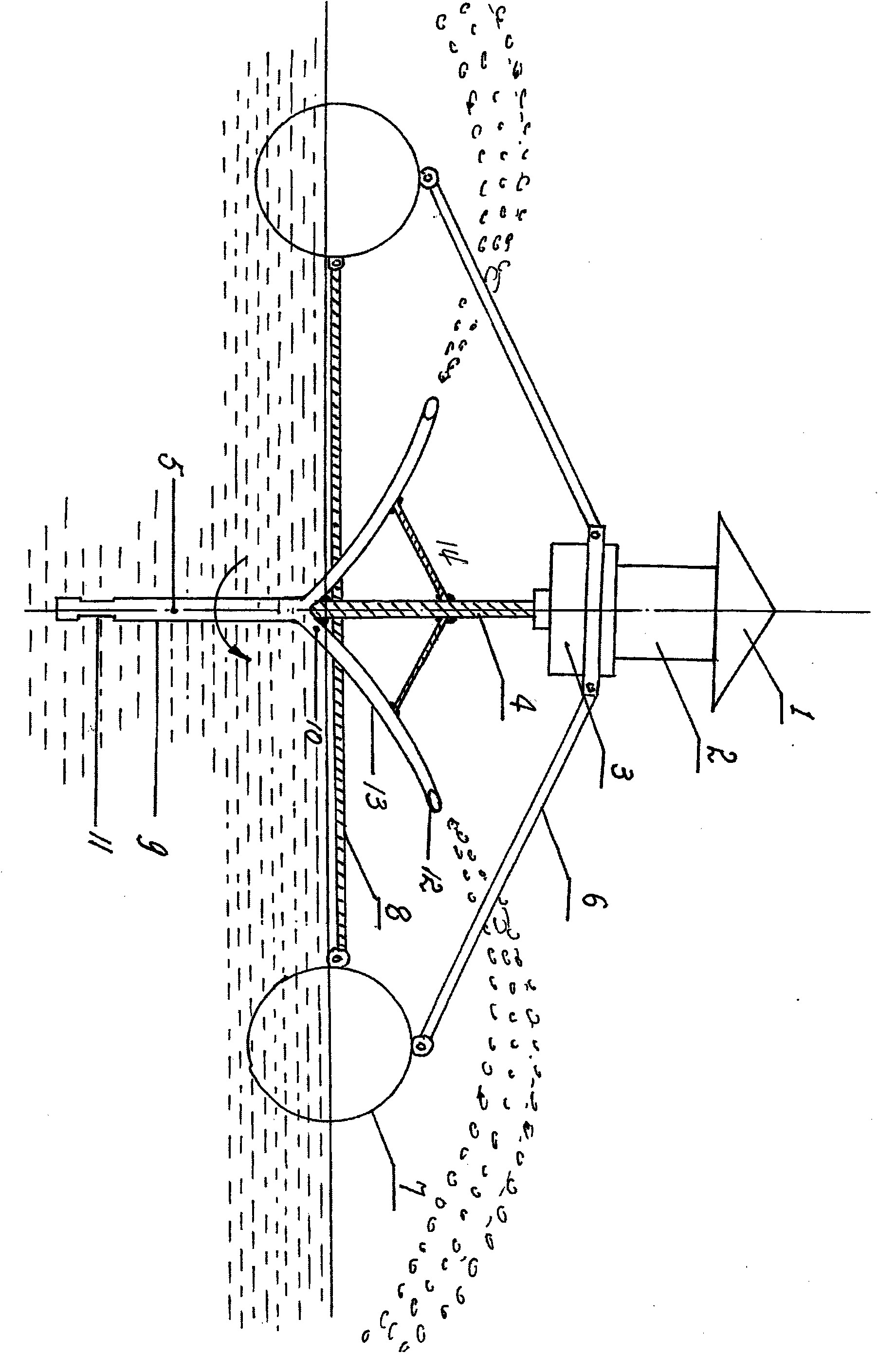

[0037] Such as figure 1 , 3 As shown, the pond oxygen generator of the present invention is made up of motor protective cap 1, motor 2, reducer 3, connecting rod 4, tubular fork-shaped water thrower 5, float 7, poles 6, 14 and connecting pipe 8; The connection method is to connect the reducer 3 under the motor 2 equipped with the motor cap 1, and then use an iron connecting rod 4 (30mm in diameter and 330mm in length) to connect the reducer 3 with the tubular fork-shaped water thrower 5 below. Connection; motor 2 side, symmetrically connect three struts 6, each strut 6 (diameter is 20mm, length is 1400mm), and then respectively connect a float 7, three floats 7 are connected with connecting pipe 8, meanwhile, the floats 7 fix with the shore with ropes. The tubular fork-shaped water thrower 5 is at the upper end of the vertical hollow tube 9 with side opening 11, communicates with the radial hollow tube 10, and the two form a sealed passage, so that water flows from the verti...

Embodiment 2

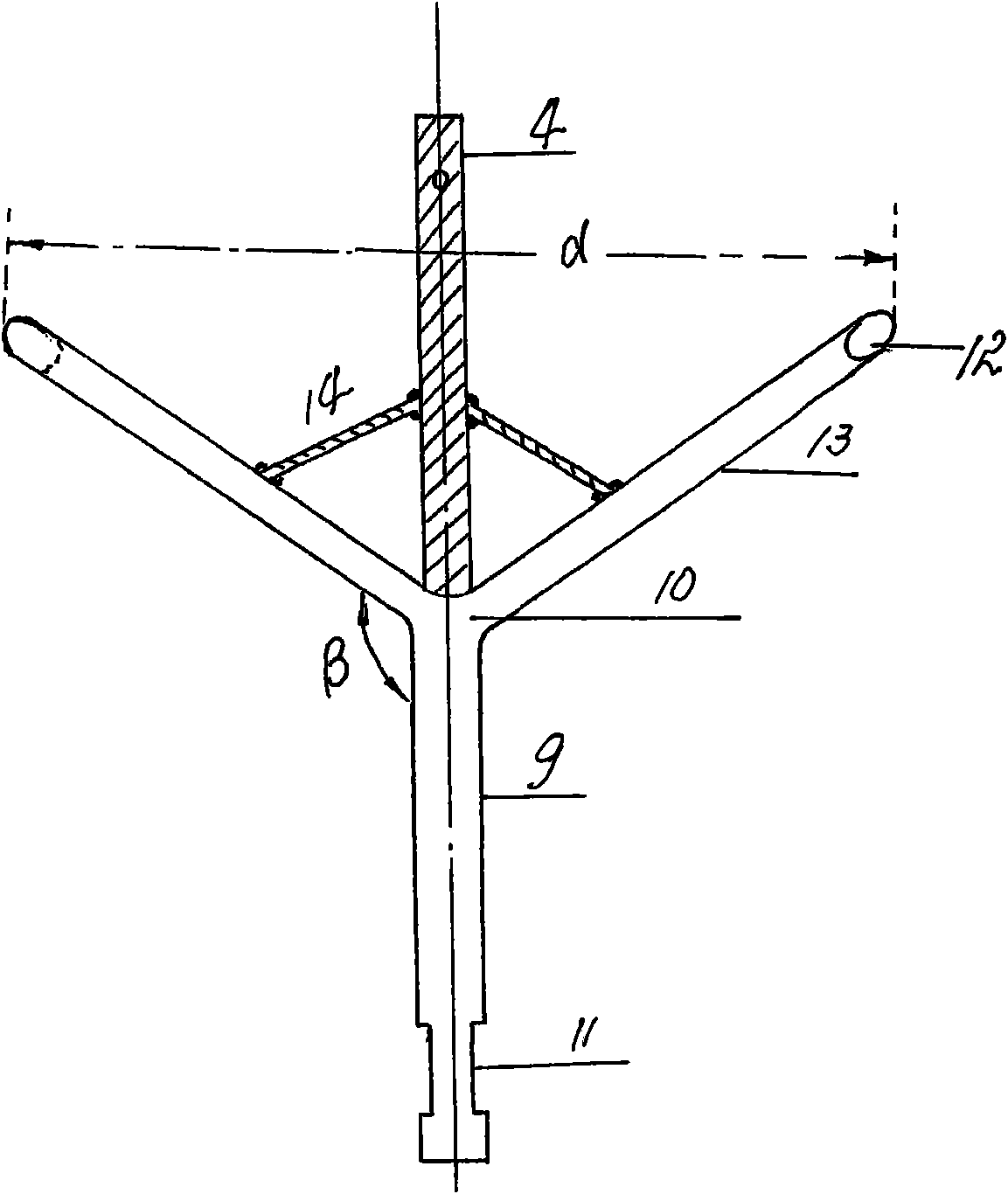

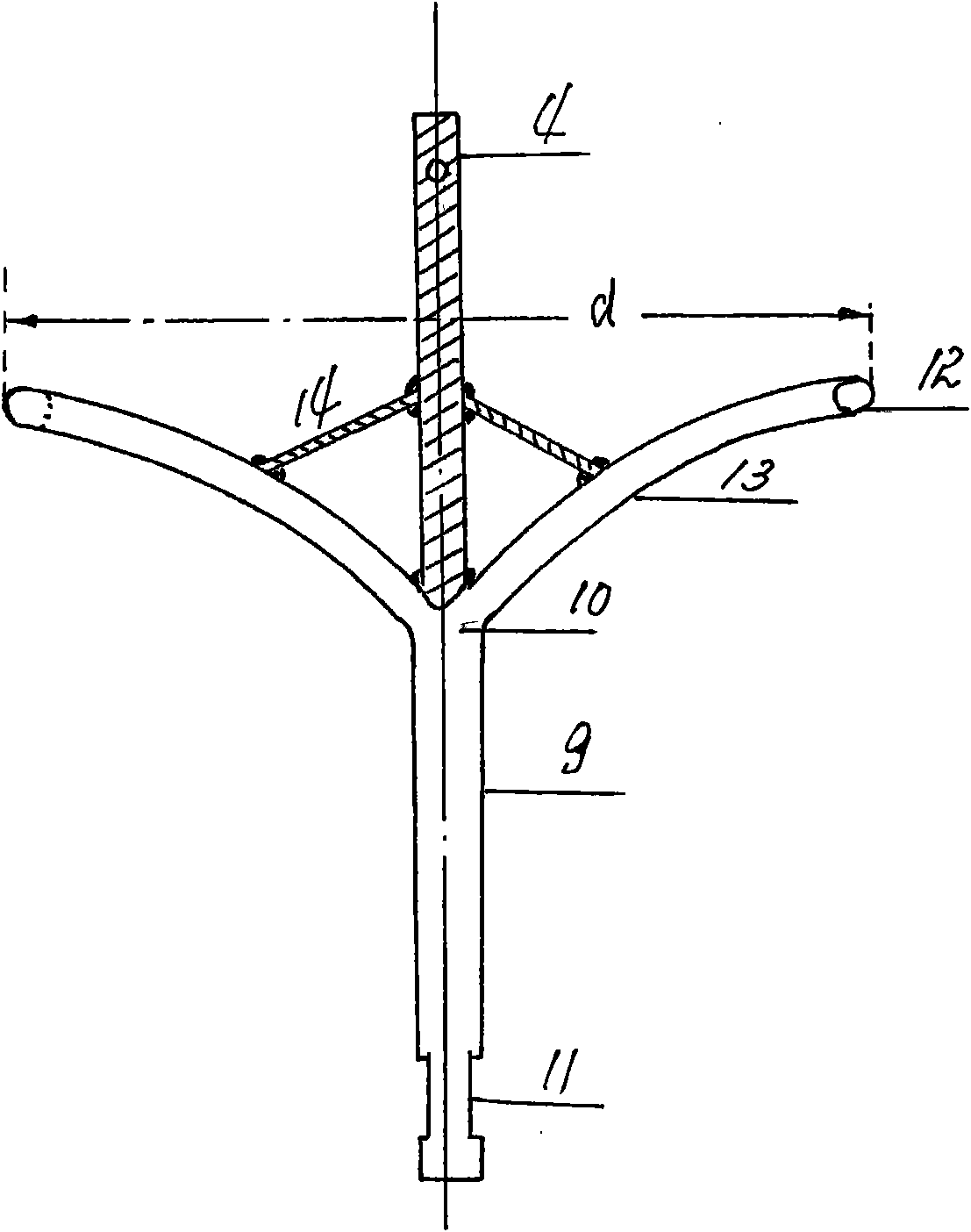

[0043] Such as figure 2 As shown, the radial hollow circular tube 10 is formed by radially arranging two bifurcated tubes 13 at equal angles and at equal intervals. Each bifurcated pipe 13 is a straight pipe, and the included angle β with the vertical hollow pipe 9 is 135°, and the others are the same as in Embodiment 1.

Embodiment 3

[0045] The motor 2 adopts a 1500-watt three-phase AC motor. The rotation diameter d of the radial hollow circular tube 10 is 800 mm, and the inner diameter of the bifurcated tube 13 is 25 mm. The radial hollow circular tube 10 is formed by three branched tubes 13 arranged radially at equal angles and at equal intervals. Each bifurcated pipe 13 is in the shape of a parabolic arc, the focal length of the parabolic curve of its axis is 400mm, the angle θ formed between the end face of the notch 12 and the pipe axis is 45°, and the inner diameter of the vertical hollow circular pipe 9 is 45mm , the length is 280mm. On the lower tube wall of the vertical hollow tube 9, two rectangular side openings 11 are symmetrically and evenly opened. The distance C between the bottom edge of the side opening 11 and the bottom end of the vertical hollow tube 9 is 30mm. The length a of the side opening 11 in the vertical direction is 50mm, and its width b is 20mm. Others are with embodiment 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com