Fluidized roadbed soil and construction method

A technology for roadbed soil and dregs, which is applied in applications, household appliances, ceramic products, etc., can solve the problems of artificial vibration, environmental pollution, artificial paving, etc., to improve fluidity and strength, improve physical properties, and enhance physical properties. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] During the construction of a permeable subgrade in Zhenjiang City, a large amount of muck was produced during the excavation process, and the dregs contained a certain amount of rocks. Combined with the local conditions, carry out on-site fluidized backfill treatment on the muck, and the main operation steps on site are as follows:

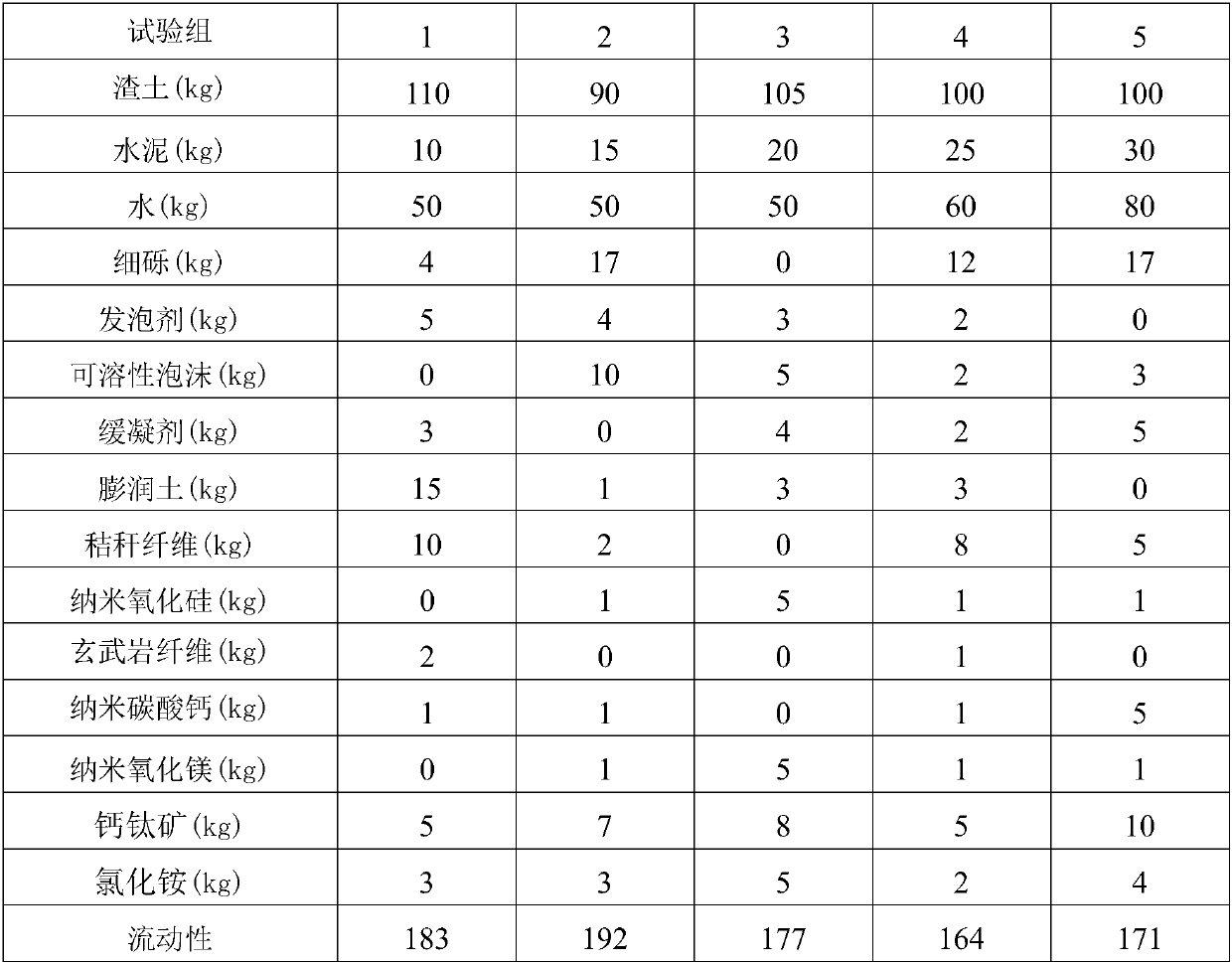

[0042] (1) field test: according to laboratory test result (adopting method of the present invention and raw material ratio preparation table 1 laboratory test fluidized subgrade soil), the mixing ratio of final construction is determined to be: slag: 100 parts, 32.5 ordinary silicic acid 25 parts of salt cement, 60 parts of water, 12 parts of fine gravel, 2 parts of foaming agent, 2 parts of soluble foam particles, 2 parts of retarder, 3 parts of bentonite, 8 parts of straw fiber, 1 part of nano silicon oxide, 1 part of basalt fiber 1 part of nano-calcium carbonate, 1 part of nano-magnesium oxide, 5 parts of perovskite, and 2 parts of ammo...

Embodiment 2

[0057] During the construction of a permeable subgrade in Zhenjiang City, a large amount of muck was produced during the excavation process, and the dregs contained a certain amount of rocks. Combined with the local conditions, carry out on-site fluidized backfill treatment on the muck, and the main operation steps on site are as follows:

[0058] (1) field test: according to laboratory test results (adopting the laboratory test fluidized subgrade soil of table 2 prepared by the method of the present invention and raw material proportioning), the final mixing ratio of determining construction is: slag: 100 parts, 42.5 ordinary silicic acid 20 parts of salt cement, 60 parts of water, 8 parts of fine gravel, 2 parts of foaming agent, 1 part of soluble foam particles, 4 parts of retarder, 3 parts of bentonite, 10 parts of straw fiber, 1 part of nano silicon oxide, 3 parts of basalt fiber 1 part of nano-calcium carbonate, 1 part of nano-magnesium oxide, 7 parts of perovskite, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com