Tea roller sorting device

A sorting device and drum technology, used in solid separation, sieves, grilles, etc., can solve the problems of easy damage to tea leaves, reduced work efficiency, increased production energy consumption, etc., to achieve efficient classification and screening, improve product quality, Damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

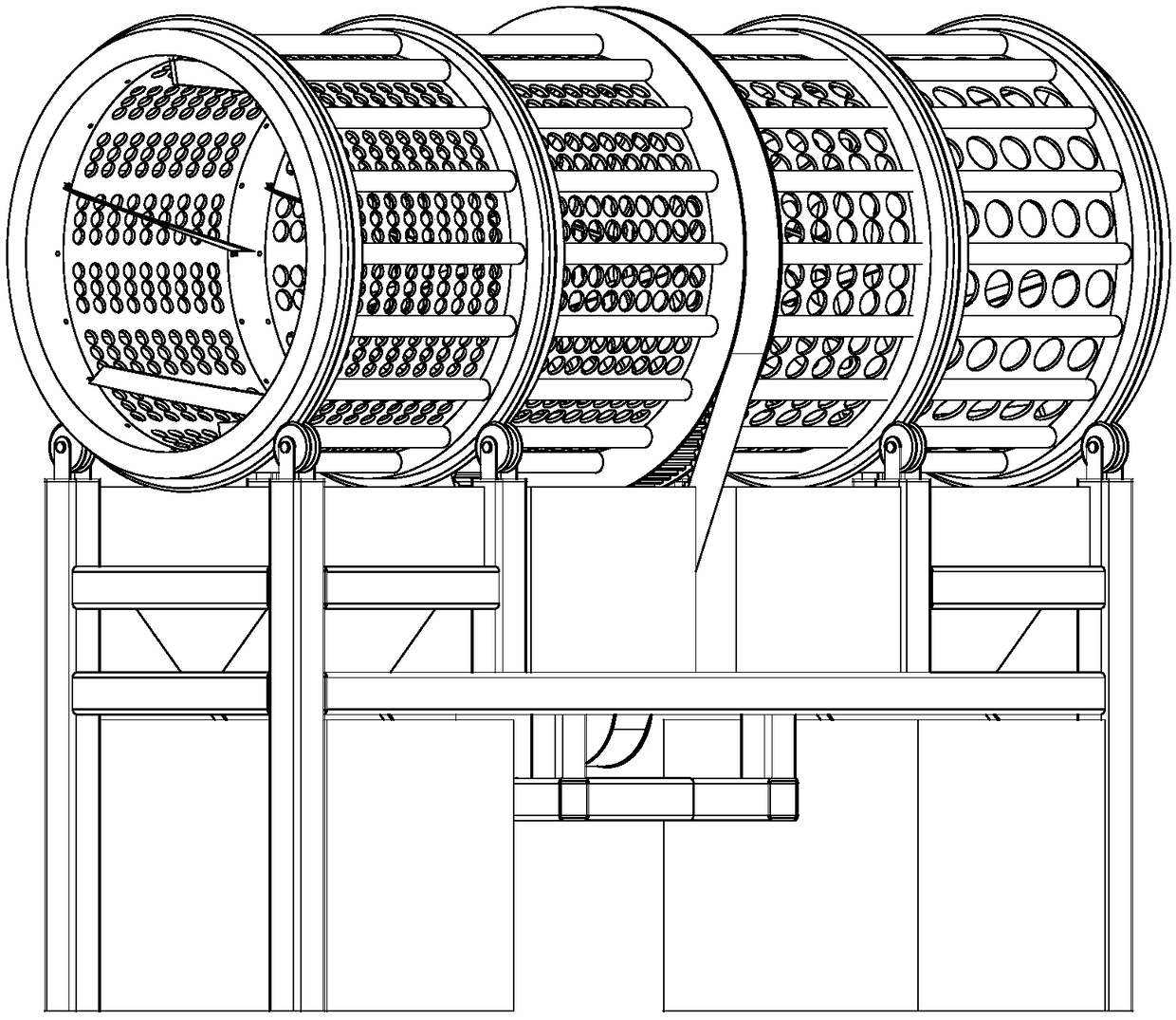

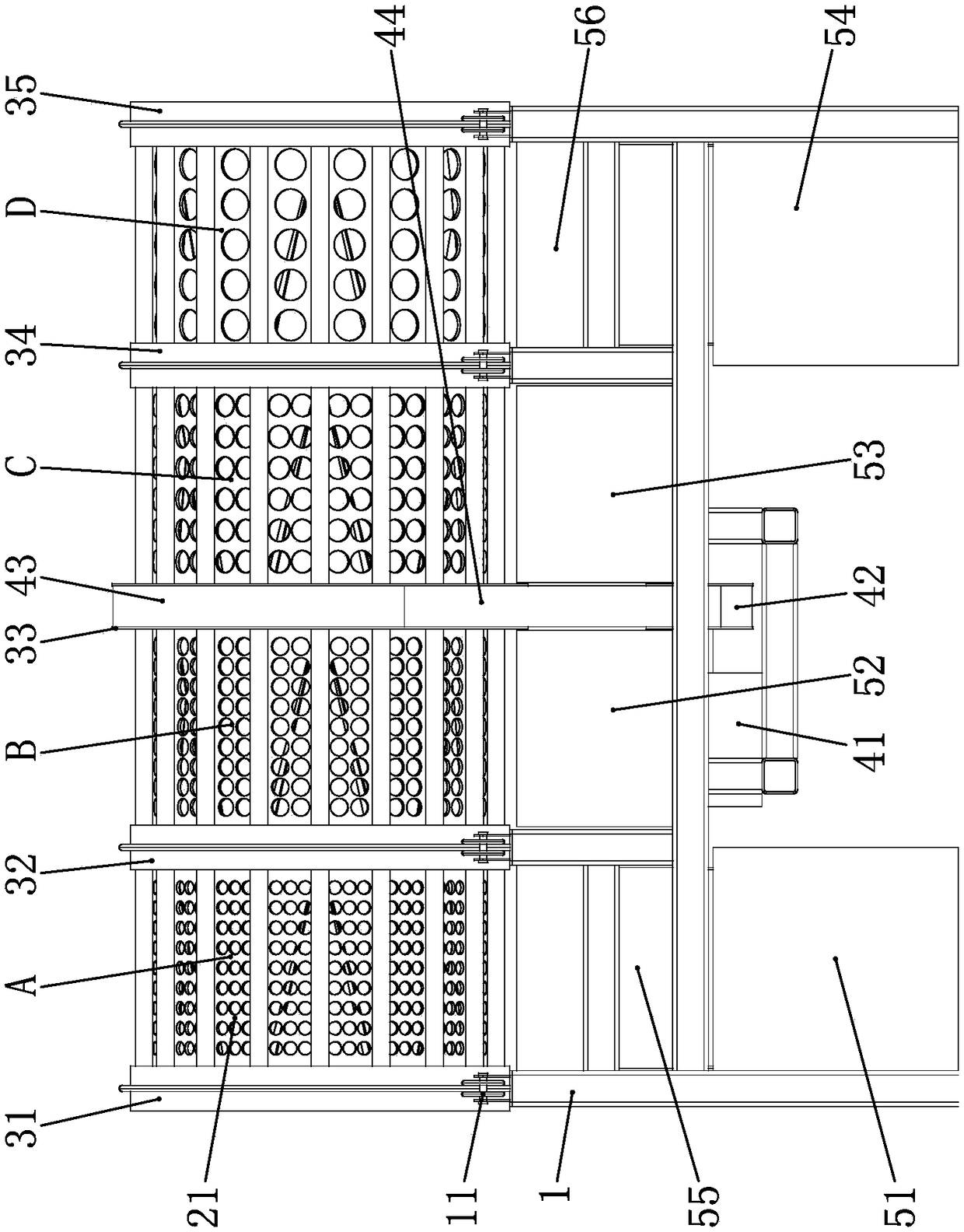

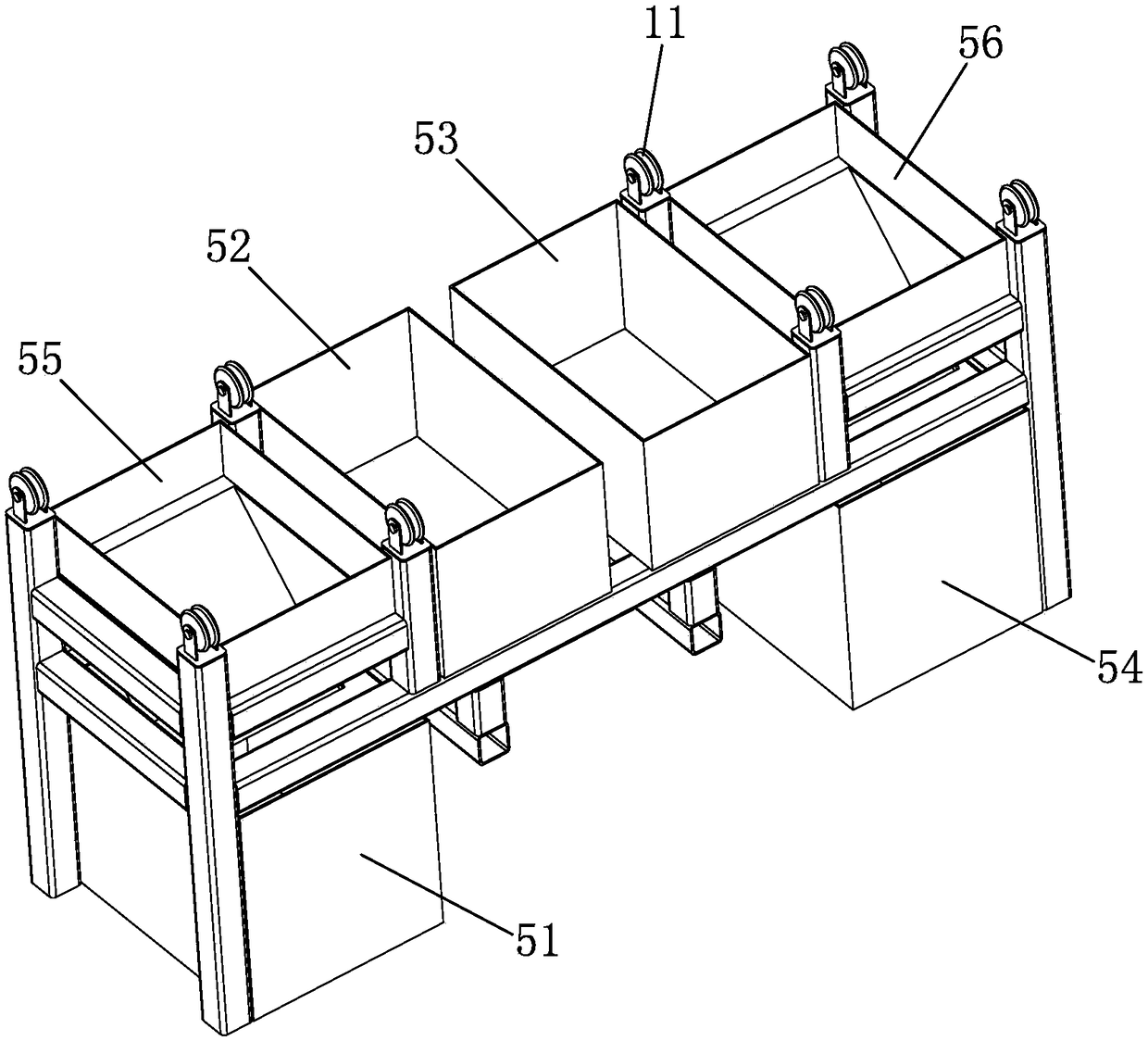

[0023] A tea roller sorting device includes a support platform 1 on which a sorting cylinder, a power mechanism and a material-feeding mechanism are arranged respectively.

[0024] The sorting drum is a horizontally arranged cylindrical shell and is positioned on the support platform so as to be rotatable around a horizontal axis. Such as figure 2 As shown, the left end of the sorting cylinder is the inlet and the right end is the outlet, the inlet is provided with a feed hopper (omitted in the figure), and the outlet is provided with a discharge hopper (omitted in the figure). The sorting cylinder is formed by axial connection of several sections, the cylinder wall of each section is a flexible screen 21, and a number of spiral plates 22 are arranged on the inner peripheral surface of the cylinder w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com