Rinsing tank used in tailing regeneration treatment of regeneration papermaking

A treatment process and rinsing tank technology, applied in the field of rinsing tanks, can solve the problems of separation of unfavorable impurities, inability to fully disperse feeding parts, inability to fully expose and separate impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

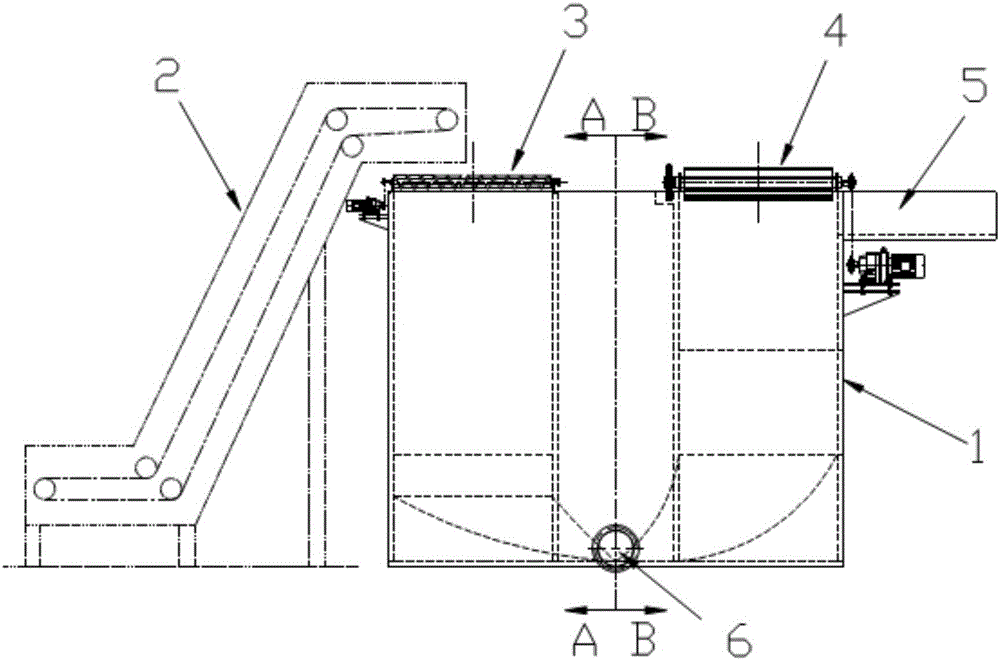

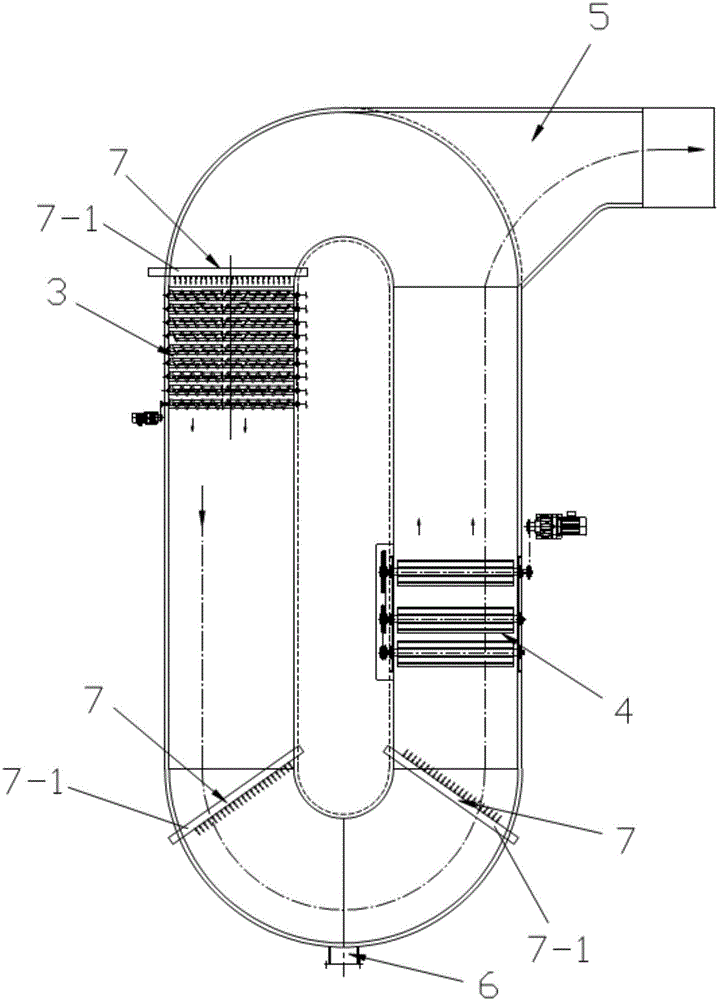

[0048] see Figure 1-Figure 4 , The rinsing tank in the recycling process of recycled papermaking tailings in this embodiment is mainly composed of a tank body 1 and a breaking device 3 provided on the tank body 1 , a shear separation cleaning device 4 and a material booster device 7 . in:

[0049] see Figure 1-Figure 4 , the tank body 1 has an annular structure, and an annular flow channel is formed inside; the bottom of the tank body 1 is provided with a sediment discharge port 6 , and the top is provided with a floating material discharge port 5 .

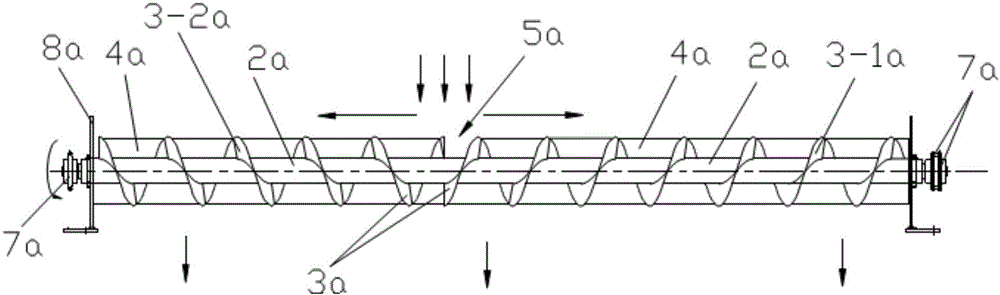

[0050] see Figure 1-Figure 4 , Figure 6-Figure 8 , the dispersing device 3 is arranged at the feeding position in the tank body 1, the dispersing device 3 includes a plurality of dispersing units 1a arranged together, and each dispersing unit 1a includes a dispersing rotating shaft 2a, which is located at the dispersing unit 1a The helical blade 3a on the rotating shaft 2a and the tearing part 4a arranged on the rotating sha...

Embodiment 2

[0069] The difference between this embodiment and the embodiment is that in this embodiment:

[0070] see Figure 14 , in the dispersing device 3, the dispersing unit 1a is arranged in a multi-layer structure in the vertical direction; a plurality of dispersing units 1a in each layer of dispersing units 1a are arranged in parallel on the same level; Wherein, the lower part of the uppermost layer of dispersing units 1a is immersed in the cleaning solution 11a, and the rest of the dispersing units 1a are immersed in the cleaning solution 11a. Figure 14Only two floors are shown in the figure, from top to bottom are the first floor dispersal unit 1-1a and the second floor dispersal unit 1-2a. In the dispersing unit 1a of the same layer above, the former dispersing unit 1a disperses the material 10a while forwarding it, and the latter dispersing unit 1a takes over the transported material 10a and continues to disperse it and convey it forward. After a plurality of breaking-up un...

Embodiment 3

[0074] The difference between this embodiment and the embodiment is that in this embodiment:

[0075] see Figure 16 with Figure 17 , in the dispersing device 3, in the dispersing unit 1a on the same floor, the left-handed blades 3-1a and the right-handed blades 3-2a in two adjacent dispersing units 1a are respectively arranged on different sides of the dispersing shaft 2a. End, that is: when the left-handed blade 3-1a (or right-handed blade 3-2a) in the first dispersing unit 1a is set at the left end (or right end) of the dispersing shaft 2a, the second adjacent The left-handed blades 3-1a (or right-handed blades 3-2a) of each dispersing unit 1a are arranged at the right end (or left end) of the dispersing shaft 2a; and all the dispersing shafts 2a turn in the same direction. The advantage of adopting this arrangement is that since the left-handed blades 3-1a and the right-handed blades 3-2a in two adjacent dispersing units 1a are respectively arranged at different ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com