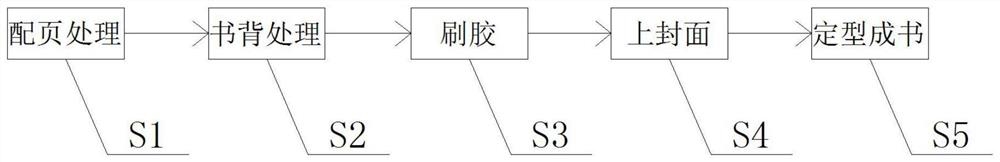

Book gluing and binding method

A book and gluing technology, which is applied in the direction of book binding, adhesives for binding, compound continuous process of book processing, etc., can solve the problem of affecting the strength of books, lack of equipment for book page detection, poor performance of EVA hot melt adhesive, etc. problem, to achieve the effect of saving production raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

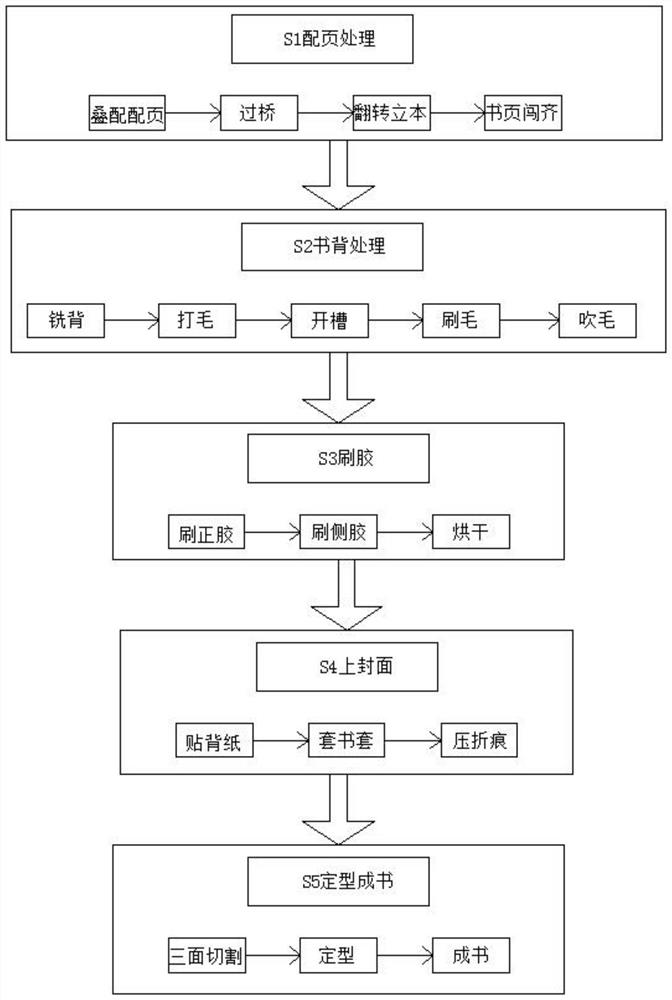

Embodiment 1

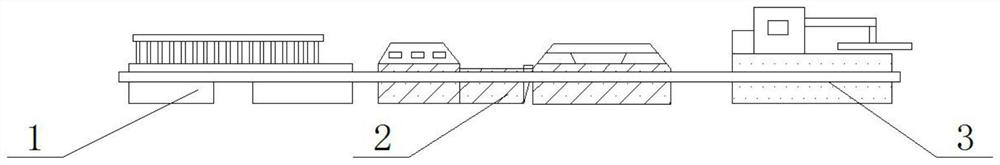

[0065] The bottom end of the page rushing mechanism 11 is movably equipped with a transmission chain belt 110, a baffle plate 15 is fixedly installed above the transmission chain belt 110, a pressure control valve 19 is fixedly installed on the outside of the baffle plate 15, and a length is fixedly installed on the baffle plate 15. Sensor 16, the lower right side of length sensor 16 is equipped with stop book rod 17, the inside of first beam 12 is installed with page 18, and the top of page 18 is fixedly installed with first beam 12, and the bottom of first beam 12 is movably installed with For the width scanner 111 , the second beam 14 is fixedly installed on the rear side of the first beam 12 , and the gripping plate 13 is movably installed on the bottom of the second beam 14 .

[0066] Due to equipment failure or improper production operation, there must be situations in which book pages 18 are not aligned or missing pages are folded during the book binding process, but the...

Embodiment 2

[0068] A milling disc 216 is fixedly installed on the left end of the book back processing mechanism 21, a pressing plate 211 is movably installed above the milling disc 216, a book clamping plate 212 is fixedly installed on one side of the pressing plate 211, and a slotting roller 215 is movably installed on the right side of the milling disc 216 A brush 214 is fixedly installed on the right side of the grooving roller 215, an air nozzle 213 is fixedly installed on the right side of the brush 214, a 219 is movably installed at the middle position of the top surface of the milling disc 216, and a milling device 219 is movably installed on the upper side of the turntable 219. Knife 218, suction tube 217 is fixedly installed below the rotating disk 219, dust collection cover 2110 is fixedly installed on the outside of suction tube 217, air pump 2111 is fixedly installed on the bottom of dust collection cover 2110, and the middle position of grooved roller 215 is movably installed ...

Embodiment 3

[0071] The bottom of the gluing mechanism 22 is fixedly equipped with a glue pool 226, and the left end of the glue pool 226 is movably installed with a first rubber roller 221, and the right side of the first rubber roller 221 is fixedly equipped with a first scraper 222, which is fixed on the first scraper 222. A distance sensor 227 is installed, a second rubber roller 223 is installed movable on the right side of the first scraper 222, a lifting platform 225 is fixedly installed on the outside of the second rubber roller 223, and a second scraper is fixedly installed on the right side of the second rubber roller 223 224.

[0072] The gluing process and the use of glue are the two most critical factors affecting the quality and efficiency of book binding. The existing book binding uses EVA hot melt adhesive. Then it is easy to soften, so that the quality of the processed books is poor, and the cooling time of the EVA hot melt adhesive is relatively poor, which makes the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com