Patents

Literature

38results about How to "Realize hierarchical screening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

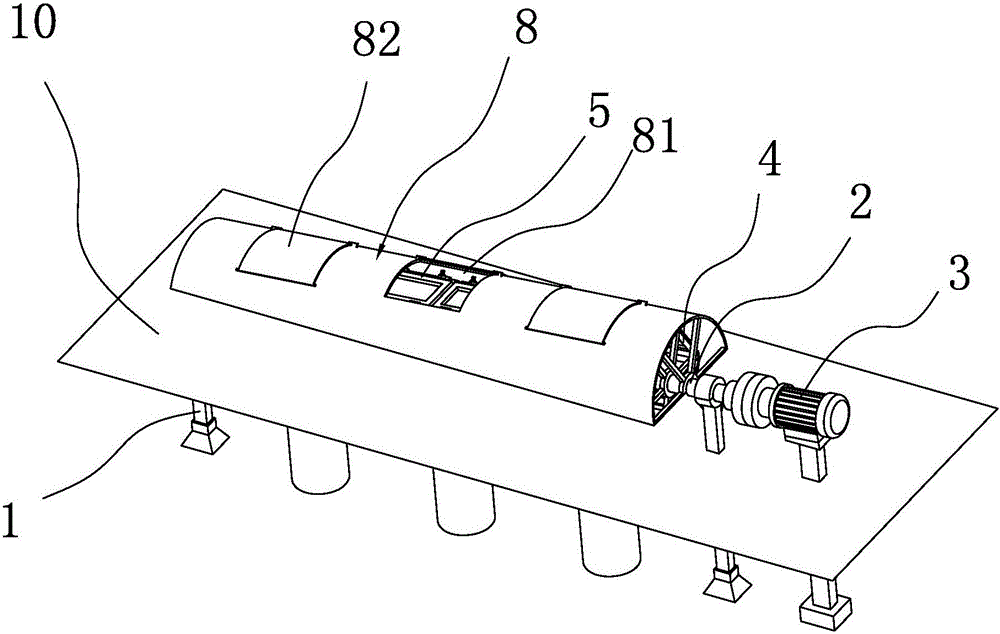

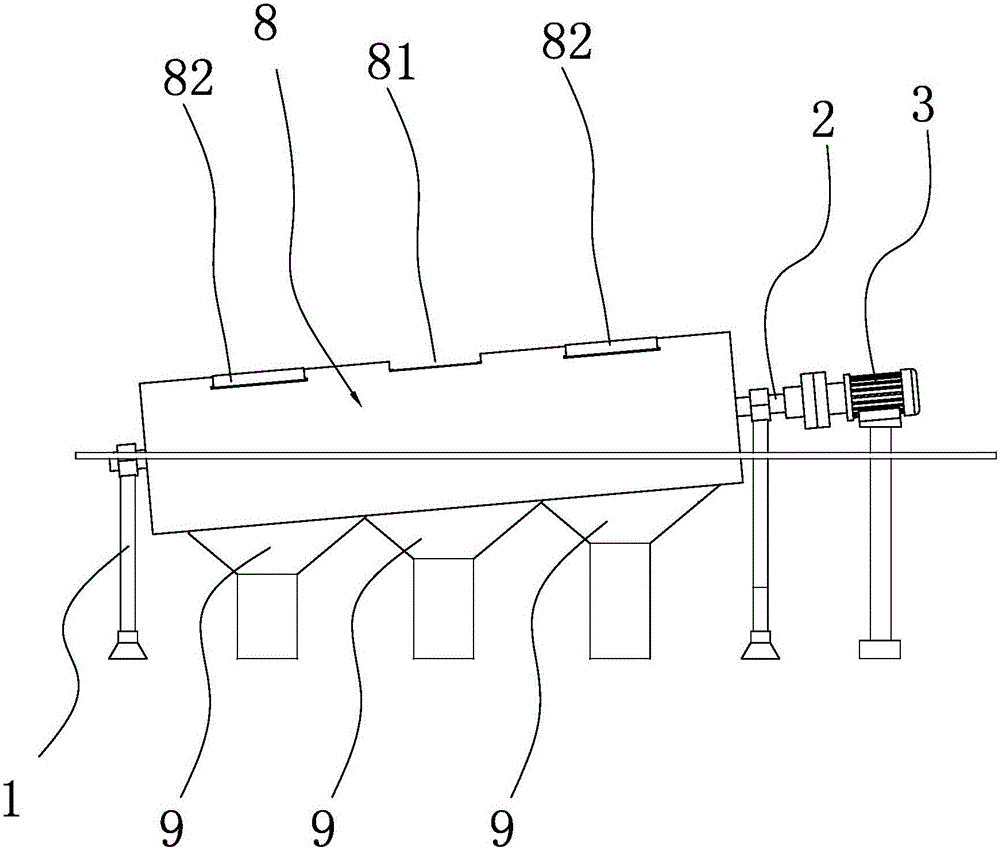

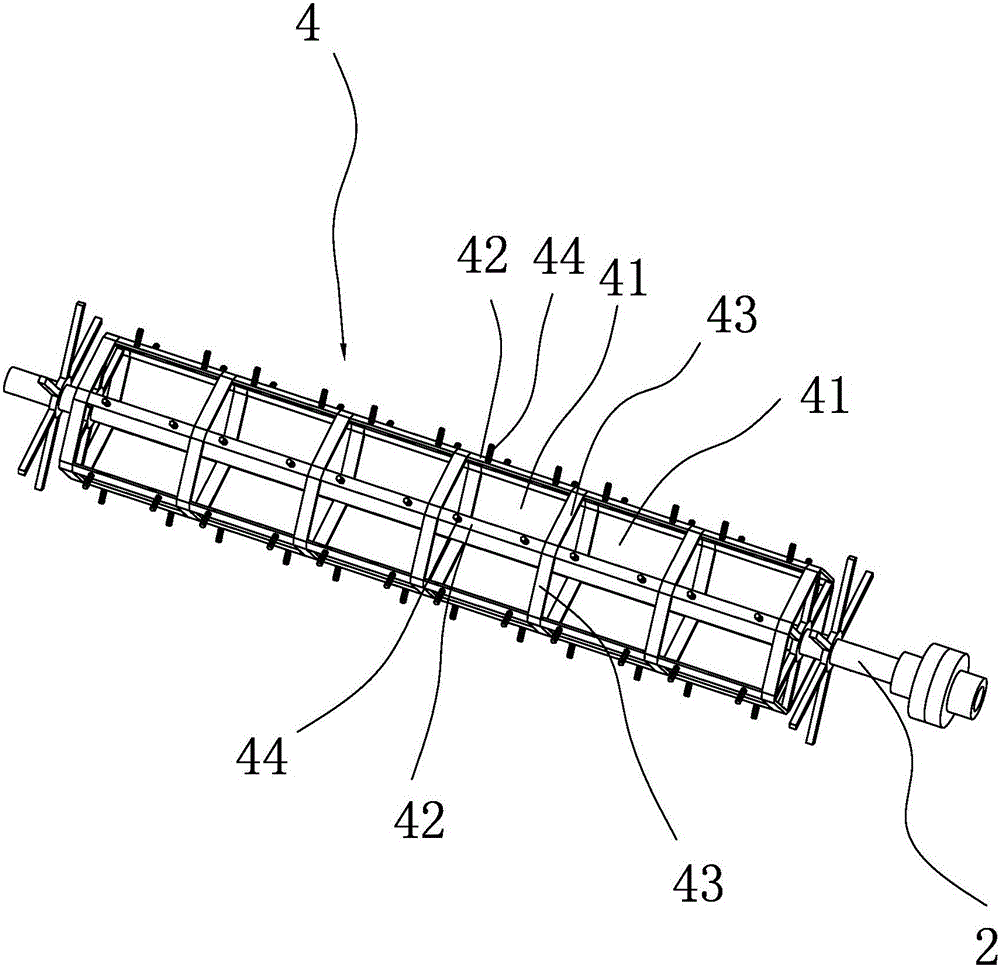

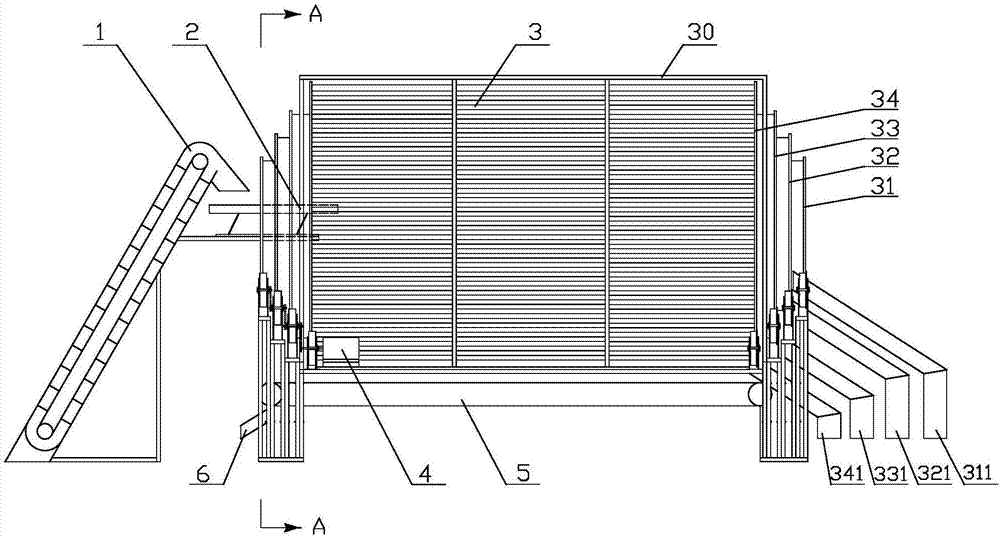

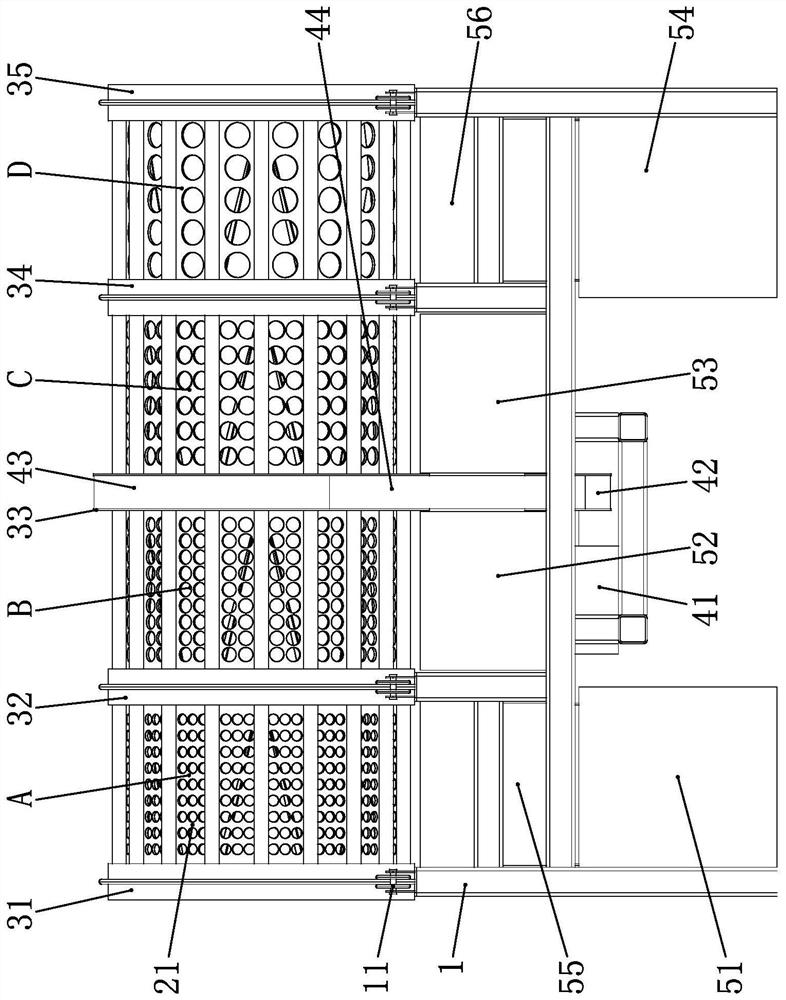

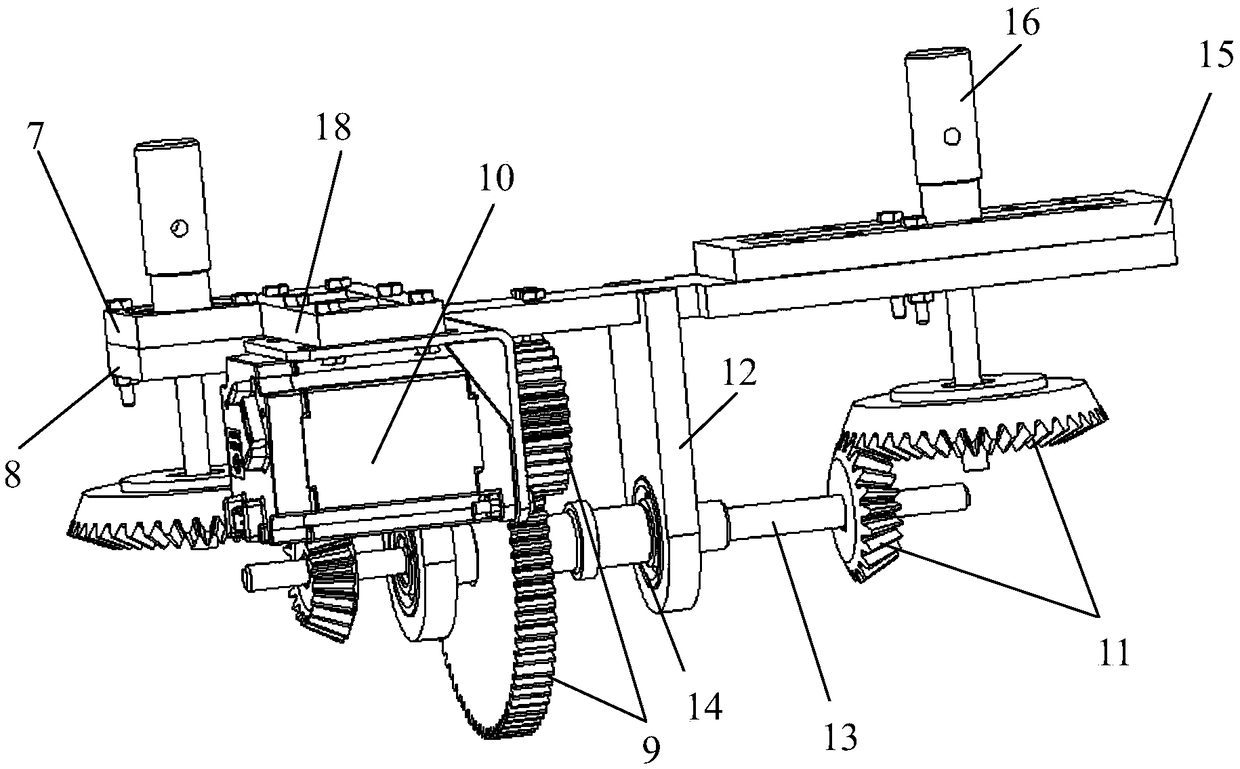

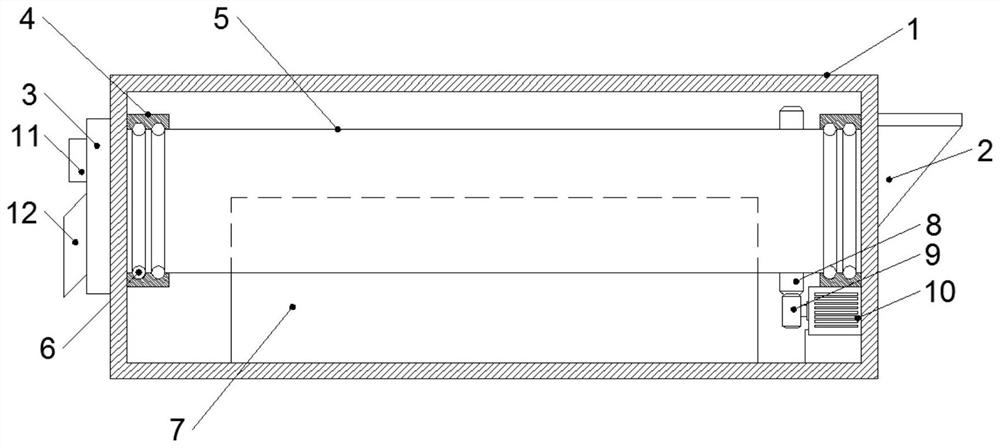

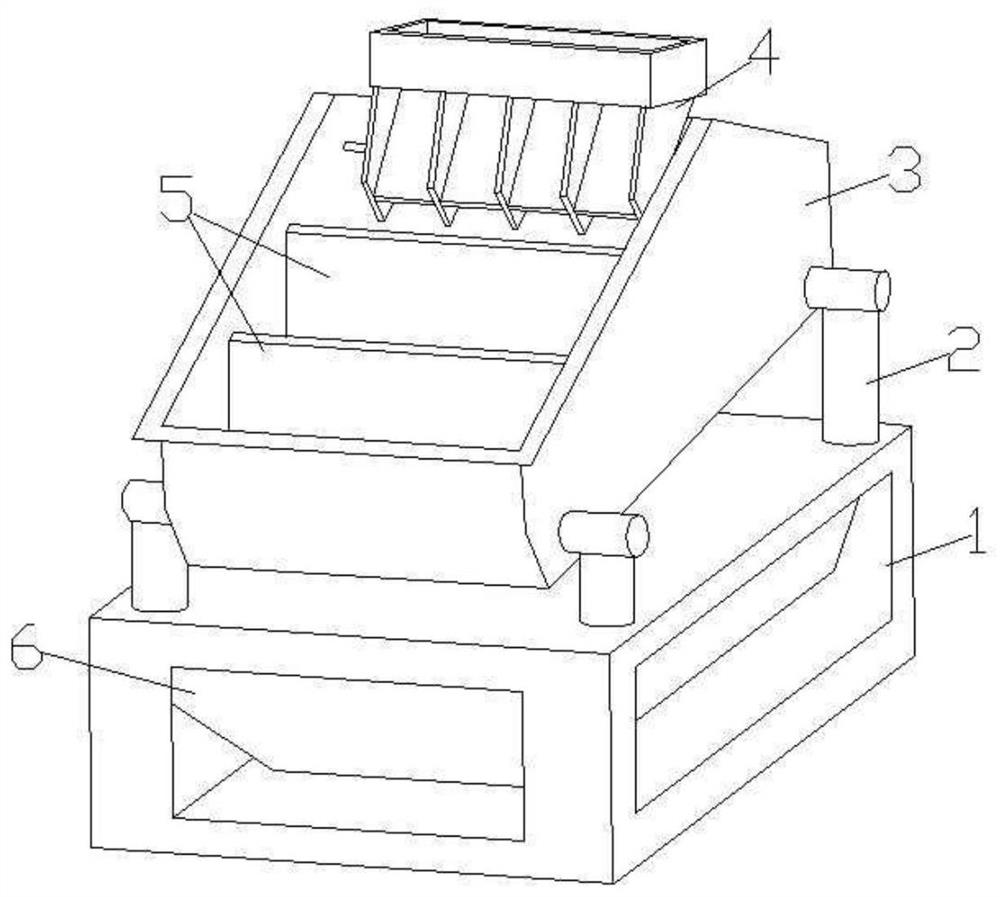

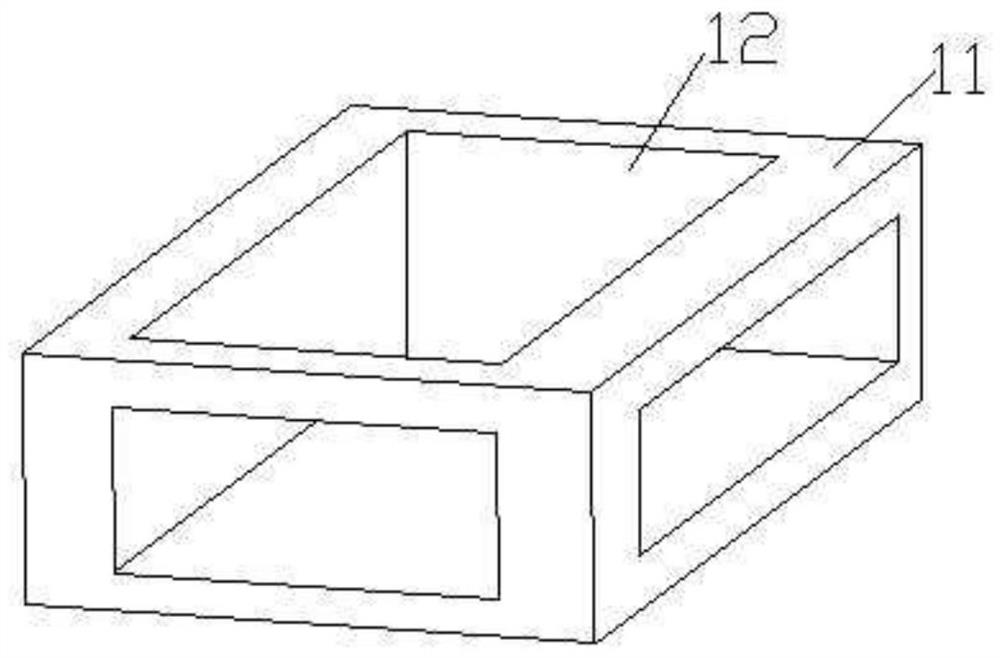

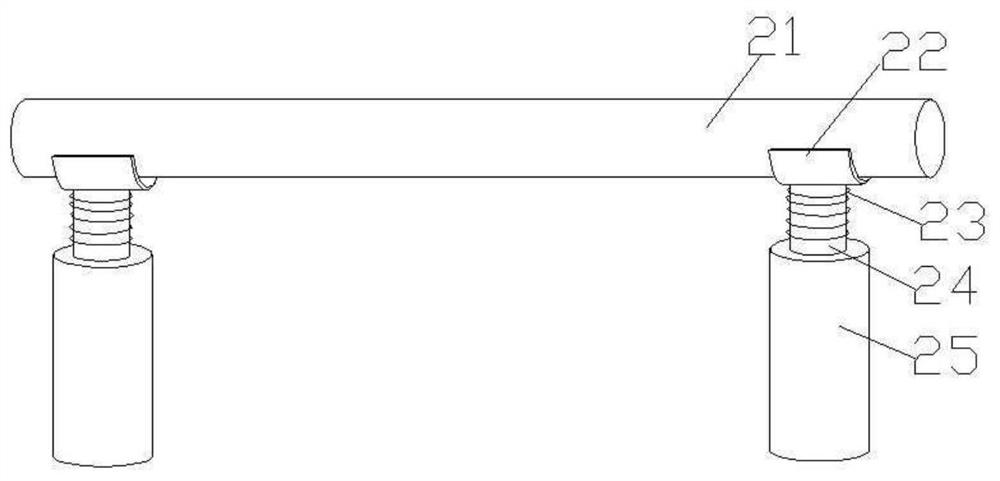

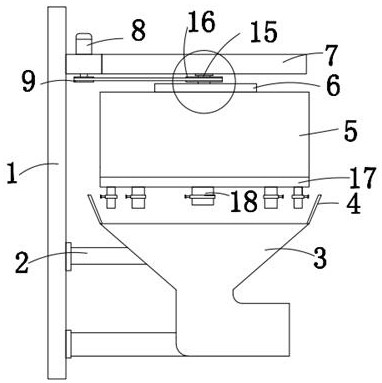

Stagewise drum screen device for sand grading separation

ActiveCN105834089AAvoid downtimeRealize hierarchical screeningSievingScreeningEngineeringMechanical engineering

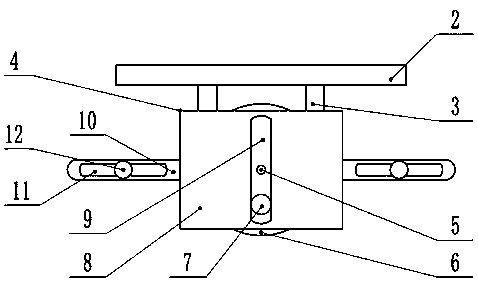

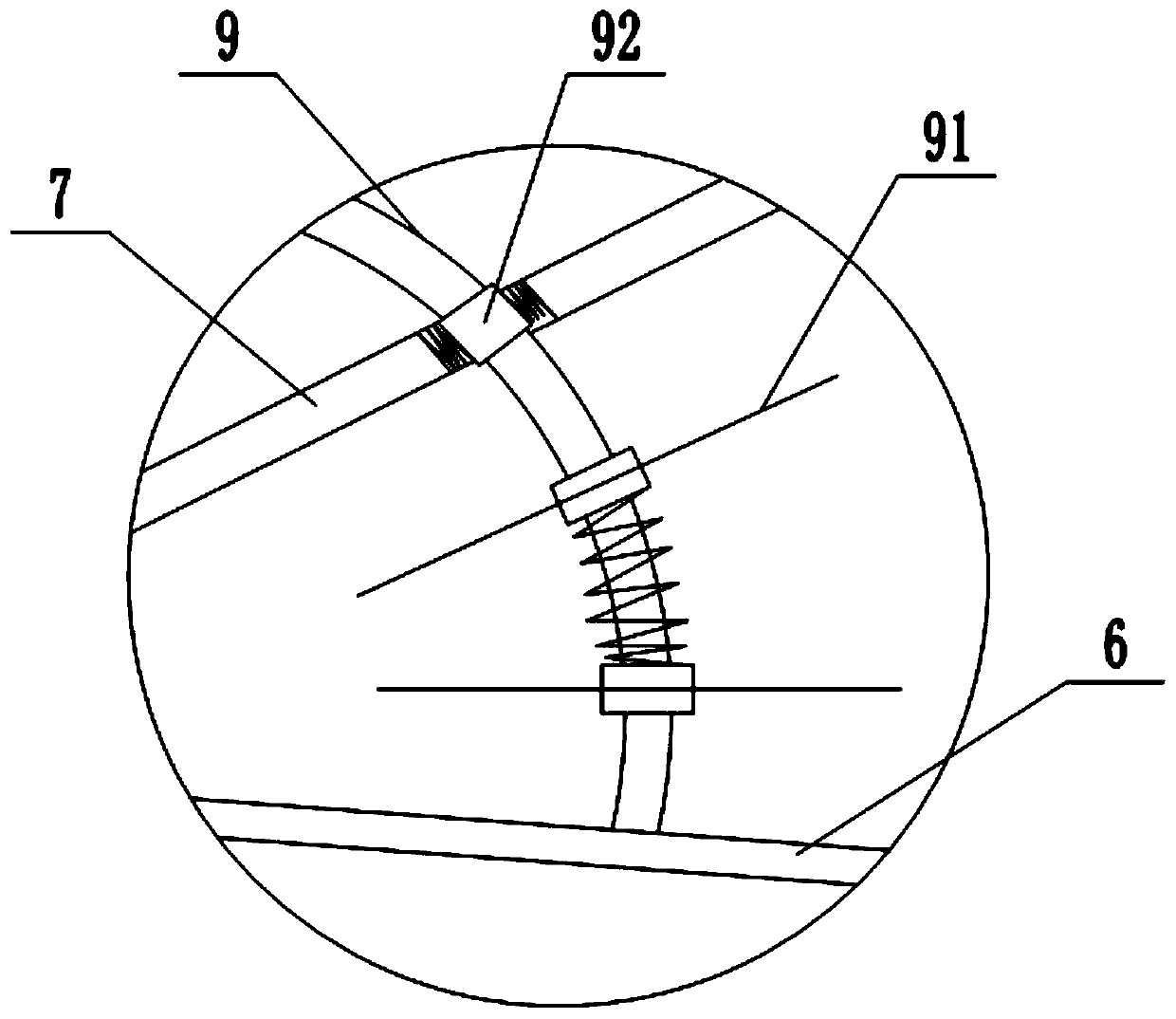

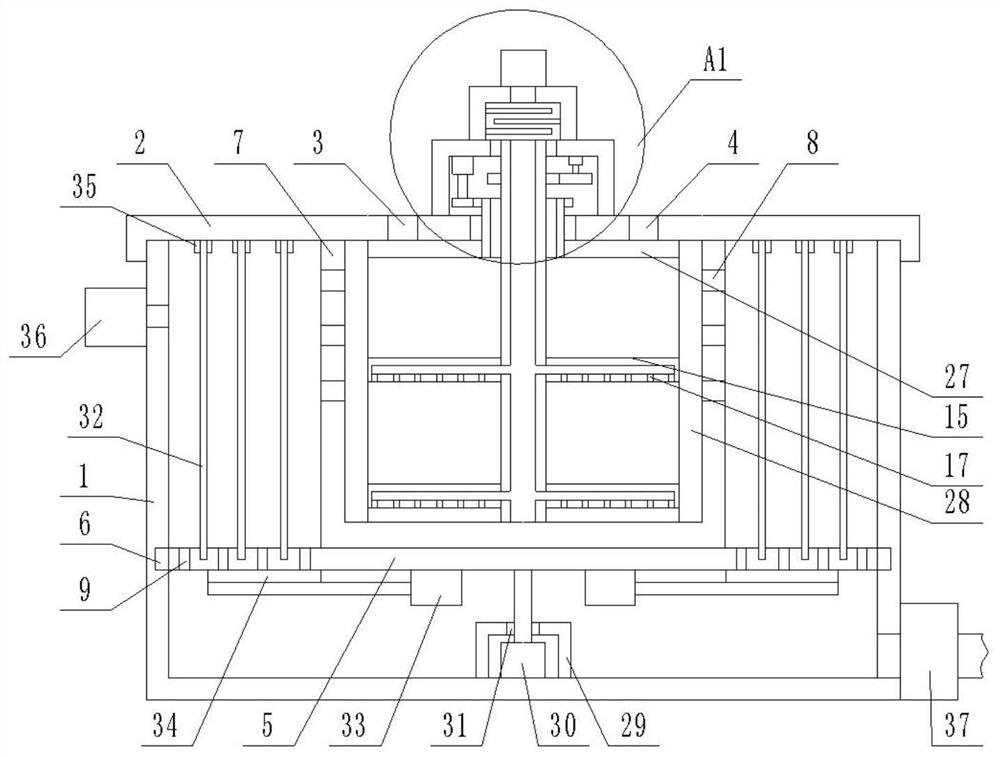

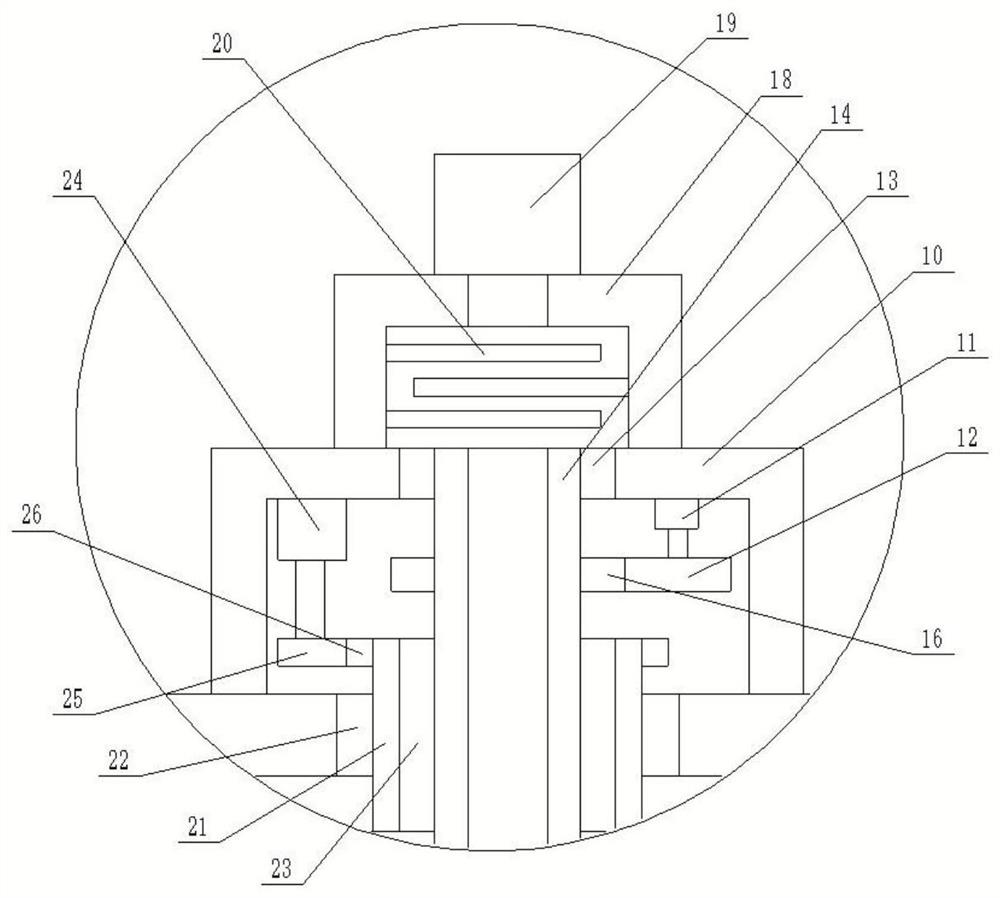

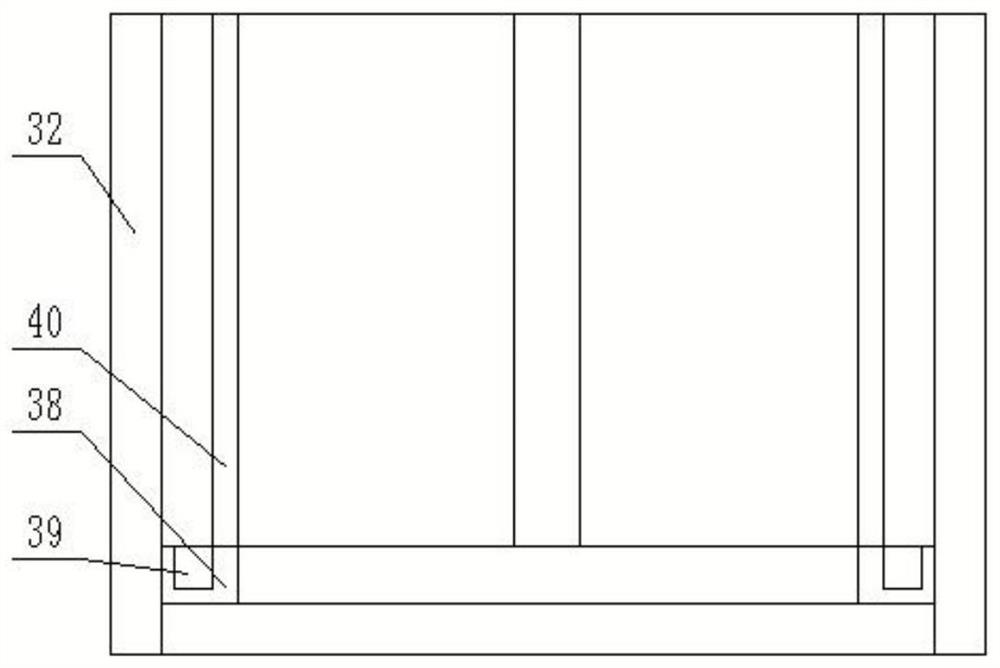

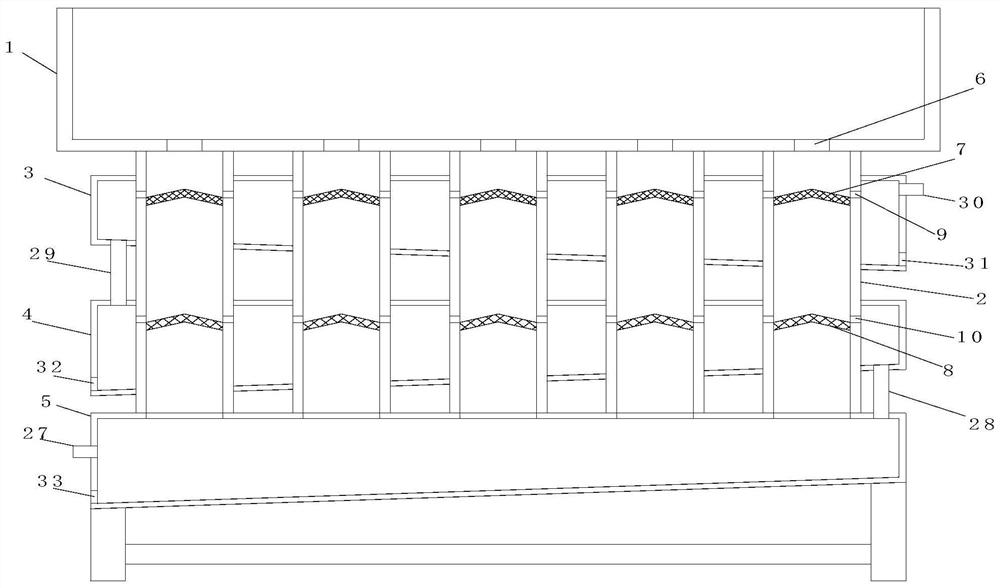

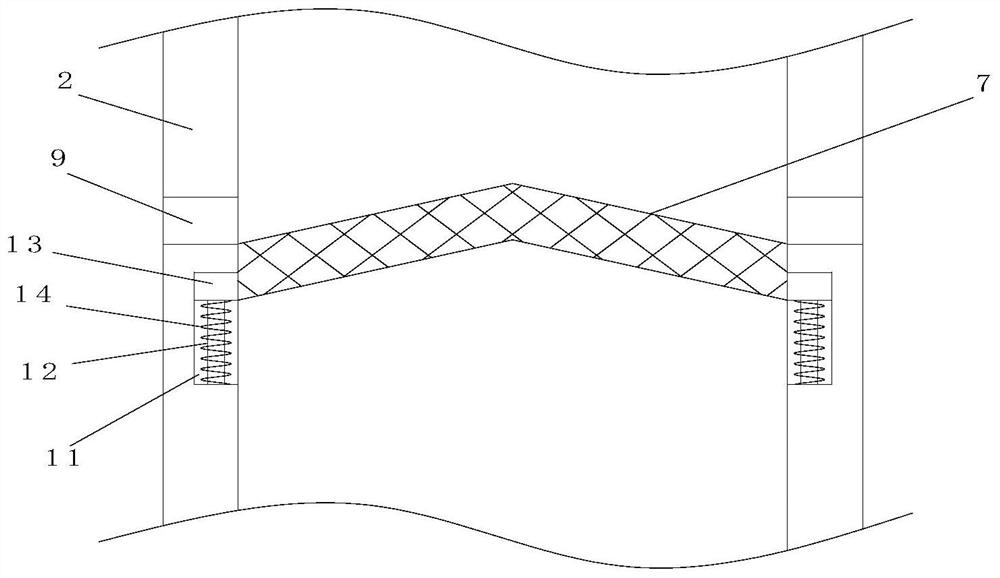

The invention relates to a stagewise drum screen device for sand grading separation, belongs to the technical field of processing building materials and aims at solving the technical problems how to realize grading screening of sand grading separation and rapid change of a screen mesh. The stagewise drum screen device for sand grading separation comprises a rack, a rotary shaft, a drive part used for driving the rotary shaft to rotate, a drum frame and a plurality of screen mesh components used for screening sand stones in a grading manner, wherein the rotary shaft is rotationally connected to the rack; the drum frame sleeves and is fixedly connected with the rotary shaft; a plurality of openings which are sequentially formed in the axial direction of the rotary shaft are formed in the side surfaces of the drum frame; and the screen mesh components are detachably connected to the drum frame and in addition covers the corresponding opening. According to the stagewise drum screen device for sand grading separation, each screen mesh component has the advantages of very convenience in disassembling, easiness in cleaning and changing, capabilities of reducing dusts and protecting workers from being hurt by splashing sand grains and convenience in changing the screen mesh components.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

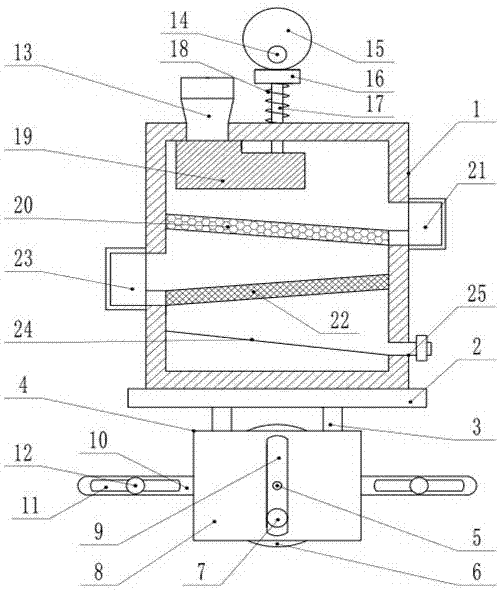

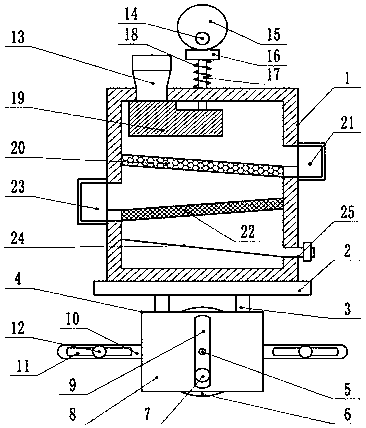

Highly-efficient filtering device for waterborne coating

InactiveCN107335265AHigh purityRealize hierarchical screeningMoving filtering element filtersWater basedFiltration

The invention discloses a high-efficiency filter device for water-based paint, which comprises a casing, a base, a swing device, a second drive motor of the casing, an eccentric wheel, a stopper, a filter screen A and an impurity box A, and a swing device is arranged under the base , an eccentric wheel is installed on the second drive motor, a limit block is arranged on the lower side of the eccentric wheel, a slide bar is fixedly installed on the limit block, and a stopper is fixedly connected to the lower end of the slide bar inside the casing. A filter screen A and a filter screen B are provided inclinedly. Drive the eccentric wheel to rotate through the second drive motor, so that the stopper and the feed port are separated intermittently, so as to realize the interval feeding of water-based paint, prevent excessive feed, and cause blockage during filtration; drive the movement through the first drive motor The plate moves left and right, so that the casing on the base moves left and right to increase the filtering speed; there are filter A and filter B inside the casing to achieve grading and screening and improve the purity of water-based paint.

Owner:盐城海之诺机械有限公司

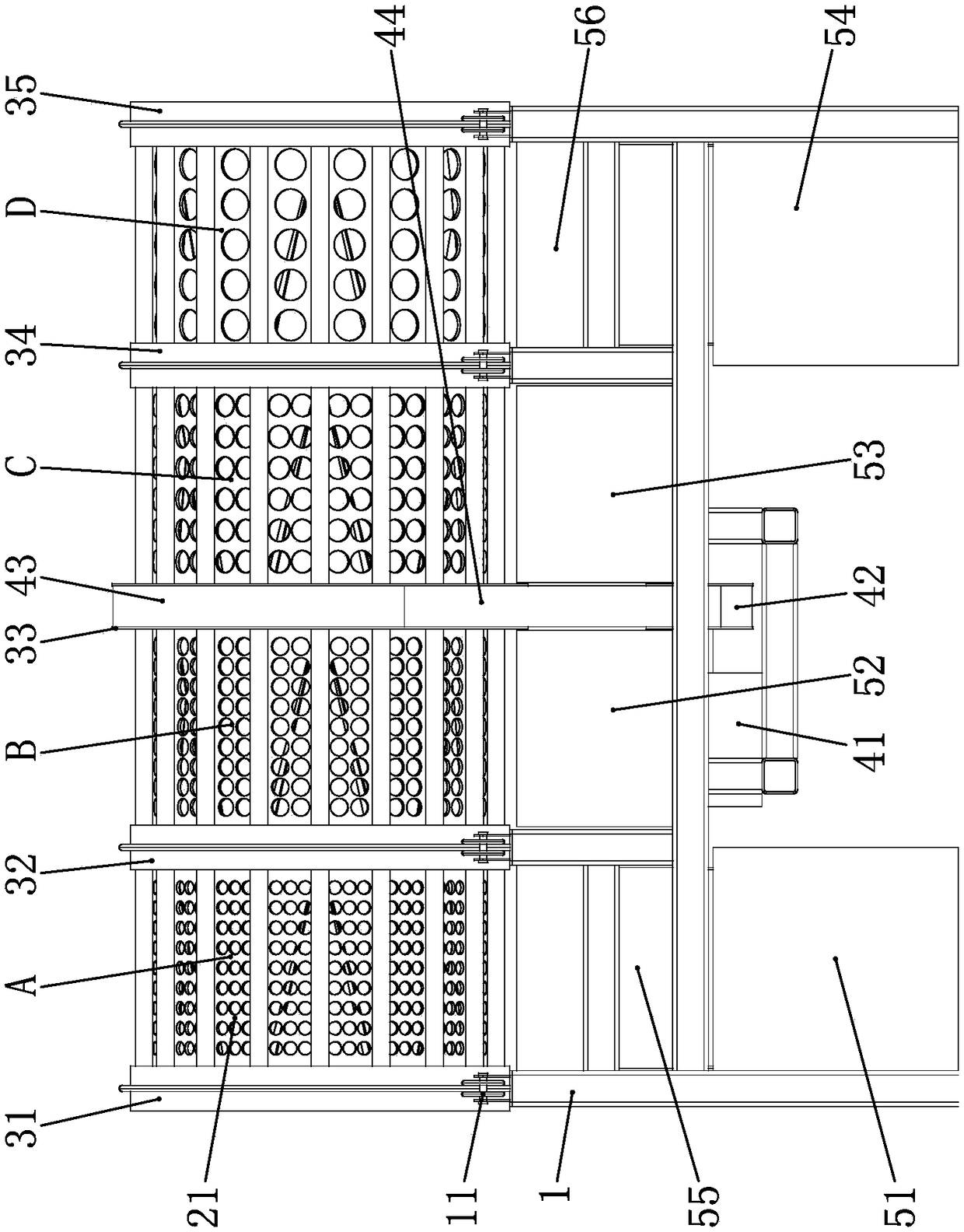

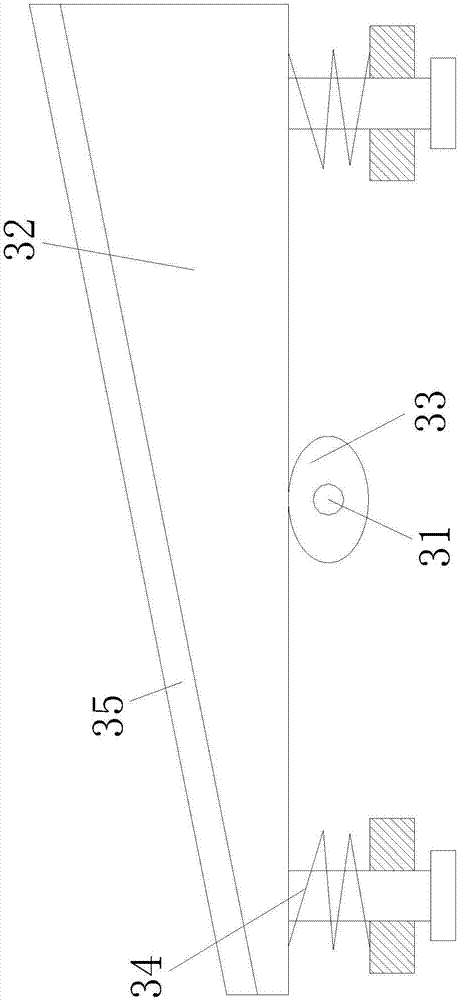

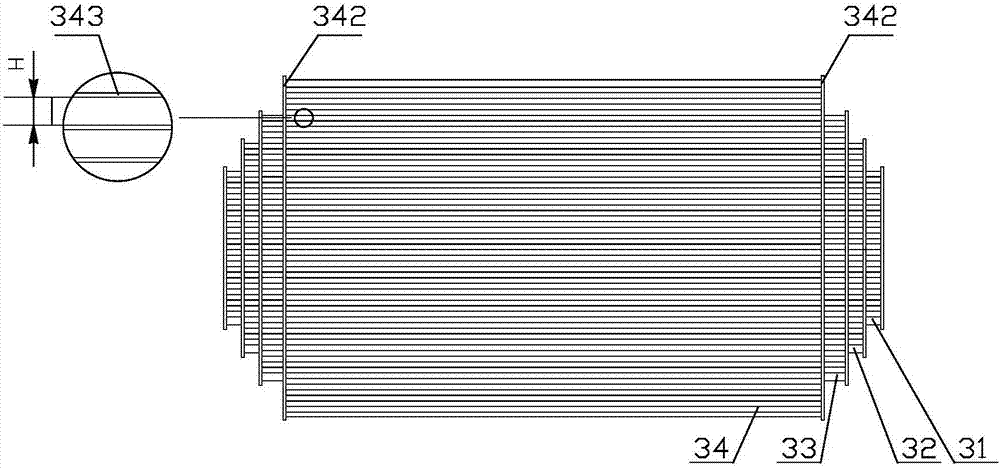

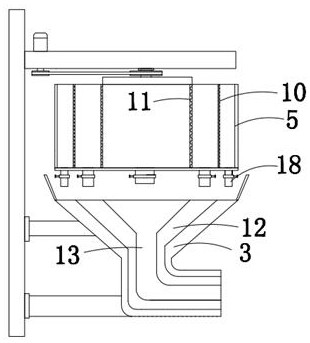

Tea roller sorting device

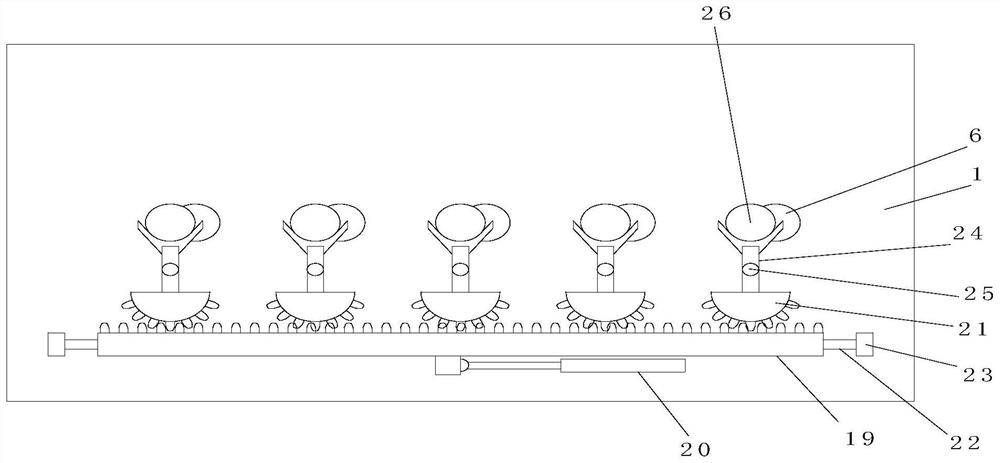

ActiveCN108499835ASpread outRealize hierarchical screeningSievingScreeningScreening effectHorizontal axis

The invention relates to a sorting device, and aims to provide a tea roller sorting device, which has the advantages of the simple and reliable structure and good screening effect, is capable of effectively improving the sorting efficiency and meets the sorting level requirements of most tea varieties. The tea roller sorting device is characterized by comprising sorting barrels, a power mechanismand a discharging mechanism; and the sorting barrels are respectively arranged on a support table and can rotate around a horizontal axis, the power mechanism is used for driving the sorting barrels to rotate, the discharging mechanism is used for collecting tea, the sorting barrels are formed in a way that a plurality of subsections are axially connected, flexible screening nets are arranged on the barrel walls of the subsections, a plurality of spiral plates are arranged on the inner circumferential surface of the barrel walls, and the aperture of the screening net of the right subsection isgreater than that of the screening net of the left subsection in two adjacent subsections.

Owner:ZHEJIANG SCI-TECH UNIV

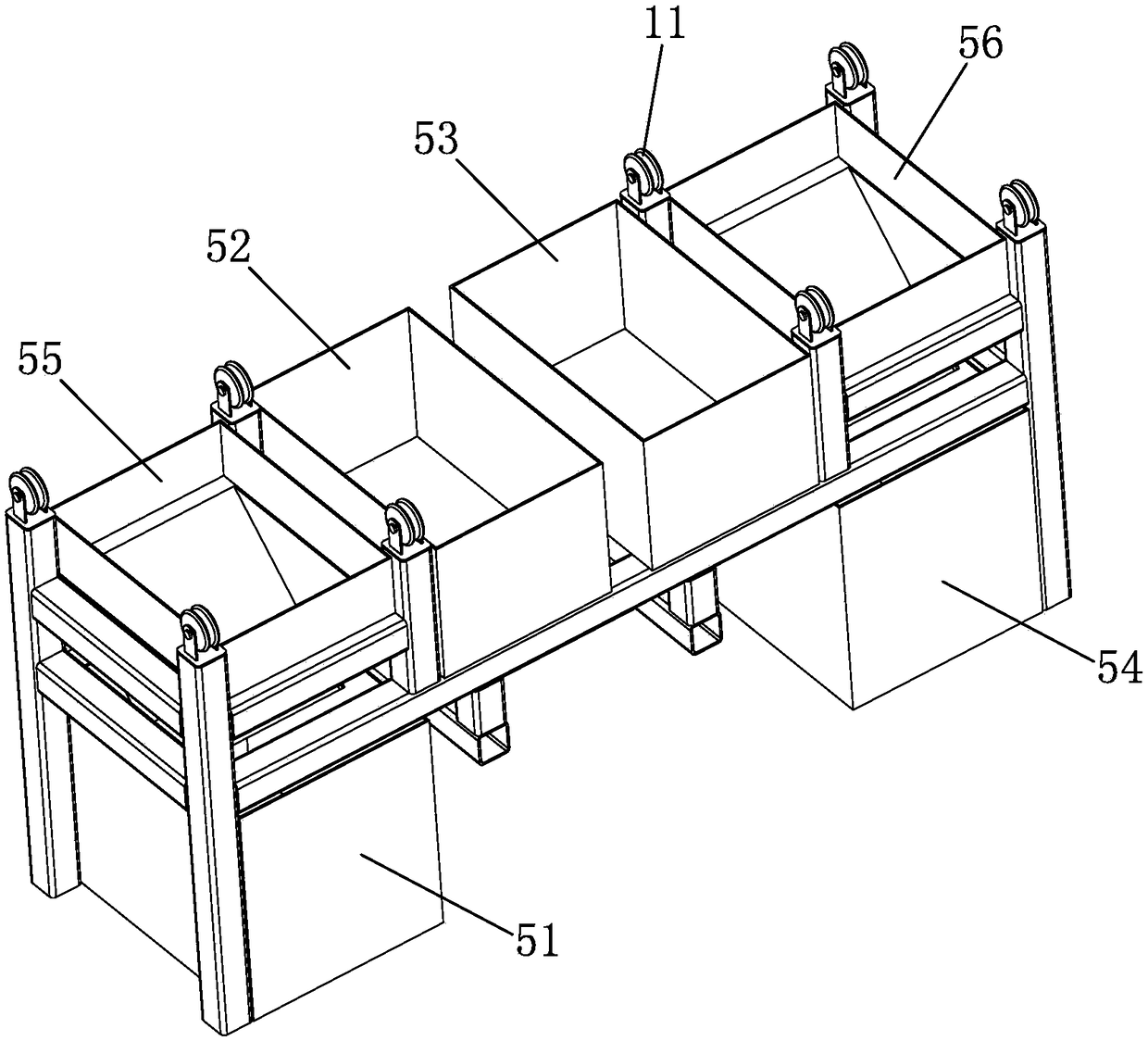

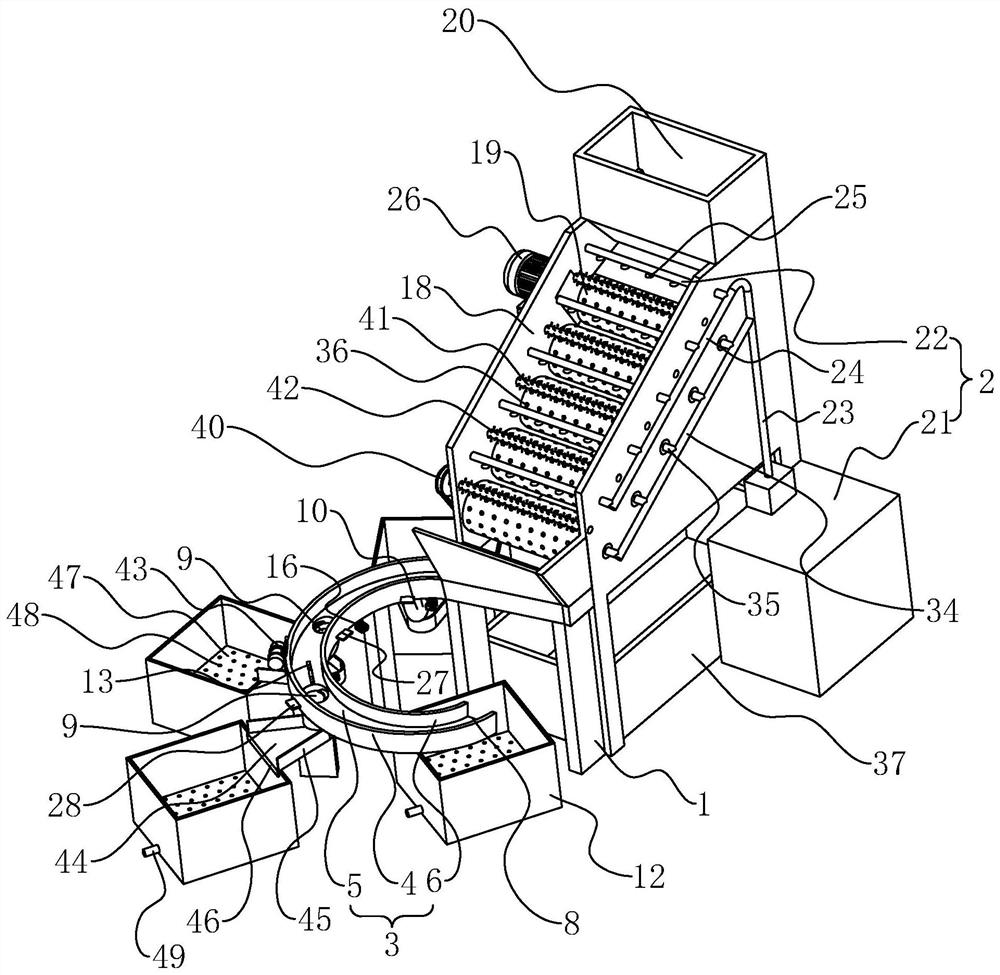

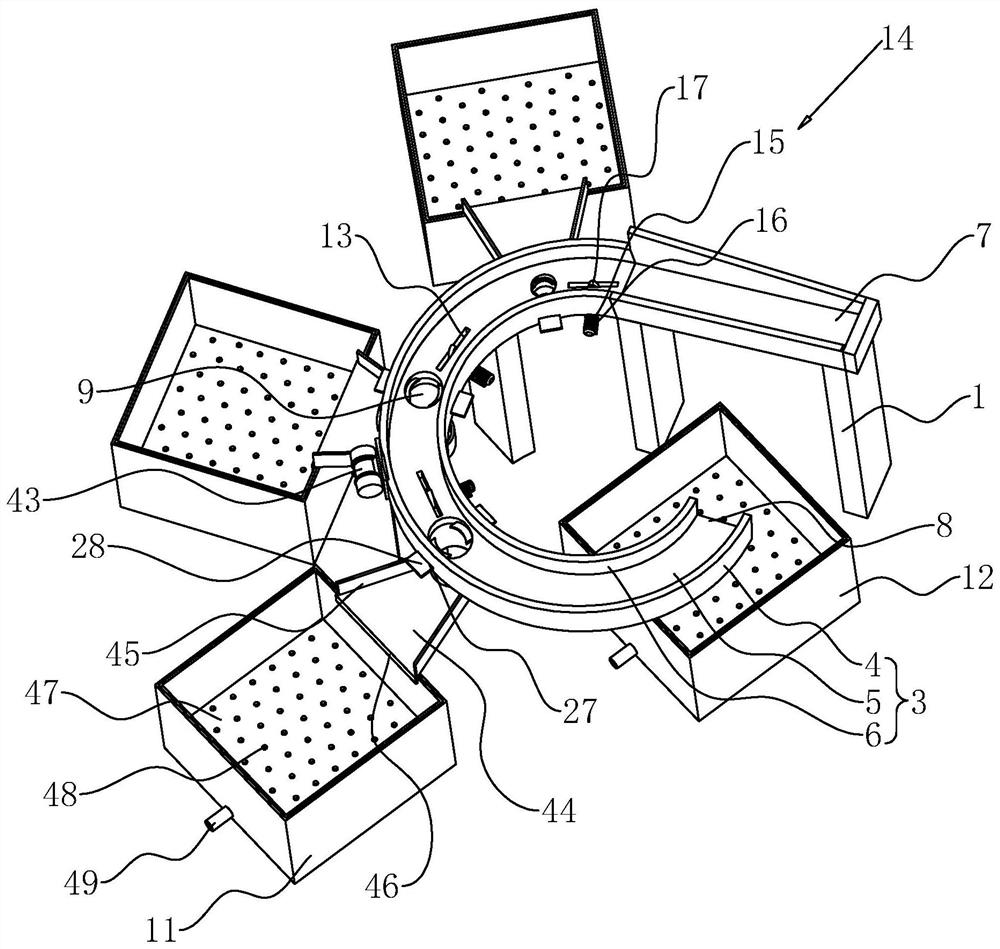

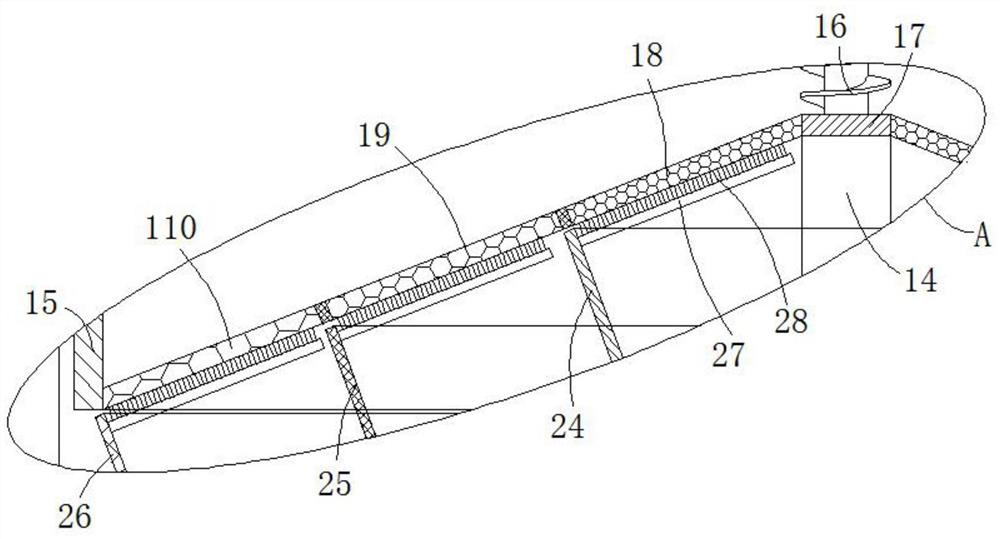

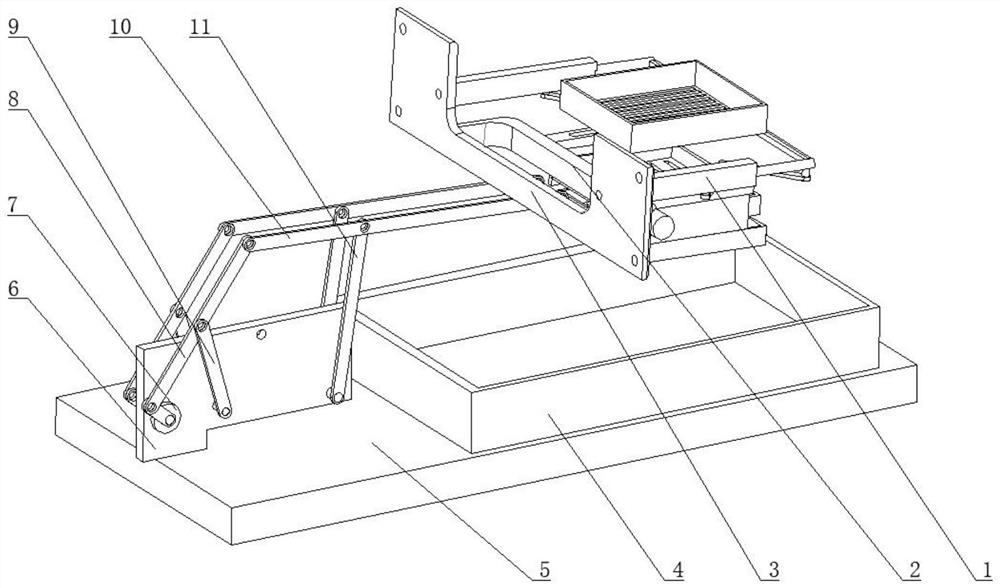

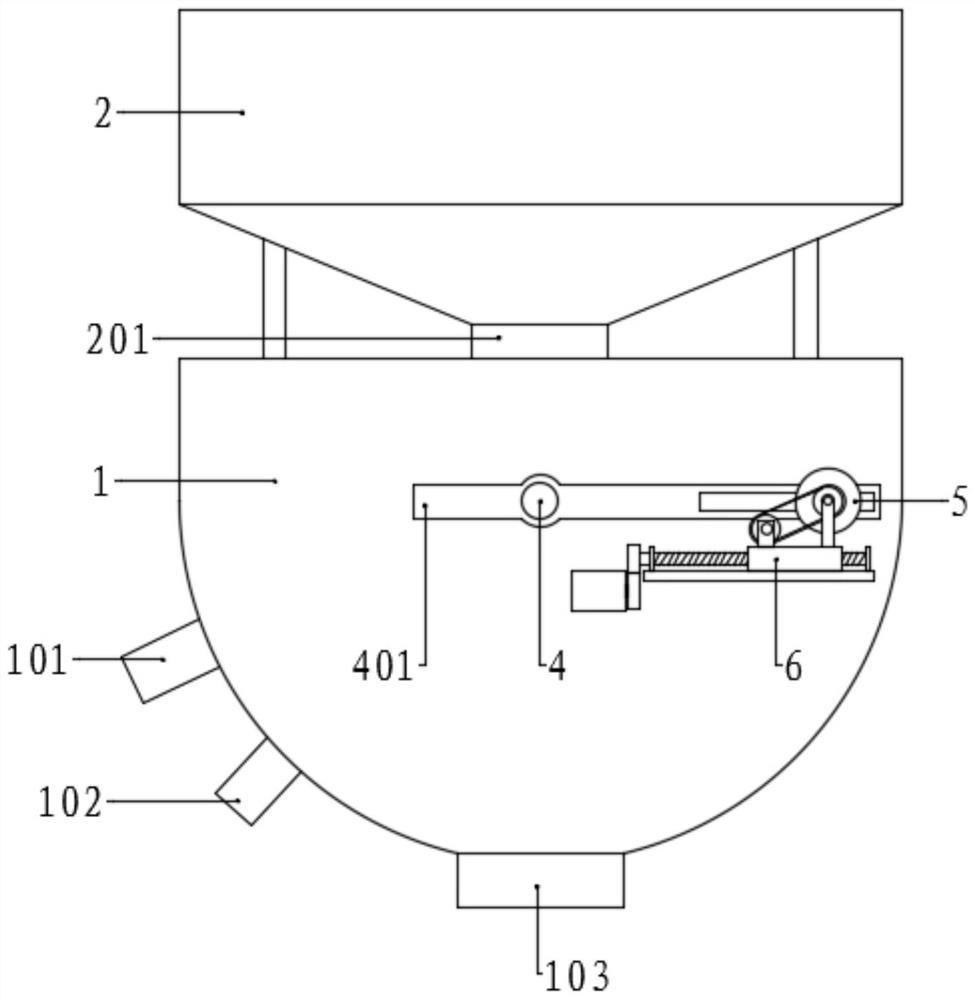

Fruit screening and conveying production line and technological process thereof

ActiveCN113042375AImprove filtering effectRealize hierarchical screeningClimate change adaptationFood treatmentElectric machineryEngineering

The invention relates to a fruit screening and conveying production line and a technological process thereof. The fruit screening and conveying production line comprises a rack, the rack is provided with a cleaning assembly and a spiral conveying disc, the diameter of the spiral conveying disc is gradually increased from top to bottom in the height direction, the spiral conveying disc comprises an outer ring plate, a bottom plate and an inner ring plate, and the spiral conveying disc is provided with a feeding port and a discharging port. A plurality of through openings are formed in the bottom plate, the diameters of the through openings are gradually increased from the end close to the feeding port to the end away from the feeding port, a discharging pipe is fixedly connected to the lower portion of the bottom plate, a first collecting box is connected to the discharging pipe, a second collecting box is arranged below the discharging port, strip-shaped grooves are formed in the positions, close to the through openings, of the bottom plate, and a shifting assembly is fixedly connected to the inner ring plate. The shifting assembly comprises a positioning plate, a first motor and a cam, and the cam is matched with the strip-shaped grooves. By arranging the spiral conveying disc and the multiple through openings, fruits are screened in a classified mode according to the sizes of the fruits, and the screening effect on the fruits is good.

Owner:栖霞禾福果蔬有限公司

High-efficiency water-based paint filtering device

InactiveCN107583340AHigh purityRealize hierarchical screeningMoving filtering element filtersWater basedMechanical engineering

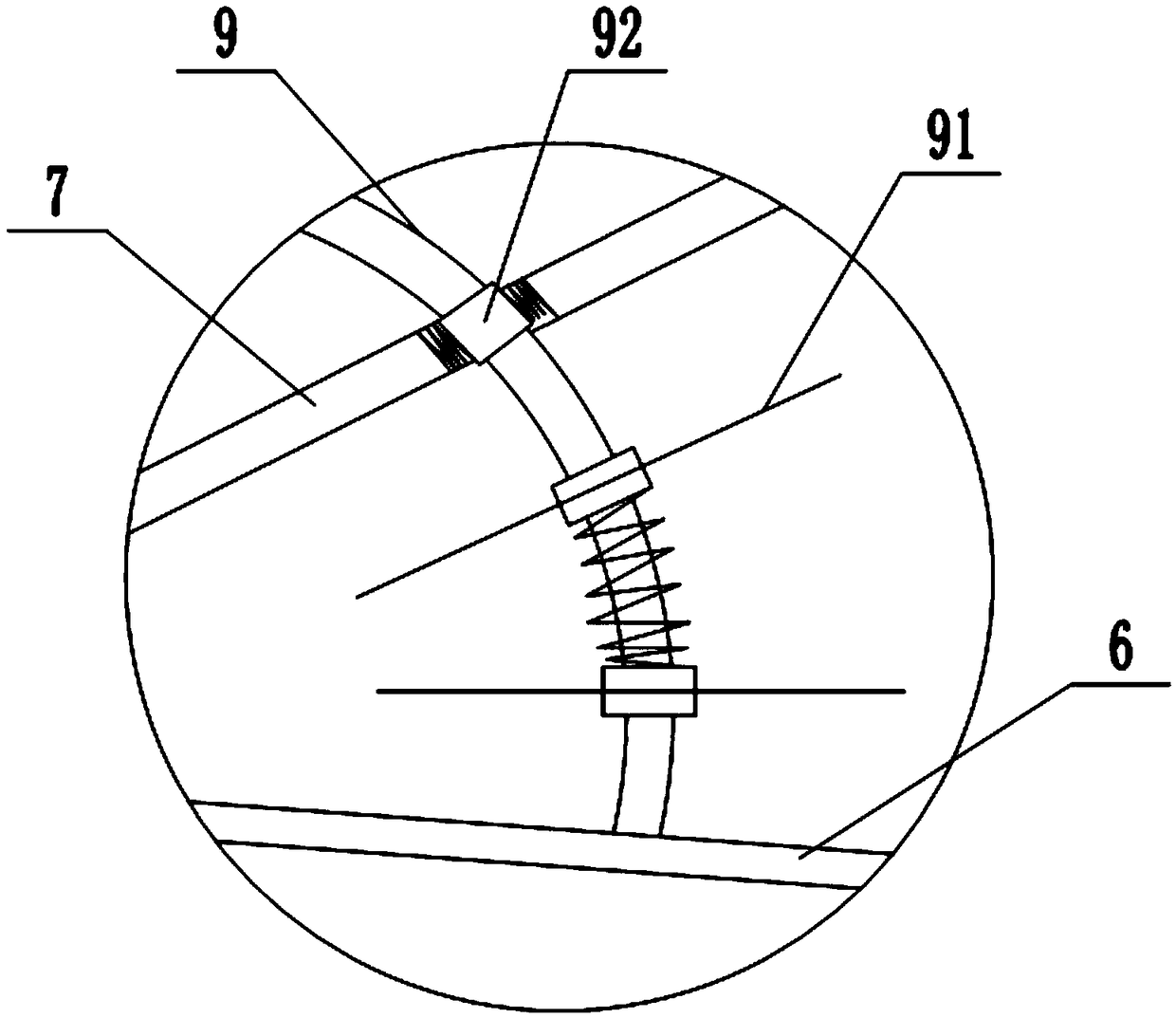

The invention discloses a high-efficiency water-based paint filtering device which comprises a machine casing, a base, a swinging device, a machine casing second driving motor, an eccentric gear, a stopping block, a filter screen A and an impurity box A, wherein the swinging device is arranged under the base, the eccentric gear is arranged on the second driving motor, a limit block is arranged onthe lower side of the eccentric gear, a slide rod is fixedly arranged on the limit block, the lower end of the slide rod is arranged in the machine casing and fixedly connected with the stopping block, and the filter screen A and a filter screen B are obliquely arranged in the machine casing. The eccentric gear is driven by the second driving motor to rotate, so that the stopping block and the feeding opening can be separated intermittently; thus, water-based paint can be fed at intervals, feeding too many materials is prevented, and plug in filtering is avoided; the first driving motor can drive a movable plate to move left and right, so that the machine casing on the base can move left and right to improve a filtering speed; the filter screen A and the filter screen B are arranged in themachine casing to achieve classified screening and improve purity of the water-based paint.

Owner:蒋丹丹

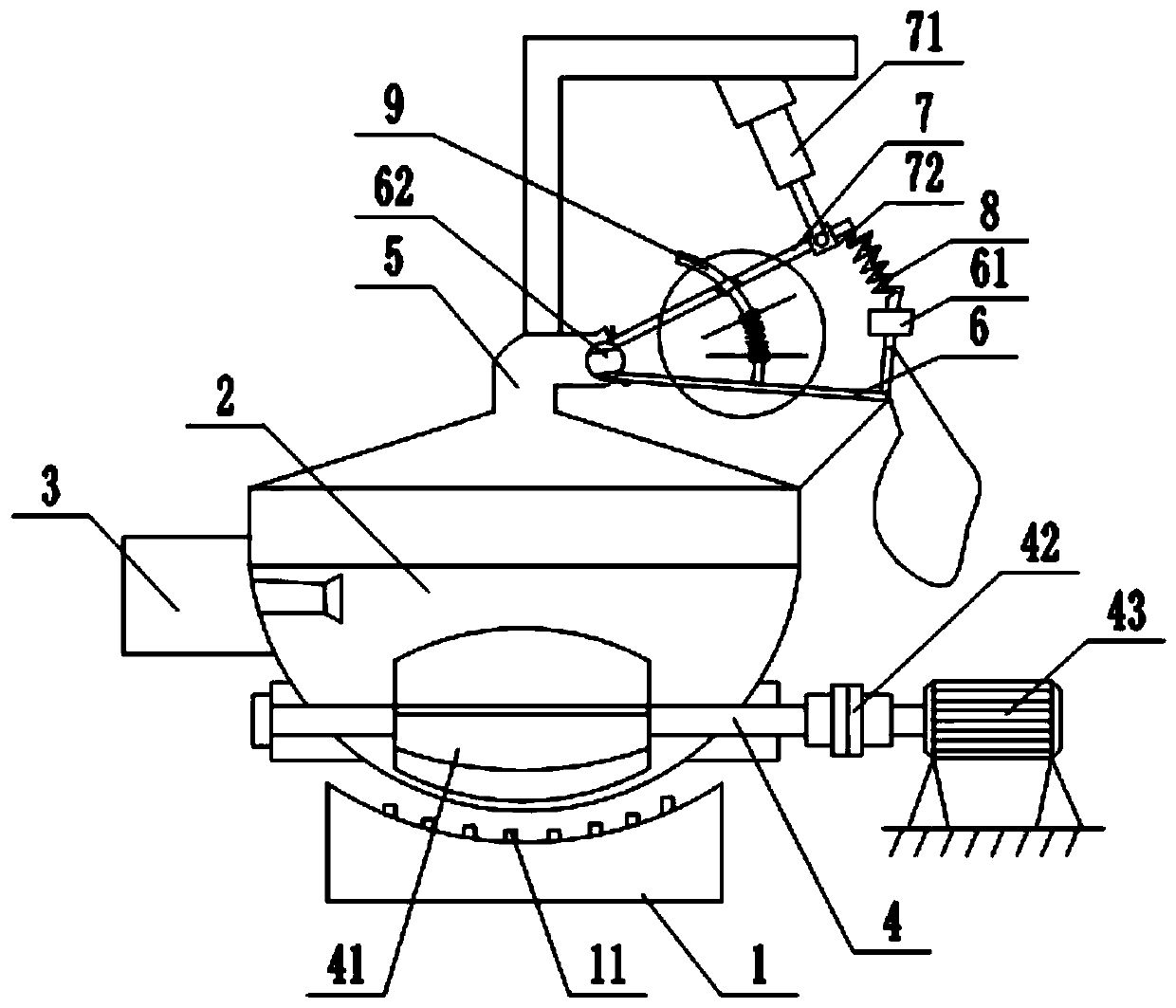

Dust remover for frying rice and making powder

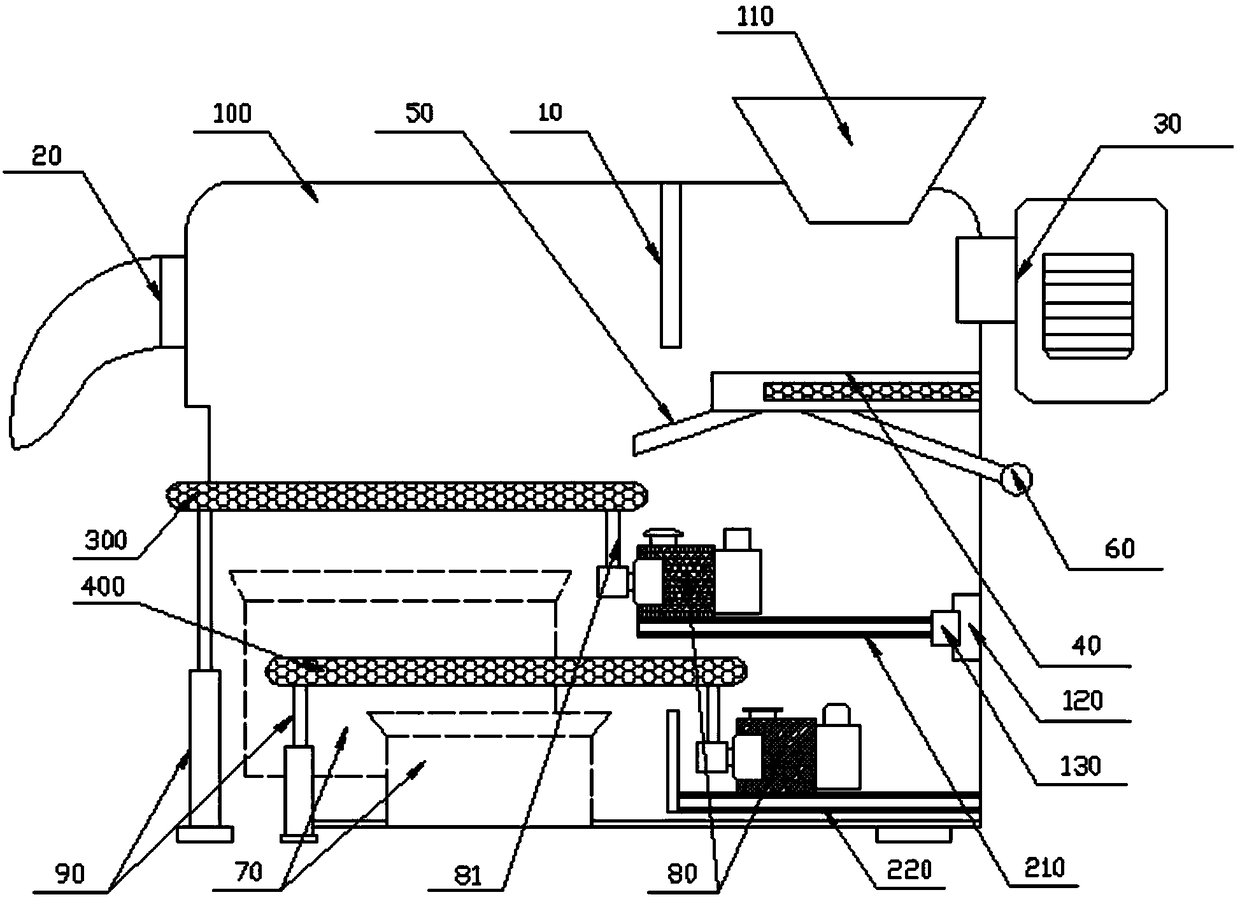

ActiveCN108606345AAvoid Uncollectable DefectsImprove the efficiency of dust suctionFood treatmentEngineeringBellows

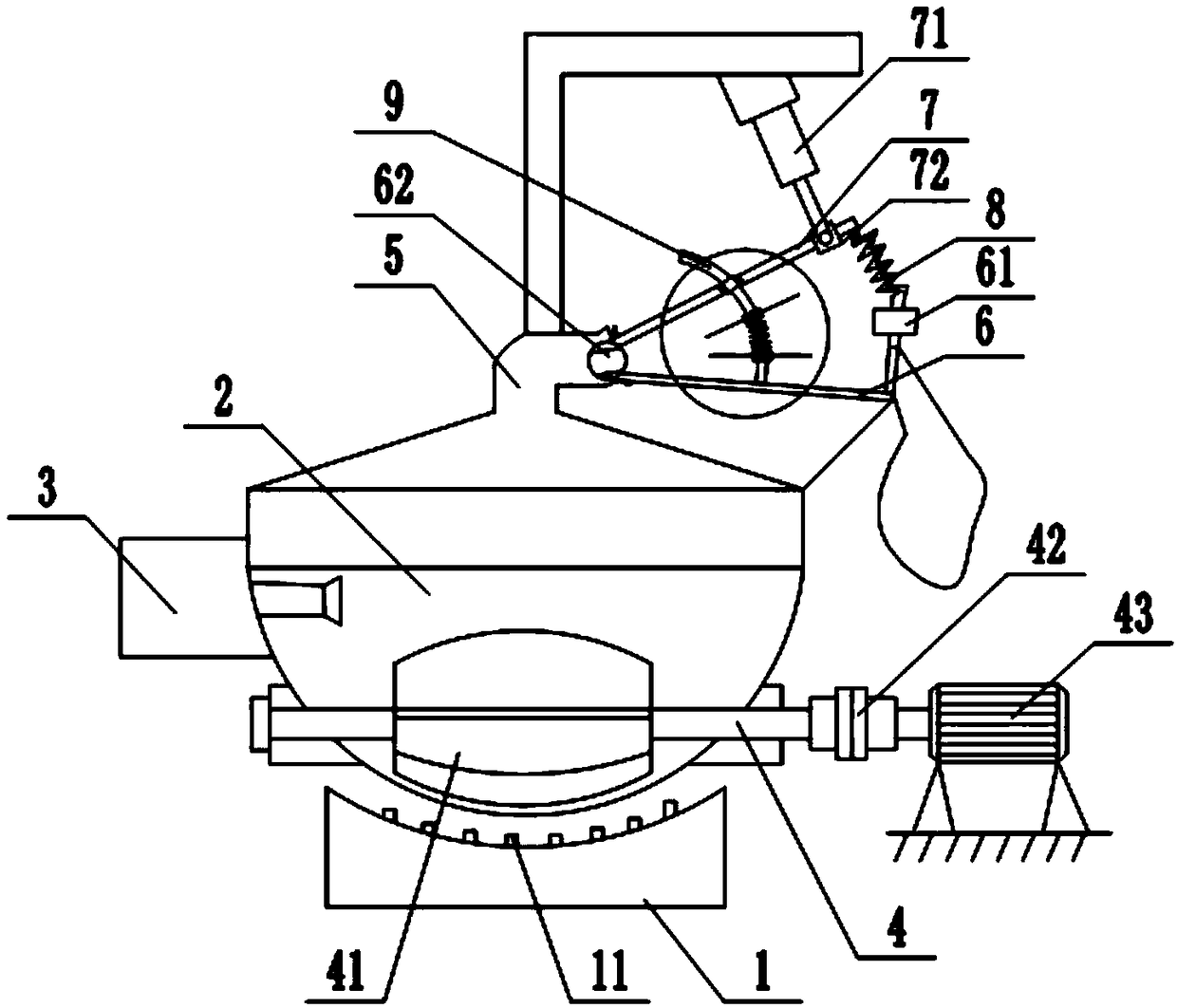

The application of the invention relates to an auxiliary device of a baking machine, and discloses a dust remover for frying rice and making powder. The dust remover comprises a pan body, a heater anda dust removing mechanism, wherein the dust removing mechanism is mounted at the upper end of the pan body; a rotating shaft is rotatably connected to the inner part of the pan body; a plurality of blades are fixedly connected to the rotating shaft; the dust removing mechanism comprises a dust discharging pipe, a first folding plate, a second folding plate and an arc-shaped sliding rod; the dustdischarging pipe is connected to the top end of the pan body and communicates with the inner part of the pan body; the first folding plate is fixedly connected to the end part of the dust dischargingpipe; the second folding plate is rotatably connected to the end part of the dust discharging pipe; elastic ripple curtains are respectively connected to the edge of the first folding plate and the edge of the second folding plate; and the first folding plate, the second folding plate and the ripple curtains are jointly closed to form a cavity. According to the scheme of the dust remover disclosedby the invention, a foldable bellows mechanism is utilized to absorb dust in the pan body; the area for which an active collecting manner is suitable covers the whole pan body, so that the defect that in the prior art, dust in individual locations cannot be collected is avoided, and the efficiency of absorbing dust is greatly improved.

Owner:重庆市长寿区可又可食品有限公司

Construction waste sieving device

ActiveCN109569897AFast cutting speedUniform Suspension StrengtheningRotary centrifugesEngineeringArchitectural engineering

The invention discloses a construction waste sieving device. The construction waste sieving device comprises a supporting frame, a cylinder is internally provided with a second sieving meshed cylinderand a first sieving meshed cylinder, wherein the first sieving meshed cylinder is located in the second sieving meshed cylinder; and a rotating shaft is arranged at the upper end of a transverse plate, the top end of the rotating shaft is connected with a supporting plate through a bearing seat, the left side of the supporting plate is welded to the supporting frame, and an electromotor is installed at the left end of the top of the supporting plate. The electromotor is started to drive a first transmission belt wheel to rotate, due to the action of centrifugal force, when the particle size of construction waste brick residues in the first sieving meshed cylinder is smaller than the mesh diameter of the first sieving meshed cylinder, the construction waste brick residues with small particle size are thrown into the second sieving meshed cylinder; and when the particle size of the construction waste brick residues dropping into the second sieving meshed cylinder is smaller than the mesh diameter of the second sieving meshed cylinder, the construction waste brick residues are thrown into the cylinder; and the graded sieving of the construction waste brick residues can be realized byarranging the first sieving meshed cylinder and the second sieving meshed cylinder.

Owner:江苏营特泰克智能环保设备有限公司

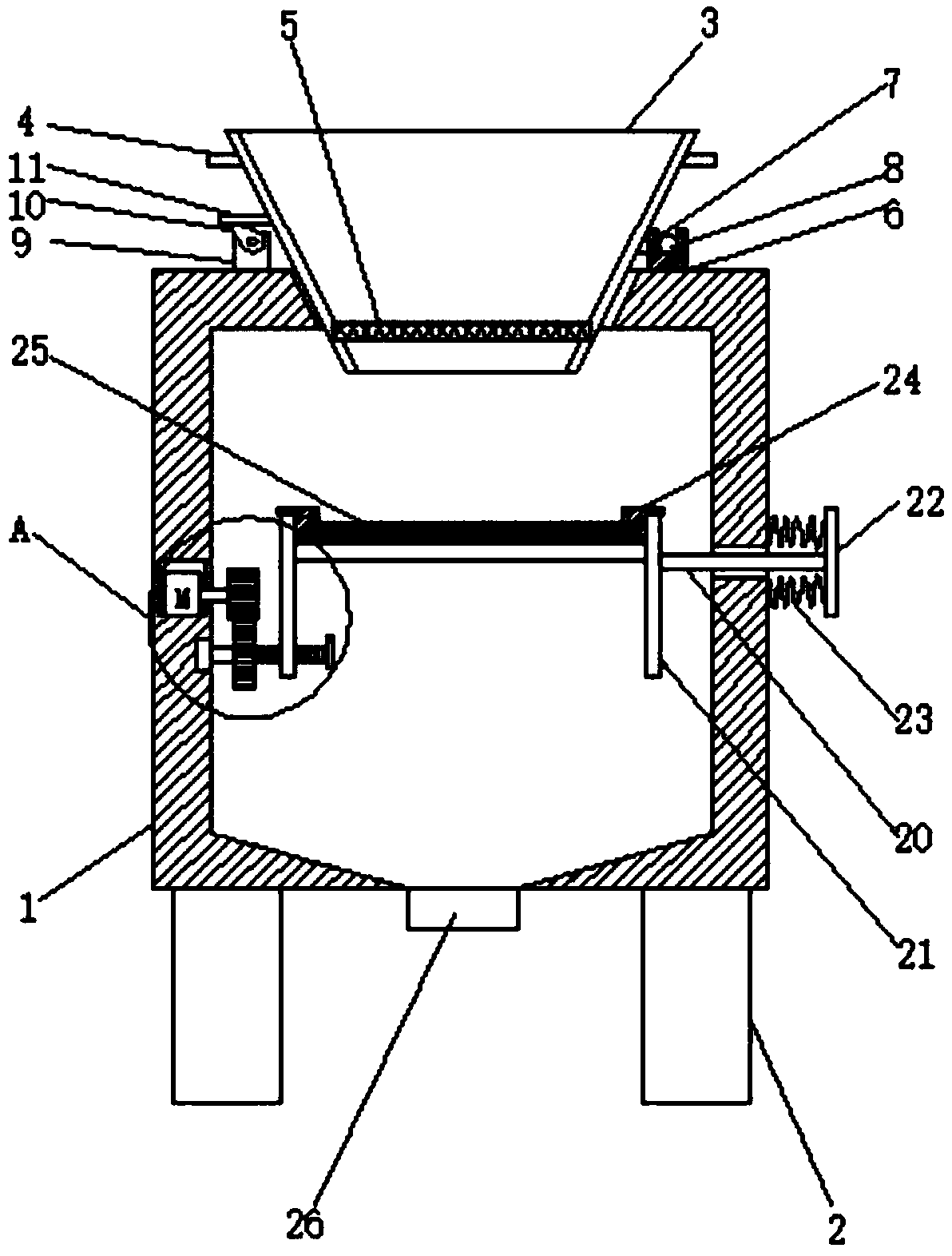

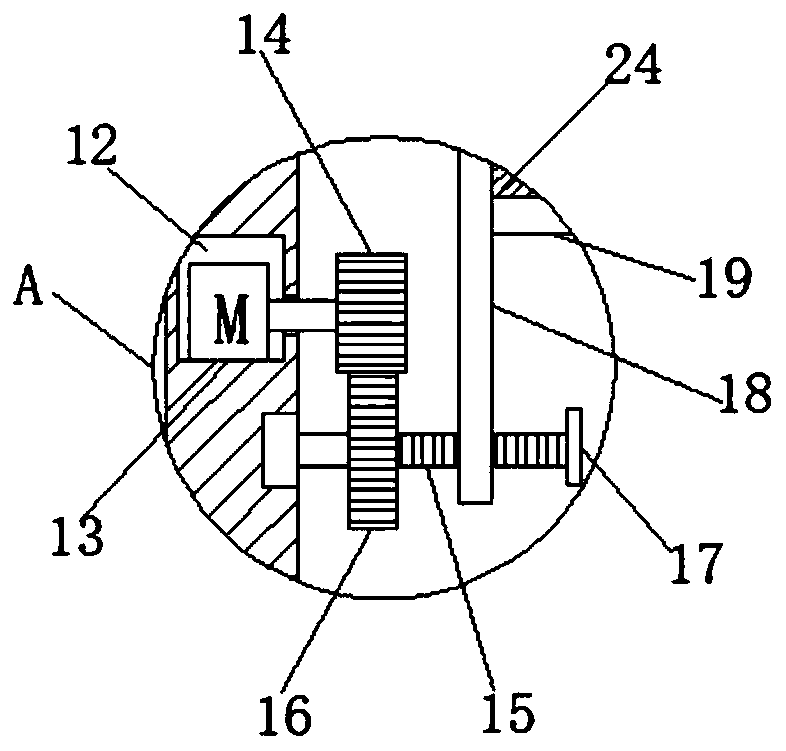

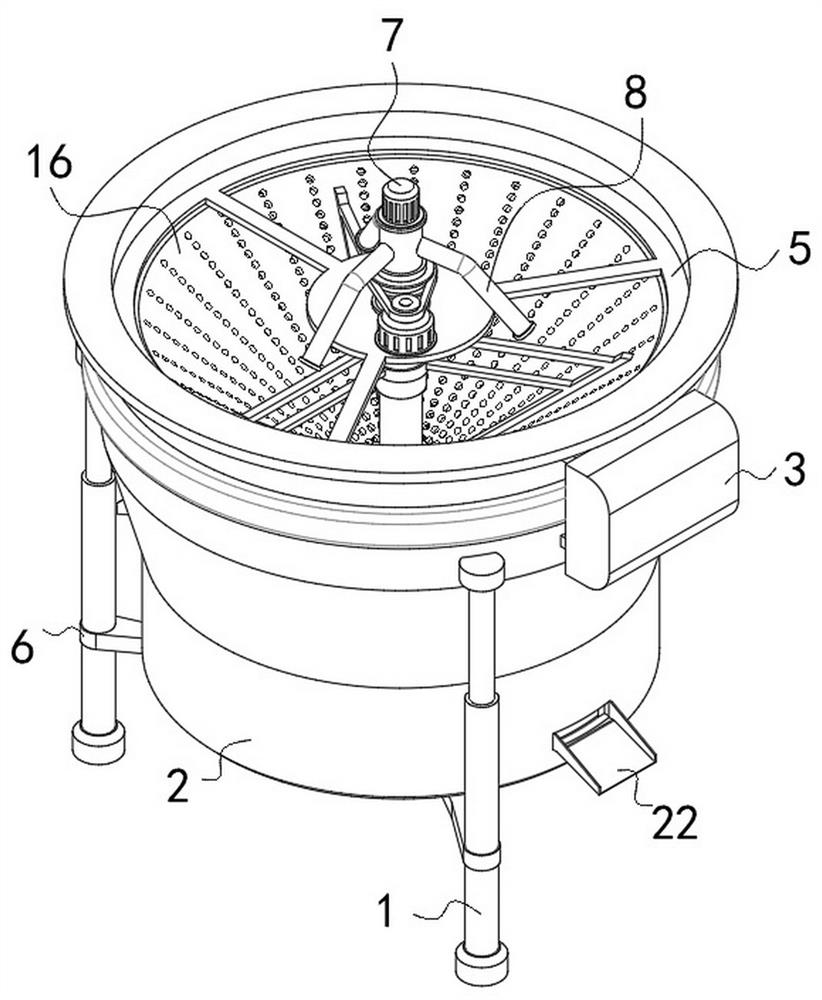

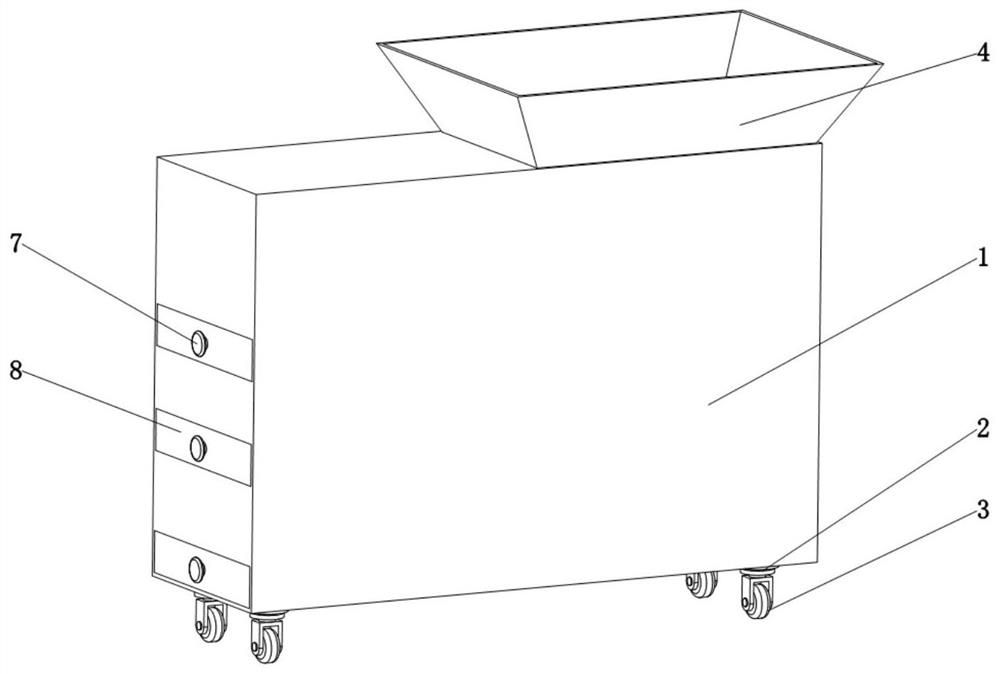

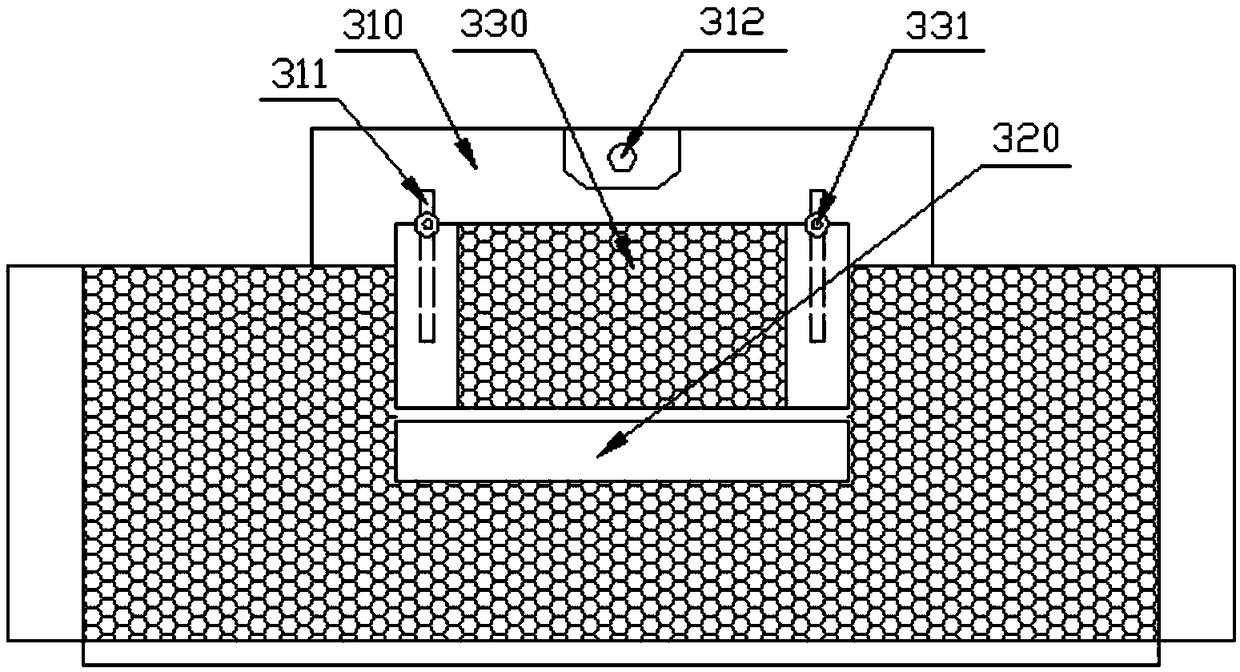

River sand screening device for building

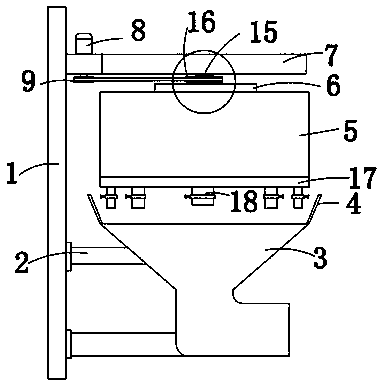

InactiveCN109013340AImprove screening efficiencyRealize hierarchical screeningSievingGas current separationPrimary screeningEngineering

The invention discloses a river sand screening device for a building. The river sand screening device comprises a barrel. A feeding hopper is arranged at the upper end of the barrel, the lower end ofthe feeding hopper penetrates through the side wall of the barrel and extends into the barrel, and the inner wall of the feeding hopper is fixedly connected with a primary screening net. The upper endthe barrel is fixedly connected with a first supporting seat, and a U-shaped groove is formed in the first supporting seat. A fixing rod is fixedly connected to the side wall of the feeding hopper, and the end, away from the feeding hopper, of the fixing rod is fixedly connected with a rotary shaft. A supporting plate is fixedly connected to the side wall of the feeding hopper, and the supportingplate and the fixing rod are symmetrical. A second supporting seat is fixedly connected to the upper end of the barrel, and the second supporting seat and the first supporting seat are symmetrical. Afirst motor is fixed to the second supporting seat. The river sand screening device is simple in structure, grading screening can be achieved, the time and labor are saved, the screening efficiency is high, and river sand which does not pass through the screening net can be poured out easily after screening.

Owner:梁林燕

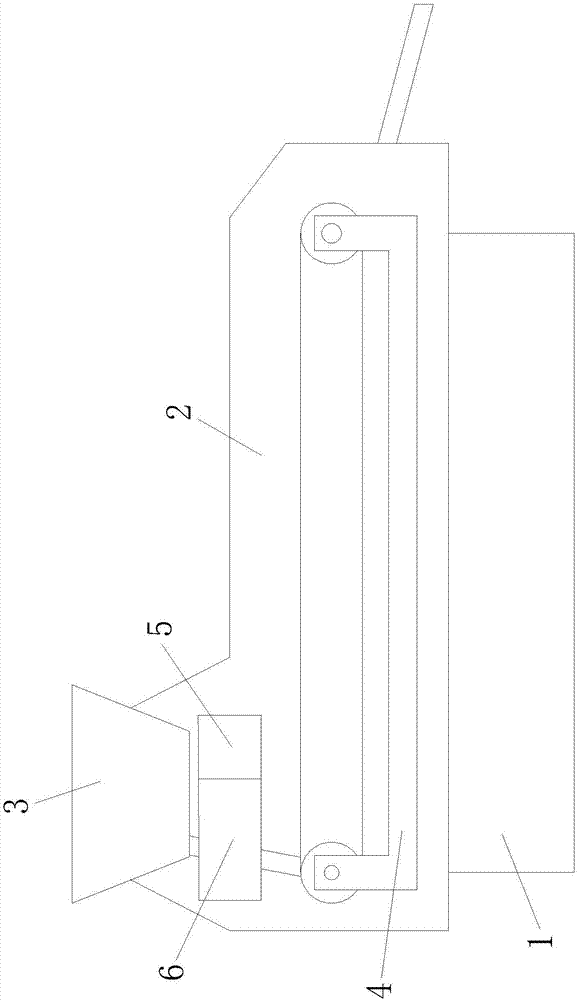

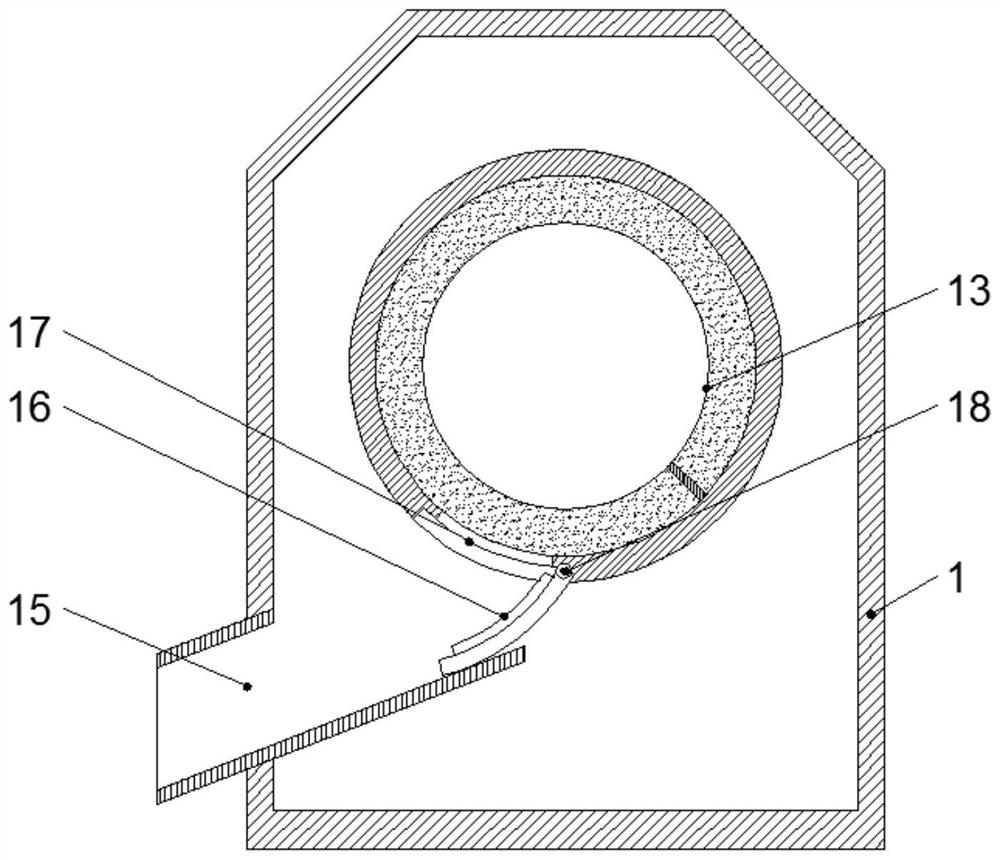

Graded belt type magnetic separating device

InactiveCN108114812ARealize hierarchical screeningSimple structureMagnetic separationMineral particlesEngineering

The invention relates to the field of belt type magnetic separating machines, in particular to a graded belt type magnetic separating device. The graded belt type magnetic separating device comprisesa scavenging mechanism and a magnetic screening mechanism; the scavenging mechanism is located below the magnetic screening mechanism, the scavenging mechanism and the magnetic screening mechanism each have the magnetic separating function, the magnetic screening mechanism is provided with a magnetic separating belt, meshes are formed in the magnetic separating belt. The device is simple in structure, the screening device and the magnetic separating device are organically combined, through the meshes, graded screening of mineral particles with different sizes can be achieved, the screening speed and the screening precision are improved, and the mutual interference in the magnetic separating process due to mixing of large and small particles can be effectively avoided, the magnetic separating belt with the meshes is adopted to carry out graded magnetic separation on the minercal particles, the magnetic separating machine and the screening machine are combined into a whole, the cost is lower, occupied area of the device is reduced, and usability and practicability of the device are improved.

Owner:PANZHIHUA JIUDINGZHIYUAN INTPROP OPERATION CO LTD

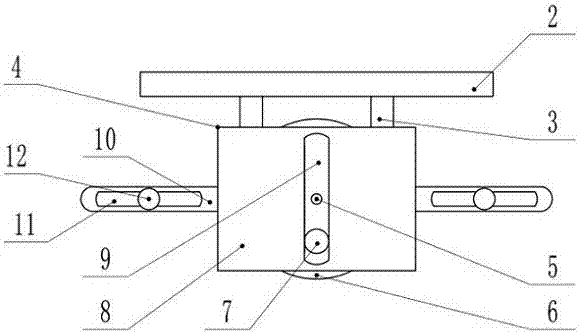

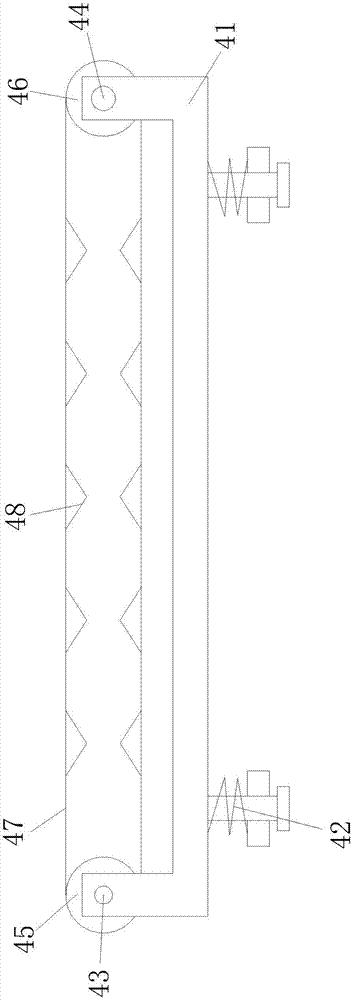

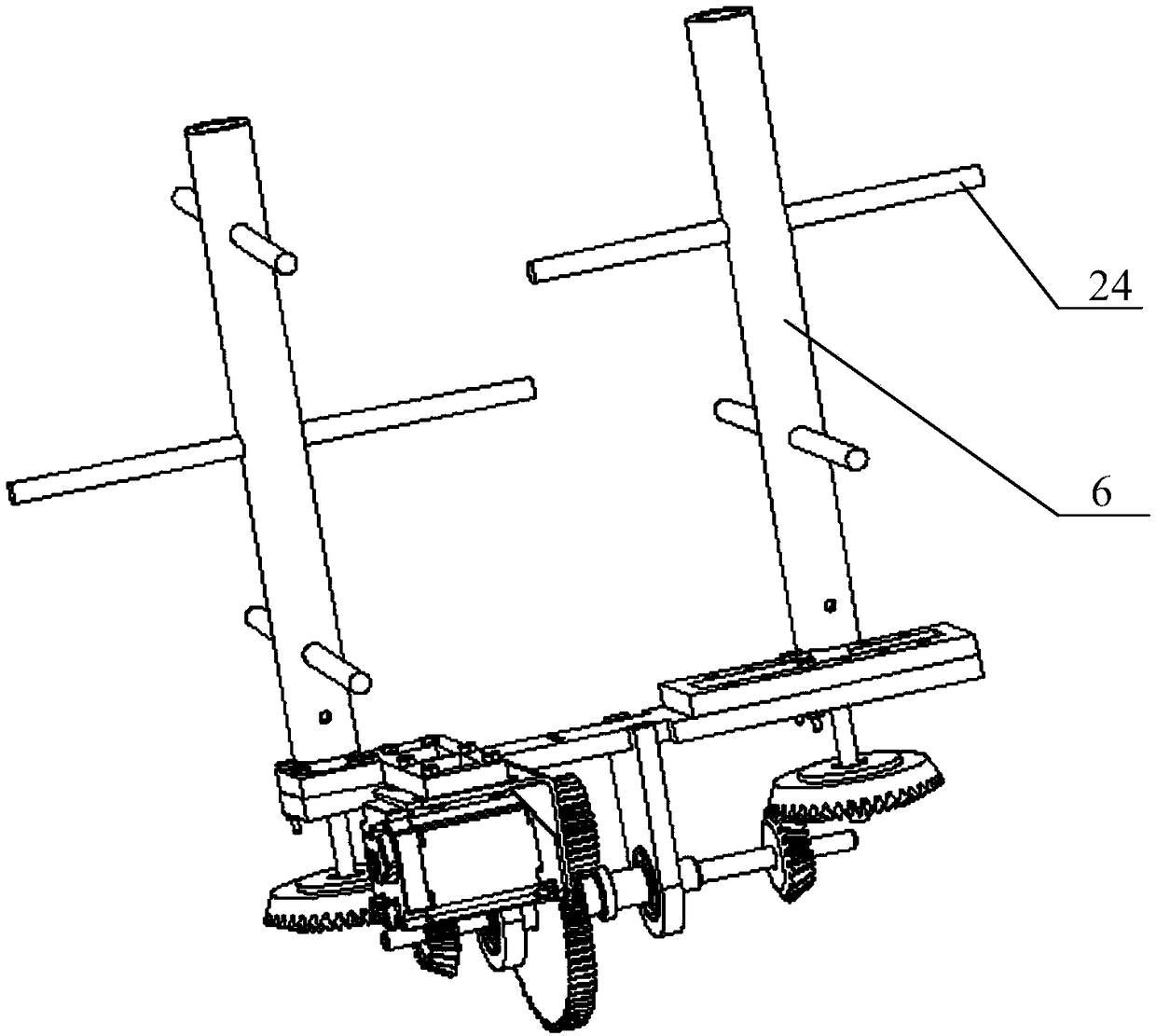

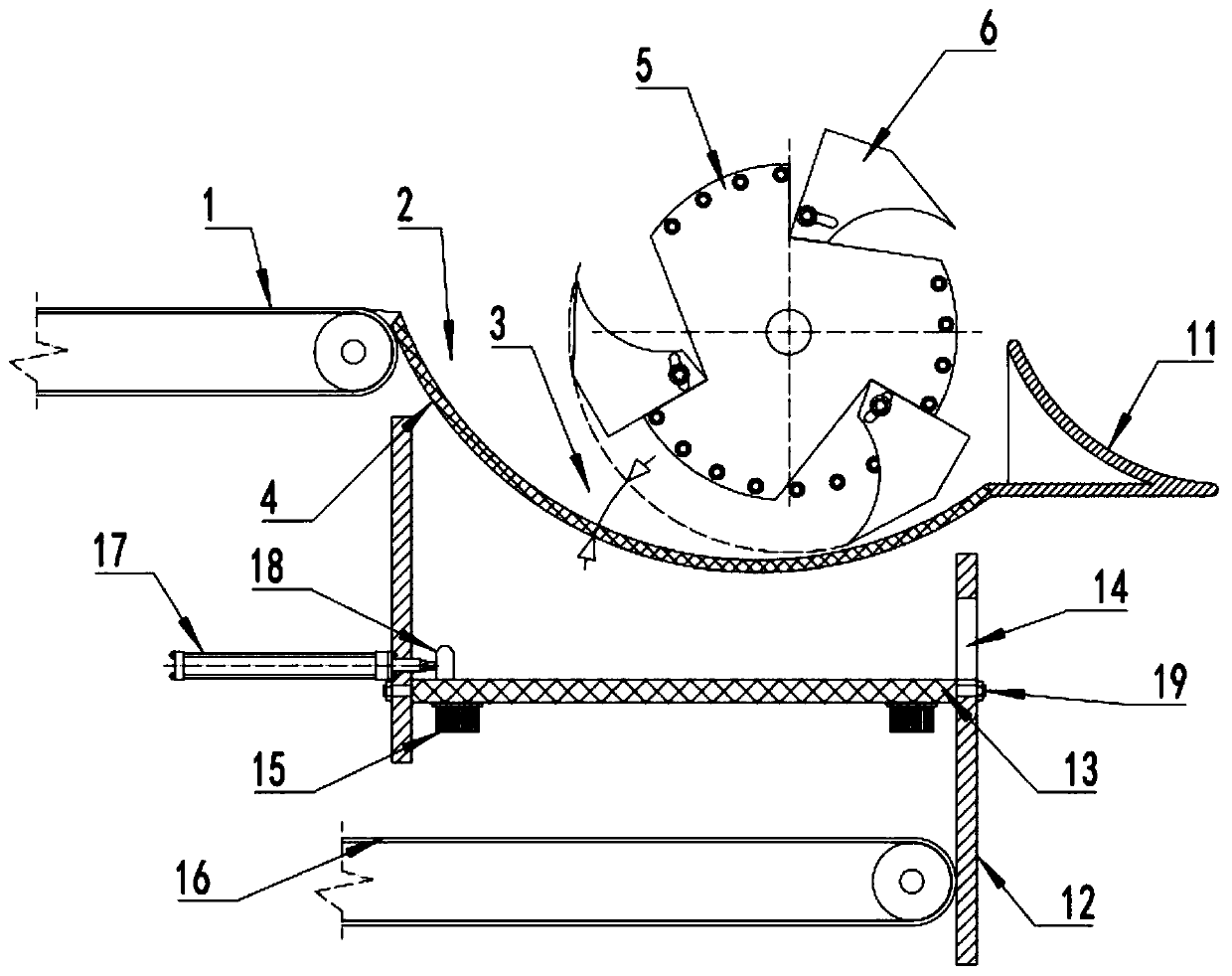

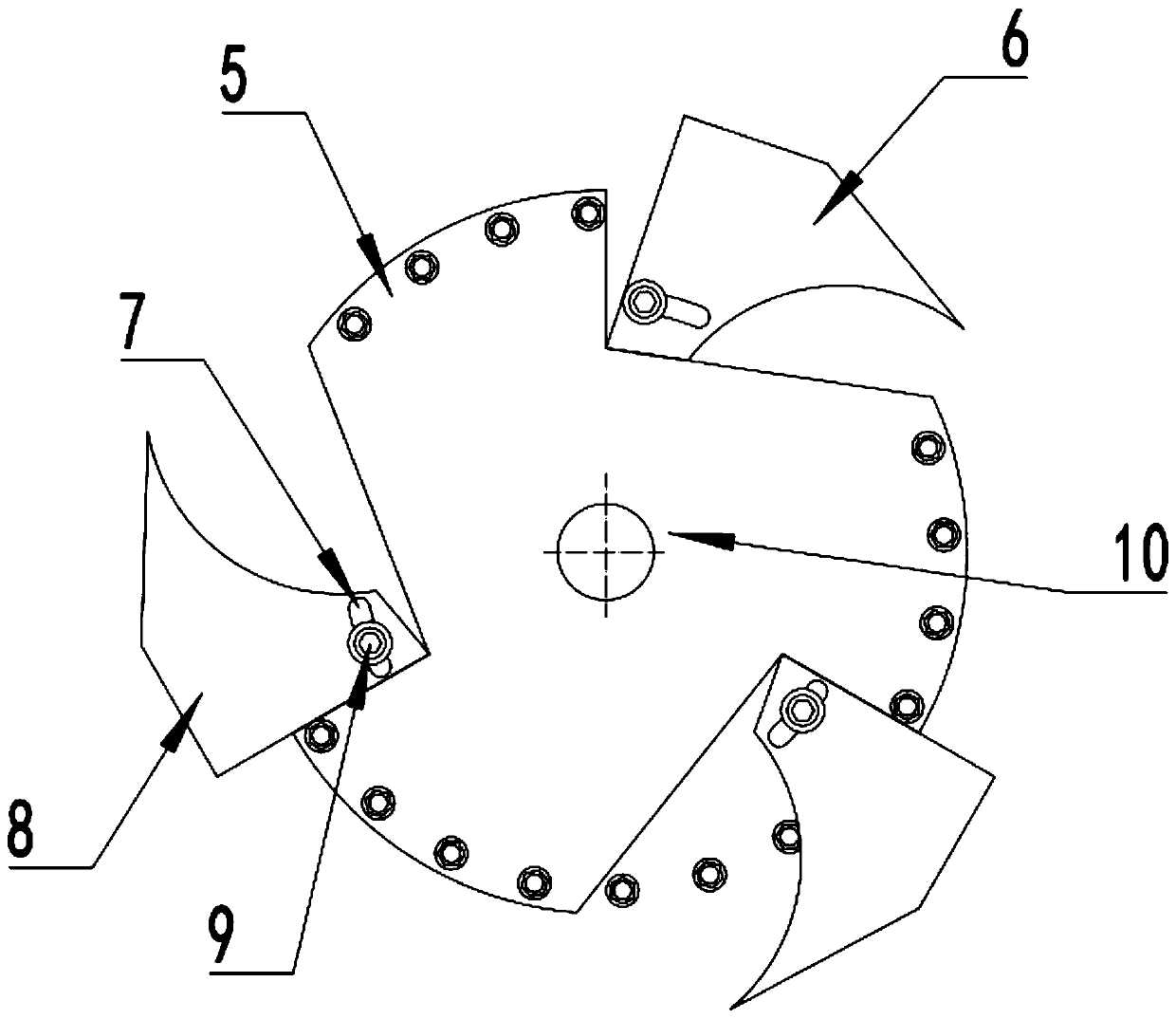

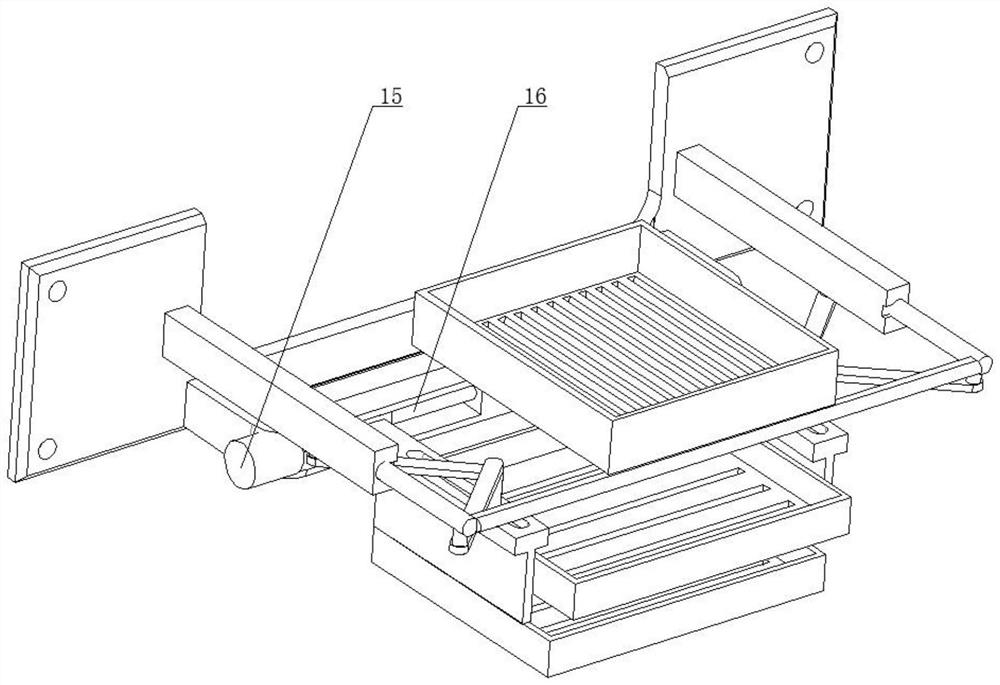

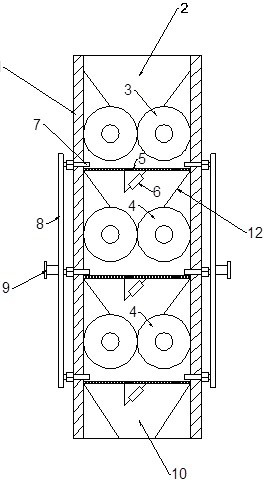

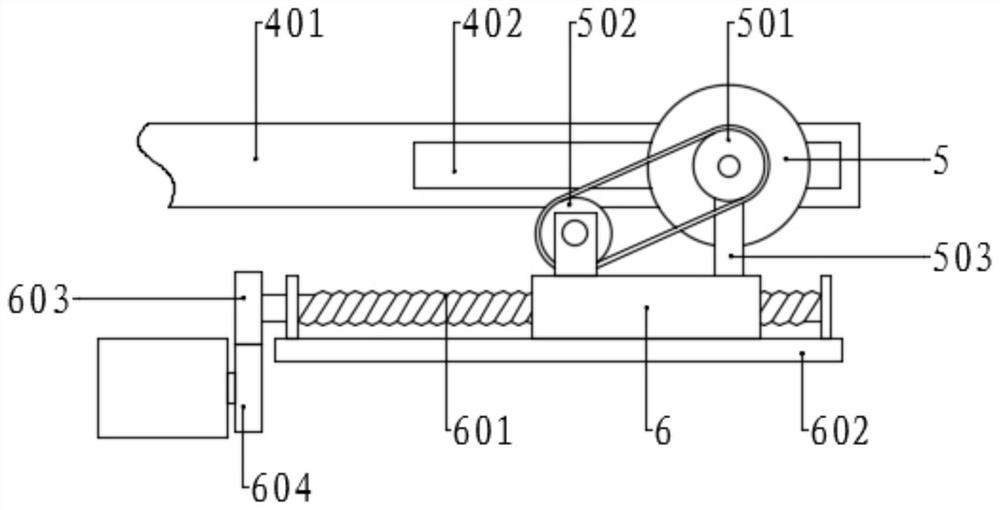

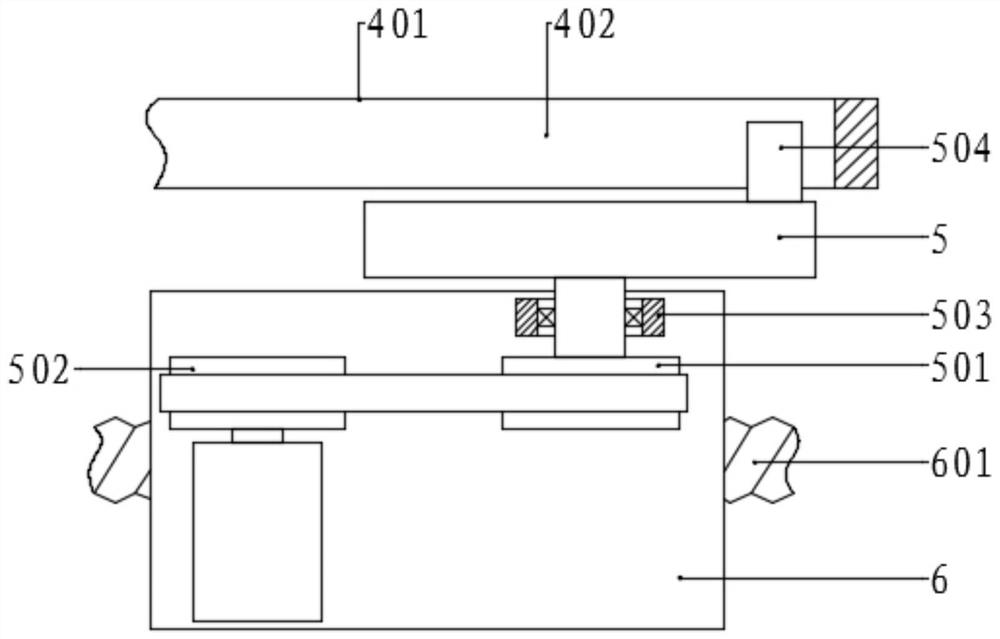

Pellet sorting device

InactiveCN107876402ARealize hierarchical screeningReduce manufacturing costSievingGas current separationEngineeringDistributed power

The invention discloses a pellet sorting device. The pellet sorting device comprises a rack, wherein a shell is installed on the rack; a primary sorting device and a secondary sorting device are installed in the shell; and a driving device is installed on the rack, a power conversion assembly is installed on the shell, and the power conversion assembly is used for distributing power generated by the driving device to the primary sorting device and the secondary sorting device. According to the pellet sorting device, the primary sorting device is coordinated with the secondary sorting device, so that grading screening of pellets is realized, the pellets with the large diameter and the small diameter are screened out, and therefore the size of the pellets is ensured, and production cost of the pellets is saved; and power is supplied to work of the primary sorting device and the secondary sorting device through the power of the driving device, so that manufacturing and using cost of the device is reduced.

Owner:安徽省恒伟铋业有限公司

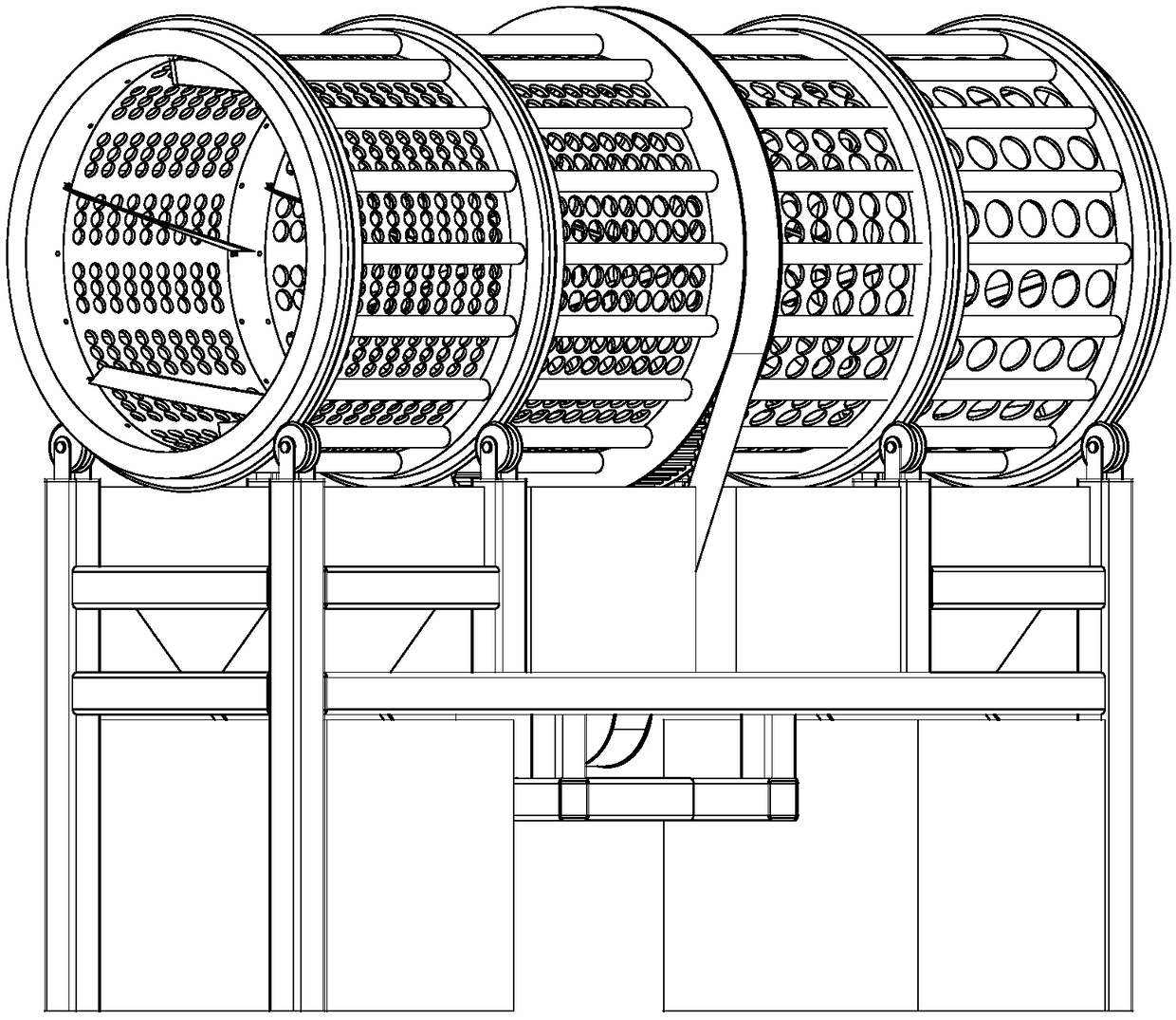

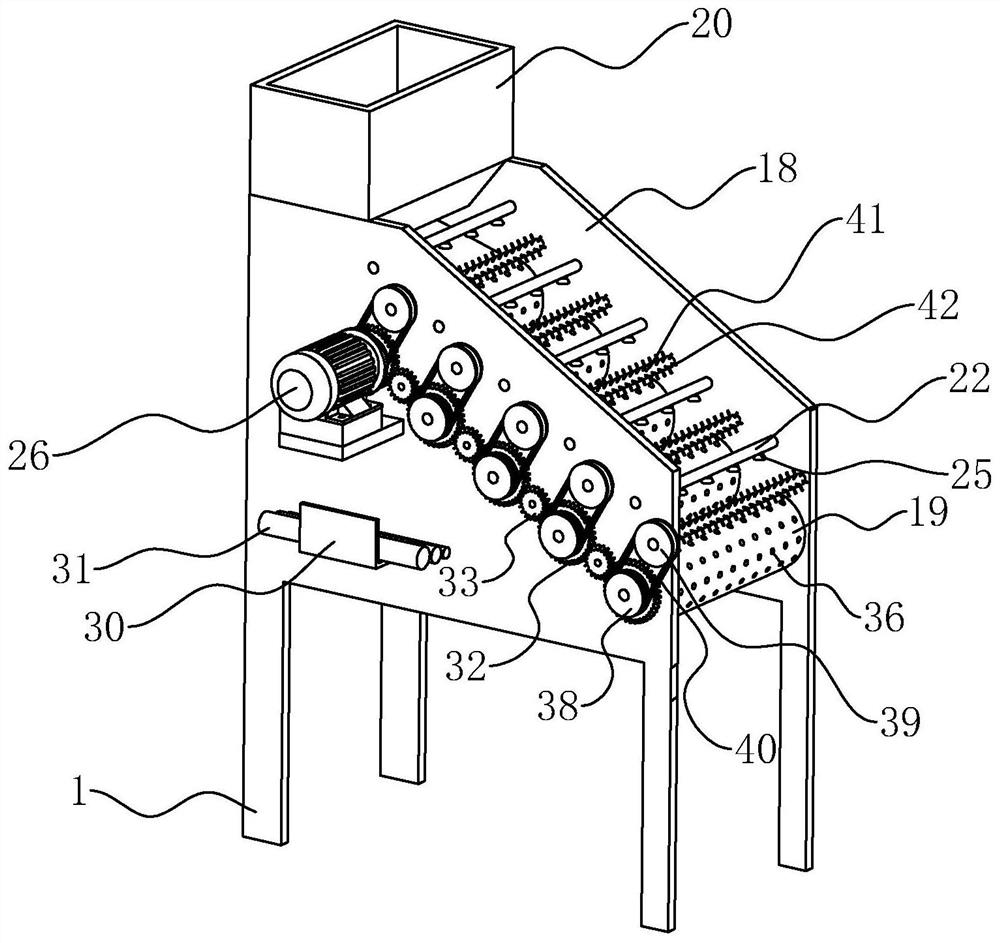

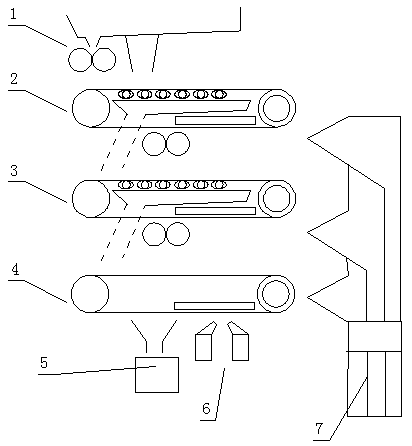

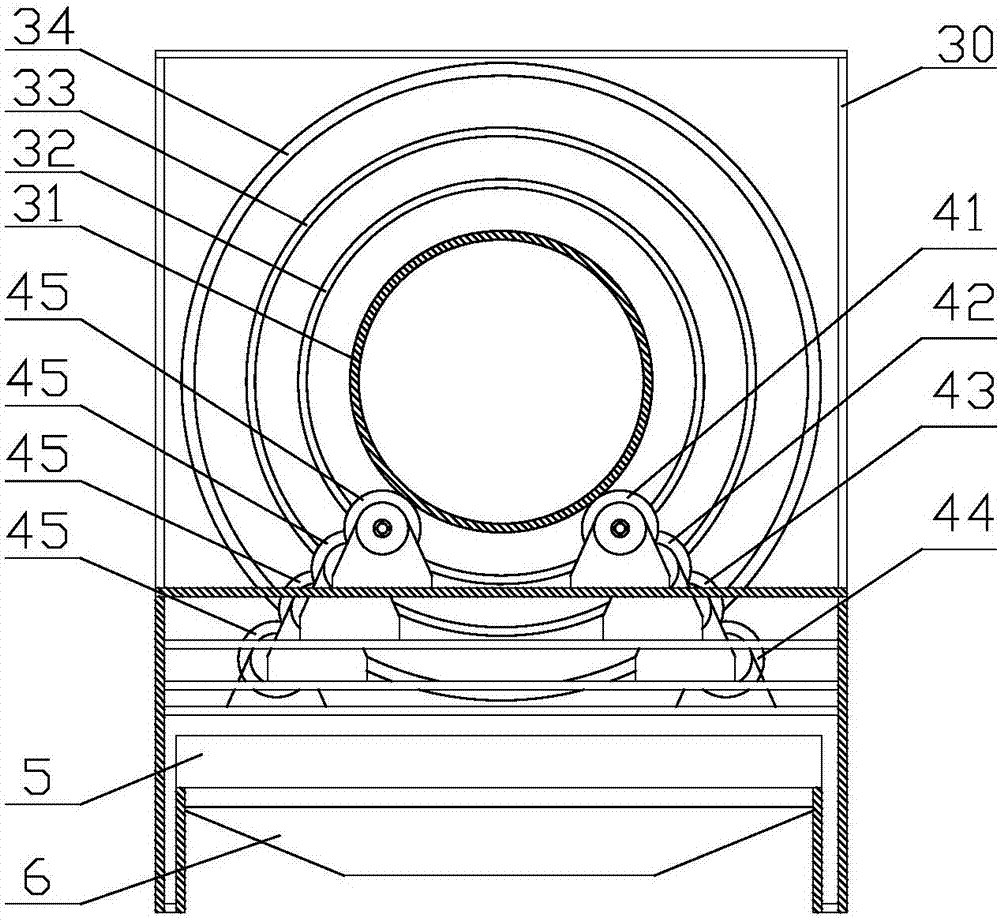

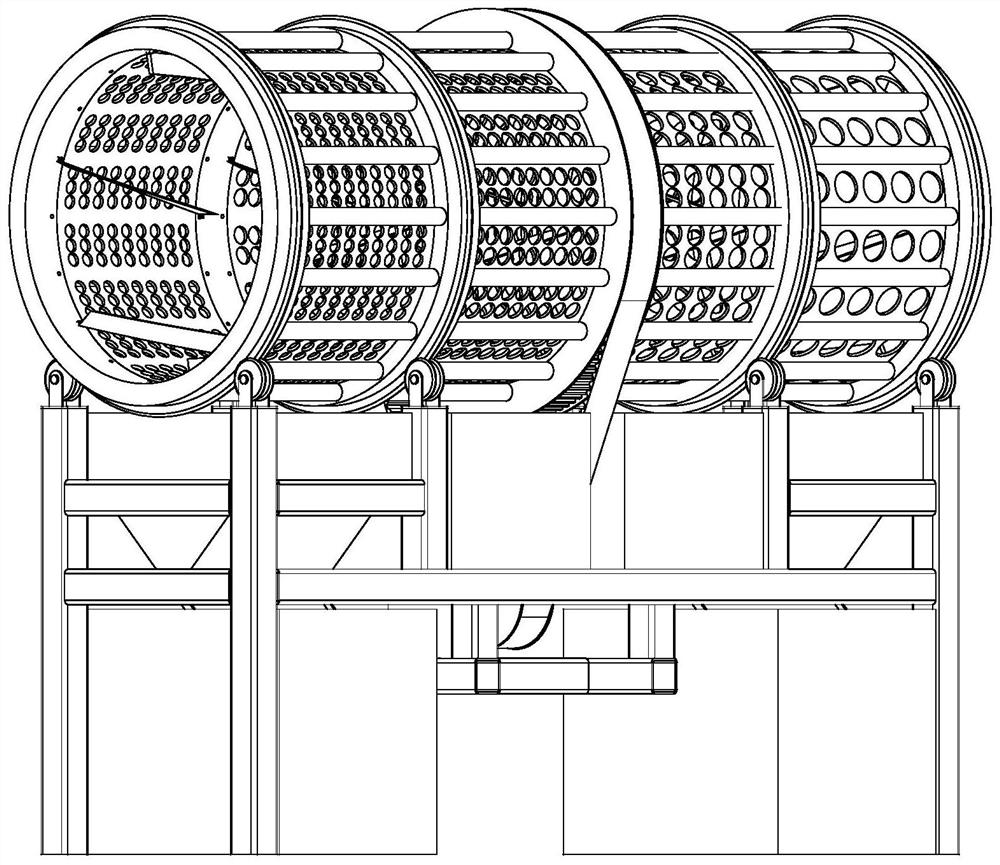

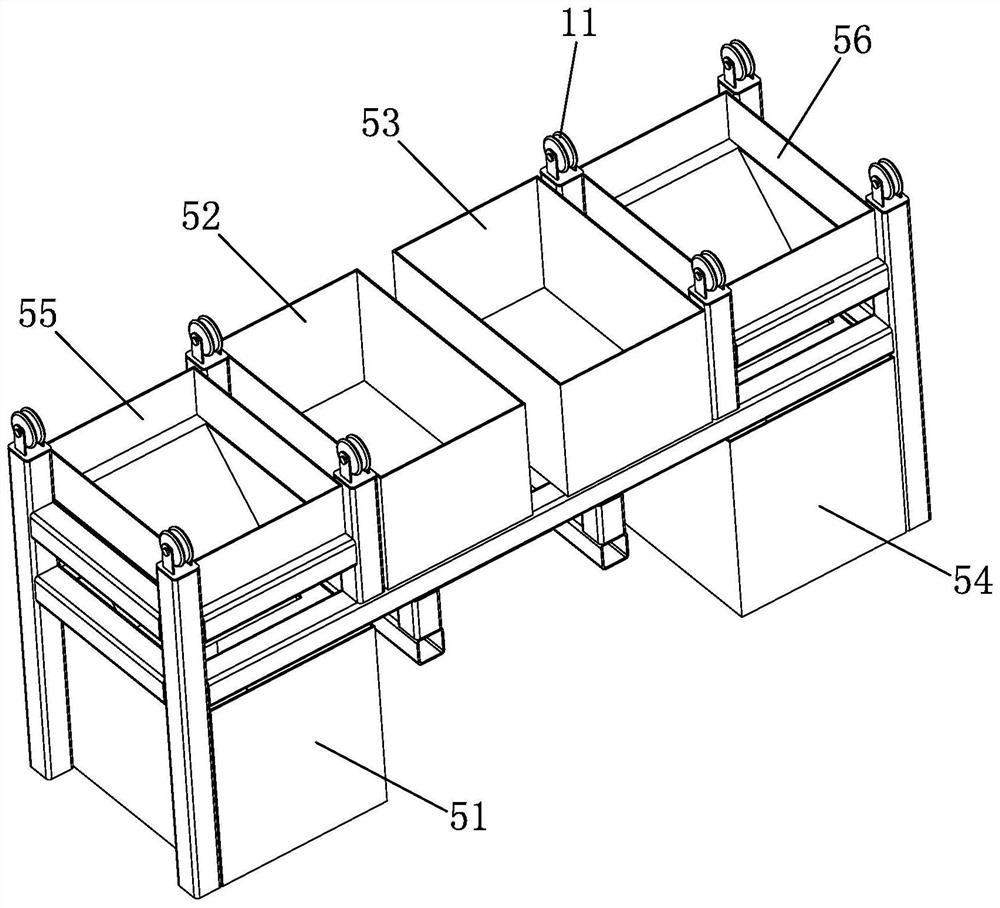

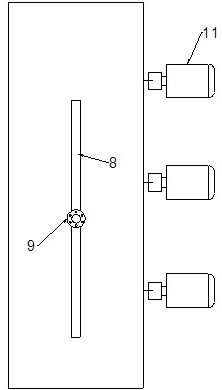

Roller type fresh leaf screening machine for making tea

The invention discloses a roller type fresh leaf screening machine for making tea. The roller type fresh leaf screening machine comprises a lifter, a vibratory feeder, a combined roller screen and a driving mechanism. The combined roller screen is provided with a frame and four roller screen bodies, wherein the four roller screen bodies are each of a cylindrical structure, each roller screen body is divided into four layers which are sleeved from inside to outside, the lengths are gradually reduced from inside to outside, and the diameters are gradually increased from inside to outside. The four roller screen bodies are different in screen hole size, the size of screen holes at the innermost layer is the largest, and the sizes of screen holes are reduced from the innermost layer to the outside layer by layer. The four roller screen bodies are overlapped, fresh leaves are screened according to different features of single buds, one bud with one leaf, one bud with two leaves, one bud with three or four leaves, and single pieces, and thus graded screening of the fresh leaves is achieved. A variable-frequency motor is adopted to achieve stepless regulation, and the roller type fresh leaf screening machine is simple in structure, easy to operation and suitable for application and popularization.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Dust collector for rice flour milling

ActiveCN108606345BAvoid Uncollectable DefectsImprove the efficiency of dust suctionFood treatmentDust controlStructural engineering

The application of the invention relates to an auxiliary device of a baking machine, and discloses a dust remover for frying rice and making powder. The dust remover comprises a pan body, a heater anda dust removing mechanism, wherein the dust removing mechanism is mounted at the upper end of the pan body; a rotating shaft is rotatably connected to the inner part of the pan body; a plurality of blades are fixedly connected to the rotating shaft; the dust removing mechanism comprises a dust discharging pipe, a first folding plate, a second folding plate and an arc-shaped sliding rod; the dustdischarging pipe is connected to the top end of the pan body and communicates with the inner part of the pan body; the first folding plate is fixedly connected to the end part of the dust dischargingpipe; the second folding plate is rotatably connected to the end part of the dust discharging pipe; elastic ripple curtains are respectively connected to the edge of the first folding plate and the edge of the second folding plate; and the first folding plate, the second folding plate and the ripple curtains are jointly closed to form a cavity. According to the scheme of the dust remover disclosedby the invention, a foldable bellows mechanism is utilized to absorb dust in the pan body; the area for which an active collecting manner is suitable covers the whole pan body, so that the defect that in the prior art, dust in individual locations cannot be collected is avoided, and the efficiency of absorbing dust is greatly improved.

Owner:重庆市长寿区可又可食品有限公司

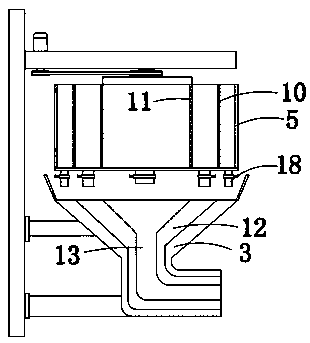

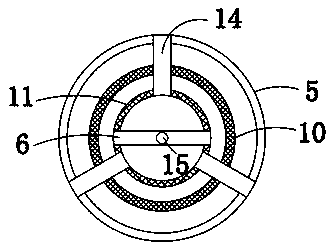

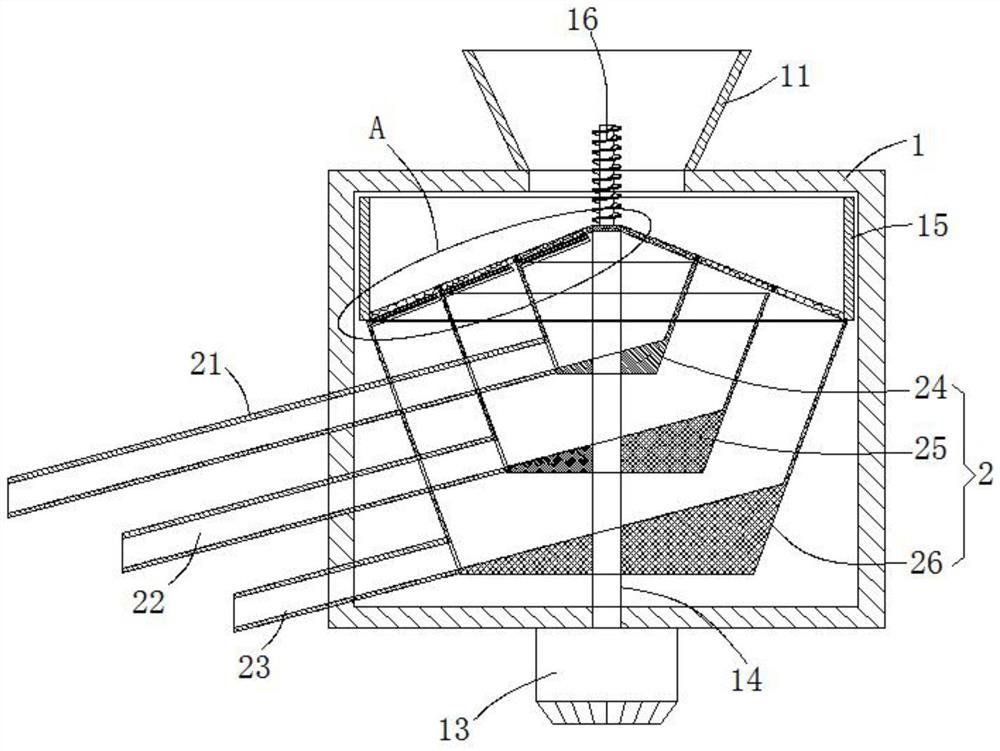

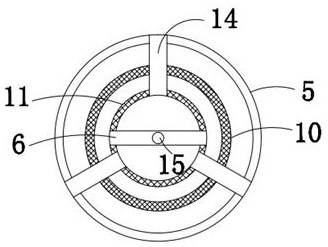

Separation equipment and method for micro-plastic in plateau lake sediments

PendingCN113828427ALow production costIncrease collection speedCentrifugesPlastic recyclingEngineeringStructural engineering

The invention discloses separation equipment and method for micro-plastic in plateau lake sediments. The separation equipment comprises a separation cylinder, wherein the top surface of the separation cylinder is open, an end cover is detachably connected to the top surface of the separation cylinder, a stirring device is arranged on the end cover, a vent hole and a feeding hole are formed in the top surface of the end cover, and a centrifugal device is arranged in the end cover; the centrifugal device comprises a rotating mechanism, the rotating mechanism is arranged at the bottom of an inner cavity of the separation cylinder, a centrifugal plate is fixedly connected to the top surface of the rotating mechanism, a first sealing bearing is arranged between the peripheral wall of the centrifugal plate and the inner wall of the separation cylinder, a liquid storage cavity is formed between the bottom surface of the centrifugal plate and the bottom of the inner wall of the separation cylinder, a centrifugal cylinder is fixedly connected to the center of the top surface of the centrifugal plate, a plurality of liquid outlet holes are formed in the top of the centrifugal cylinder at equal intervals in the circumferential direction, a plurality of filtering mechanisms are sequentially arranged outside the centrifugal cylinder in a sleeving mode, the inner cavity of the centrifugal cylinder is divided into a plurality of filtering cavities by the filtering mechanisms, a plurality of liquid discharging holes are formed in the centrifugal plate, and the filtering cavities communicate with the liquid storage cavity through the liquid discharging holes; and a plurality of water discharging mechanisms are arranged on the bottom surface of the centrifugal plate at equal intervals in the circumferential direction.

Owner:GUIZHOU UNIV

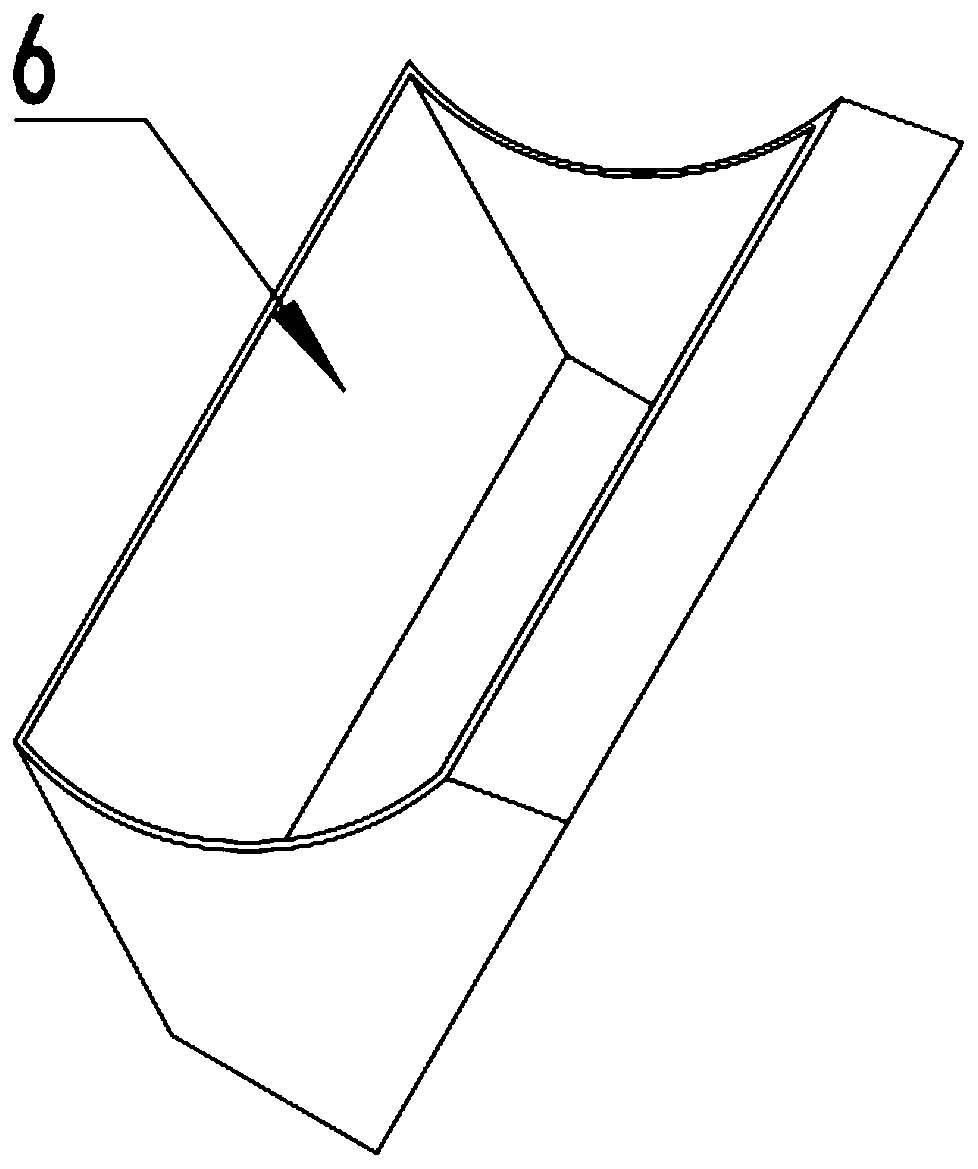

Primary screening and grading device for plastic particles

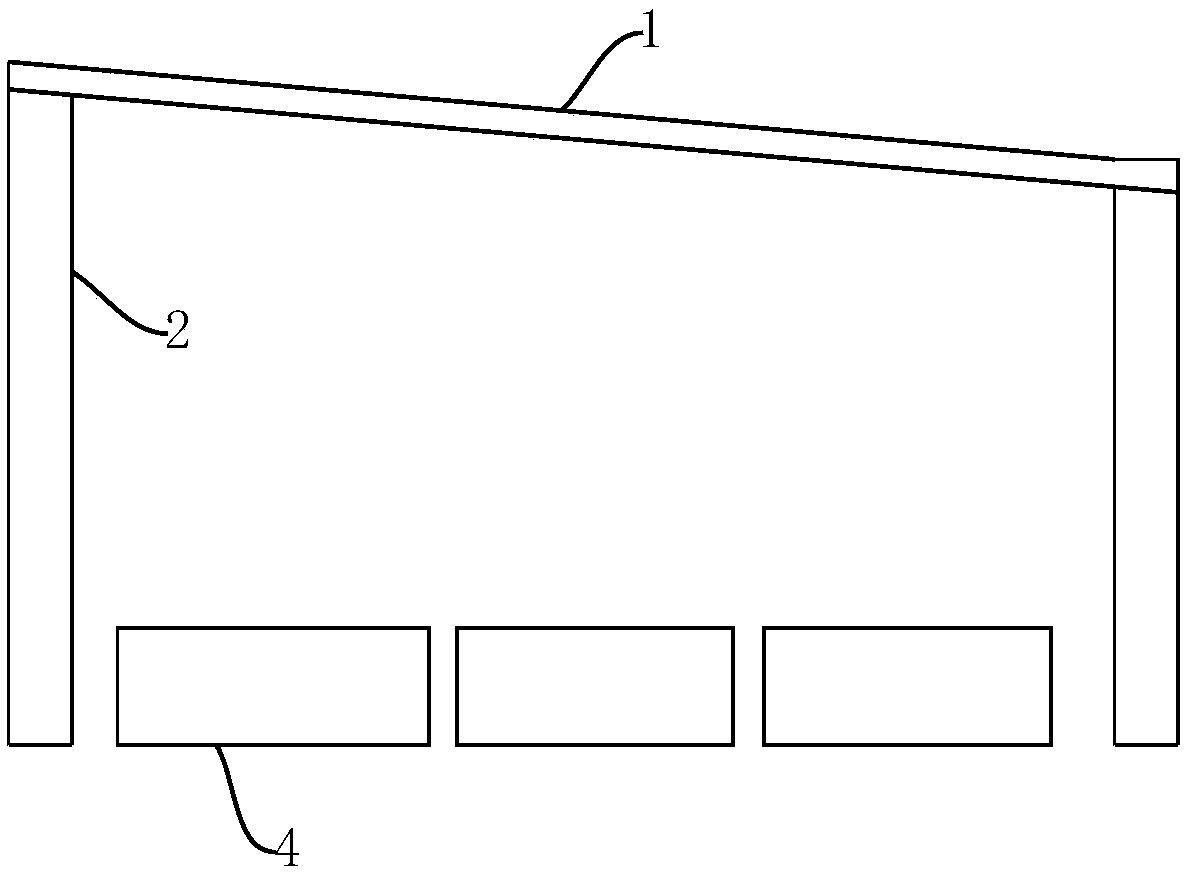

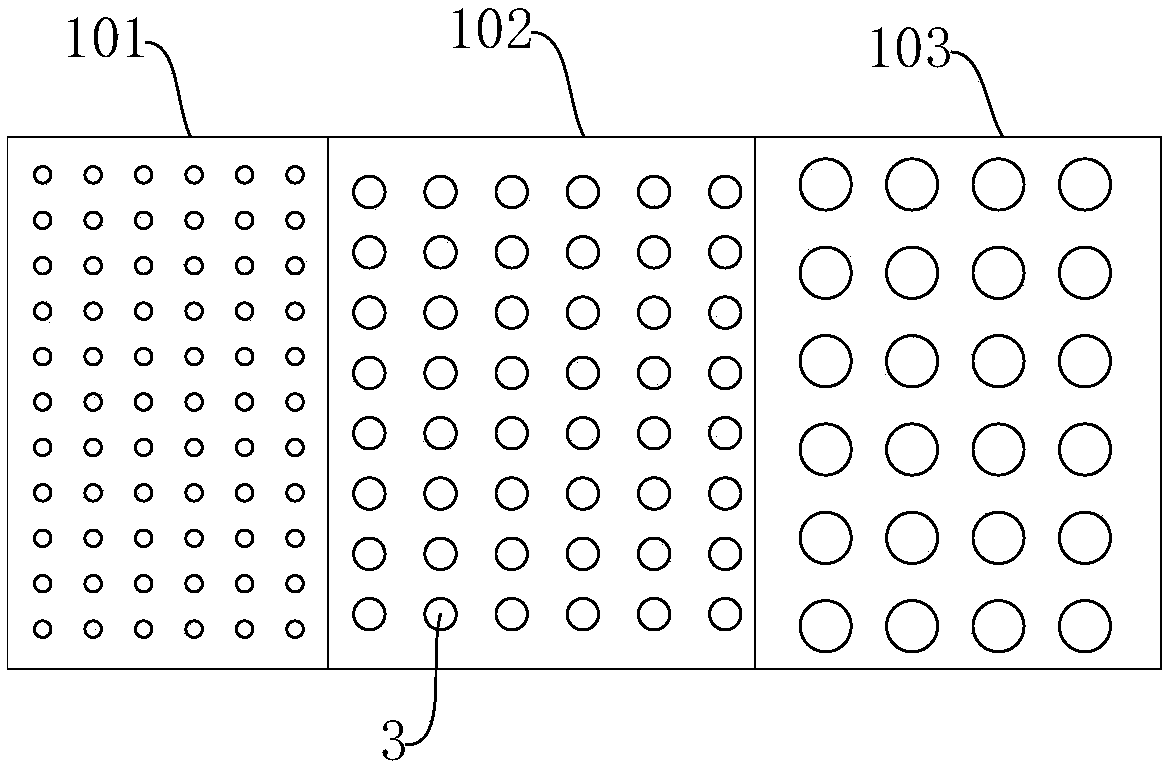

The invention particularly relates to a primary screening and grading device for plastic particles. The primary screening and grading device comprises a screening plate and supporting rods, wherein the supporting rods are arranged under the screening plate; the screening plate is obliquely arranged and comprises a first screening area, a second screening area and a third screening area; a plurality of screen holes are formed in each of the first screening area, the second screening area and the third screening area; the first screening area is located at the higher end of the screening plate;the third screening area is located at the lower end of the screening plate; the second screening area is located between the first screening area and the third screening area; the diameter of the screening holes in the first screening area is smaller than the diameter of the screening holes in the second screening area; and the diameter of the screening holes in the second screening area is smaller than the diameter of the screening holes in the third screening area. The device has the advantages of being simple in overall structure, low in cost, capable of preliminarily realizing grading andscreening of the plastic particles and simple and convenient in operation.

Owner:四川省爱琴海服装设计有限公司

A kind of tea roller sorting device

ActiveCN108499835BSpread outRealize hierarchical screeningSievingScreeningStructural engineeringMechanical engineering

The invention relates to a sorting device. The purpose is to provide a tea drum sorting device with simple and reliable structure, good screening effect, which can effectively improve the sorting efficiency and is suitable for sorting grade requirements of most tea varieties. The technical solution is: a tea roller sorting device, characterized in that the device includes a sorting cylinder respectively arranged on a support platform and rotatable around a horizontal axis, a power mechanism for driving the rotation of the sorting cylinder, and a device for collecting tea leaves. Blanking mechanism; the sorting cylinder is formed by axially connecting several sections, the sectioned cylinder wall is a flexible screen and several spiral plates are arranged on the inner circumference of the cylinder wall; among the two adjacent sections, the right The screen aperture of the side segment is larger than the screen aperture of the left segment.

Owner:ZHEJIANG SCI-TECH UNIV

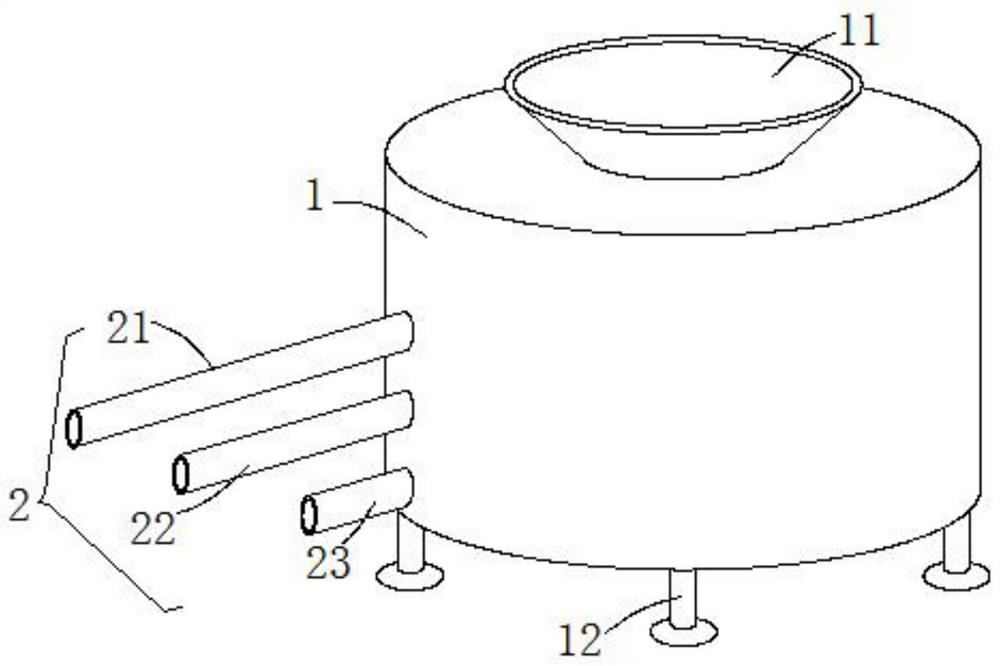

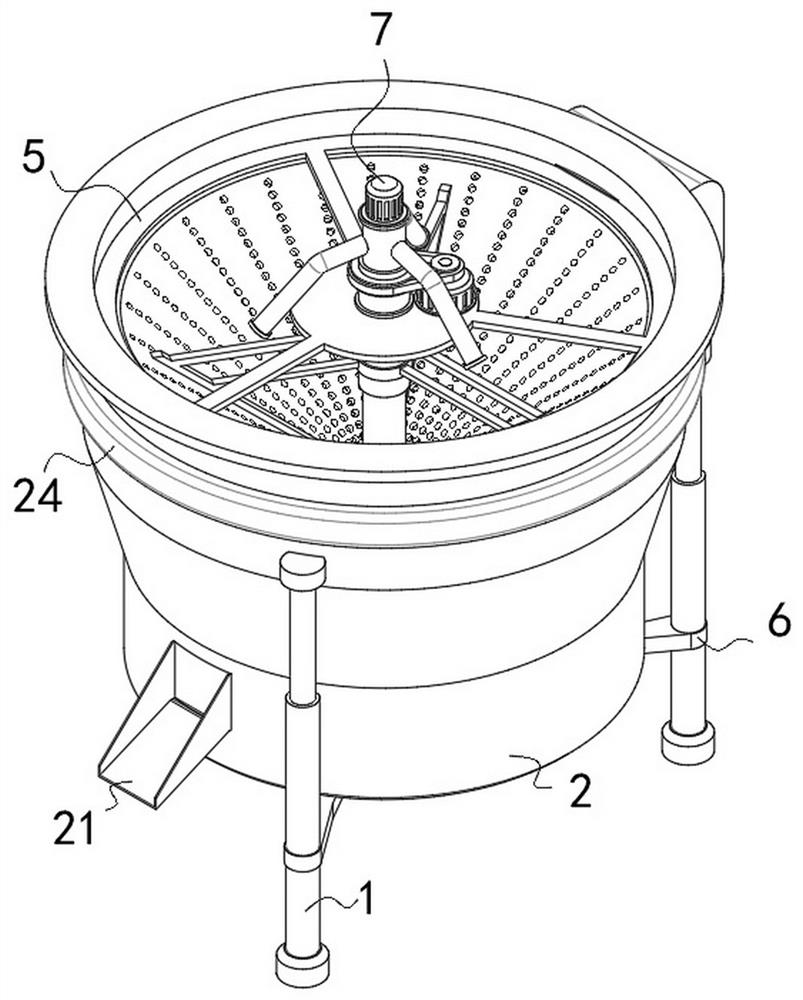

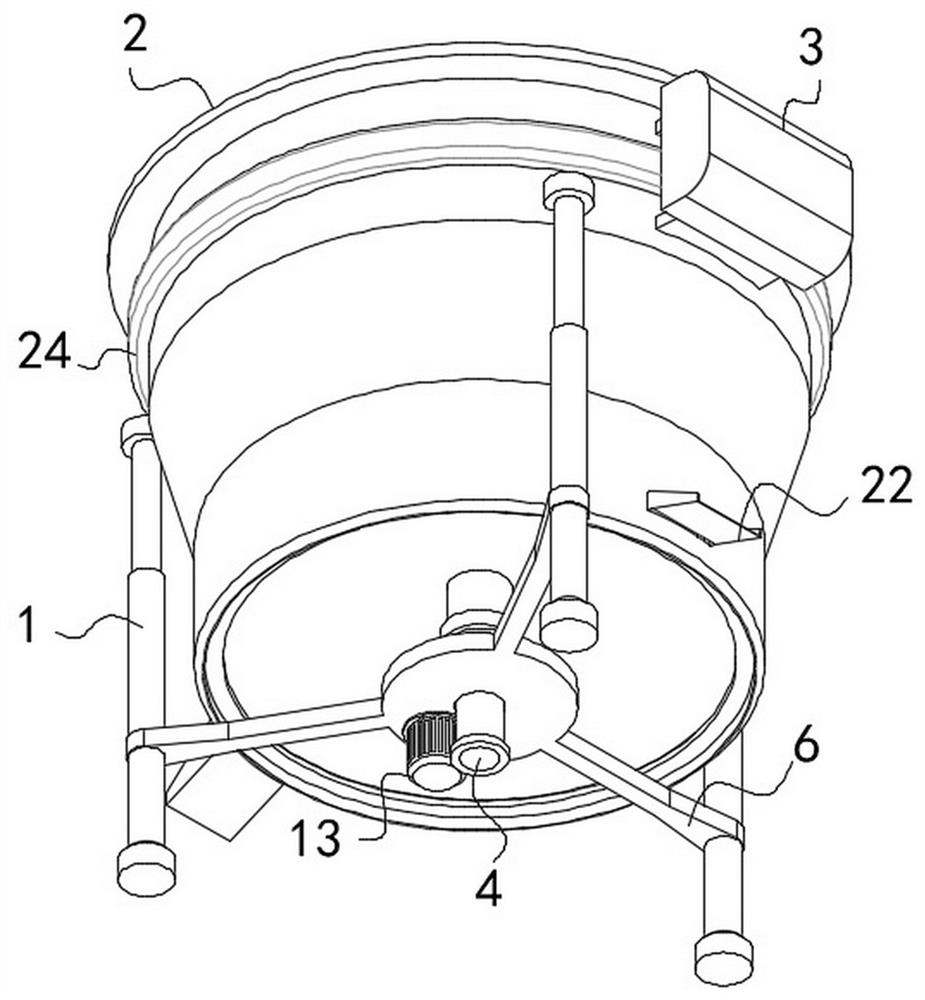

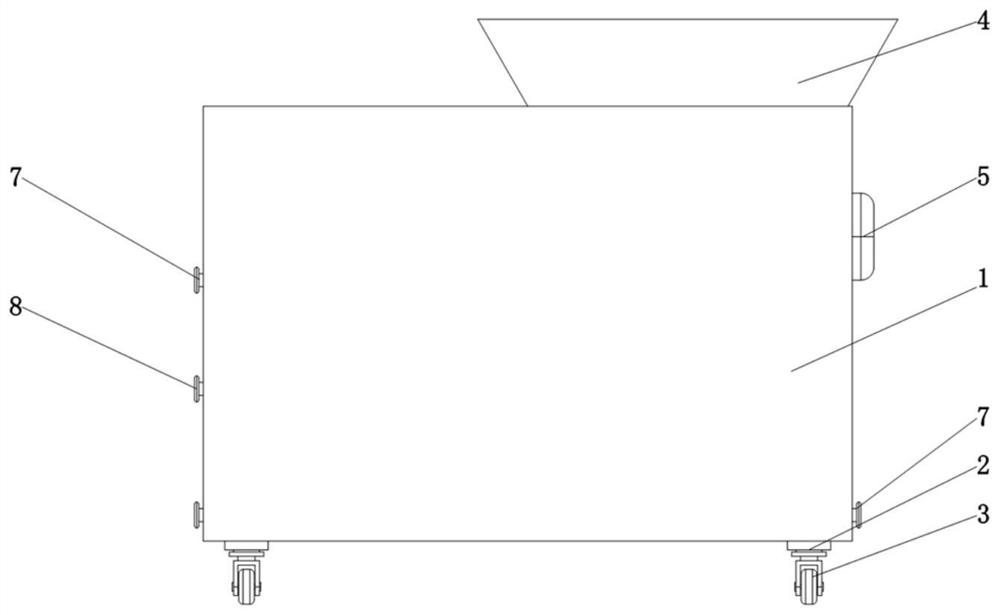

Filtering device for neodymium iron boron waste recovery

PendingCN112934712ARealize hierarchical screeningEffective sieving operationTransportation and packagingMetal-working apparatusPhysical chemistryEnvironmental engineering

The invention discloses a filtering device for neodymium iron boron waste recovery, and relates to the technical field of neodymium iron boron production, the filtering device comprises a treatment barrel and a filtering mechanism, a plurality of supporting legs are vertically arranged at the edge position of the bottom end face of the treatment barrel, the interior of the treatment barrel is of a hollow structure, and a wide-mouth feeding hopper is arranged at an opening in the top end of the treatment barrel. The filtering mechanism is arranged in the treatment barrel. According to the filtering device for neodymium iron boron waste recovery, the filtering mode of a traditional rare earth waste recovery filtering device is changed, a graded screening structure is achieved through the filtering mechanism, graded filtering of rare earth waste can be achieved, and metal particles with different particle sizes in the rare earth waste can be effectively screened.

Owner:ANHUI JINSANLONG RENEWABLE RESOURCES

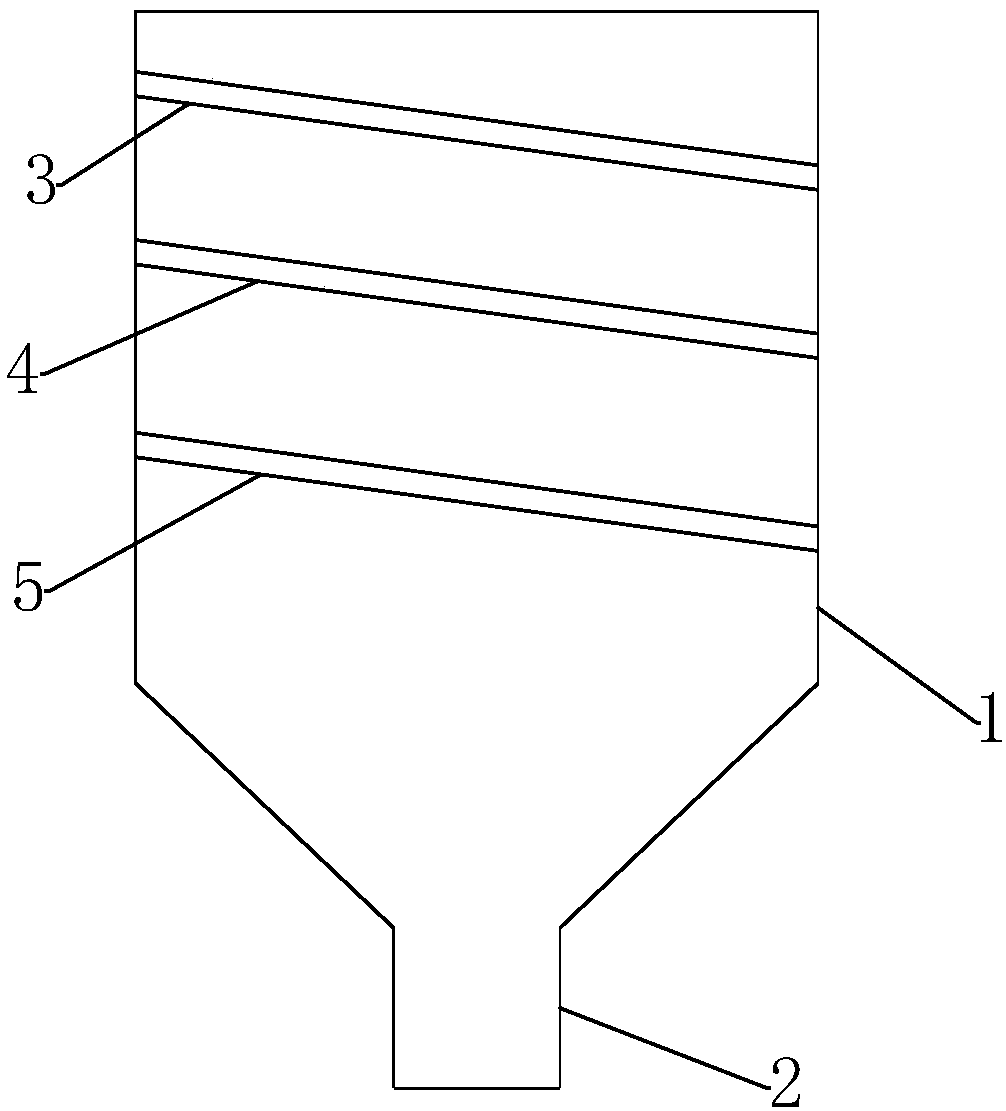

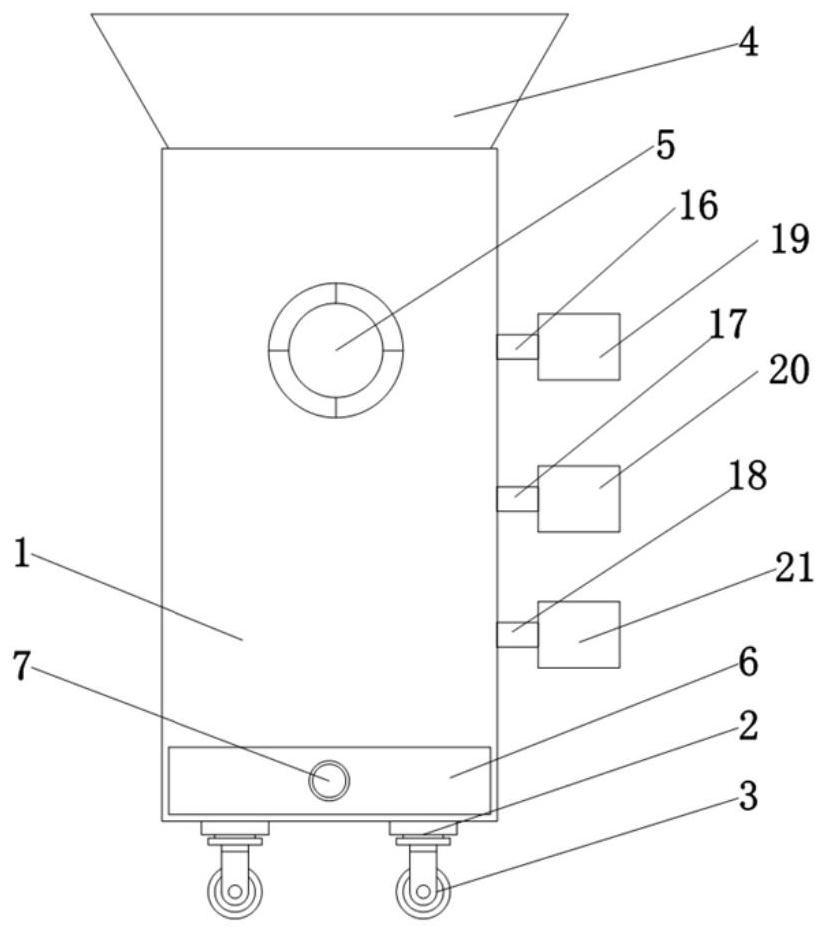

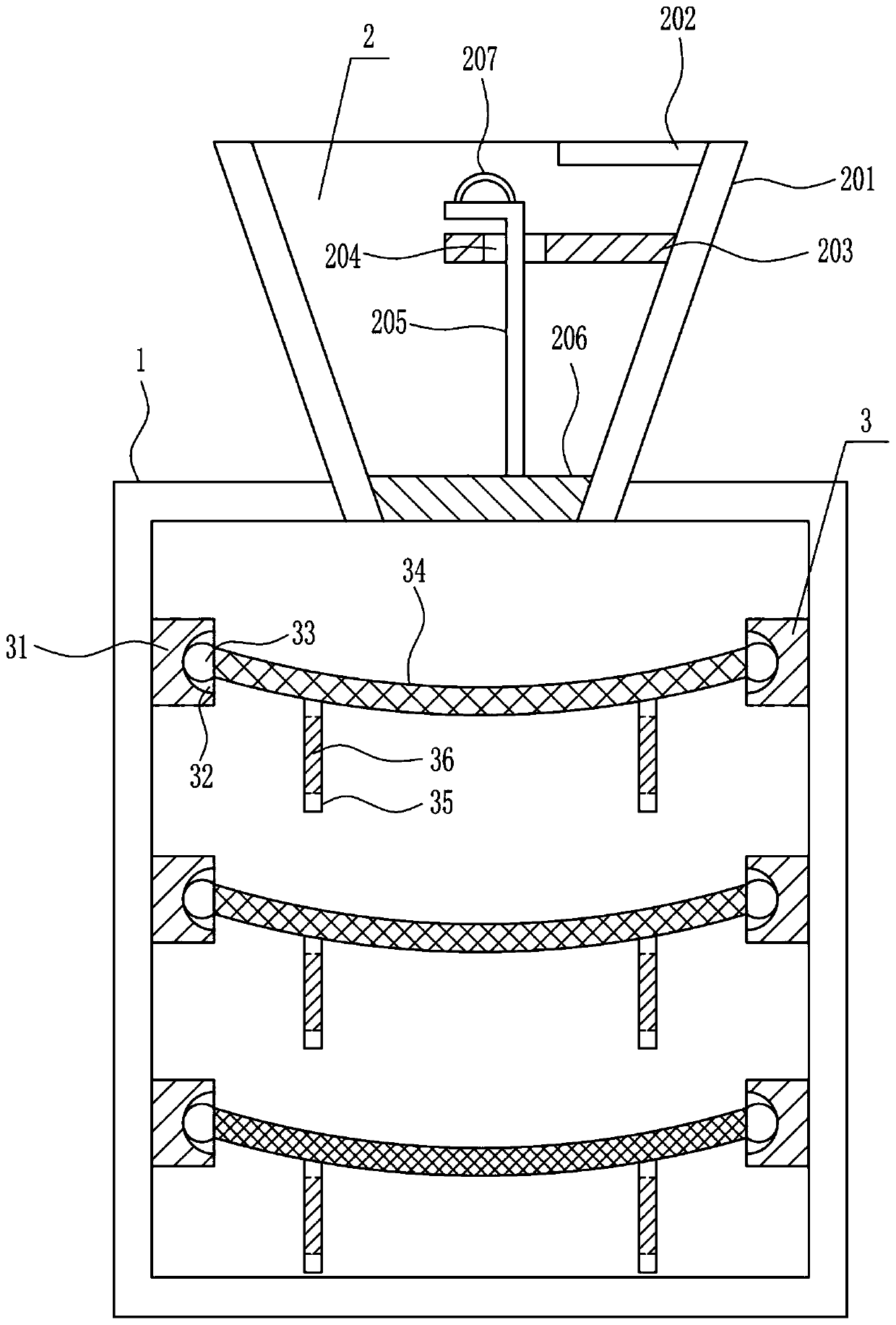

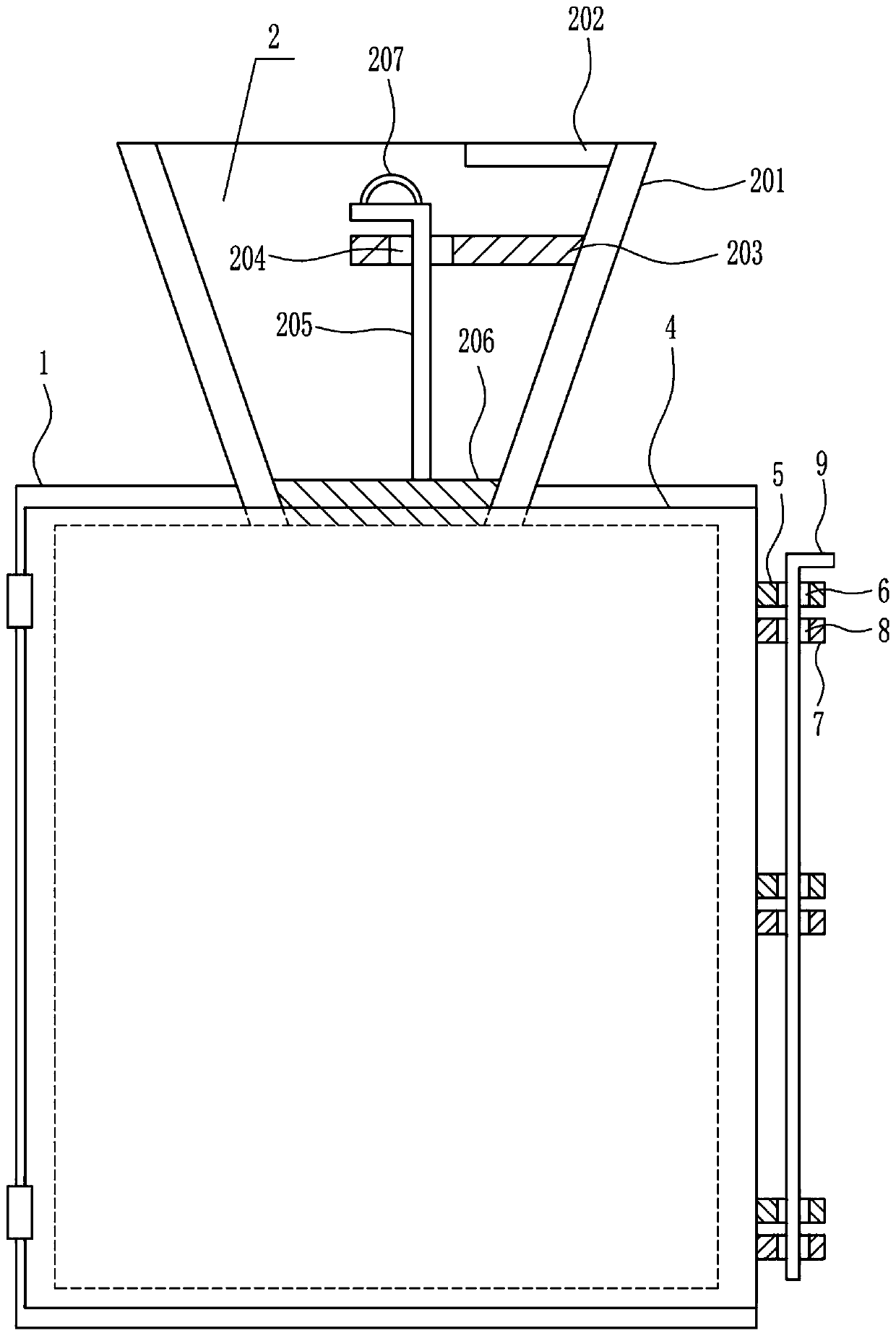

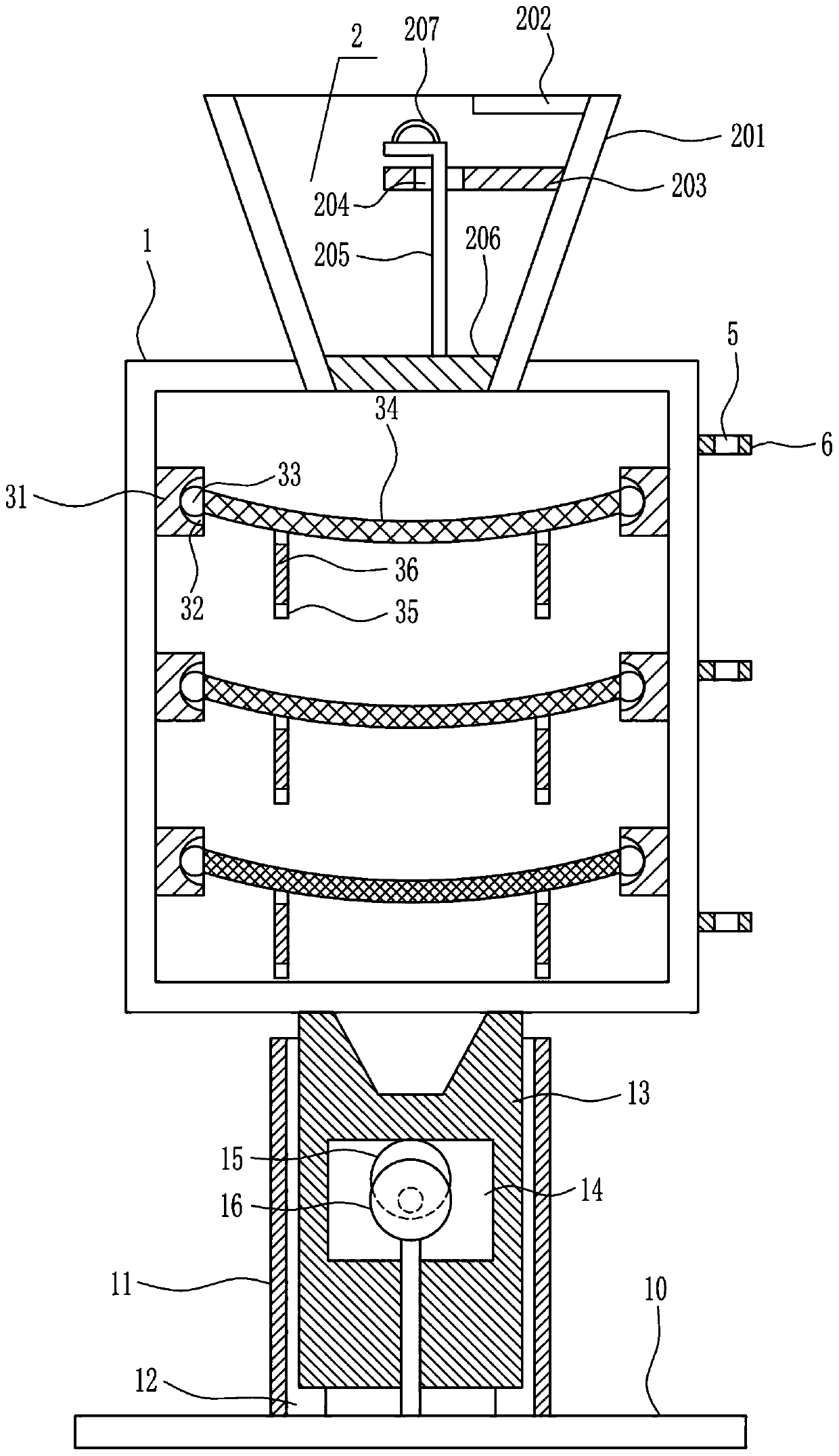

Feeding impurity-removing device

InactiveCN107639033ARealize hierarchical screeningImprove filtering effectSievingGas current separationEngineeringFilter effect

The invention relates to the technical field of filtering devices, in particular to a feeding impurity-removing device which comprises a feeding barrel with the two ends open. The bottom of the feeingbarrel is communicated with a feeding pipe. A first filter screen, a second filter screen and a third filter screen are sequentially arranged in the feeding barrel from top to bottom. The mesh diameter of the first filter screen is larger than that of the second filter screen, and the mesh diameter of the second filter screen is larger than that of the third filter screen. The device can achieveclassified screening of impurities filtered out while being good in filtering effect, and the device is simple in structure and low in cost.

Owner:彭州市永力机械厂

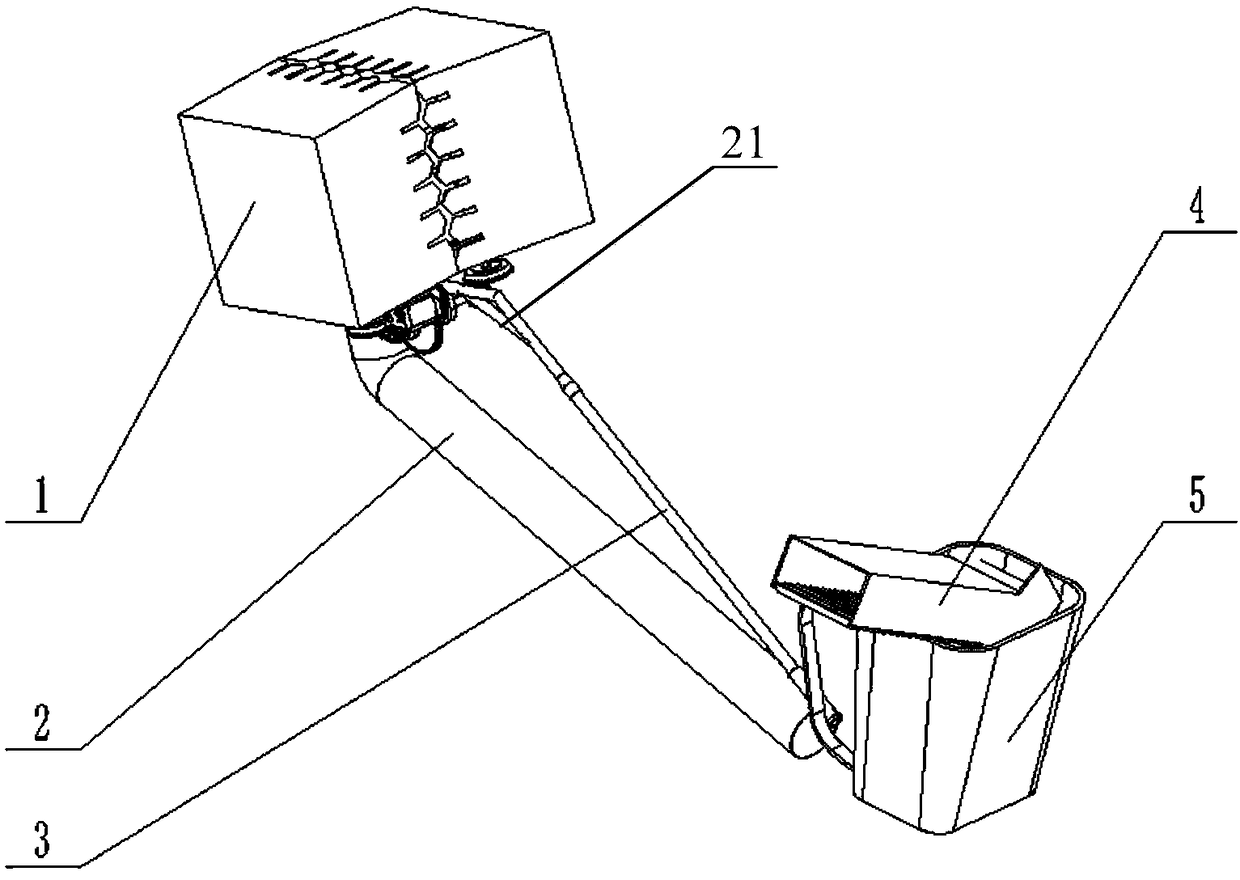

Jujube picking machine

The invention discloses a jujube picking machine which comprises a power source, a transmission device, a picking device, a fruit conveying device, a screening device, a collecting device and a stretchable device. The power source is placed at the bottom of the collecting device, the screening device is installed at the top of the collecting device and connected with the bottom of the picking device through the fruit conveying device, the stretchable device is fixedly installed at the bottom of the picking device, and the transmission device is installed at the bottom of the picking device. Byadopting the jujube picking machine, in the jujube picking process, adaptability adjustment is performed for branches of different sizes, picked jujubes are directly collected, screening and gradingcan be completed according to the sizes of jujubes, and therefore the picking efficiency is improved.

Owner:CHONGQING JIAOTONG UNIVERSITY

Inclined bucket type multi-stage particulate matter screening method applying magnetite

InactiveCN112893134AExtended stayImprove filtering effectSievingGas current separationParticulatesMagnetite

The invention discloses an inclined bucket type multi-stage particulate matter screening method applying magnetite. A base is included, a screening shell body is fixedly mounted on the top face of the base, a hot air generating assembly is fixedly mounted on one surface of the screening shell body through a connecting piece, a material conveying pipe is fixedly installed at the axis position of the screening shell body, a first supporting plate is fixedly mounted on the top face of the screening shell body, a second support plate is fixedly mounted between the opposite surfaces of the base, the circumferential side face of the material conveying pipe is separately connected with the first supporting plate and the second supporting plate, a spiral material conveying mechanism is fixedly mounted in the interior of the material conveying pipe, the upper part of the material conveying pipe is fixedly provided with three circulating material pipes in a communicating mode, a first driving ring and a second driving ring are rotationally connected to the peripheral side face of the material conveying pipe through bearings from top to bottom, and a driven ring is rotationally connected to a position, corresponding to a position between the first driving ring and the second driving ring, of the peripheral side face of the material conveying pipe through the bearings.

Owner:点栈(绍兴)智能科技有限公司

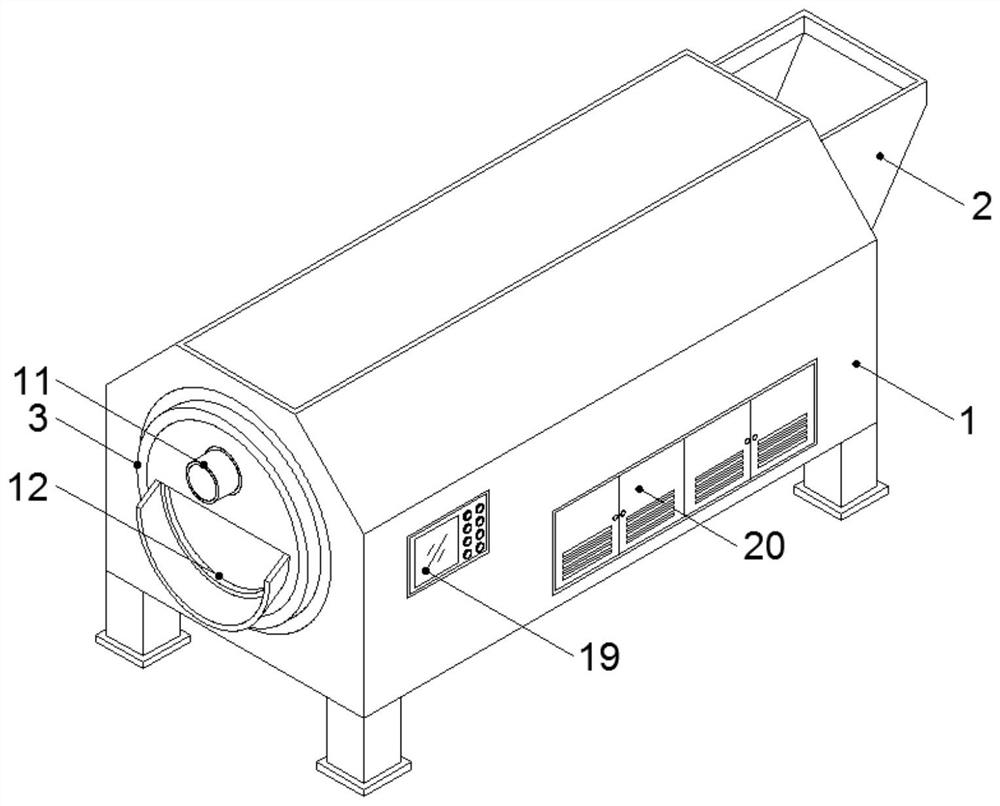

Silicon carbide micro-powder drying and grading integrated device

PendingCN112076978AQuick flipFast shippingSievingDrying solid materials with heatCarbide siliconSpiral blade

The invention discloses a silicon carbide micro-powder drying and grading integrated device. The silicon carbide micro-powder drying and grading integrated device comprises a main machine body, wherein openings are formed in the left side and the right side of the main machine body correspondingly, a feeding hopper and a sealing cover are connected to the openings respectively, fixing bases are fixedly installed at the inner side, close to the openings, of the interior of the main machine body, and a drying cylinder is fixedly installed through the fixing bases; and a plurality of sets of fixing rings are fixedly installed in the drying cylinder, spiral blades are fixedly installed at the two sides, close to filter screens, of the inner wall of the drying cylinder, a heating base is fixedly installed at the bottom, close to the drying cylinder, of the main machine body, and the outer side face of one end of the drying cylinder is fixedly sleeved with a gear ring; and an output shaft ofa motor is fixedly sleeved with a gear, and the gear is engaged with the gear ring. The silicon carbide micro-powder drying and grading integrated device is simple and reasonable in structure, novelin design, easy to operate, high in drying efficiency and grading efficiency and convenient to widely popularize and use.

Owner:连云港浩森矿产品有限公司

Gravel sorting device for construction

InactiveCN111589697AImplement automatic filteringRealize import and exportSievingGas current separationStructural engineeringMechanical engineering

The invention is applicable to the technical field of construction equipment, and provides a gravel sorting device for construction. The sorting device comprises a coarse screen, a rotating roller, aseparating screen box and a fine screen, the coarse screen is mounted at a top opening of the separating screen box and is of an arc-shaped structure; the rotating roller is mounted at the upper part,corresponding to the coarse screen, of the separating screen box; mounting positions for hinging and mounting a hopper are arranged on the rotating roller at equal intervals; the hopper comprises atleast one mixing hopper and at least one shoveling hopper; and a plurality of open slots are formed in a hopper body of the mixing hopper and are used for spreading gravel in the coarse screen, and awaist-shaped hole is formed in the hopper; and the gravel sorting device has the beneficial effects that due to the arrangement of the rotating roller, the mixing hopper and the shoveling hopper on the rotating roller, gravel can be effectively spread to improve the screening effect, meanwhile, screened gravel can be automatically output outwards, manual interference is basically not needed in thewhole process, and automatic screening, feeding, discharging, unloading and the like of the gravel can be achieved.

Owner:许光福

A chemical fertilizer granule grading equipment

ActiveCN112058617BRealize hierarchical screeningSievingScreeningAgricultural engineeringStructural engineering

Owner:住商肥料(青岛)有限公司

A construction waste screening device

ActiveCN109569897BRealize hierarchical screeningAdd creep modeRotary centrifugesBrickArchitectural engineering

Owner:江苏营特泰克智能环保设备有限公司

Sand screening device for civil engineering

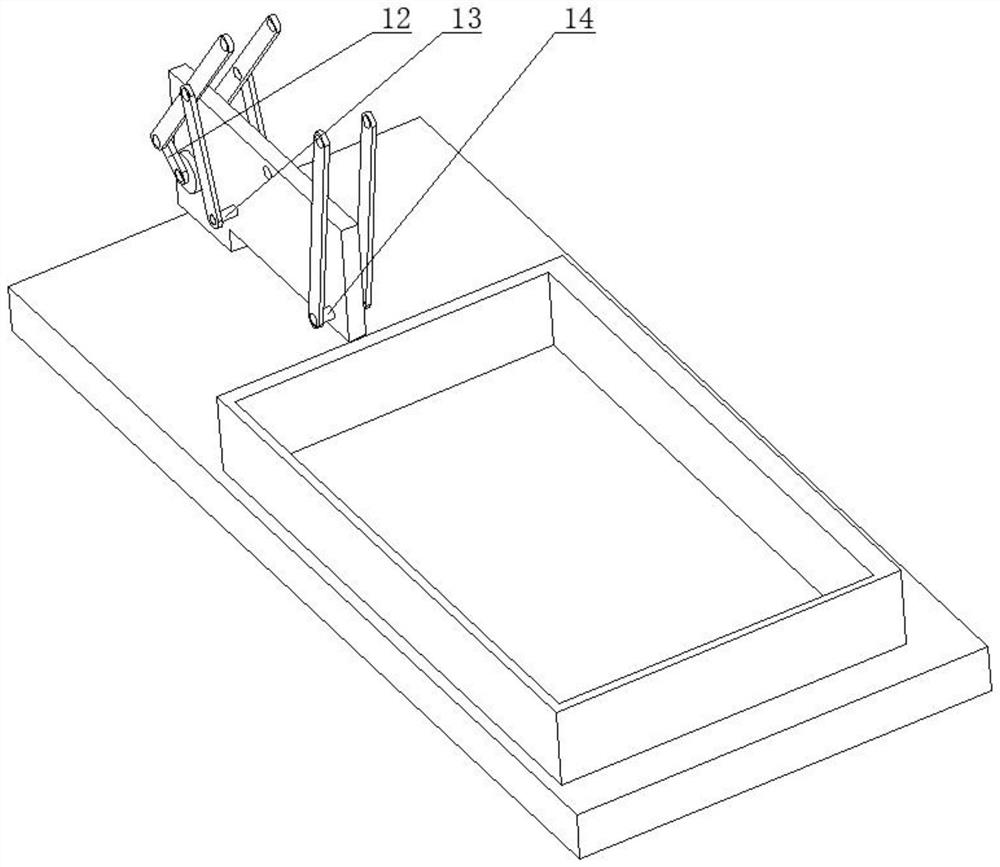

ActiveCN114178169AAchieve swingRealize hierarchical screeningSievingScreeningArchitectural engineeringMechanical engineering

The civil engineering gravel screening device comprises a bottom plate and is characterized in that the bottom plate is fixedly connected with a first box, the bottom plate is fixedly connected with an L-shaped plate, the L-shaped plate is fixedly connected with a first circular shaft, the L-shaped plate is fixedly connected with a second circular shaft, the L-shaped plate is fixedly connected with a swing mechanism, and the swing mechanism is fixedly connected with a screening mechanism. The invention relates to the field of screening equipment, in particular to a civil engineering gravel screening device. The technical problem to be solved by the invention is to provide the civil engineering sand and stone screening device which is convenient for civil engineering sand and stone screening.

Owner:HEBEI UNIV OF ENVIRONMENTAL ENG

Waste collecting device for automobile part machining

ActiveCN113231299AImprove magnetismHigh vibration frequencySievingScreeningMotor vehicle partWaste material

The invention belongs to the technical field of automobile part machining, and discloses a waste collecting device for automobile part machining. The waste collecting device comprises a body, bases are fixedly installed at the four corners of the bottom of the body, a collecting opening is fixedly formed in the right side of the top of the body, and a vibrator is fixedly installed at the top of the right side of the body. A waste groove penetrating into the body is formed in the bottom of the right side of the body, a first screen plate, a second screen plate and a third screen plate are sequentially installed on the right side of an inner cavity of the body from top to bottom, and a plurality of through grooves are symmetrically formed in the front side and the rear side of the body. The bottoms of the four bases are fixedly connected with universal wheels through damping devices. A rotationally connected inclined plate is arranged in the collecting opening. The screening efficiency of screen cloth is improved, the screen cloth is prevented from being blocked, classified screening is achieved, waste of different sizes is treated in a distinguished mode, follow-up recycling is facilitated, the resource utilization rate is increased, and the practicability is improved.

Owner:义乌市择木工业产品设计有限公司

A Quantifiable Gravel Multi-stage Screening Device for Concrete

ActiveCN107694906BTo achieve quantitative additionRealize hierarchical screeningSievingScreeningScreening durationEngineering

Owner:HEFEI DONGKAI NEW BUILDING MATERIALS

Cereal quantitative screening device

PendingCN112934672ARealize hierarchical screeningAchieve dryingSievingScreeningAgricultural engineeringElectrical and Electronics engineering

The invention provides a cereal quantitative screening device which comprises a feeding groove, multiple screening cylinders, a first collecting cylinder, a second collecting cylinder and a third collecting cylinder. Multiple feeding holes are formed in the bottom end of the feeding groove, and a quantitative feeding assembly for quantitatively feeding materials into the feeding holes is mounted at the bottom end of the multiple feeding groove. The multiple screening cylinders are vertically arranged below the feeding groove, the top ends of the screening cylinders are connected with the bottom of the feeding groove, and the multiple screening cylinders communicate with the multiple feeding holes correspondingly. A first screen and a second screen which are arranged up and down are mounted in each screening cylinder. The first collecting cylinder is arranged below the feeding groove. The second collecting cylinder is arranged below the first collecting cylinder. The third collecting cylinder is arranged below the second collecting cylinder. According to the cereal quantitative screening device, graded screening of cereal can be achieved by arranging the screening cylinders, the first screens and the second screens, and collection of cereal of different grades can be achieved by arranging the first collecting cylinder, the second collecting cylinder and the third collecting cylinder.

Owner:全椒县汊河农机服务专业合作社

Tea fresh leaf sorting equipment

InactiveCN109013329AImprove screening efficiencySimple structureSievingGas current separationEngineeringBud

The invention discloses tea fresh leaf sorting equipment. The tea fresh leaf sorting equipment comprises a machine body; a feed hopper is arranged at the top of the machine body; a flow separation netand a dust removing bag are arranged on the left side of the feed hopper; an air blower is arranged on the right side of the feed hopper; a vibration screen and a cooperative guide plate are arrangedunder the air blower; an impurity discharge port is aslant arranged under the guide plate; a cooperative one-bud and one-leaf sorting mechanism is arranged under the guide plate; a cooperative one-bud and two-leaf sorting mechanism is arranged under the one-bud and one-leaf sorting mechanism; and cooperative storage cylinders are arranged under the one-bud and one-leaf sorting mechanism and the one-bud and two-leaf sorting mechanism. The tea fresh leaf sorting equipment is simple in structure and convenient to use, realizes classified sorting of one-bud one-leaf and one-bud two-leaf of tea fresh leaves, improves the sorting efficiency of the tea fresh leaves, reduces the economical cost, is suitable for popularization and application, and meets actual application requirements.

Owner:XINYANG NORMAL UNIVERSITY

Dispersing and grinding device for paint production

PendingCN112844793AEvenly dispersedImprove grinding uniformityGrain treatmentsMaterials scienceGrinding

The invention relates to a dispersing and grinding device for paint production, which comprises: a grinding channel, the grinding channel is vertically or obliquely arranged, and the upper and lower ports of the grinding channel are respectively provided with a feed port and a discharge port; a first grinding roller and at least one second grinding roller are sequentially arranged in the grinding channel from top to bottom, and a vibrating screen is respectively arranged directly below the first grinding roller and the second grinding roller; and air nozzles are symmetrically arranged above the vibrating screen, and the air nozzles are connected with a fan and used for providing forward and reverse blowing air to the position above the vibrating screen. Uniform grinding of a paint filler can be achieved, and the problem that in the prior art, grinding is not uniform is solved.

Owner:宁夏嘉铂睿环保科技集团有限公司

Chemical material screening device facilitating rapid separation and impurity removal

ActiveCN113058845ARealize impurity removalRealize hierarchical screeningSievingScreeningEngineeringMechanical engineering

The invention discloses a chemical material screening device facilitating rapid separation and impurity removal in the technical field of chemical material screening. The chemical material screening device comprises a screening box and a feeding hopper, the interior of the screening box is connected with a screening assembly through rotating shafts, and the outer side end of one rotating shaft extends out of the screening box and is connected with a rotating mechanism; the rotating mechanism comprises a swinging assembly and a moving assembly, the swinging assembly drives a first screen and a second screen to swing back and forth in a small range to screen materials, and impurity removal and graded screening are achieved at the same time under the action of the first screen and the second screen; the swinging assembly is adjusted to the left side section of a connecting groove through the moving assembly, the rotation amplitude of a follow-up rotating rod is increased, and then the left side ends of the first screen and the second screen can rotate to groove openings of a first discharging groove and a second discharging groove correspondingly, and therefore, impurities and materials accumulated on the first screen and the second screen can be discharged and collected respectively.

Owner:BINZHOU POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com