Roller type fresh leaf screening machine for making tea

A technology of trommel screen and screening machine, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of poor fluidity, poor effect, fresh leaf classification, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

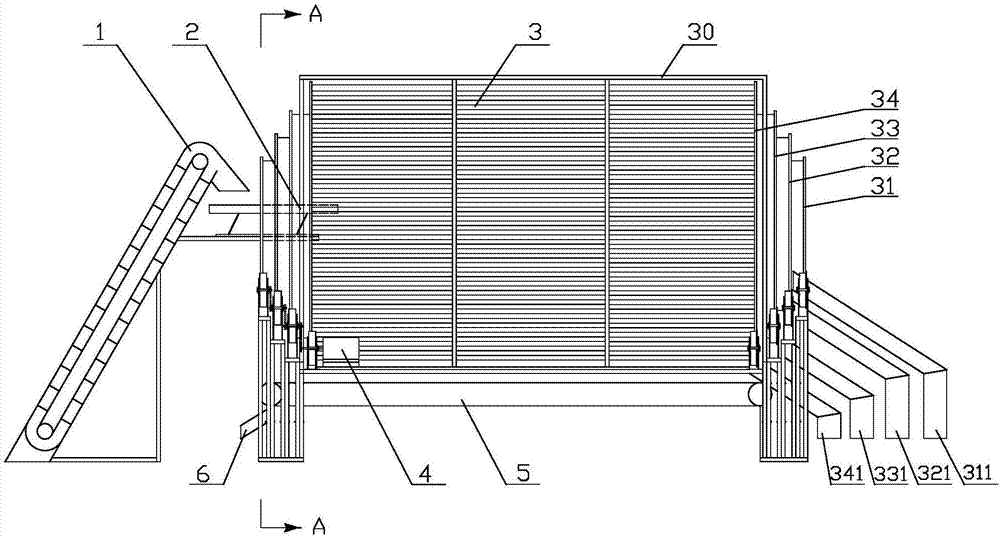

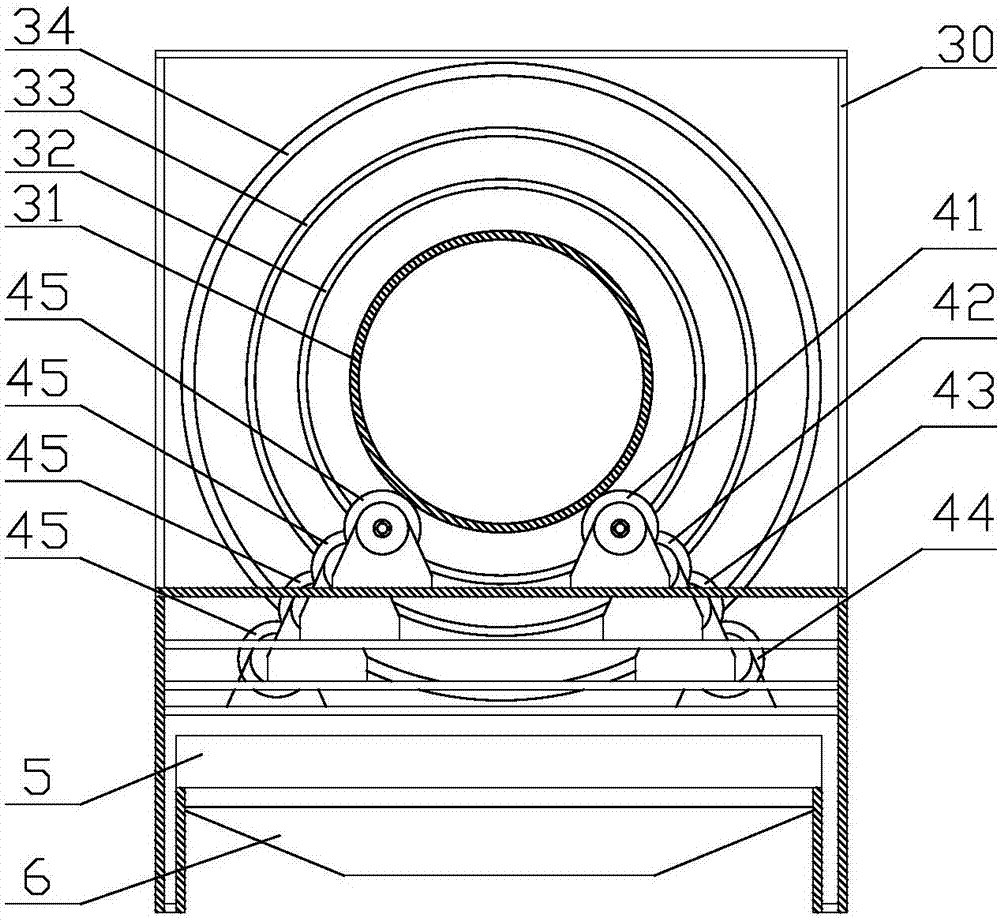

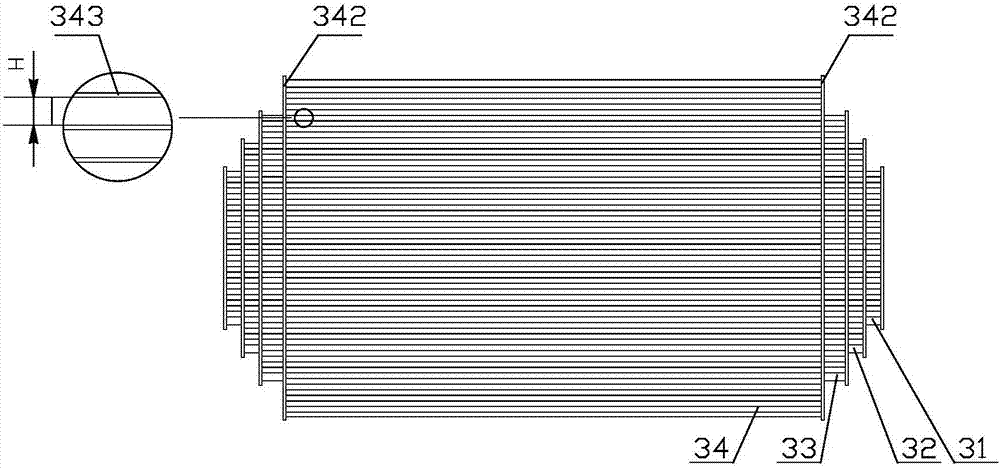

[0031] see Figure 1 ~ Figure 2 , a drum type fresh leaf screening machine for tea making, comprising a hoist 1, a vibrating feeder 2, a combined drum screen 3 and a driving mechanism 4. The combined trommel 3 is provided with a frame 30 and four trommels, and the four trommels are cylindrical structures with different diameters and lengths. The outer length decreases one by one, and the diameter increases one by one. The innermost layer is the first trommel 31 with the longest length and the smallest diameter, and the second trommel 32, the third trommel 33 and the fourth trommel 34 are arranged outward in turn. The mesh sizes of the four sieves are different, the mesh size of the first drum sieve 31 is the largest, and decreases layer by layer toward the outer layer, and the mesh size of the fourth drum screen 34 is the smallest. The frame 30 is provided with a driving mechanism 4 with a driving wheel and a supporting wheel, and the driving mechanism 4 is provided with a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com