Method for controlling reactive voltages of transformer substation based on magnetic control reactor (MCR)

A voltage control method and substation technology, applied in reactive power compensation, AC network voltage adjustment, reactive power adjustment/elimination/compensation, etc., can solve problems such as voltage instability, switching oscillation, frequent action, etc. The effect of small wave, low voltage level and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

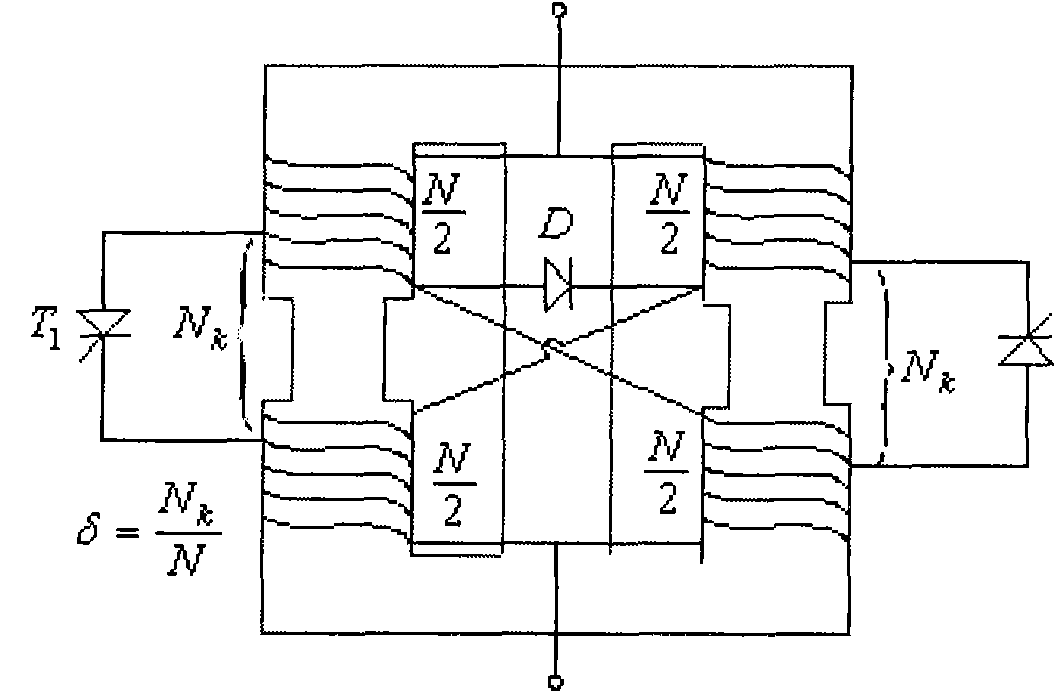

[0038] In the present invention, the MCR body is an iron-core transformer, and the coil wiring principle of the auto-excited MCR is as follows: figure 1 As shown, the number of turns symmetrically wound on the side columns of the reactor is Of the two coils, the windings of each leg have a tap ratio of The taps are connected between them with a thyristor T 1 , T 2 , the upper and lower main windings of different cores are cross-connected and connected in parallel to the power supply, and the power supply voltage is e=E m sin ωt. When the MCR winding is connected to the supply voltage, the thyristor T 1 , T 2 A voltage around 1% of the supply voltage is induced across the terminals. The positive half cycle of the power supply voltage triggers the conduction of the thyristor T 1 , where N 1 =N-N k , to generate a DC control current i′ in the loop k and i″ k ;Trigger conduction thyristor T in the negative half cycle of power supply voltage 2 , forming a DC control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com