Filtering device for neodymium iron boron waste recovery

A waste recycling and filtration device technology, applied in magnetic materials, transportation and packaging, classification, etc., can solve the problems of inability to sieve metal particles, do not have a hierarchical sieving structure, and cannot classify and filter rare earth waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

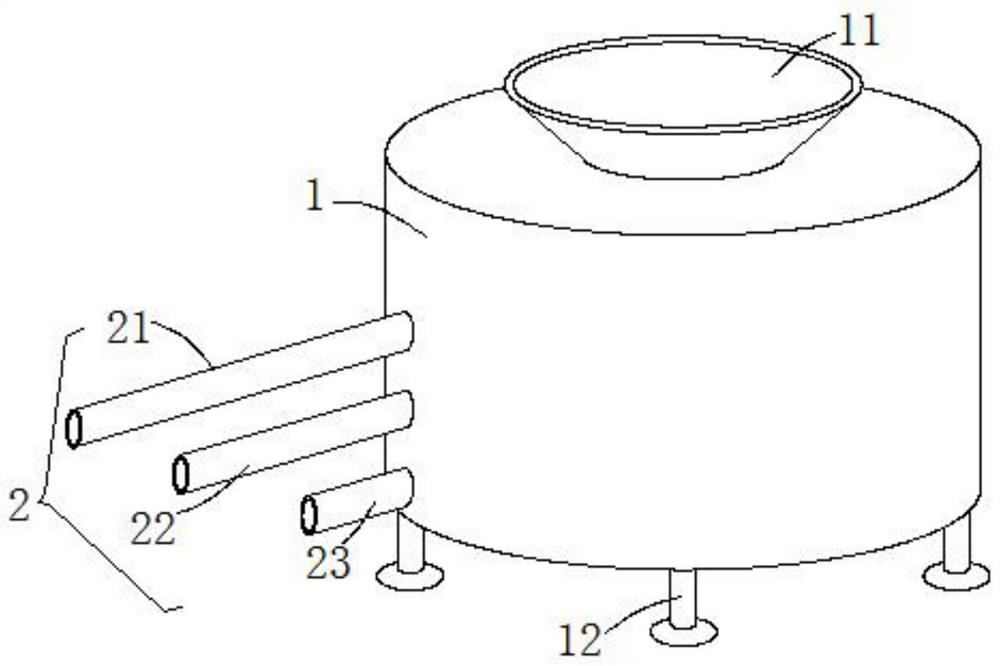

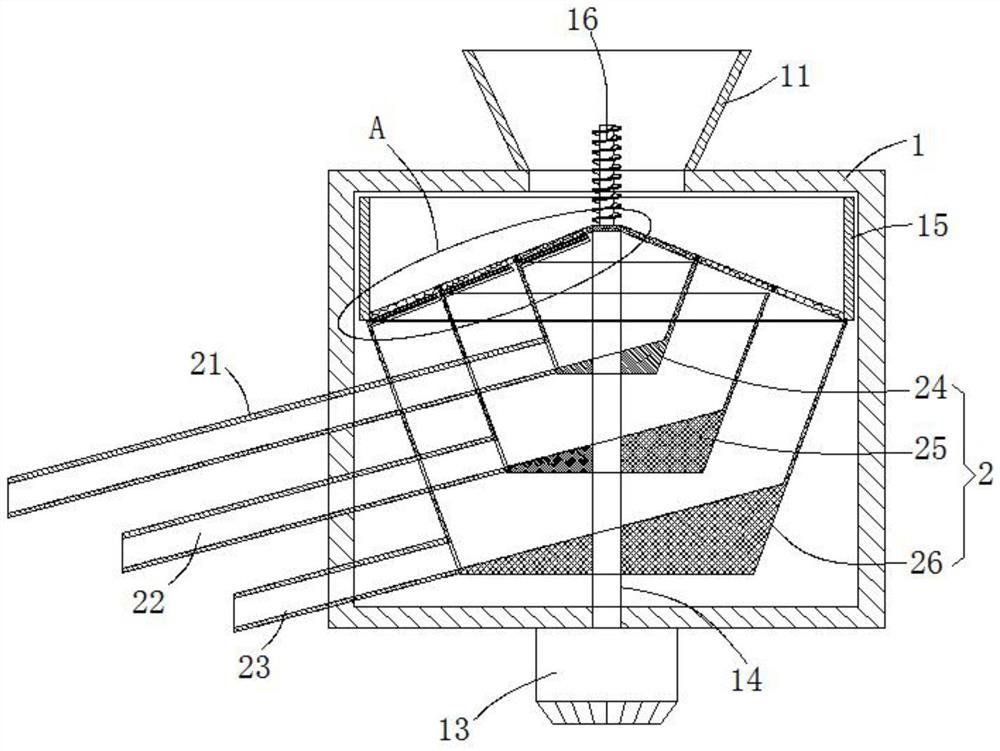

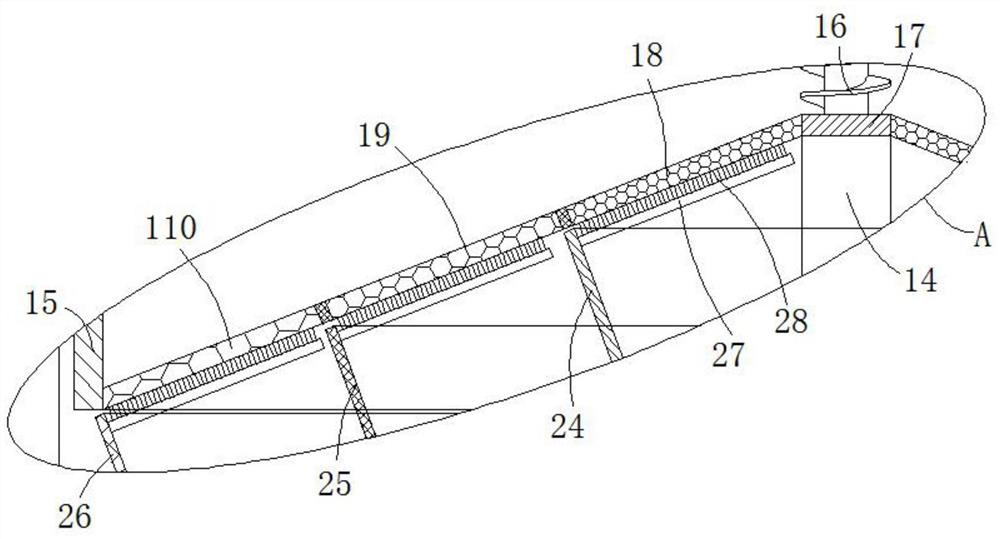

[0021] see Figure 1-3 , the present embodiment provides a filter device for recycling NdFeB waste, including a treatment cylinder 1 and a filter mechanism 2, the edge of the bottom surface of the treatment cylinder 1 is vertically provided with several support legs 12, which are supported by the support legs 12 The entire processing cylinder 1, the interior of the processing cylinder 1 is a hollow structure, and the top opening is provided with a wide-mouthed feeding hopper 11, through which waste materials can be put into the processing cylinder 1, so that the filtering mechanism 2 to carry out the filtering operation, the filtering mechanism 2 is arranged inside the processing cylinder 1, the filtering mode of the traditional rare earth waste recovery and filtering device is changed, and the filtering mechanism 2 is used to realize the graded screening structure, which can realize the graded filtration of the rare earth waste, and can remove the rare earth waste Metal parti...

Embodiment 2

[0029] see Figure 1-3 , further improvements have been made on the basis of Example 1:

[0030] In order to solve the problem of how to avoid the sieving holes of the first umbrella filter screen 18, the second umbrella filter screen 19 and the third umbrella filter screen 110 from being blocked, the primary receiving cylinder 24, the secondary receiving cylinder 25 and the The inner top opening of the three-stage receiving tube 26 is provided with an umbrella-shaped filter cover 17 sidewalls flush with each other for cleaning rods 27, and the side walls of the three cleaning rods 27 are provided for cleaning the first umbrella-shaped filter screen 18 respectively. , the cleaning brush 28 of the second umbrella-shaped filter screen 19 and the third umbrella-shaped filter screen 110, by setting the cleaning brush 28, when the umbrella-shaped filter cover 17 rotates with the transmission rod 14, the first umbrella-shaped filter screen can be made 18. The second umbrella-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com