A Quantifiable Gravel Multi-stage Screening Device for Concrete

A screening device and concrete technology, applied in the fields of screening, solid separation, chemical instruments and methods, etc., can solve the problems of high labor consumption and insufficient screening, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

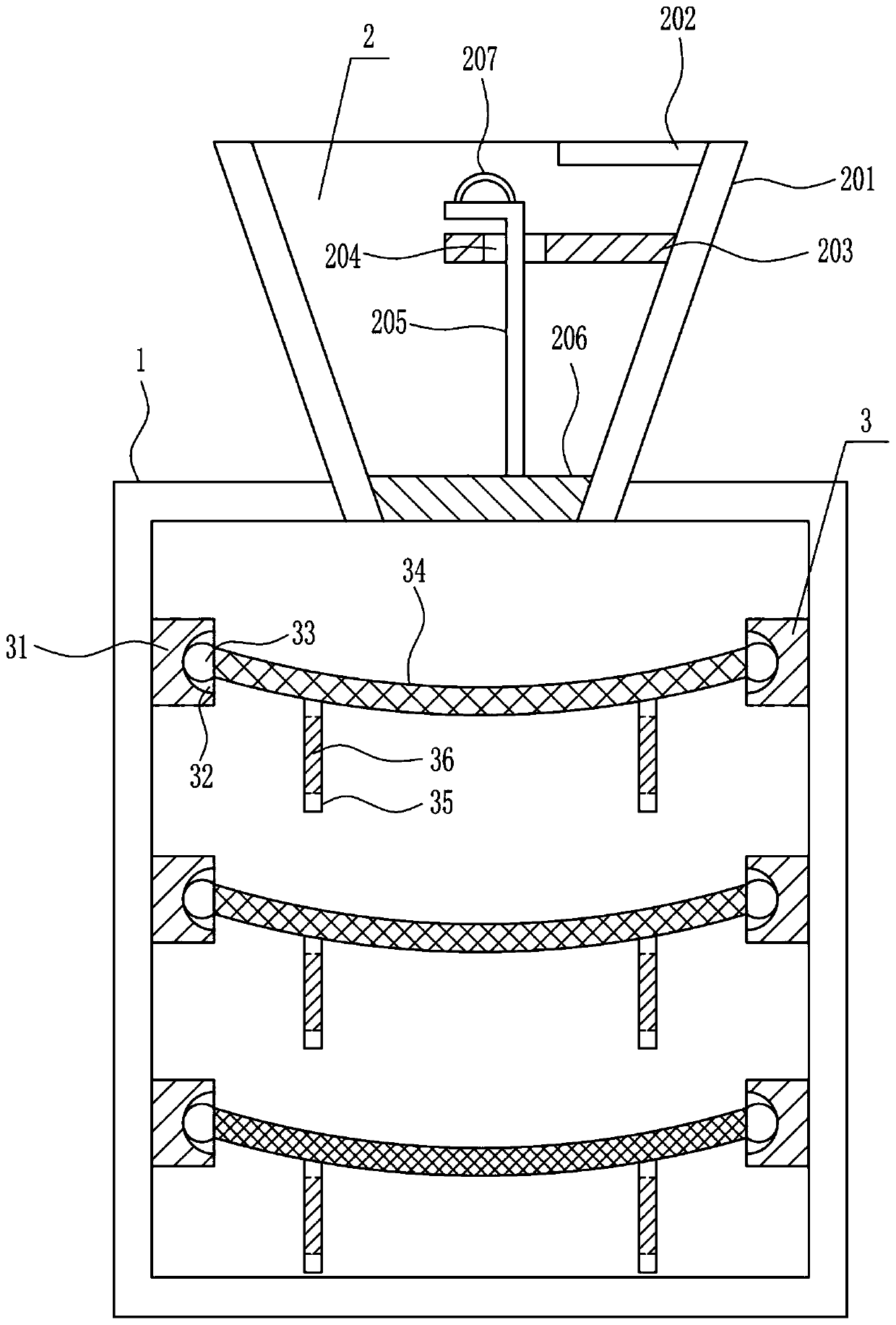

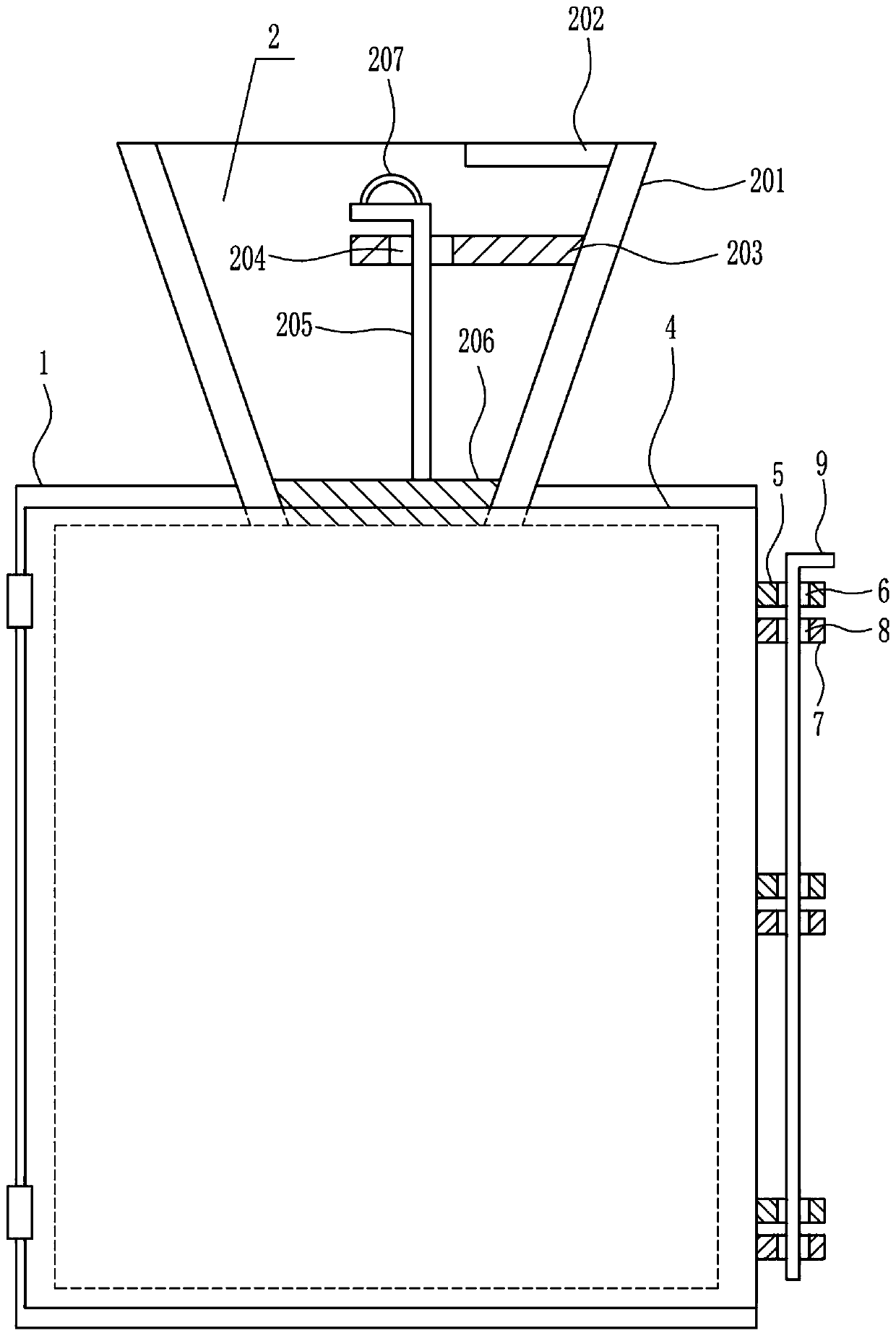

[0032] A quantitative gravel multi-stage screening device for concrete, such as Figure 1-5As shown, it includes a screening box 1 , a feeding mechanism 2 and a screening mechanism 3 , a feeding mechanism 2 is arranged on the upper part of the screening box 1 , and a screening mechanism 3 is evenly arranged in the screening box 1 .

Embodiment 2

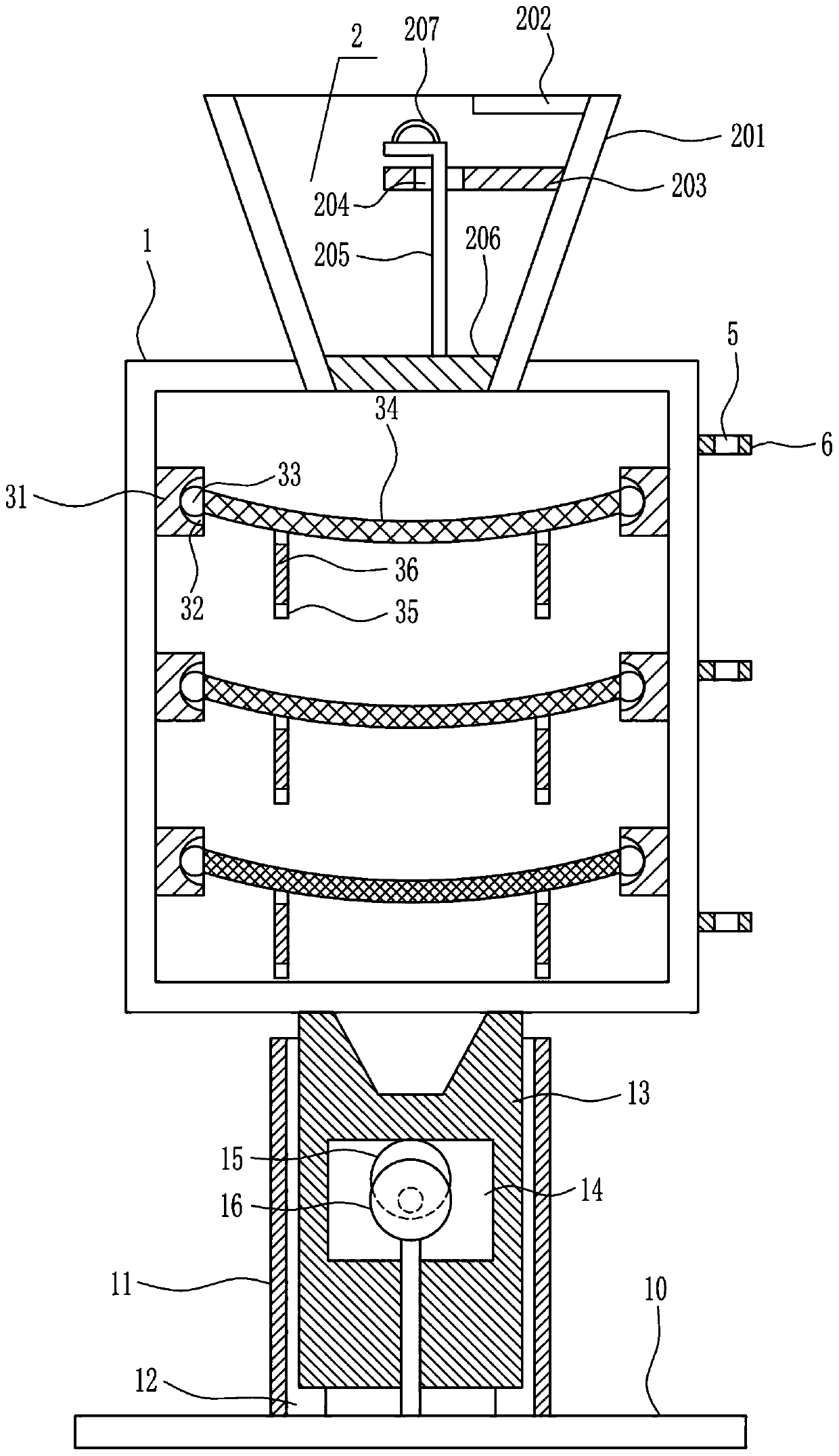

[0034] A quantitative grit multi-stage screening device for concrete, such as Figure 1-5 As shown, it includes a screening box 1 , a feeding mechanism 2 and a screening mechanism 3 , a feeding mechanism 2 is arranged on the upper part of the screening box 1 , and a screening mechanism 3 is evenly arranged in the screening box 1 .

[0035] The feeding mechanism 2 includes a feeding box 201, a blocking rod 202, a mounting plate 203, a pull rod 205, a clamping block 206 and a first handle 207. The top of the screening box 1 is connected to the feeding box 201, and the upper part of the inner right wall of the feeding box 201 is connected There is a blocking rod 202, a mounting plate 203 is connected to the middle of the inner right wall of the feeding box 201, a first through hole 204 is opened on the left side of the mounting plate 203, and a pulling rod 205 is arranged in the first through hole 204, and the pulling rod 205 cooperates with the blocking rod 202 The top of the pu...

Embodiment 3

[0037] A quantitative grit multi-stage screening device for concrete, such as Figure 1-5 As shown, it includes a screening box 1 , a feeding mechanism 2 and a screening mechanism 3 , a feeding mechanism 2 is arranged on the upper part of the screening box 1 , and a screening mechanism 3 is evenly arranged in the screening box 1 .

[0038] The feeding mechanism 2 includes a feeding box 201, a blocking rod 202, a mounting plate 203, a pull rod 205, a clamping block 206 and a first handle 207. The top of the screening box 1 is connected to the feeding box 201, and the upper part of the inner right wall of the feeding box 201 is connected There is a blocking rod 202, a mounting plate 203 is connected to the middle of the inner right wall of the feeding box 201, a first through hole 204 is opened on the left side of the mounting plate 203, and a pulling rod 205 is arranged in the first through hole 204, and the pulling rod 205 cooperates with the blocking rod 202 The top of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com