Nano carbon material compression pelletizing device for rubber and process method

A nano-carbon material, compression granulation technology, applied in the direction of die extrusion granulation, etc., can solve the problems of high cost and complicated operation, and achieve the effects of easy control, simple and stable process method, and good product stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

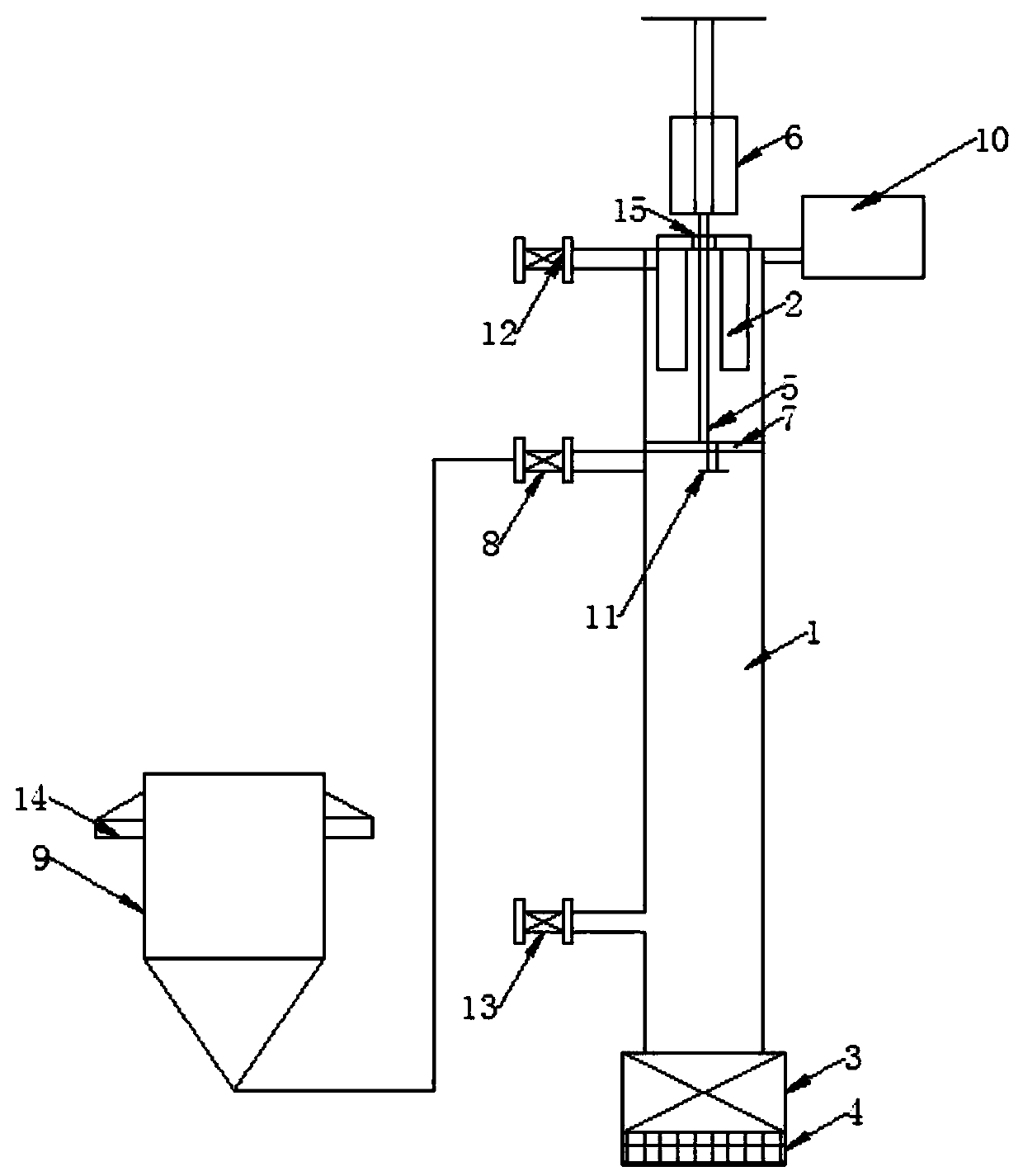

[0055] A nano-carbon material compression granulation device for rubber, the compression granulation device includes a compression chamber 1, a hydraulic device, a feed control device, a filter device 2, a vacuum pumping device, a back blowing device, a feeding device 3 and a granulation device 4;

[0056] The hydraulic device is located at the top of the compression chamber 1, and the hydraulic device includes a hydraulic rod 5 located in the compression chamber 1, the top of the hydraulic rod 5 is connected to the hydraulic device 6, and the bottom end of the hydraulic rod 5 is connected to the binder plate 7;

[0057] The feed control device is connected to the feed valve 8 arranged under the pressing plate 5 through the material pipeline, and the feed control device includes a weighing tank 9;

[0058] The filter device 2 is arranged above the pressing plate 7, and the filter device 2 includes a plurality of metal filter rods;

[0059] The vacuum pumping device includes a v...

Embodiment 2

[0064] On the basis of embodiment 1, the feed control device also includes a weighing module 14 arranged at the feed port of the weighing tank 9;

[0065] The circular hole diameter size of granulator 4 is 7mm;

[0066] The lower end of the through-hole pipe 11 is provided with a filter screen;

[0067] The backflushing device is a gas curtain or gas blowing port that uses inert gas for backflushing.

Embodiment 3

[0069] On the basis of Example 2, the feed valve 8 is a DN50 gate valve; the blowback valve A12 is a DN25 pulse valve, and the blowback valve B13 is a DN32 gate valve; the pressing plate 7 is a 20mm thick 304 plate; the hydraulic rod 5 is provided with a sealing plate Root 15; discharge gate valve is DN300 knife gate valve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com