Preparing method of potato pulp dough and continuous processing device of potato pulp dough

A potato and dough technology, applied in dough mixers, structural components of mixing/kneading machinery, mixing/kneading with vertical installation tools, etc., can solve the problems of difficult molding, difficult storage, lack of solutions, etc. Product cost, browning prevention, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

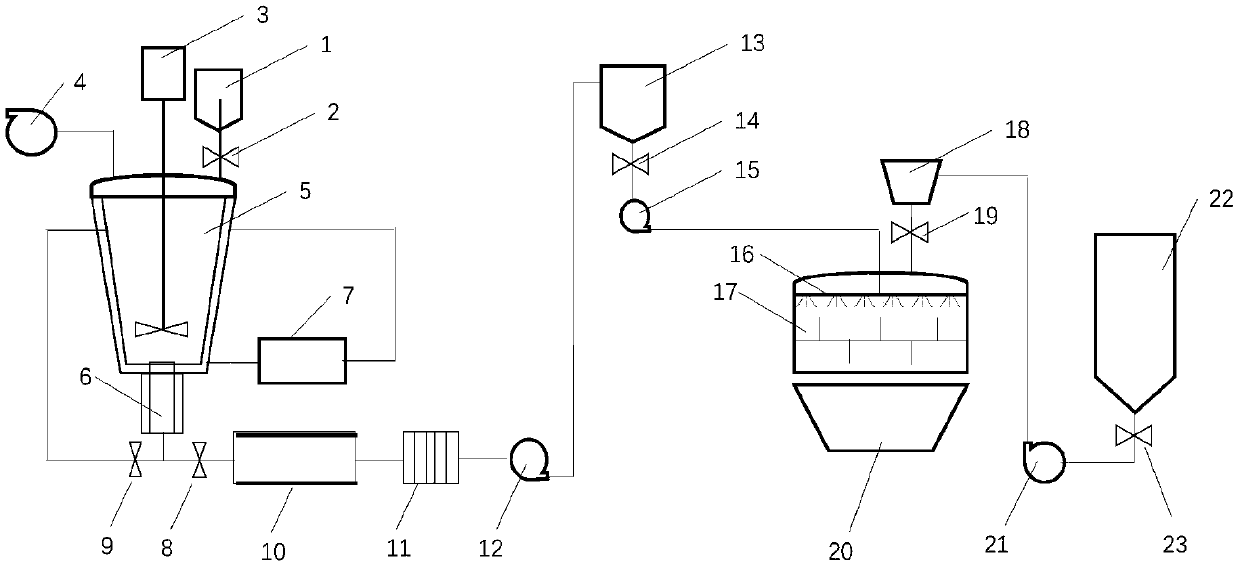

[0038] The present embodiment provides a kind of preparation method of continuous processing potato pulp dough, adopts figure 1 Described device is specifically:

[0039] 1) Dice the potatoes, enter the mixing tank 5 through the feeder 1, close the stop valve 2 and the stop valve 8, open the stop valve 9, start the vacuum pump 4, and make the vacuum degree of the tank not higher than -0.09MP; and Start the cooling device 7 to keep the tank temperature at 10°C;

[0040] 2) Turn on the pulverizing agitator 3 and the high-speed shear homogenizing device 6. The high-speed shearing speed is 5000 rpm so that the diced potatoes in the tank are cyclically sheared and pulverized until they can pass through a 70-mesh sieve to obtain potato pulp;

[0041] 3) Close the vacuum pump 4 and the shut-off valve 9, open the shut-off valve 8, the power-on high-temperature instant enzyme-killing device 10 and the rapid plate cooler 11; , heating the potato pulp to 105°C within 1min and maintaini...

Embodiment 2

[0045] The present embodiment provides a kind of preparation method of continuous processing potato pulp dough, adopts figure 1 Described device is specifically:

[0046] 1) Dice the potatoes, enter the mixing tank 5 through the feeder 1, close the stop valve 2 and the stop valve 8, open the stop valve 9, start the vacuum pump 4, and make the vacuum degree of the tank not higher than -0.09MP; and Start the cooling device 7 to keep the tank temperature at 5°C;

[0047] 2) Turn on the pulverizing agitator 3 and the high-speed shear homogenizing device 6. The high-speed shearing speed is 15000 rpm so that the diced potatoes in the tank are cyclically sheared and pulverized until they can pass through a 120-mesh sieve to obtain potato pulp;

[0048] 3) Close the vacuum pump 4 and the shut-off valve 9, open the shut-off valve 8, the power-on high-temperature instant enzyme-killing device 10 and the rapid plate cooler 11; , heating the potato slurry to 135°C within 0.5min and mainta...

Embodiment 3

[0052] The present embodiment provides a kind of preparation method of continuous processing potato pulp dough, adopts figure 1 Described device is specifically:

[0053] 1) Dice the potatoes, enter the mixing tank 5 through the feeder 1, close the stop valve 2 and the stop valve 8, open the stop valve 9, start the vacuum pump 4, and make the vacuum degree of the tank not higher than -0.09MP; and Start the cooling device 7 to keep the tank temperature at 10°C;

[0054] 2) Turn on the pulverizing agitator 3 and the high-speed shear homogenizing device 6. The high-speed shearing speed is 8000 rpm so that the diced potatoes in the tank are cyclically sheared and pulverized until they can pass through an 80-mesh sieve to obtain potato pulp;

[0055] 3) Close the vacuum pump 4 and the shut-off valve 9, open the shut-off valve 8, the power-on high-temperature instant enzyme-killing device 10 and the rapid plate cooler 11; , heating the potato slurry to 115°C within 0.8min and main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com