Catalyst addition device and addition method for preparation of o-tert-butylcyclohexanol

A technology of tert-butylcyclohexanol and adding device, which is applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve problems such as unified activation treatment, affecting the rate of material generation, affecting cleaning work, etc., to achieve the reaction Efficient process, ensure catalytic activity, and the effect of convenient addition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

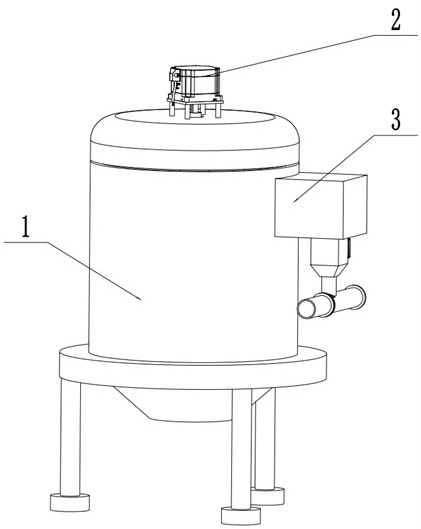

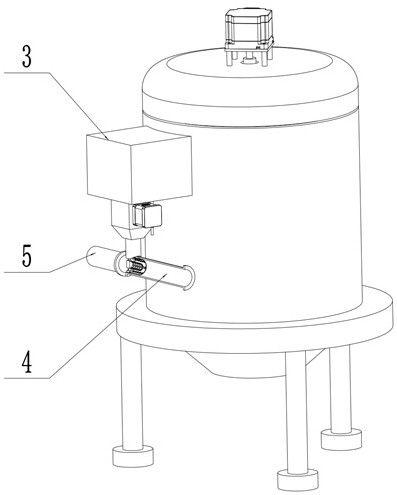

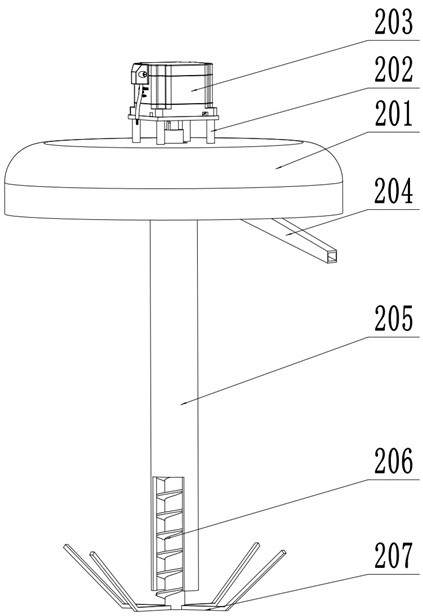

[0029] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 The catalyst adding device for the preparation of o-tert-butylcyclohexanol is shown, the storage bucket 1 is cylindrical made of stainless steel, the storage bucket 1 is used to load the solid catalyst, and the lower end of the feeding mechanism 2 is arranged inside the storage bucket 1 , the upper end of the feeding mechanism 2 and the upper end of the storage bucket 1 are installed through a detachable connection structure. When catalyst needs to be added to the storage bucket 1, the feeding mechanism 2 can be removed from the storage bucket 1; The function is to be able to transport the catalyst from the storage barrel 1 to the quantitative mechanism 3, and the quantitative mechanism 3 is arranged on the outer surface of the storage barrel 1. The function of the quantitative mechanism 3 is to be able to load a certain amount of catalyst. When the catalyst dose reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com