Patents

Literature

287results about How to "Fall fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and devices for desmopressin drug delivery

InactiveUS20090042970A1Reduce urine productionRestore normal urine productionBiocidePowder deliveryDecreased sodiumSide effect

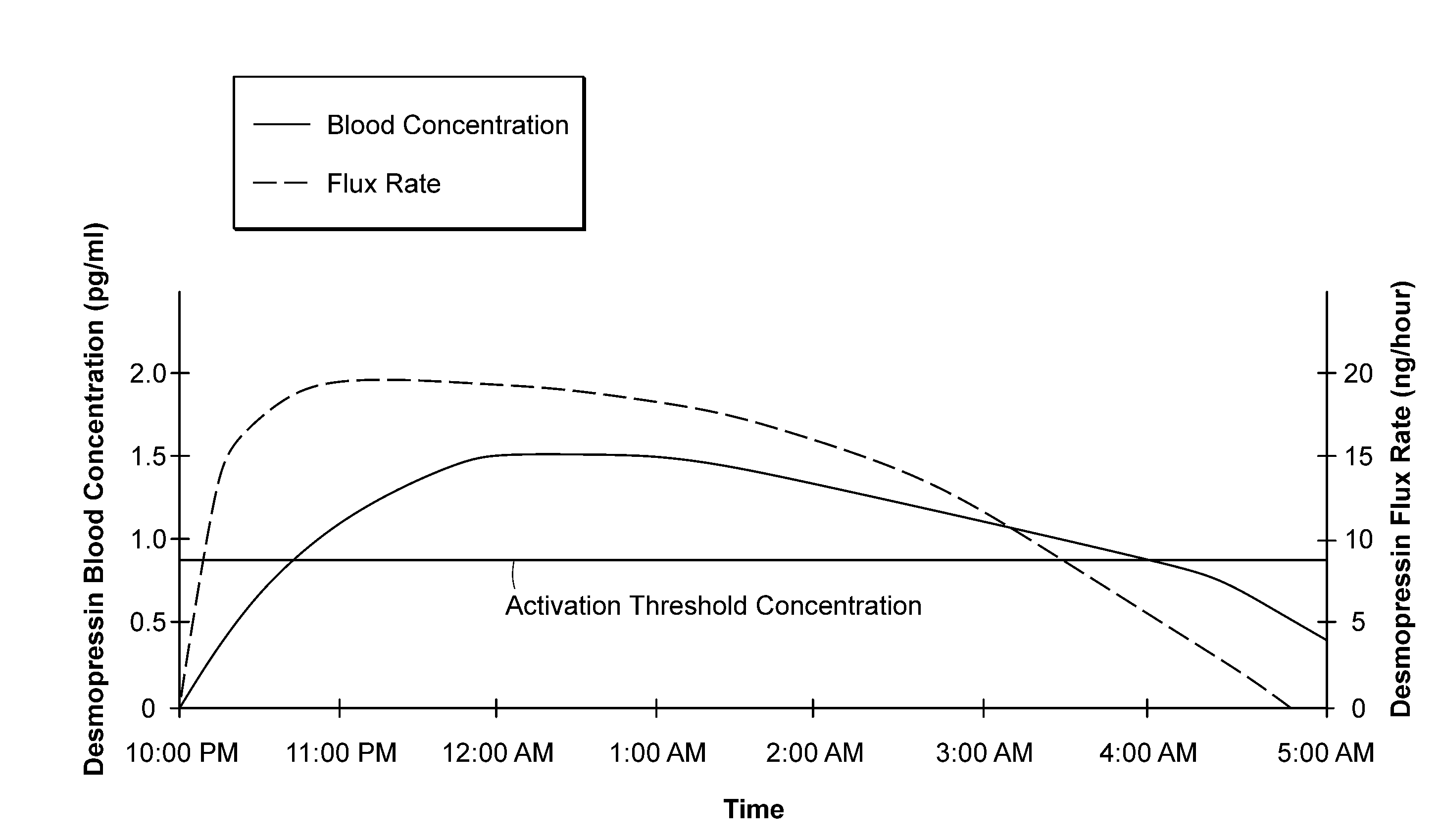

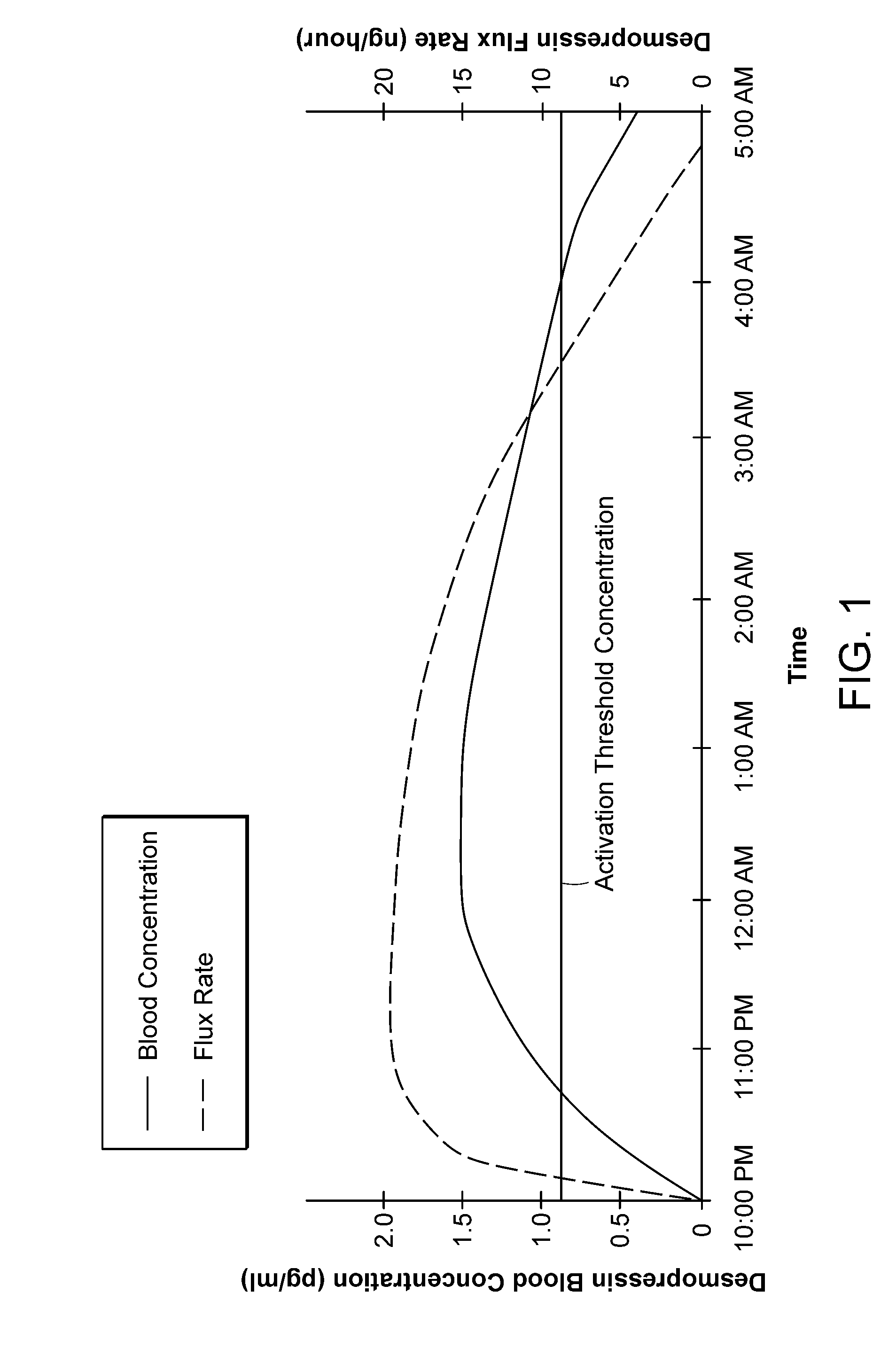

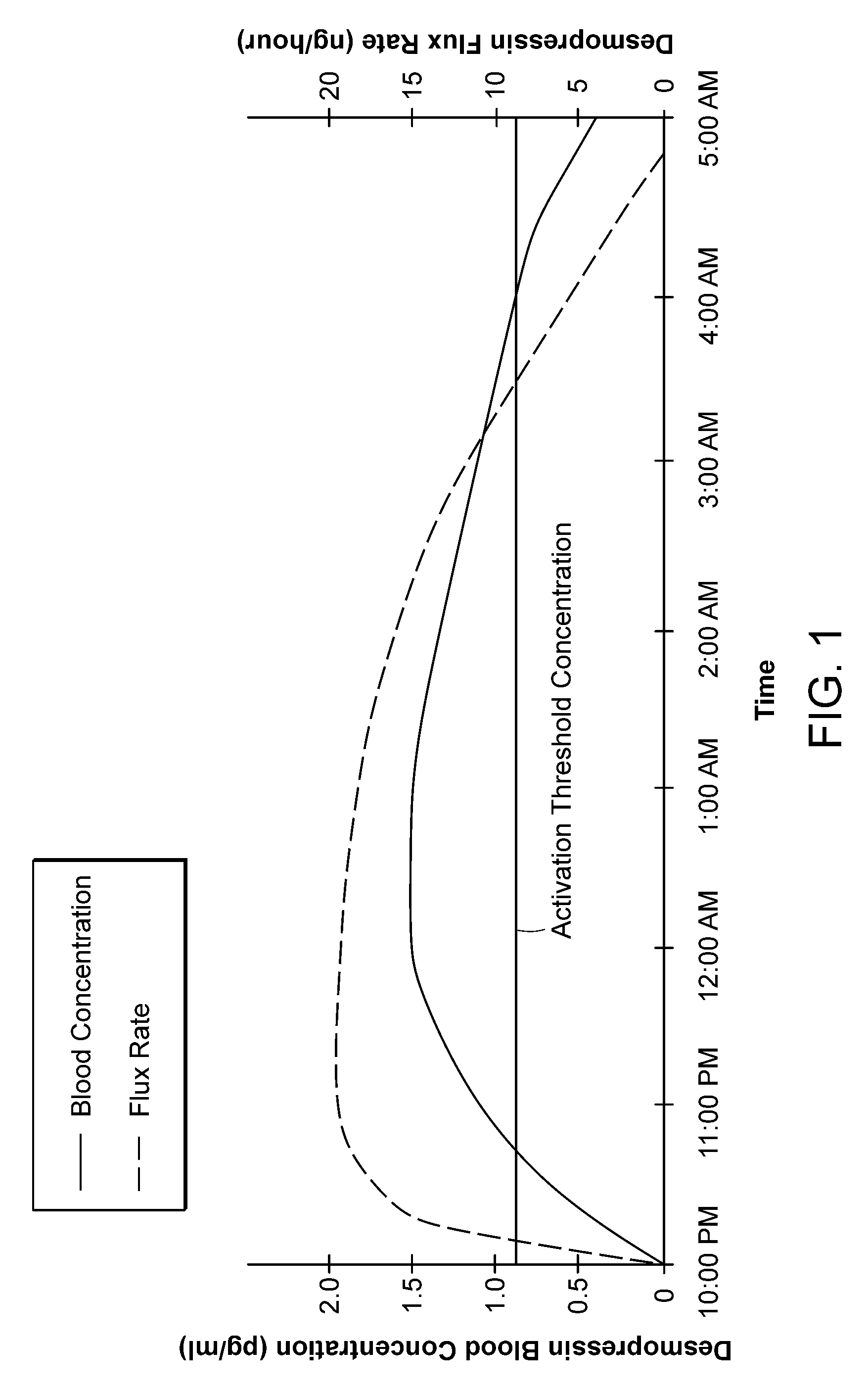

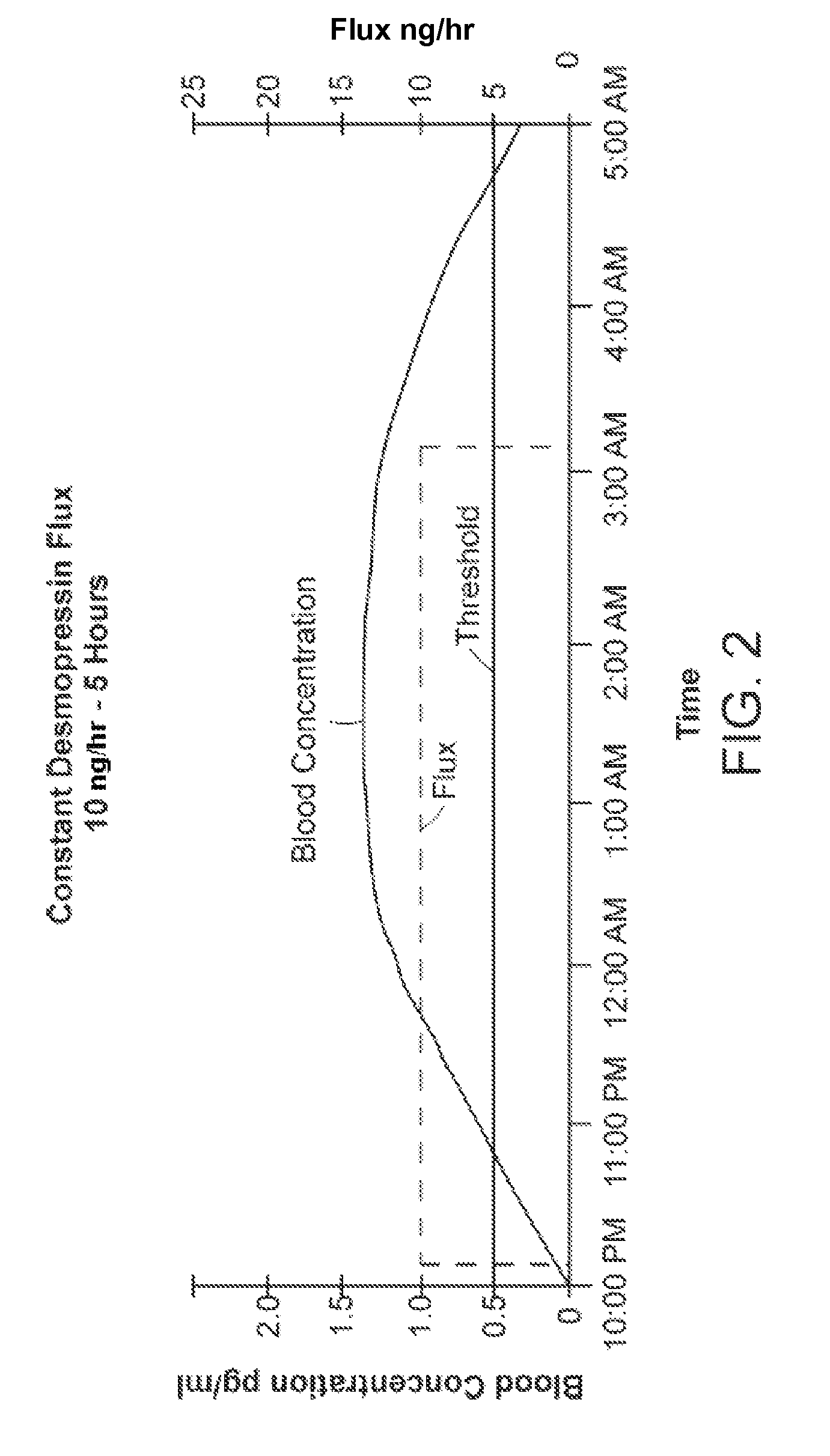

Disclosed are devices for urine voiding postponement, and methods for treating conditions such as central diabetes insipidus, enuresis, nocturia, urinary frequency or incontinence. The devices deliver a desmopressin flux through the skin of a patient in a low dose amount just necessary to achieve a desired anti-diuretic effect without undesirable side effects such as hyponatremia. The devices are designed to permit a state of normal urinary production to return quickly after the desmopressin flux is terminated.

Owner:SERENITY PHARMA CORP

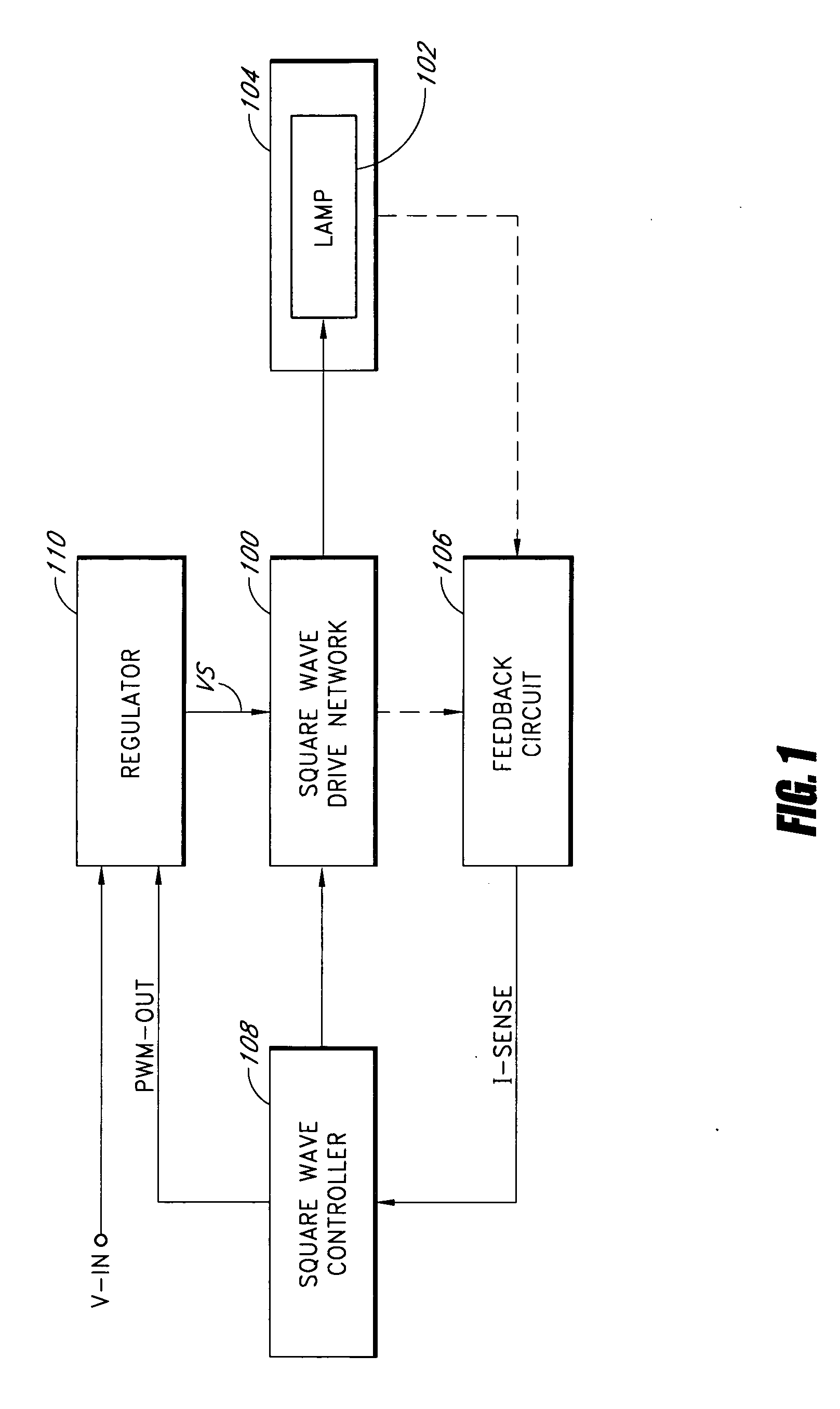

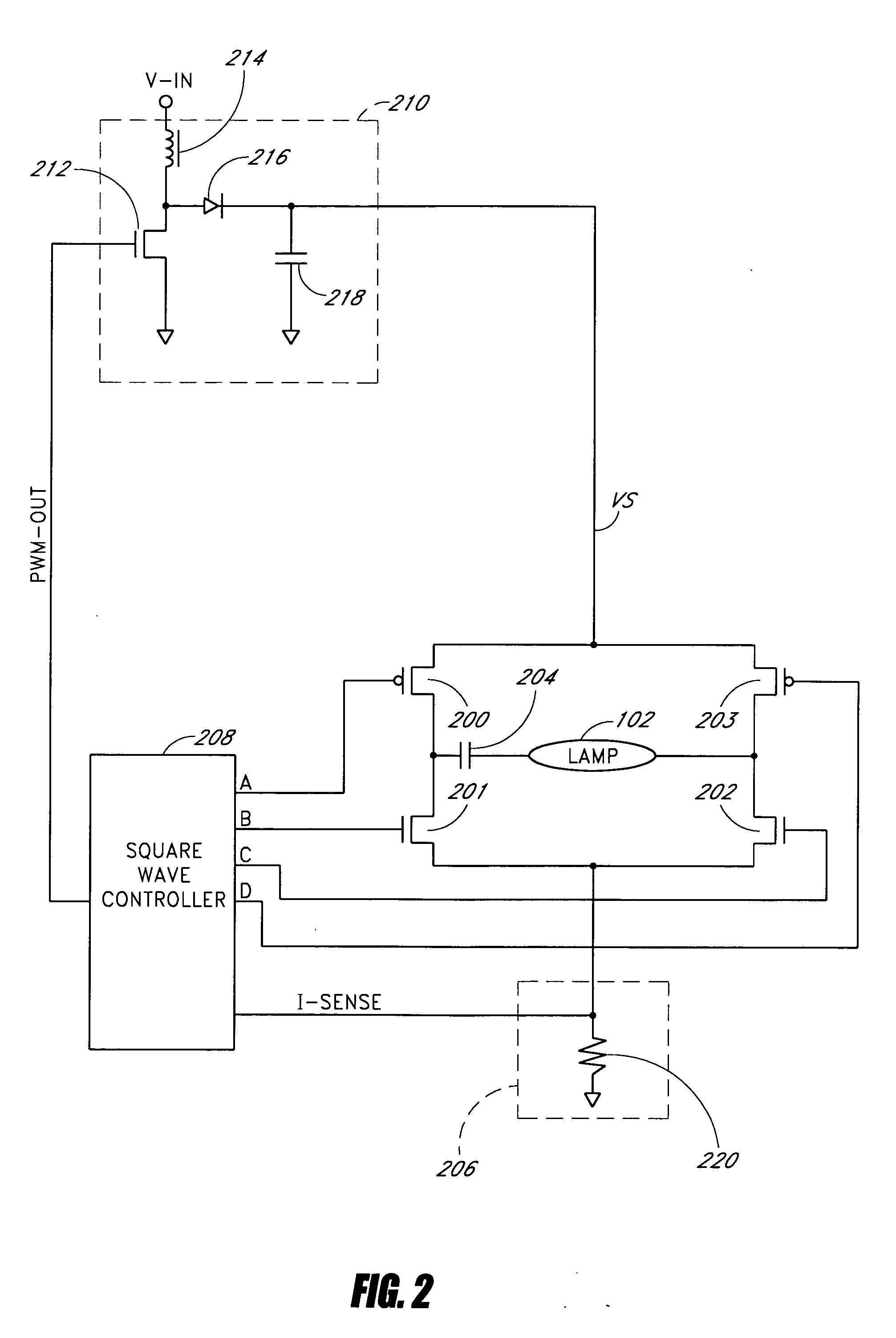

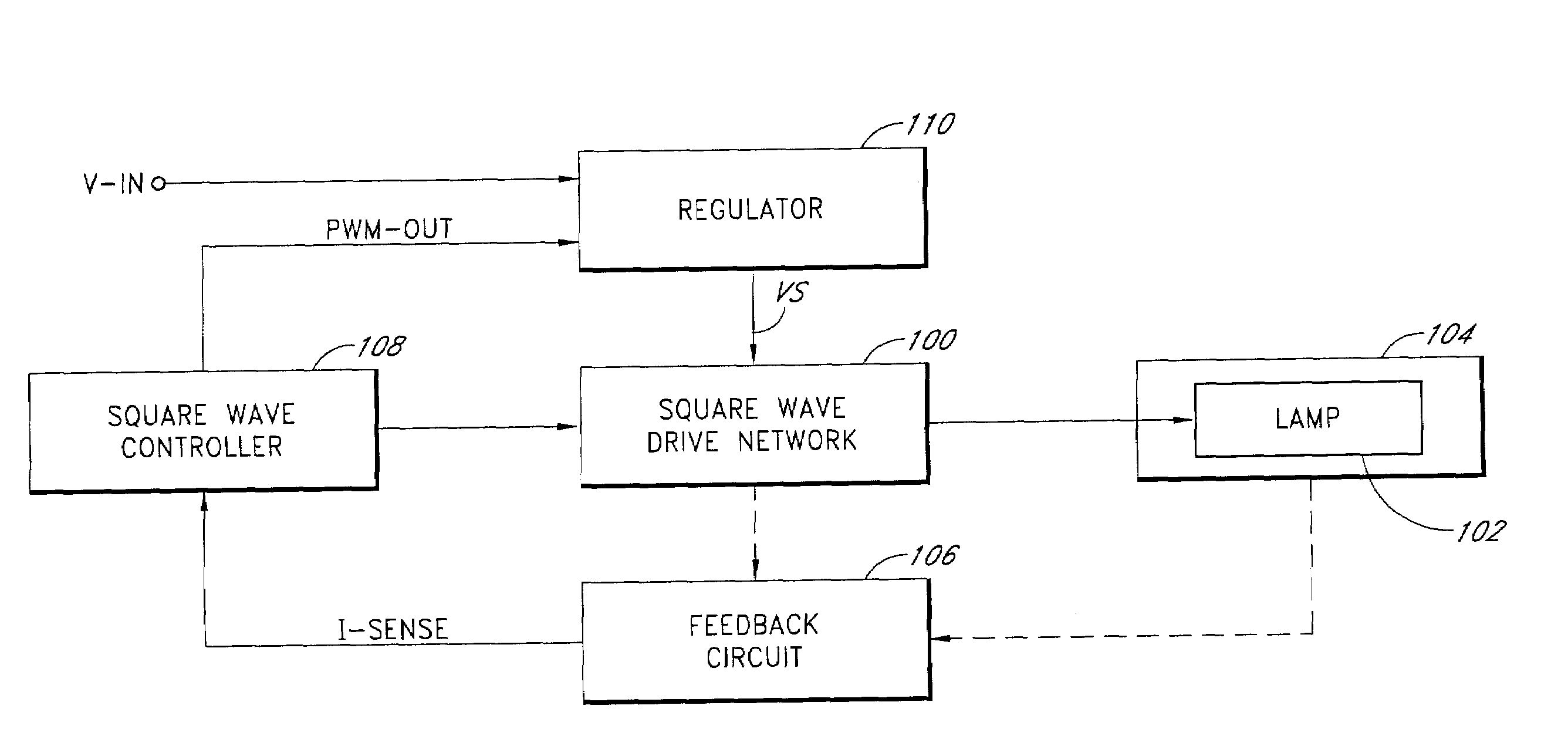

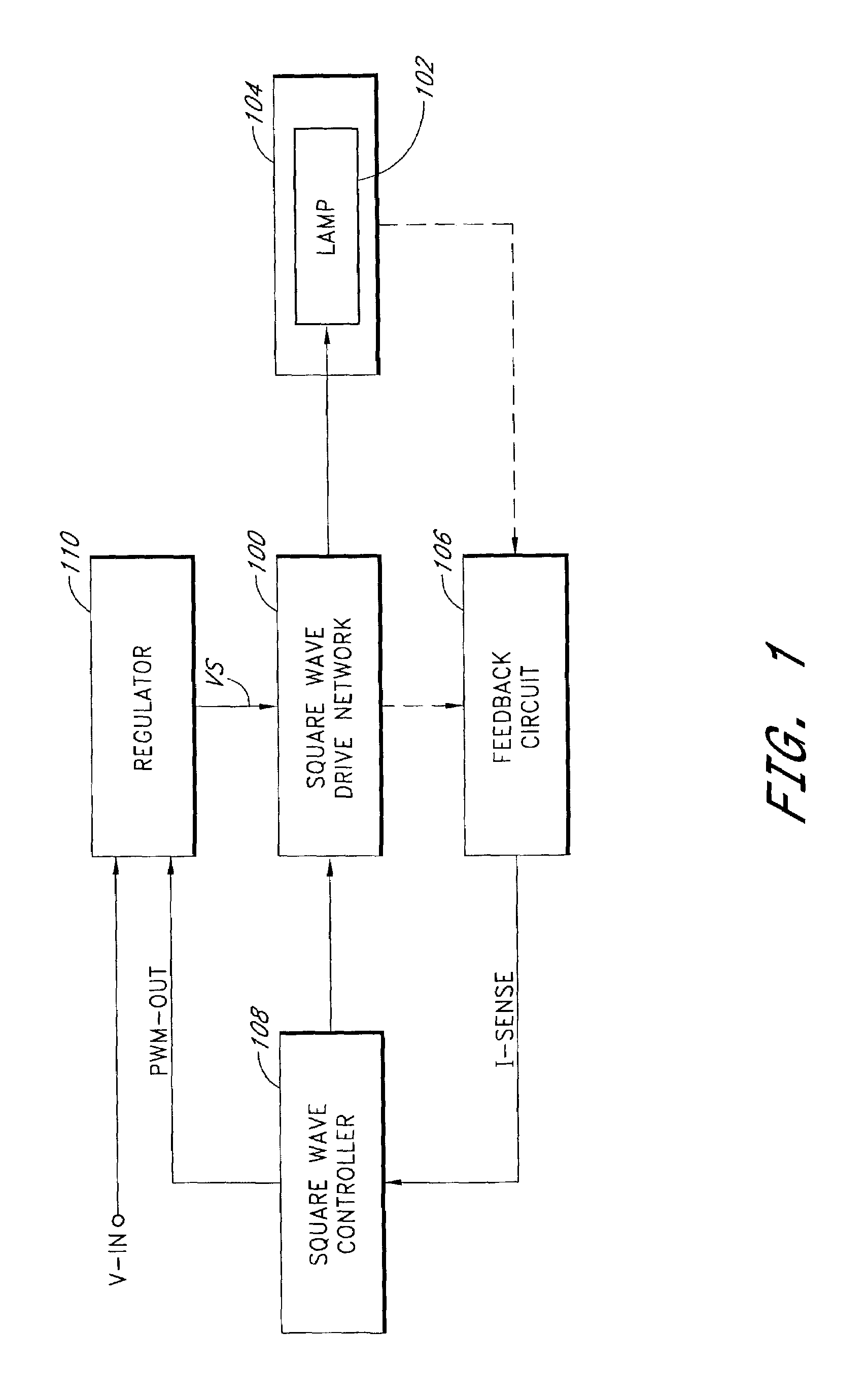

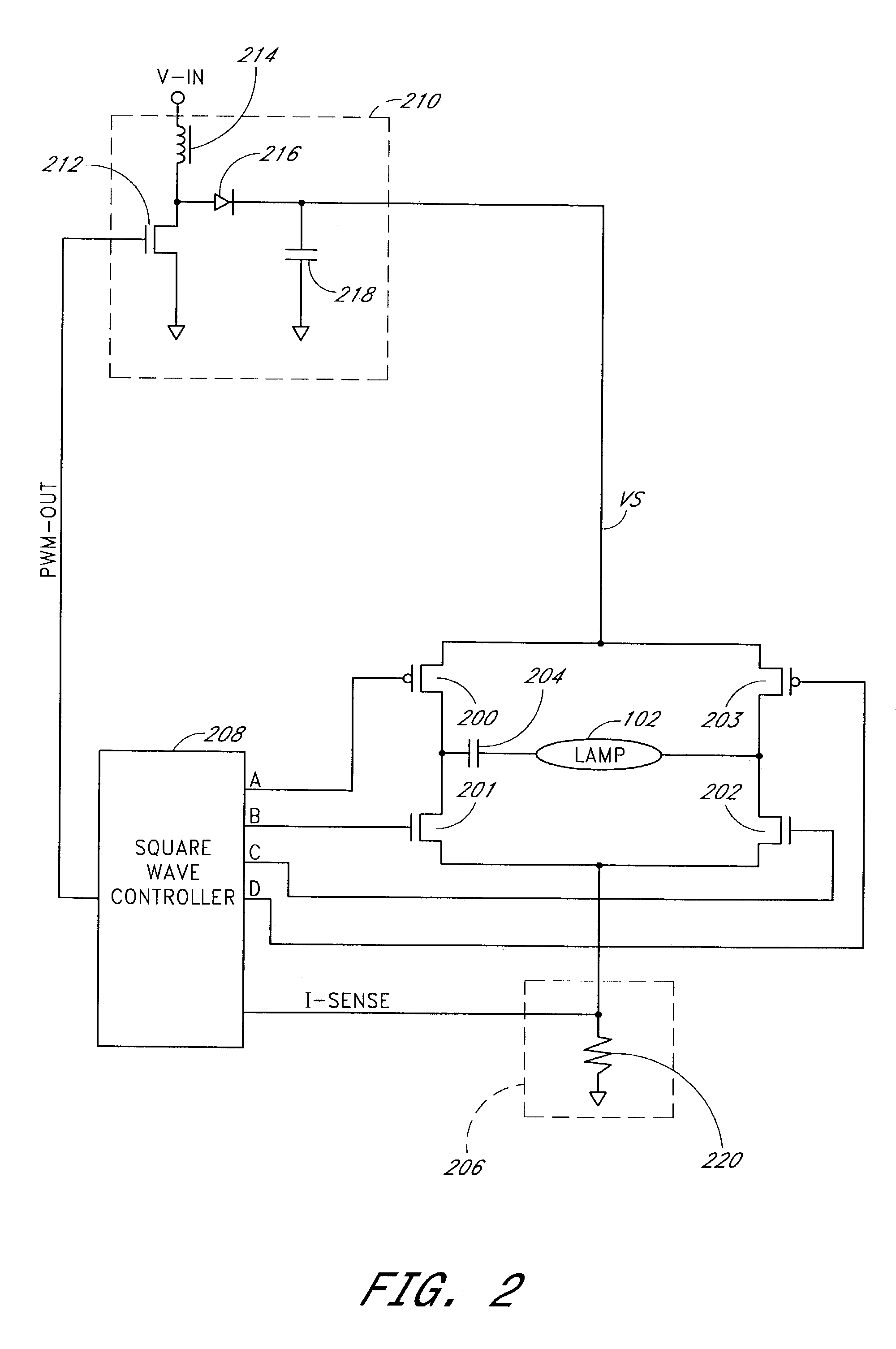

Square wave drive system

InactiveUS20060022612A1Improve efficiencyProlong lifeElectric light circuit arrangementElectric discharge lampsLamp currentPeak value

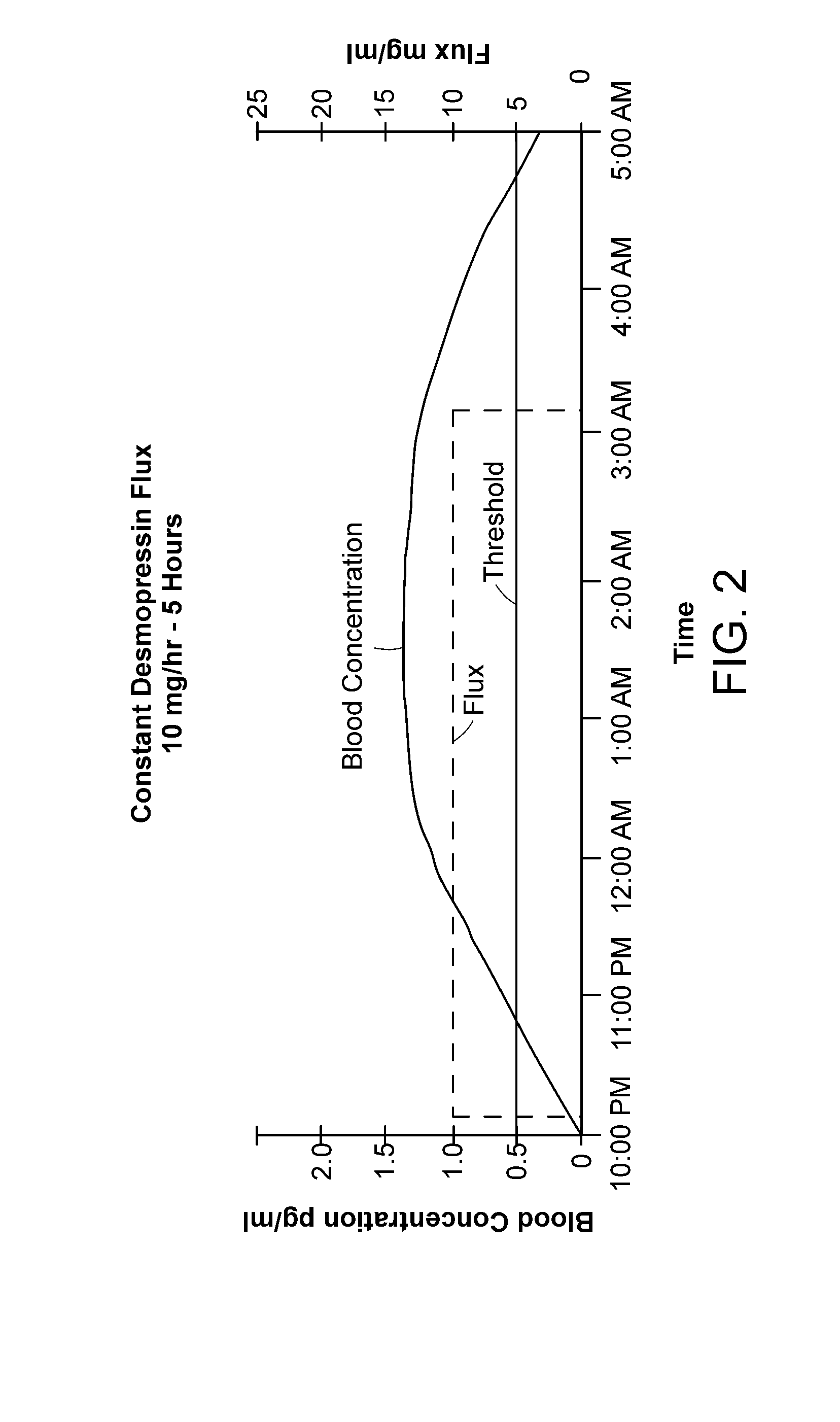

A power conversion circuit improves lamp operating life and lamp efficiency by driving a fluorescent lamp with a square wave signal. The square wave signal is an alternating current signal with relatively fast transition times. The square wave signal advantageously reduces lamp current crest factor for more efficient operation of the fluorescent lamp.

Owner:BANK OF AMERICA NAT TRUST & SAVINGS ASSOC

Square wave drive system

InactiveUS6969958B2Improve efficiencyProlong lifeElectric light circuit arrangementElectric discharge lampsEngineeringLamp current

A power conversion circuit improves lamp operating life and lamp efficiency by driving a fluorescent lamp with a square wave signal. The square wave signal is an alternating current signal with relatively fast transition times. The square wave signal advantageously reduces lamp current crest factor for more efficient operation of the fluorescent lamp.

Owner:MICROSEMI

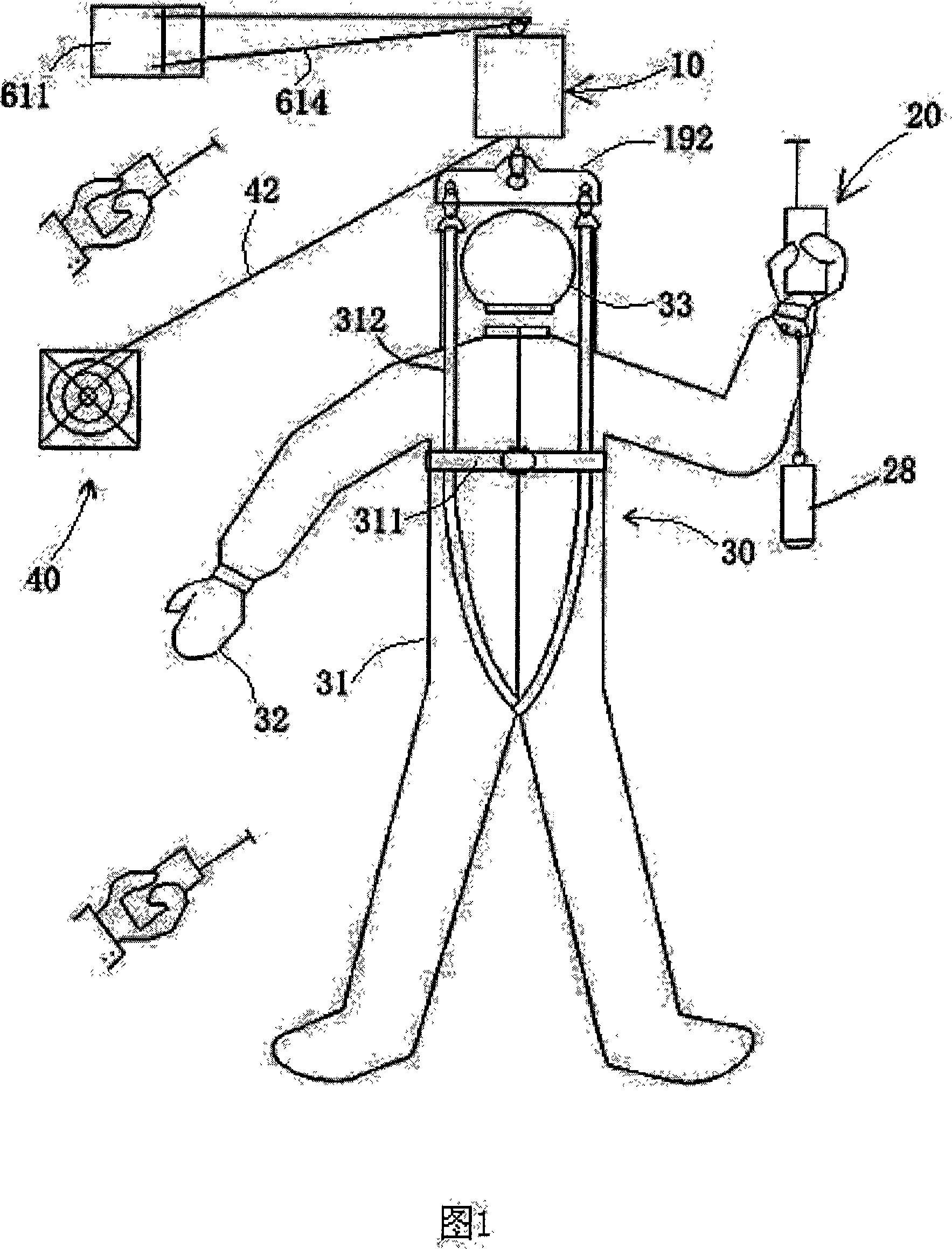

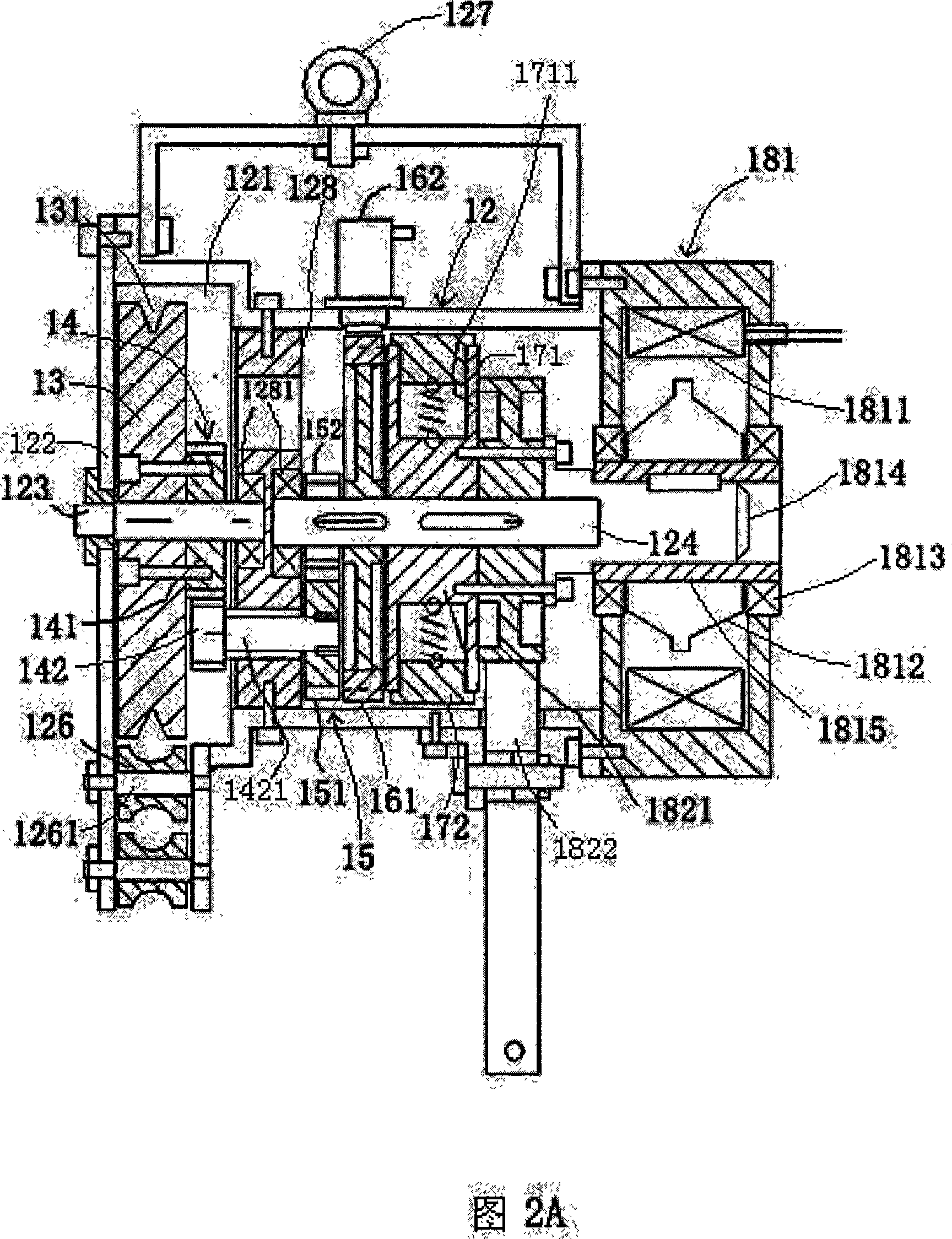

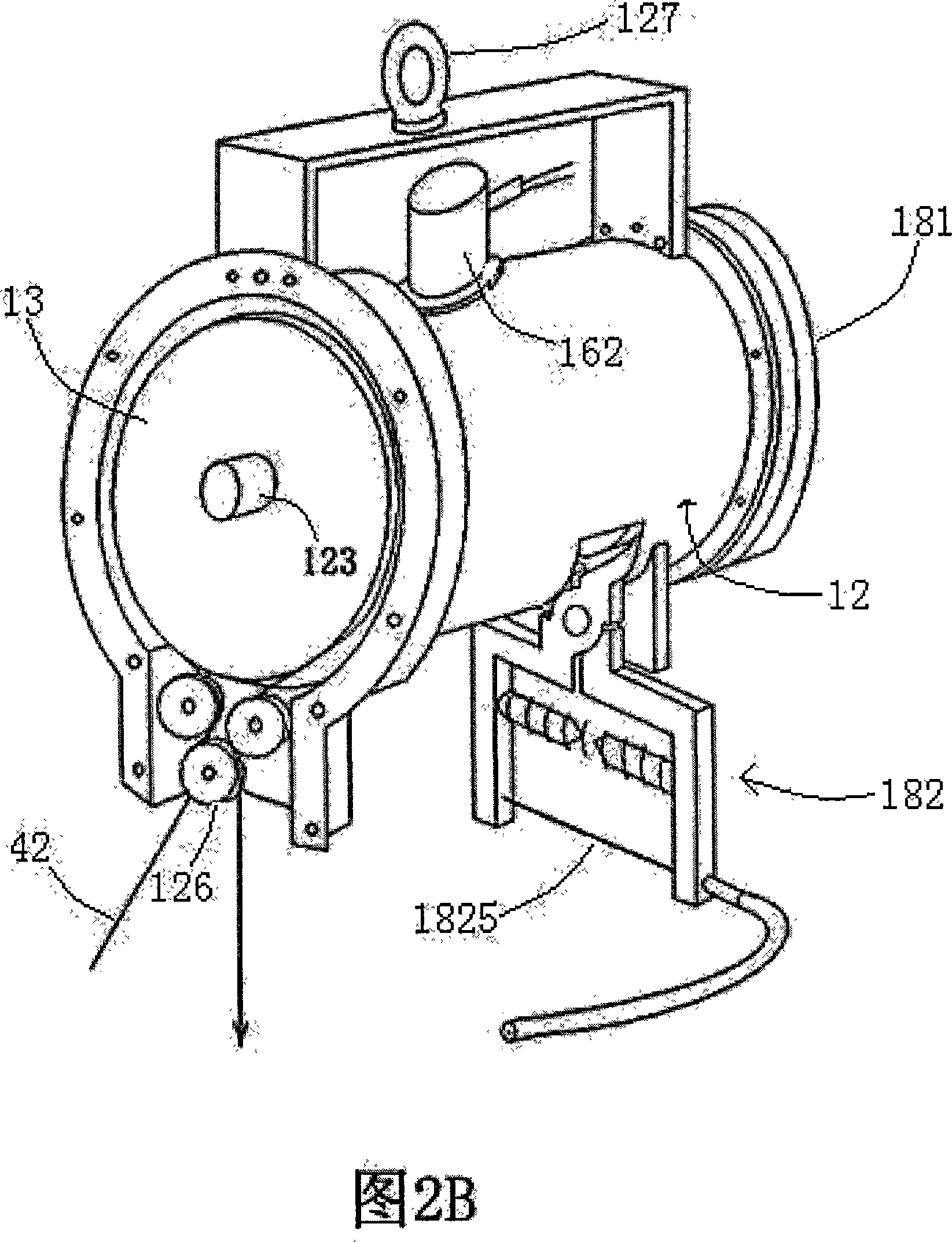

Fire disaster self-saving high-speed escaping machine that can be operated and controlled by micro-computer in wireless mode

InactiveCN101095971AEliminate critical defectsQuick and efficient escapeProgramme controlTelemetry/telecontrol selection arrangementsFire - disastersHand held

The invention relates to a fire self-rescuing high-speed life device controlled by micro computer, which can be controlled without wire. The device comprises host computer component, at least a hand-hold wireless remote controller, falling load device and sling component, wherein the host computer component is set at the special life port of building or in the refuge safe room and is connected with the building. The hand-hold wireless remote controller is taken by escaping man or escaping man, escort and ground meeting man all take hand-hold wireless remote controller. The falling load device is connected with the host computer component. The sling component is connected with the falling load device and the host computer component respectively. The device also comprises an air locator, which control the air location of falling load device and the distance between the falling load device and the building outer wall. The air locator is connected with the falling load device and is communicated with the hand-hole wireless remote controller without wire. The device can be controlled by escaping man or escaping man and ground rescuing man. It can control falling speed and space location. It is provided with fire proof and collision prevention performance and safe and reliable use.

Owner:唐海山

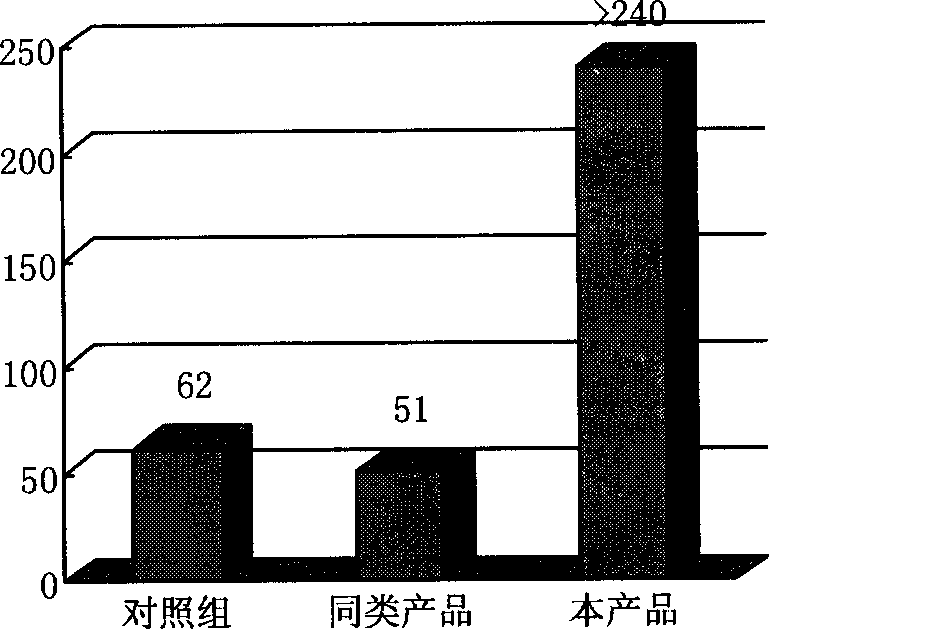

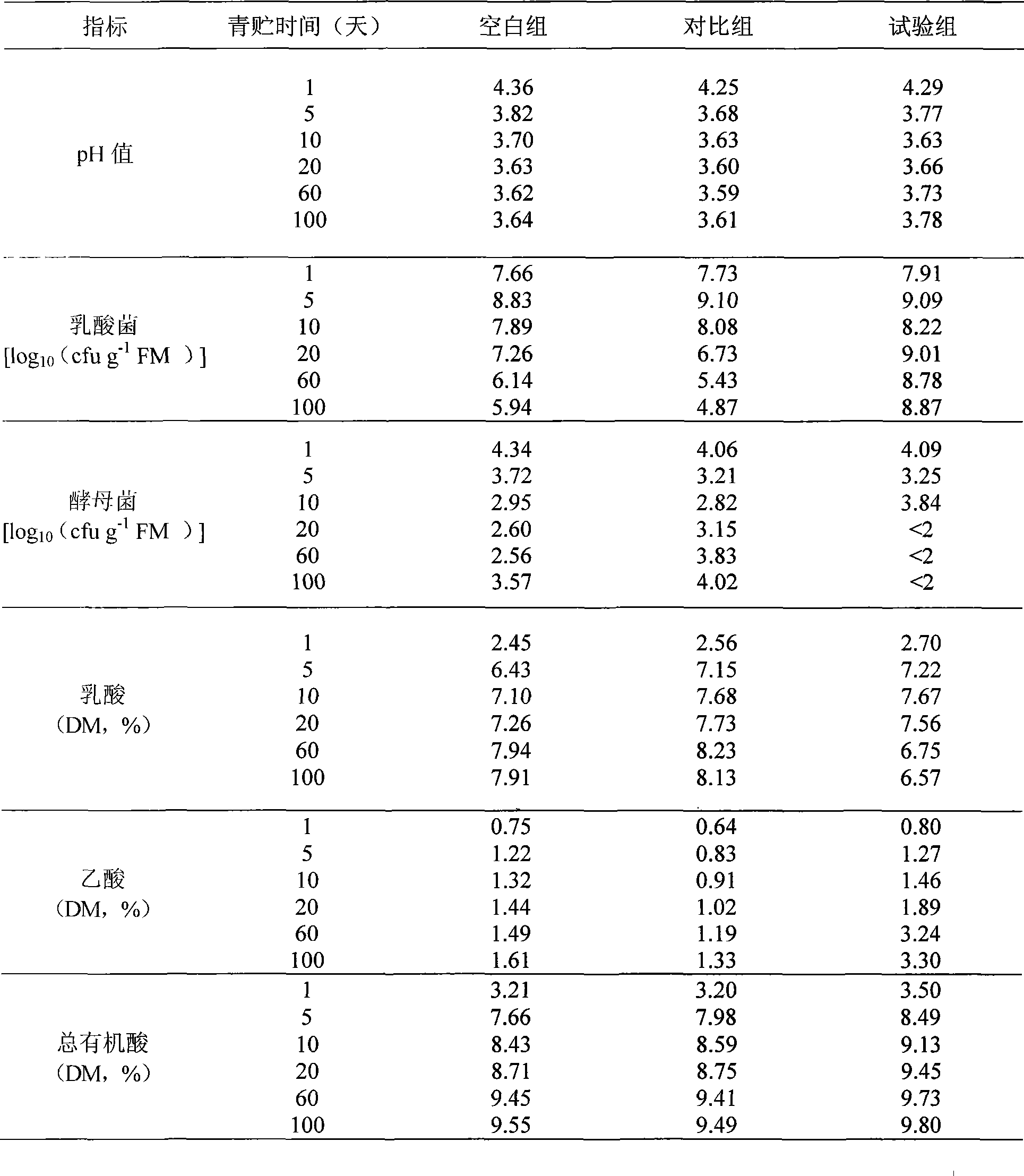

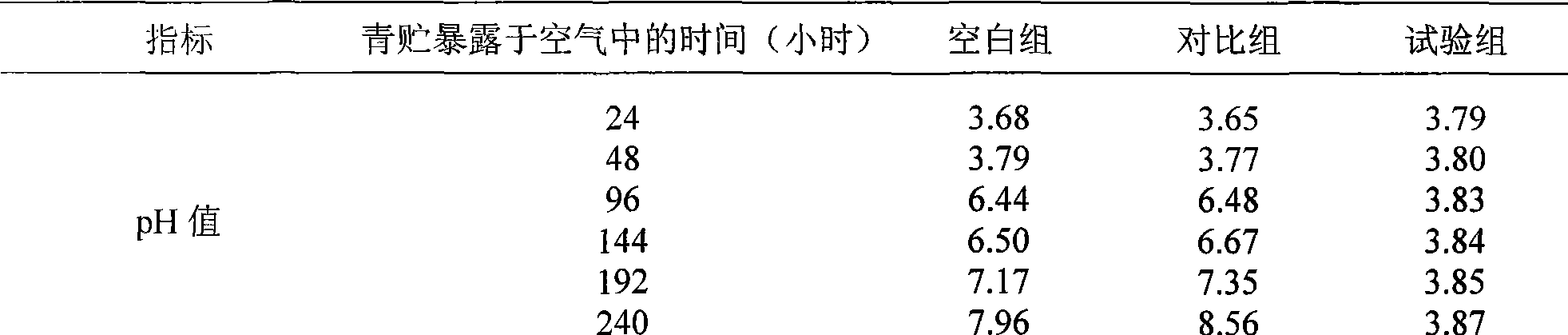

Composite microbial inoculant for corn silage and use method thereo

The invention discloses an inoculant containing homofermentation malolactic bacteria and heterofermentation malolactic bacteria for corn silage and using method thereof. The composite microorganism inoculant for corn silage includes 2*10<9>cfu / g-5*10<10>cfu / g of lactobacillus buchneri and 5*10<9>cfu / g-1*10<11>cfu / g of lactobacillus plantarum. The composite microorganism inoculant for corn silage provided by the present invention employs the homofermentation malolactic bacteria and the heterofermentation malolactic bacteria as acid generation source, thereby increasing preservation effect of corn silage forage. When silage forage prepared from the inoculant of the present invention is used as forage of cow, milk yield and butterfat rate can be increased.

Owner:HENAN AGRICULTURAL UNIVERSITY

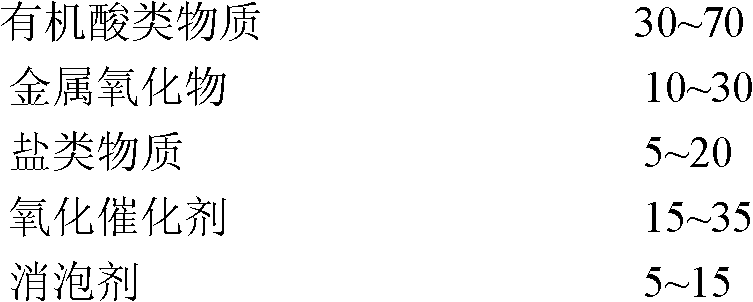

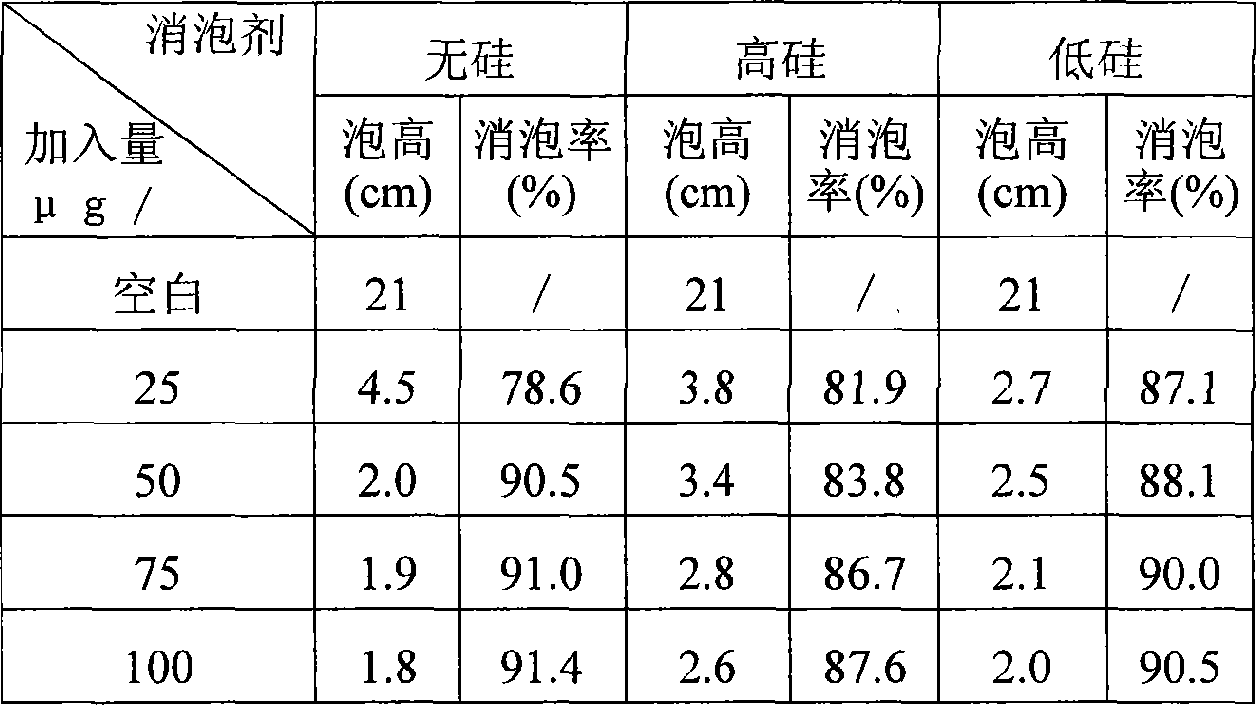

Limestone-gypsum wet desulfurization additive

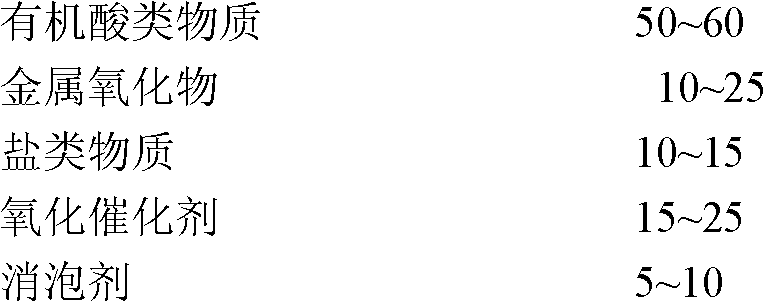

InactiveCN102847428APromote SO2 dissolutionPromote dissolutionDispersed particle separationGypsumOrganic acid (substance)

The invention relates to an additive, especially relates to an additive used for limestone-gypsum method flue gas desulfurization. The technical problem solved by the invention is in order to provide an additive capable of preventing desulfurization absorption tower scaling, and slurry overflowing, avoiding demister blockage, and improving desulfurization efficiency. In order to solve the above problem, the technical proposal taken by the invention adopts organic acid substance 30-70, metal oxide 10-30, salt substance 5-20, oxidation catalyst 15-35, and antifoaming agent 5-15. The technical proposal has obvious effect in defoaming, scaling reduction, demister blockage, slurry overflowing prevention, and desulfurization efficiency improvement.

Owner:SNTO TECH GRP

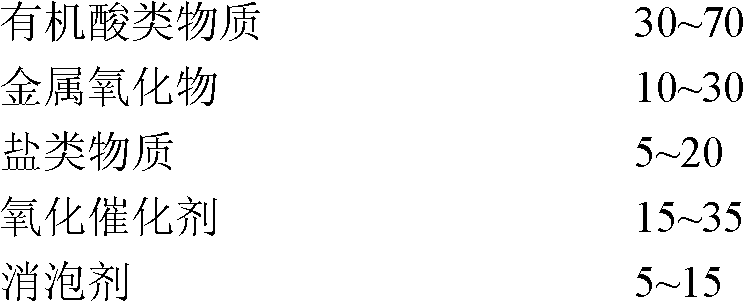

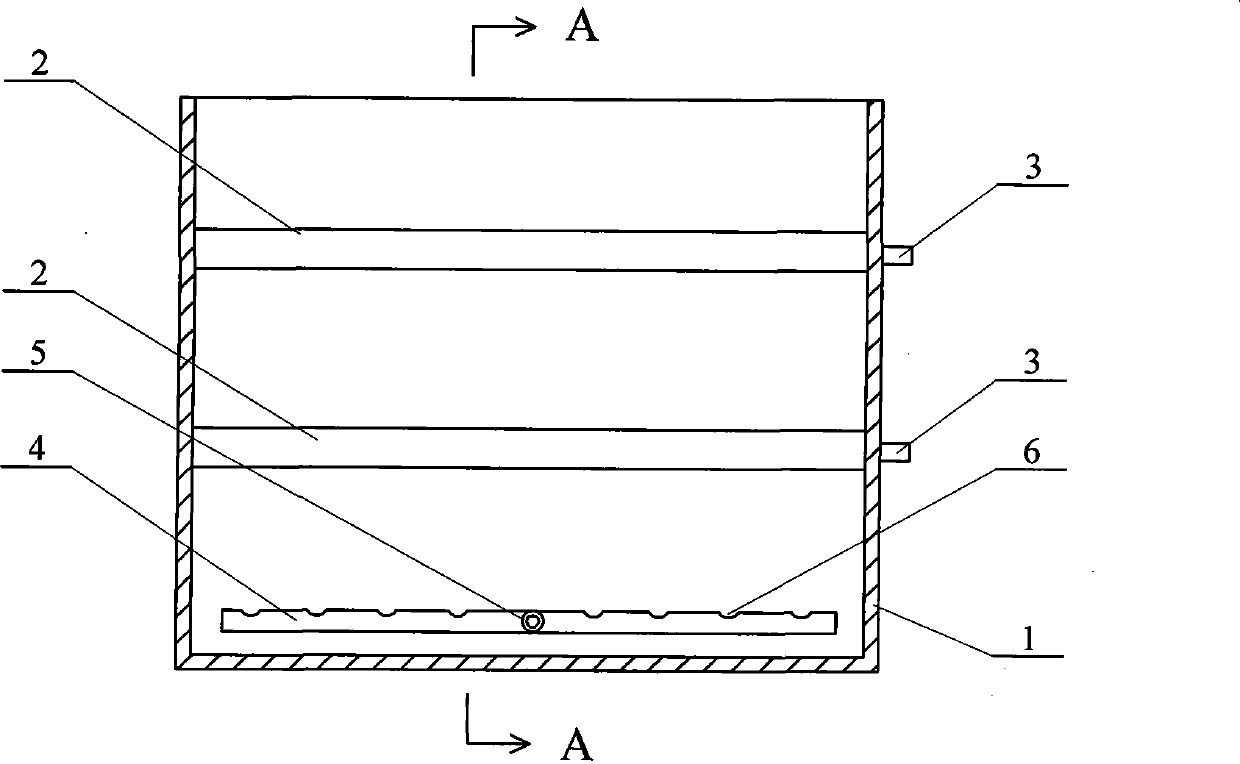

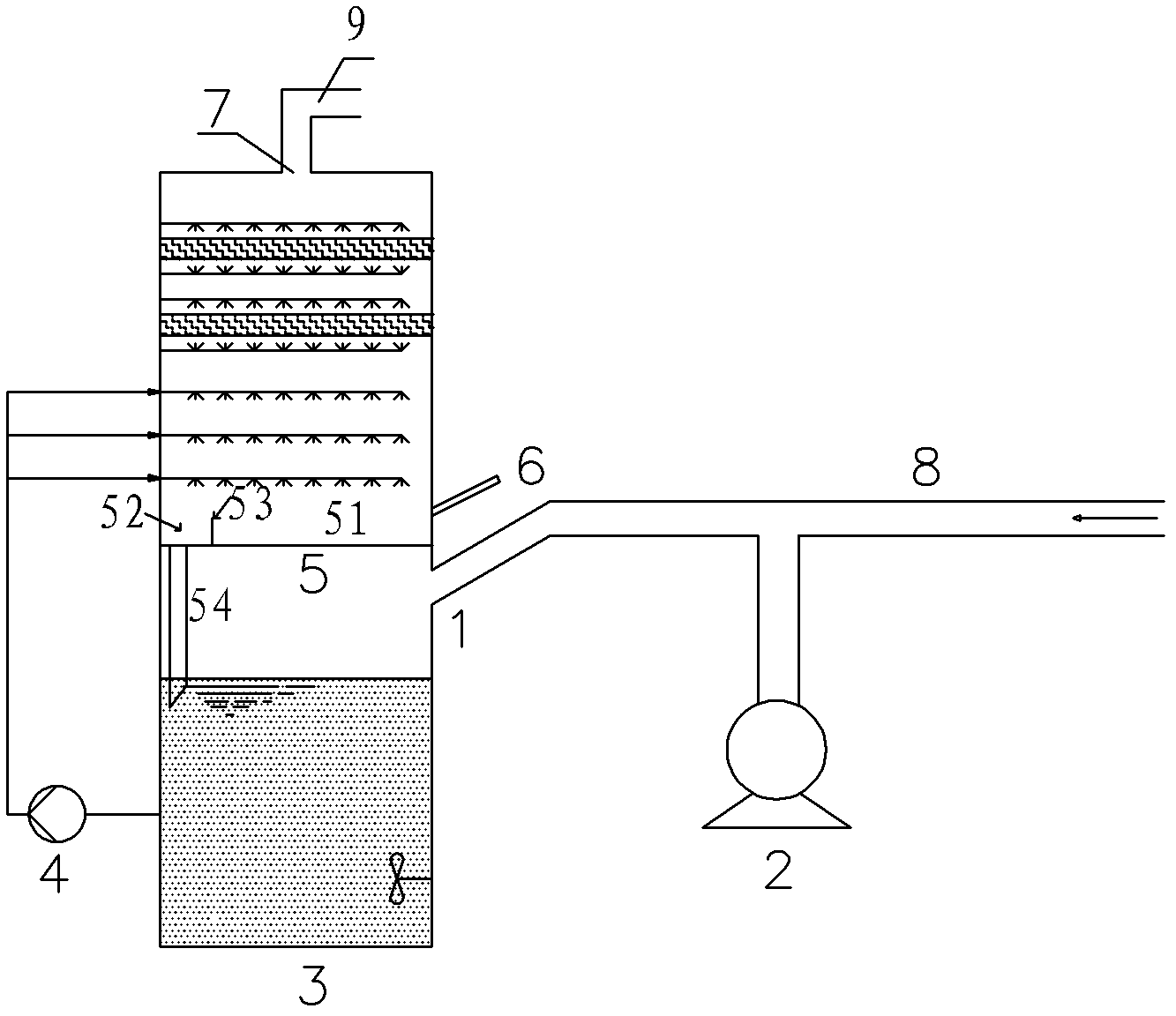

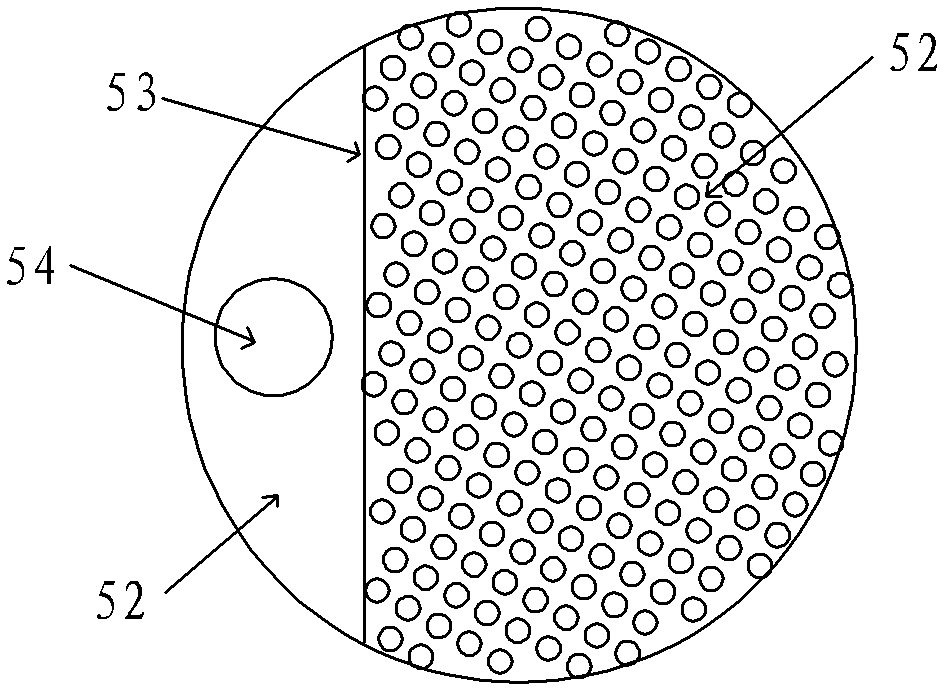

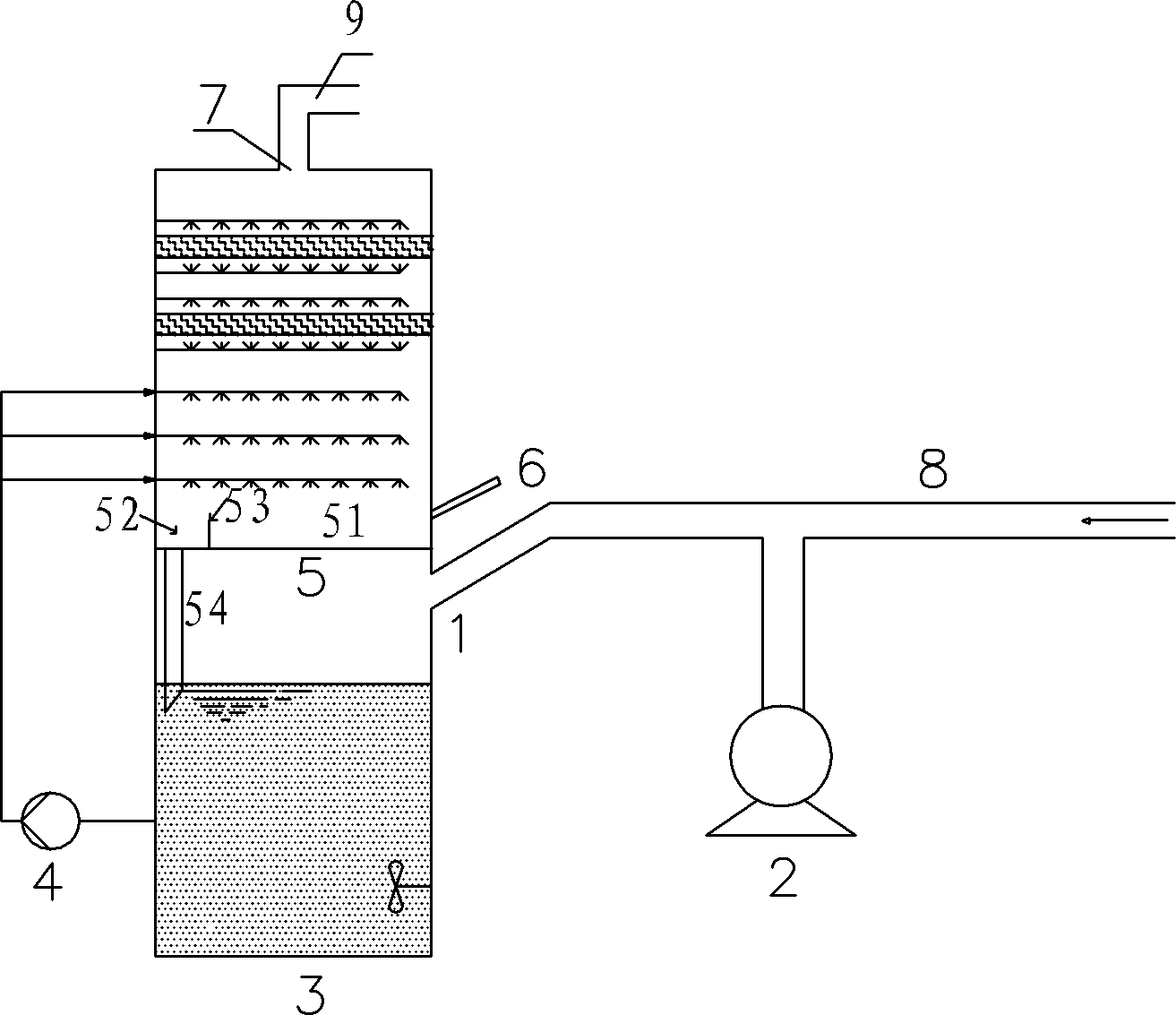

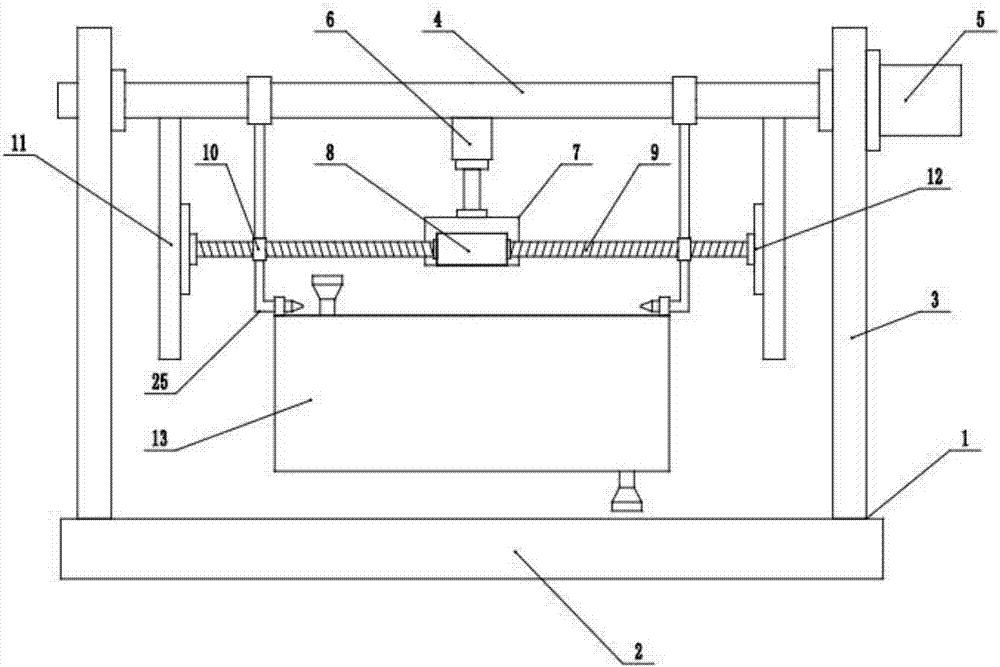

Solid waste high temperature aerobic composting method using stereoscopic ventilating apparatus

InactiveCN101372427AImprove mass transfer effectImprove uniformity and stabilityBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringCompost

A high-temperature and aerobic composting method for solid wastes which adopts a vertical ventilation device relates to a high-temperature and aerobic composting method for the solid wastes. The composting method aims at solving the problems that in the aerobic fermentation process, the conventional bottom ventilation method causes obvious uneven fermentation at the upper part and the lower part of a stacking body in a fermentation device, thus quality stability and uniformity of the fermented product are affected. In the composting method, middle air distribution pipes are fixed in a fermentation tank arranged at the lower side of an inverted ventilating slot; both the bottom part and the middle part of the fermentation tank adopt intermittent ventilation type, the ventilation time is 5-30 minutes, intermittent time is 15-120 minutes and ventilation rate is 0.03-2m<3> / (min m<3> mixing materials). The composting method increases the contact area between air and materials; air direction forms a reverse rotational flow, which increases residence time of fresh air in the fermentation device, thus improving the mass transfer efficiency, and the operational cycle of a single fermentation is shortened by over 1 / 4.

Owner:李伟光 +1

Additive for suppressing and delaying foam generation in coking reaction tower and its prepn process

InactiveCN101045880ASuppress and eliminate generationReduce entrainmentThermal non-catalytic crackingEpoxyHeptyl alcohol

The present invention is additive for suppressing and delaying foam generation in coking reaction tower and its preparation process, and relates to oil refining additive technology. The additive is prepared through compounding high molecular weight block polyether 30-50 wt%, fatty alcohol 20-40 wt% and solvent 20-40 wt%, where, the high molecular weight block polyether is block copolymer of ethylene glycol, epoxy ethane and epoxy propane of molecular weight 10,000-20,000, and the fatty alcohol is isocotanol or 3-enanthol, and the solvent is water solution of alcohol. The preparation process includes the first feeding solvent into reaction kettle and heating slowly to 40-60 deg.c, adding block polyether and fatty alcohol in the ratio via stirring to react for 1-2 hr, cooling and filtering off solid impurity to obtain the product. The additive can suppress and delay foam generation in coking reaction tower effectively.

Owner:SHENYANG POLYTECHNIC UNIV

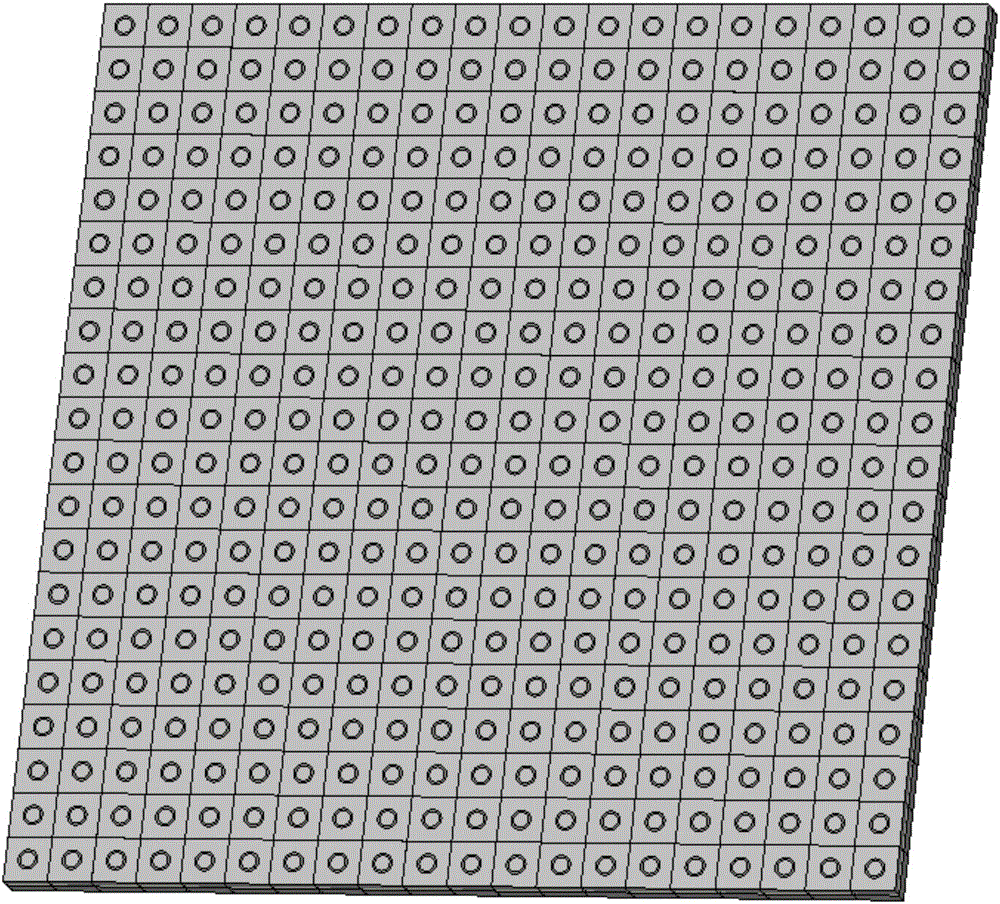

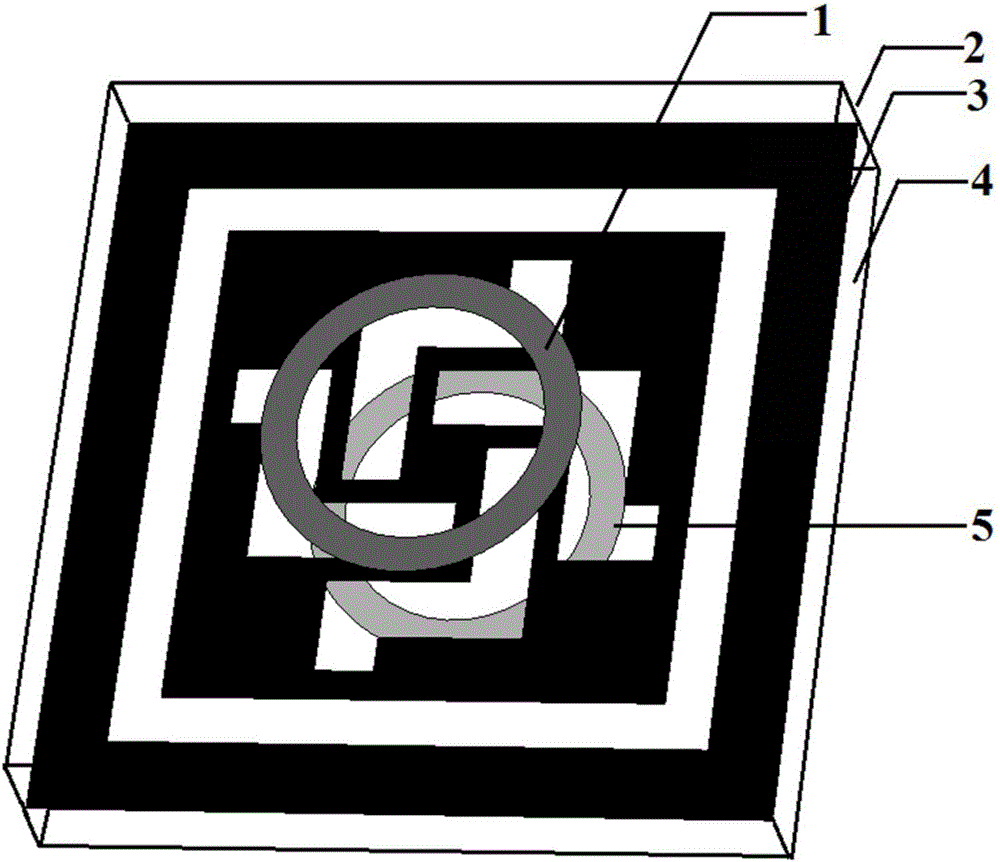

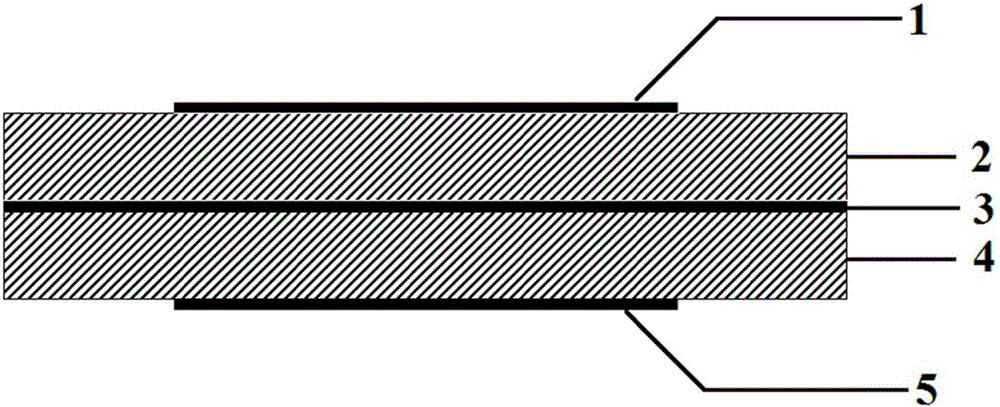

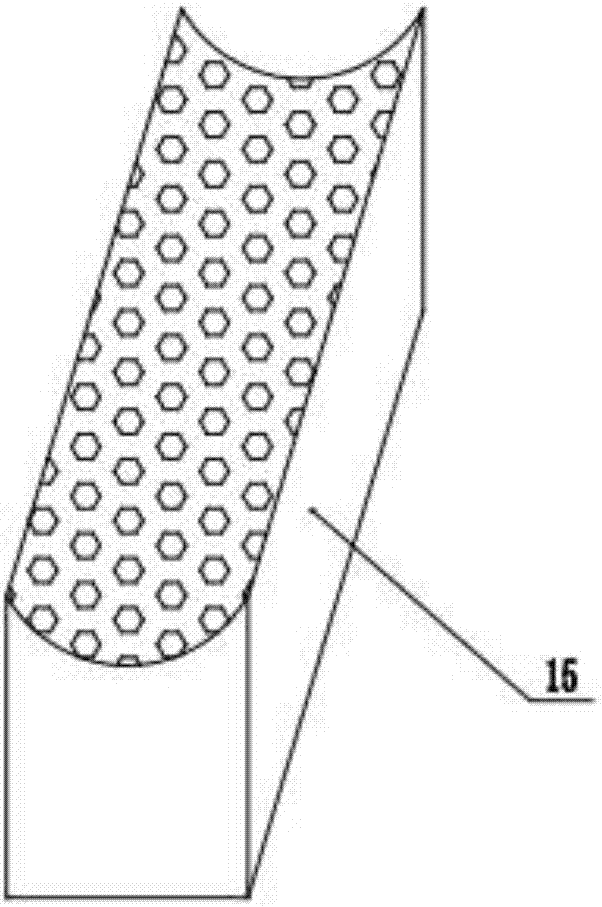

Ultra broadband mobile communication radome based on antenna-filter-antenna array

ActiveCN105914462AImprove passband characteristicsHigh selectivityRadiating element housingsEngineeringUnit structure

The invention discloses an ultra broadband mobile communication radome based on an antenna-filter-antenna array. The radome is a periodic frequency selection surface which is mainly formed by a plurality of same period unit structure arrays. Each period unit is mainly formed by upper and lower layers of dielectric layers, upper and lower layers of circular ring metal patch layers and a metal slit layer between the two dielectric layers. An electromagnetic field in a space hits the radome and successively passes through three layers of selective filtering of an upper layer metal layer, the metal slit layer and a lower layer metal layer, and then the electromagnetic field with a needed frequency range is output from the lower layer metal layer and clutter energy can be greatly restrained. The radome is suitable for the design of the ultra broadband mobile communication radome. A passband width is large, in-band insertion losses are small and are stable, and frequency selectivity performance is good. The radome has a great application value in the fields of mobile communication, a radar and the like.

Owner:ZHEJIANG UNIV

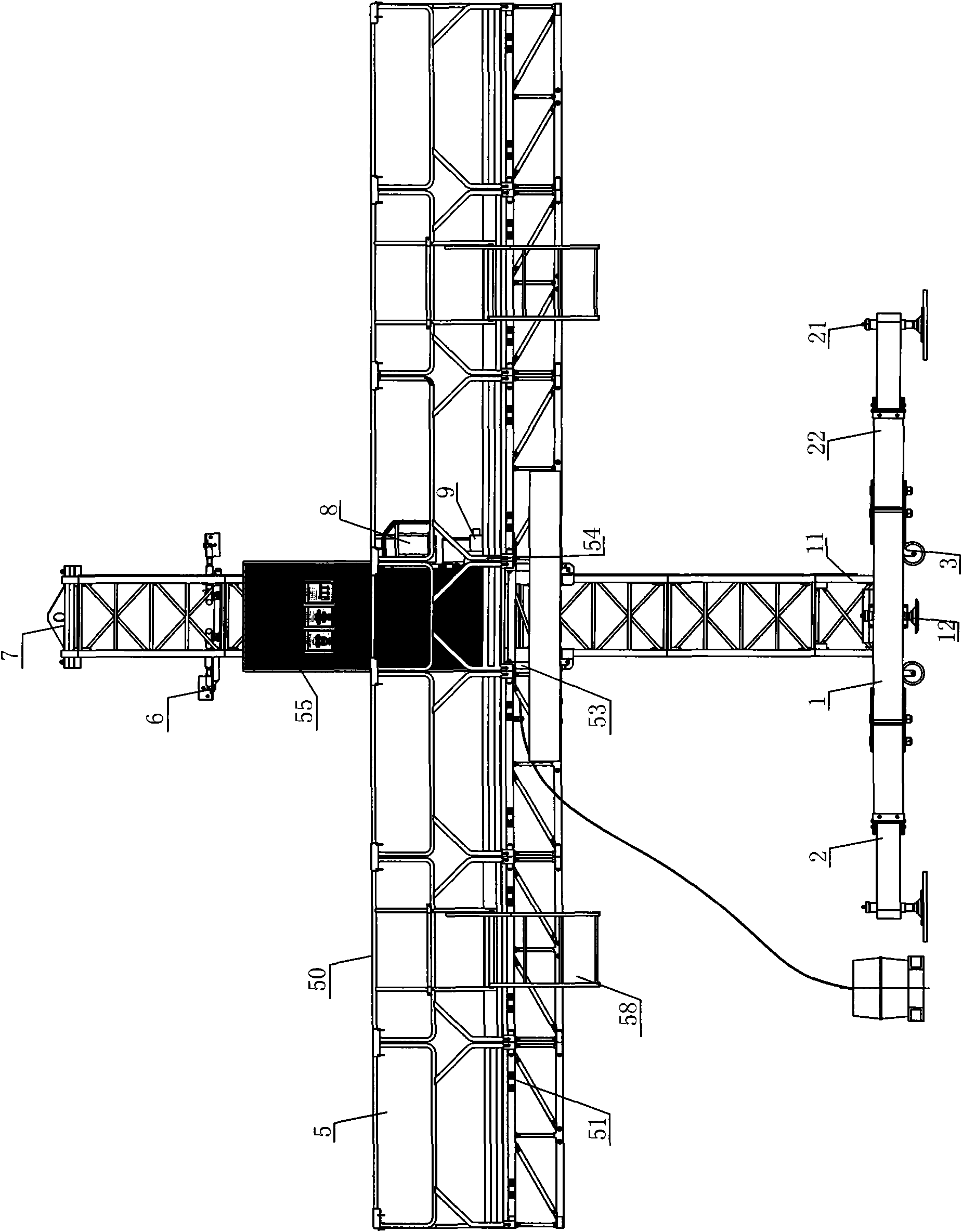

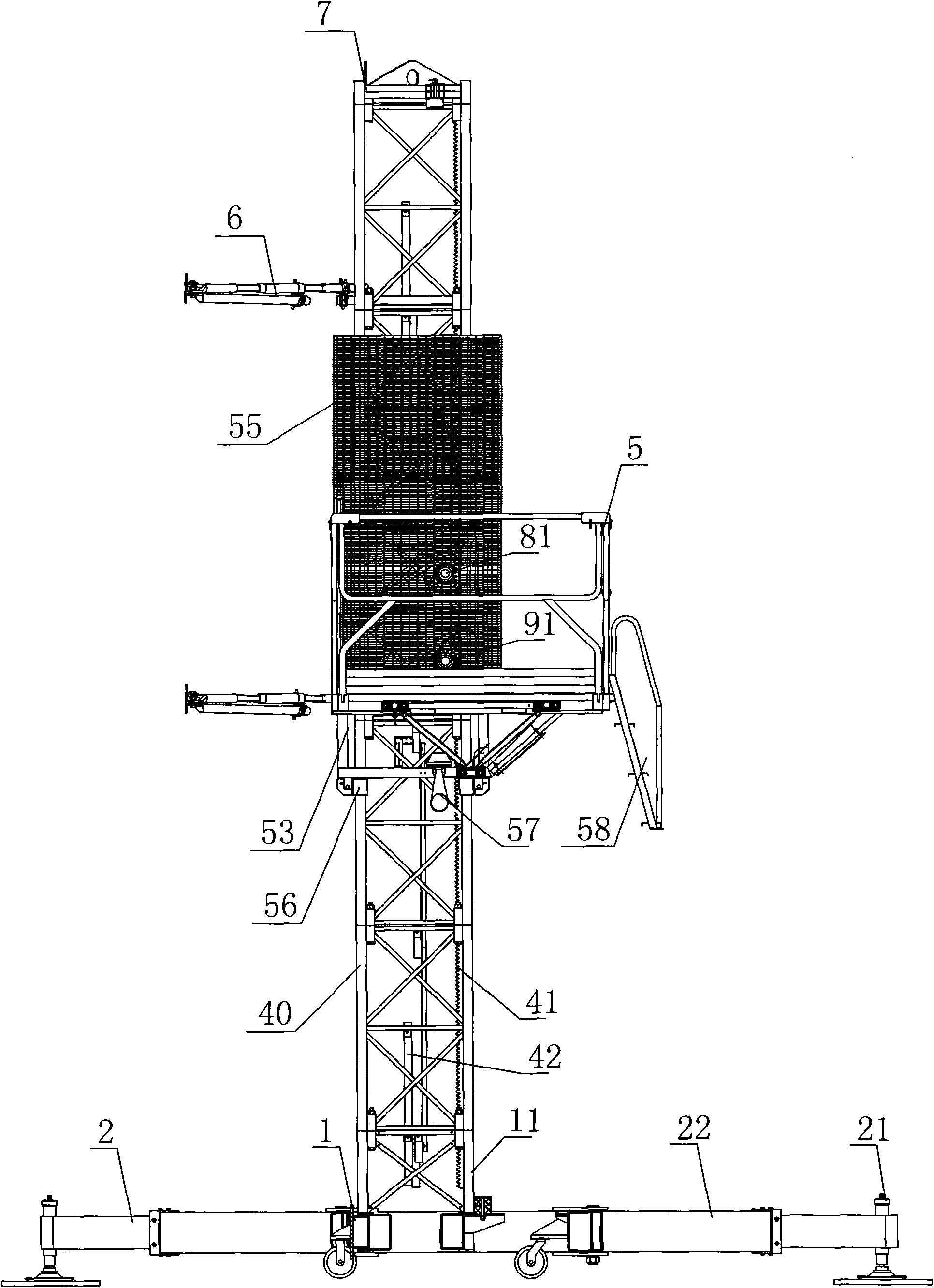

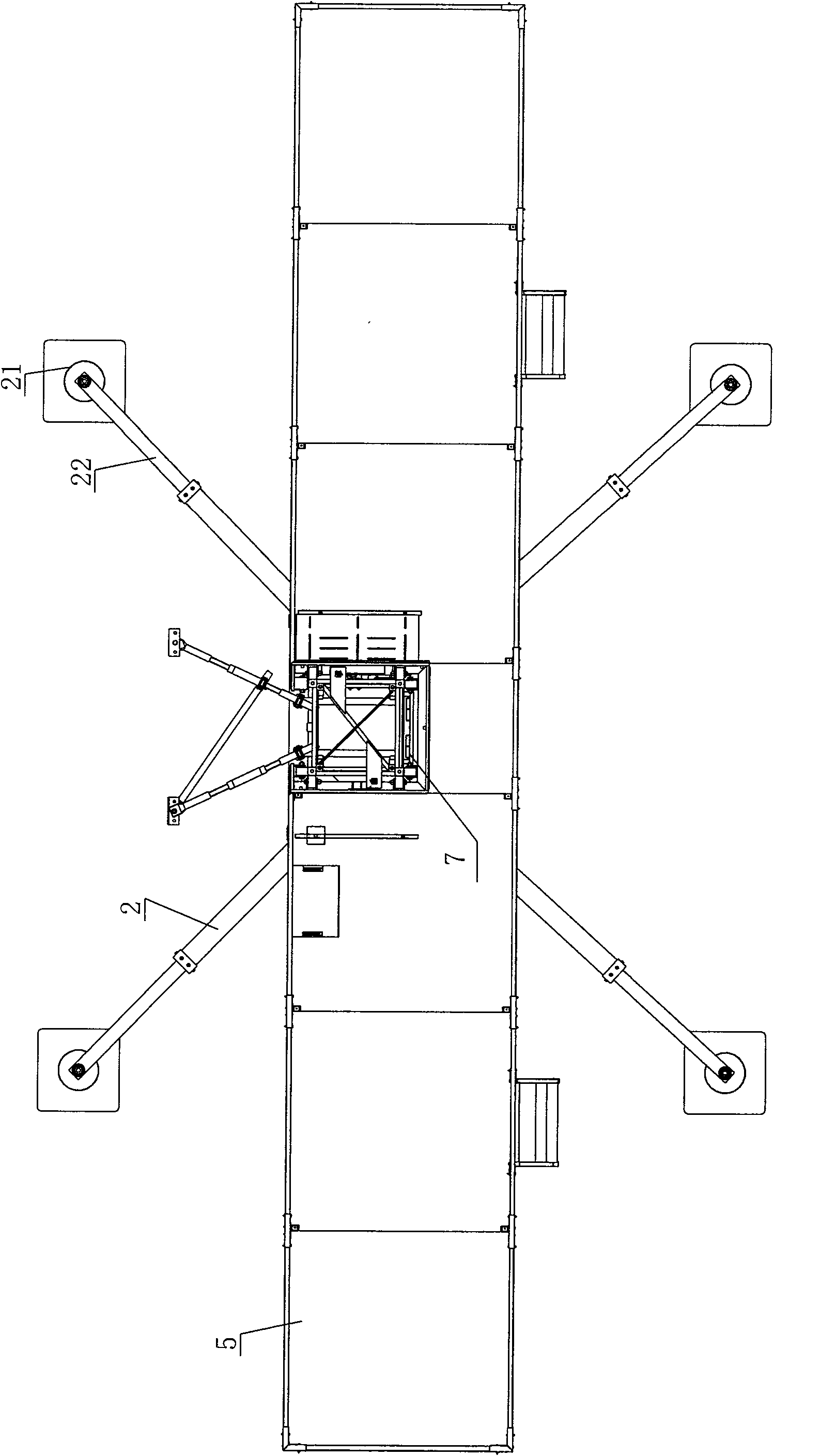

Mast climbing type aerial working platform

The invention relates to an aerial working device. A mast climbing type aerial working platform comprises a vertical tower assembly and a platform assembly, the vertical tower assembly is composed of a top cap and a plurality of standard knots of frame structures, the standard knots are in fixed connection, the standard knots are fixedly and detachably connected with a connection frame and the top cap, sides of the connection frame and the standard knot are respectively provided with teeth bars, the teeth bars are connected with each other to compose a tooth-shaped rail; a mounting rack is mounted on the platform assembly, the vertical tower is arranged through the mounting rack, rolling wheels are arranged on the mounting rack, the rolling wheels and the standard knots are pasted rollingly, a fixed plate is fixedly arranged on the mounting rack, a motor and an anti-drop gear are respectively engaged with the teeth bars. The invention extends the range of the platform surface, the standard knots can be added unlimitedly, the lifting height of the platform surface can be extended, the invention has characteristics of large working range, high lifting height, safety and reliability.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

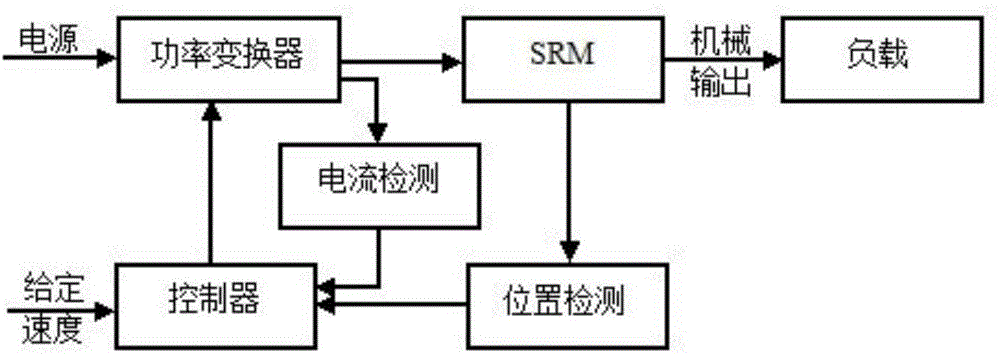

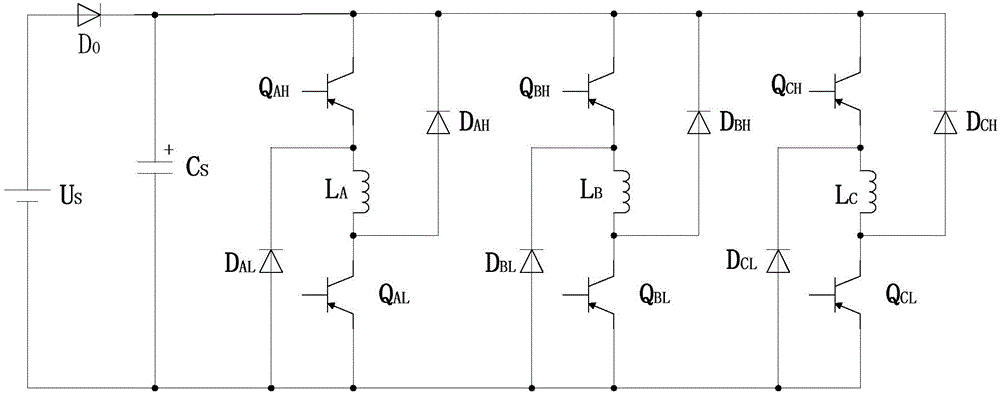

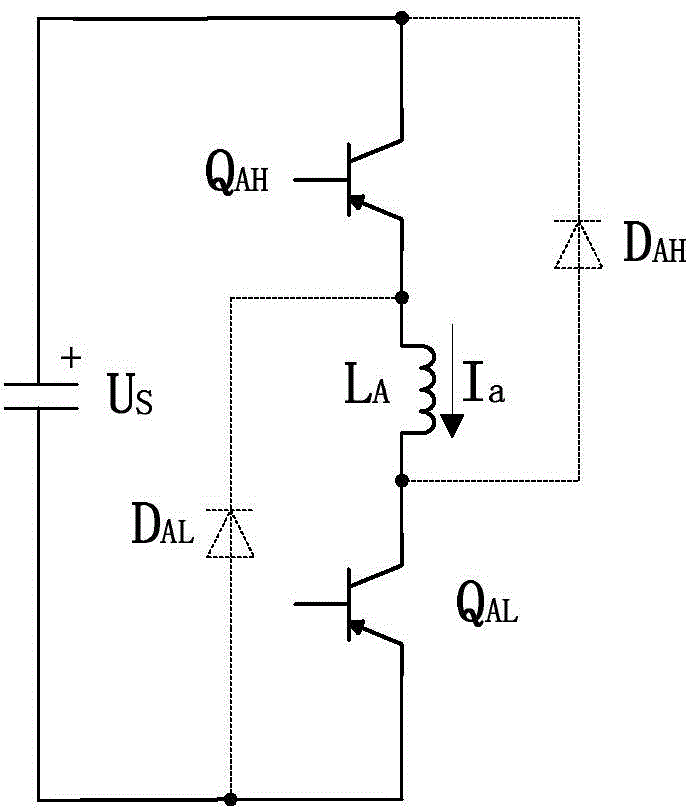

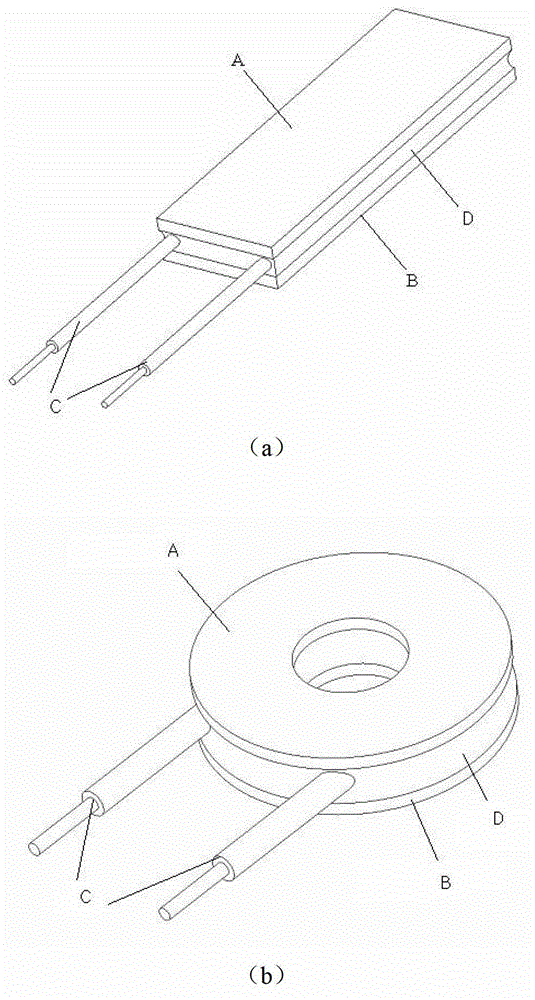

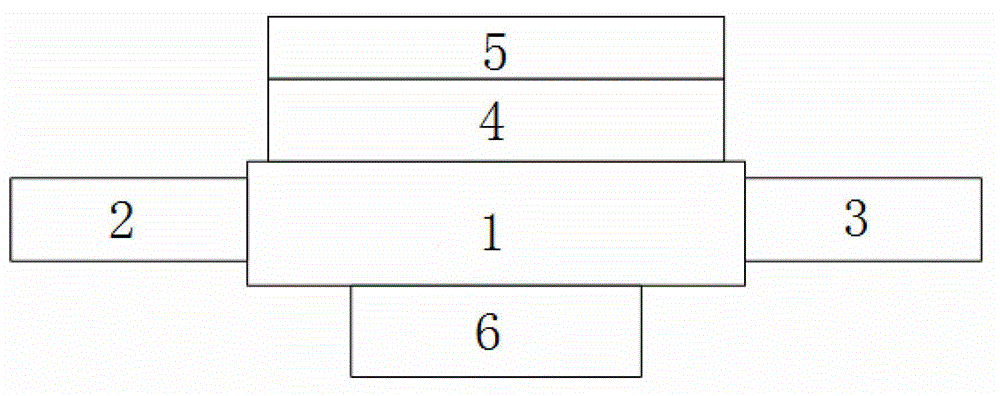

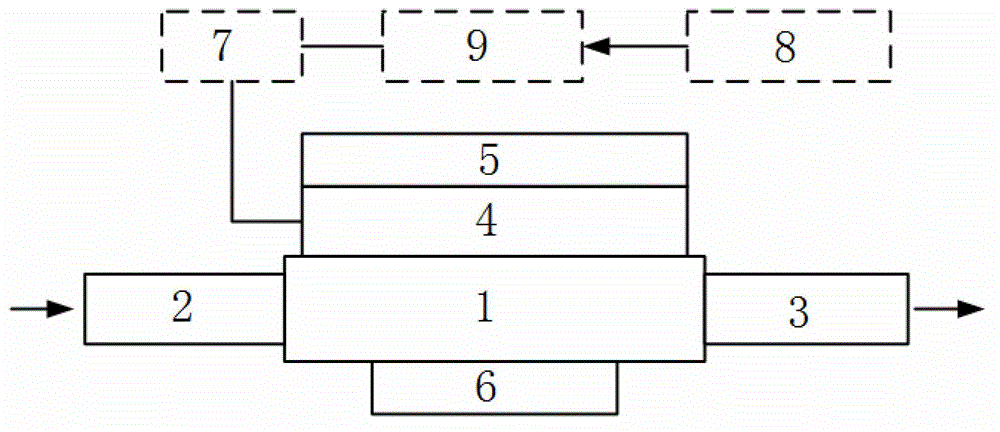

Three-level motor power converter achieving quick demagnetization

InactiveCN105322838AFall fastShorten the timeTorque ripple controlSingle motor speed/torque controlPhase currentsCapacitance

The invention discloses a three-level motor power converter achieving quick demagnetization, and the converter comprises an upper DC power supply, a lower DC power supply, a three-phase winding, an upper three-phase power device, a low three-phase power device, a filtering capacitor, an energy storage capacitor, and six freewheel diodes. Compared with the topological structure of a conventional three-phase switching magnetic resistance motor power converter, the converter is additionally provided with the upper DC power supply, adjusts the voltage of the upper DC power supply to be greater than the exciting voltage of the lower DC power supply thorough a voltage adjuster, enables the decrease speed of a phase current at a follow current stage to be increased, increases the discharge speed of a phase winding, prolongs the time when the current of the phase winding maintains the maximum effective value while eliminating a braking torque, increases the output power of a system, and reduces the torque ripple.

Owner:NANJING UNIV OF TECH

Micro-flow controller based on peltier effect

ActiveCN103149949AImprove heating efficiencyImprove efficiencyFlow control using electric meansElectricityActive cooling

The invention discloses a micro-flow controller based on the peltier effect. The controller comprises a flow restrictor, a gas inlet, a gas outlet, at least one peltier semiconductor device and at least one heat sink. Gas enters the flow restrictor from the gas inlet, after a flow restriction effect is achieved, micro-flow of propellant flows out from the gas outlet, and the flow restrictor and the heat sink are respectively arranged on two faces of a peltier semi-conductor device. By charging the peltier semi-conductor device with electricity and controlling the peltier semi-conductor device, active heating, active cooling and insulation operation can be carried out on the flow restrictor, so that the flow restrictor can fast regulate and stabilize flow of the gas in a large range. Compared with a common micro-flow controller subjected to heating wire active heating and power-off passive cooling, the micro-flow controller carries out active heating and active cooling on the flow restrictor, expands the regulating range of the flow restrictor, and improves regulating speed of the flow restrictor. Efficiency of the peltier semi-conductor device is higher than that of the heating wire during heating.

Owner:SHANGHAI INST OF SPACE PROPULSION

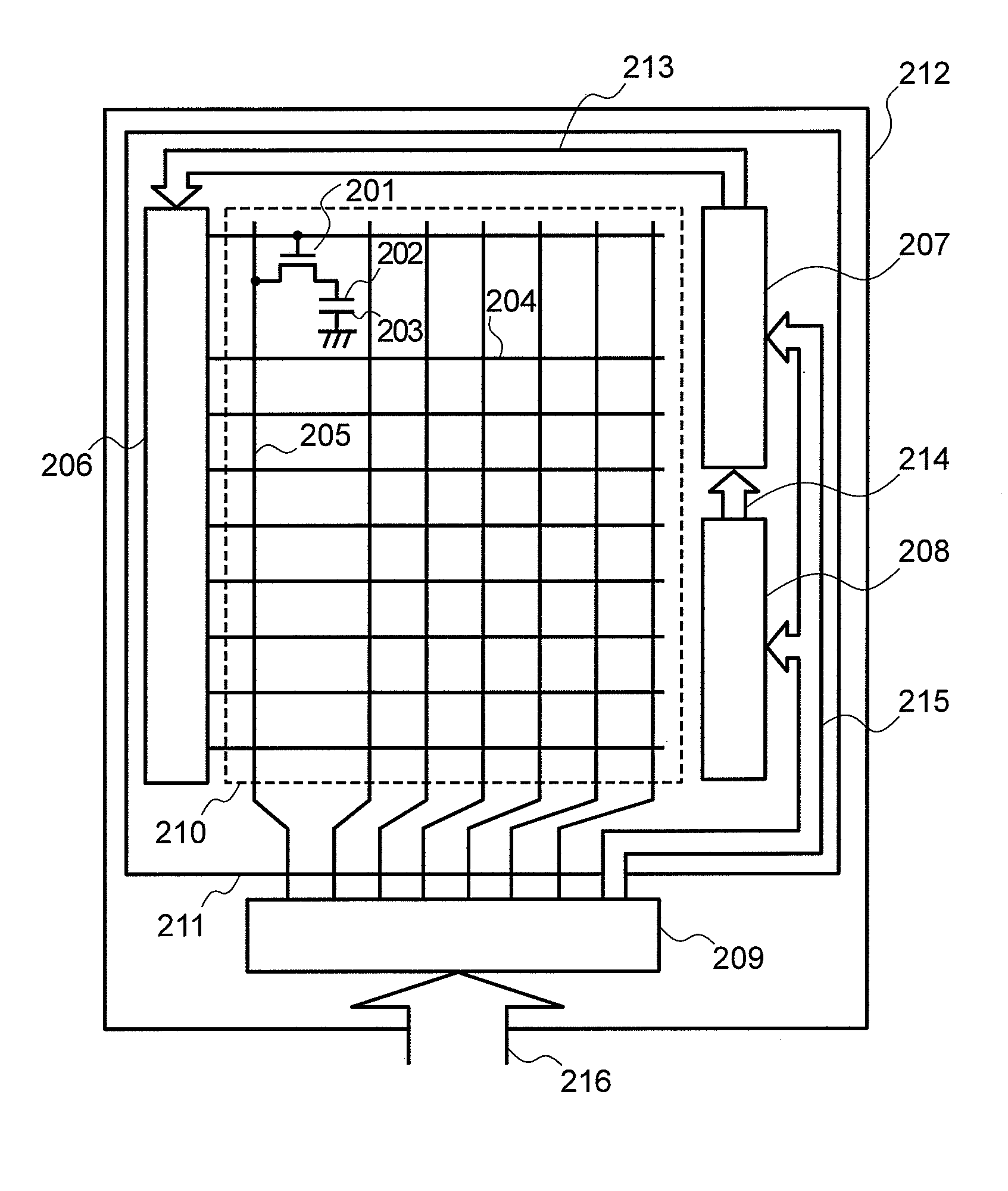

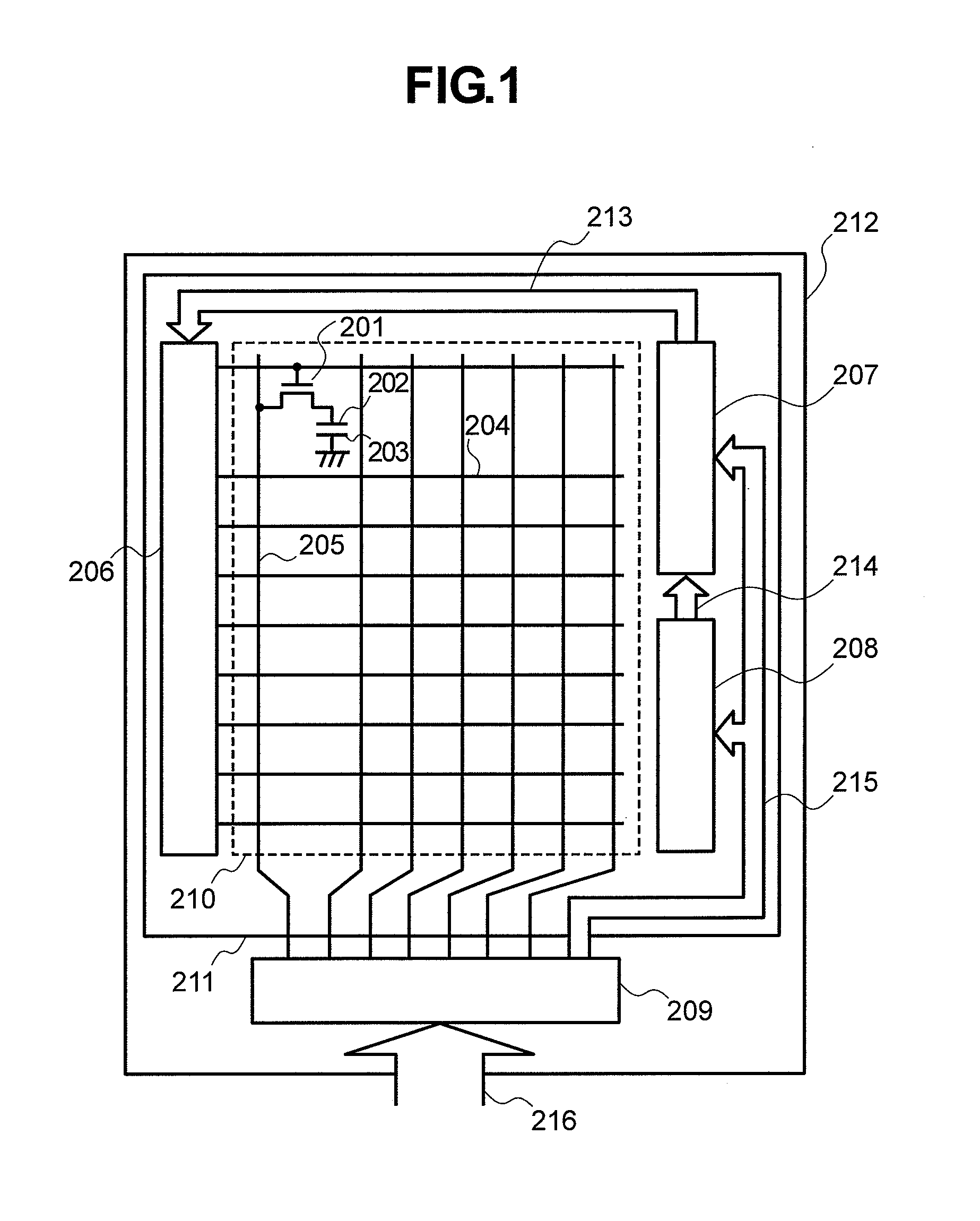

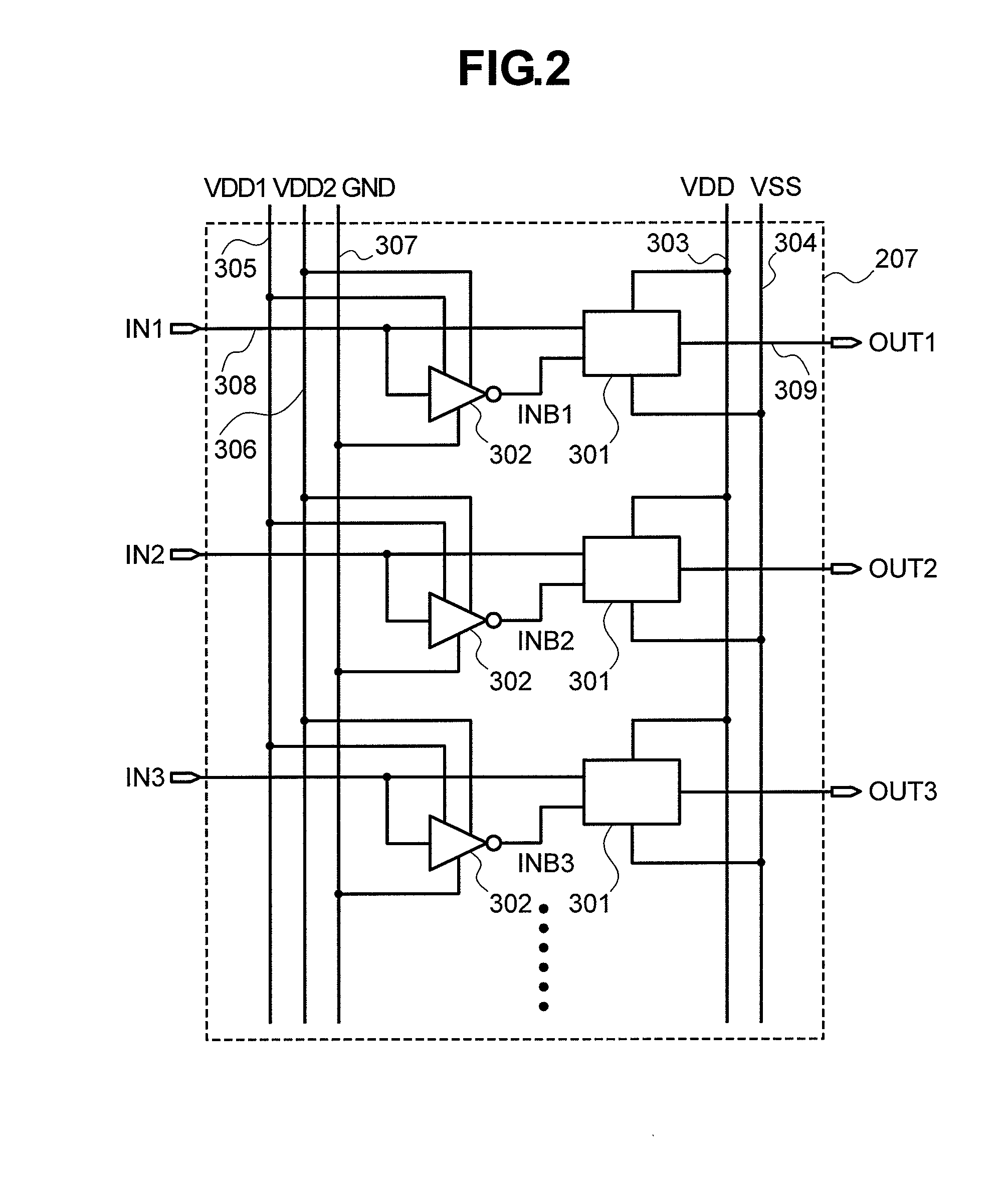

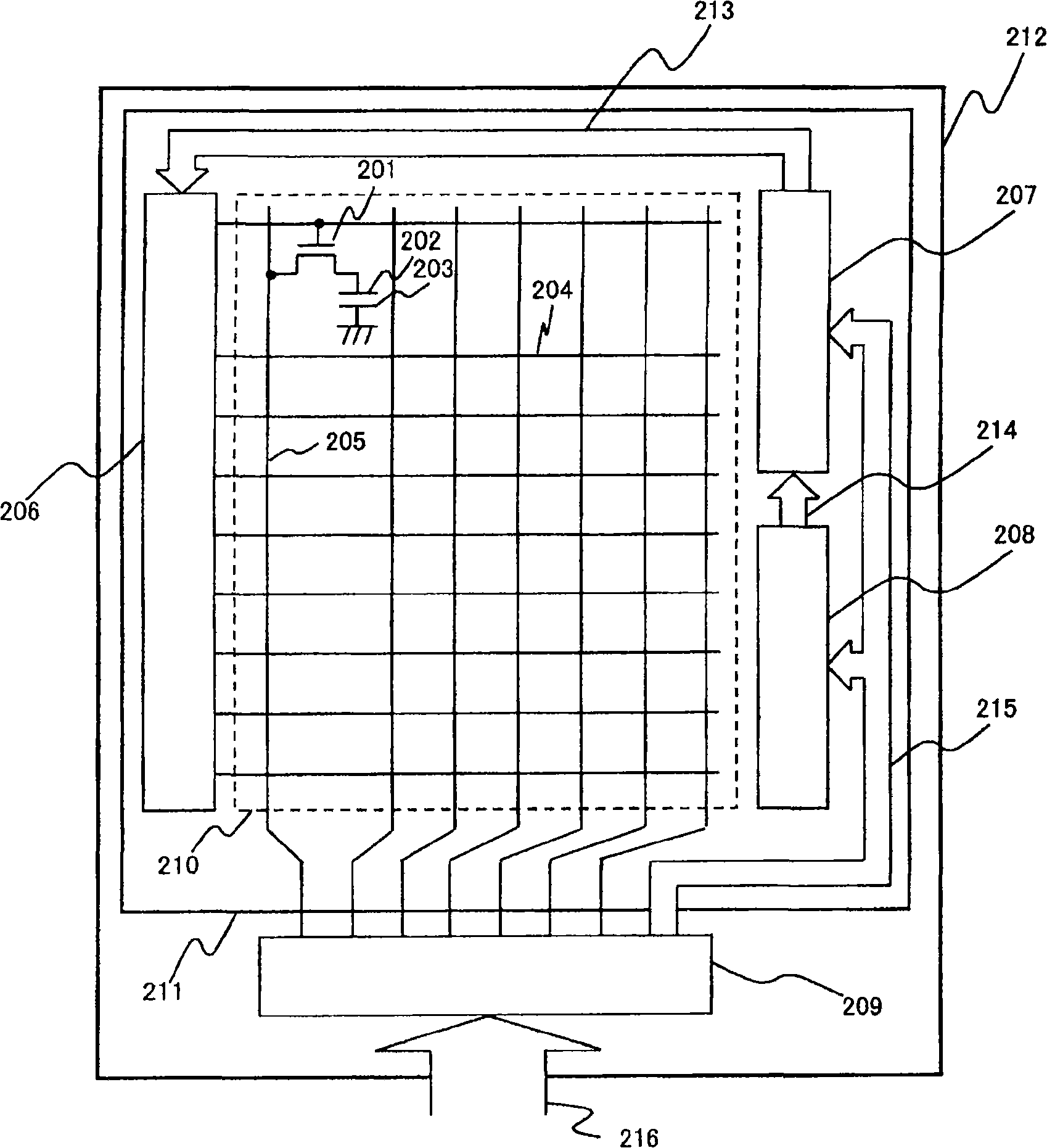

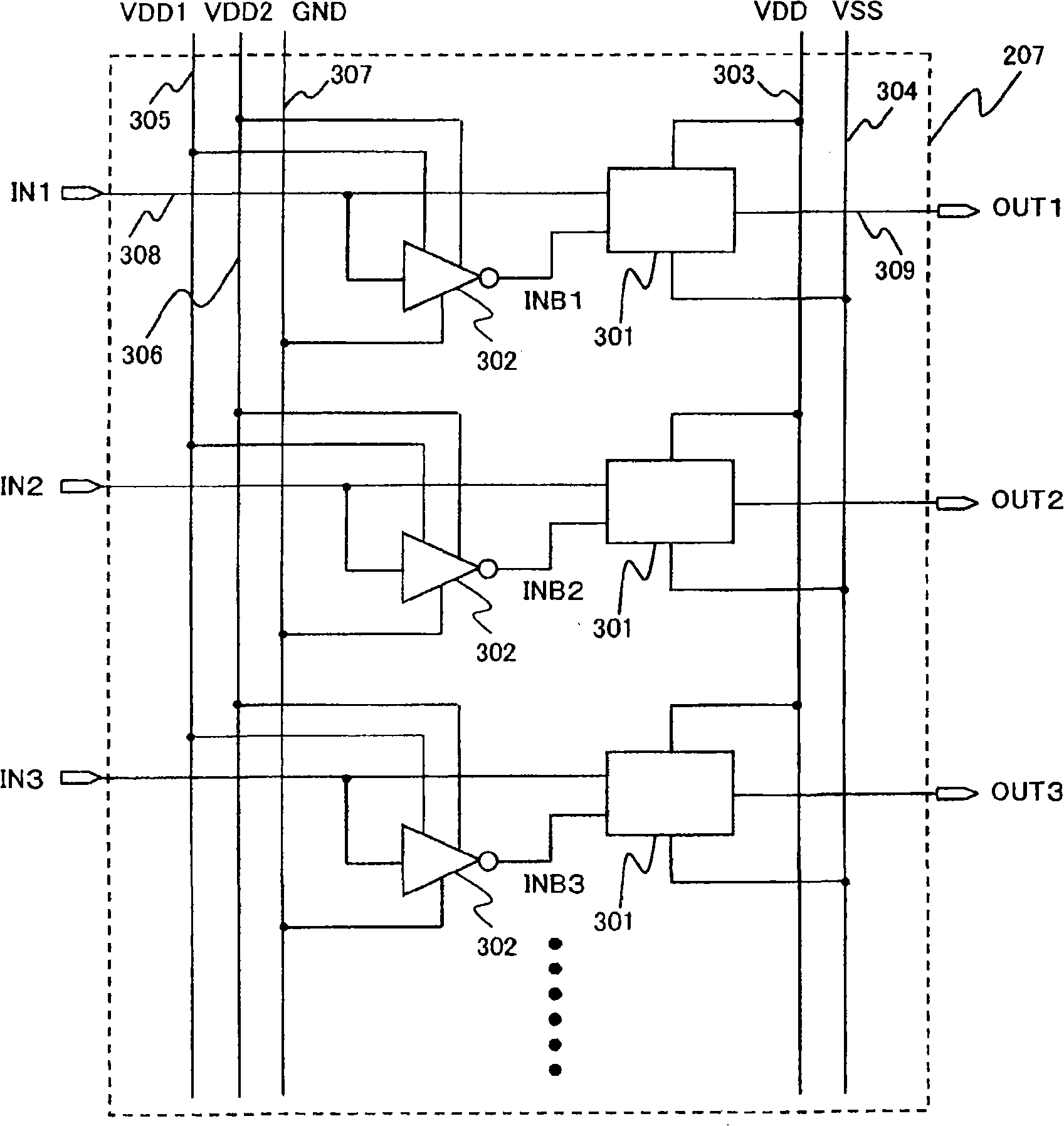

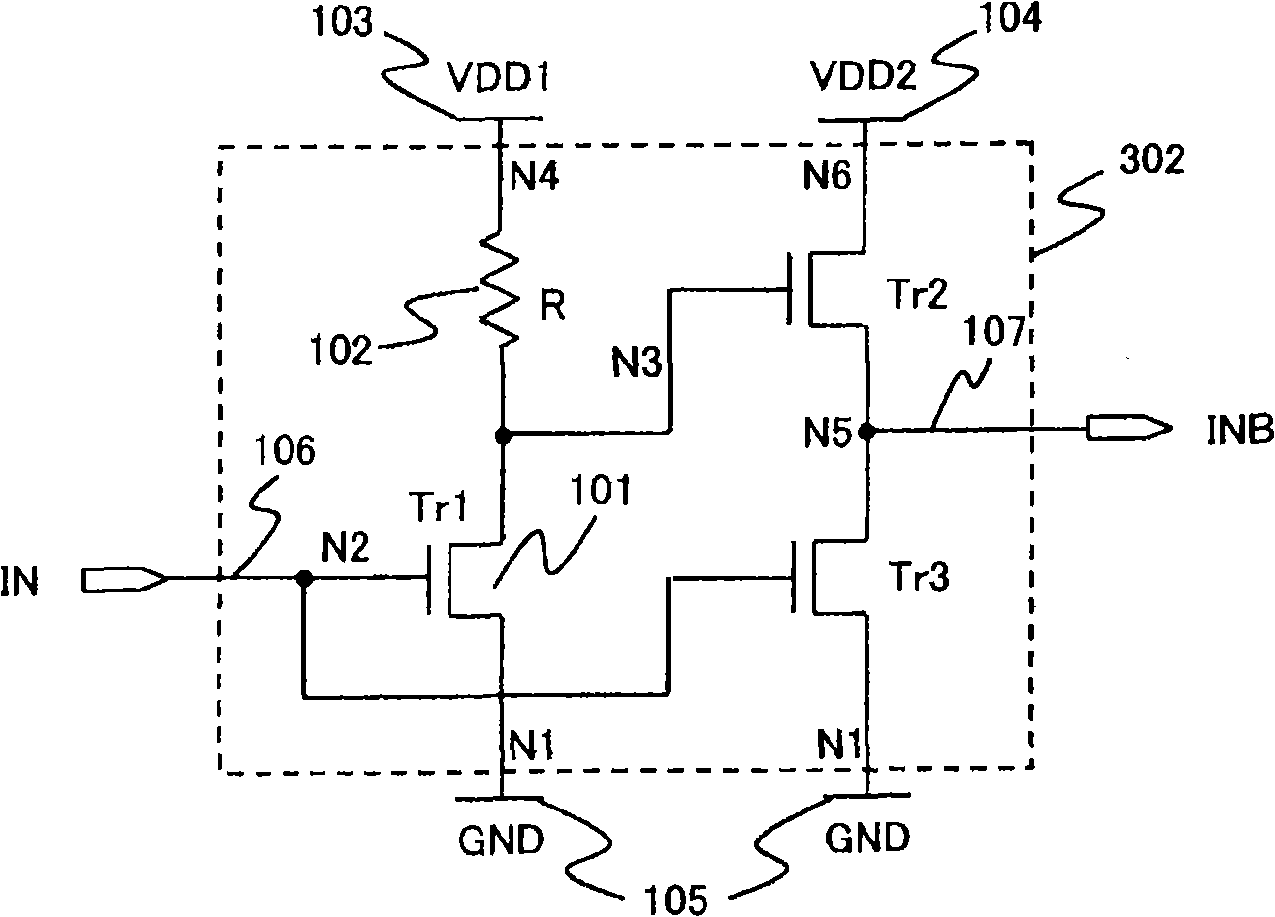

Display device

ActiveUS20080278650A1Reduce current consumptionLess affectedCathode-ray tube indicatorsNon-linear opticsHigh resistanceDisplay device

An inverter includes an input inverter having a high-resistance load and a first transistor and an output buffer including second and third transistors coupled in series. A power supply voltage is provided to satisfy an inequality VDD1>VDD2+Vth where VDD1 is the power supply voltage of the input inverter, VDD2 is the power supply voltage of the output buffer, and Vth is the threshold voltage of the transistors. Use of the high-resistance load allows an output waveform to rise and fall quickly, as well as reduces current consumption.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

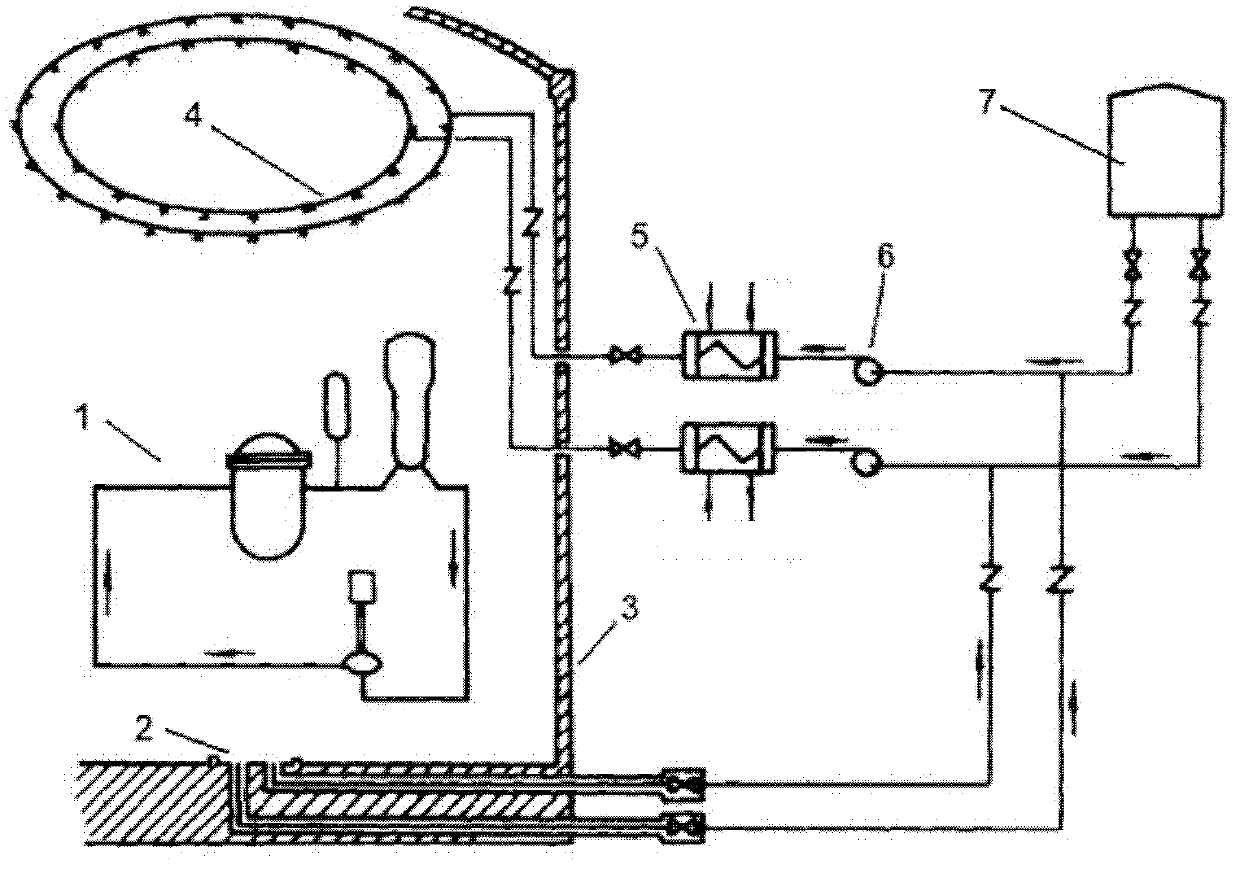

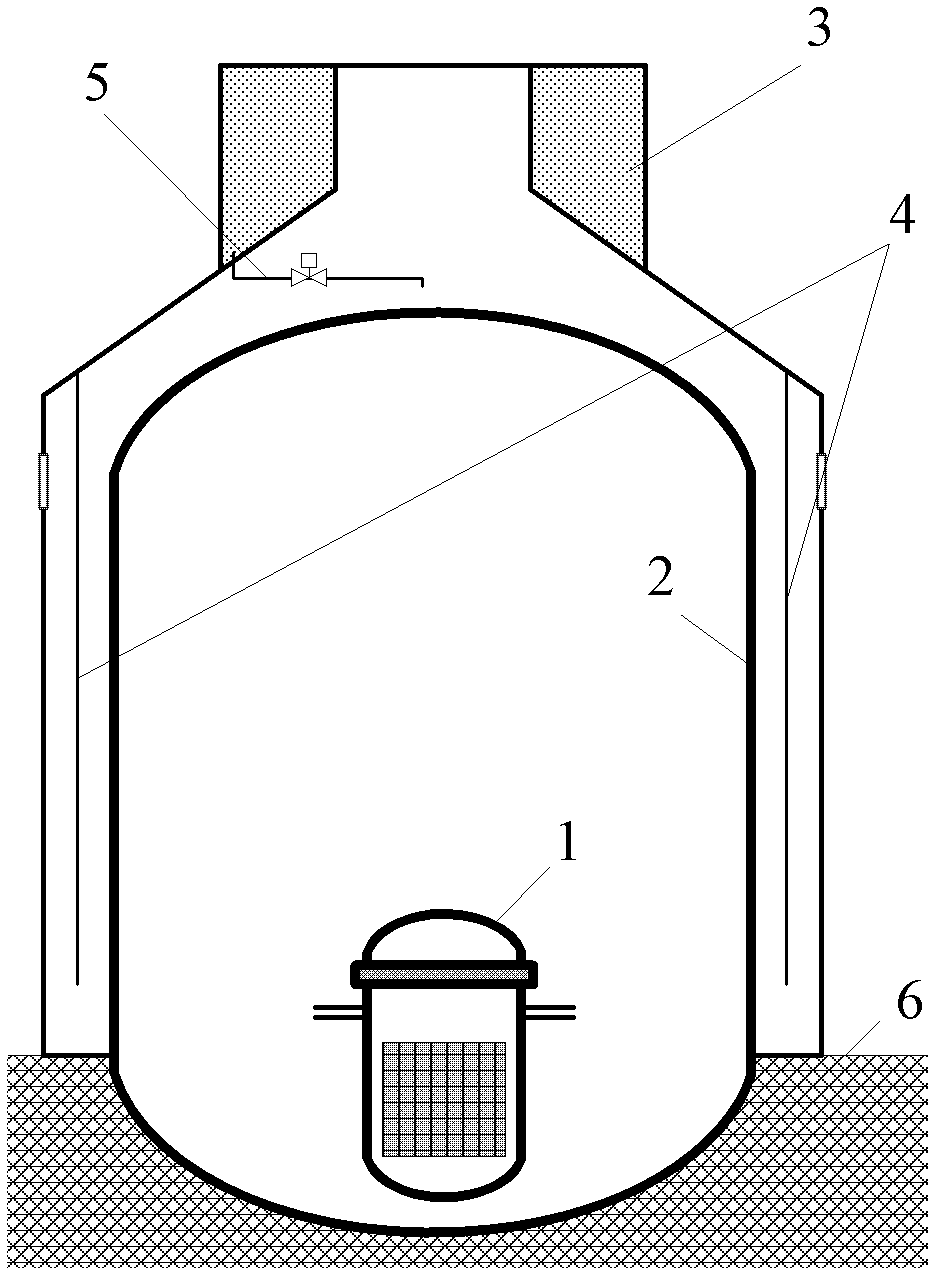

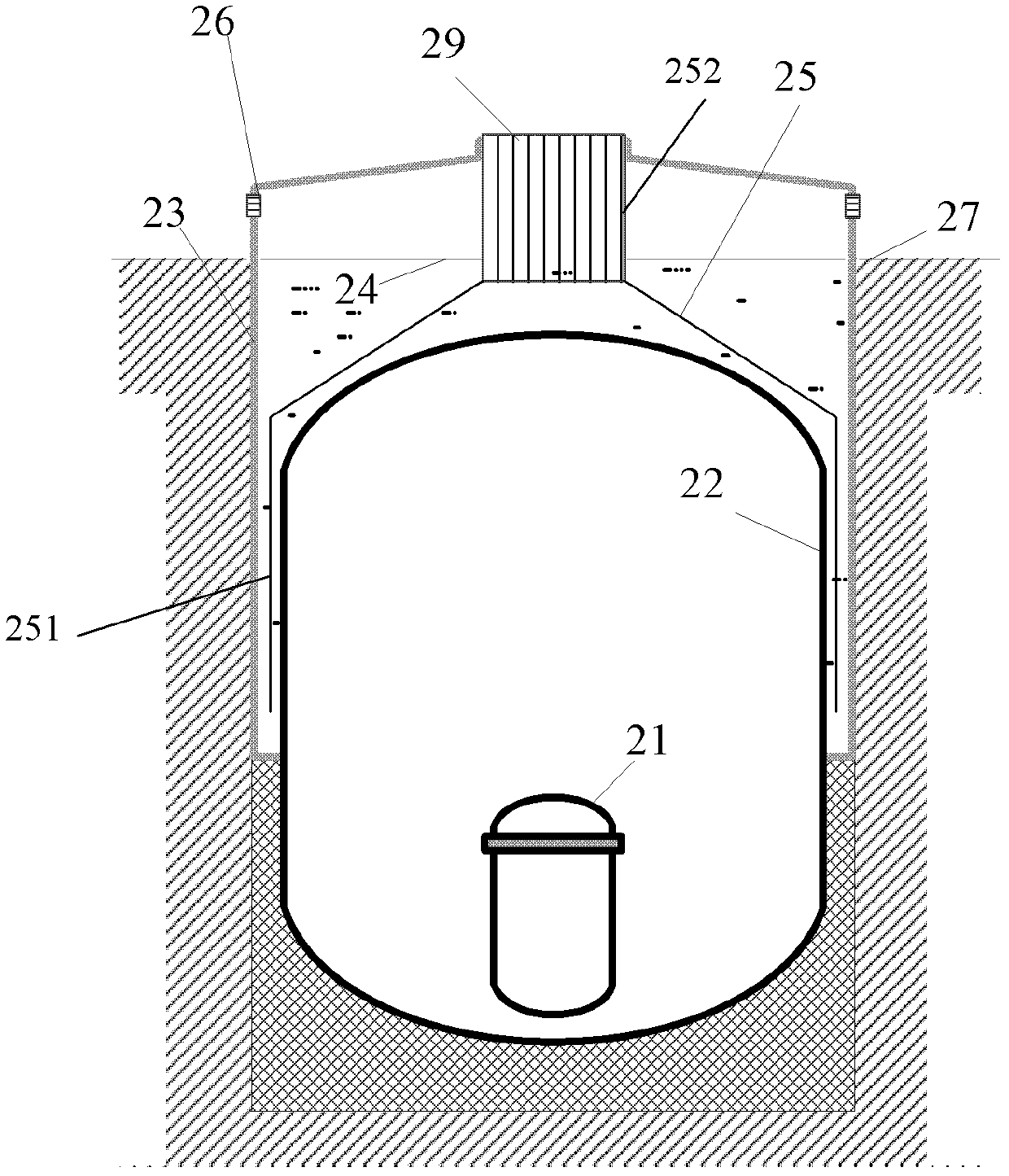

Water logging and air cooling combined passive containment cooling system and method

InactiveCN103295655ARealize self-startStable heat transferNuclear energy generationCooling arrangementWell loggingEngineering

The invention provides a water logging and air cooling combined passive containment cooling system and method. The system is completely self-started, free of intermediate control procedure and high in reliability. The is characterized by comprising a cooling pool and an air flow guide cover, wherein the cooling pool can submerge a containment, the air flow guide cover is arranged at the outside of the containment in the cooling pool, the air flow guide cover is provided with a surrounding part surrounding the containment, and a flow guide part located above the top part of the containment and extending to the atmosphere, the surrounding part and the flow guide part are connected into an entirety, the cooling pool is provided with an air inlet, and the air inlet of the cooling pool, the surrounding part of the air flow guide cover and the flow guide part form an air flow passage with a chimney effect.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

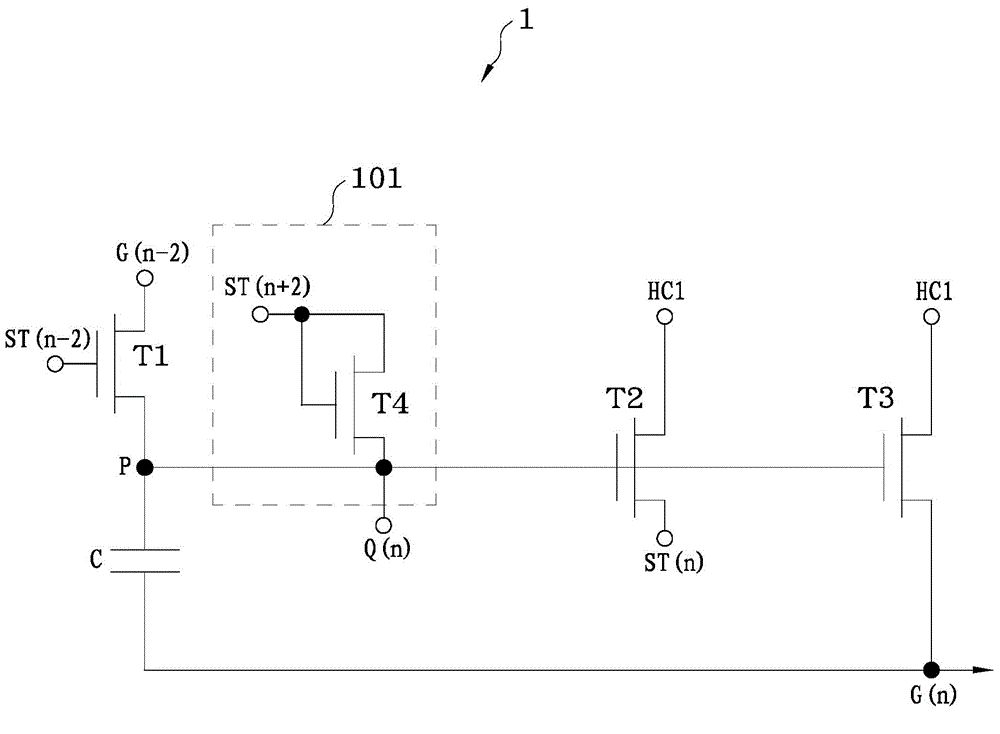

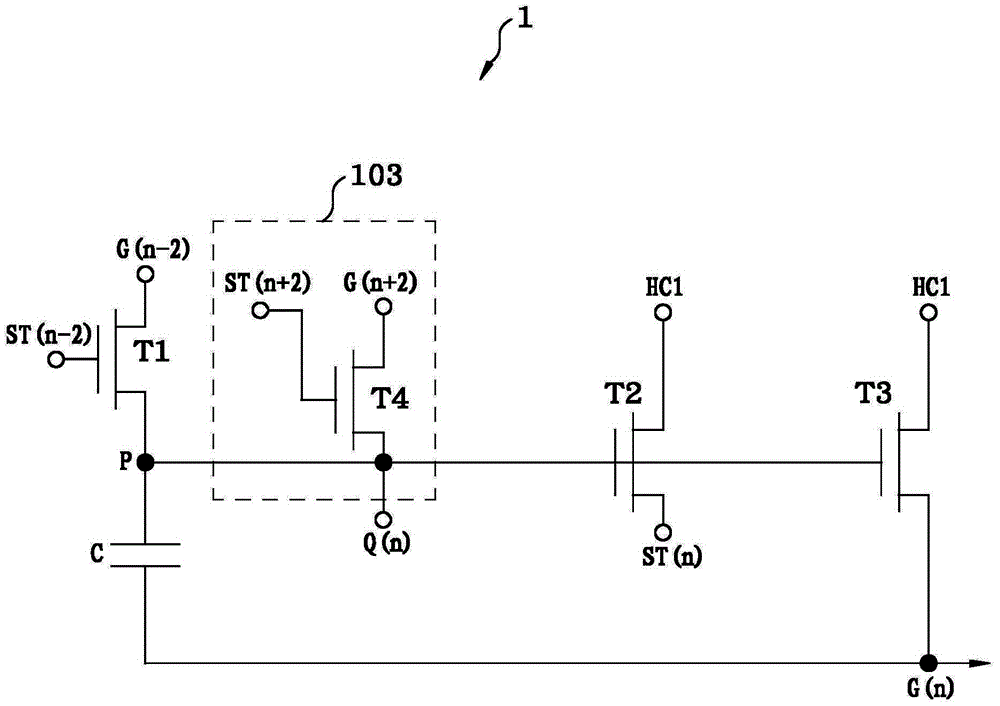

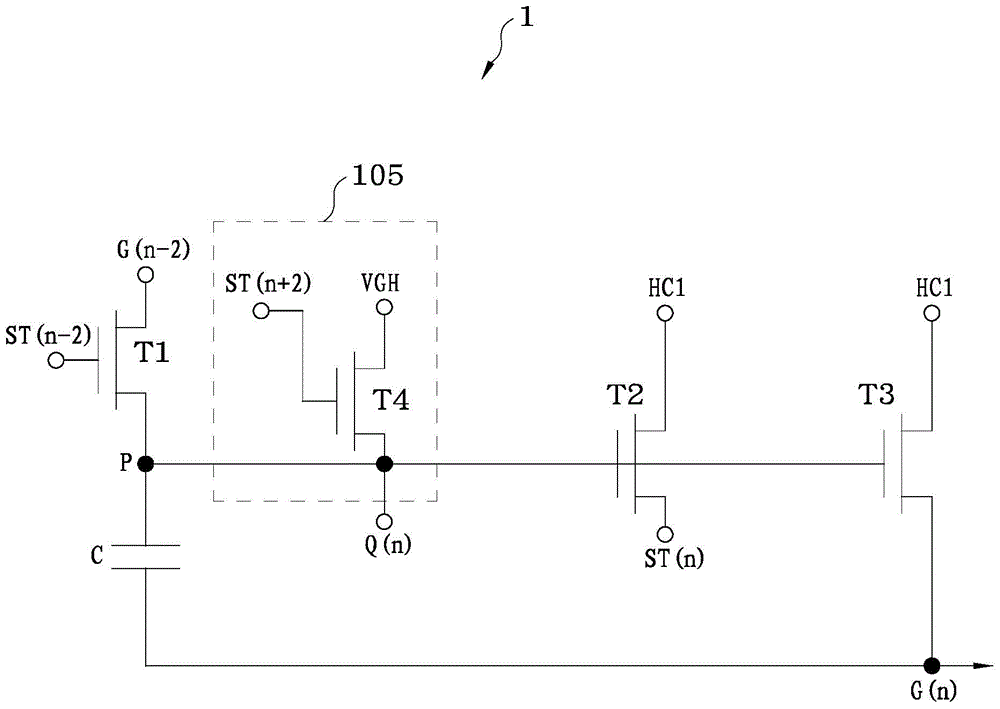

Drive circuit and shifting register thereof

InactiveCN103606359AReduce power consumptionFall fastStatic indicating devicesShift registerControl signal

The invention provides a drive circuit and a shifting register thereof. The drive circuit comprises a first transistor, a second transistor, a third transistor and a signal intensifying circuit. The first end of the first transistor receives an (n-2)th gate drive signal, and the control end of the first transistor receives an (n-2)th control signal. The first end of the second transistor receives a high-frequency clock pulse signal, the second end of the second transistor outputs an nth control signal, and the control end of the second transistor is electrically connected with the second end of the first transistor in a coupling mode. The first end of the third transistor receives the high-frequency clock pulse signal, and the second end of the third transistor outputs an nth gate drive signal. The signal intensifying circuit receives an (n+2)th control signal, and the descending speed of the nth gate drive signal is increased by heightening the voltage potential of a common node. Compared with the prior art, according to the drive circuit and the shifting register thereof, the descending process of the nth gate drive signal can be accelerated so that the corresponding transistors can be fast closed, and therefore power consumption of a circuit is reduced, and the circumstance that power consumption is high is avoided so as to protect an electronic assembly of a circuit board against damage.

Owner:AU OPTRONICS CORP

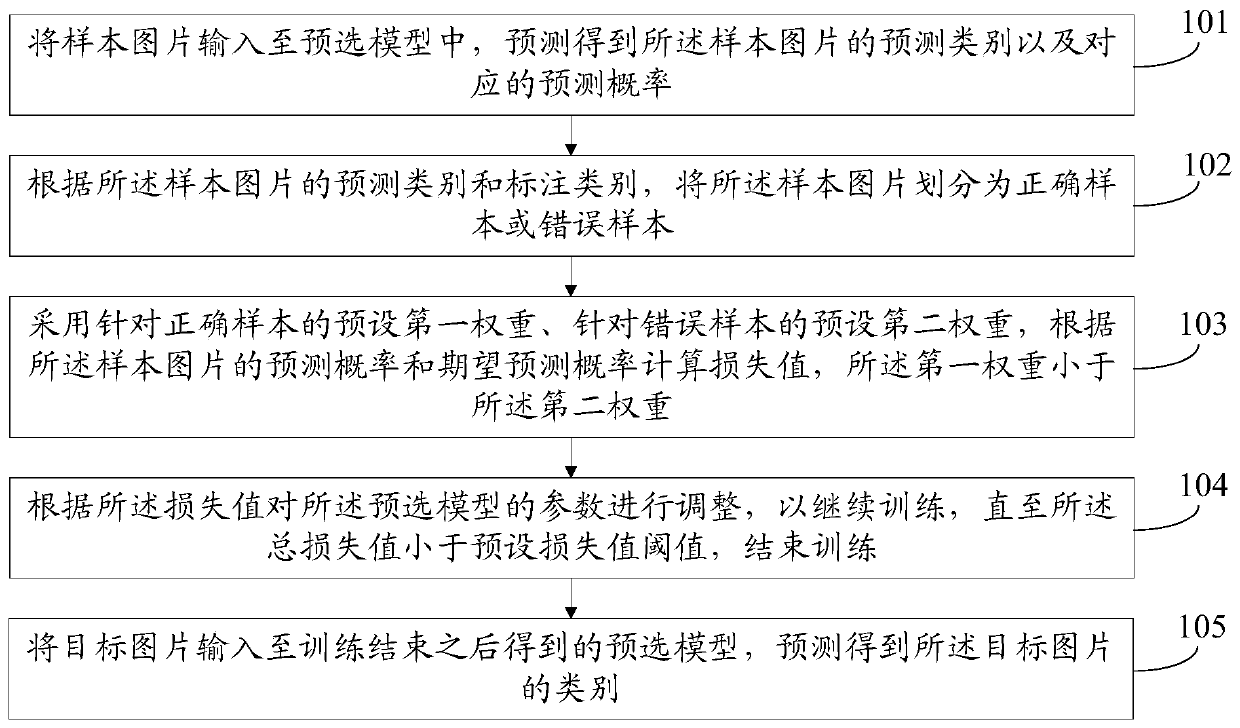

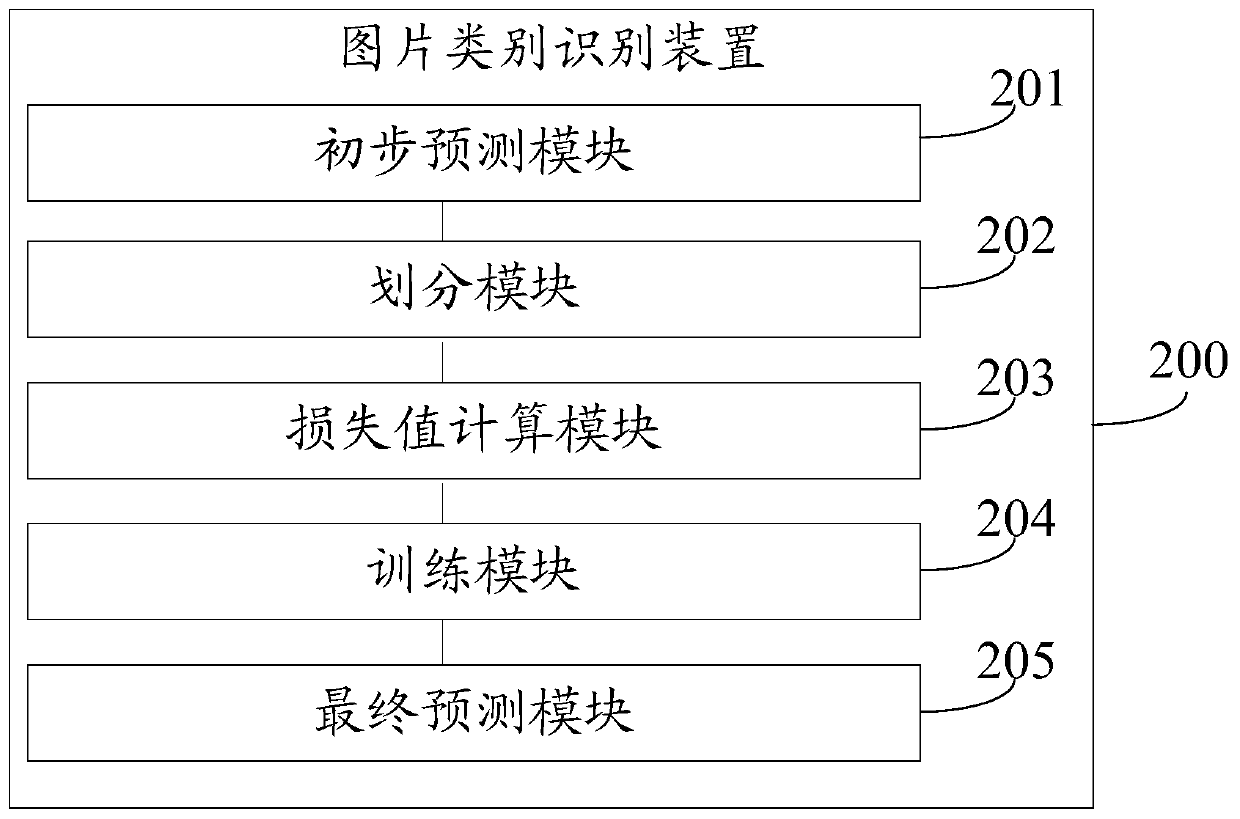

Picture category identification method and device

ActiveCN110084271AFast convergenceFall fastCharacter and pattern recognitionAlgorithmPrediction probability

The embodiment of the invention provides a picture category identification method and device, and the method comprises the steps: inputting a sample picture into a pre-selected model, and carrying outthe prediction, so as to obtain the prediction category and corresponding prediction probability of the sample picture; calculating a loss value according to the prediction probability and the expected prediction probability of the sample picture by adopting a preset first weight for a correct sample and a preset second weight for an error sample, with the first weight being smaller than the second weight; and adjusting parameters of the pre-selected model according to the loss value to continue training until the total loss value is smaller than a preset loss value threshold value, and ending the training. In the above method, when the loss value of image classification model training is calculated, the first weight corresponding to the correct sample is set to be smaller than the secondweight of the error sample, so that the training process can pay more attention to the sample which is difficult to pay more attention to, thereby accelerating the reduction speed of the loss value,and further accelerating the convergence speed of the model at lower cost.

Owner:TONGDUN HLDG CO LTD

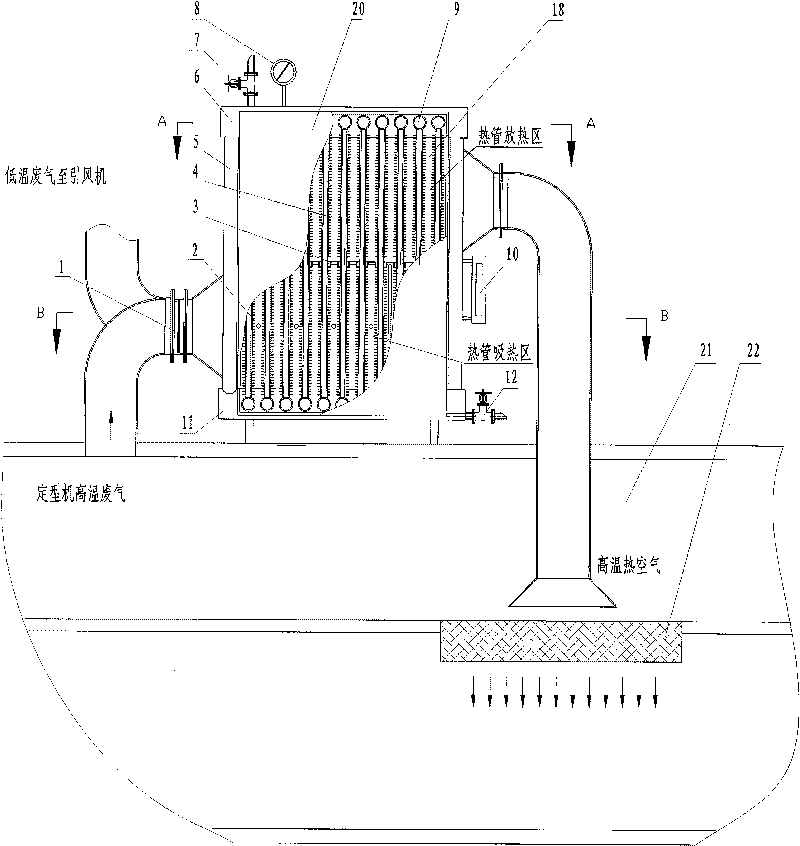

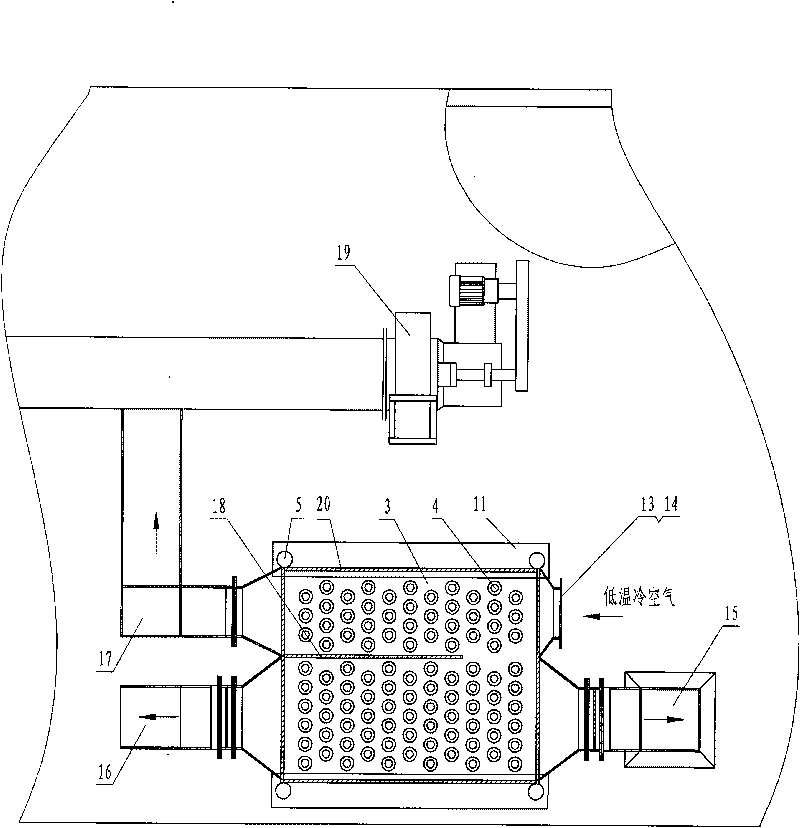

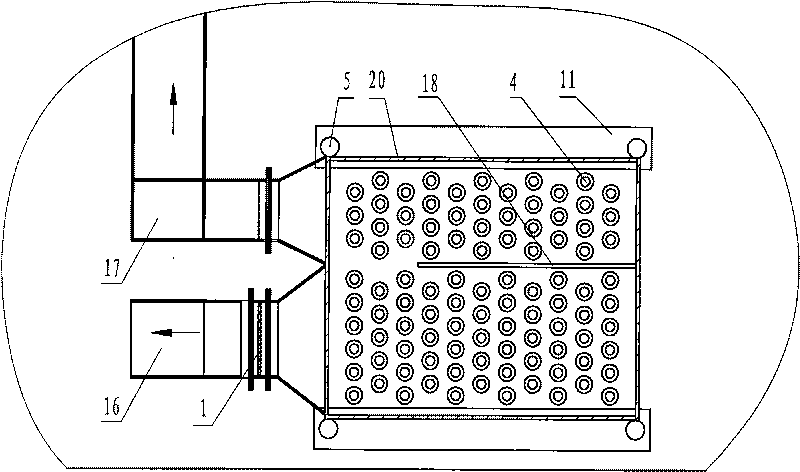

Waste heat exchange device for textile setting machine

InactiveCN101749976AEasy maintenance and repairImprove heat transfer effectTextile treatment machine arrangementsIndirect heat exchangersEngineeringPhase state

The invention relates to a main working auxiliary machine for a textile machinery setting machine, and discloses a waste heat exchange device for a textile setting machine. The device comprises a plurality of fin heat pipes (4) which are vertically arranged, and the upper and lower ends of the fin heat pipes are communicated with container connecting pipelines (9) to form heat transfer rows; and a plurality of heat transfer rows are arranged in parallel, an upper container (6) and a lower container (11) are communicated and connected to form a rectangular heat transfer body, and a middle pipe plate (3) divides the rectangular heat transfer body into an upper half heat transfer body and a lower half heat transfer body. Upper and lower guide plates (18) vertically divide a heat absorption layer and a heat release layer respectively, and an air inlet, an air inlet passage, a turning passage, an air outlet passage and an air outlet are formed on each layer surface respectively; and a working substance down pipe (5), a liquid filling port (7) and a working substance discharge port (12) are arranged between the upper and lower containers. The invention provides the scheme of vertically arranging the fin heat pipes (10) for the first time, so the heat absorption and heat release of the device are more sufficient and the effect is better; the device is more favorable for phase state conversion for the medium in the fin heat pipes; and the heat exchange device for the setting machine is convenient to maintain, and the medium is convenient to change.

Owner:李天德

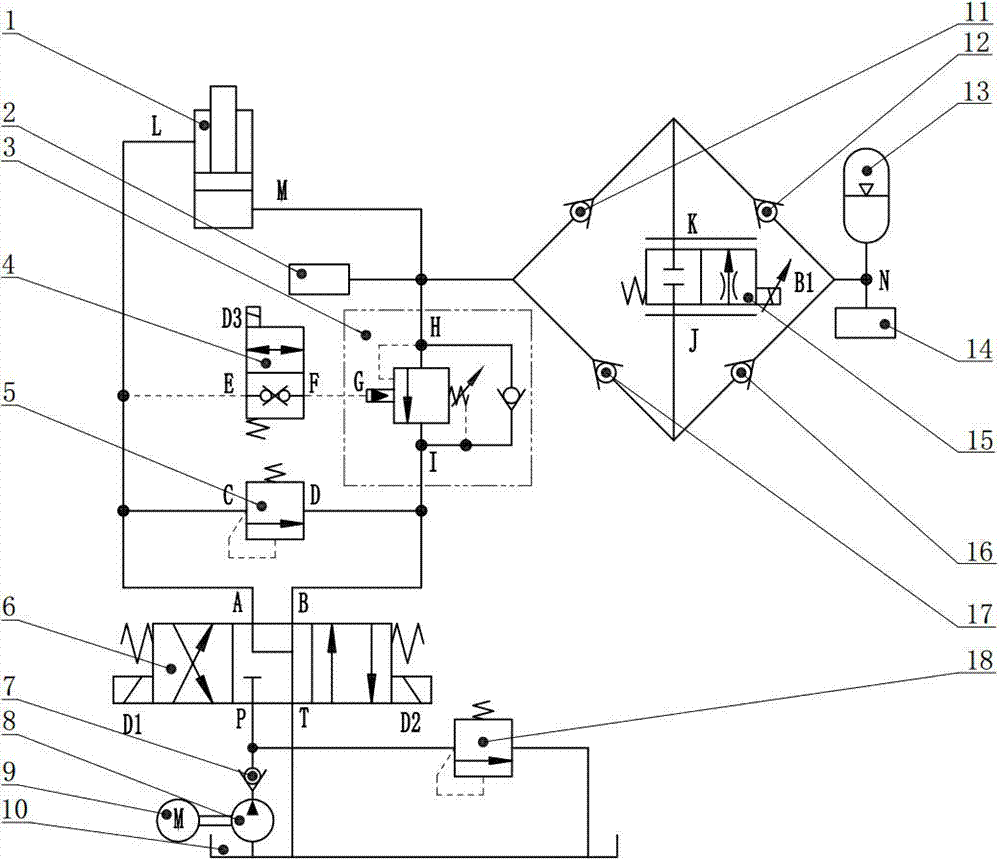

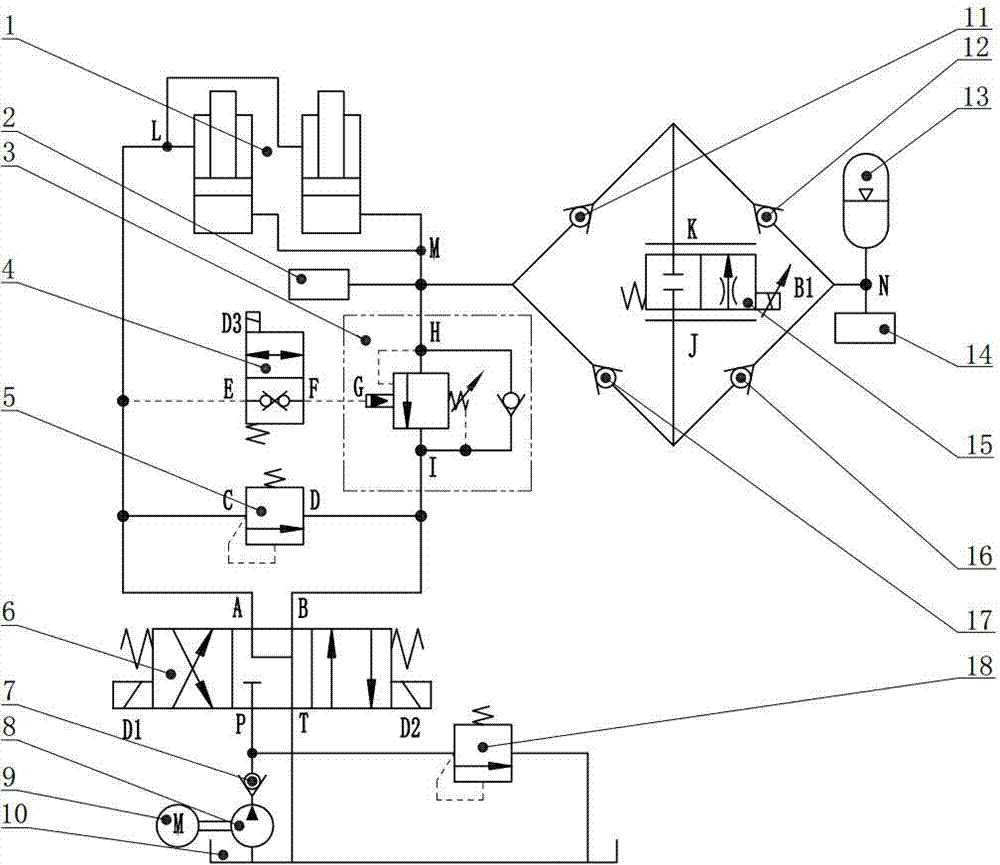

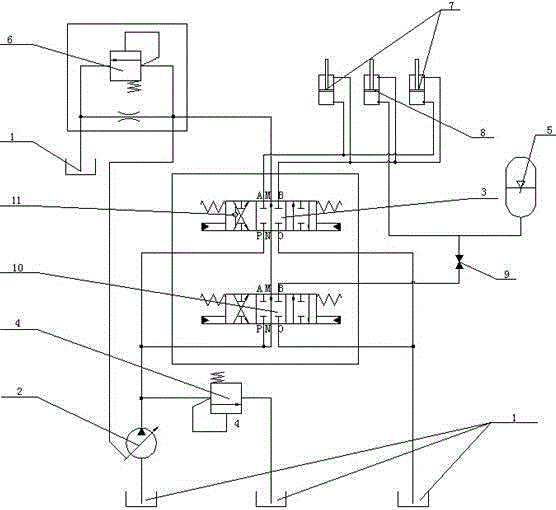

Engineering machinery movable arm potential energy variable amplitude energy recovery device

ActiveCN104747544AReduce energy supplyTo achieve the purpose of energy savingSoil-shifting machines/dredgersFluid-pressure actuator componentsHydraulic pumpFuel tank

The invention relates to an engineering machinery movable arm potential energy variable amplitude energy recovery device which comprises a movable arm oil cylinder, a pressure sensor, a balance valve, a two-position two-way electromagnetic valve, overflow valves, a three-position four-way electromagnetic reversing valve, one-way valves, a hydraulic pump, a motor, an oil tank, an energy accumulator, a proportional flow valve and a controller. The motor is in mechanical transmission connection with the hydraulic pump. The hydraulic pump is connected with the oil tank and the one-way valves. The three-position four-way electromagnetic reversing valve is connected with the one-way valves, the oil tank, the movable arm oil cylinder and the balance valve. The balance valve is connected with a large-cavity oil port of the movable arm oil cylinder and the two-position two-way electromagnetic valve. The two-position two-way electromagnetic valve is connected with the three-position four-way electromagnetic reversing valve. The first overflow valve is connected with the three-position four-way electromagnetic reversing valve. The proportional flow valve is connected with the one-way valves. A proportional flow valve oil port is connected with the one-way valve. The third one-way valve is connected with the fourth one-way valve and the energy accumulator. The second overflow valve is connected with the one-way valves and the oil tank. The energy recovery device has the advantages of saving energy, recovering variable amplitude energy and being fast in dynamic response.

Owner:TONGJI UNIV

Sieve-plate tower used for sintering machine flue gas desulfurization and desulfurization process thereof

InactiveCN102512939ALarge specific surface areaImprove absorption efficiencyDispersed particle separationFlue gasSlurry

The invention discloses a sieve-plate tower used for sintering machine flue gas desulfurization and a desulfurization process thereof, and belongs to the field of resource and environment protection. The device comprises an absorption tower, wherein the absorption tower is provided with a flue gas inlet, a flue gas outlet and a desulfurizer inlet, a demisting layer, a spraying layer, a sieve plate and a pulp chest are sequentially arranged in the absorption tower from top to bottom, the desulfurizer inlet is positioned above the flue gas inlet, the sieve plate is positioned between the desulfurizer inlet and the flue gas inlet, an overflow weir is arranged above the sieve plate, the sieve plate is divided into an overflow area and a gas liquid contact area by the overflow weir, sieve pores of the sieve plate are arranged in the gas liquid contact area, the gas liquid contact area is positioned at one side of the sieve plate close to the desulfurizer inlet, and an overflow pipe is arranged under the overflow area. The desulfurization process comprises the following steps that: sintering machine flue gas enters the absorption tower to be reacted with the desulfurizer at the gas liquid contact area and then is discharged after sulfur dioxide is removed, and desulfurized pulp generated by the reaction of the flue gas and the desulfurizer overflows into the pulp chest of the absorption tower. The invention is used for removing the sulfur dioxide in the sintering machine flue gas, the flue gas desulfurization efficiency is improved, and the desulphurization energy consumption is reduced.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Manufacturing method for desulfurization and denitrification agent additive by limestone-gypsum method

InactiveCN103691288AImprove solubilityReduce solubilityDispersed particle separationOrganic acidEnvironmental engineering

The invention discloses a manufacturing method for a desulfurization and denitrification agent additive by a limestone-gypsum method. The manufacturing method is characterized in that the additive consists of the components in percentage by weight: 40-60 percent of a catalytic promoter substance, 20-40 percent of organic acid and salt substances and 15-40 percent of a synergist substance. The additive adopted in the manufacturing method can improve the desulfurization efficiency of an absorption tower, adapt to high-sulfur coal and enable the SO2 outlet concentration to meet a standard; furthermore, a serous fluid circulating pump can be stopped to different extents, and the aim of saving the energy can be fulfilled; moreover, the additive is easily dissolved in water and can promote dissolving of limestone and reduce the using amount of the limestone; the pH value buffering capacity of limestone serous fluid is improved, and rapid reduction of the pH value of the limestone serous fluid in a continuous sulfur dioxide absorption process is relieved; generation of calcium sulfite soft dirt is inhibited, and a demister can be prevented from being blocked. The desulfurization and denitrification agent additive has the characteristics of simplicity and convenience in use, no production of air bubbles in the using process and no corrosion to equipment; compared with the conventional limestone, the desulfurization and denitrification agent additive has the advantages that the content of NO in smoke gas can be also reduced; under the same liquid-gas-ratio condition, the desulfurization efficiency is improved by 8-18 percent, and the denitrification efficiency is over 50 percent; desulfurization and denitrification effects and a smoke gas purification effect are achieved.

Owner:高同柱

Spacing bars for porous rubber and hollow glass

InactiveCN101092867AEliminate condensationEasy to passUnits with parallel planesMolecular sievePolymer science

This invention relates to a micro-hole rubber hollow glass spacing strip used in hollow glasses composed of rubber, curing agent and aids characterizing that said rubber is composed of EPT rubber and molecular sieve activation powder with the following weight percentage: EPT rubber 100 portions, activation powder 80-200 portions.

Owner:廖昌荣

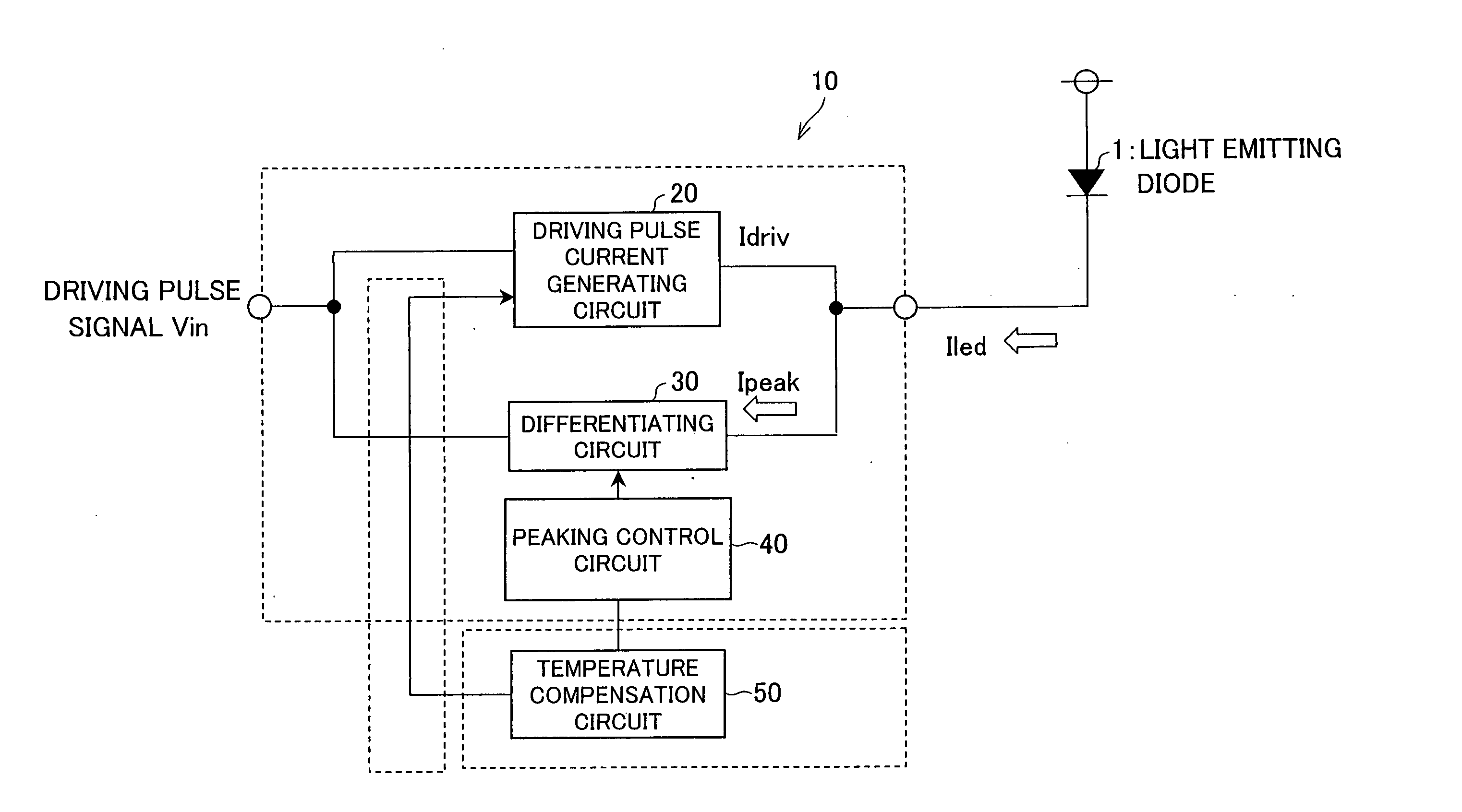

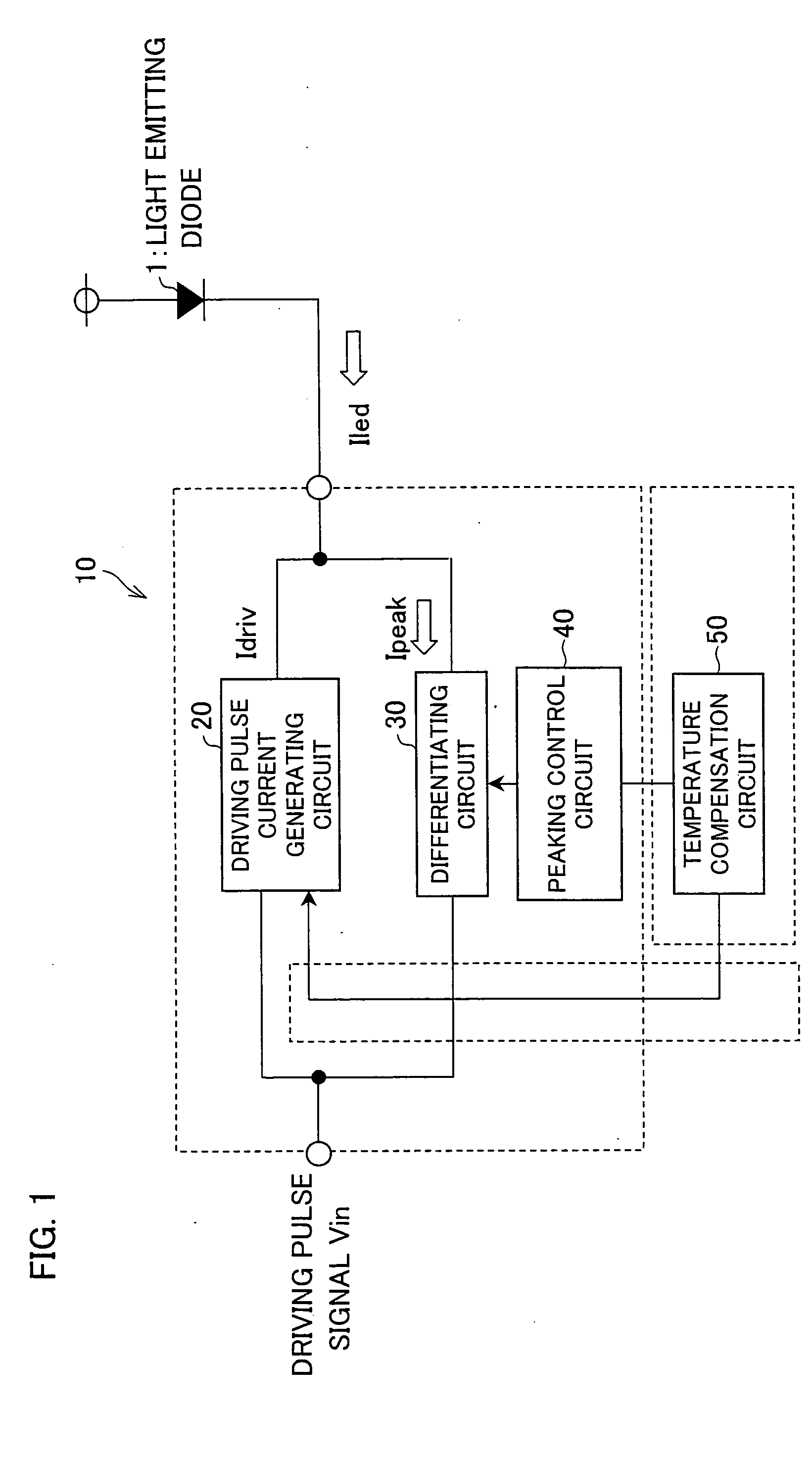

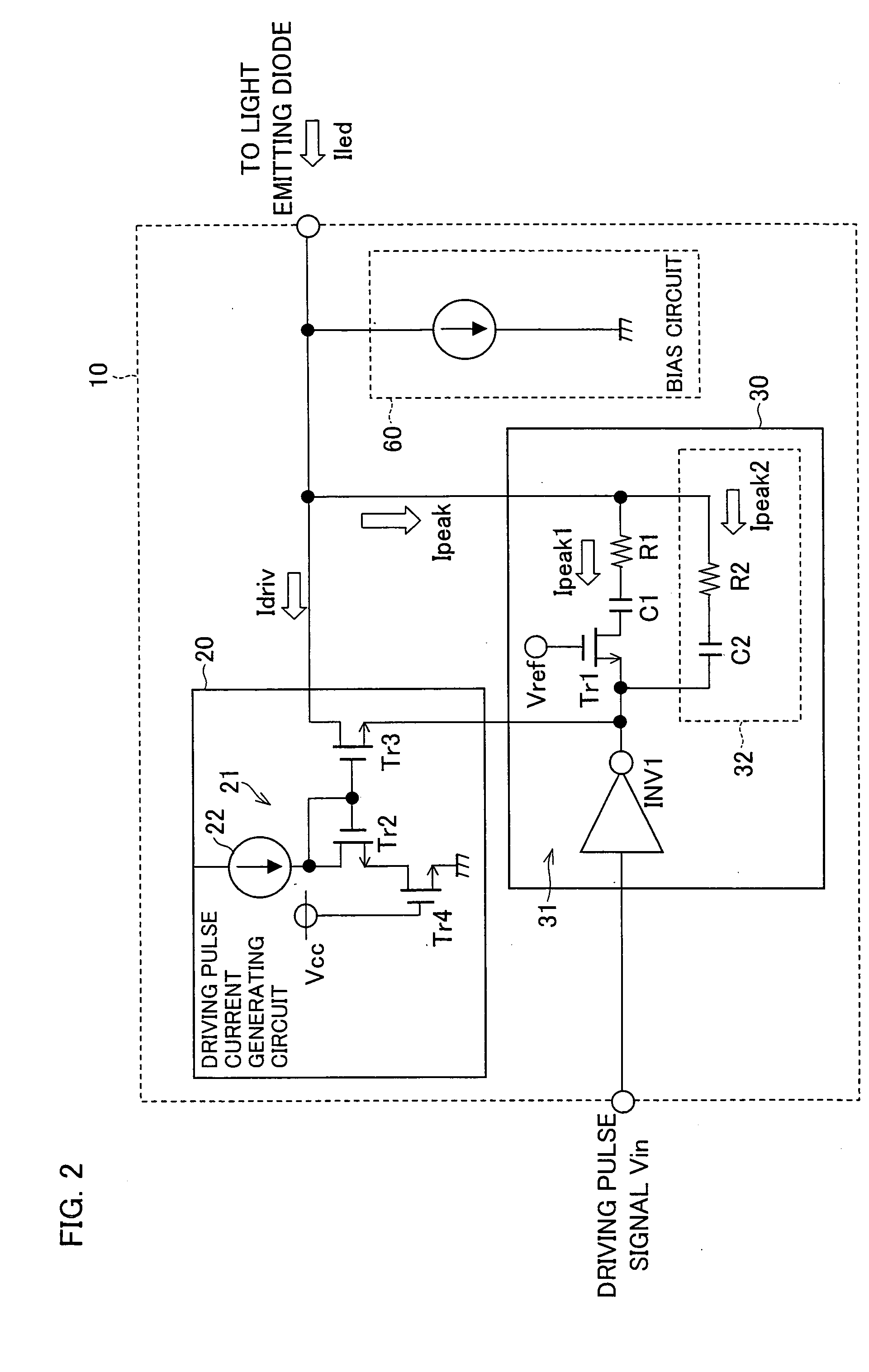

Light emitting diode driving device and optical transmission device including the same

ActiveUS20060092099A1Faster rise and fallLess overshootStatic indicating devicesElectromagnetic transmittersPeak valueEngineering

A light emitting diode driving device for driving an LED includes (i) a driving pulse current generating circuit for generating a driving current for the LED in accordance with a driving pulse signal supplied from outside and (ii) a differentiating circuit for generating a peaking current obtained by differentiating the driving pulse signal. A current that is equal to the sum of the driving current and the peaking current flows to the LED. The light emitting diode driving device further includes a peaking control circuit for controlling the magnitude of the peaking current generated from the differentiating circuit.

Owner:SHARP KK

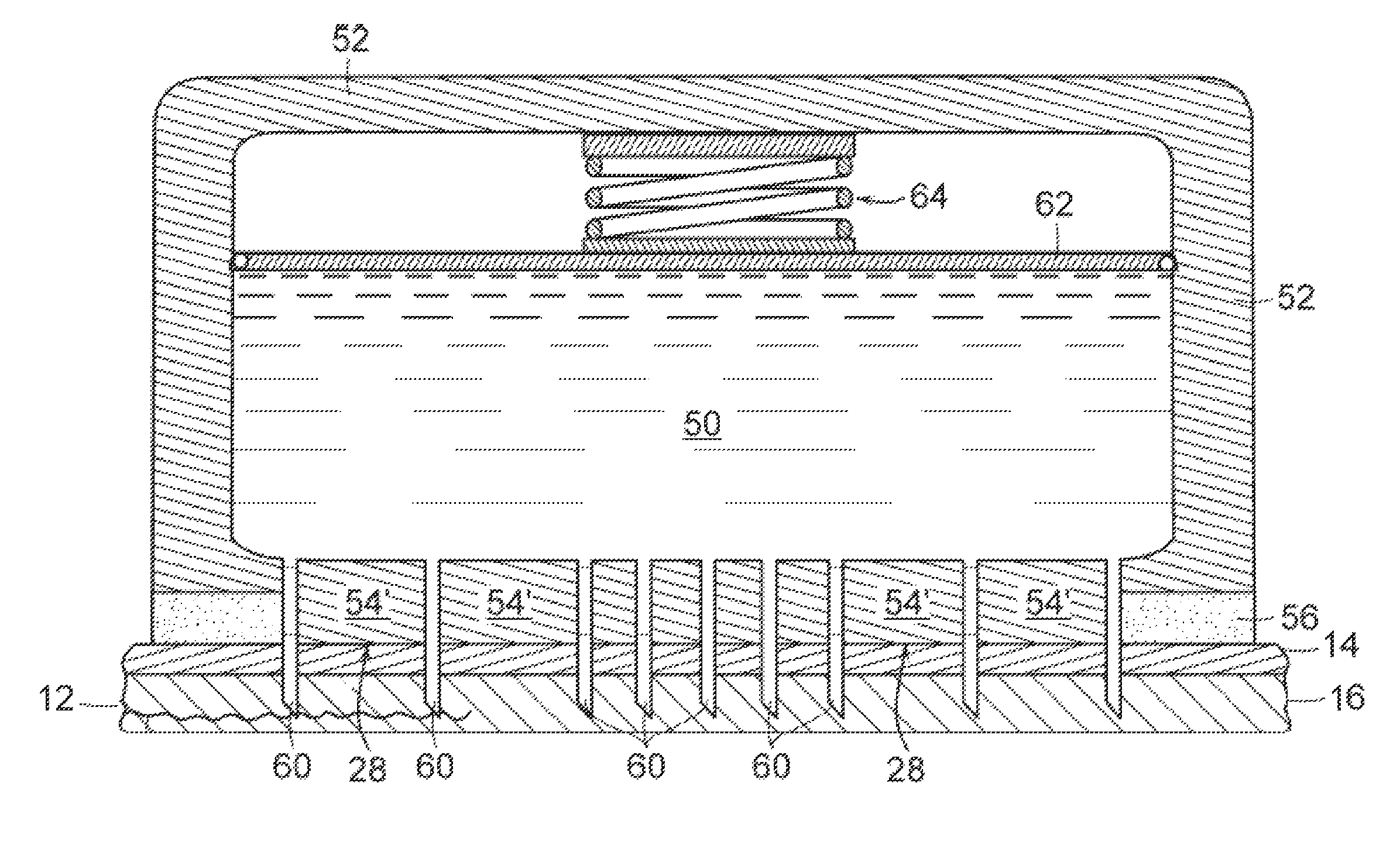

Methods and devices for desmopressin drug delivery

InactiveUS8399410B2Prevent adverse side effectsReduce productionElectrotherapyMicroneedlesDecreased sodiumSide effect

Disclosed are devices for urine voiding postponement, and methods for treating conditions such as central diabetes insipidus, enuresis, nocturia, urinary frequency or incontinence. The devices deliver a desmopressin flux through the skin of a patient in a low dose amount just necessary to achieve a desired anti-diuretic effect without undesirable side effects such as hyponatremia. The devices are designed to permit a state of normal urinary production to return quickly after the desmopressin flux is terminated.

Owner:SERENITY PHARMA CORP

Display device

ActiveCN101290751AReduce current consumptionOutput waveform risesStatic indicating devicesLogic circuitsHigh resistanceDisplay device

The invention provides a display device which forms an inverter circuit 302 by adopting an input phase inverter Tr1 of high resistance load R and an output buffer formed by two transistors Tr2 and Tr3 connected in series. When the power voltage of the input phase inverter is VDD1, the power voltage of output buffer is VDD2 and the threshold voltage of the transistor is Vth, the power voltage is supplied to satisfy inequality VDD1 >VDD2+Vth. The high resistance load R enables elevation and declination fast and reduces the consumed current.

Owner:JAPAN DISPLAY INC +1

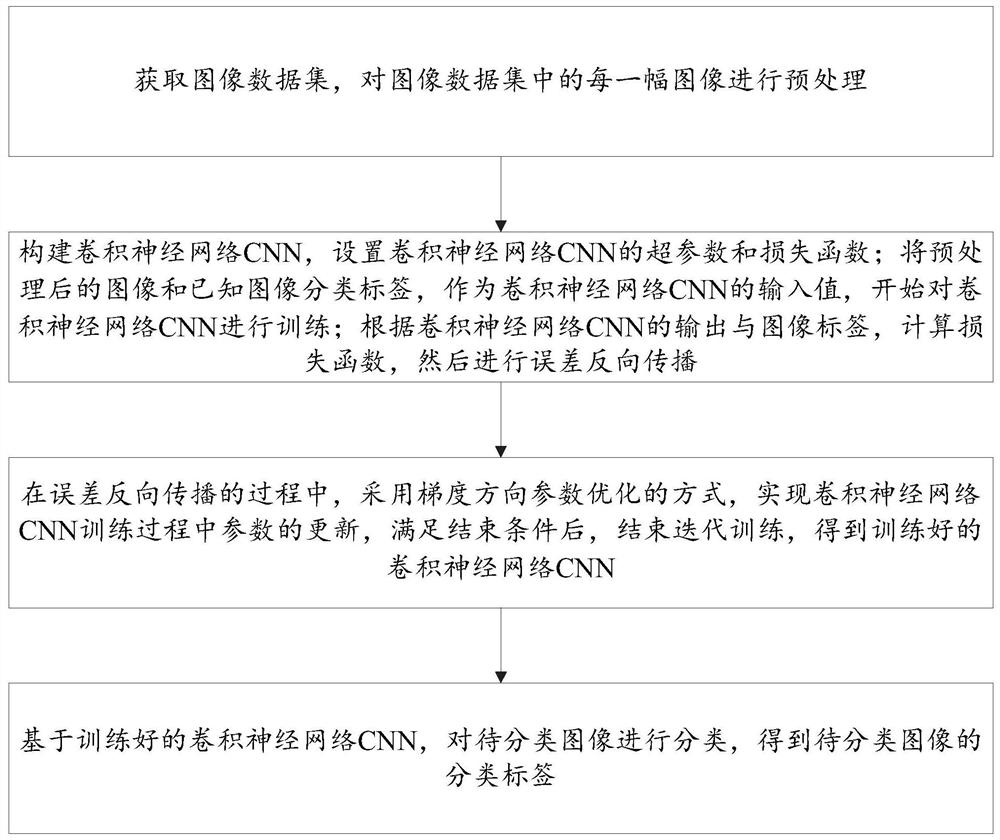

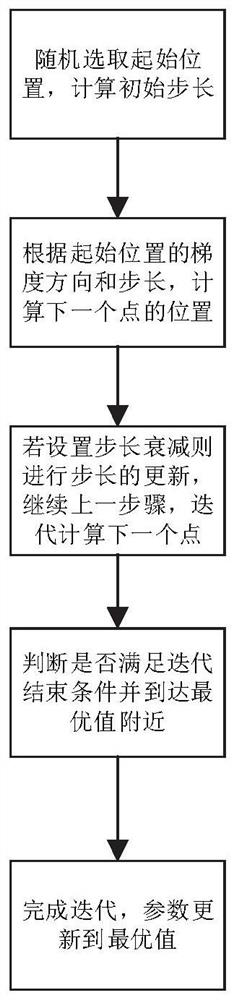

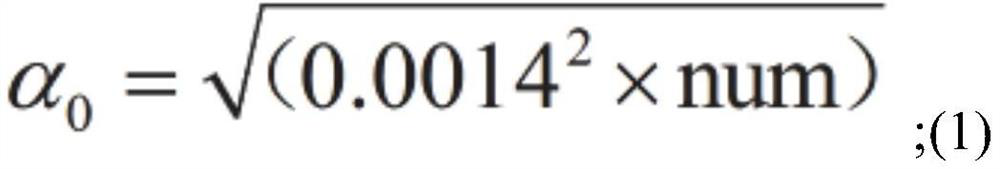

Image classification method and system of neural network based on gradient direction parameter optimization

ActiveCN113052239ANo non-convergenceOperation directlyCharacter and pattern recognitionNeural architecturesData setImaging data

The invention discloses an image classification method and system of a neural network based on gradient direction parameter optimization, and the method comprises the steps: obtaining an image data set, and carrying out the preprocessing of each image in the image data set; constructing a convolutional neural network, and setting a hyper-parameter and a loss function of the convolutional neural network; taking the preprocessed image and a known image classification label as input values of a convolutional neural network, and starting to train the convolutional neural network; calculating a loss function according to the output of the convolutional neural network and the image label, and then carrying out error back propagation; in an error back propagation process, adopting a gradient direction parameter optimization mode to realize parameter updating in a convolutional neural network training process, and after an end condition is satisfied, ending iterative training to obtain a trained convolutional neural network; and based on the trained convolutional neural network, classifying the to-be-classified image to obtain a classification label of the to-be-classified image. The method has the advantages of high image classification speed and high stability.

Owner:SHANDONG UNIV

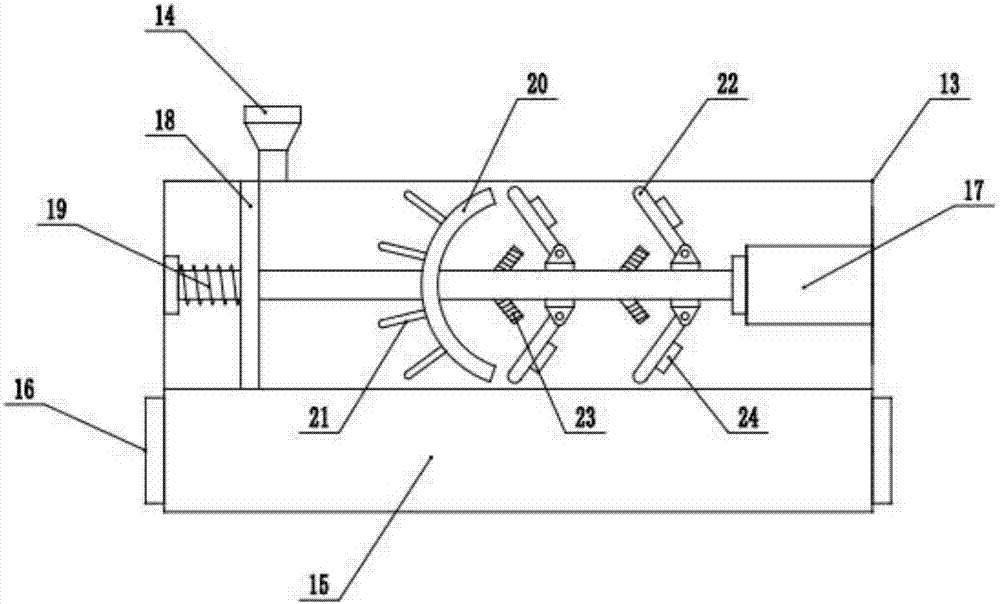

Bucket shaft double-rotating type efficient stirring and crushing device

InactiveCN107096605AEasy to insertEasy to useRotary stirring mixersTransportation and packagingMechanical engineering

Owner:林少忠

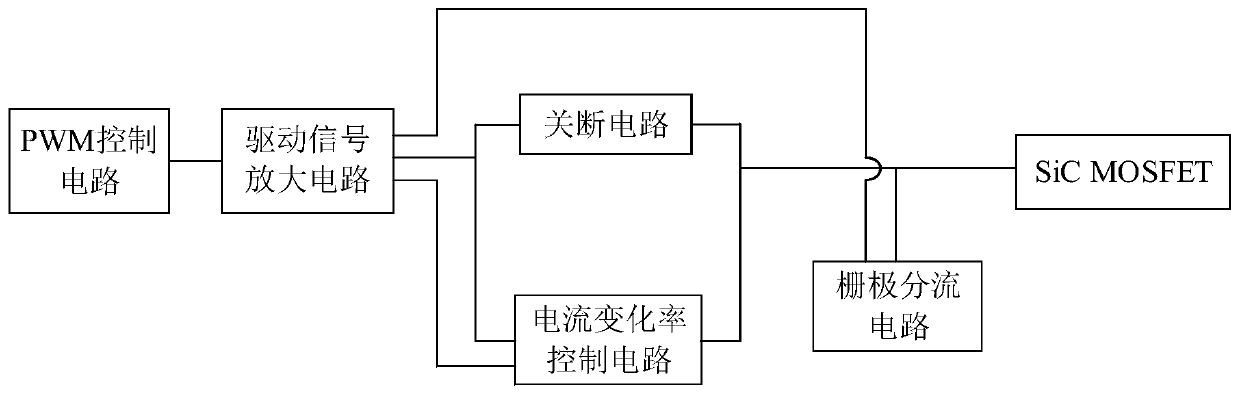

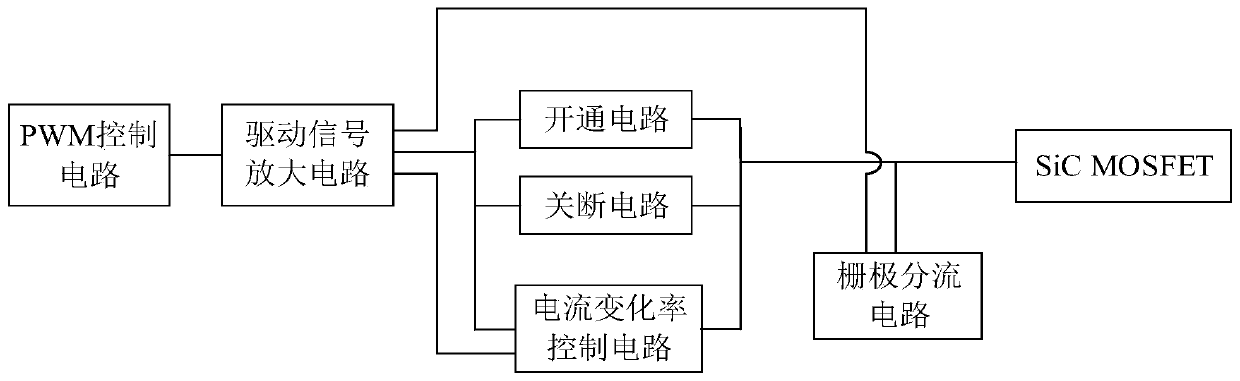

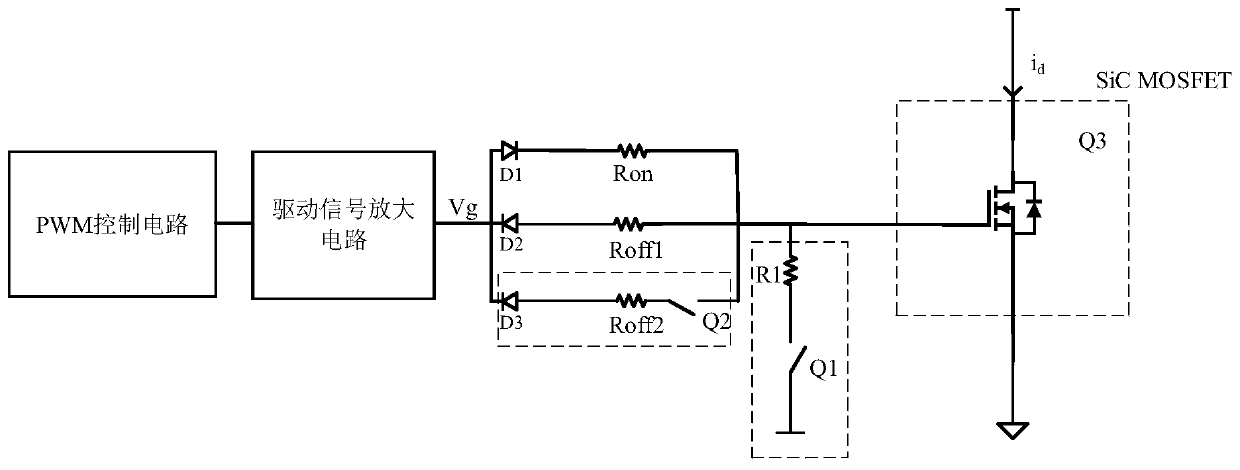

Drive circuit of silicon carbide semiconductor field effect transistor

InactiveCN110112893AIncreased shutdown speedReduce the rate of change of leakage currentEfficient power electronics conversionPower conversion systemsMOSFETLow voltage

The invention discloses a drive circuit of a silicon carbide semiconductor field effect transistor. The drive circuit comprises a PWM control circuit, a drive signal amplification circuit, a turn-offcircuit, a gate shunt circuit and a current change rate control circuit, wherein the gate shunt circuit is switched on when the turn-off circuit works to perform shunt of the gate current of a SiC MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) and accelerate the switch-off of the SiC MOSFET; the SiC MOSFET is switched off when the drain-source voltage of the SiC MOSFET is increased toa preset value; the current change rate control circuit is switched off when the drain-source voltage of the SiC MOSFET is increased to the preset value to reduce the leakage current change rate. Thegate shunt circuit is arranged to perform shunt of the gate output current in the SiC MOSFET switch-off process and speed up the decreasing speed of the gate-source voltage so as to improve the switch-off speed of the SiC MOSFET; and besides, in the switch-off process of the SiC MOSFET, the switch-off of the current change rate control circuit reduces the leakage current change rate so as to reduce the voltage peak when the SiC MOSFET is switched off, the two circuits cooperatively act to achieve the voltage reduction speed and the low-voltage peak of the high gate-source voltage and ensure the safety operation of the SiC MOSFET.

Owner:HUAZHONG UNIV OF SCI & TECH

Hydraulic excavator movable arm potential energy recovery system

PendingCN104988963ARelieve pressureImprove work efficiencySoil-shifting machines/dredgersHydraulic pumpExcavator

The invention provides the technical scheme of a hydraulic excavator movable arm potential energy recovery system. The scheme also comprises two main control oil cylinders and an auxiliary oil cylinder which are used for driving a movable arm to move, wherein the auxiliary oil cylinder is arranged in parallel with the two main control oil cylinders; cylinder rods of the two main control oil cylinders and a cylinder rod of the auxiliary oil cylinder synchronously move; a hydraulic pump is communicated with rod cavities and rodless cavities of the two main control oil cylinders and a rod cavity of the auxiliary oil cylinder by a second reversing valve; and a rodless cavity of the auxiliary oil cylinder is communicated with an energy accumulator. According to the invention, the potential energy produced when the auxiliary oil cylinder descends can be recovered in the energy accumulator; the energy accumulator releases the stored potential energy when the movable arm ascends; and compared with the prior art, the whole hydraulic system has the advantages that the energy consumption is greatly reduced; heating is reduced; and the reutilization of energy is realized.

Owner:SHANDONG LISHIDE MACHINERY

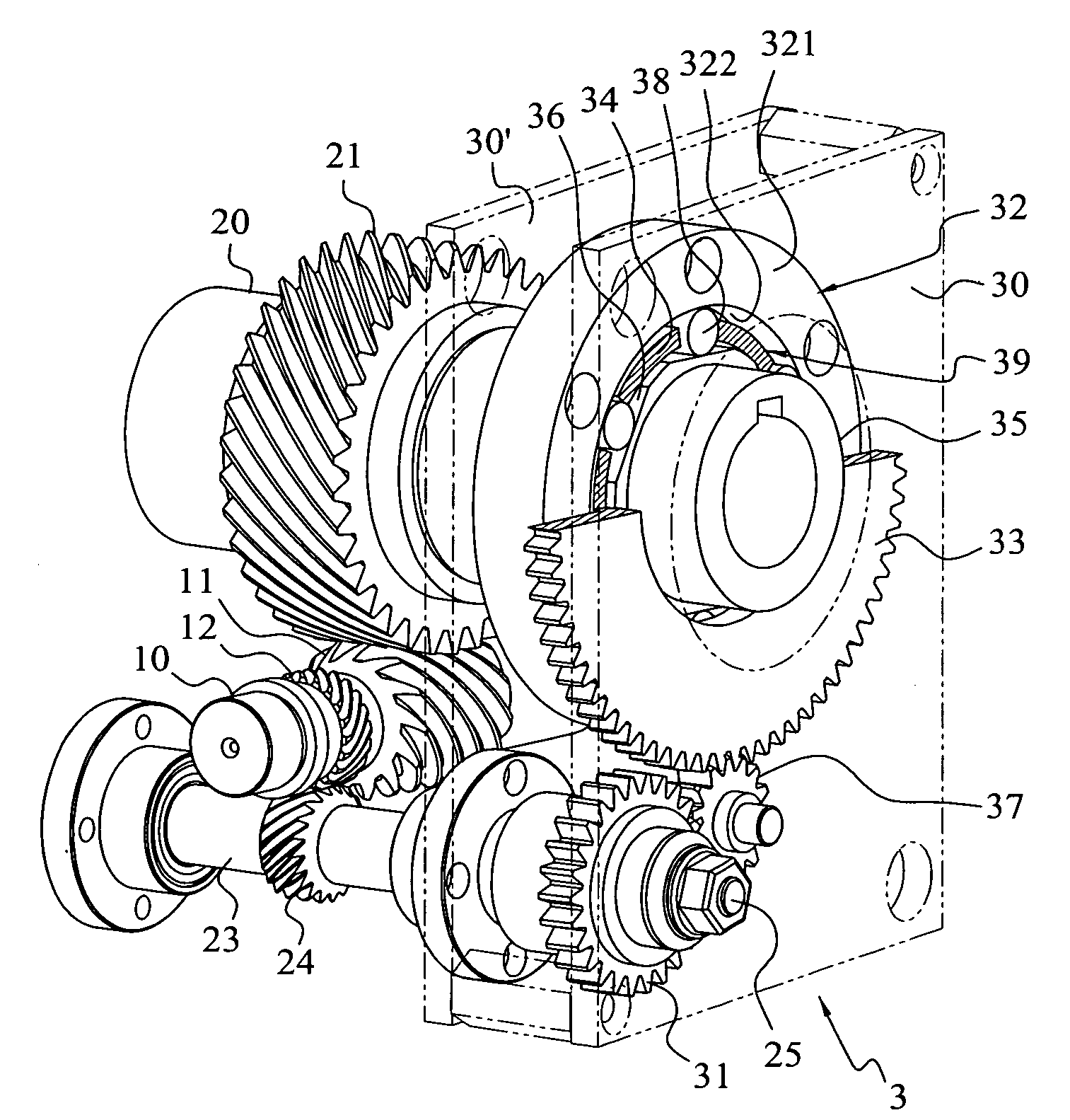

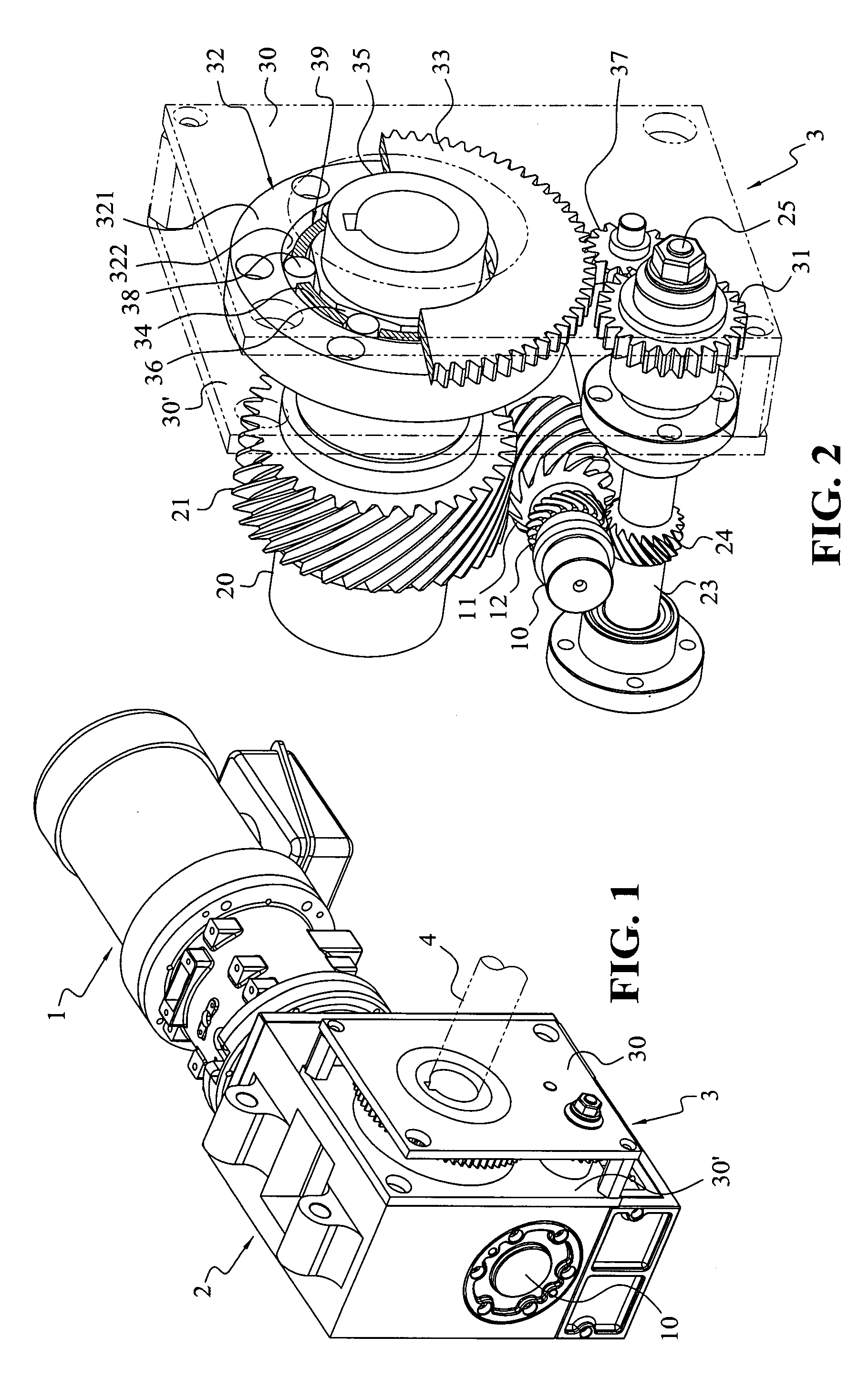

Governor device for door

ActiveUS20080185469A1Improve protectionFall fastDoor/window protective devicesReelsElectric machineryEngineering

This invention disclosed a speed limit device for door, which comprises: an input shaft with one end driven by a door motor, and having the first gear and the second gear configured at the other end simultaneously driving a hollow shaft and a third shaft, and the center of the hollow shaft accommodates and fixes one end of a reel, and the third shaft is connected with an extension shaft; a brake device, which includes an active gear fixed with the extension shaft; a passive gear is pivoted on a hub, and the hub is fixed with the reel and rotating with the hollow shaft; an inert wheel located between the active gear and the passive gear to adjust the passive gear to have the same rotation speed with the hollow shaft; a clutch mechanism, which could restrain the synchronous operation between the passive gear and the hub without any positional difference, and when the rotation speed of the reel has the abnormal change, the clutch mechanism will generate the positional difference to lock the hub from the losing speed and falling of the rolling door.

Owner:HSIEH CHUNG HSIEN

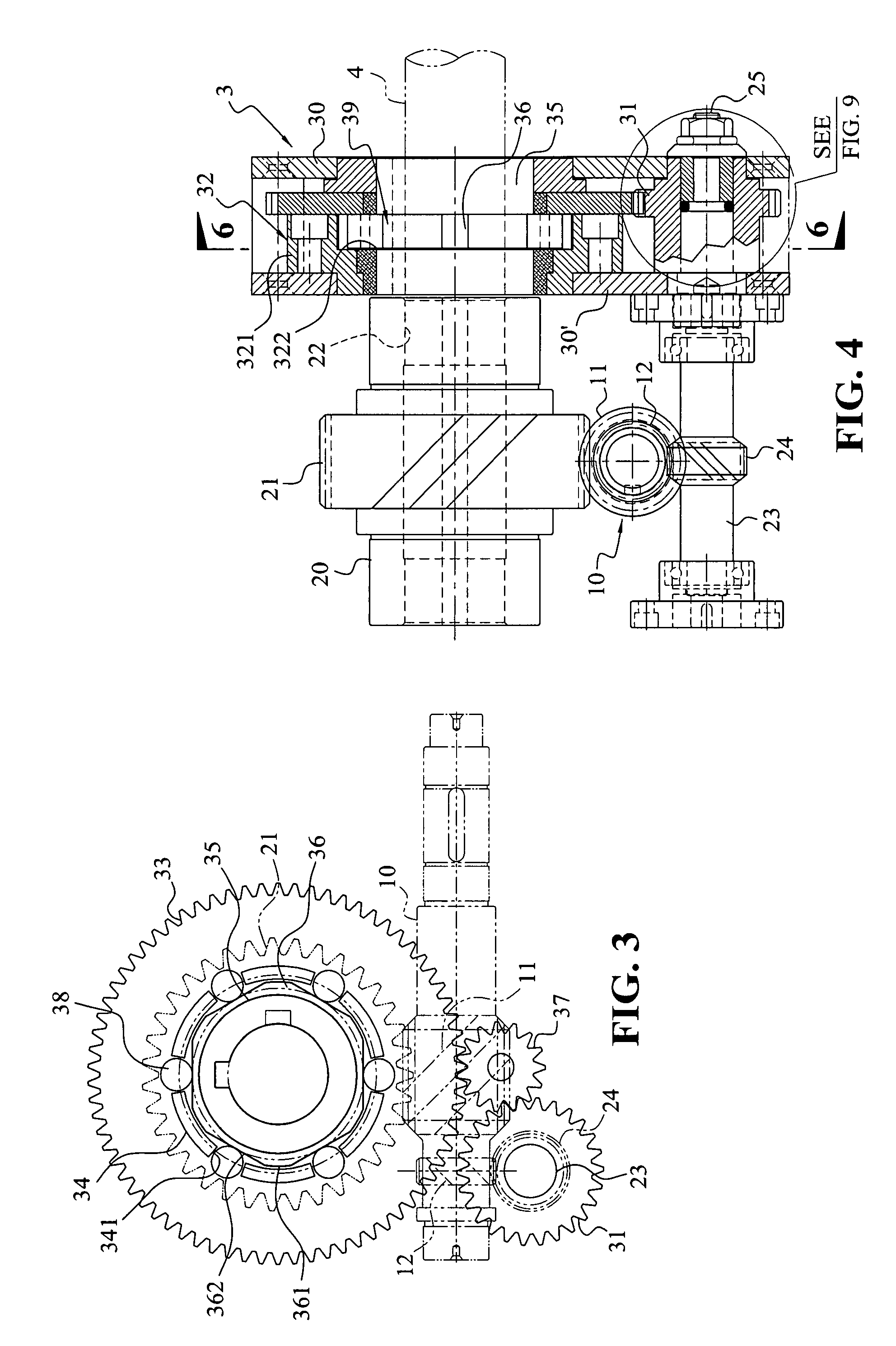

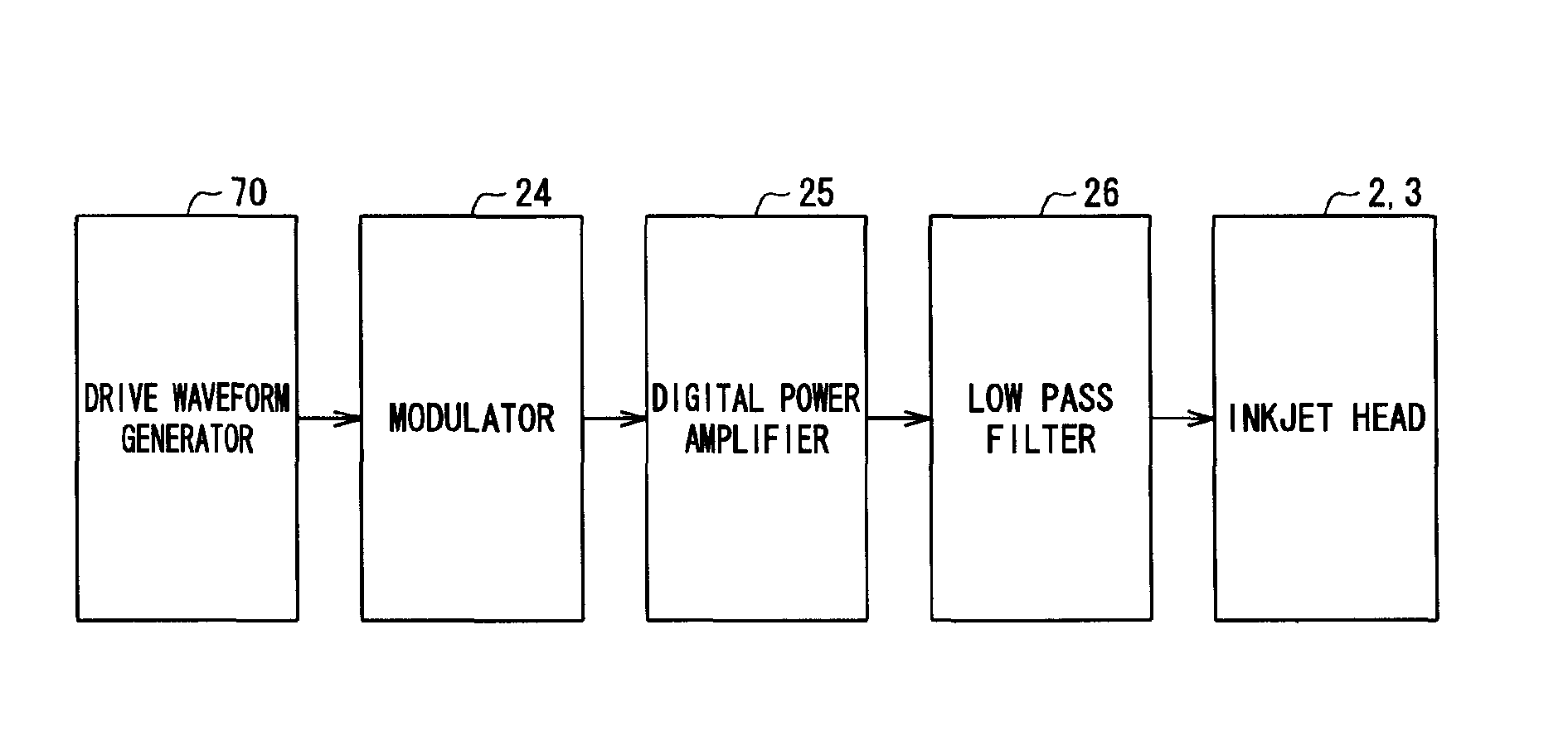

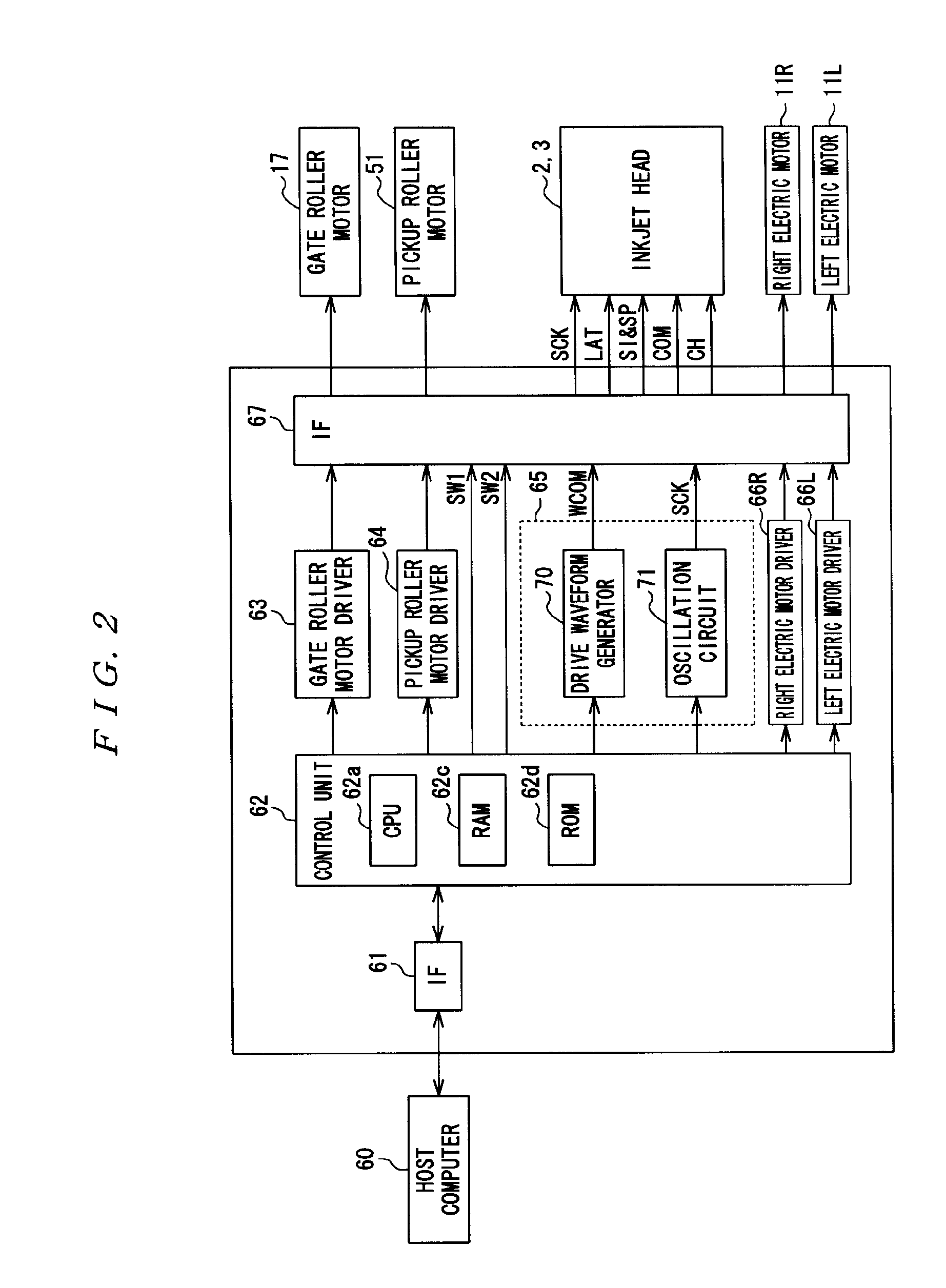

Head drive apparatus of inkjet printer and inkjet printer

InactiveUS8240798B2Rapid riseFall fastOther printing apparatusDc amplifiers with modulator-demodulatorLow-pass filterInk printer

A head drive device of an inkjet printer having a nozzles and corresponding actuators that jet liquid drops. A drive section that generates a drive signal to the actuators. The head drive device includes a drive waveform signal which is used as a reference of a signal to control drive of the actuators. A modulating section modulates a pulse of a drive waveform signal generated by the drive waveform generating system. A low pass filter smoothes a power-amplified modulated signal subjected to the power amplification by the digital power amplifier and supplies the signal as a drive signal to the actuators. A frequency characteristics adjusting section adjusts frequency characteristics of the low pass filter as a function of the number of the actuators.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com