Micro-flow controller based on peltier effect

A Peltier effect, micro-flow technology, applied in the direction of using electrical device flow control, etc., can solve the problems of limiting the performance of the flow controller, not lower than the ambient temperature, etc., to achieve a wide range of gas flow adjustment, rapid increase in flow, Realize the effect of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

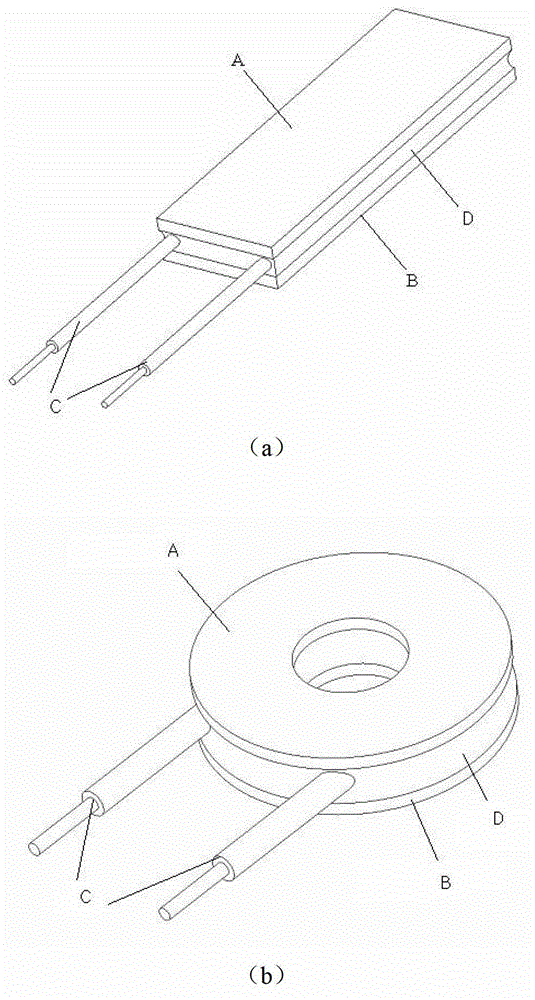

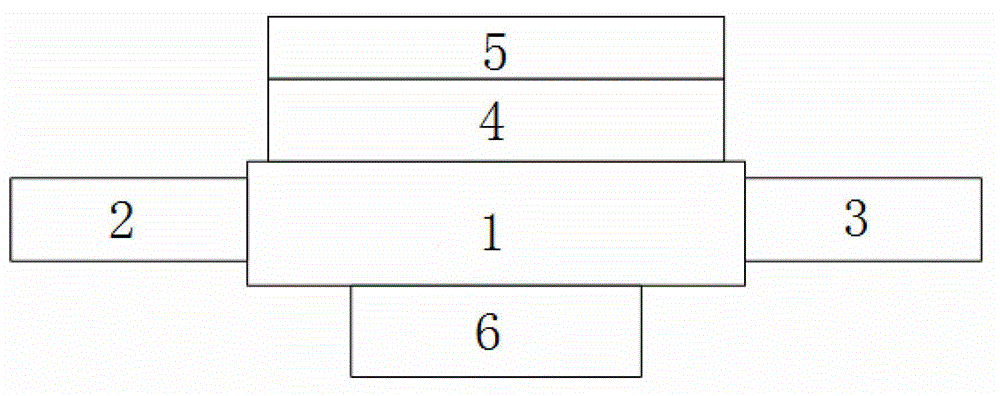

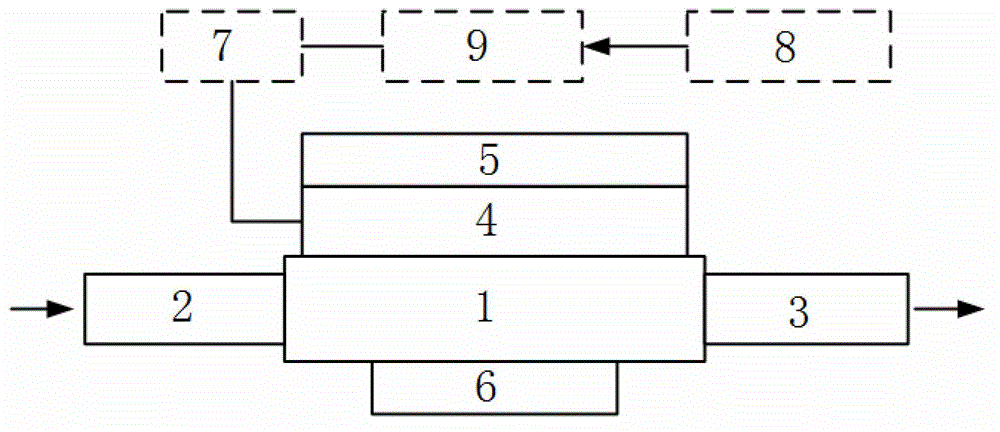

[0043] The heat-conducting substrate of the Peltier semiconductor device of the micro-flow controller of this embodiment is installed on the throttling device along the direction of gas flow (herein, this micro-flow controller is called "horizontal Peltier micro-flow controller") , and using a square Peltier semiconductor device, Figure 4 A schematic diagram of its structure. The micro-flow controller is composed of throttle 1, gas inlet 2, gas outlet 3, Peltier semiconductor device 4, heat sink 5, and temperature sensor 6. The two sides of the Peltier semiconductor device are throttle and heat sink respectively. The heat sink can be circular or square, and the size of the surface attached to the Peltier semiconductor device should be able to cover the Peltier semiconductor heat-conducting substrate. The Peltier semiconductor device and the temperature sensor can be fixed to the restrictor by gluing or screwing, and the heat sink can be fixed to the Peltier semiconductor dev...

specific Embodiment approach 2

[0045] This embodiment is a horizontal Peltier microflow controller, and two square Peltier semiconductor devices are used. Figure 5 A schematic diagram of its structure. The micro-flow controller consists of a throttle 1, a gas inlet 2, a gas outlet 3, a Peltier semiconductor device 4, a heat sink 5, and a temperature sensor 6, and the two sides of the Peltier semiconductor device are respectively a throttle and a heat sink. The heat sink can be circular or square, with a circular central hole in the center, and the size of the surface that is bonded to the Peltier semiconductor device must be able to cover the Peltier semiconductor heat-conducting substrate. The Peltier semiconductor device and the temperature sensor can be fixed to the restrictor by gluing or screwing, and the heat sink can be fixed to the Peltier semiconductor device by gluing or screwing, or can be connected by screws, etc. way directly to the restrictor. The two Peltier semiconductor devices can be el...

specific Embodiment approach 3

[0048] This embodiment is a horizontal Peltier micro-flow controller, and uses three square Peltier semiconductor devices, Figure 6 A schematic diagram of its structure. The micro-flow controller is composed of throttle 1, gas inlet 2, gas outlet 3, Peltier semiconductor device 4, heat sink 5, and temperature sensor 6. The two sides of the Peltier semiconductor device are throttle and heat sink respectively. The Peltier semiconductor device and the temperature sensor can be fixed to the restrictor by gluing or screwing, and the heat sink can be fixed to the Peltier semiconductor device by gluing or screwing, or can be connected by screws, etc. way directly to the restrictor. The three Peltier semiconductor devices can be electrically connected in parallel or in series, and the temperature variation of the heat-conducting substrate facing the restrictor is consistent.

[0049] Compared with the horizontal-mounted Peltier micro-flow controller using one and two Peltier semico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com