Solid waste high temperature aerobic composting method using stereoscopic ventilating apparatus

A solid waste and ventilation device technology, applied in fertilization devices, applications, organic fertilizers, etc., can solve problems that affect the stability and uniformity of fermentation product quality, uneven fermentation, etc., and achieve shortened mass transfer distance and mass transfer efficiency High, improved stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

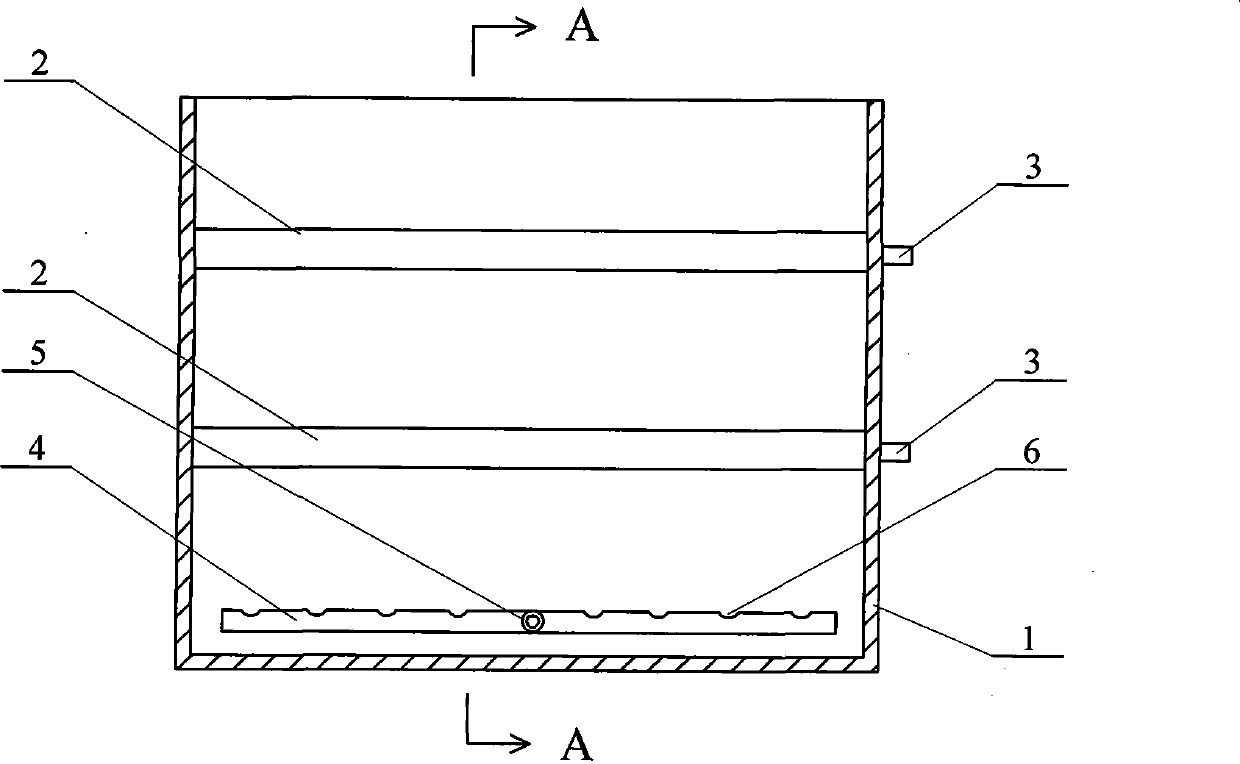

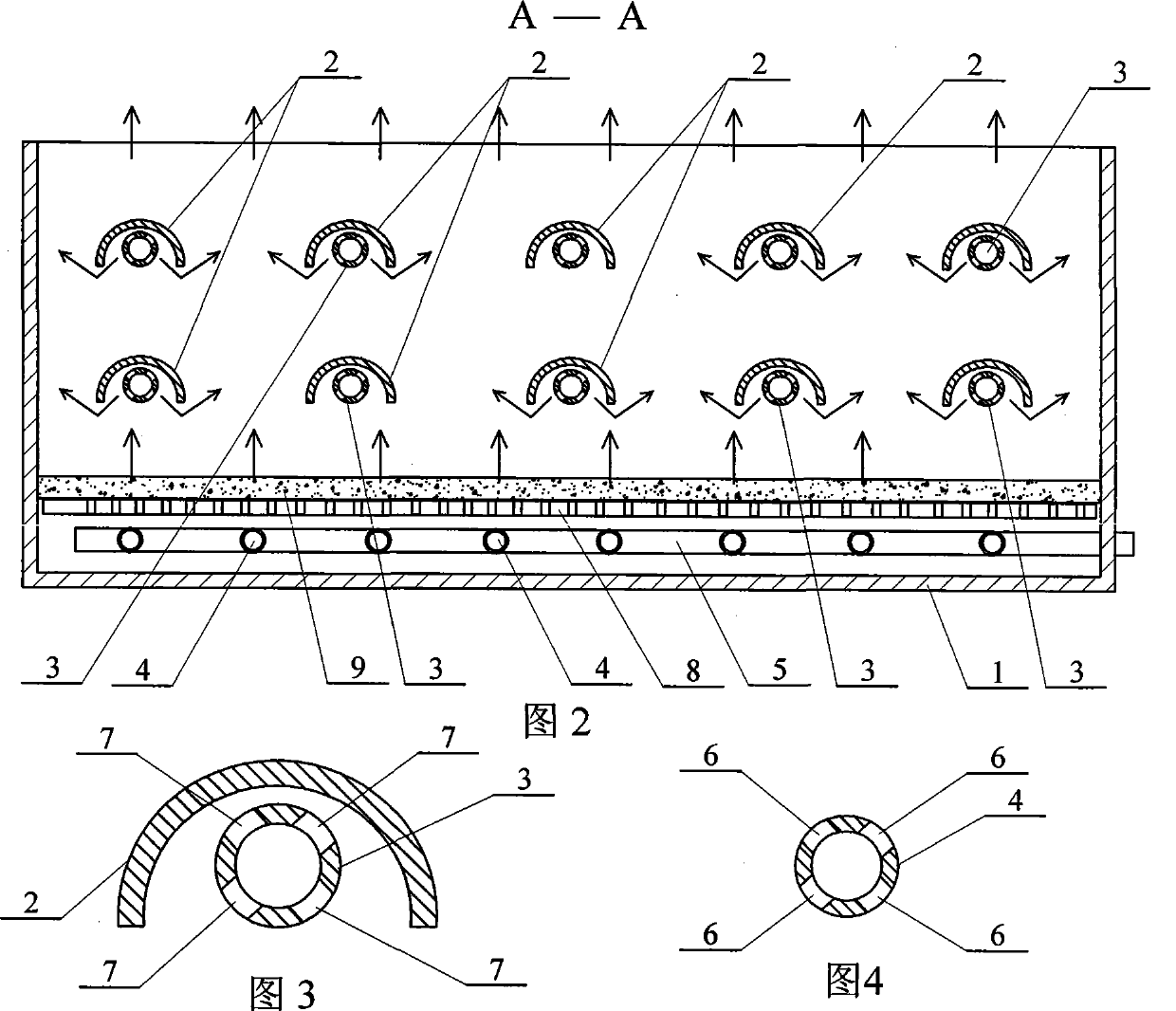

[0010] Specific implementation mode one: (see figure 1 ~ Fig. 4) The three-dimensional ventilation device adopted in the method of this embodiment comprises a fermentation tank 1, an inverted ventilation tank 2, an intermediate air distribution pipe 3, a bottom air distribution pipe 4 and a connecting pipe 5, and the bottom air distribution pipe 4 has an air distribution hole 6, The bottom air distribution pipe 4 is arranged at the bottom of the fermentation tank 1, the bottom air distribution pipe 4 is connected with the connecting pipe 5, the inverted ventilation tank 2 is fixed in the middle of the fermentation tank 1, and the middle air distribution pipe 3 is fixed under the inverted ventilation tank 2 In the fermenter 1 on the side, there is a ventilation hole 7 on the air distribution pipe 3 in the middle; the process of this method is as follows: Step 1, after mixing the organic solid waste and the conditioning agent according to the volume ratio of 1:0.6~3, put it into ...

specific Embodiment approach 2

[0011] Specific implementation mode two: (see figure 1 ~ FIG. 4) The inverted ventilation slot 2 in this embodiment is an inverted triangular slot or an inverted arc-shaped slot. The height of the inverted ventilation slot 2 is 5-30 cm and the width is 3-25 cm. The cross-section of the inverted triangular groove is an isosceles triangle with an apex angle of 30° to 120°. The diameter of the middle air distribution pipe 3 is 3-10 cm, and the diameter of the ventilation holes 7 on the middle air distribution pipe 3 is 0.3-2.5 cm.

specific Embodiment approach 3

[0012] Specific implementation mode three: (see figure 1 ~ Fig. 4) The inverted ventilation slot 2 and the middle air distribution pipe 3 described in this embodiment are both arranged horizontally in the fermentation tank 1, and the inverted ventilation slot 2 and the middle air distribution pipe 3 are all one to six or more layers , the space between the upper and lower layers of inverted ventilation slots 2 is greater than 0.1m, and the horizontal spacing of the inverted ventilation slots 2 is within the range of 0.2 to 2m. The number of inverted ventilation slots 2 is determined by the properties of fermented organic solids and the size of the fermentation tank. It is determined that the air blower is sent to the fermenter by the middle air distribution pipe 3. The ventilation at the bottom of the fermentation tank adopts the connection pipe 5 to distribute the air through the bottom air distribution pipe 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com