Three-level motor power converter achieving quick demagnetization

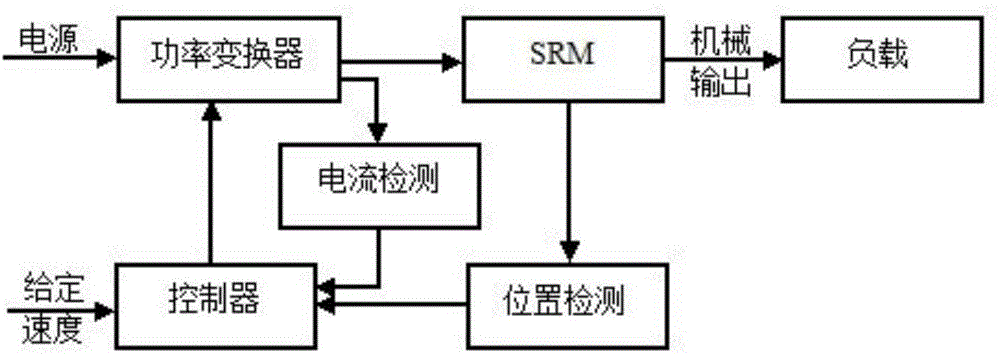

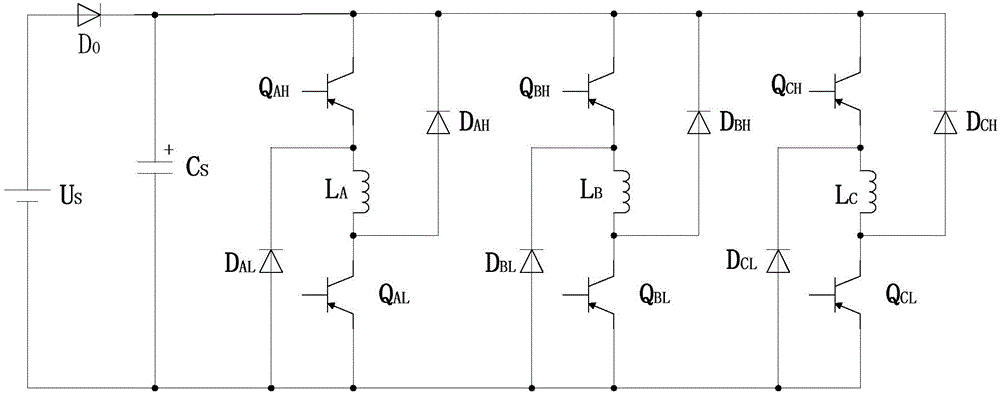

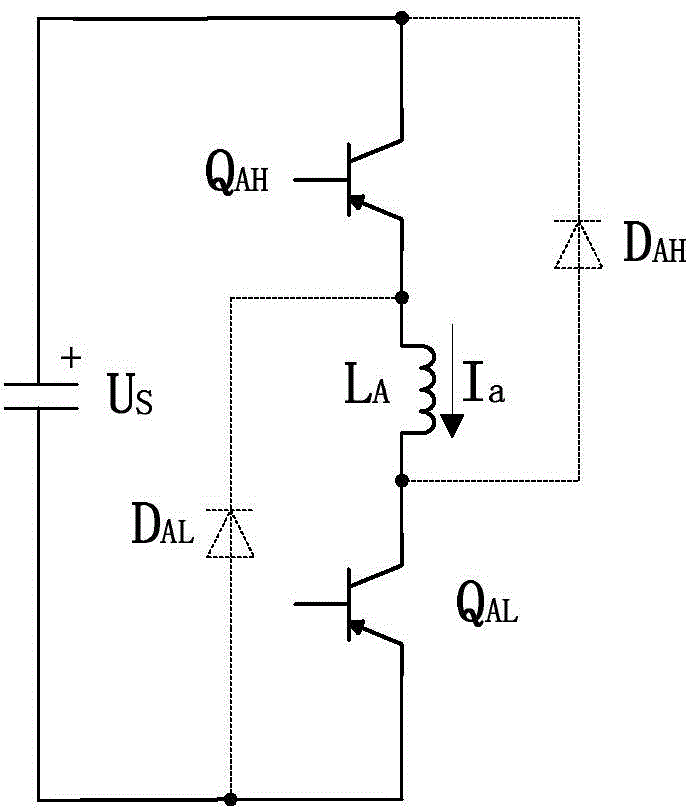

A motor power, three-level technology, applied in the direction of a single motor speed/torque control, torque ripple control, etc., can solve the effect of affecting the output torque of the system, prolong the braking torque action time, and fail to reach the rated motor rating. power and other issues, to achieve the effect of eliminating braking torque, reducing torque ripple, and increasing discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The 6 / 4-pole switched reluctance motor speed control system is selected as the application object. The two DC power supplies are obtained from a single-phase 220V AC through a voltage stabilizing transformer followed by a bridge rectifier circuit. The rectifier circuit is connected with a voltage regulator. Adjust the voltage regulator so that the voltage of the lower power supply is 100V, and the voltage of the upper power supply is adjusted according to the operating conditions; In this example, a photoelectric position sensor (composed of three slot-type optocouplers and a disk) is used to detect the running position of the motor rotor; the Hall current sensor element sampling method is used for current detection. A Hall current sensor is connected to the three-phase outlets of the converter; the main control unit adopts DSP, and the DSP is connected with the three-phase power converter drive signal, current detection signal, three-phase position detection signal and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com