Limestone-gypsum wet desulfurization additive

A technology of wet desulfurization and additives, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of slurry overflow in the absorption tower, poor gypsum crystallization, and high price, and achieve high desulfurization efficiency and low cost. , promote the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

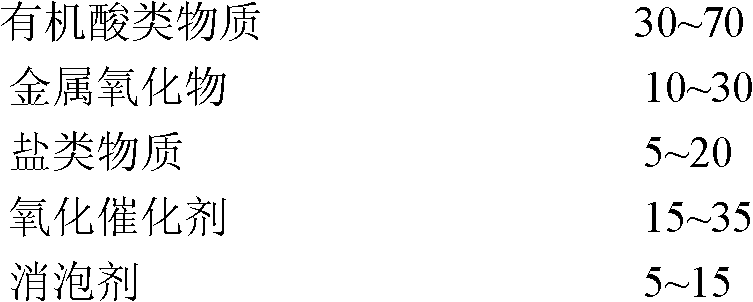

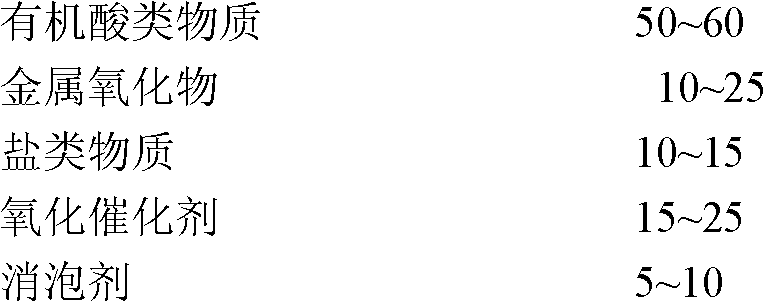

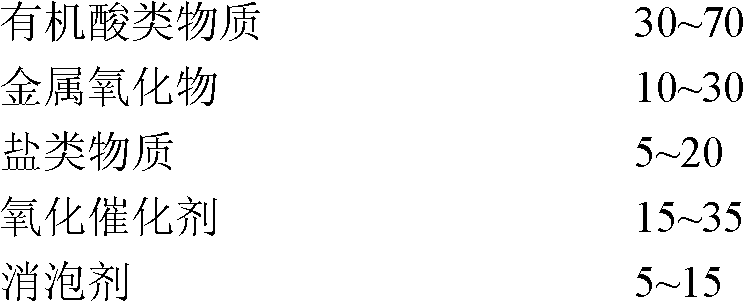

Method used

Image

Examples

Embodiment 1

[0037] A limestone-gypsum wet desulfurization additive, its components and weight percent are: adipic acid 2, humic acid 4, citric acid 5, benzoic acid 12, glutaric acid 1, succinic acid 1, oxalic acid 1 , 4 p-hydroxybenzoic acid, 6 sodium oxide, 10 potassium oxide, 3 calcium oxide, 7 magnesium oxide, 4 aluminum oxide, 10 magnesium carbonate, 3 calcium carbonate, 3 magnesium chloride, 4 calcium chloride, 2 potassium permanganate, sulfur Ammonium sulfosulfate 2, sodium thiosulfate 2, peracetic acid 2, sodium hypochlorite 1, hydrogen peroxide 1, polysiloxane 2, sodium stearate 5, polyoxyethylene ether 3.

[0038] Flue gas SO2 concentration at the inlet of the desulfurization system is 2500mg / Nm 3 ; Liquid-gas ratio 10.1; Calcium-sulfur ratio 1.1. The additive concentration is 800mg / L, and the measured 24-hour desulfurization efficiency is more than 93%, which is 9% higher than that without additives on average.

Embodiment 2

[0040] A limestone-gypsum wet desulfurization additive, its composition and weight percent are: adipic acid 10, humic acid 5, citric acid 2, benzoic acid 2, glutaric acid 5, succinic acid 6, p-hydroxybenzoic acid 3. Sodium oxide 10, potassium oxide 2, calcium oxide 5, magnesium oxide 1, magnesium carbonate 5, calcium carbonate 3, potassium permanganate 10, ammonium thiosulfate 2, sodium thiosulfate 5, peracetic acid 3, sodium hypochlorite 15. Polysiloxane 2, Sodium Stearate 4.

[0041] The flue gas SO2 concentration at the inlet of the desulfurization system is 2300mg / Nm 3 ; Liquid-gas ratio 10.0; Calcium-sulfur ratio 1.1. The additive concentration is 900mg / L, and the measured 24-hour desulfurization efficiency is over 95%, which is 8% higher than that without additives on average.

Embodiment 3

[0043] A limestone-gypsum wet desulfurization additive, its composition and weight percent are: glutaric acid 15, succinic acid 15, oxalic acid 4.4, potassium oxide 20, calcium oxide 7, magnesium chloride 8, calcium chloride 10, sulfur Sodium sulfite 4, peracetic acid 10, sodium stearate 3.6, polyoxyethylene ether 3.

[0044] Flue gas SO2 concentration at the inlet of the desulfurization system is 2500mg / Nm 3 ; Liquid-gas ratio 10.1; Calcium-sulfur ratio 1.1. The additive concentration is 1000mg / L, and the measured 24-hour desulfurization efficiency is more than 93%, which is 8% higher than that without additives on average.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com