Patents

Literature

31results about How to "Restore production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

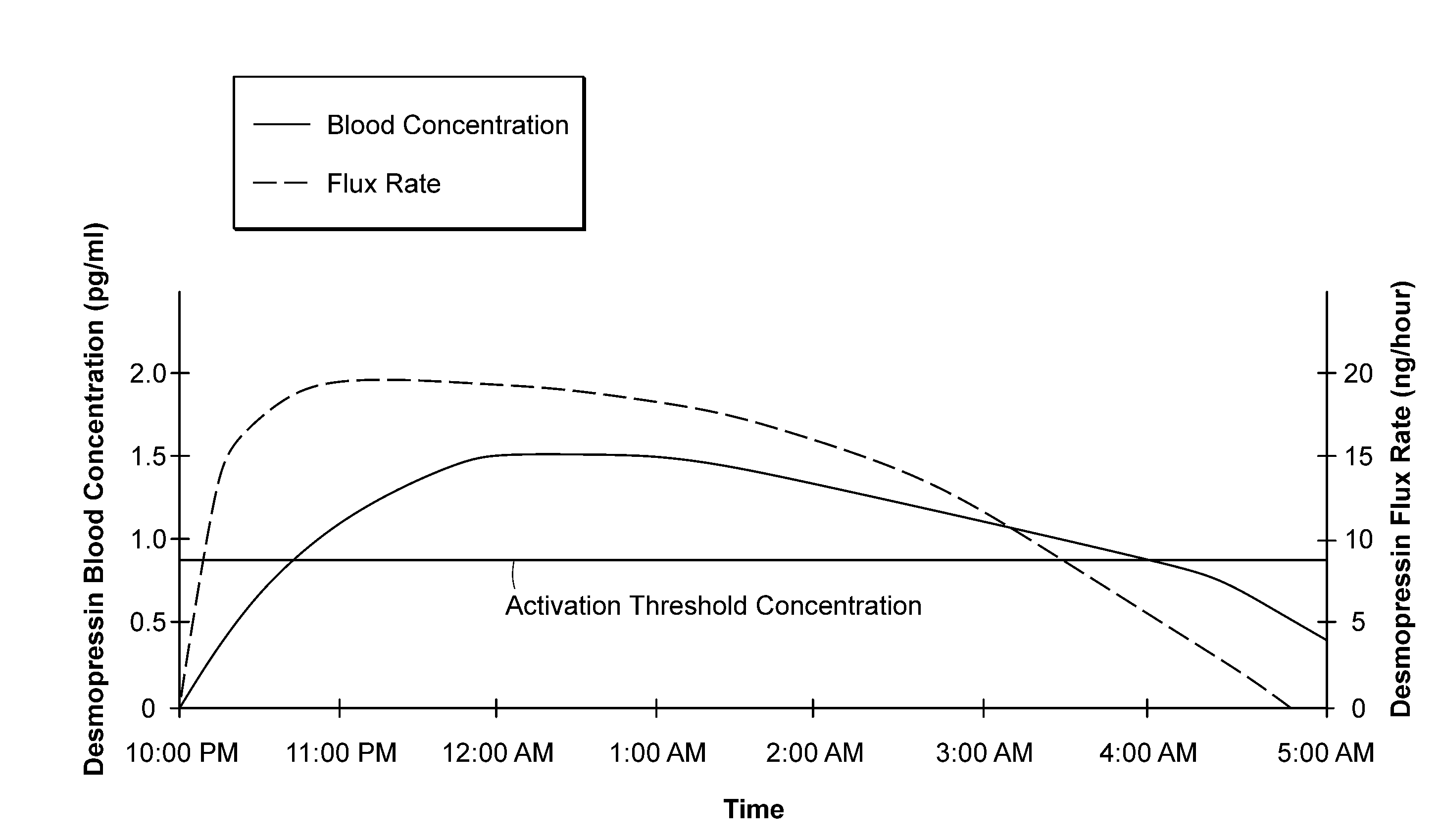

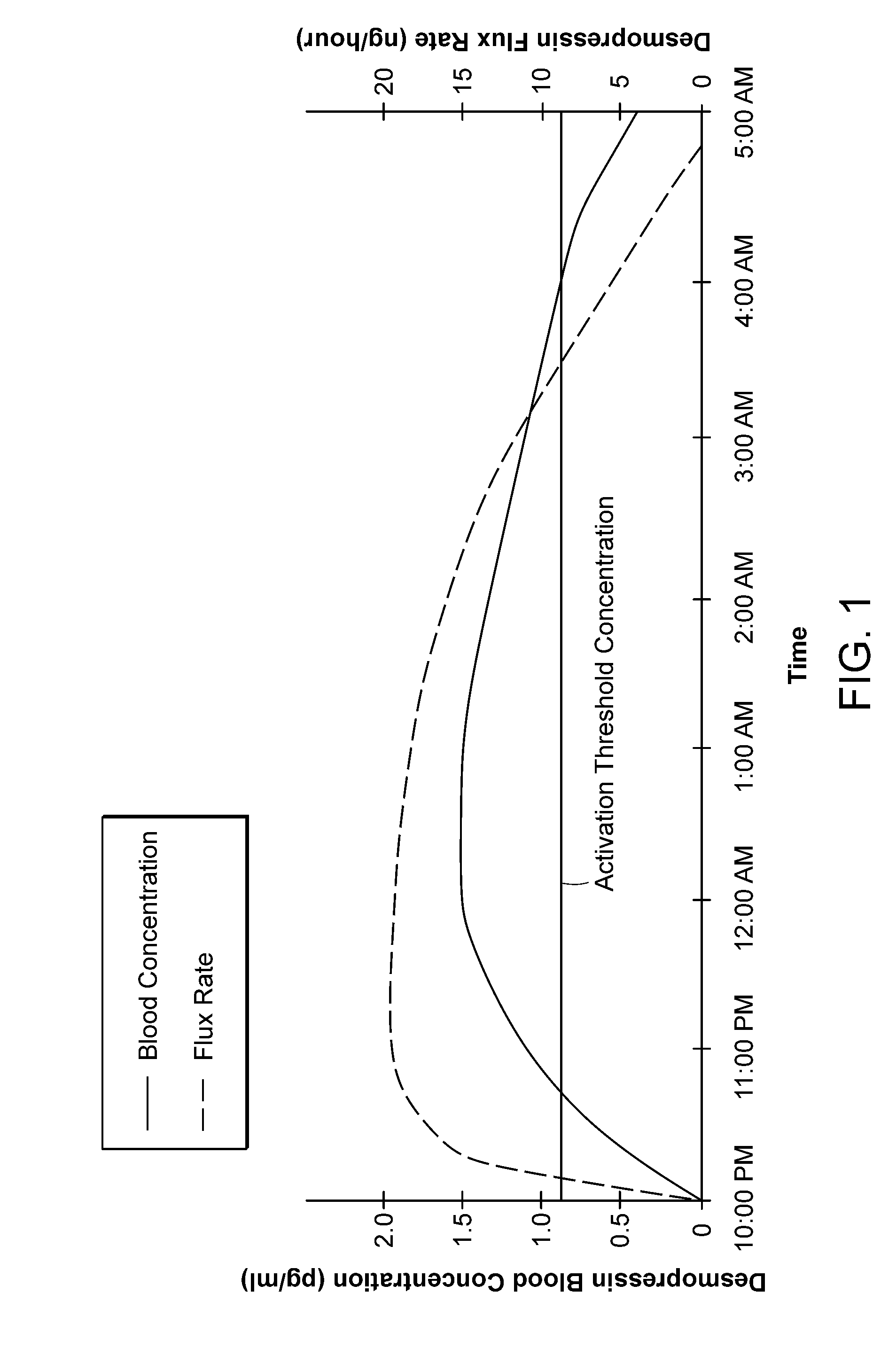

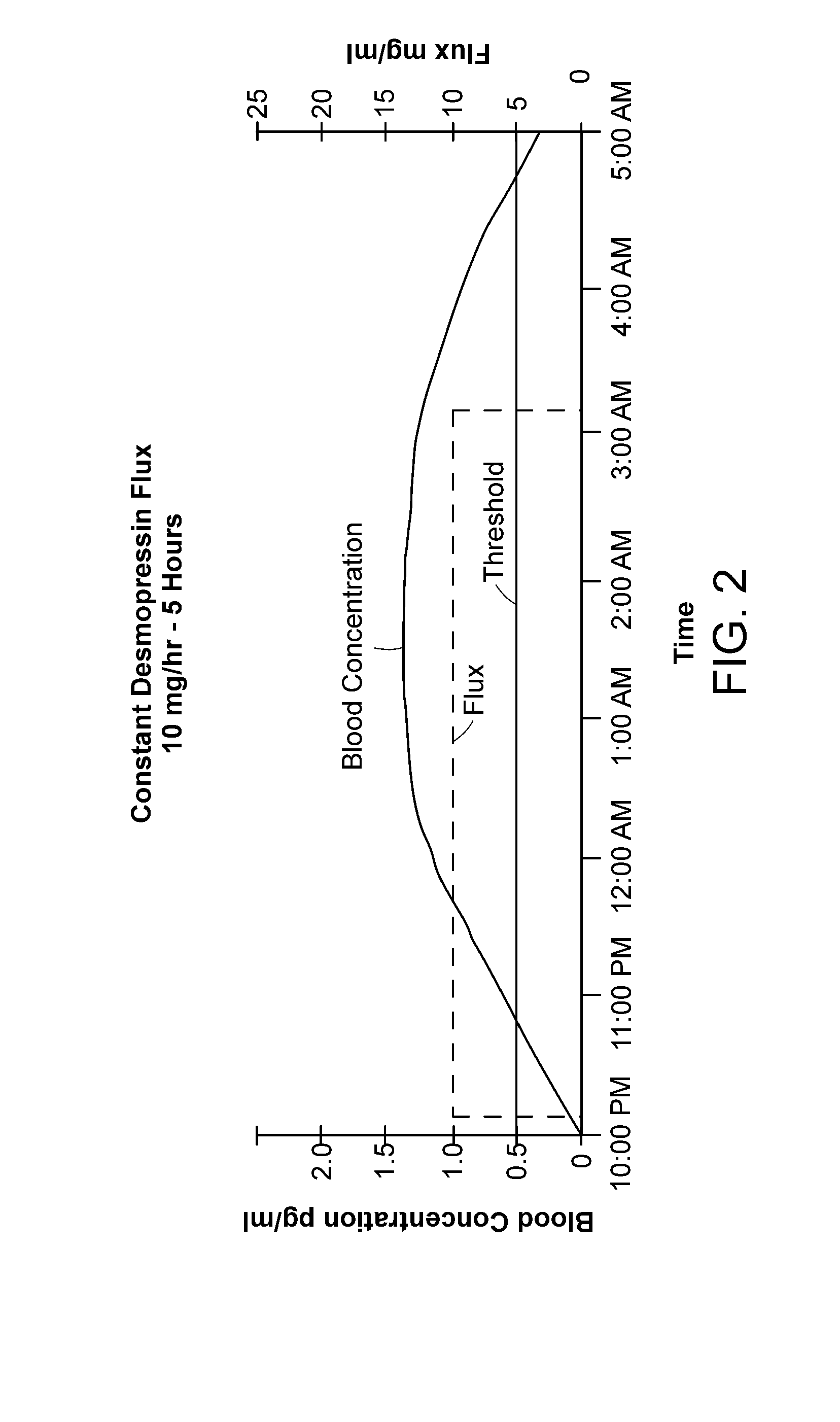

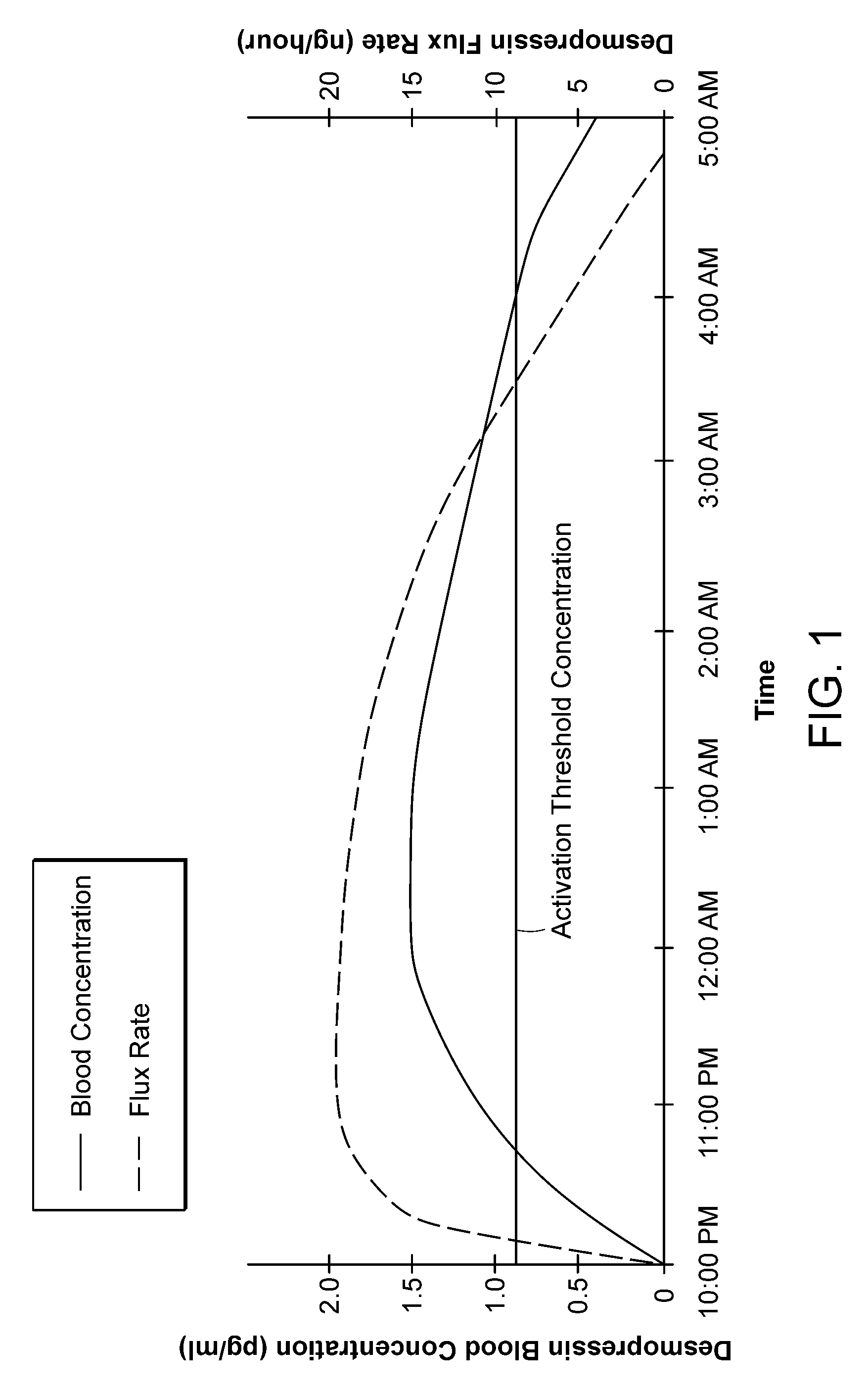

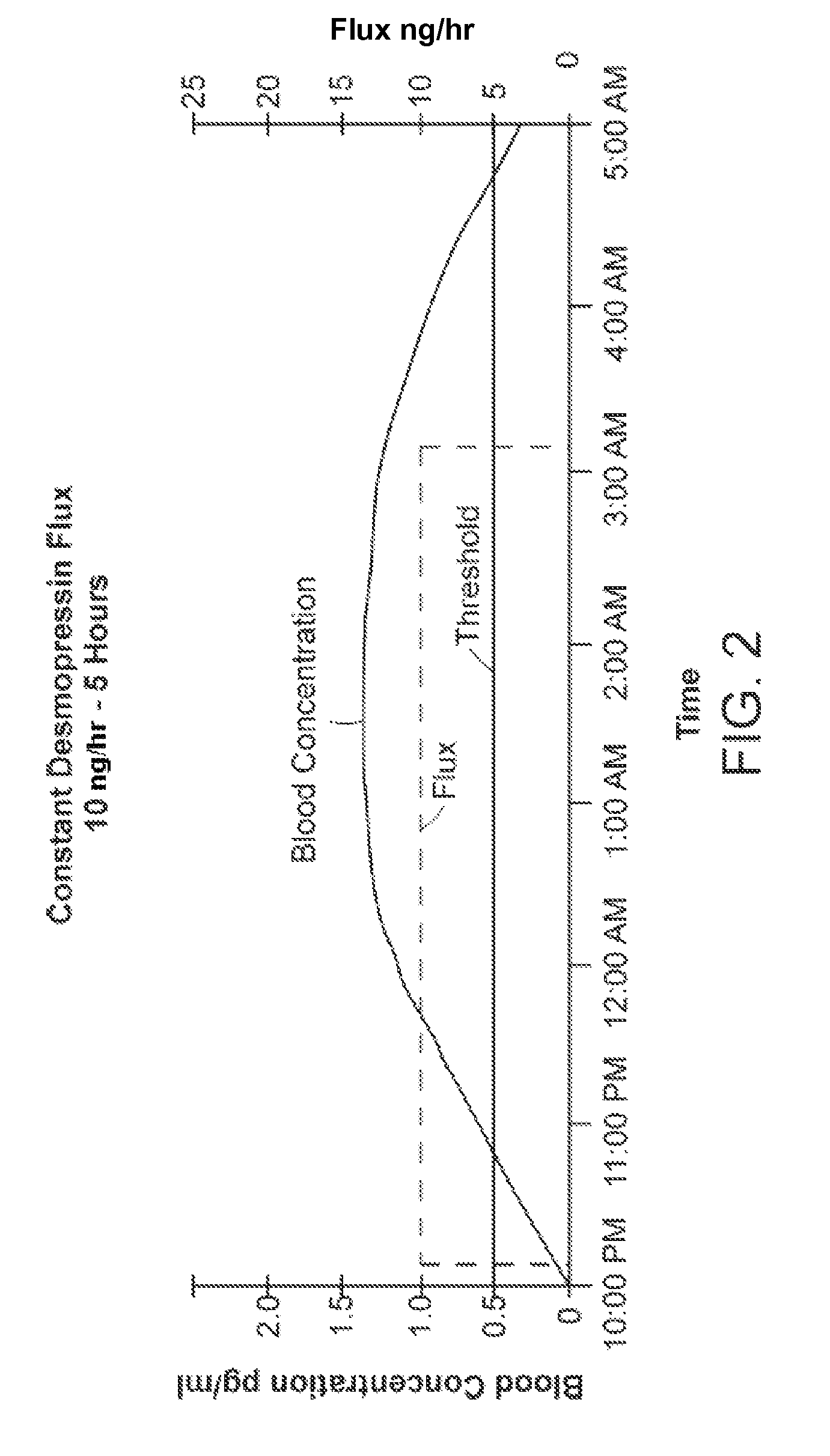

Methods and devices for desmopressin drug delivery

InactiveUS20090042970A1Reduce urine productionRestore normal urine productionBiocidePowder deliveryDecreased sodiumSide effect

Disclosed are devices for urine voiding postponement, and methods for treating conditions such as central diabetes insipidus, enuresis, nocturia, urinary frequency or incontinence. The devices deliver a desmopressin flux through the skin of a patient in a low dose amount just necessary to achieve a desired anti-diuretic effect without undesirable side effects such as hyponatremia. The devices are designed to permit a state of normal urinary production to return quickly after the desmopressin flux is terminated.

Owner:SERENITY PHARMA CORP

Sugarcane detoxication tissue culturing and fast propagating method

InactiveCN101138321AIncrease in sizeEasy to inoculateCultivating equipmentsHorticulture methodsAxillary budBud

The present invention relates to a method for virus-free tissue culture and rapid propagation of sugarcane belonging to the technical field of plant propagation. The method comprises the following steps that the terminal buds or auxiliary buds of the sugar cane is taken as the explants and the virus-free tissue culture seedlings are propagated in mass after the callus tissue inducement and culture, plant differentiation culture, proliferation culture, radication culture and virus test. The present invention is characterized in that the explants adopted are large and the operation is easy; the inoculation survival rate is high; the detoxification is simple, convenient, fast and thorough; the propagation coefficient per month is 5 to 10 times and the speed is fast which is fit for breeding in factory and commercial production.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

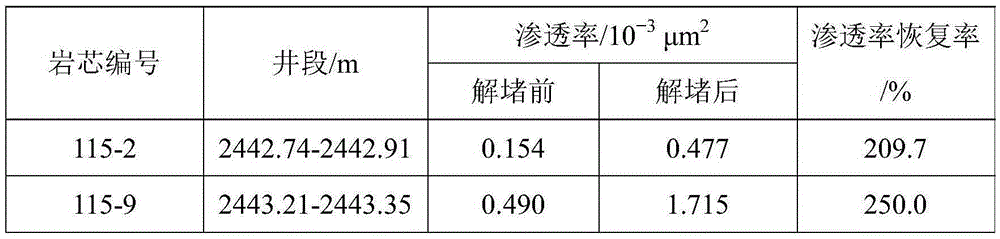

Compound plug removal agent for tight sandstone oil reservoir

ActiveCN105255467AUnblock pollutionImprove the effective permeabilityDrilling compositionAcetic acidThree stage

The invention discloses a compound plug removal agent for a tight sandstone oil reservoir, and belongs to the technical field of oilfield exploitation. The compound plug removal agent is composed of prepad fluid, main body fluid and post-pad fluid, wherein the prepad fluid and the post-pad fluid each contains hydrochloric acid, potassium chloride, ethylenediaminetetraacetic acid, water plug removal agents, corrosion inhibitor and ethylene glycol butyl ether, and the main body fluid contains fluosilicic acid, hydrochloric acid, potassium chloride, ethylenediaminetetraacetic acid, water plug removal agents, corrosion inhibitor and ethylene glycol butyl ether. According to pollution plugging which possibly occurs in the development process of the tight sandstone oil reservoir, corresponding treatment fluid in the compound plug removal agent is sequentially infused into the reservoir according to the three stages of front, middle and rear, and the purposes of removing reservoir plugging, increasing effective permeability of the reservoir, improving the plug removal effect and recovering per-well production can be achieved. The hydrochloric acid is matched with the fluosilicic acid to serve as the components of the main body fluid, plug removal is achieved, and meanwhile the reservoir is protected against secondary pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

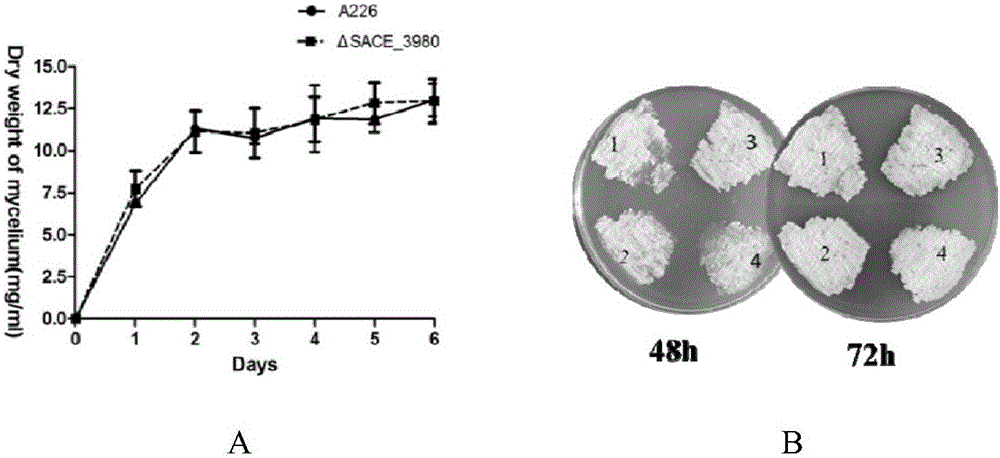

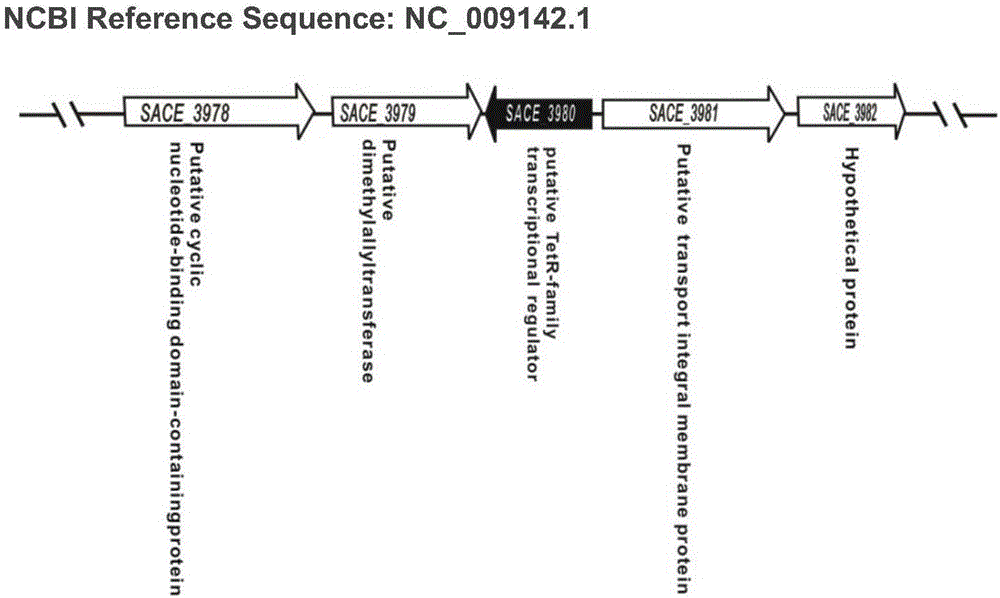

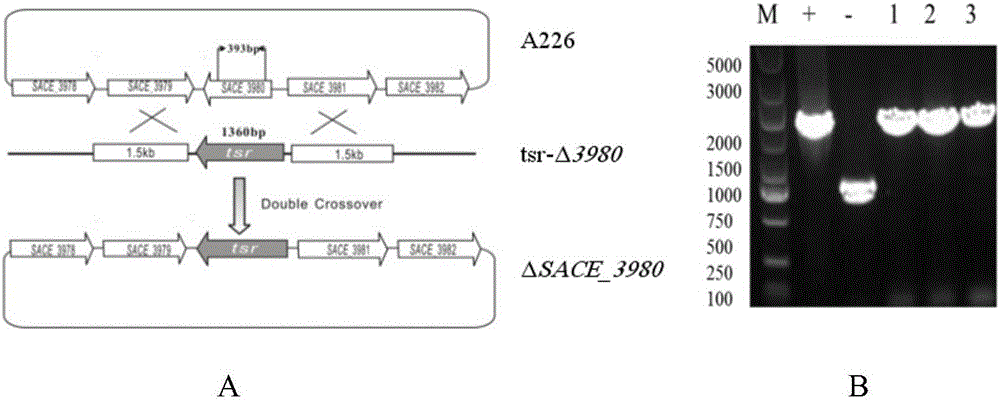

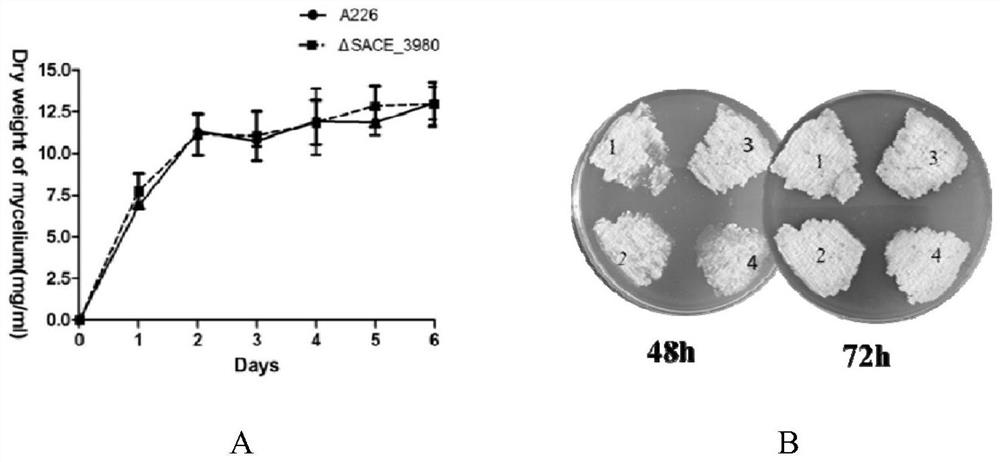

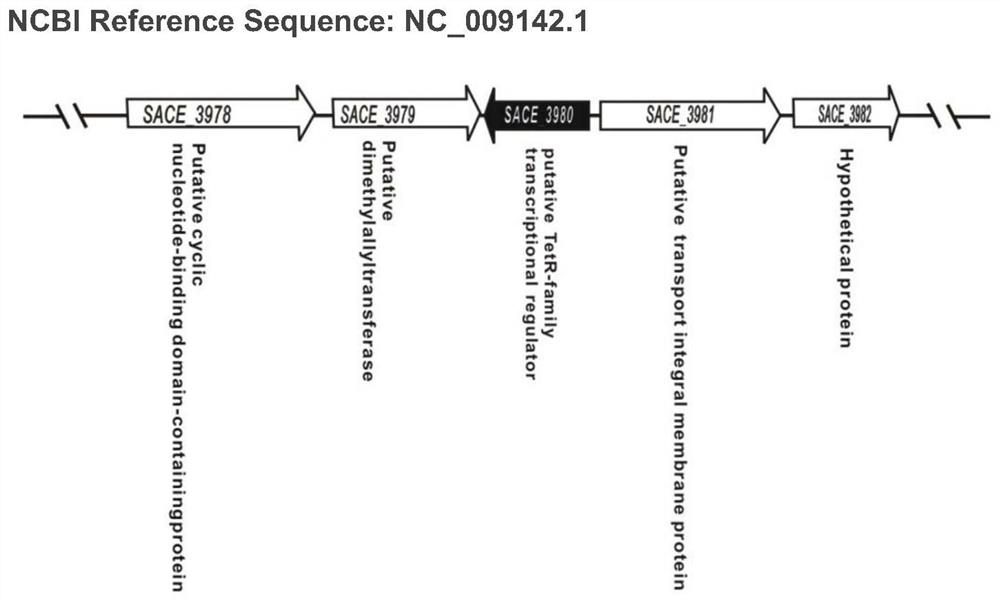

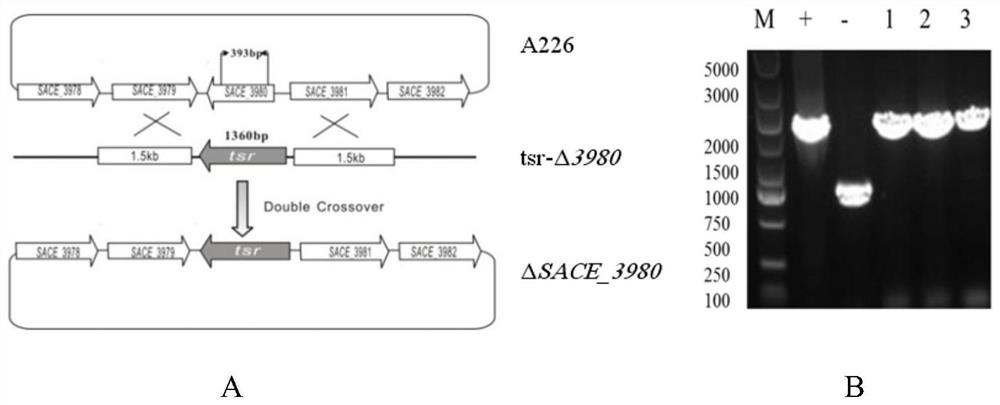

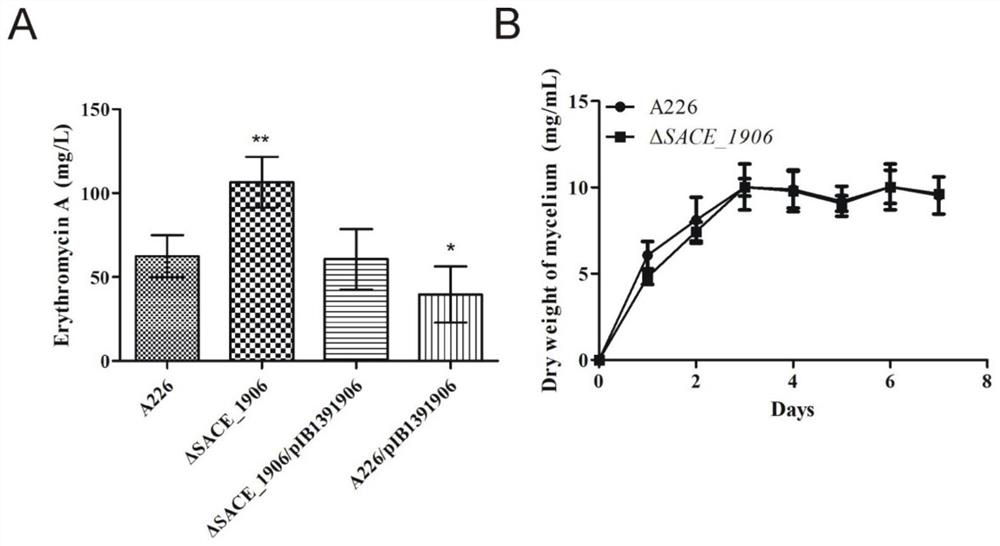

Method for increasing erythromycin yield by transforming saccharopolyspora erythraea SACE_3980 gene

ActiveCN106520866AImprove fermentation yieldIncrease productionFungiMicroorganism based processesBiotechnologyTetR

The invention discloses a method for increasing the erythromycin yield by transforming the saccharopolyspora erythraea SACE_3980 gene. In saccharopolyspora erythraea, the gene SACE_3980 is subjected to transcription regulation by genetic engineering and through TetR-deficient family to obtain an engineering strain with high erythromycin yield; and by adopting the obtained strain for fermentation production of erythromycin, the yield can be remarkably increased, and a new technical support is provided for increasing the erythromycin yield in industrial production.

Owner:ANHUI UNIVERSITY

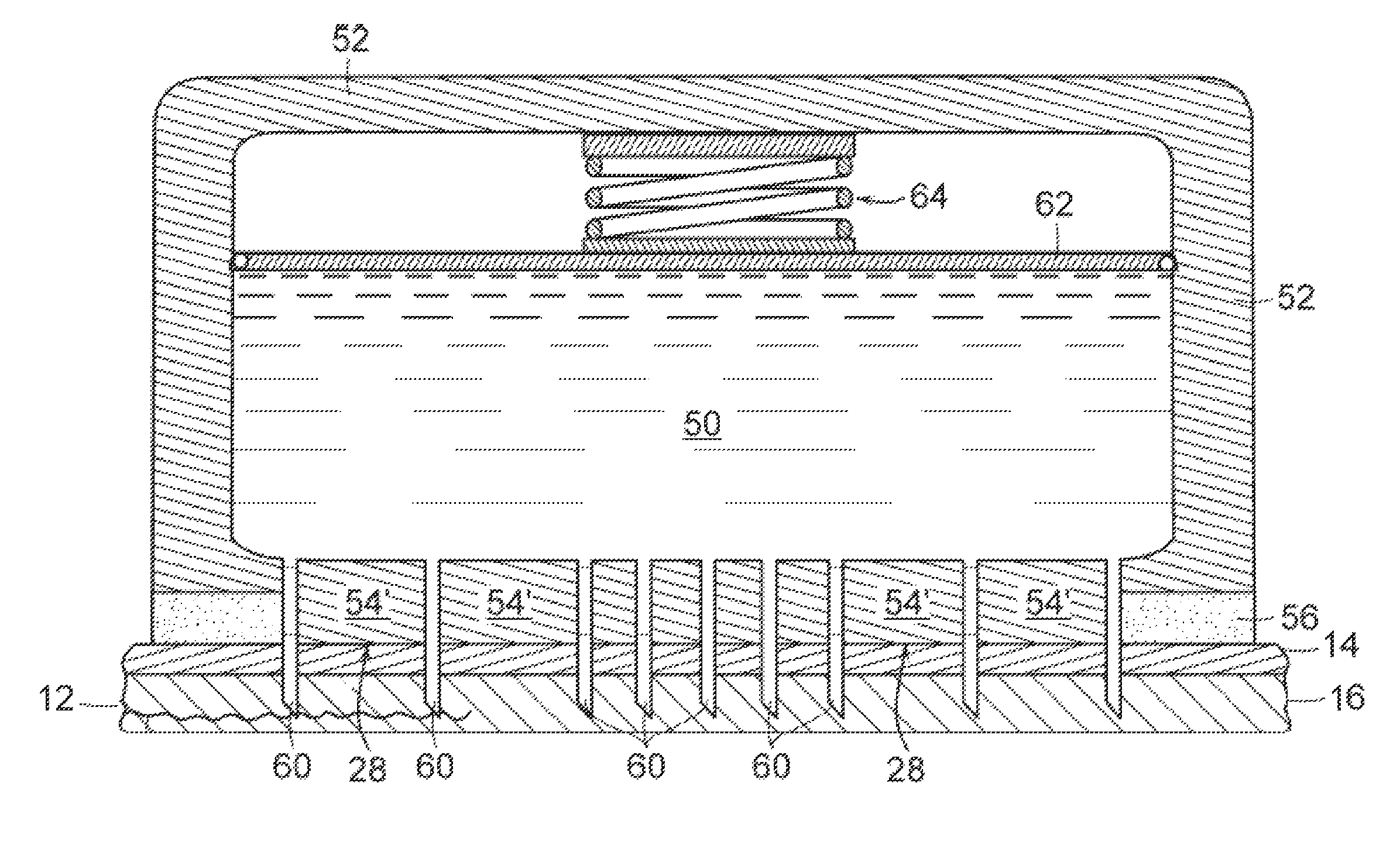

Methods and devices for desmopressin drug delivery

InactiveUS8399410B2Prevent adverse side effectsReduce productionElectrotherapyMicroneedlesDecreased sodiumSide effect

Disclosed are devices for urine voiding postponement, and methods for treating conditions such as central diabetes insipidus, enuresis, nocturia, urinary frequency or incontinence. The devices deliver a desmopressin flux through the skin of a patient in a low dose amount just necessary to achieve a desired anti-diuretic effect without undesirable side effects such as hyponatremia. The devices are designed to permit a state of normal urinary production to return quickly after the desmopressin flux is terminated.

Owner:SERENITY PHARMA CORP

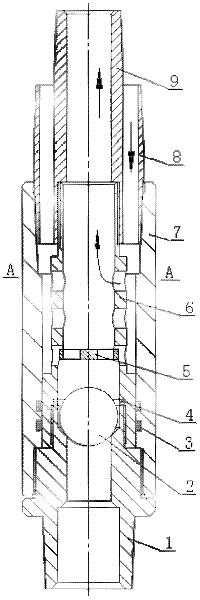

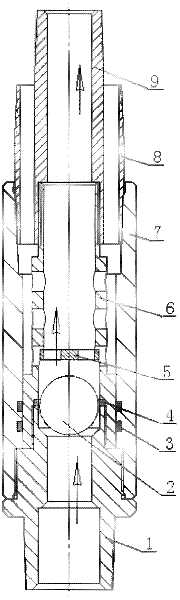

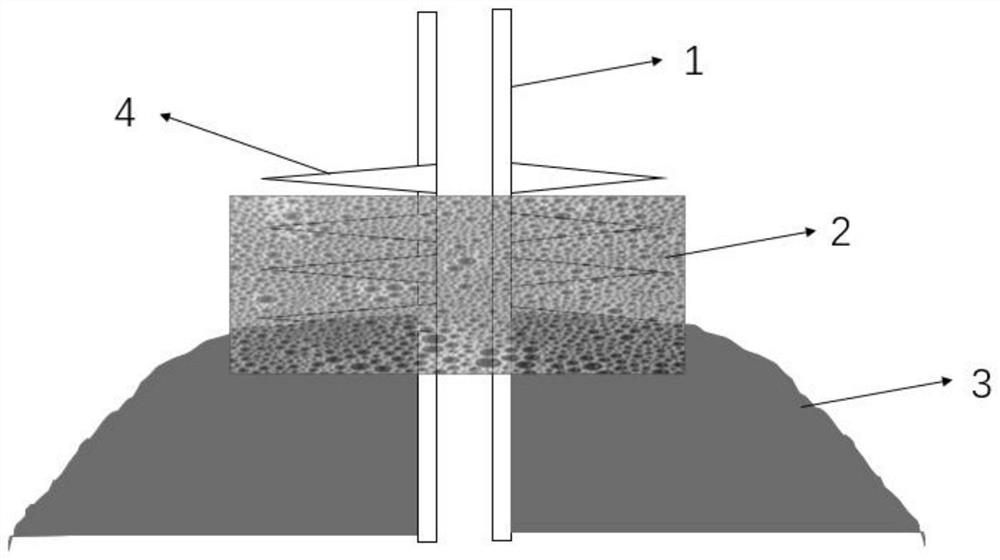

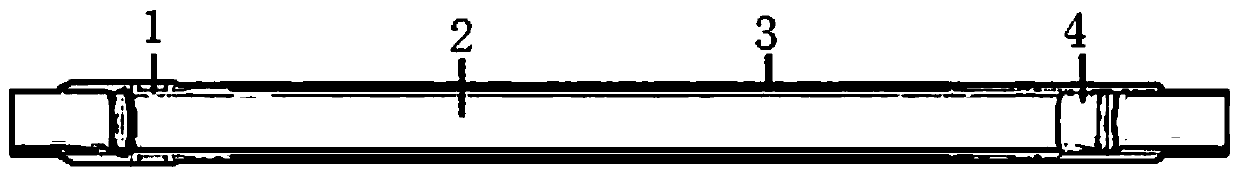

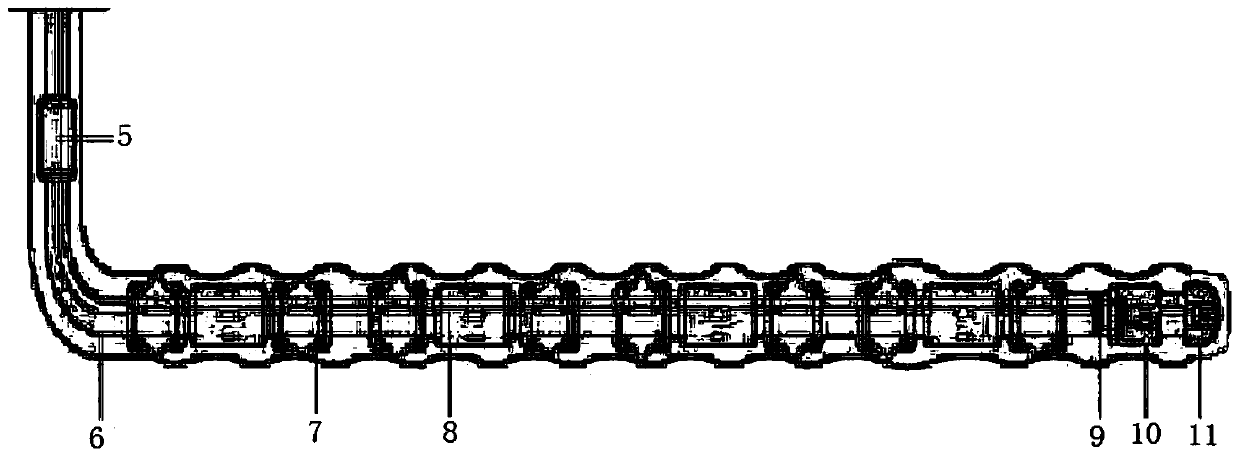

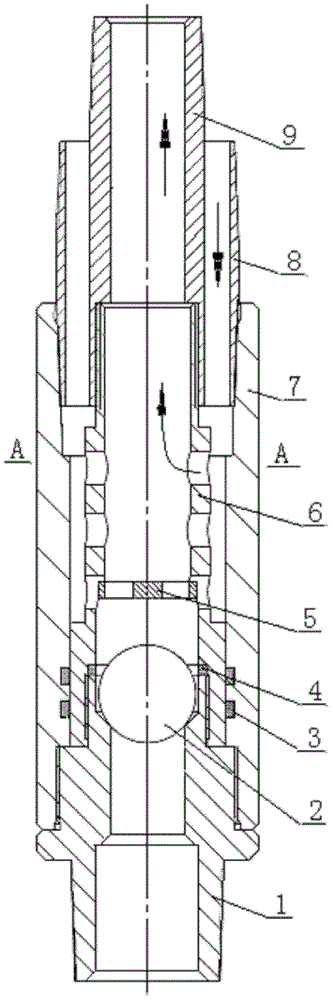

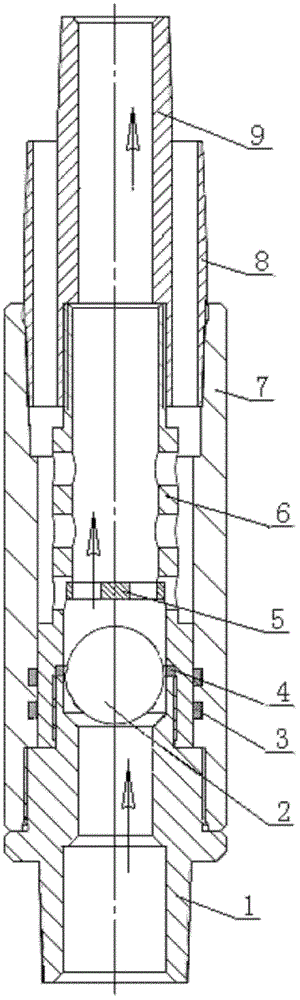

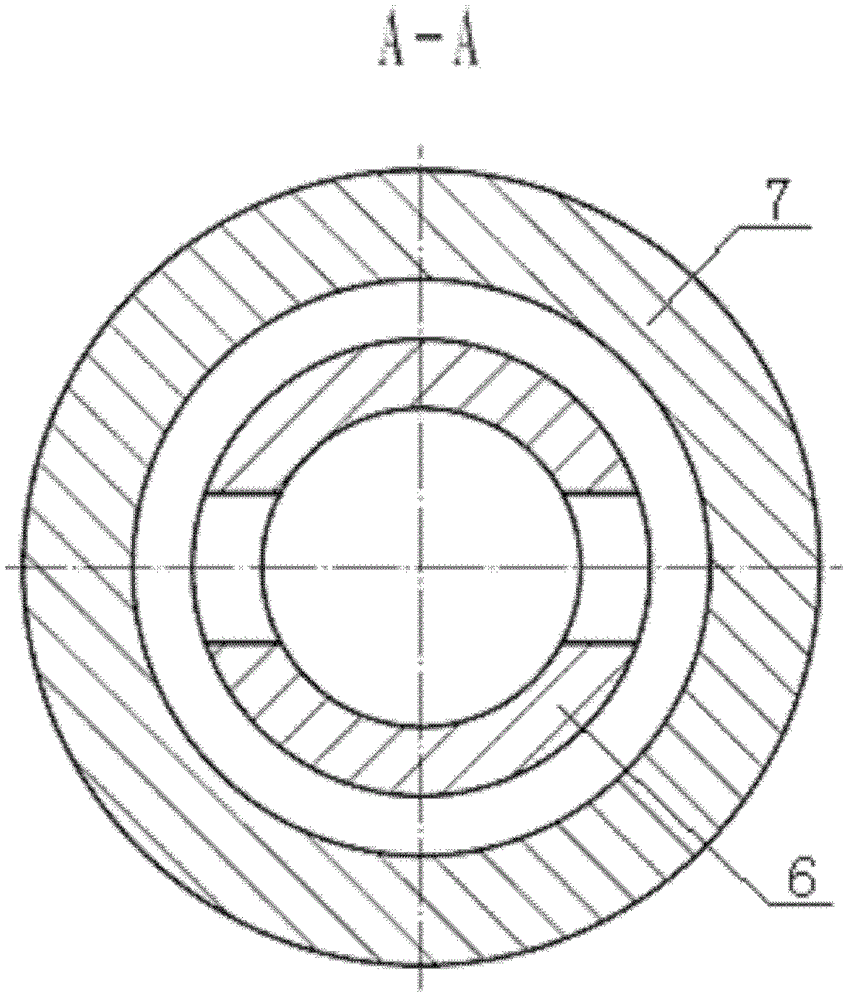

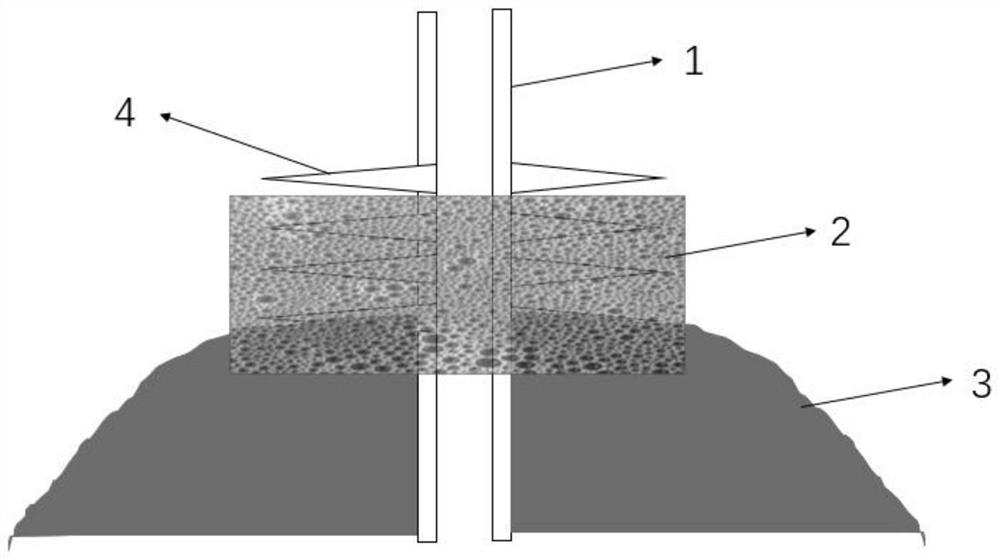

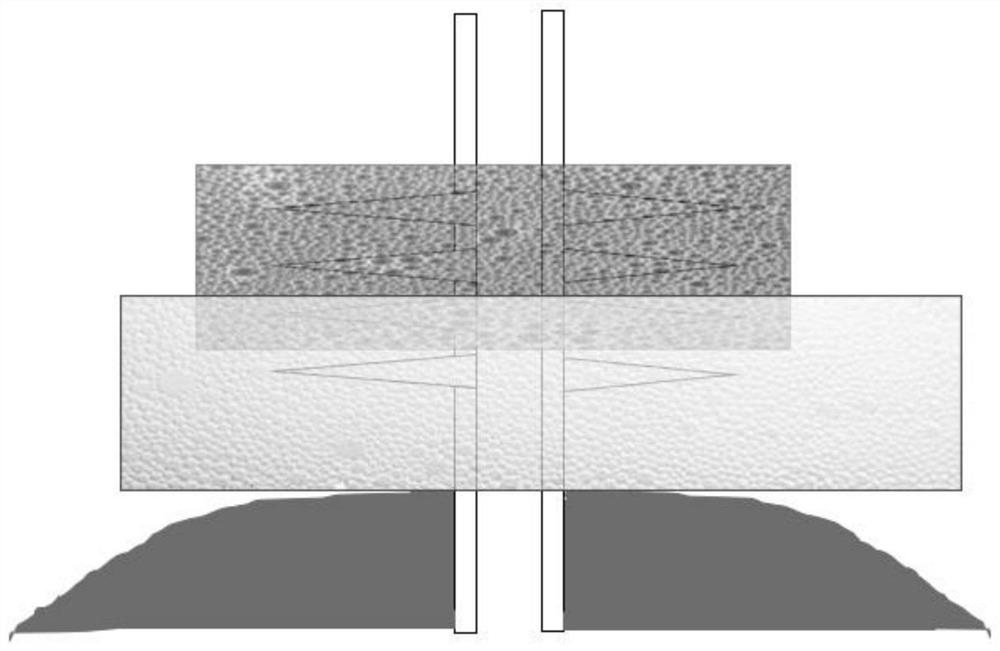

Coal-seam gas dual-channel well-washing valve

The invention relates to a coal-seam gas dual-channel well-washing valve, and is applied to the technical field of coal-seam gas exploitation. Two external threads of different nominal diameters are arranged at the upper end of an adapter; an internal conical surface is arranged at the upper end of the center hole of the adapter, and a steel ball is arranged on the conical surface; a core barrel is connected with the upper end of the adapter; a lateral liquid inflow hole is formed on the wall of the core barrel; a liquid discharge pipe is connected with the upper end of the core barrel; an outer barrel is connected with the upper end of the adapter; circular space is formed between the inner wall of the outer barrel and the outer wall of the core barrel; a pipe joint is connected with the upper end of the outer barrel; and circular space is formed between the pipe joint and the liquid discharge pipe. The coal-seam gas dual-channel well-washing valve has the effects that a hydraulic pump truck is connected with a sleeve gate of a gas exploitation well mouth, so as to pump clean water into a well casing; well-washing water can achieve the underground blocked pump barrel and oil pipe through conversion of the water flow channels of the coal-seam gas dual-channel well-washing valve, so as to wash the underground coal dust to the ground; the well-washing water does not enter the coal seam, so as not to damage the coal seam; and production can be directly restored, and the coal-seam gas yield is rapidly restored to the yield before the pump barrel blockage caused by coal dust.

Owner:PETROCHINA CO LTD

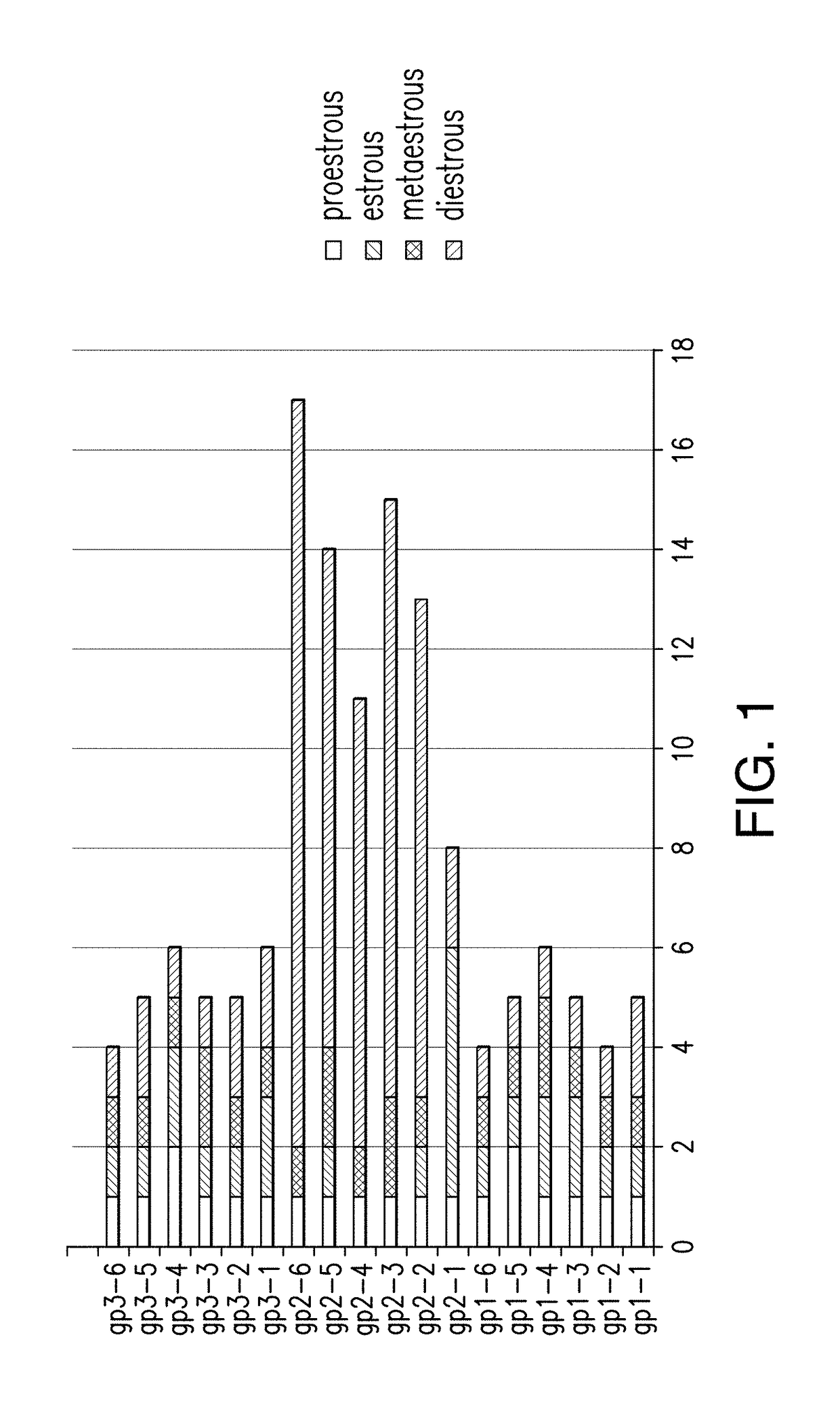

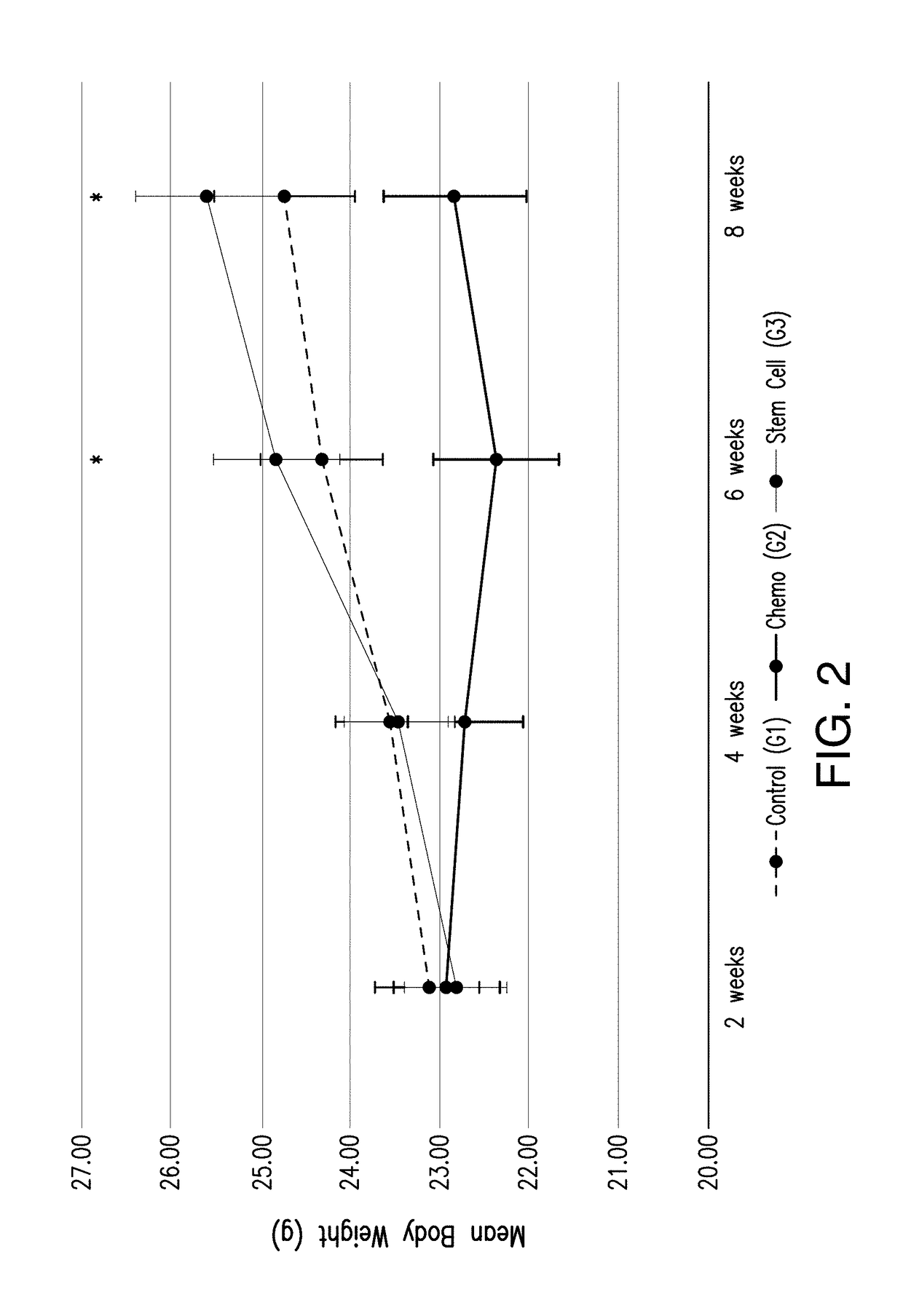

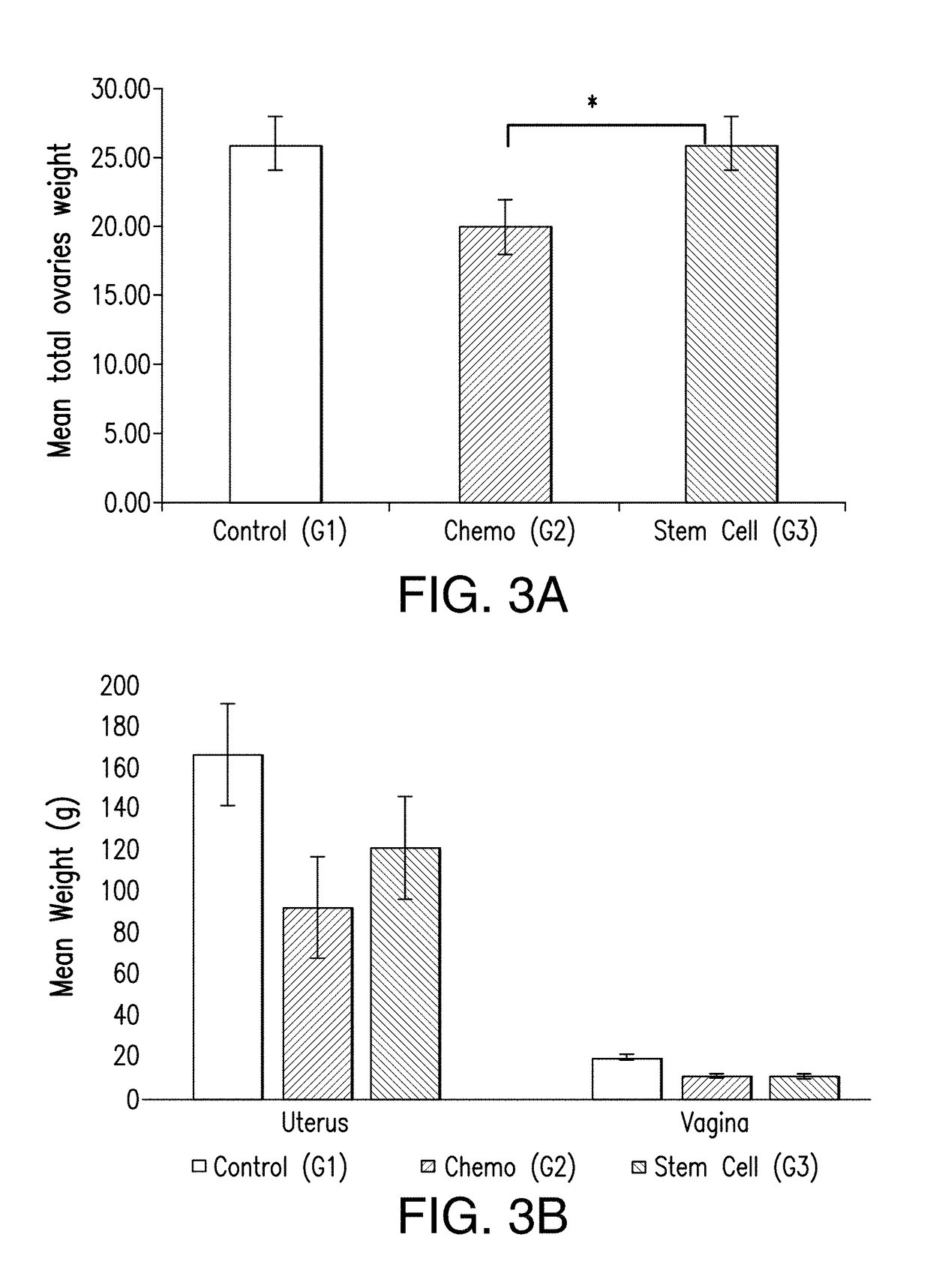

Methods and Compositions for Treating Ovarian Failure

InactiveUS20170258842A1Restore ovarian hormone productionStimulating folliculogenesisGenetically modified cellsPharmaceutical delivery mechanismSurface markerOvarian hormone

Methods and compositions for treating ovarian failure are provided. In one embodiment, the method includes administering stem cells into the ovary of a female subject in need of such treatment. The stem cells are preferably bone marrow derived stem cells (BMSC). In other embodiments, the stem cells are embryonic stem cells, adult stem cells, induced stem cells, induced pluripotent stem cells, umbilical cord blood cells, or combinations thereof. The stem cells can be autologous or heterologous. In one embodiment, the stem cells have the following surface marker profile: CD105 positive, CD166 positive, CD90 positive, and CD73 positive as well as CD14 negative, CD34 negative, CD45 negative, HLA-DR negative, and CD 19 negative. The stem cells are administered in an amount effective to restore ovarian hormone production and promote folliculogenesis.

Owner:AUGUSTA UNIV RES INST INC

Virus-free tissue culture and rapid propagation method of castor oil plants

InactiveCN105746344AEasy to inoculateImprove vaccination success ratePlant tissue cultureHorticulture methodsWarm waterBud

The invention discloses a virus-free tissue culture and rapid propagation method of castor oil plants. The method comprises the following steps: adopting current year's ripe seeds, mixing castor oil plant seeds with coarse sands according to a ratio of 1:5-8, carrying out medium speed grinding and shelling, screening to remove the coarse sands, cleaning the obtained seeds with warm water 2-3 times, immersing the washed seeds in 75% alcohol for 0.5-1.0min, disinfecting the immersed seeds with an aqueous solution of 2% sodium hypochlorite for 20-30min, and flushing the disinfected seeds with sterile water 3-5 times to obtain the flushed seeds used as explants; and carrying out induction culture, propagation culture, rooting culture, transplanting and virus detection to obtain mass propagated virus-free tissue culture seedlings, virus-free plant buds and virus-free small root tubers. Compared with present castor oil plant seedling growing methods, the method disclosed in the invention has the advantages of low inoculation and pollution rate, high transplanting survival rate and high quality.

Owner:岳兰兰

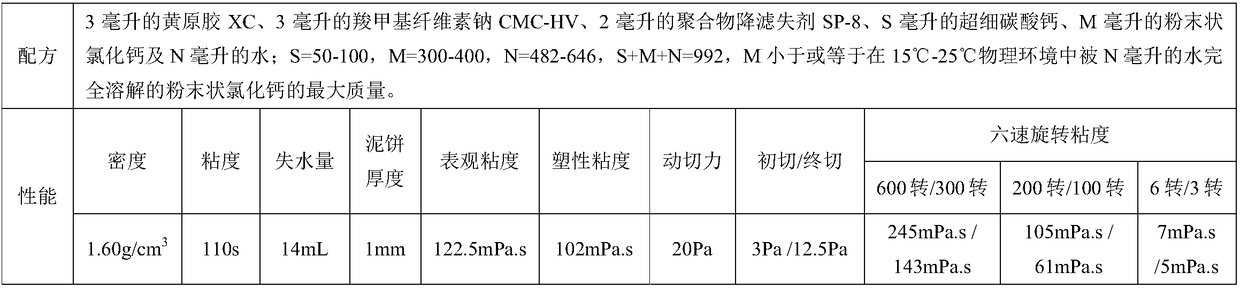

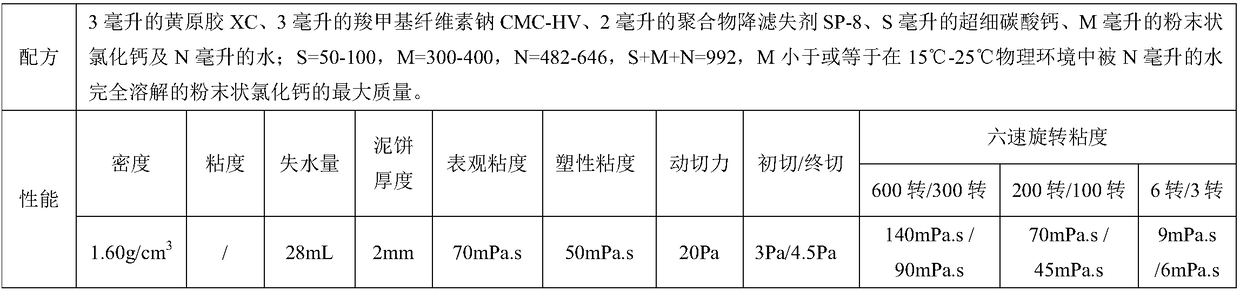

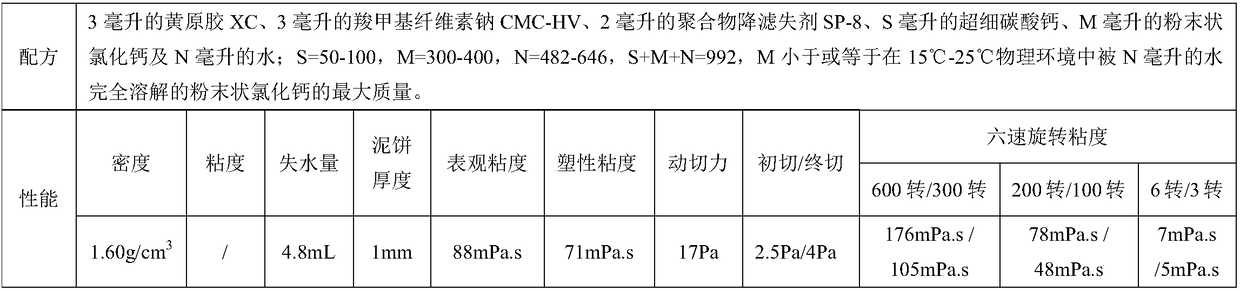

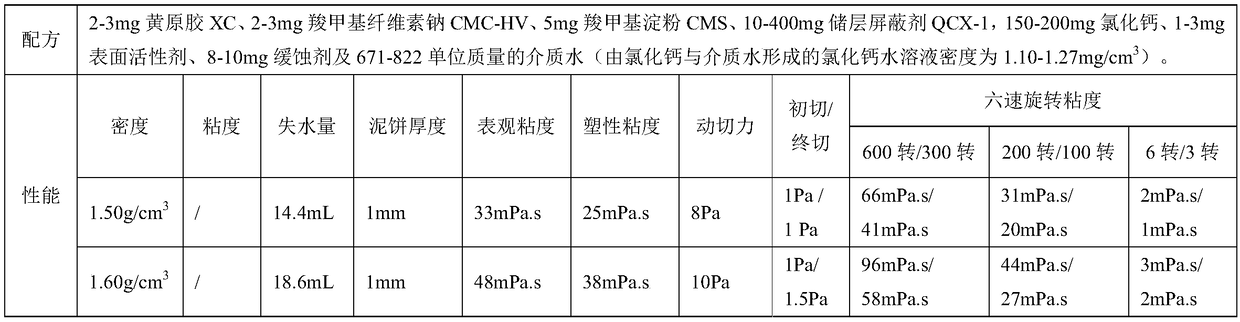

Soil-phase-free strong-inhibition shielding environment-friendly well killing fluid

The invention relates to a petroleum recovery technology, in particular to a soil-phase-free strong-inhibition shielding environment-friendly well killing fluid. The soil-phase-free strong-inhibitionshielding environment-friendly well killing fluid is prepared from X unit volume of xanthan gum XC, Y unit volume of sodium carboxymethyl cellulose CMC-HV, Z unit volume of polymer filtrate reducer SP-8, S unit volume of superfine calcium carbonate, L unit volume of carboxymethyl starch CMS, M unit volume of powdered calcium chloride and N unit volume of water, wherein X is equal to 2 to 3, Y is equal to 2 to 3, Z is equal to 0 to 2, S is equal to 50 to 100, L is equal to 0 to 10, M is equal to 300 to 400, N is equal to 482 to 646, X+Y+Z+S+L+M+N is equal to 1000, and M is smaller than or equalto the maximum mass of the powdered calcium chloride completely dissolved by the N unit volume of water in a physical environment of 15 to 25 DEG C. The soil-phase-free high-inhibition shielding environment-friendly well killing fluid can further reduce water loss (filter loss), can well overcome the liquid lock damage to reservoir caused by large filter loss, has high rheological property, can meet various well killing operations and related construction, has lower cost than a non-solid-phase well killing fluid at the same density, has low reservoir damage, has environmental protection and reservoir protection functions, and can restore the yield of an oil well to the maximum extent after completion of workover treatment.

Owner:KARAMAY GUANGHAI ENVIRONMENTAL TREATMENT CO LTD

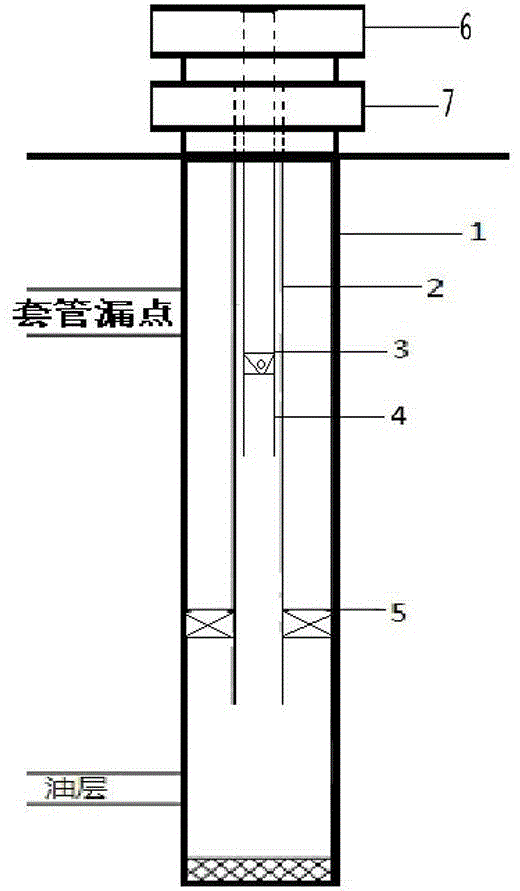

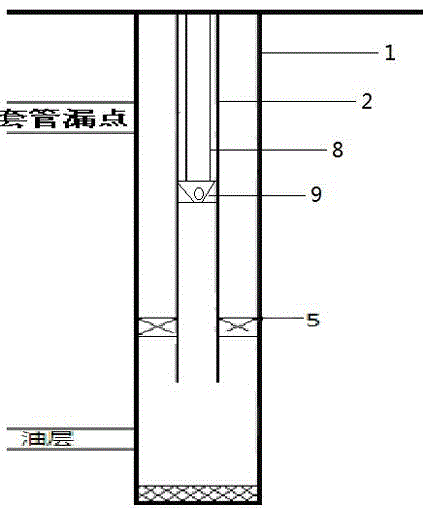

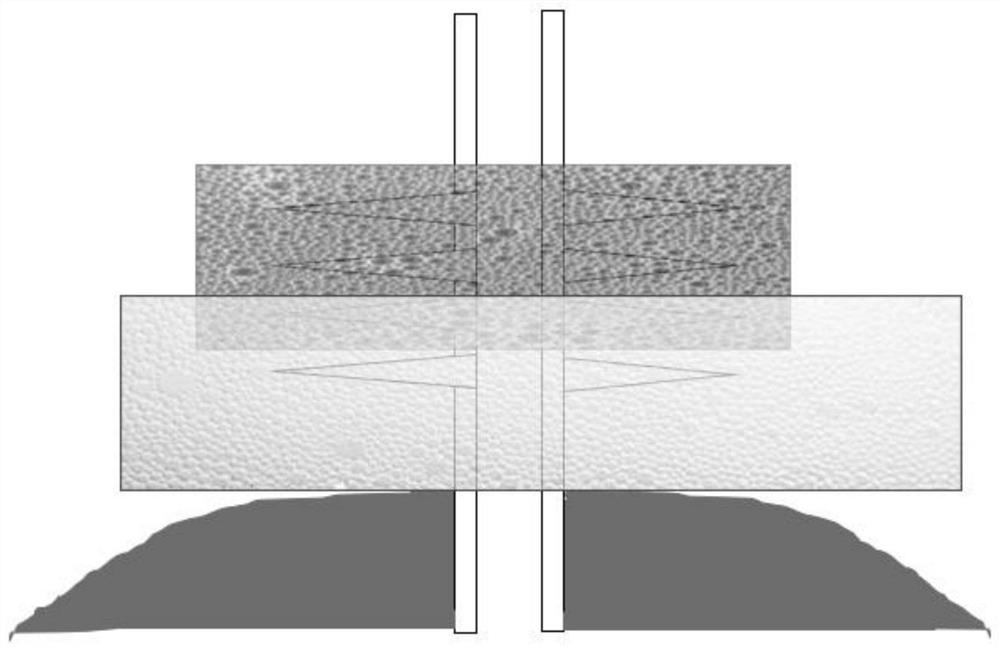

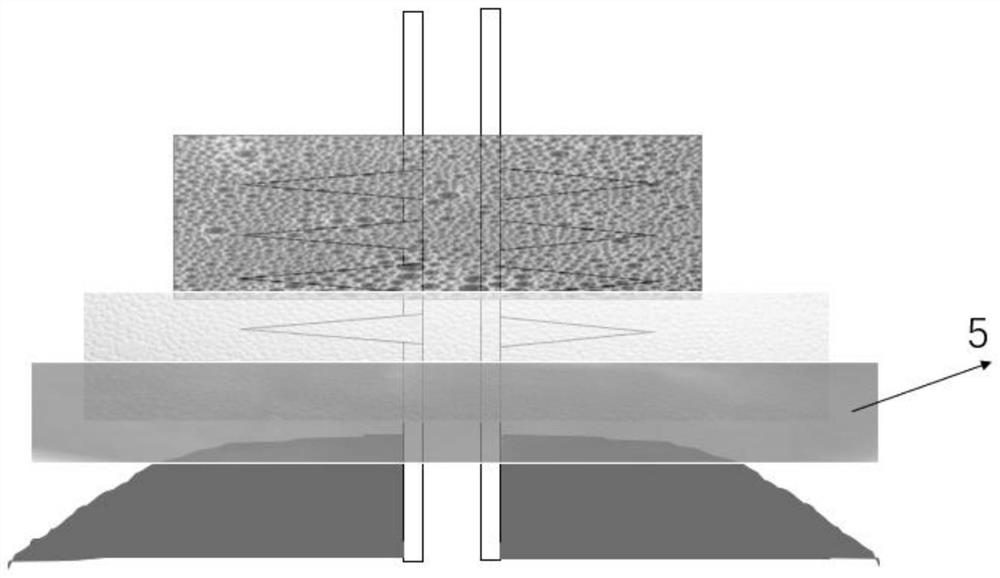

Oil recovery method for casing leaked well and dual-tubing oil recovery string adopted therein

InactiveCN104975824ARealize the operationRestore productionFluid removalEconomic benefitsHigh pressure water

The invention discloses an oil recovery method for a casing leaked well and a dual-tubing oil recovery string adopted therein. The method can be applied to part of casing leaked wells which have long sections, contain high-pressure water formations and have extremely poor leak point absorbance. According to the method, packer setting is conducted between the portion, below a leak point and above an oil reservoir, of a casing and an oil tube through a packer, and oil recovery is conducted by installing a small-diameter tubing pump in a small-diameter oil tube in the oil tube or by installing a rod type oil-well pump in a hollow sucker rod in the oil tube. The dual-tubing oil recovery string formed by the oil tube and the small-diameter oil tube or by the oil tube and the hollow sucker rod is adopted, and the small-diameter oil tube or the hollow sucker rod serves as a liquid channel, so that the casing damaged or leaked wells which have small-reducing leap-free casings, have long sections, contain high-pressure water formations and have extremely poor leak point absorbance are effectively managed. Management method is simple, investment cost is low, validity period is long, overhauling is not needed often, the problem of leakage of casings in any lengths can be solved, the yield of most casing leaked wells can be recovered, and economic benefits are remarkable.

Owner:CHINA PETROLEUM & CHEM CORP +1

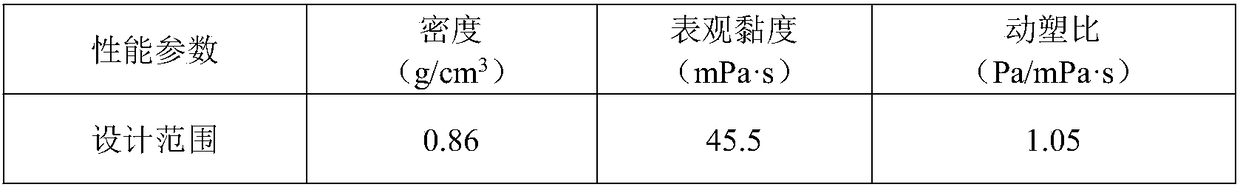

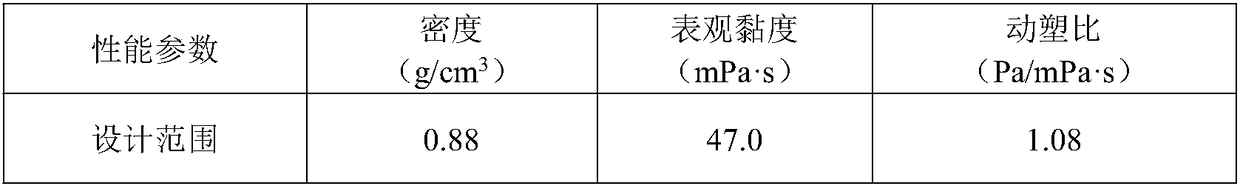

Well killing process using fuzzy ball well killing fluid for natural gas well without reduction of pressure

InactiveCN108559469AOvercoming large leakageOvercoming blocking agentDrilling compositionSealing/packingWell killApparent viscosity

The invention relates to a well killing process using a fuzzy ball well killing fluid for a natural gas well without reduction of pressure. According to the process, under the condition that the pressure of a wellhead of the natural gas well is maintained not to reduce, the fuzzy ball well killing fluid for repairing the natural gas well is prepared, wherein the density is 0.80-0.90 g / cm<3>, the apparent viscosity is 40-70 mPa s, and the dynamic plastic ratio is 0.90-1.50 Pa / mPa s. The fuzzy ball well killing fluid for repairing the natural gas well is prepared by adding 2.4-4.8 parts by weight of ball fuzz agent, 7.2-14.4 parts by weight of ball body agent and 2.4-4.8 parts by weight of ball liner agent into 1000 parts by weight of clean water. A fluid pump is utilized to directly pump the fuzzy ball well killing fluid into a well shaft at the pumping speed of 5-20 m<3> / h to achieve well killing operation under the condition that the pressure of the wellhead is not reduced, wherein the fuzzy ball well killing fluid is 0.1-2.0 times size of the well shaft. This process effectively solves the problems that in conventional natural gas well repair work, the construction period is prolonged and the subsequent formation gas production capacity recovers slowly since the pressure of the wellhead is reduced.

Owner:BEIJING LIHUILAB ENERGY TECH

Rheum officinale virus-free tissue culture fast propagation method

InactiveCN105766631APromote germinationImprove disease resistanceHorticulture methodsPlant tissue cultureMercury DichlorideAlcohol

The invention discloses a rheum officinale virus-free tissue culture fast propagation method, and belongs to the technical field of plant virus-free tissue culture fast propagation. According to the preparation method, pure triennial seed plants of rheum officinale are taken as the female parents; strong and large buds are picked from matured mother plants, then soaked in alcohol (75%), and is taken as explants after mercury dichloride disinfection, then the explants are subjected to induction culture, multiplication culture, and rooting culture so as to obtain rooted tissue culture seedlings with a height of 3 to 5 cm, rooted bulbels with a diameter of 0.2 to 0.5 cm, and rooted small earthnuts with a diameter of 0.5 to 1.0 cm, and finally the seedlings, bulbels, and small earthnuts are transplanted to a culture matrix to culture sprouts. The buds are taken as the explants to carry out virus-free culture to obtain seedlings, compared with the conventional bud breeding method, a novel breeding method is provided, the quality of rheum officinale is improved, the breeding speed is accelerated, and the method can be widely popularized and used.

Owner:岳兰兰

Selective water plugging method for high-water-cut gas well of bottom water gas reservoir

ActiveCN113404459AWon't happenImprove stabilitySurveyDrilling compositionFoaming agentWater production

The invention discloses a selective water plugging method for a high-water-cut gas well of a bottom water gas reservoir. The selective water plugging method comprises the following steps that S1, the position of a water outlet gas layer caused by bottom water coning is determined; S2, a foaming agent solution is injected into the water outlet gas layer, wherein the foaming agent solution is an aqueous solution of an ionic foaming agent, and the concentration is controlled to be 0.5%-1.2%; S3, after the step S2 is completed, nitrogen is injected, and the nitrogen enters a water production high-pressure layer to force water cone of the immediate vicinity of wellbore to fall back; S4, a plugging agent is injected into a water production channel in a directional mode, an artificial partition plate is formed in the water production layer, a bottom water channeling channel is plugged, and bottom water coning is restrained and relieved; and S5, liquid nitrogen over-displacement is carried out, and the permeability of the immediate vicinity of wellbore is recovered and reserved. According to the method, the artificial partition plate is built at the water outlet layer position of the high-water-cut gas well of the bottom water gas reservoir, intelligent selective water plugging of the high-water-cut gas well of the bottom water gas reservoir can be achieved, and the problem that the gas well yield is sharply reduced after water breakthrough of the gas reservoir is solved.

Owner:SOUTHWEST PETROLEUM UNIV

Water control fracturing method for switchable cementing sliding sleeve of horizontal well

InactiveCN111472738AImprove permeabilityOilyFluid removalWell/borehole valve arrangementsHorizontal wellsCoiled tubing

The invention discloses a water control fracturing method for a switchable cementing sliding sleeve of a horizontal well. The water control fracturing method comprises the steps that firstly, the positions of fracturing sweet hearts of all fracturing sections of the horizontal well are selected; then the switchable cementing sliding sleeve is arranged at the preset fracturing position of a casingpipe, the casing pipe with the switchable cementing sliding sleeve is tripped in, cementing of the horizontal well is carried out; secondly, a coiled tubing staged fracturing tool with a bottom seal is tripped in, the switchable cementing sliding sleeve is opened, fracturing construction is started; after one-section fracturing construction is completed, the coiled tubing staged fracturing tool with the bottom seal is lifted upwards to the next-section fracturing position, and so on to complete the fracturing construction of the whole horizontal well; and after all fracturing construction is finished, a drilling tool is lifted upwards to a vertical well section. According to the water control fracturing method for the switchable cementing sliding sleeve of the horizontal well, the switchable cementing sliding sleeve is arranged on the casing pipe, the casing pipe with the switchable cementing sliding sleeve is tripped in, accurate positioning of the water outlet layer section of the horizontal well is achieved, and the single well yield of the horizontal well is increased.

Owner:PETROCHINA CO LTD

Coal-seam gas dual-channel well-washing valve

The invention relates to a coal-seam gas dual-channel well-washing valve, and is applied to the technical field of coal-seam gas exploitation. Two external threads of different nominal diameters are arranged at the upper end of an adapter; an internal conical surface is arranged at the upper end of the center hole of the adapter, and a steel ball is arranged on the conical surface; a core barrel is connected with the upper end of the adapter; a lateral liquid inflow hole is formed on the wall of the core barrel; a liquid discharge pipe is connected with the upper end of the core barrel; an outer barrel is connected with the upper end of the adapter; circular space is formed between the inner wall of the outer barrel and the outer wall of the core barrel; a pipe joint is connected with the upper end of the outer barrel; and circular space is formed between the pipe joint and the liquid discharge pipe. The coal-seam gas dual-channel well-washing valve has the effects that a hydraulic pump truck is connected with a sleeve gate of a gas exploitation well mouth, so as to pump clean water into a well casing; well-washing water can achieve the underground blocked pump barrel and oil pipe through conversion of the water flow channels of the coal-seam gas dual-channel well-washing valve, so as to wash the underground coal dust to the ground; the well-washing water does not enter the coal seam, so as not to damage the coal seam; and production can be directly restored, and the coal-seam gas yield is rapidly restored to the yield before the pump barrel blockage caused by coal dust.

Owner:PETROCHINA CO LTD

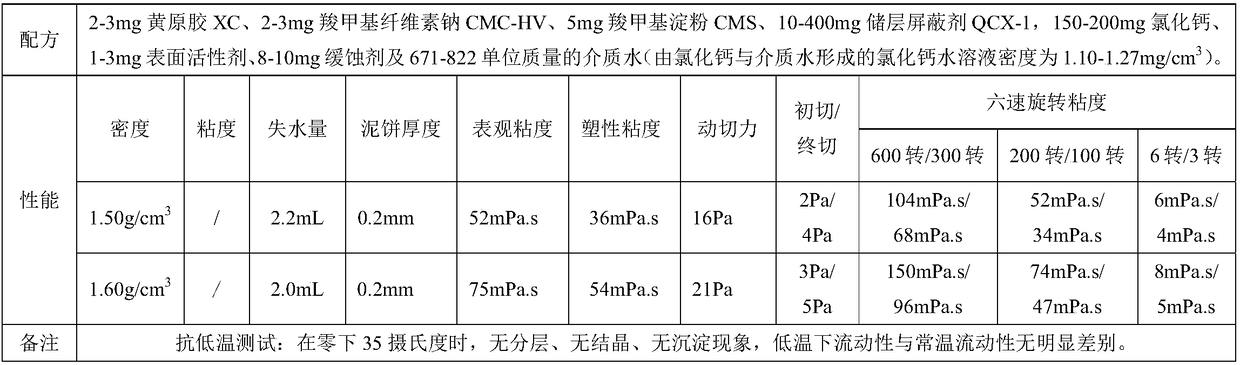

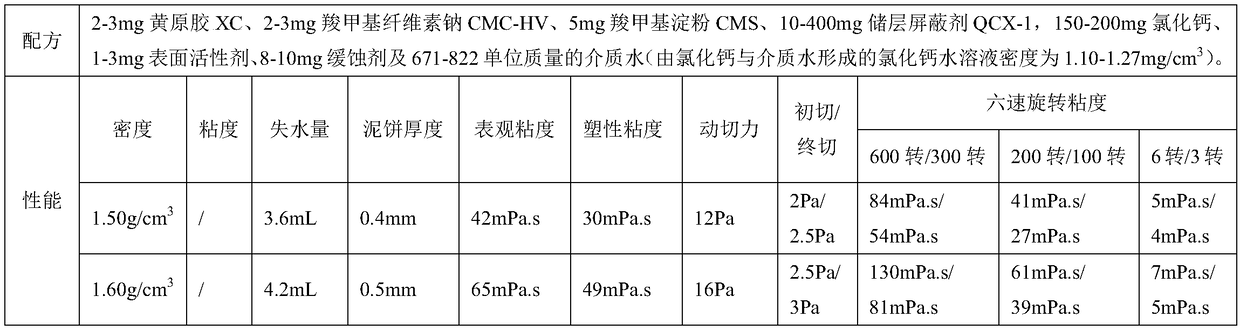

Low-temperature resistant and soil phase-free shielding environment-friendly killing fluid for oil and gas well workover

InactiveCN109233772AEliminate the effects ofRestore productionDrilling compositionUnit massVolumetric Mass Density

The invention relates to a petroleum recovery technology, belongs to an improvement of components of a killing fluid, and particularly relates to a low-temperature resistant and soil phase-free shielding environment-friendly killing fluid for oil and gas well workover. The low-temperature resistant and soil phase-free shielding environment-friendly killing fluid contains 2-3 unit mass of a suspension agent xanthan gum XC, 2-3 unit mass of a tackifier carboxymethylcellulose sodium CMC-HV, 5-10 unit mass of a fluid loss additive carboxymethyl starch CMS, 10-400 unit mass of a reservoir shieldingagent QCX-1, 150-200 unit mass of an inorganic salt weighting agent calcium chloride, 1-3 unit mass of a surfactant, 8-10 unit mass of a corrosion inhibitor and 371-822 unit mass of medium water, wherein for the maximum mass of the calcium chloride completely dissolved by the medium water in a physical environment at a temperature of lower than or equal to normal temperature, the density of a calcium chloride aqueous solution formed by the calcium chloride and the medium water is 1.10-1.27 g / cm3 in the physical environment at normal temperature. The low-temperature resistant and soil phase-free shielding environment-friendly killing fluid provided by the invention can effectively reduce the filter loss of a system after hot rolling.

Owner:克拉玛依市广振石油技术服务有限责任公司

Kiwifruit inarching method

InactiveCN102487735BExpand production advantagesRestore productionCultivating equipmentsHorticultureExperimental researchHigh humidity

The invention discloses a kiwifruit inarching method to control current leaf defoliation diseases of kiwifruit. Control is achieved by subjecting actinidia kolomikta and actinidia polygama to inarching and stock interchanging. After experimental researches succeed, a unique technical system of controlling leaf defoliation diseases of red kiwifruit is explored in Cangxi. The technical system is used with a series of techniques of agricultural measures to form technical norms, so that technical support is provided for planting high-quality kiwifruit in low altitude and high humidity areas, and planting advantages of kiwifruit are expanded.

Owner:四川苍溪猕猴桃研究所

Blocking remover composition for barite pollution of oil and gas well and preparation method thereof

The invention discloses a blocking remover composition for the barite pollution of an oil and gas well. The blocking remover composition is characterized by being prepared from the following raw materials in parts by weight: 16 to 20 parts of hydroxyethyl acetamide, 20 to 25 parts of amino acetamide, 13 to 16 parts of 3-amino-1,2,4-triazole, 12 to 16 parts of cinnamamide, 10 to 14 parts of crown ether (18-crown-6), 6 to 9 parts of sodium dihydroxytartrate, 17 to 21 parts of ethosuximide, 11 to 15 parts of ethyl salicylate, 1 to 3 parts of p-hydoxyphenylactic acid, 25 to 35 parts of ammonia liquor (40wt%), and 90 to 110 parts of water. The blocking remover can be used in a temperature range from a room temperature to 100 DEG C, and can solve the blocking and barite pollution of an oil and gas well within 4 to 8 hours. The dissolution rate of barite is greater than 90%, and the scale removing rate is more than 98%. During the de-blocking process, no corrosion happens, no dead angle exists, no scale or precipitate is generated, secondary blocking is avoided, the de-blocking speed is quick, the waste liquid does not need to be delivered to the ground, and the de-blocking is safe and corrosion-free.

Owner:GANSU HEIMA PETROCHEM ENG

A selective water plugging method for high water cut gas wells in bottom water gas reservoirs

ActiveCN113404459BWon't happenImprove stabilitySurveyDrilling compositionFoaming agentWater production

The invention discloses a method for selective water plugging of high water-cut gas wells in bottom water gas reservoirs. The foaming agent solution is an aqueous solution of an ionic foaming agent, and the concentration is controlled at 0.5%-1.2%; S3, after the completion of step S2, inject nitrogen, so that the nitrogen enters the water-producing high pressure layer, forcing the water cone in the near-wellbore zone to fall back; S4, injecting The blocking agent enters the water-producing channel directionally, and forms an artificial baffle in the water-producing layer to block the channel of bottom water channeling, inhibit and alleviate the coning of bottom water; The method is to establish an artificial baffle at the water production layer of the gas well with high water cut in the bottom water gas reservoir, which can realize intelligent selective water plugging of the gas well with high water cut in the bottom water gas reservoir, and solve the problem that the gas well production decreases sharply after the gas reservoir breaks through.

Owner:SOUTHWEST PETROLEUM UNIV

Method for improving erythromycin production by transforming Saccharopolyspora erythromycetes sace_3980 gene

ActiveCN106520866BImprove fermentation yieldIncrease productionFungiMicroorganism based processesBiotechnologyMicrobiology

Owner:ANHUI UNIVERSITY

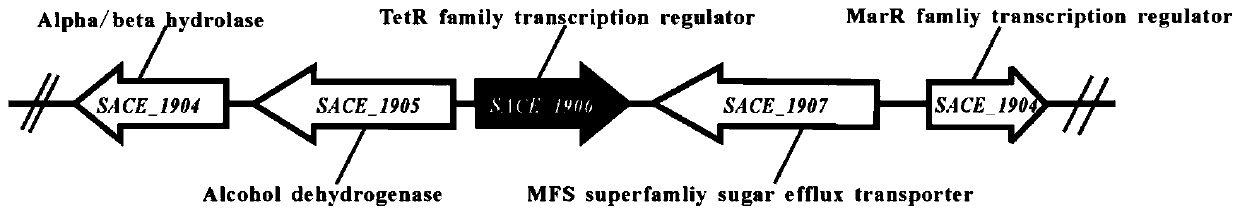

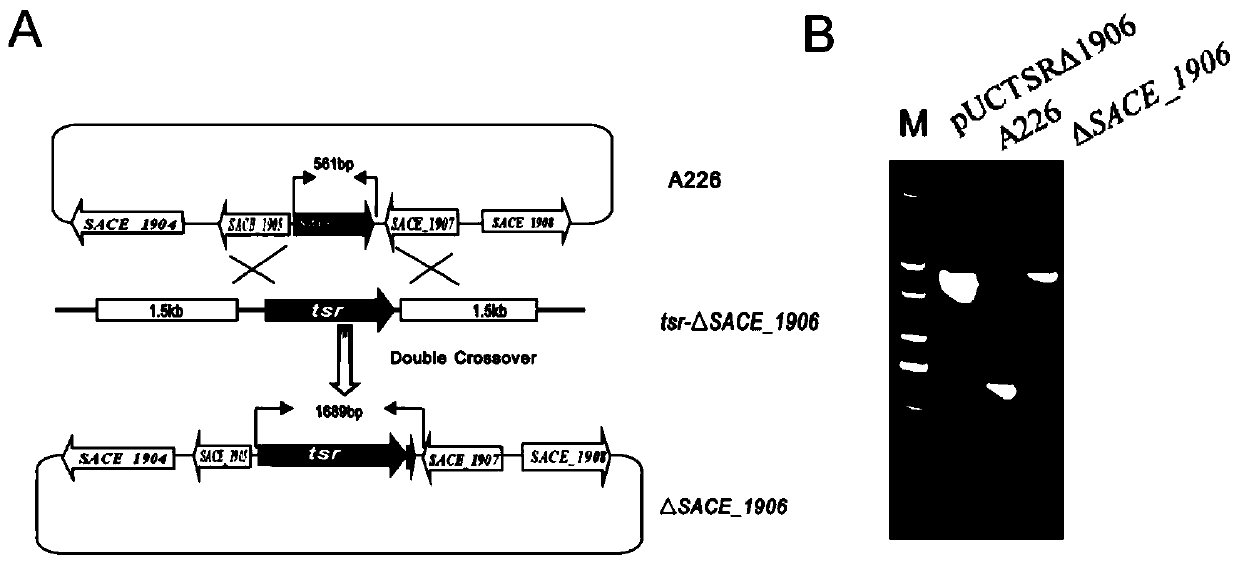

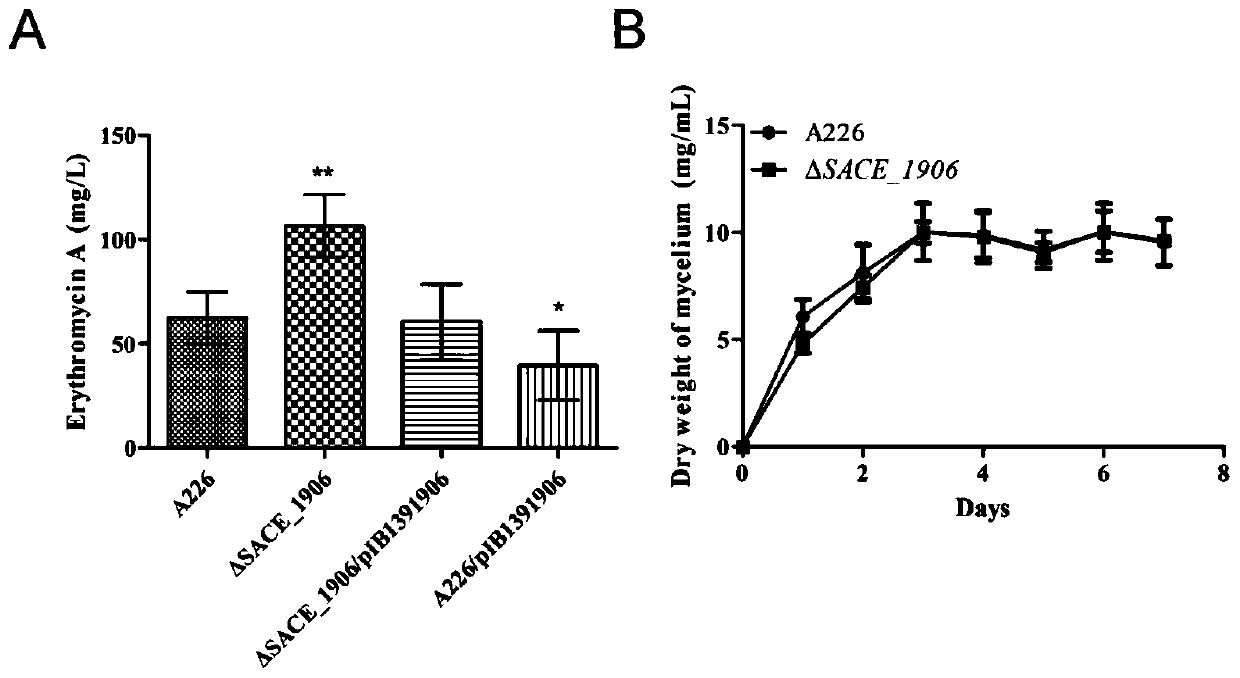

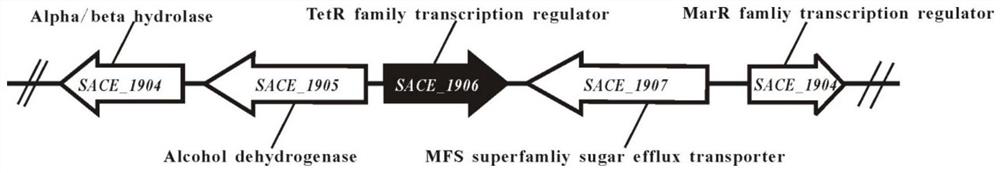

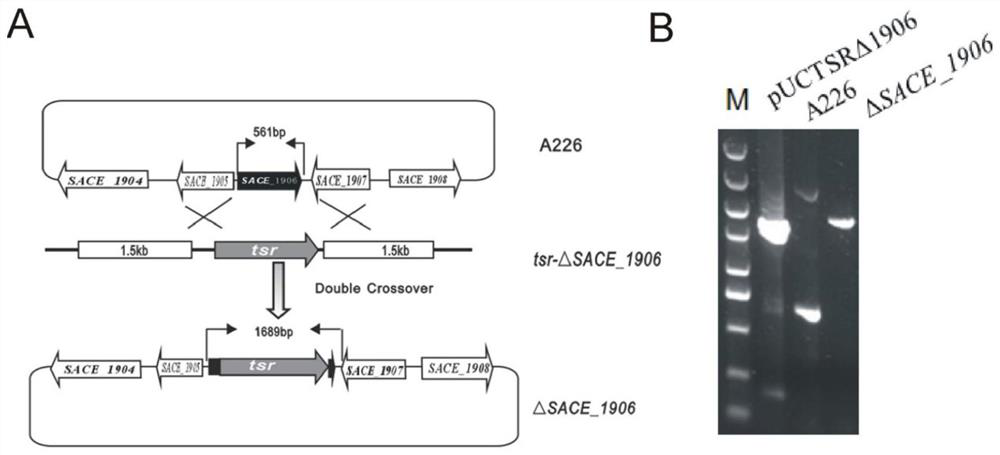

Method for increasing yield of erythromycin through saccharopolyspora erythraea SACE_1906 gene pathway

ActiveCN111197019AIncrease productionRestore productionBacteriaMicroorganism based processesSaccharopolyspora erythraeaGenetic engineering

The invention discloses a method for increasing the yield of erythrocin through a saccharopolyspora erythraea SACE_1906 gene pathway. The SACE_1906 gene is inactivated in the saccharopolyspora erythraea through a genetic engineering approach, the target gene SACE_1905 of the saccharopolyspora erythraea is overexpressed to obtain the saccharopolyspora erythraea erythromycin high-yield engineering strain, the erythromycin is produced by fermenting the strain, and the yield of the erythromycin can be increased by fermenting the strain obtained by the technology.

Owner:ANHUI UNIVERSITY

Root-replacement method for prolonging economic life of plum and apricot plants

ActiveCN108990678ARestore productionShort recovery periodGraftingCultivating equipmentsBudGermination

The invention discloses a root-replacement method for prolonging the economic life of plum and apricot plants, and belongs to the technical field of plant cultivation. The root-replacement method comprises the following steps: (1) washing root collars having the length of 10 cm-15 cm of plants, dipping the gauze in a mixed solution of potassium permanganate and thiophanate-methyl, and covering theroot collar with the gauze; (2) cutting the cortex in trunks of the plants two rounds, and removing phloem between the two cutting rings; (3) using a mixed matrix to cover around the two cutting rings, and filling and leveling the root collars with soil; (4) watering the soil with a mixed solution of rooting powder and a seaweed extract, and using a blank film to cover tree discs having the diameter of 1 meter; and (5) spraying the plants with water every 10-15 days within 2 months after germination of leaf buds. The root-replacement method effectively solves the phenomenon of premature agingof trees caused by three main factors: poor growth of root collars of trees, poor affinity of rootstocks and scions and poor growth of roots, can achieve high yield and stable yield, can improve thefruit quality and effectively prolong the economic life of fruit trees, and is simple, efficient and fast.

Owner:SICHUAN AAS HORTICULTURE RES INST

Three-stage breeding method of healthy purple yam miniature potato

The invention discloses a three-segment healthy purple micro yam breeding method, and belongs to the field of yam seedling breeding methods. The three-segment rapid yam seedling breeding method is utilized in the seedling growing method, healthy micro yam seedlings without soil-borne diseases and yam-borne diseases are produced from purple yam seedlings without yam tubers and are non-contact with soil, factorial production is implemented, a large amount of healthy micro yam seedlings are bred intensively, breeding efficiency of purple yam seedlings can be improved, and production cost can be reduced. Yield of purple yams is increased by 15 to 20% per mu, original fine species and yield of the purple yams are recovered, and planting benefits of soil per unit area is increased.

Owner:镇远县百福农业科技示范有限公司

A kind of rejuvenation method of Chinese fir with crown buried dry method ear picking nursery

InactiveCN108738967BRestore productionInhibition of germinationCultivating equipmentsHorticulture methodsAgricultural engineeringPlant propagation

The invention relates to the technical field of plant propagation, and provides a rejuvenation method for a cutting orchard by a burying-drying method of cunninghamia lanceolata with crown. The stepsof the cutting orchard managed for a long term are crown rebuilding and branch cutting surface rebuilding; the steps of the decayed cutting orchard due to management failure are crown rebuilding, branch cutting surface rebuilding, soil improvement and water and fertilizer management, so that the rejuvenation problem of the cutting orchard by the burying-drying method of the cunninghamia lanceolatawith the crown is solved.

Owner:福建省洋口国有林场 +3

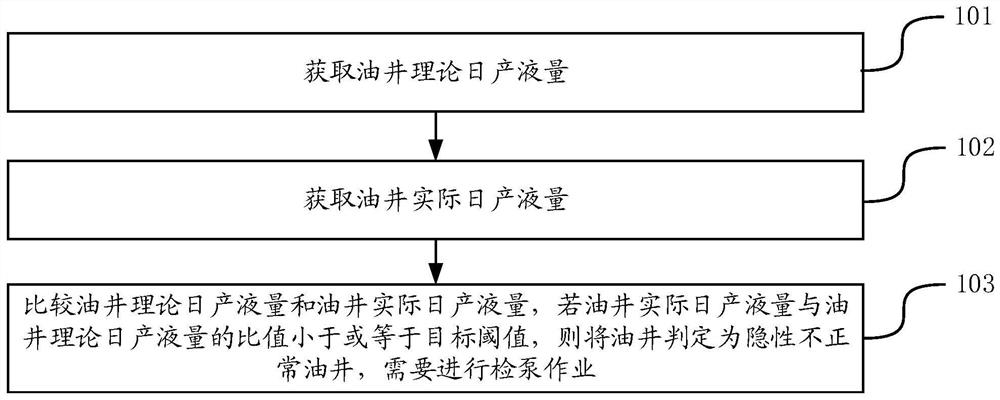

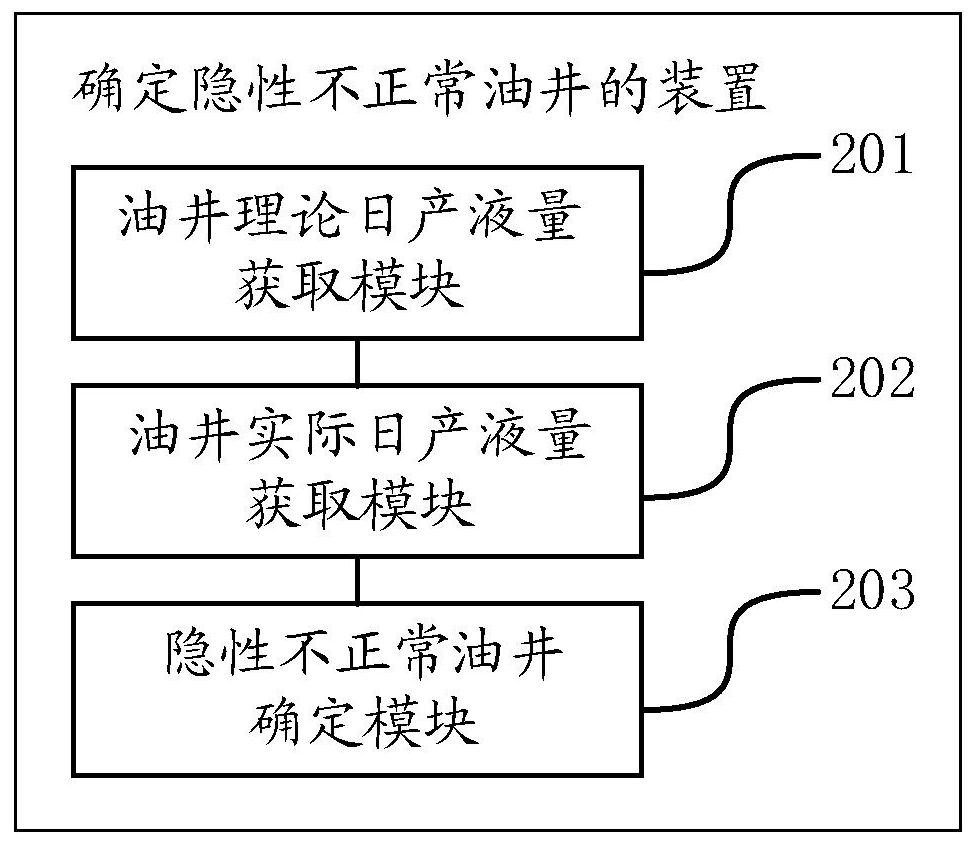

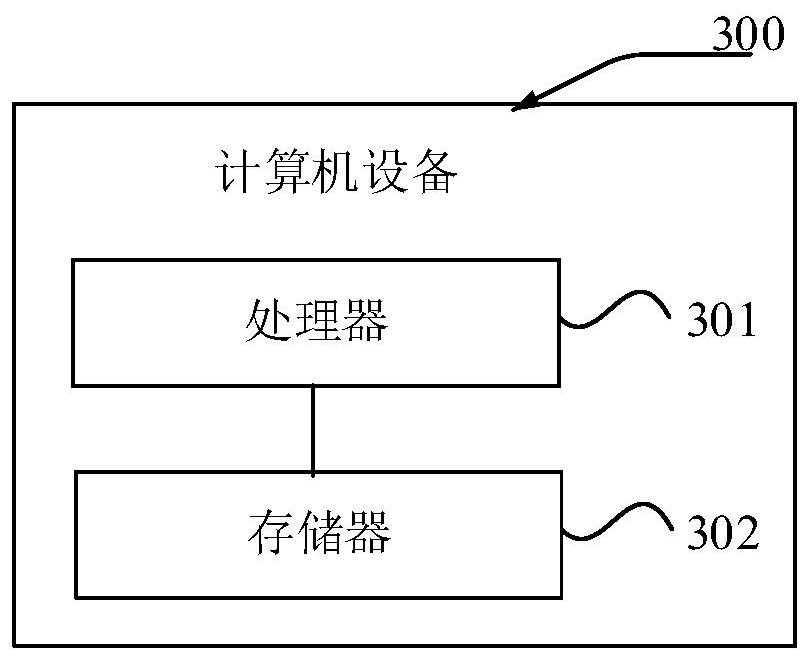

Method and device for determining implicit abnormal oil well

PendingCN111963161ARestore productionReduce "sick" production timePump testingSurveyOil wellOil field

The invention provides a method and device for determining an implicit abnormal oil well, and belongs to the technical field of oil field oil extraction. The method comprises the following steps: based on known parameters such as oil layer flow pressure, oil layer permeability, pump setting depth, crude oil viscosity and the like, determining the theoretical daily liquid production of an oil wellthrough a relation formula among the working fluid level variation of the oil well, the oil layer liquid supply amount, the oil well pump leakage amount and the theoretical daily liquid production ofthe oil well; comparing the theoretical daily fluid production capacity of the oil well with the actual daily fluid production capacity of the oil well; if the ratio of the actual daily fluid production of the oil well to the theoretical daily fluid production of the oil well is less than or equal to a target threshold; judging the oil well as a hidden abnormal oil welland carrying out pump detection operation, so that pump detection operation can be carried out on a hidden abnormal oil well in time, the 'sick' production time of the hidden abnormal oil well is shortened, the oil well yield isrecovered as soon as possible, and the purpose of improving the total yield between two times of pump detection construction, field oil well application for more than 300 times and average single-well annual oil increase by 216 tons are achieved.

Owner:PETROCHINA CO LTD

A Composite Plugging Removal Agent for Tight Sandstone Reservoirs

ActiveCN105255467BUnblockImprove the effective permeabilityDrilling compositionAcetic acidThree stage

The invention discloses a compound plug removal agent for a tight sandstone oil reservoir, and belongs to the technical field of oilfield exploitation. The compound plug removal agent is composed of prepad fluid, main body fluid and post-pad fluid, wherein the prepad fluid and the post-pad fluid each contains hydrochloric acid, potassium chloride, ethylenediaminetetraacetic acid, water plug removal agents, corrosion inhibitor and ethylene glycol butyl ether, and the main body fluid contains fluosilicic acid, hydrochloric acid, potassium chloride, ethylenediaminetetraacetic acid, water plug removal agents, corrosion inhibitor and ethylene glycol butyl ether. According to pollution plugging which possibly occurs in the development process of the tight sandstone oil reservoir, corresponding treatment fluid in the compound plug removal agent is sequentially infused into the reservoir according to the three stages of front, middle and rear, and the purposes of removing reservoir plugging, increasing effective permeability of the reservoir, improving the plug removal effect and recovering per-well production can be achieved. The hydrochloric acid is matched with the fluosilicic acid to serve as the components of the main body fluid, plug removal is achieved, and meanwhile the reservoir is protected against secondary pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sugarcane detoxication tissue culturing and fast propagating method

InactiveCN101138321BIncrease in sizeEasy to inoculateCultivating equipmentsHorticulture methodsAxillary budPlant propagation

The present invention relates to a method for virus-free tissue culture and rapid propagation of sugarcane belonging to the technical field of plant propagation. The method comprises the following steps that the terminal buds or auxiliary buds of the sugar cane is taken as the explants and the virus-free tissue culture seedlings are propagated in mass after the callus tissue inducement and culture, plant differentiation culture, proliferation culture, radication culture and virus test. The present invention is characterized in that the explants adopted are large and the operation is easy; theinoculation survival rate is high; the detoxification is simple, convenient, fast and thorough; the propagation coefficient per month is 5 to 10 times and the speed is fast which is fit for breeding in factory and commercial production.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

A method for improving the production of erythromycin through the Saccharopolyspora erythromyces sace_1906 gene pathway

ActiveCN111197019BIncrease productionRestore productionBacteriaMicroorganism based processesBiotechnologyMicrobiology

The invention discloses a kind of SACE_ 1906 A method for improving the production of erythromycin by genetic means, inactivating in Saccharopolyspora erythromycetes through genetic engineering SACE_1906 genes, and overexpress their target genes SACE_1905 The high-yield engineering strain of erythromycin of Saccharopolyspora erythromycetes is obtained, and the obtained strain is fermented to produce erythromycin, and the fermentation of the strain obtained by the technology can increase the yield of erythromycin.

Owner:ANHUI UNIVERSITY

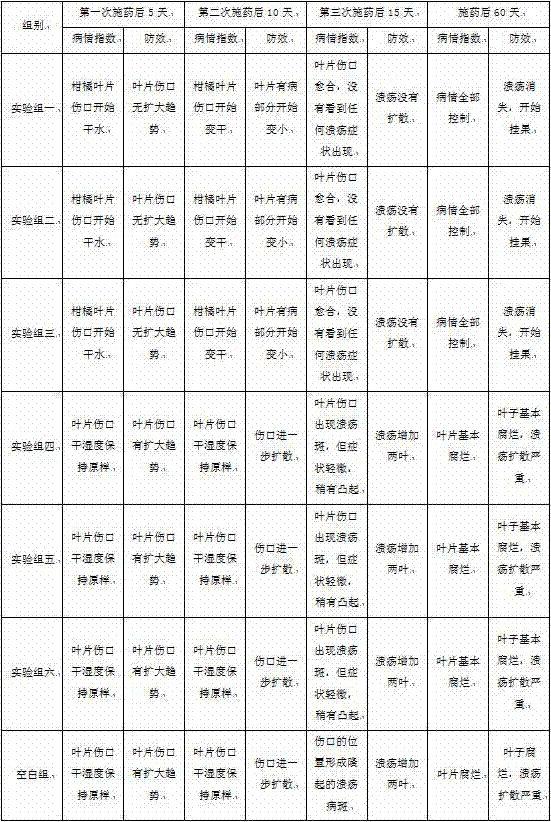

Method for producing biological agent for preventing and curing citrus canker by using chicken manure water

The invention discloses a method for producing biological agent for preventing and curing citrus canker by using chicken manure water. The agent comprises the following raw materials in parts by weight: 1000 to 2000 parts of chicken manure water, 1 to 20 parts of papaya enzyme, 5 to 10 parts of ferrous sulfate, 50 to 100 parts of elephantopus scaber and 50 to 100 parts of chinaberry leaves. The production method comprises the following steps: adding elephantopus scaber and chinaberry leaves into white spirit according to the weight ratio of 1 to 10, soaking for 10 to 15 days, and filtering toobtain a medicinal liquor; taking chicken manure water, papaya enzyme and ferrous sulfate in parts by weight, uniformly mixing the chicken manure water, papaya enzyme and ferrous sulfate, and puttingthe mixture into a fermentation tank for fermentation for 3 to 5 days to obtain a fermented mixture; adding the obtained fermented mixture into the obtained medicinal liquor according to the weight ratio of 100 to 1, uniformly mixing, stacking and tightening with plastic cloth, carrying out sealing fermentation, controlling the temperature in the range of 20 DEG C to 25 DEG C, controlling the humidity in the range of 65% to 75%, and fermenting for 10 to 15 days to obtain the biological agent for preventing and curing the citrus canker.

Owner:封之强

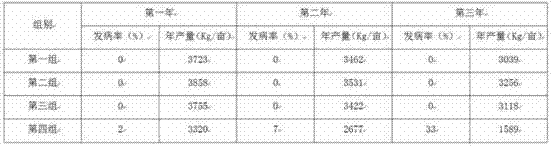

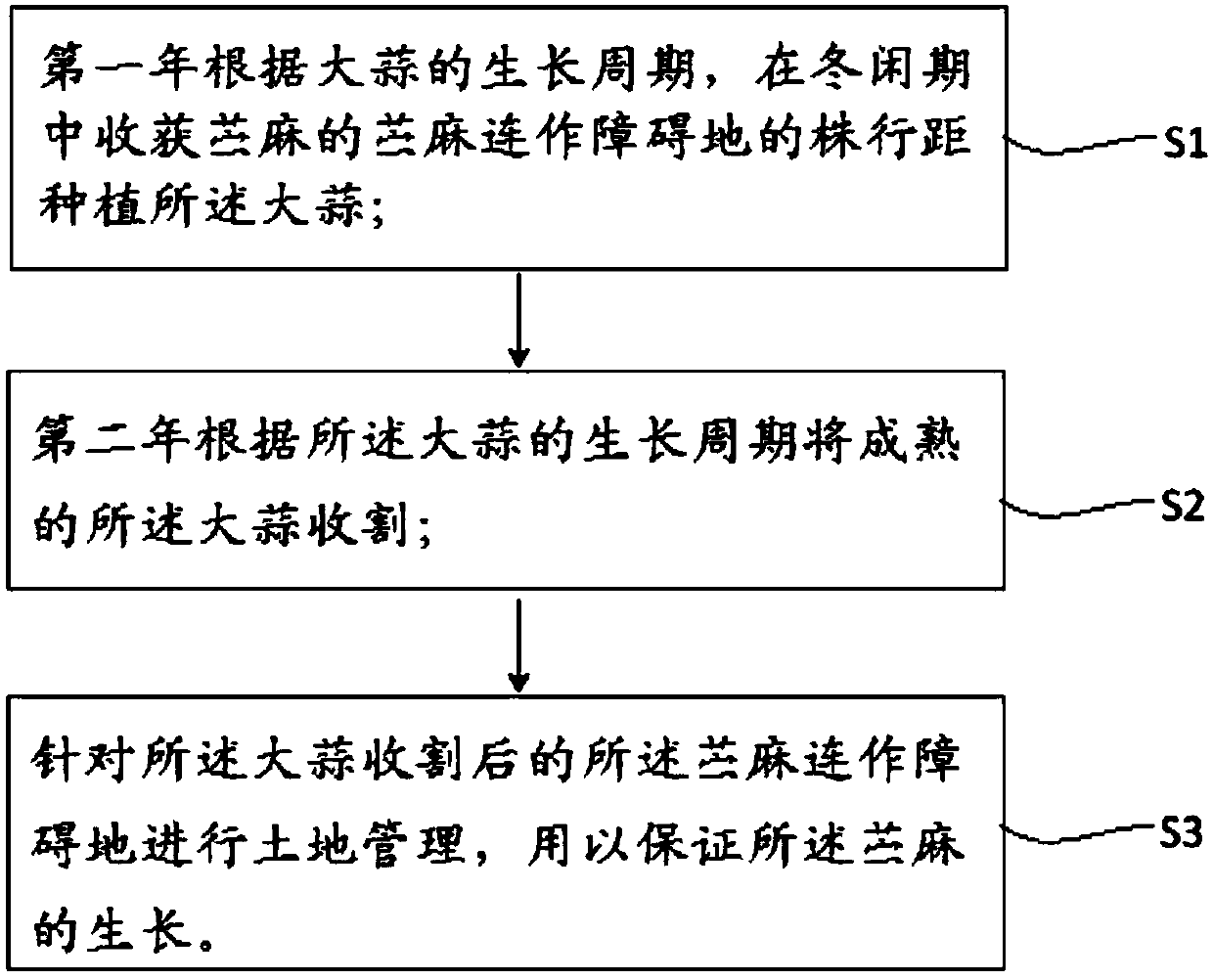

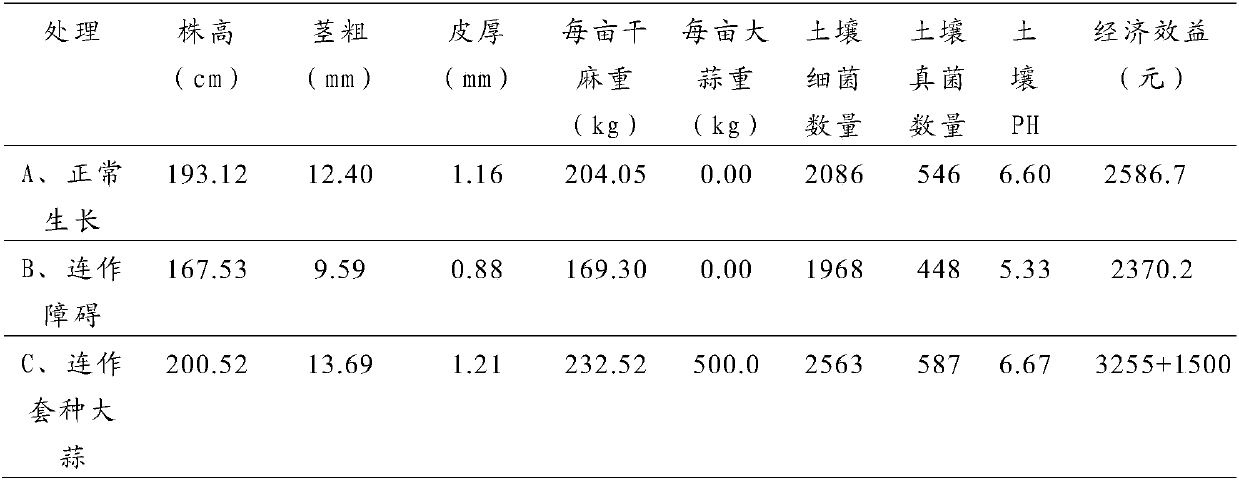

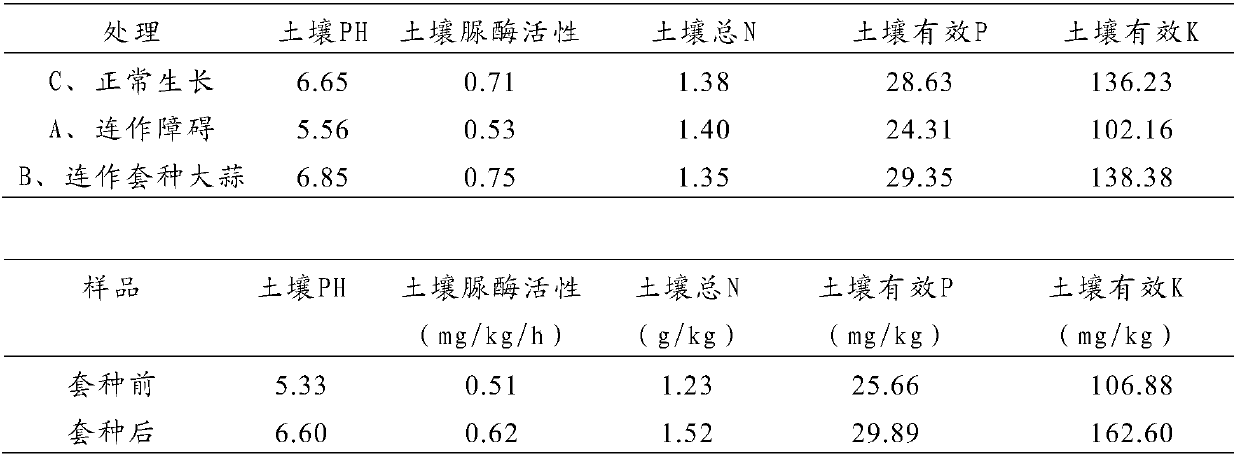

Planting method for relieving ramie successive cropping obstacles

InactiveCN109566319AAlleviate continuous cropping obstaclesRestore productionBulb cultivationCultivating equipmentsEconomic benefitsCommunity structure

The invention discloses a planting method for relieving ramie successive cropping obstacles. The method includes the steps of harvesting garlic planted in row spacings in a ramie successive cropping obstacle land of ramie in the winter idle period in the first year according to the growth cycle of the garlic, harvesting mature garlic in the second year according to the growth cycle of the garlic,and conducting land management for the garlic-harvested ramie successive cropping obstacle land for ensuring the growth of the ramie. According to the planting method, through the promoting allelopathy of the garlic for the ramie, the soil structure and the microbial community structure are improved, the successive cropping obstacle of the ramie is relieved, the yield of the ramie is recovered, meanwhile the yield of the garlic is increased, and higher economic benefits are realized.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com