Patents

Literature

39results about How to "Improve the effective permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

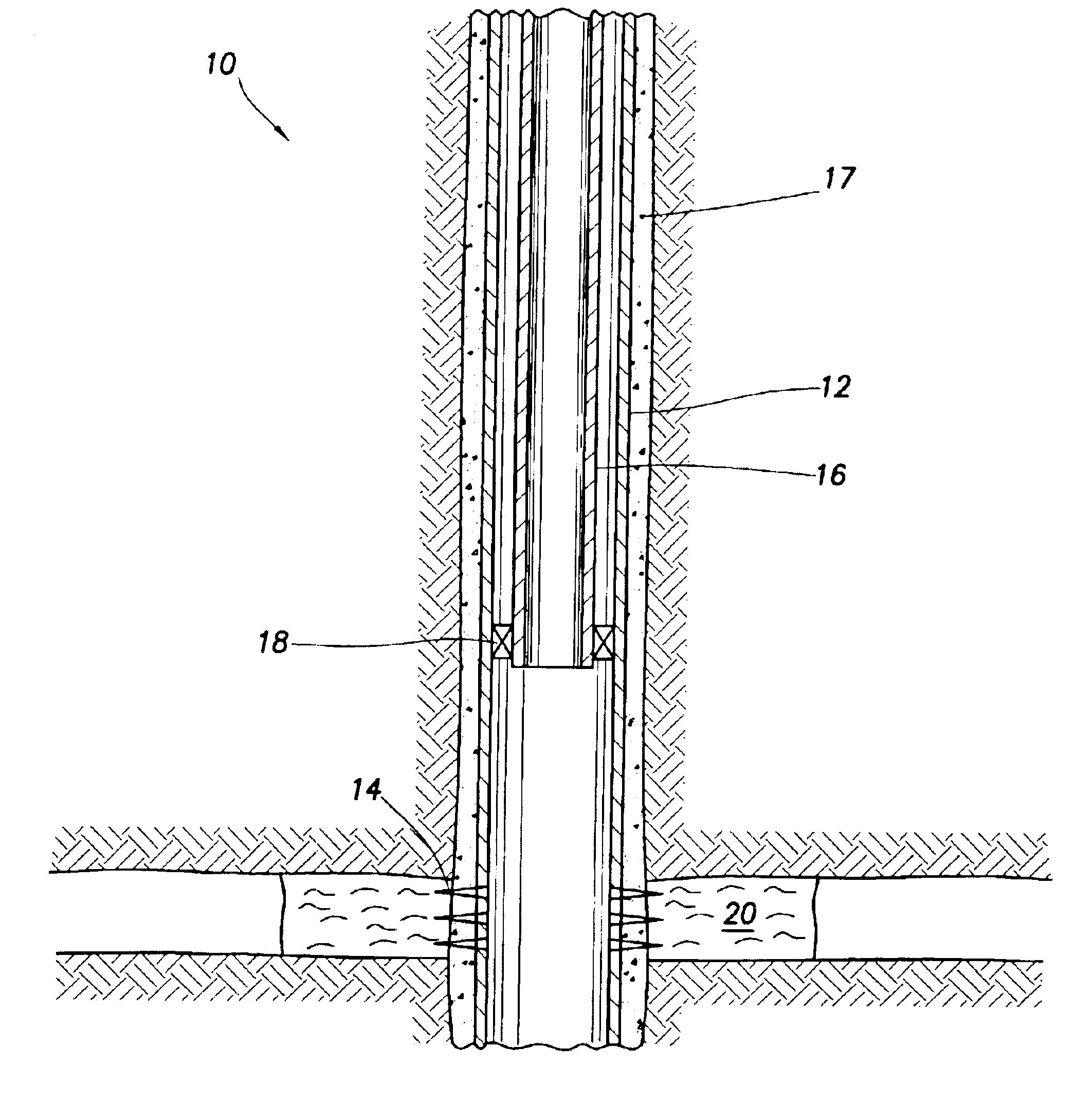

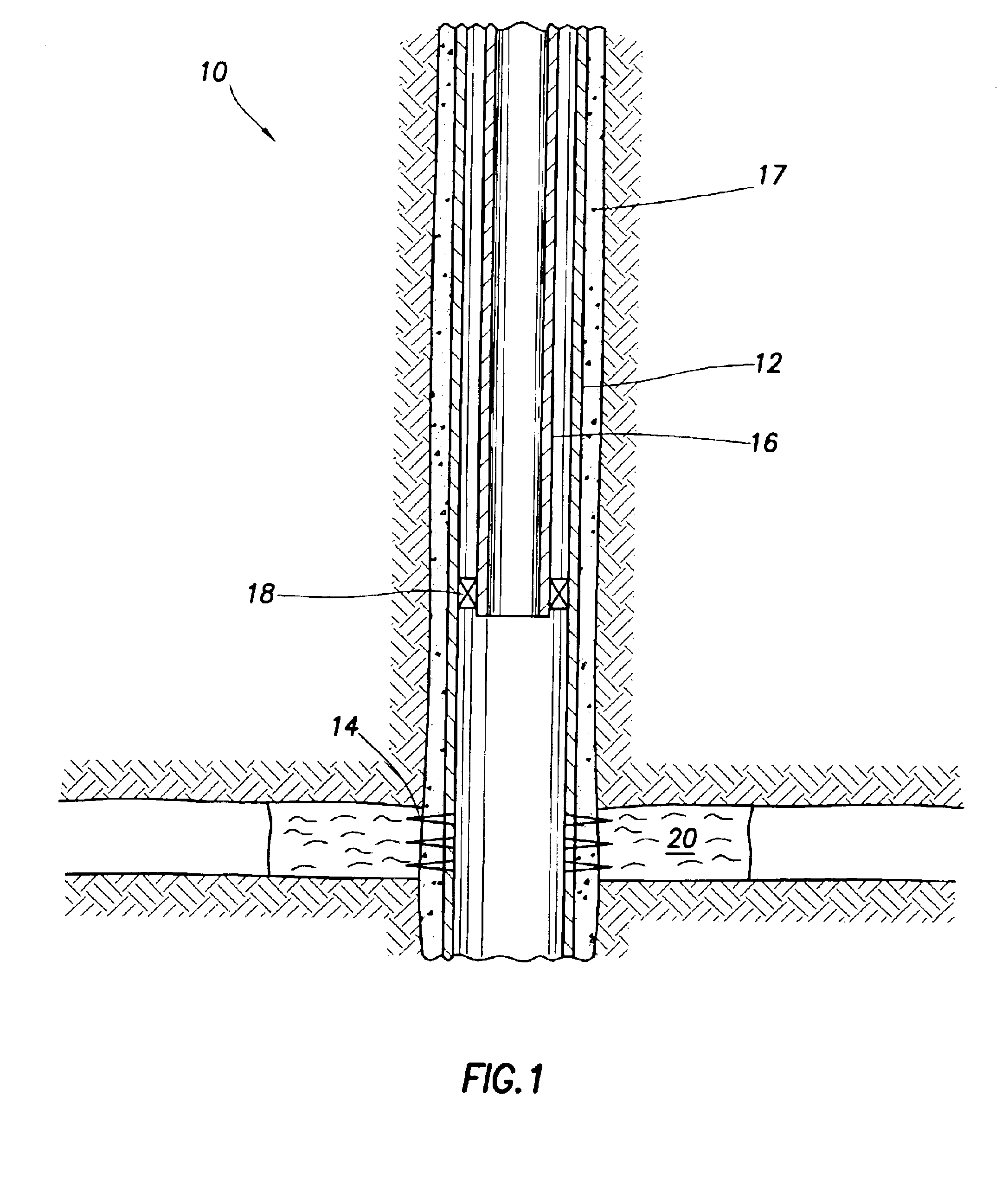

Method for reducing permeability restriction near wellbore

InactiveUS6945327B2Improve breathabilityEfficient removalSurveyFluid removalRetrograde condensationHydraulic fracturing

Method is provided for increasing the productivity of gas wells producing from reservoirs where retrograde condensation occurs around the wells. An oil-wetting surfactant is injected in a solvent to oil wet the formation for a selected distance around a well or a hydraulic fracture intersecting the well. A pre-flush liquid, such as carbon dioxide, alcohol or similar products and mixtures thereof, may be used to reduce water saturation before injection of the surfactant. The method may also be applied to increase the productivity of oil wells producing from reservoirs where breakout of solution gas occurs near the well.

Owner:ELY & ASSOCS

Amorphous alloy powder core and nano-crystal alloy powder core having good high frequency properties and methods of manufacturing the same

InactiveUS6827557B2High molding densityLow dependence on frequencyTransportation and packagingMetal-working apparatusOrganic solventShell molding

A method of manufacturing an amorphous alloy core including the steps of mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in liquid phase on the surface of the alloy powder to make a powder of composite particles, molding the power of composite particles, and performing a heating treatment thereon. This invention also discloses a method of manufacturing a nano-crystal alloy core including the steps of (a) mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in the liquid phase on the surface of the alloy powder to make composite particles, molding the composite particles at room temperature, and performing a heating treatment thereon at a temperature higher than the crystallization starting temperature of the alloy; and (b) performing a heating treatment on an amorphous alloy powder at over a crystallization starting temperature to make a nano-crystal phase, mixing a solution made by solving a polyimide / phenolic resin binder in an organic solvent therewith, evenly coating the binder in liquid phase on the surface of the alloy powder to make composite particles, and molding the power of composite particles at 100 to 300° C.

Owner:KIM KYU JIN +3

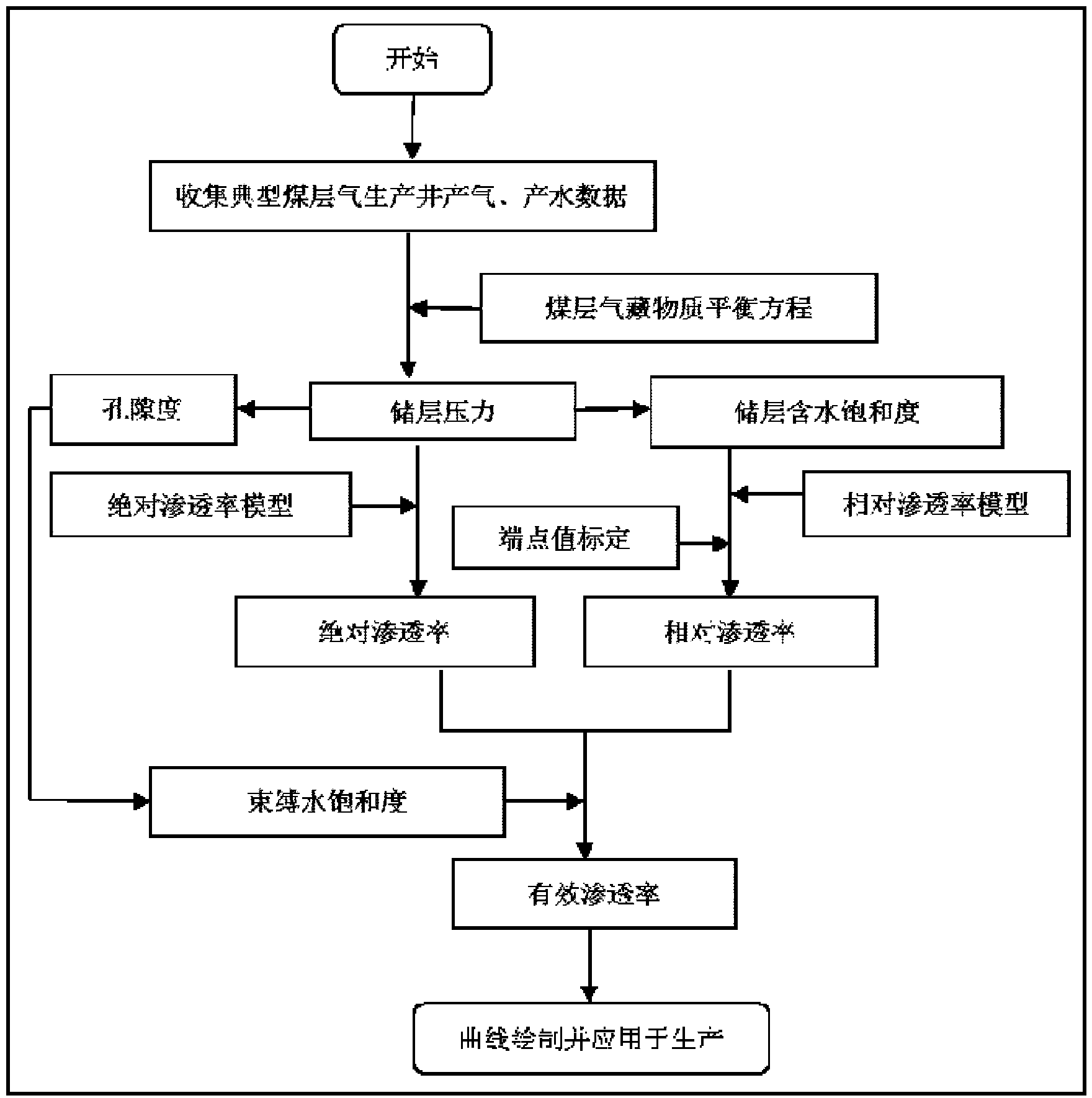

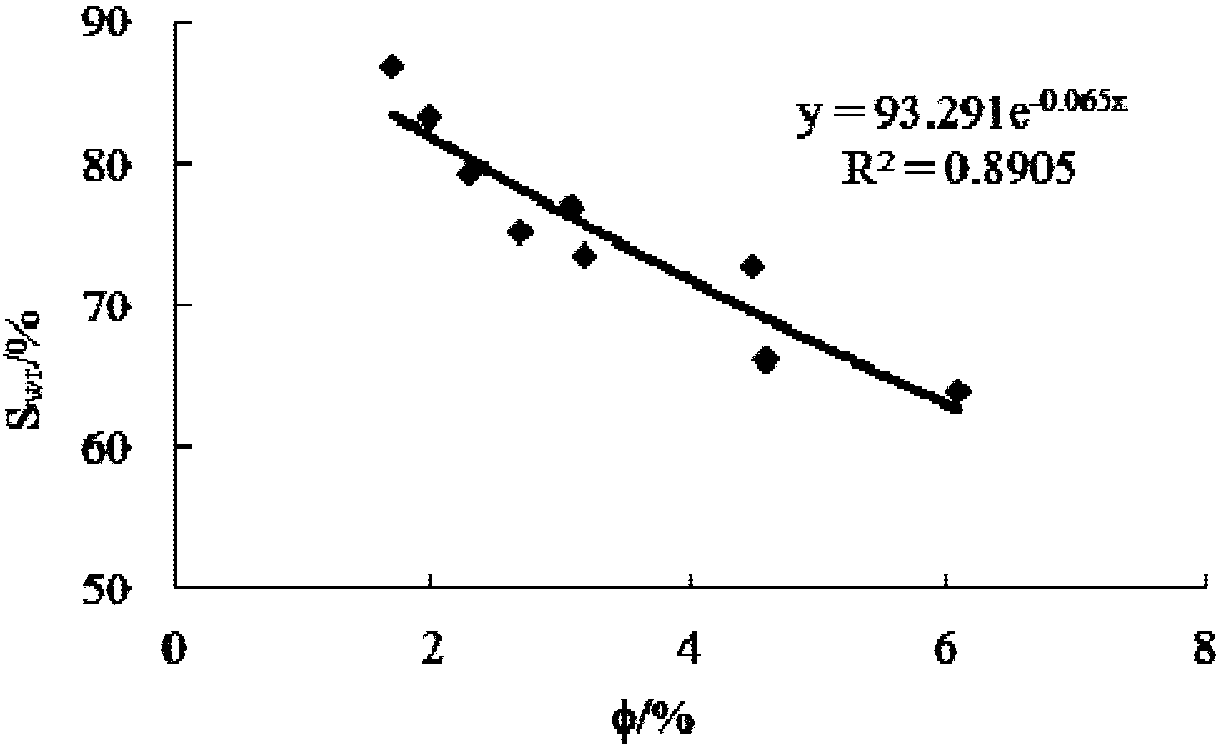

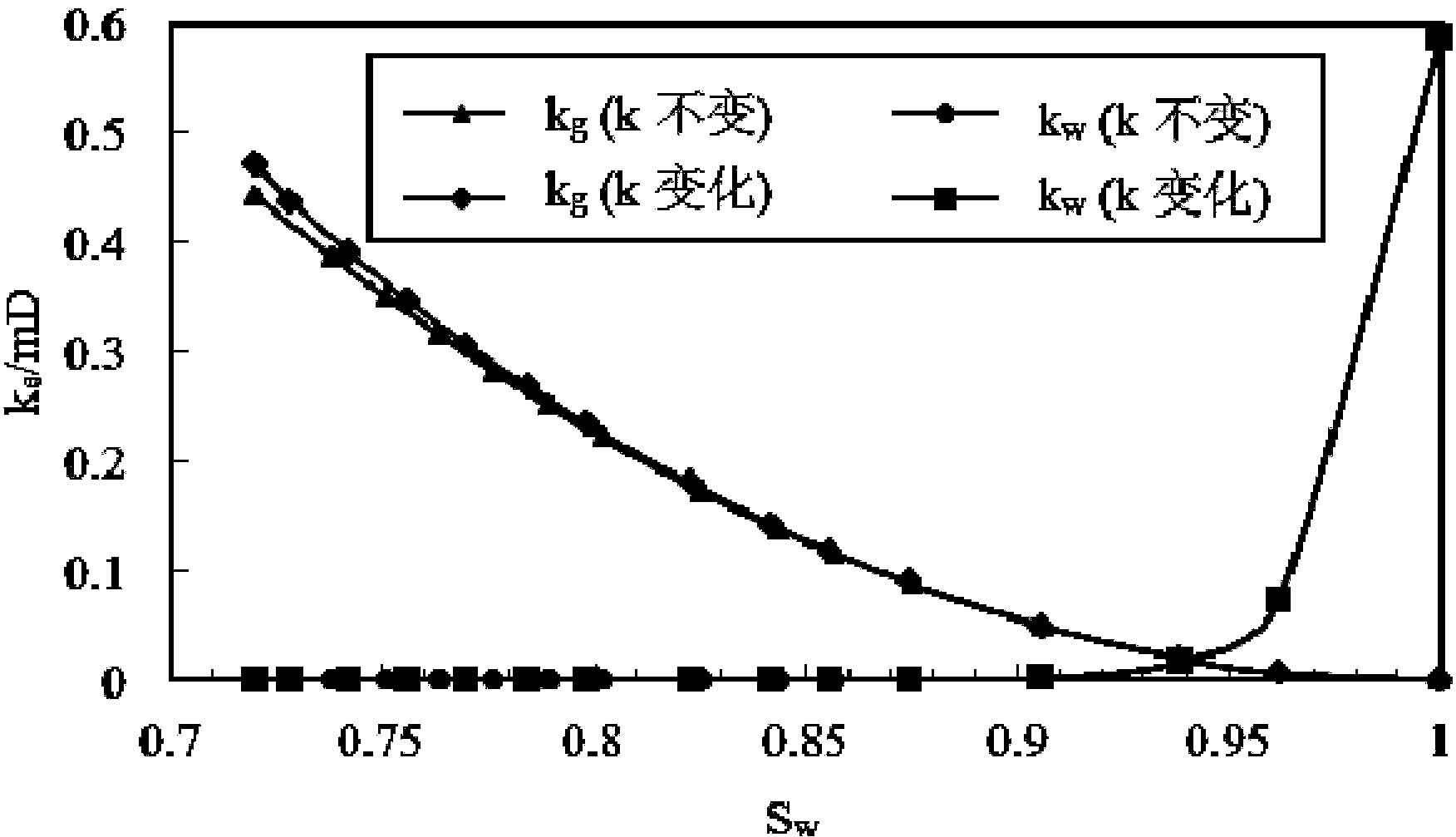

Method for measuring gas and water relative permeability curve through coal-bed gas well production data

InactiveCN104018829AGood two-phase seepage characteristicsImprove accuracyBorehole/well accessoriesMaterial balanceGas phase

The invention discloses a method for measuring a gas and water relative permeability curve through coal-bed gas well production data. Average reservoir pressure and average water saturation are obtained with a material balance method, and therefore changes between absolute permeability and relative permeability can be obtained; changes of irreducible water saturation are predicted through the relation between irreducible water saturation and porosity; the absolute permeability and the relative permeability generated after end points are calibrated are coupled in the same state, a domain average effective permeability dynamic prediction model can be obtained, and an effective permeability curve can be obtained. The method solves the problem that in a laboratory, the relative permeability curve can not be accurately measured easily. Compared with the prior art, the positive and negative effect of a coal reservoir can be well reflected, the gas phase effective permeability can be effectively improved, and a powerful basis is provided for accurately predicting a gas and water output law of a coal-bed gas well and predicting future yield of a producing well.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method of Treating the Near-Wellbore Zone of the Reservoir

ActiveUS20120305255A1High Effective PermeabilityIncrease productivityFluid removalDrilling compositionParaffin waxPorosity

The invention describes a method for treating near-wellbore zones involving the steps of injecting a magnesium metal with a catalyst into the desired area of the formation to be treated. Subsequently, combustive-oxidizing solution (COS) is injected into the zone of the formation to be treated. The COS initially reacts with the magnesium, which in turn initiates a vigorous oxidation reaction of the COS. The reaction gases and heat produced by the COS oxidation reaction are harnessed to enhance the productivity of the well by creating fractures in the treatment zone and by melting of paraffin and resin deposits in the treatment zone. As a final step, acid is injected into the formation to react with the formation thereby further enhancing the porosity of the fractures. In one embodiment, the COS uses ammonium nitrate as the oxidizer, and in another, urea or ethylene glycol may be added as a reaction fuel.

Owner:RIVERBEND

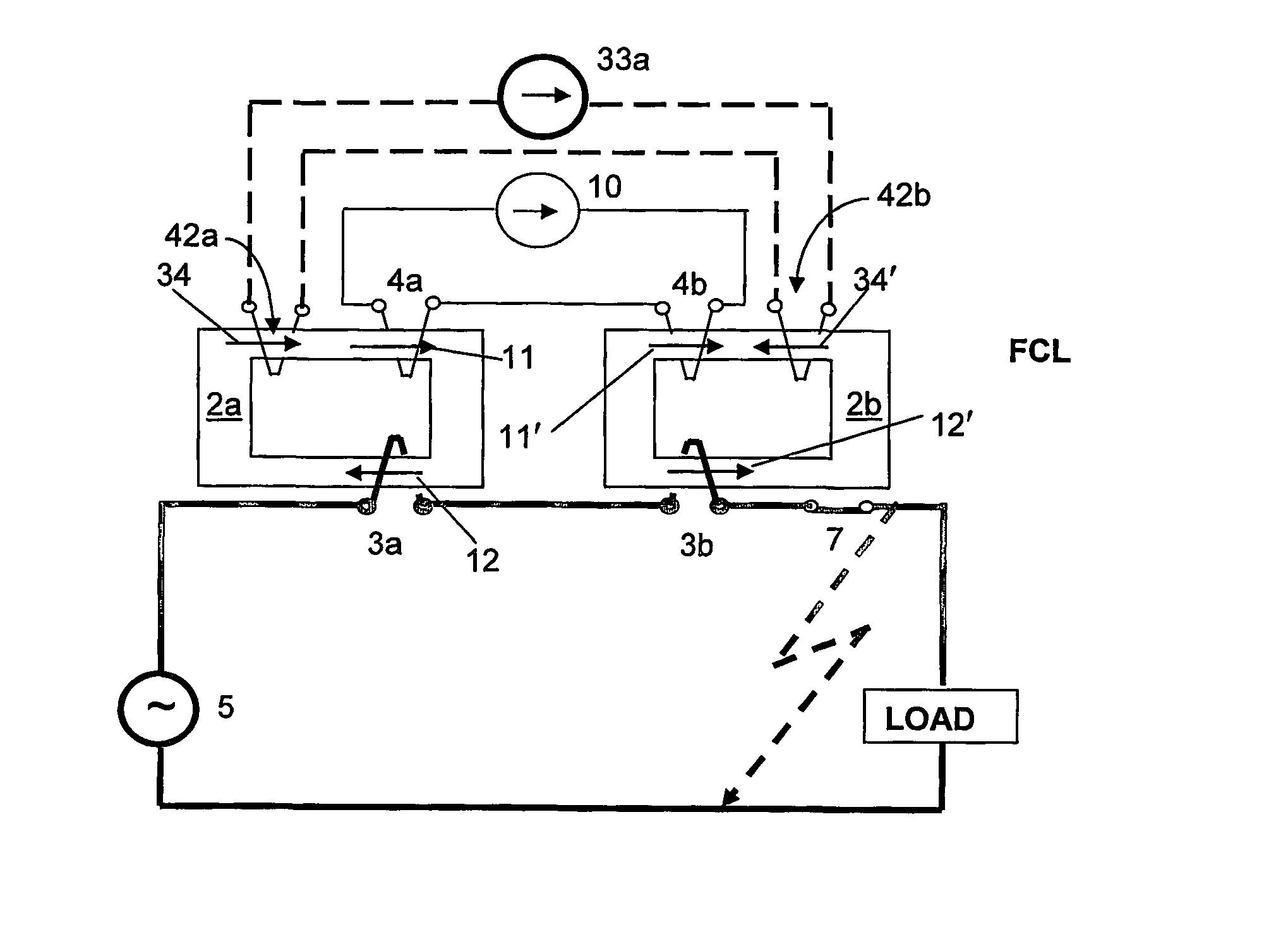

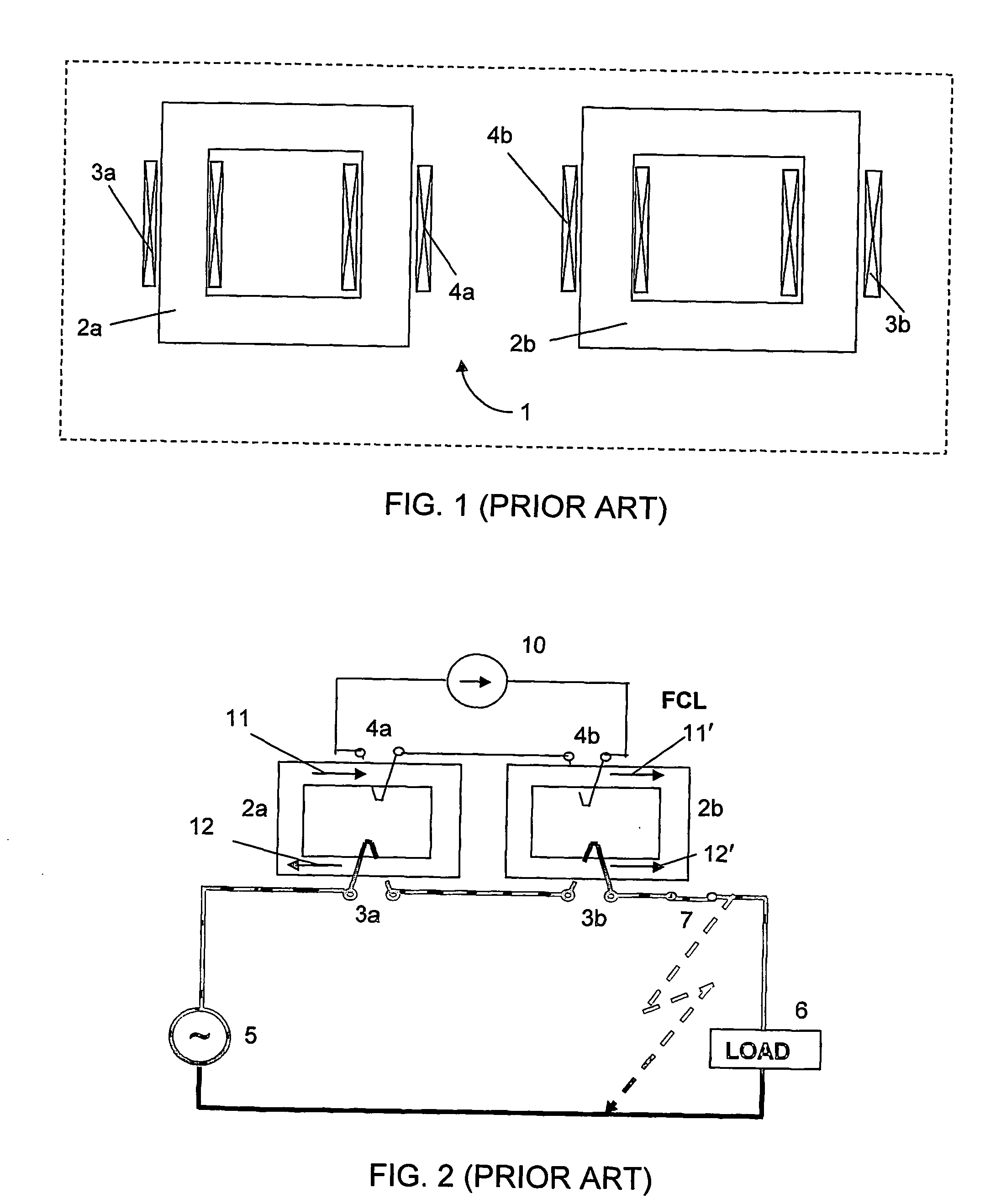

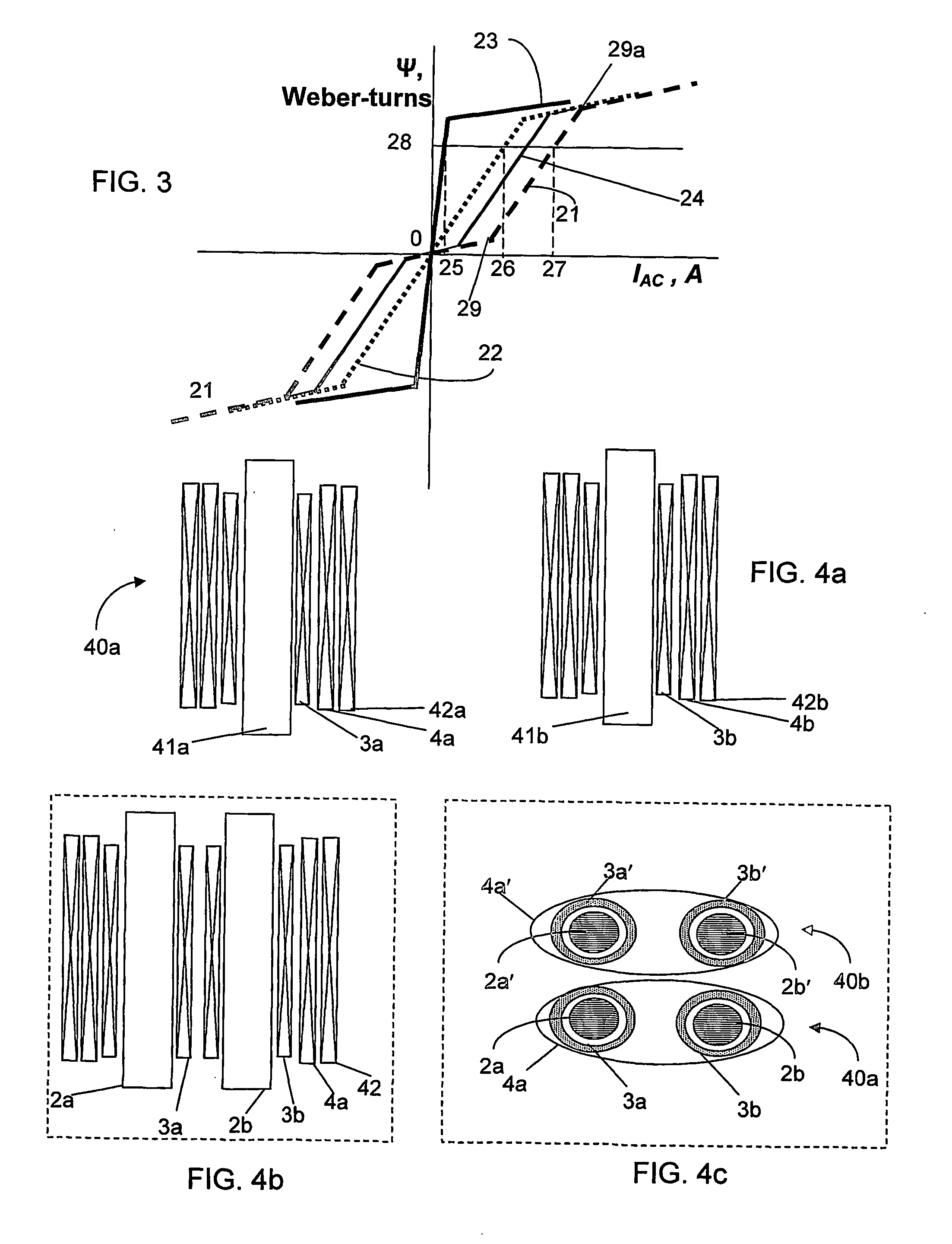

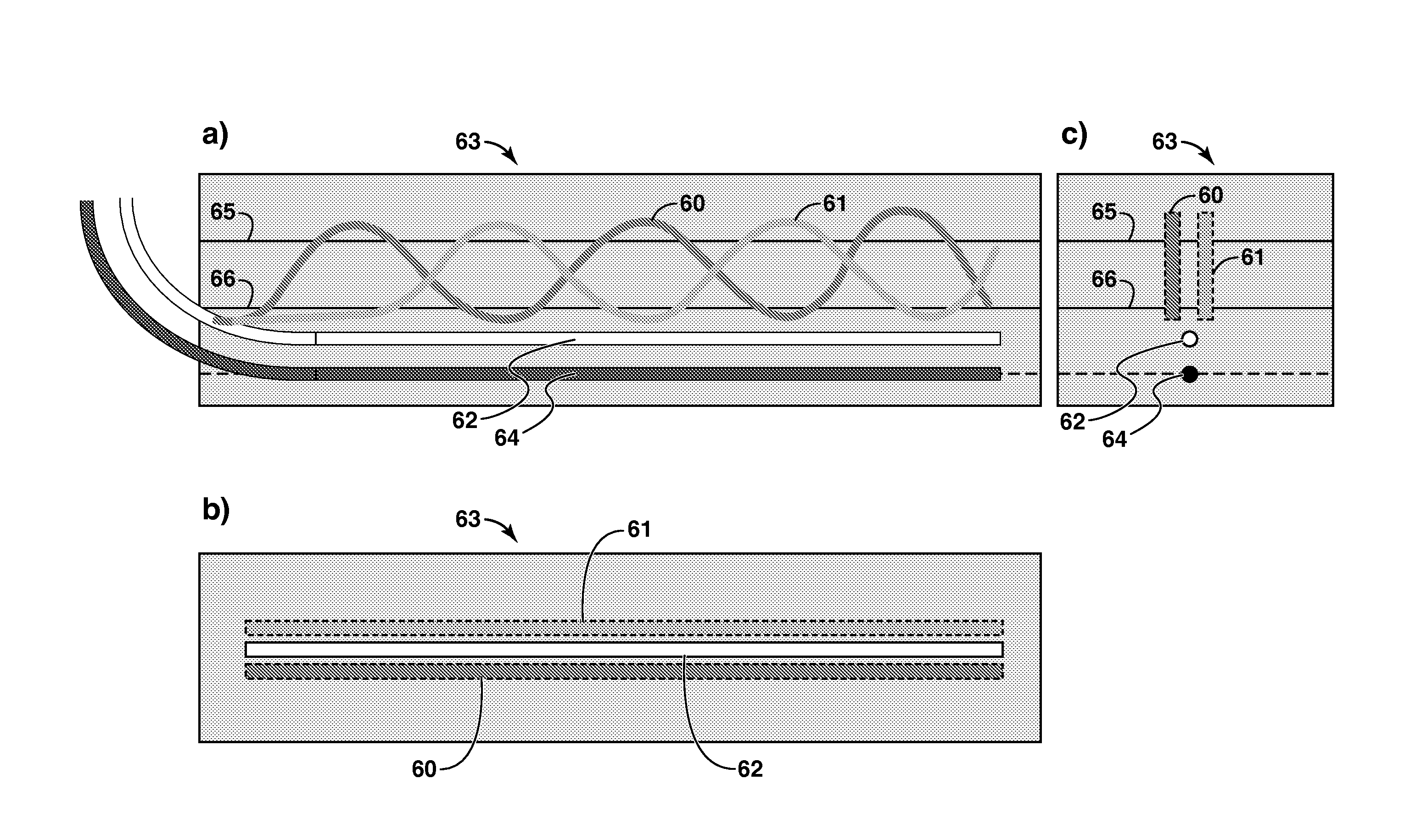

Fault current limiters (fcl) with the cores staurated by superconducting coils

InactiveUS20060158803A1Reduce weightDecrease dimensionEmergency protective arrangements for limiting excess voltage/currentSuperconductor elements usageAlternating currentHigh pressure

A superconducting short circuit current limiter (40a) for an alternating current system includes AC reactors having superconducting direct current bias windings (4a, 4b) that at normal conditions maintain the reactor's cores in saturated state. There are at least two AC coils (3a, 3b) for each phase operating at opposite half periods or at both half periods. The reactor may also have an additional feedback coil (42a, 42b) that at least partly compensates for the bias field of the superconducting coil at fault conditions enhancing a limiting capacity of the reactor. The reactor's core can be configured for decreasing its dimensions and mass as compared with known devices and for decreasing core losses. High voltage / high current devices include several standard modules connected in series or / and in parallel. A positional relationship of the modules is defined for decreasing necessary numbers of Amp?re-turns of superconducting and non-superconducting coils.

Owner:BAR ILAN UNIV

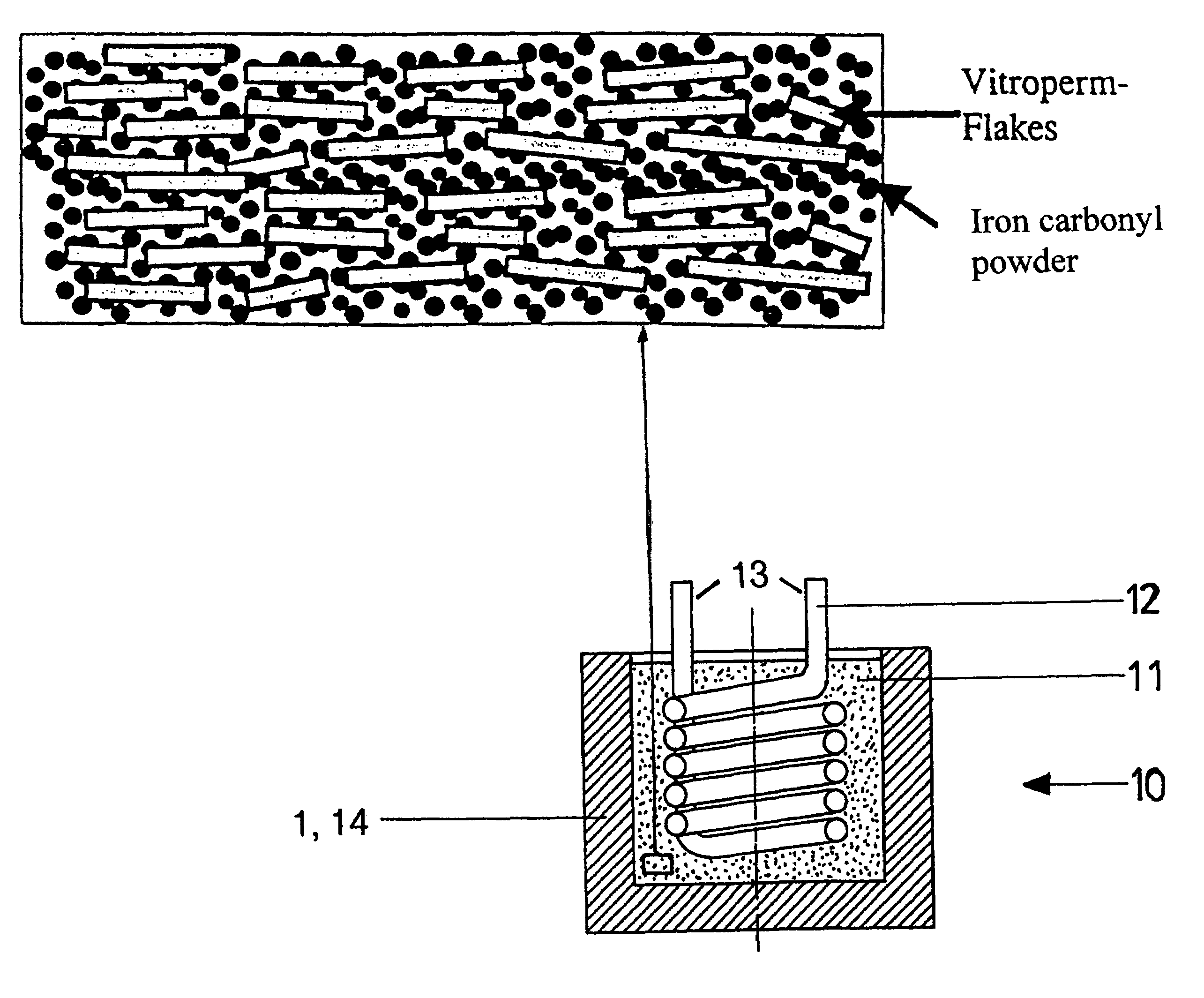

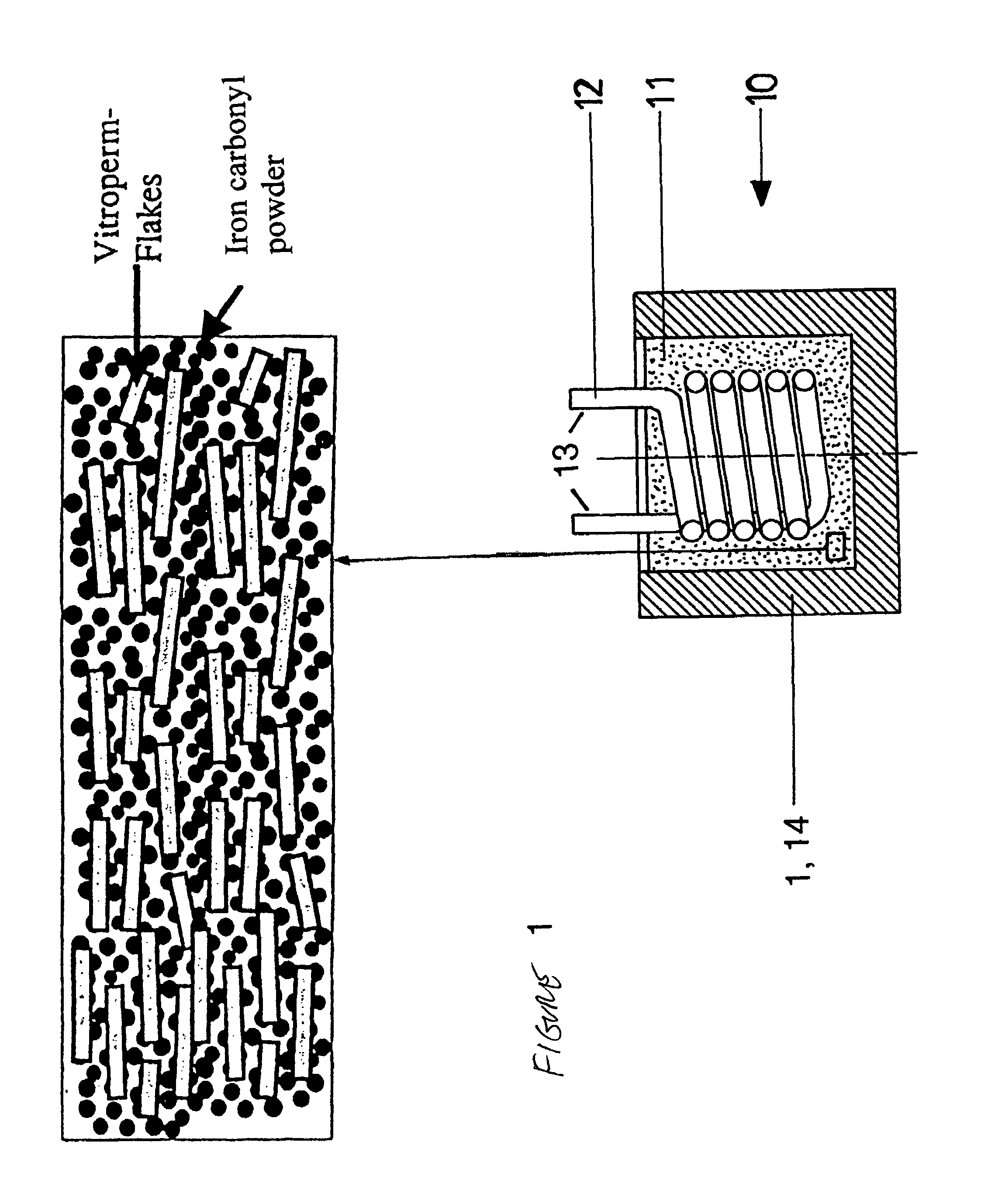

Inductive component and method for producing the same

InactiveUS7532099B2Higher ferromagnetic packing densityIncrease field strengthTransformers/inductances casingsInorganic material magnetismInductorInductance

The invention relates to an inductive component (10) whose soft-magnetic core (11) consists of a powder composite. Said powder composite is produced by mixing a ferromagnetic amorphous or nanocrystalline alloy powder with a ferromagnetic dielectric powder and a thermoplastic or duroplastic polymer. Unlike conventional injection-molded or cast soft-magnetic cores, cores from a composite comprising a dielectric ferromagnetic powder allow for packing densities of substantially more than 55% by volume.

Owner:VACUUMSCHMELZE GMBH & CO KG

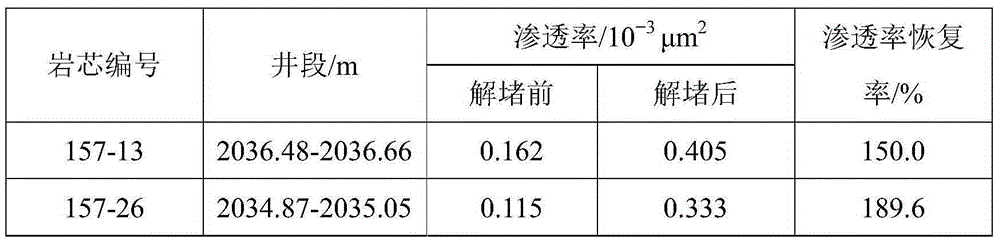

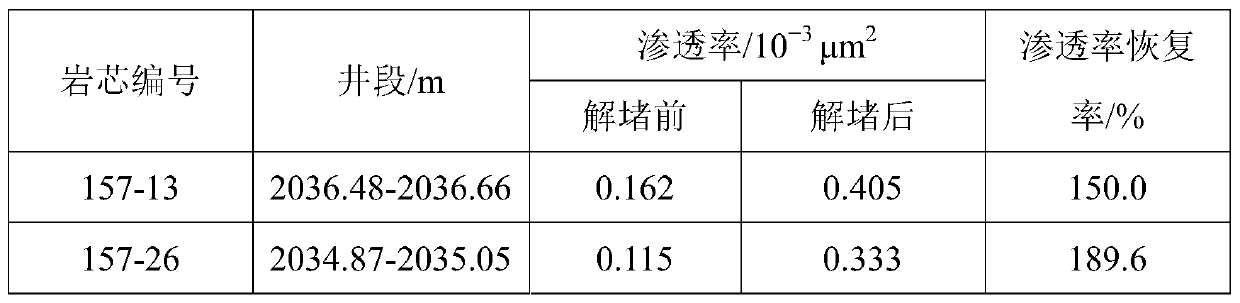

Slow blockage removing agent for oil well and blockage removing method

ActiveCN105255466AUnblock pollutionFree from secondary injuryDrilling compositionClay mineralsFluoboric acid

The invention discloses a slow blockage removing agent for an oil well and a blockage removing method, and belongs to the technical field of oil field exploitation. The slow blockage removing agent is prepared from prepad fluid, main fluid and post-pad fluid, the prepad fluid and the post-pad fluid both take hydrochloric acid as the main component of acid fluid for removing inorganic scale precipitation and dissolving reaction residues, and the main fluid takes glacial acetic acid and fluoboric acid as the main components of acid fluid for stabilizing clay mineral of a reservoir stratum, decreasomg the acid rock reaction speed, enlarging the blockage removing radius and increasing the blockage removing depth. For a fracturing production horizontal well, the treatment fluid is injected into the reservoir stratum in the former stage, the intermediate stage and the later stage, and liquid nitrogen is simultaneously injected, so that residual reaction fluid can be quickly drained after blockage removing construction is performed; pollution blockage near a well bore of the oil well can be effectively removed, the effective permeability near the well bore is increased, the individual-well producing rate is increased, damage caused by excessive acid corrosion to the rock framework of the reservoir stratum can be avoided, and therefore the reservoir stratum can be prevented from being subjected to secondary damage.

Owner:CHINA PETROLEUM & CHEM CORP +1

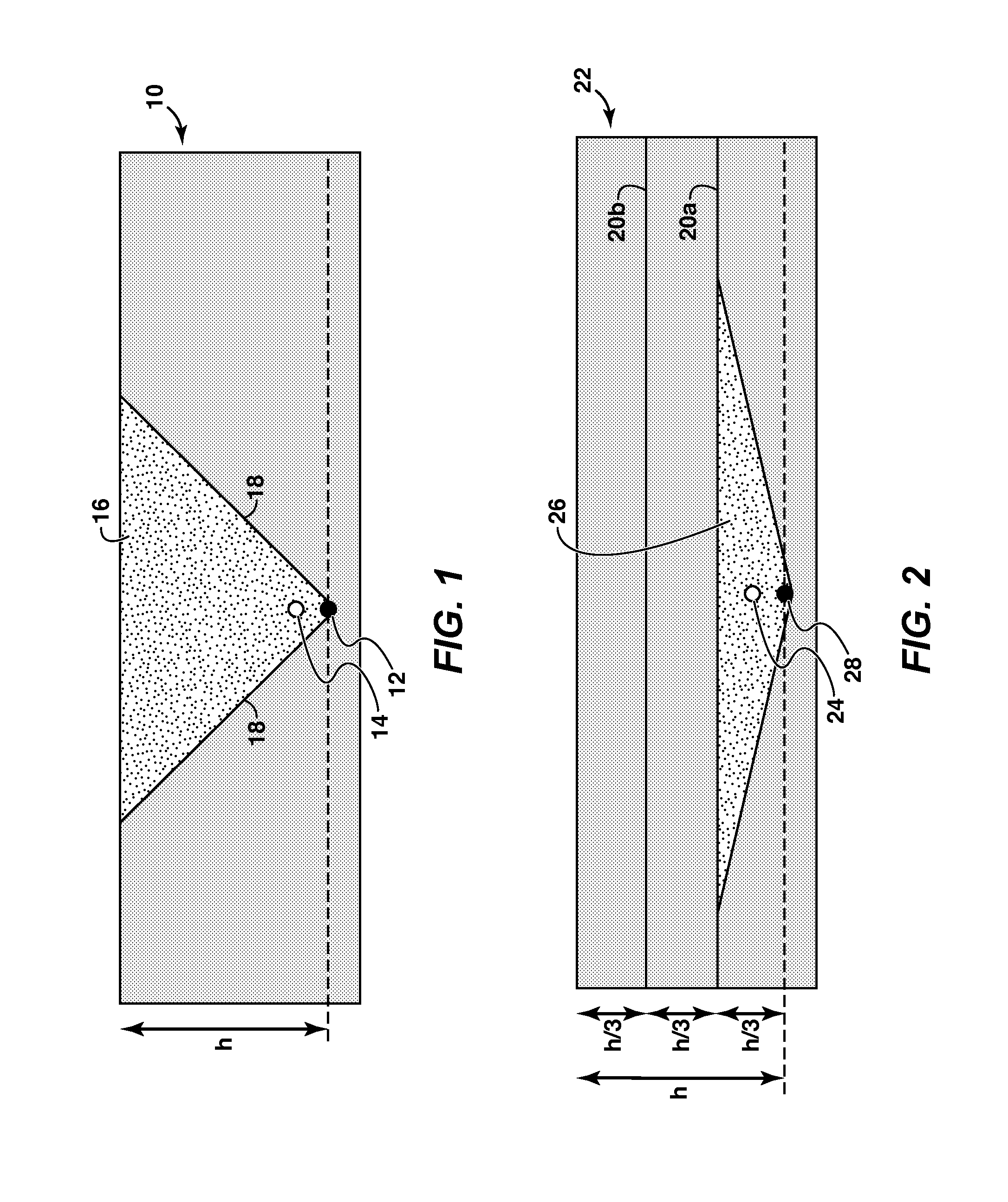

Method and System For Enhancing A Recovery Process Employing One or More Horizontal Wellbores

InactiveUS20110272153A1Improve breathabilityIncrease heightFluid removalEngineeringRecovery procedure

The present invention relates generally to a system and method for enhancing a recovery process employing one or more substantially horizontal wellbores. More particularly, the present invention relates to a method and system for enhancing a recovery process employing one or more horizontal wellbores by providing a zone of increased permeability in a hydrocarbon reservoir to facilitate vertical movement of flowable materials through the reservoir to thereby enhance the recovery process. In some embodiments, the reservoir comprises one or more vertical permeability impediments.

Owner:EXXONMOBIL UPSTREAM RES CO

Alcohol-base fracturing fluid

An alcohol-based fracturing liquid for oil or gal well is prepared from low-carbon alcohol and its thickening agent, water, cross-linking agent, degelating agent, pH regulator and surfactant. It can remove the water locking in stratum, so benefiting the return of liquid from stratum.

Owner:CHANGQING GASOLINEEUM EXPLORATION BUREAU

Amorphous alloy powder core and nano-crystal alloy powder core having good high frequency properties and methods of manufacturing the same

InactiveUS20020124914A1High molding densityLow dependence on frequencyTransportation and packagingMetal-working apparatusOrganic solventRoom temperature

A method of manufacturing an amorphous alloy core including the steps of mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in liquid phase on the surface of the alloy powder to make a powder of composite particles, molding the power of composite particles, and performing a heating treatment thereon. This invention also discloses a method of manufacturing a nano-crystal alloy core including the steps of (a) mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in the liquid phase on the surface of the alloy powder to make composite particles, molding the composite particles at room temperature, and performing a heating treatment thereon at a temperature higher than the crystallization starting temperature of the alloy; and (b) performing a heating treatment on an amorphous alloy powder at over a crystallization starting temperature to make a nano-crystal phase, mixing a solution made by solving a polyimide / phenolic resin binder in an organic solvent therewith, evenly coating the binder in liquid phase on the surface of the alloy powder to make composite particles, and molding the power of composite particles at 100 to 300° C.

Owner:KIM KYU JIN +3

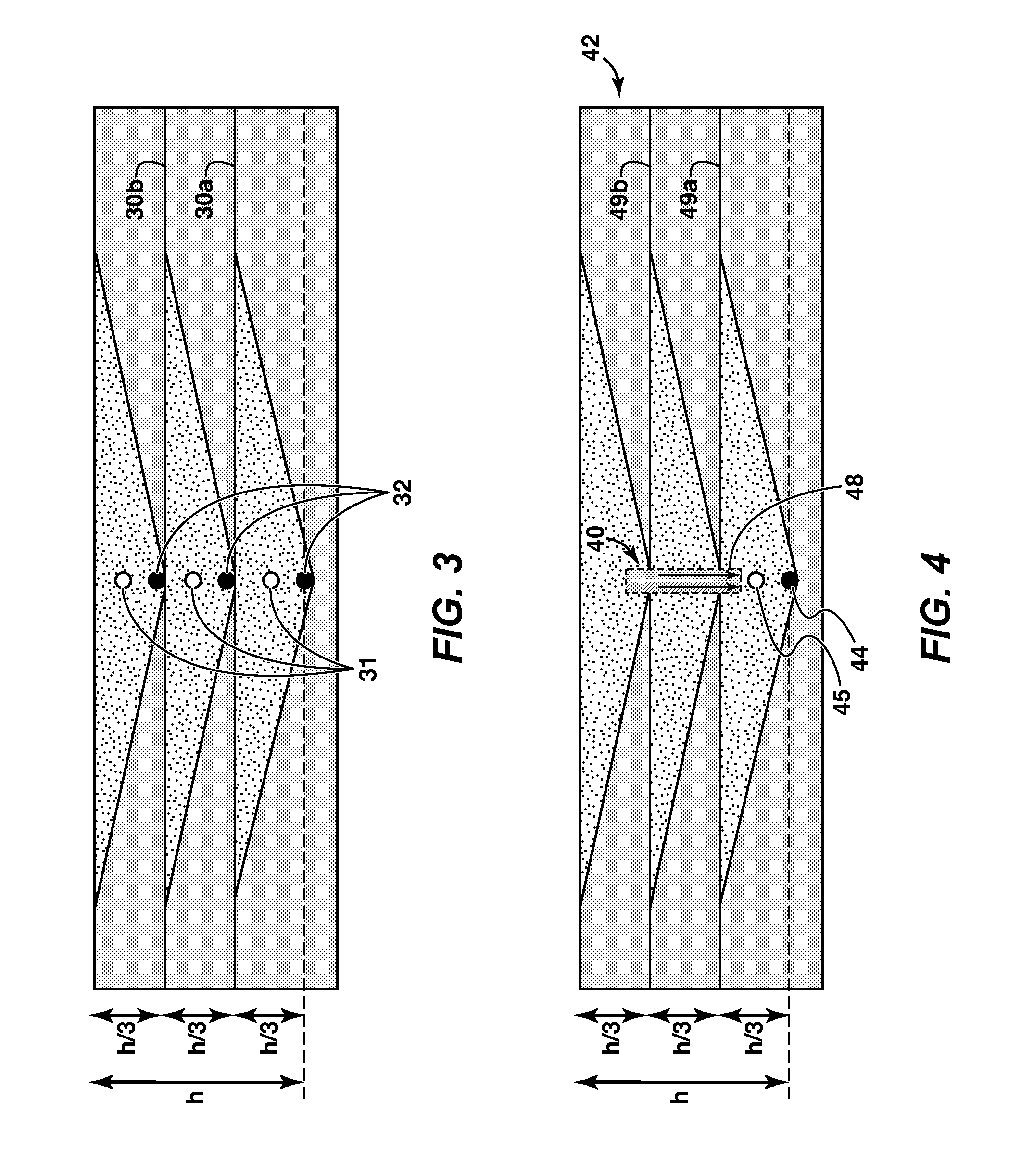

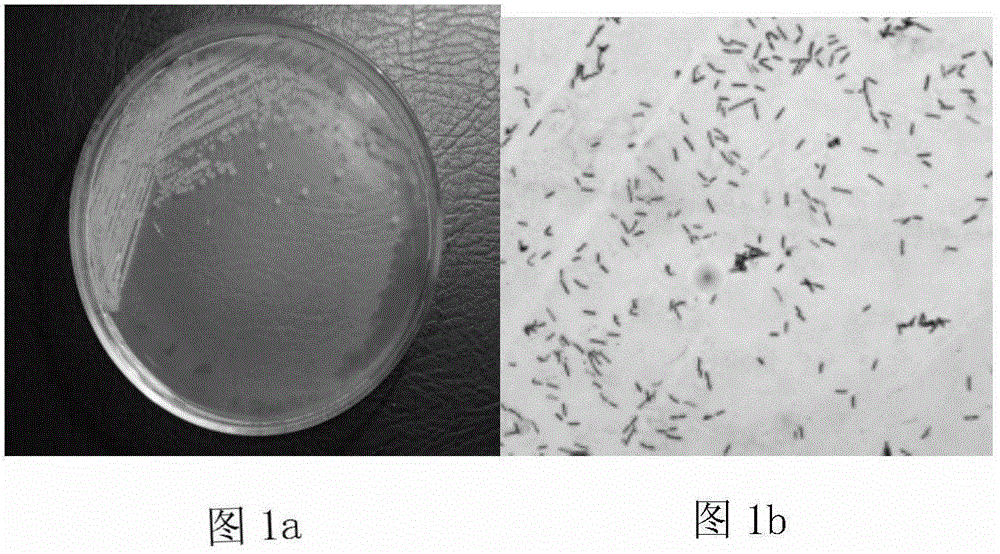

Pseudomonas aeruginosa and its application

ActiveCN104371940AStrong oil displacement performanceReduce interfacial tensionBacteriaMicroorganism based processesMicrobial oilMetabolite

The invention relates to a Pseudomonas aeruginosa and its application. The microbial preservation number of Pseudomonas aeruginosa QHH S1-27-2 is CCTCC NO:M2012468. The Pseudomonas aeruginosa is applied to high salinity reservoir microbial oil recovery. The Pseudomonas aeruginosa can growth with crude oil as a sole carbon source, and a biological surfactant component in the metabolites of the Pseudomonas aeruginosa can reduce oil-water interfacial tension, so the effective permeability of reservoirs is increased to a certain extent, the oil displacement efficiency of injected water is improved, and the crude oil recovery rate is improved.

Owner:PETROCHINA CO LTD

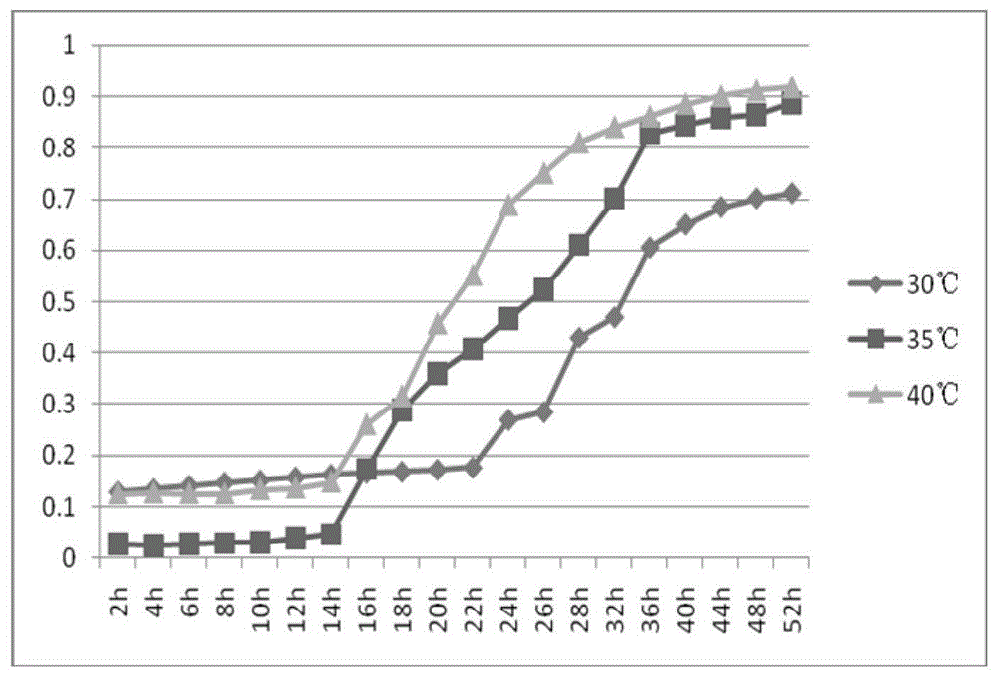

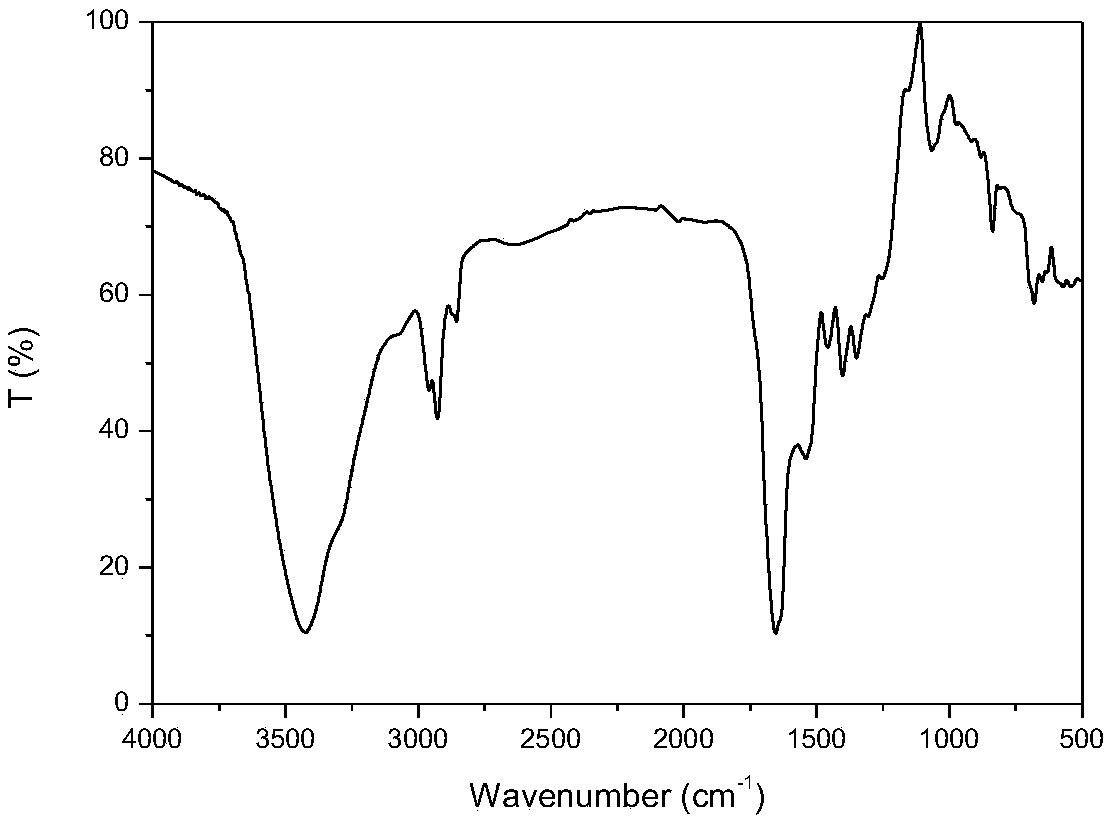

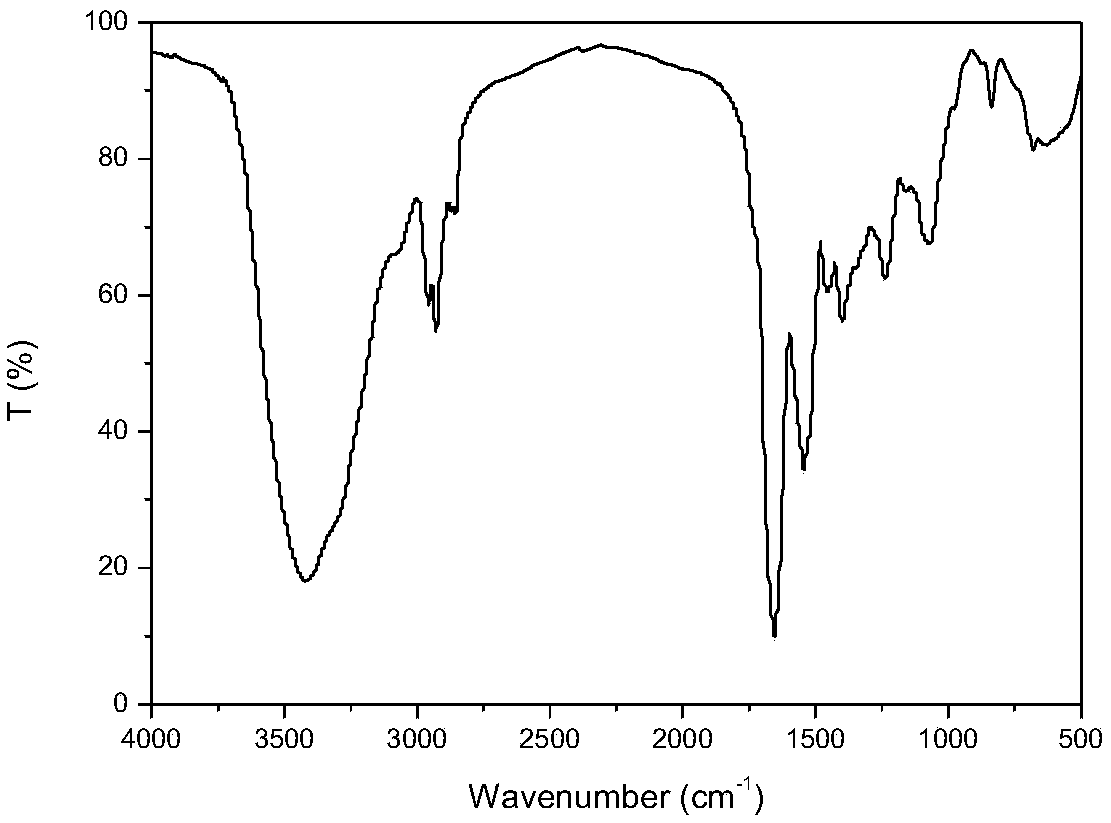

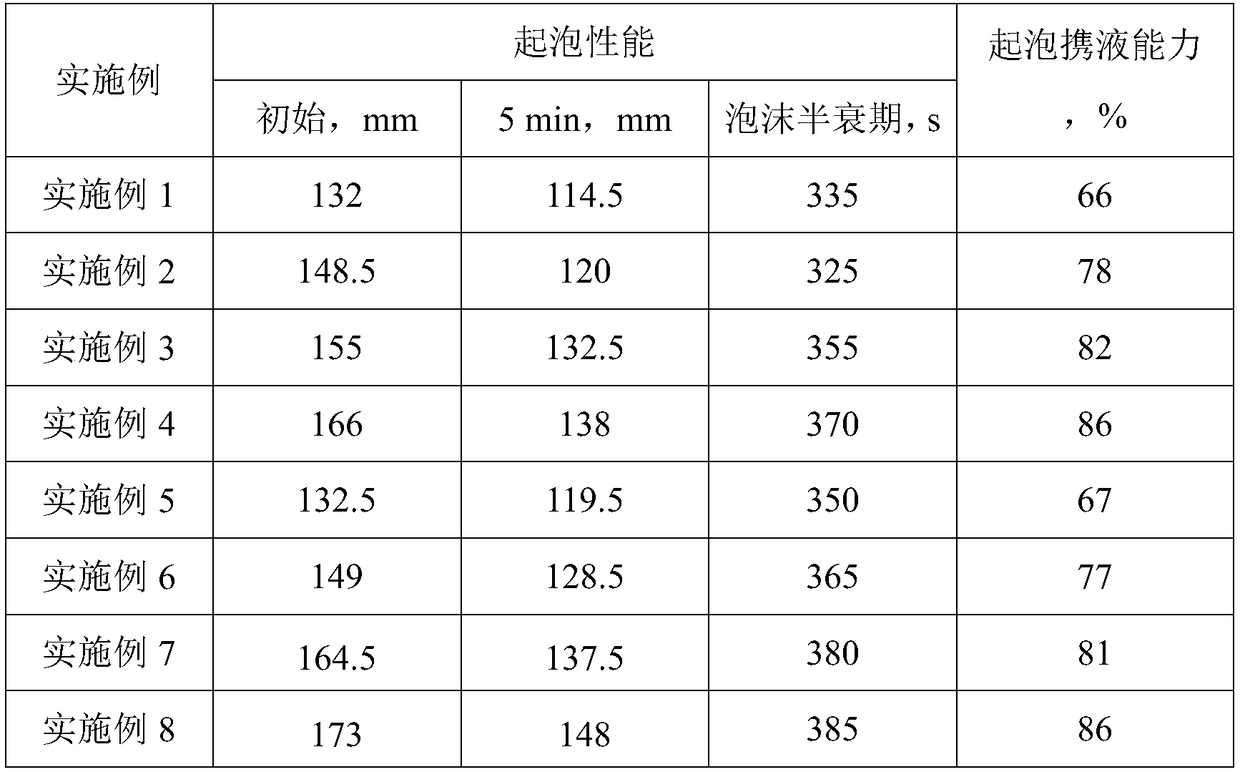

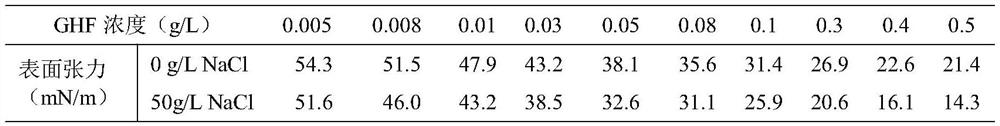

Salt-resistant and high-temperature-resistant foam discharge agent and method for preparing same

ActiveCN108373912APromote environmental protectionReduce contentDrilling compositionSURFACTANT BLENDLipopeptide

The invention relates to a salt-resistant and high-temperature-resistant foam discharge agent and a method for preparing the same, and belongs to the technical field of oil and gas field development.The salt-resistant and high-temperature-resistant foam discharge agent comprises, by weight, 0.2-0.5% of anionic-nonionic surfactant composite systems, 0.02-0.08% of microbial fermentation liquor andthe balance water. The microbial fermentation liquor is glycolipid producing biological surfactant or lipopeptide producing biological surfactant microbial strain fermentation liquor. The salt-resistant and high-temperature-resistant foam discharge agent and the method have the advantages that the salt-resistant and high-temperature-resistant foam discharge agent has salt-resistant and high-temperature-resistant foaming, foam stabilizing and liquid carrying ability and is excellent in condensate oil resistance and methanol tolerance, and accordingly the salt-resistant and high-temperature-resistant foam discharge agent and the method are favorable for environmental protection and sustainable development of oil and gas fields.

Owner:PETROLEUM ENG TECH RES INST CHINA PETROLEUM & CHEM CORP NORTH CHINA OIL & GAS CO +1

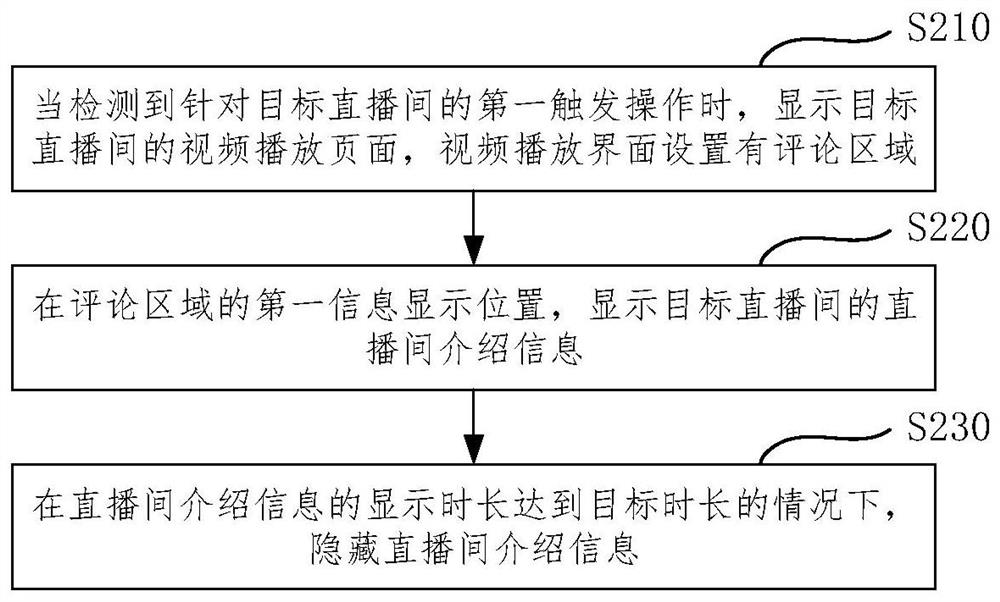

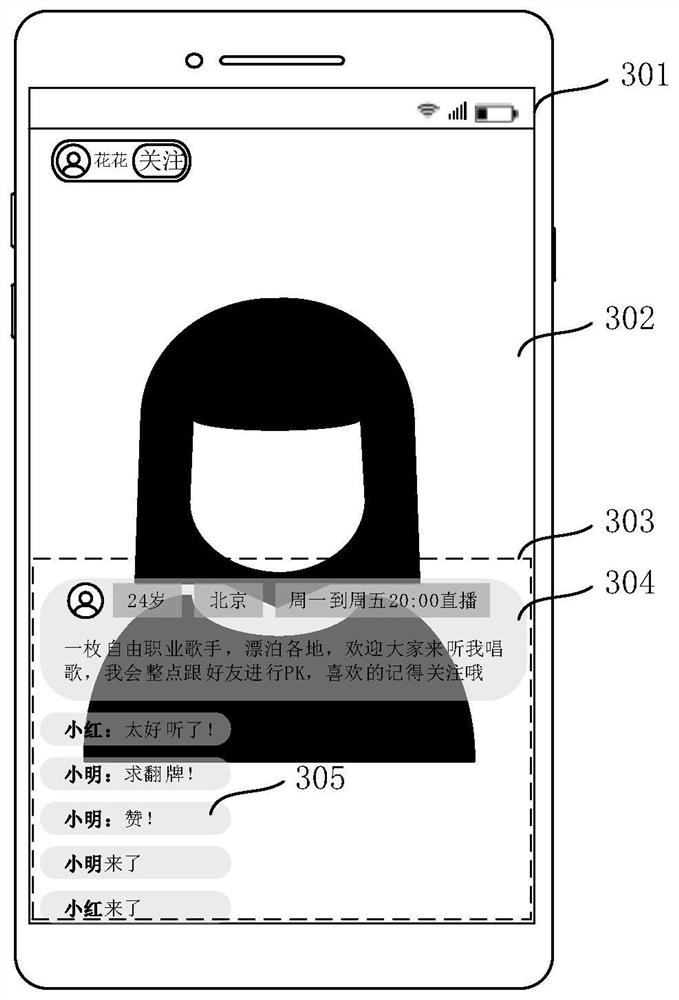

Information display method and device, equipment and medium

PendingCN112351300AImprove experienceImprove the effective permeabilitySelective content distributionEngineeringLive video

The invention relates to an information display method and device, equipment and a medium. The information display method comprises the steps that when a first trigger operation for a target live broadcast room is detected, displaying a video playing page of the target live broadcast room, wherein the video playing interface is provided with a comment area; displaying live broadcast room introduction information of the target live broadcast room at a first information display position of the comment area; and under the condition that the display duration of the live broadcast room introductioninformation reaches the target duration, hiding the live broadcast room introduction information. According to the embodiment of the invention, the effective permeability of the live video content ofthe live broadcast room can be improved, and the user experience is improved.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

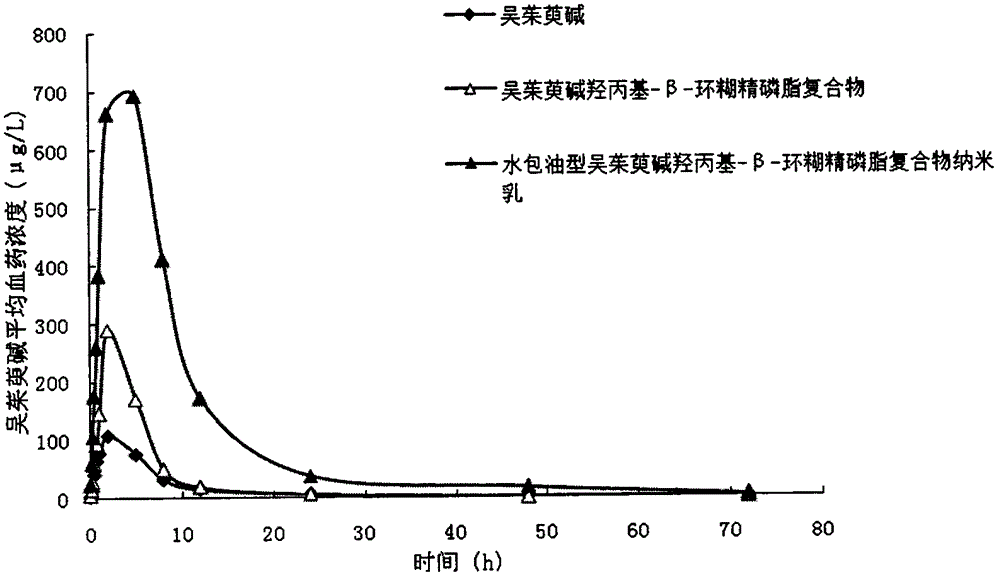

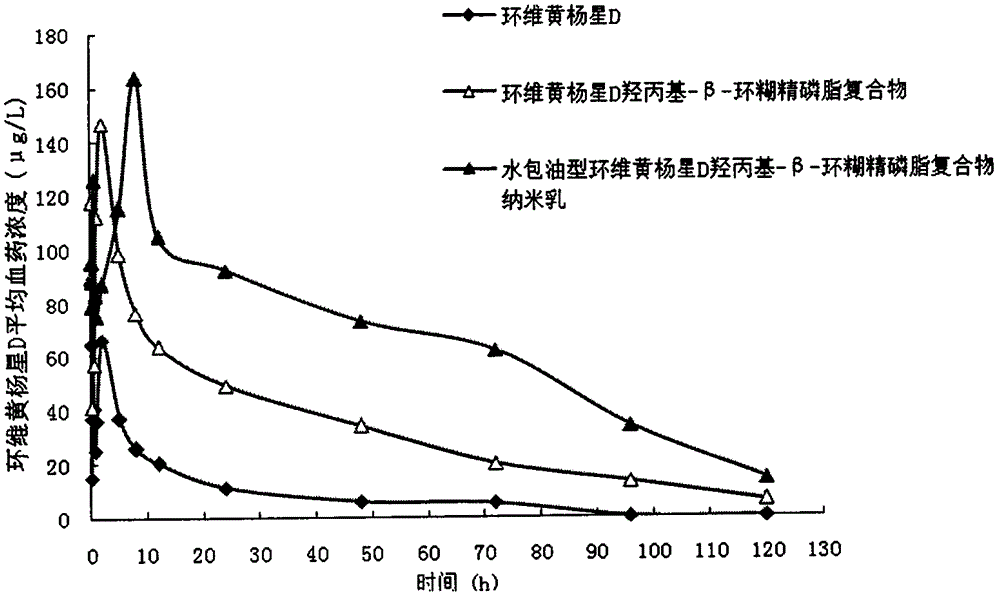

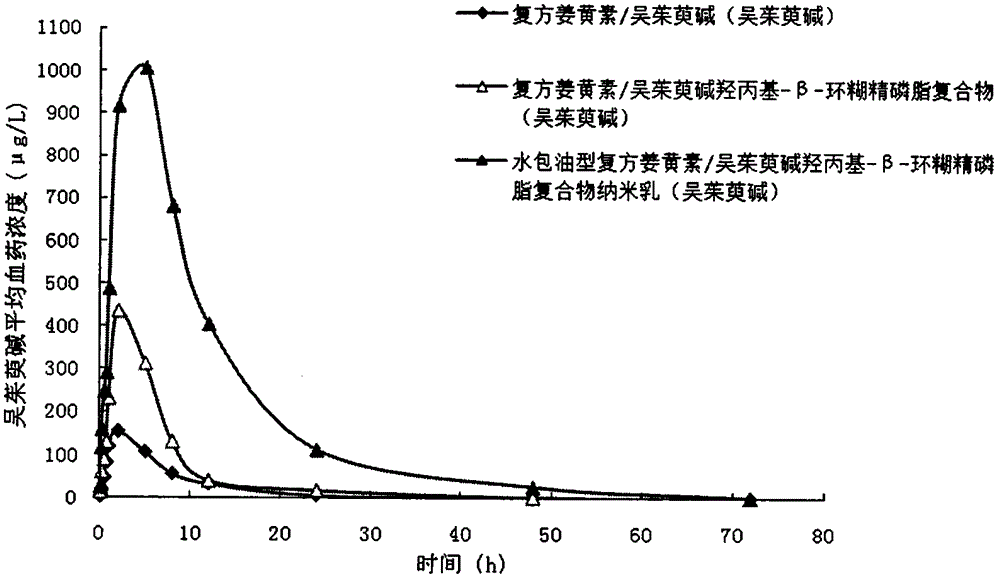

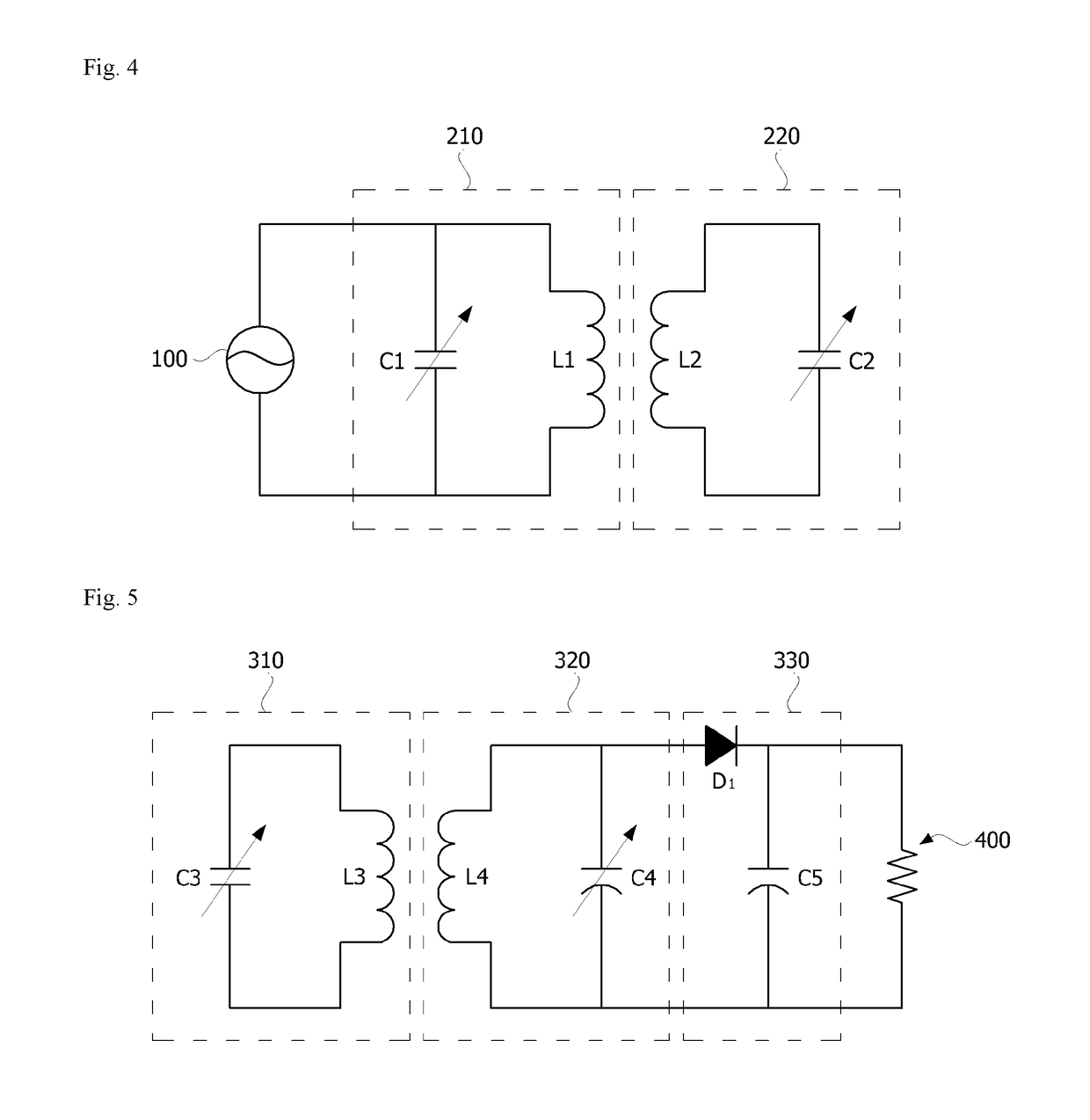

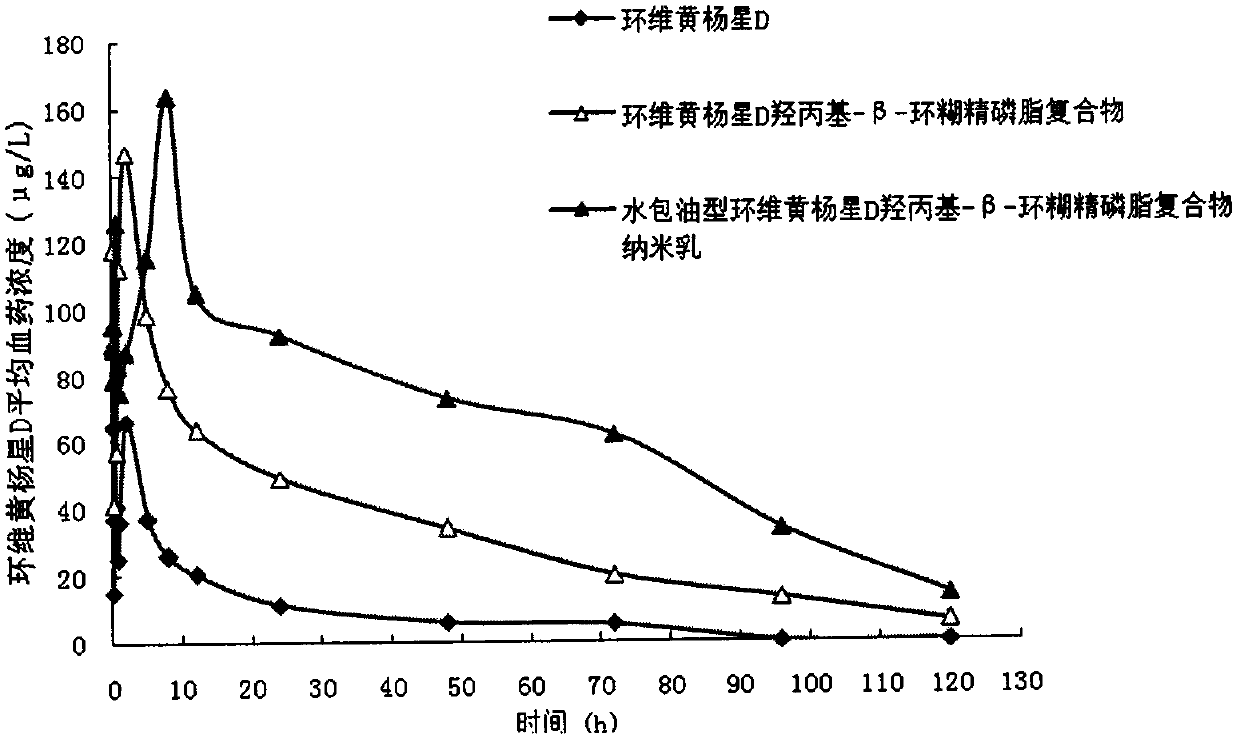

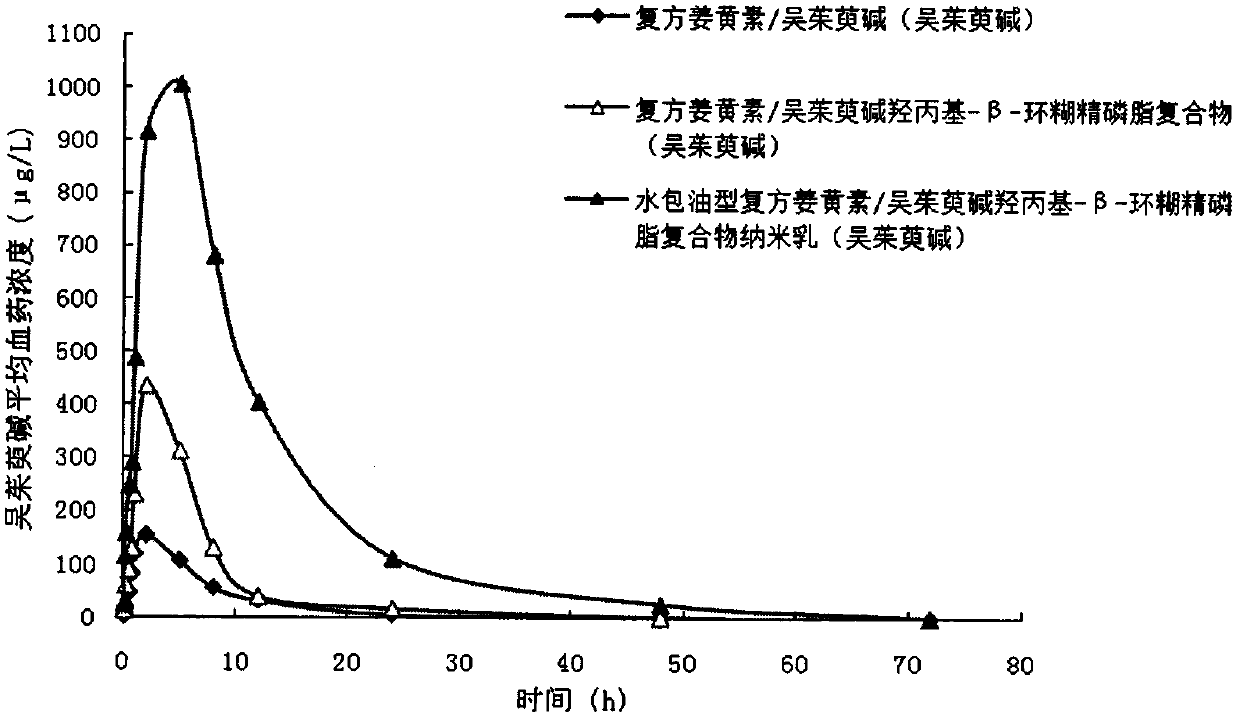

Oil-in-water nano-emulsion capable of obviously improving bioavailability of insoluble medicament and preparation method for oil-in-water nano-emulsion

ActiveCN106038488AImprove bioavailabilityPromote absorptionHydroxy compound active ingredientsKetone active ingredientsSolubilityWater soluble

The invention belongs to the field of medicinal preparation, and relates to oil-in-water nano-emulsion capable of obviously improving the bioavailability of an insoluble medicament and a preparation method for the oil-in-water nano-emulsion. According to the prepared oil-in-water nano-emulsion, the water solubility of the medicament can be achieved, absorption of the medicament can be promoted, and the bioavailability of the medicament can be improved.

Owner:CHONGQING MEDICAL UNIVERSITY

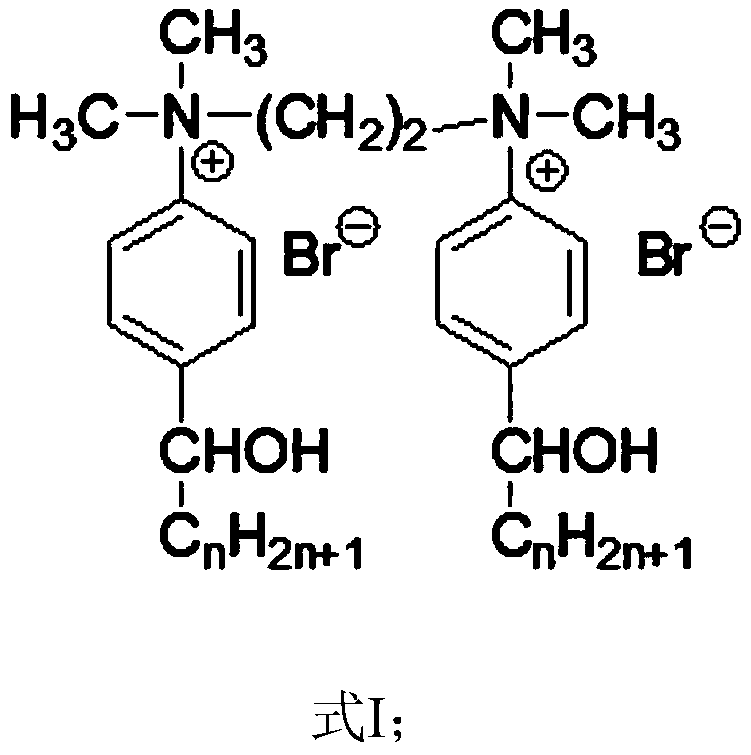

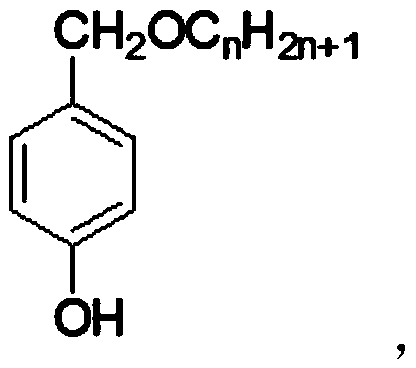

Wetting reversal agent for pressure reduction and augmented injection of ultra-low permeability reservoir and preparation method thereof

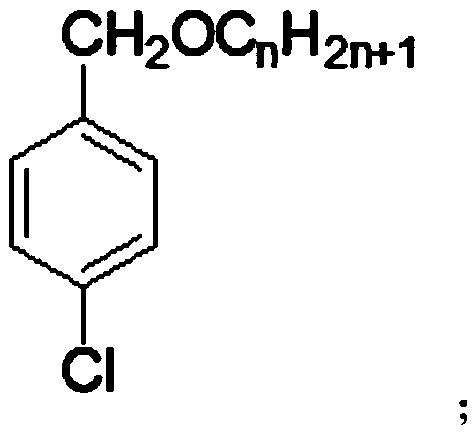

InactiveCN111234795AImprove injection abilityReduce thicknessOrganic compound preparationPreparation by reductive alkylationActive agentEthylene glycol monoethyl ether

The invention provides a wetting reversal agent for pressure reduction and augmented injection of an ultra-low permeability reservoir. The wetting reversal agent is prepared from the following raw materials: a cationic gemini surfactant, a nonionic surfactant, an efficient anti-swelling swelling shrinkage agent, ethanol, ethylene glycol monoethyl ether and deionized water. The cationic gemini surfactant has a structure as shown in a formula I which is described in the specification, wherein n is equal to 3-18. The invention provides the wetting reversal agent for pressure reduction and augmented injection of an oil field and a preparation method of the wetting reversal agent. The effects of pressure reduction, augmented injection and yield increase of the sensitive ultra-low-permeability hydrophilic water-injection high-pressure oil reservoir are improved.

Owner:XIAN AODE PETROCHEM ENG TECH CO LTD

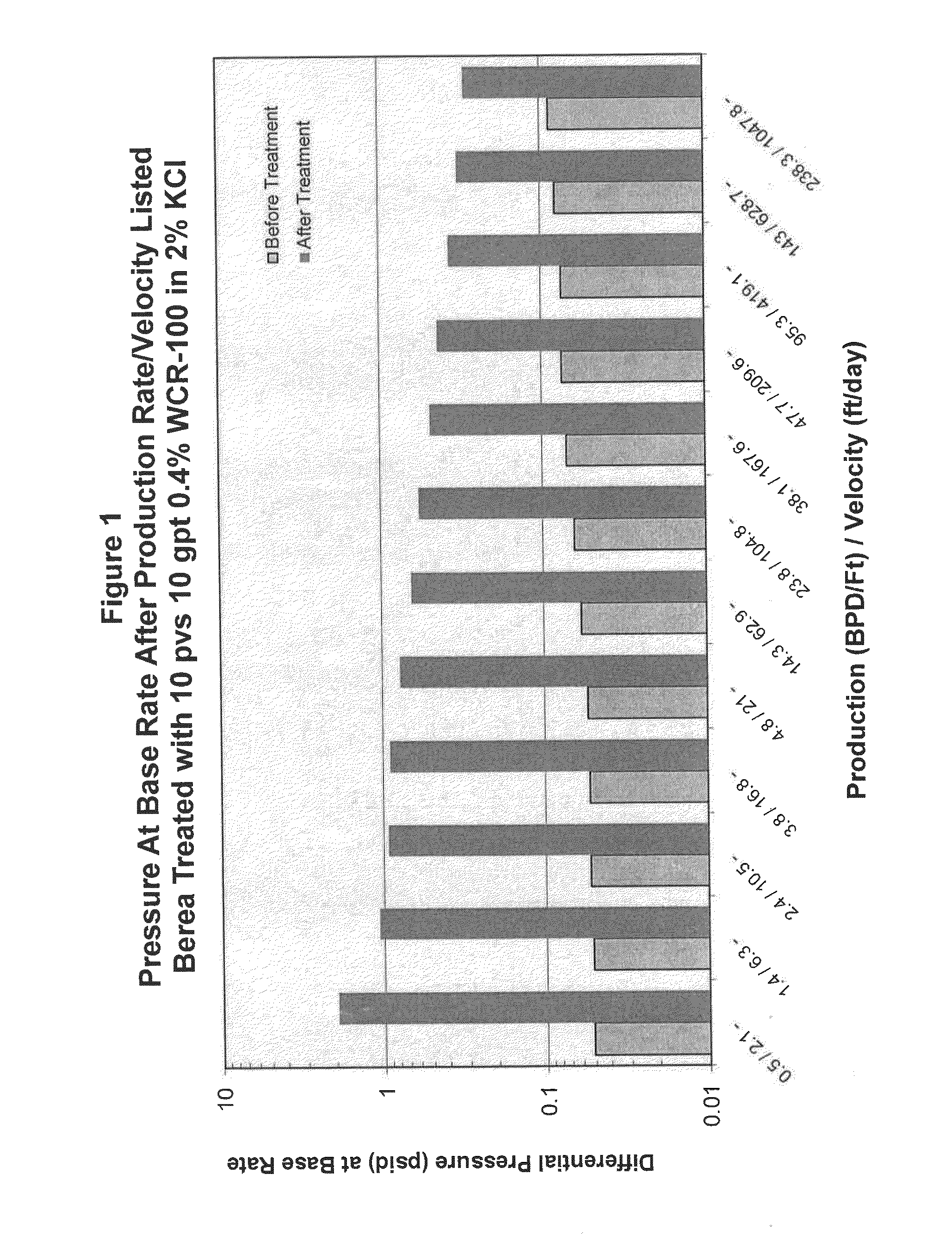

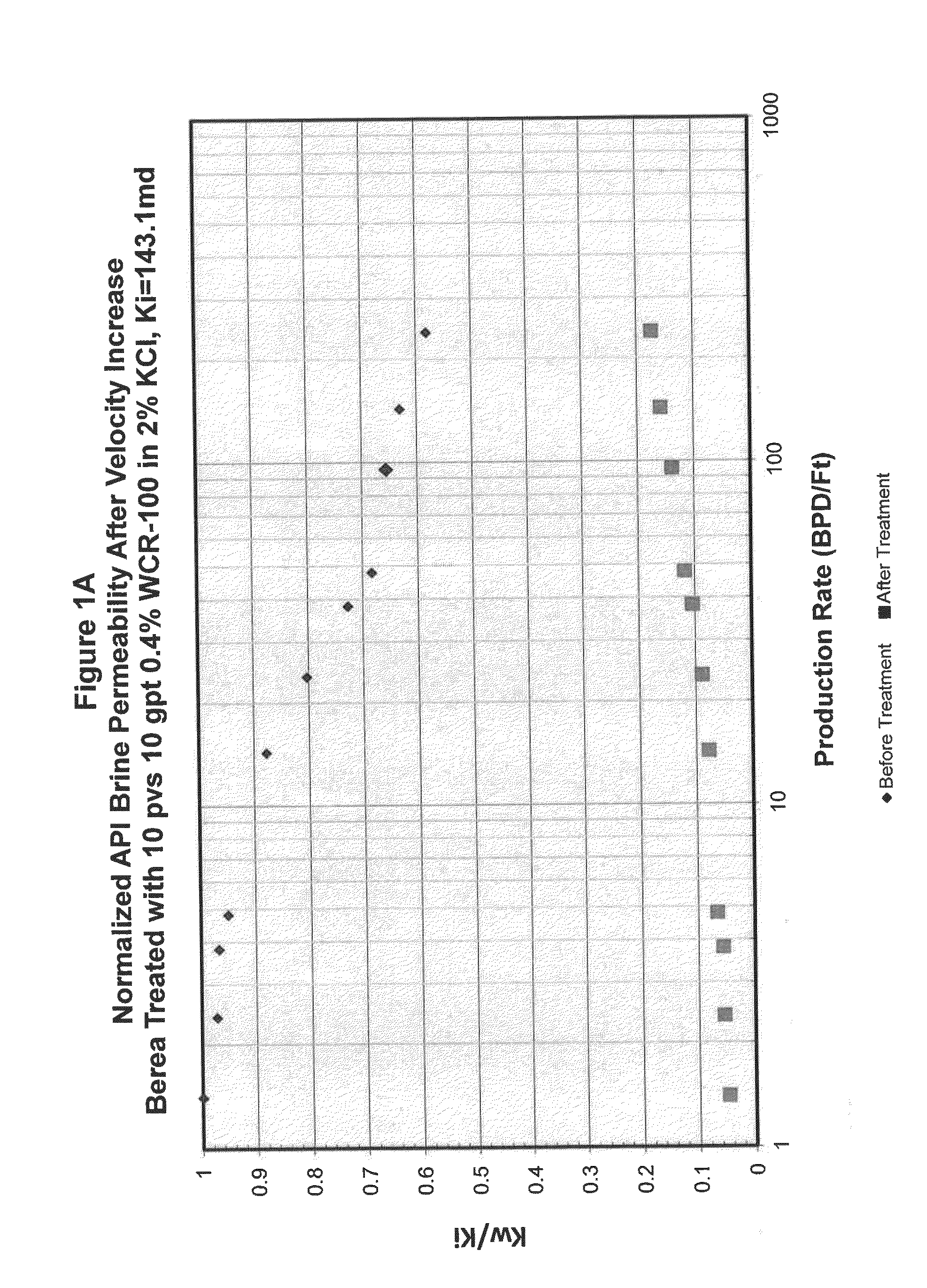

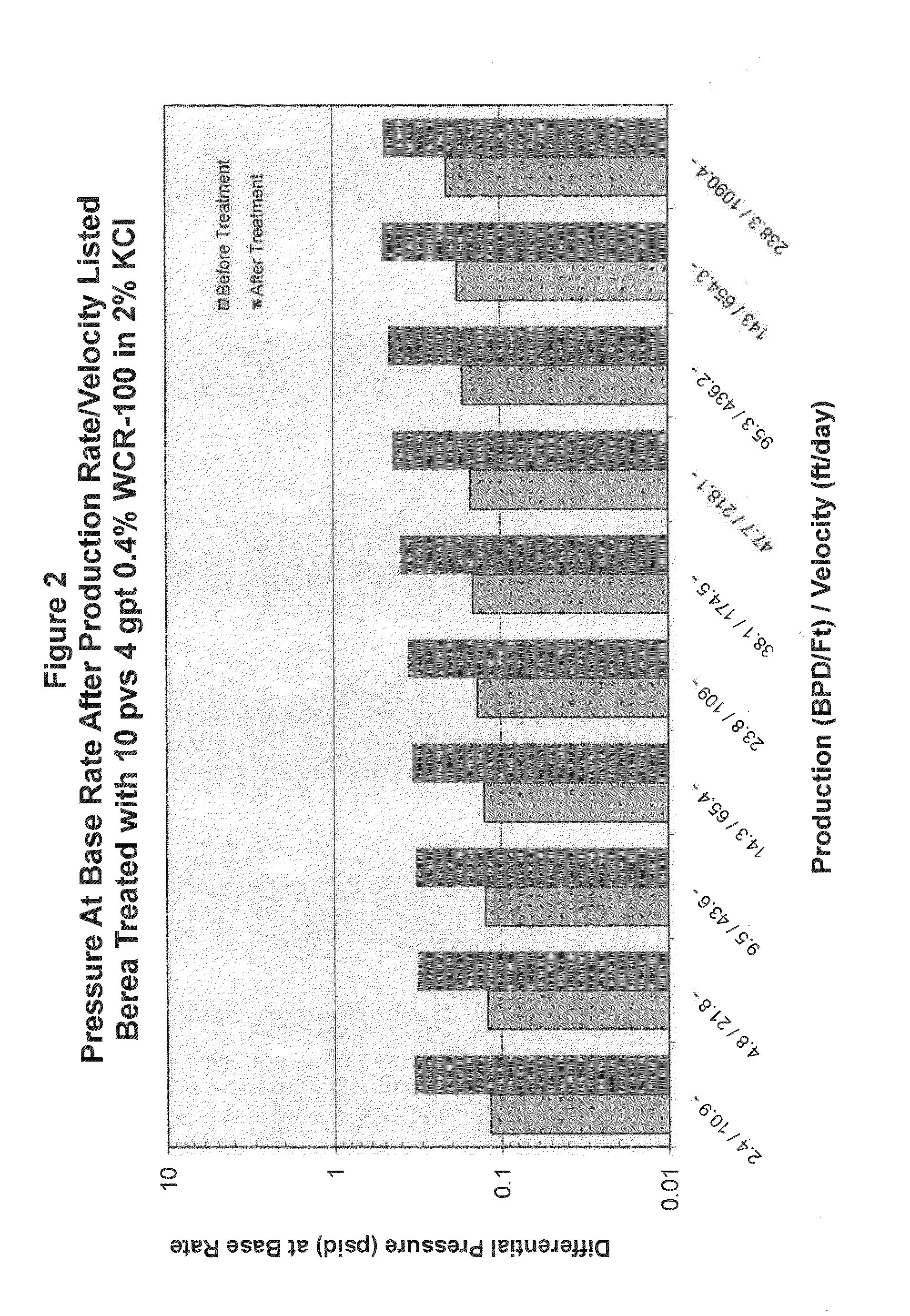

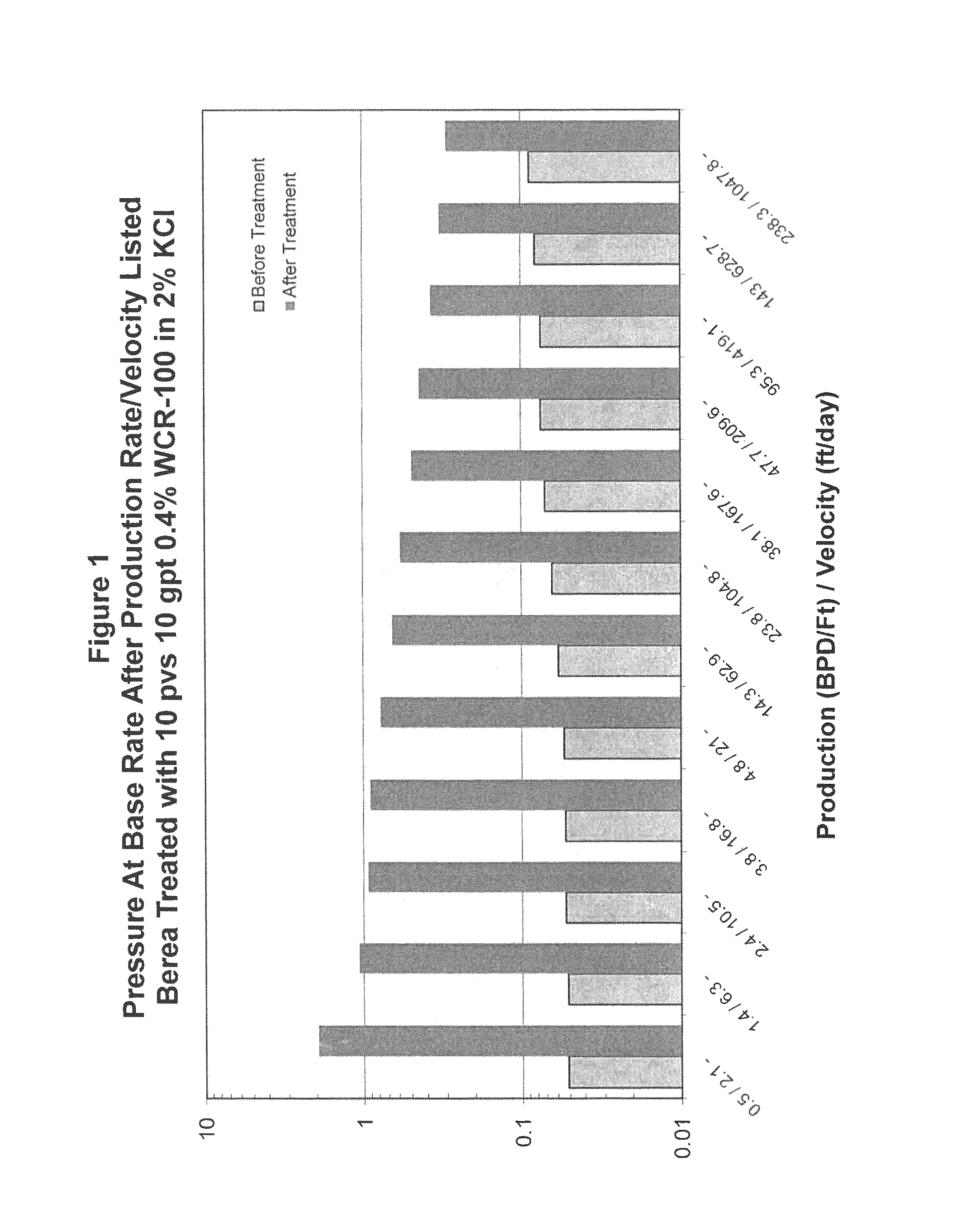

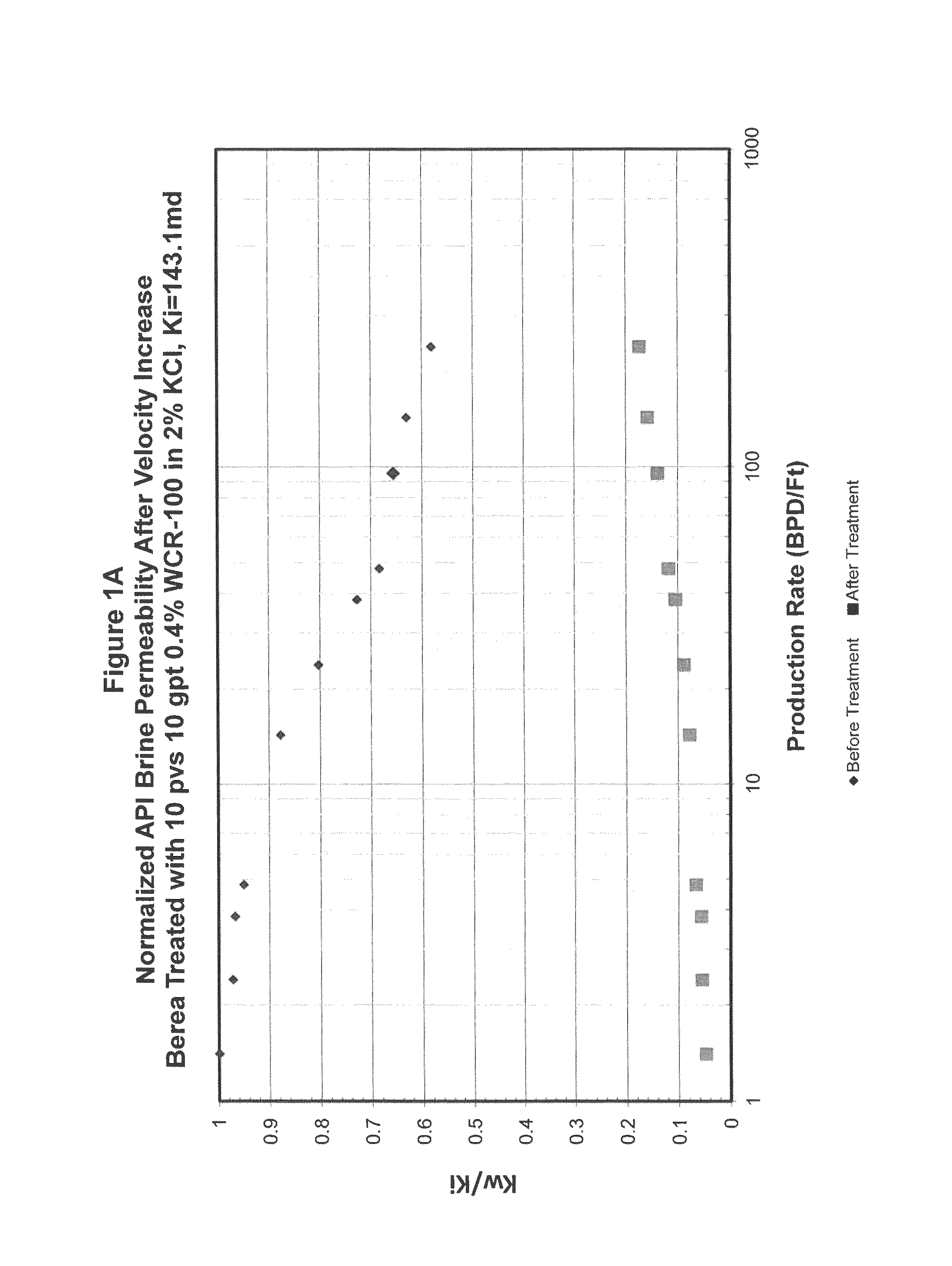

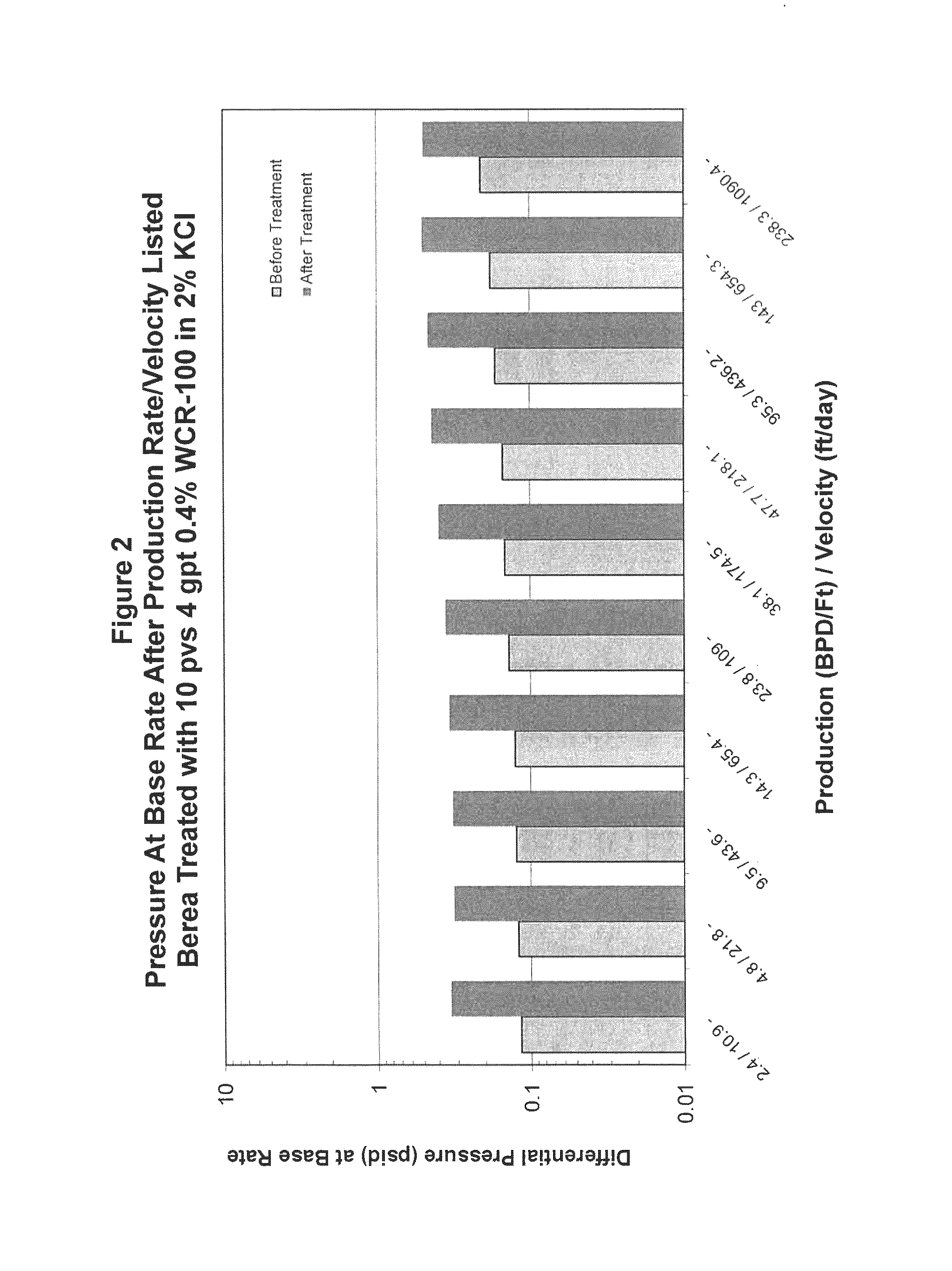

Chemical treatment method and additive used to treat fines migration and flow through porous media

ActiveUS20140116691A1Reducing fine migrationPromote migrationFluid removalFlushingChemical treatmentPorous medium

Methods for reducing fines migration in a porous subterranean reservoir are disclosed. In certain aspects, the methods include introducing a composition comprising a water-soluble or dispersible branched polyhydroxyetheramine into the porous subterranean reservoir, maintaining a sufficient temperature in the porous subterranean reservoir for a period of time, adsorbing the composition onto a surface of the porous subterranean reservoir, and stabilizing at least a portion of the fines present in the porous subterranean reservoir. Methods for enhancing an effective permeability of a porous subterranean reservoir are also disclosed. In connection with the disclosed methods, a treatment composition can be used and in certain aspects, the treatment composition can be a reaction product of bisphenol A, an ethanol amine, diethanol amine, and a monofunctionalized polyoxyalkyleneamine.

Owner:CHAMPIONX USA INC

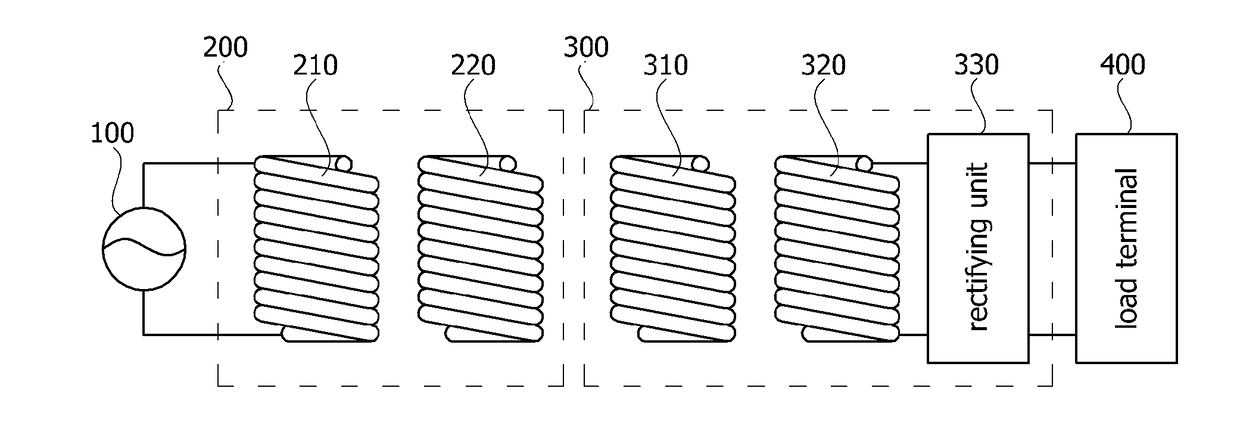

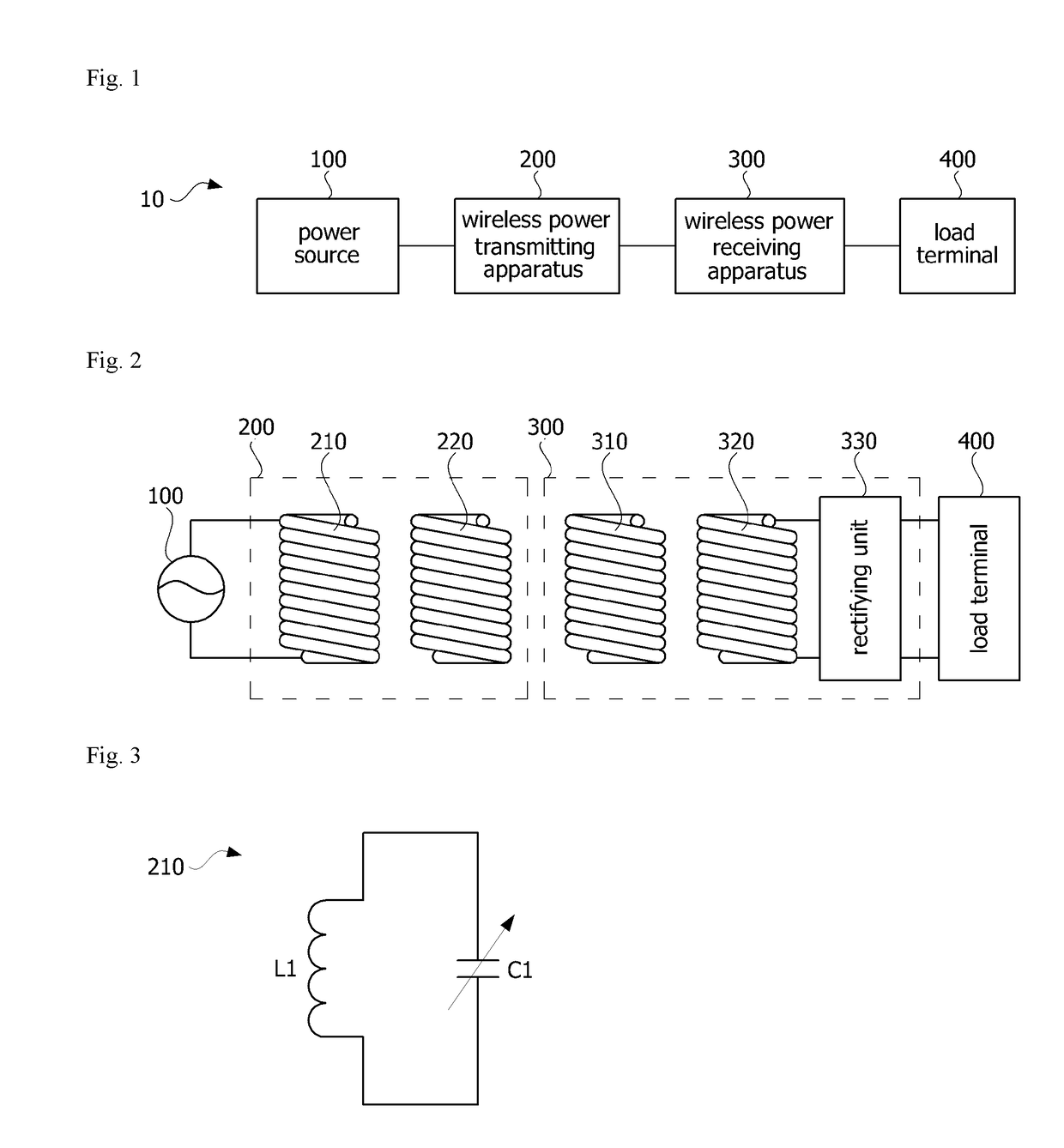

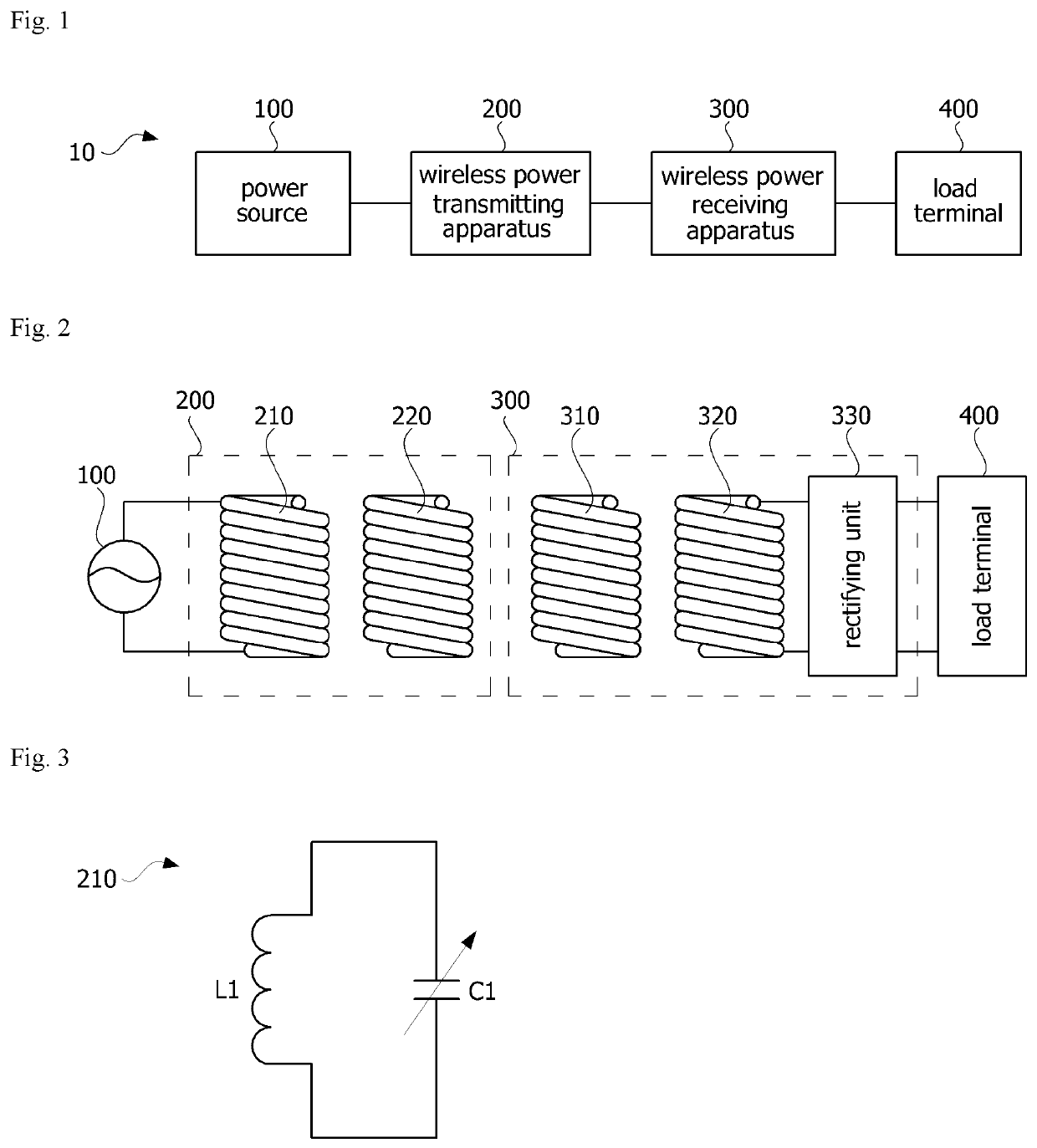

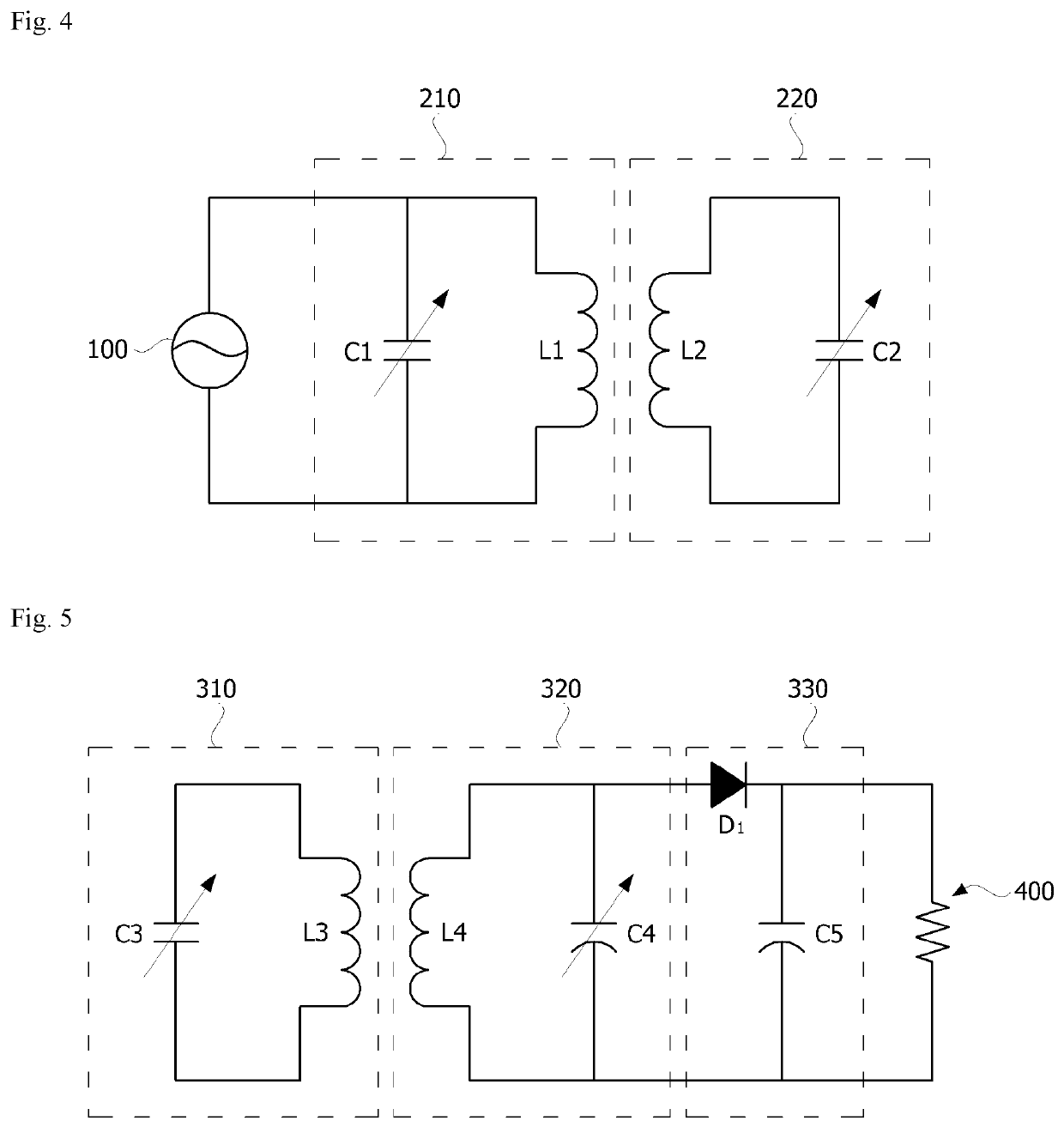

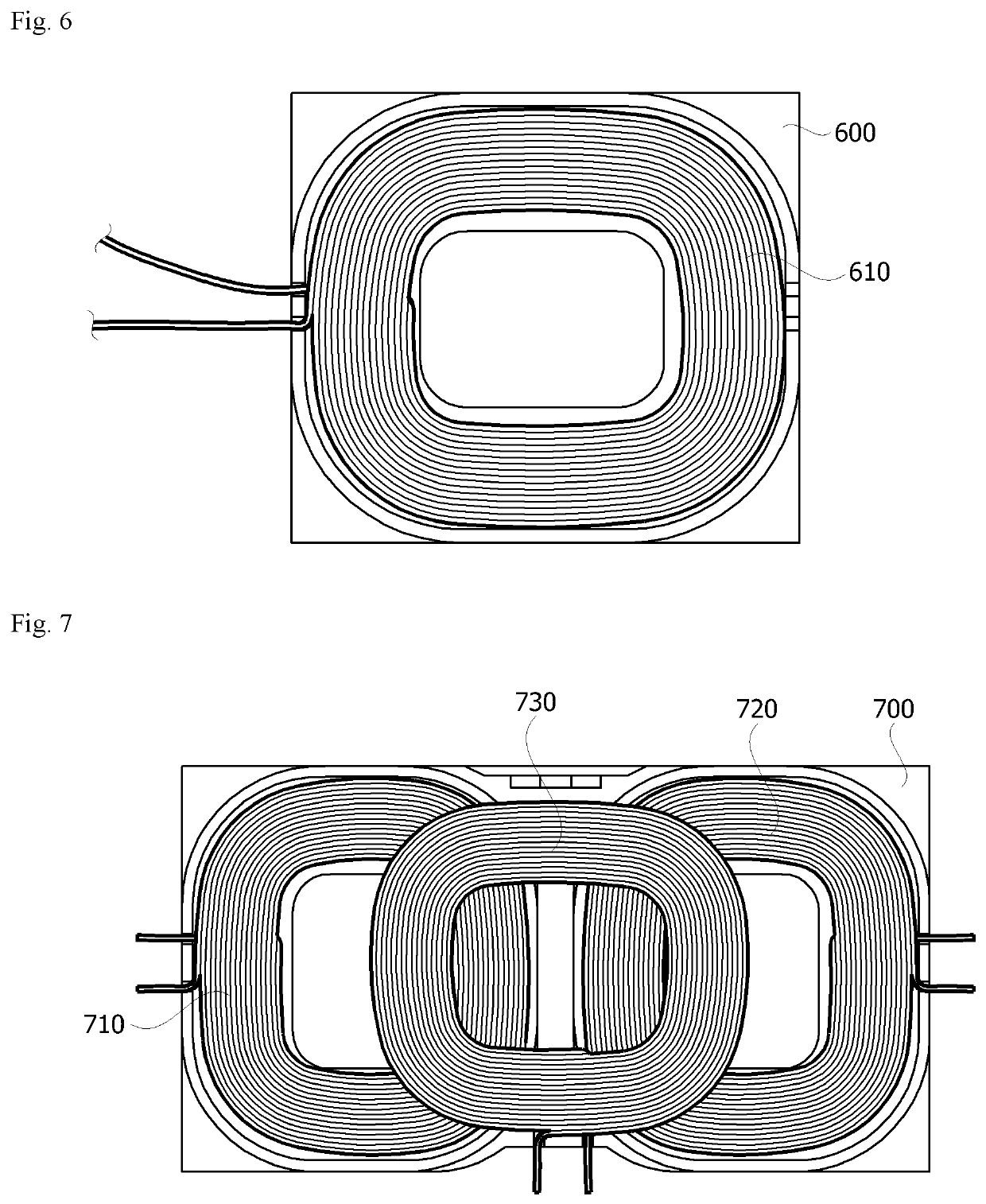

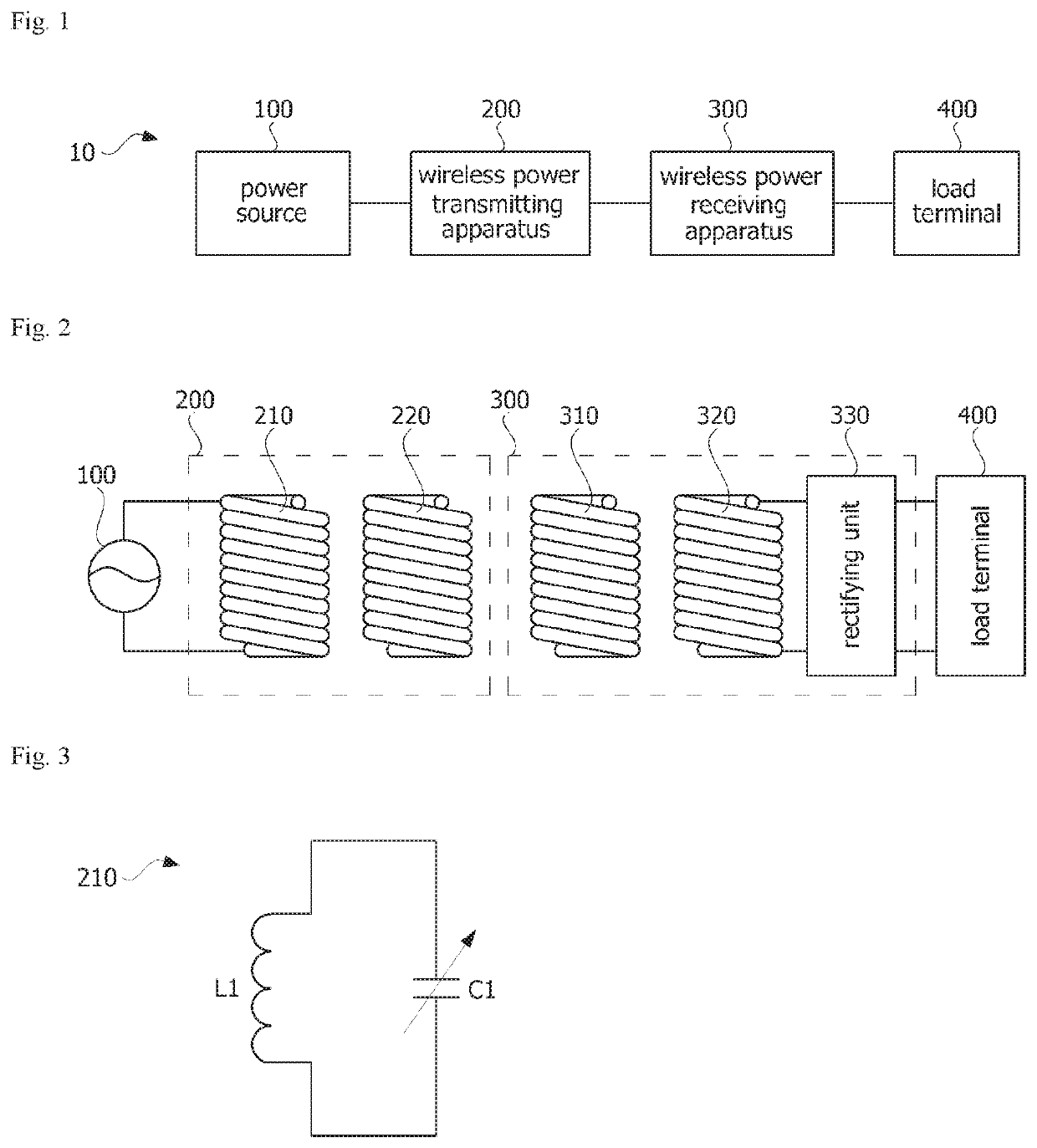

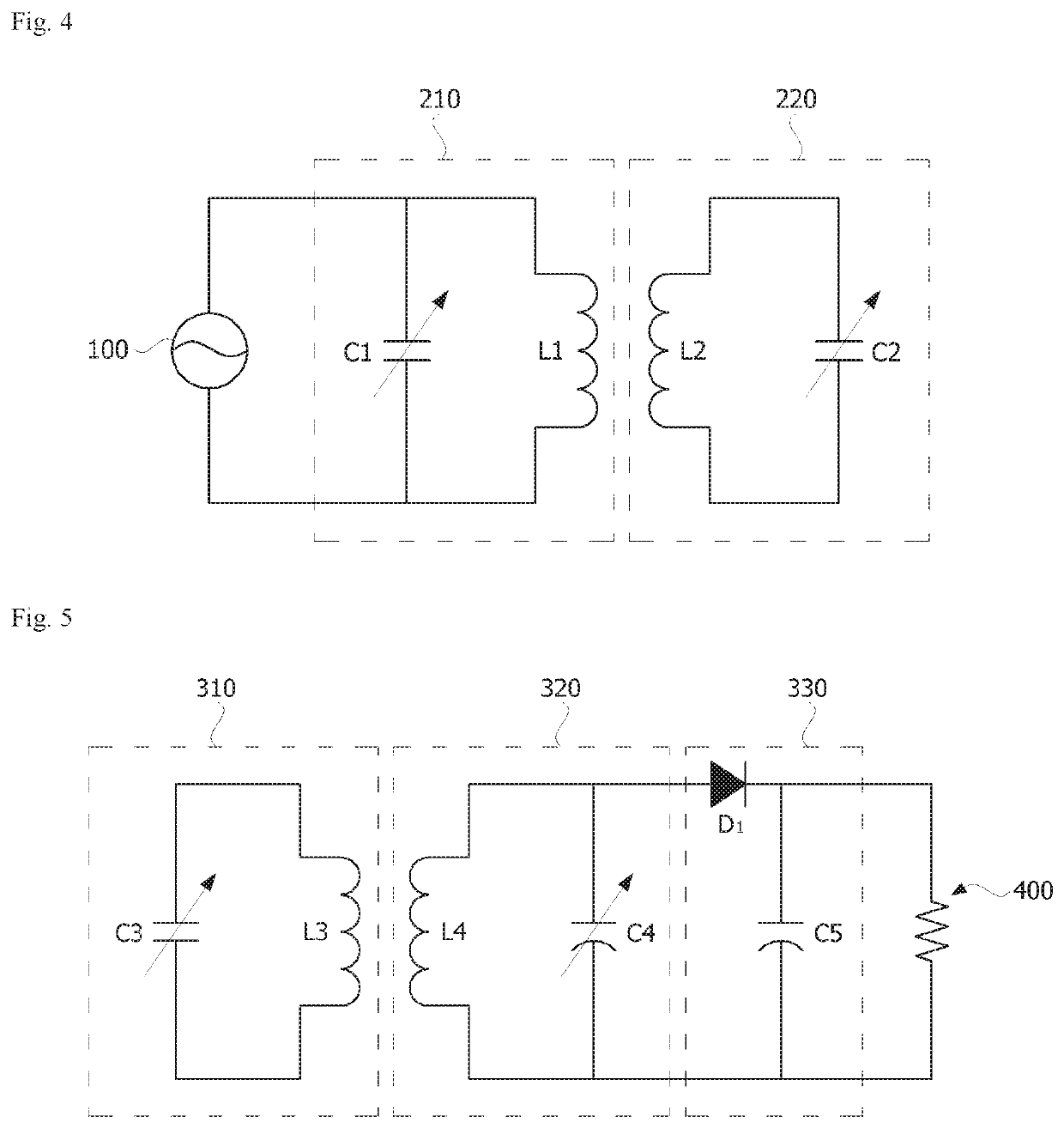

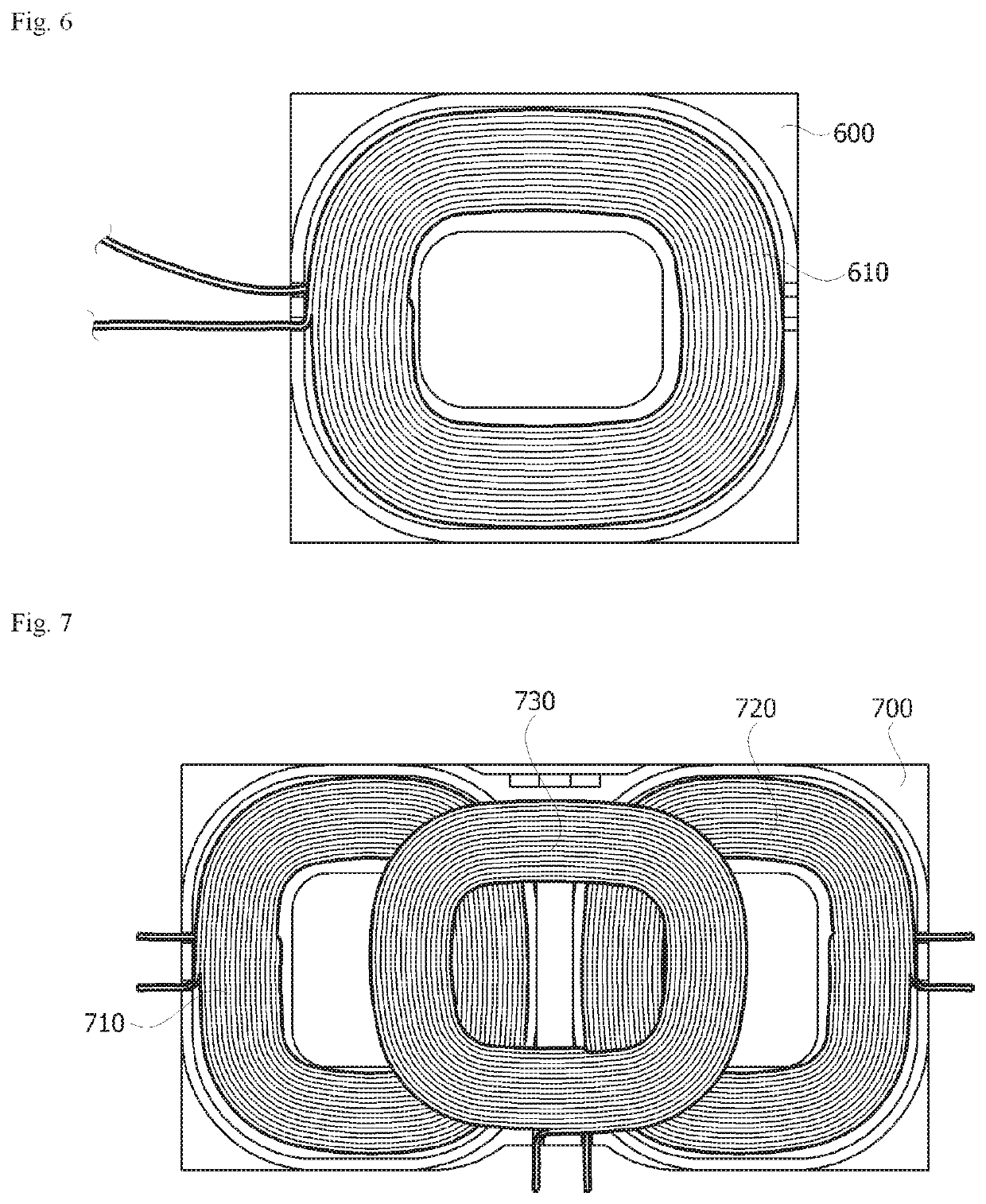

Wireless power transmitting apparatus and wireless power receiving apparatus

ActiveUS20170222472A1Improve the effective permeabilityEfficient powerBatteries circuit arrangementsTransformersElectric power transmissionMagnetic layer

According to an aspect of the present invention, a wireless power transmitting apparatus of a wireless charging system includes a substrate, a first bonding layer formed on the substrate, a soft magnetic layer formed on the first bonding layer, a second bonding layer formed on the soft magnetic layer and a transmitting coil formed on the second bonding layer, wherein at least one of the first bonding layer and the second bonding layer includes a magnetic substance.

Owner:SCRAMOGE TECH LTD

A kind of oil-in-water type nanoemulsion and preparation method thereof that obviously improves the bioavailability of insoluble drugs

ActiveCN106038488BImprove bioavailabilityPromote absorptionHydroxy compound active ingredientsKetone active ingredientsSolubilityWater soluble

The invention belongs to the field of medicinal preparation, and relates to oil-in-water nano-emulsion capable of obviously improving the bioavailability of an insoluble medicament and a preparation method for the oil-in-water nano-emulsion. According to the prepared oil-in-water nano-emulsion, the water solubility of the medicament can be achieved, absorption of the medicament can be promoted, and the bioavailability of the medicament can be improved.

Owner:CHONGQING MEDICAL UNIVERSITY

Using synthetic acid compositions as alternatives to conventional acids in the oil and gas industry

ActiveUS20170096596A1Improve the effective permeabilityReduce and remove wellbore damageCleaning apparatusFluid removalGlycerolPropanediol

A synthetic acid composition for use in oil industry activities, said composition comprising: urea and hydrogen chloride in a molar ratio of not less than 0.1:1; a metal iodide or iodate; an alcohol or derivative thereof. Optionally, formic acid or a derivative thereof; propylene glycol or a derivative thereof, ethylene glycol glycerol or a mixture thereof; cinnamaldehyde or a derivative thereof; and a phosphonic acid derivative can be added to the composition.

Owner:FLUID ENERGY GRP LTD

Nanometer poly-silicon emulsion and preparing method and application thereof

The invention discloses a nanometer poly-silicon emulsion. The nanometer poly-silicon emulsion is prepared from 40-50 parts of hydrophobic nanosilicon dioxide, 10-15 parts of a sodium hydroxide aqueous solution, 10-15 parts of fatty alcohol-polyoxyethylene ether AEO-9, 8-10 parts of sodium alpha-olefin sulfonate and 5-10 parts of cocoalkanoylamido propyl betaine in 300-500 parts of deionized water. According to the formula proportion, part of the deionized water, fatty alcohol-polyoxyethylene ether AEO-9, sodium alpha-olefin sulfonate and cocoalkanoylamido propyl betaine are taken and uniformly mixed to be heated and stirred until a solution is clarified, cooling is conducted, the hydrophobic nanosilicon dioxide and the sodium hydroxide aqueous solution are added, the PH value is controlled to 8-10, the remaining part of deionized water is added, heating is conducted until the materials are boiled, turbid and then clarified, and then the nanometer poly-silicon emulsion is obtained. According to the nanometer poly-silicon emulsion, secondary pollution can be reduced, and the problems are effectively solved that in the later development period, the water injection pressure is high, the water injection amount does not meet the injection allocation requirement, and the injection increase validity period is short.

Owner:陕西一诺油气工程技术服务有限公司

Novel corrosion inhibition package

ActiveUS20200032400A1Easy injectionReduce pressureDrilling compositionBorehole/well accessoriesPropanolActive agent

An inhibition corrosion package for use with an acidic composition, where the package comprises a terpene component; a propargyl alcohol or derivative thereof; at least one amphoteric surfactant; and a solvent. Also disclosed are acidic compositions combining the corrosion inhibition package according to a preferred embodiment of the present invention for use in various industrial operations including but not limited to oil and gas operations. Also disclosed are methods of use of such compositions.

Owner:DORF KETAL CHEM FZE

Wireless power transmitting apparatus and wireless power receiving apparatus

ActiveUS11146092B2Improve the effective permeabilityIncrease powerBatteries circuit arrangementsTransformersTransmitter coilMechanical engineering

According to an aspect of the present invention, a wireless power transmitting apparatus of a wireless charging system includes a substrate, a first bonding layer formed on the substrate, a soft magnetic layer formed on the first bonding layer, a second bonding layer formed on the soft magnetic layer and a transmitting coil formed on the second bonding layer, wherein at least one of the first bonding layer and the second bonding layer includes a magnetic substance.

Owner:NERA INNOVATIONS LTD

Chemical treatment method and additive used to treat fines migration and flow through porous media

ActiveUS9169430B2Reducing fine migrationPromote migrationFluid removalFlushingChemical treatmentPorous medium

Methods for reducing fines migration in a porous subterranean reservoir. In certain aspects, the methods include introducing a composition including a water-soluble or dispersible branched polyhydroxyetheramine into the porous subterranean reservoir, maintaining a sufficient temperature in the porous subterranean reservoir for a period of time, adsorbing the composition onto a surface of the porous subterranean reservoir, and stabilizing at least a portion of the fines present in the porous subterranean reservoir. A treatment composition can be used and in certain aspects, the treatment composition can be a reaction product of bisphenol A, an ethanol amine, diethanol amine, and a monofunctionalized polyoxyalkyleneamine.

Owner:CHAMPIONX USA INC

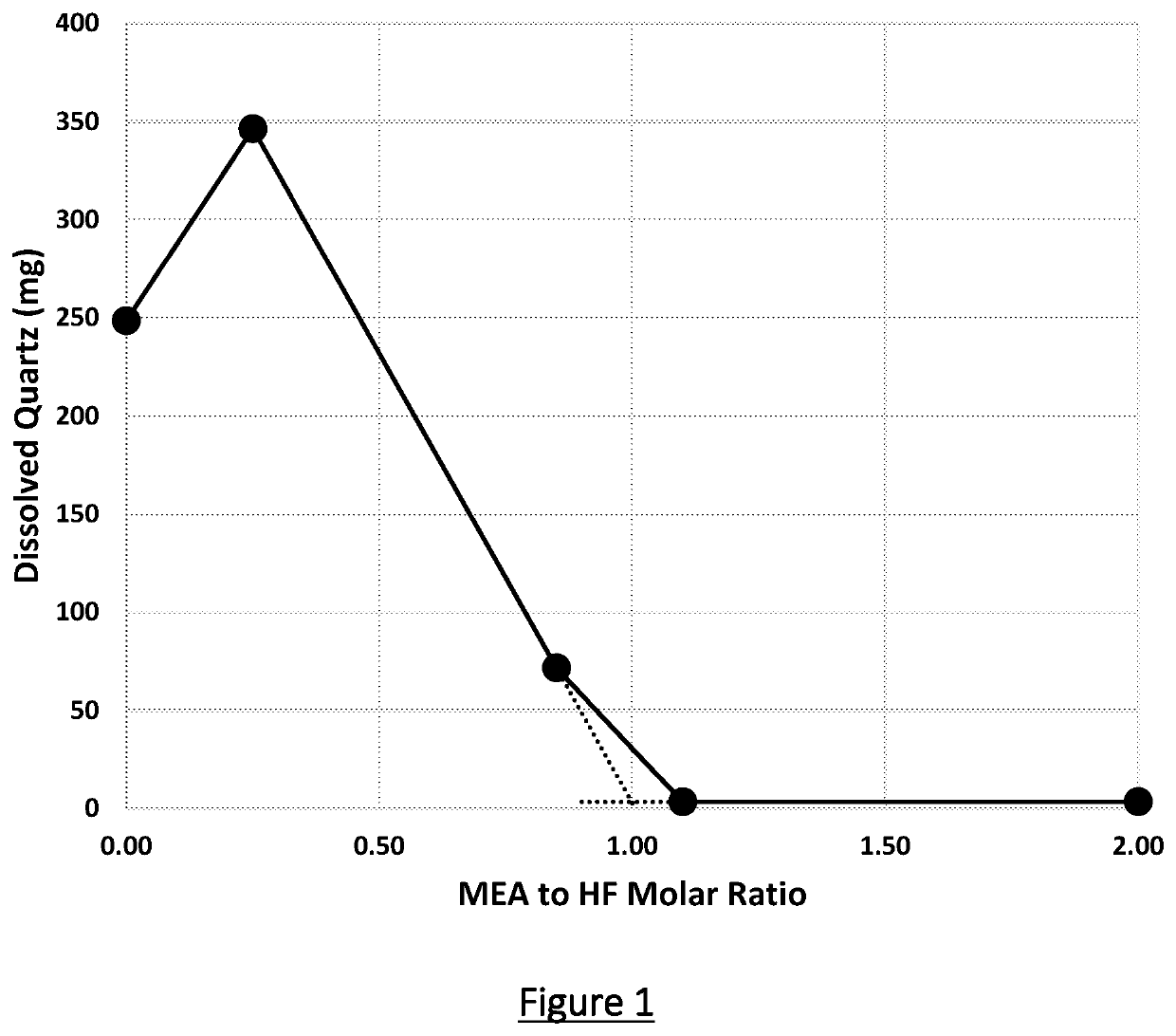

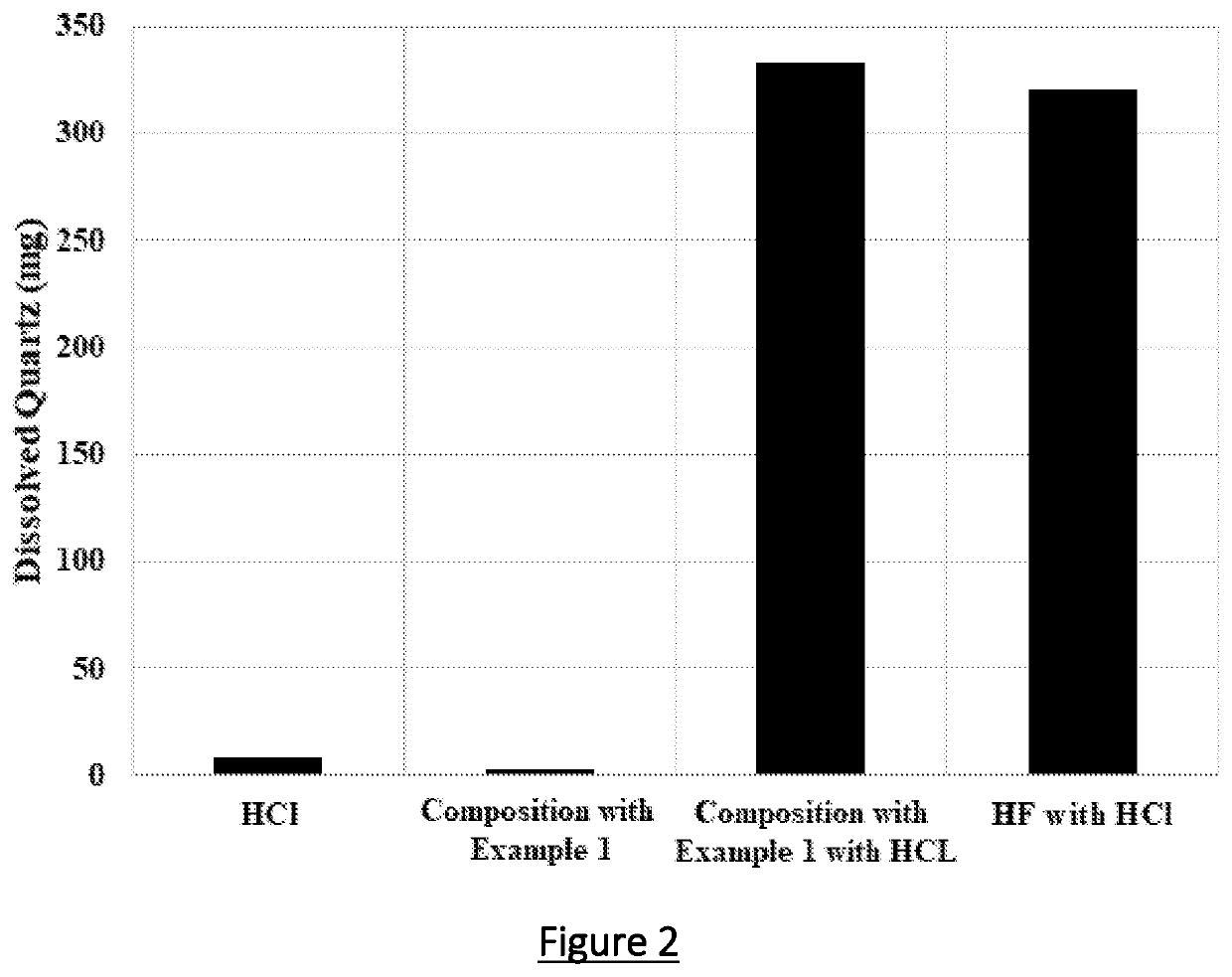

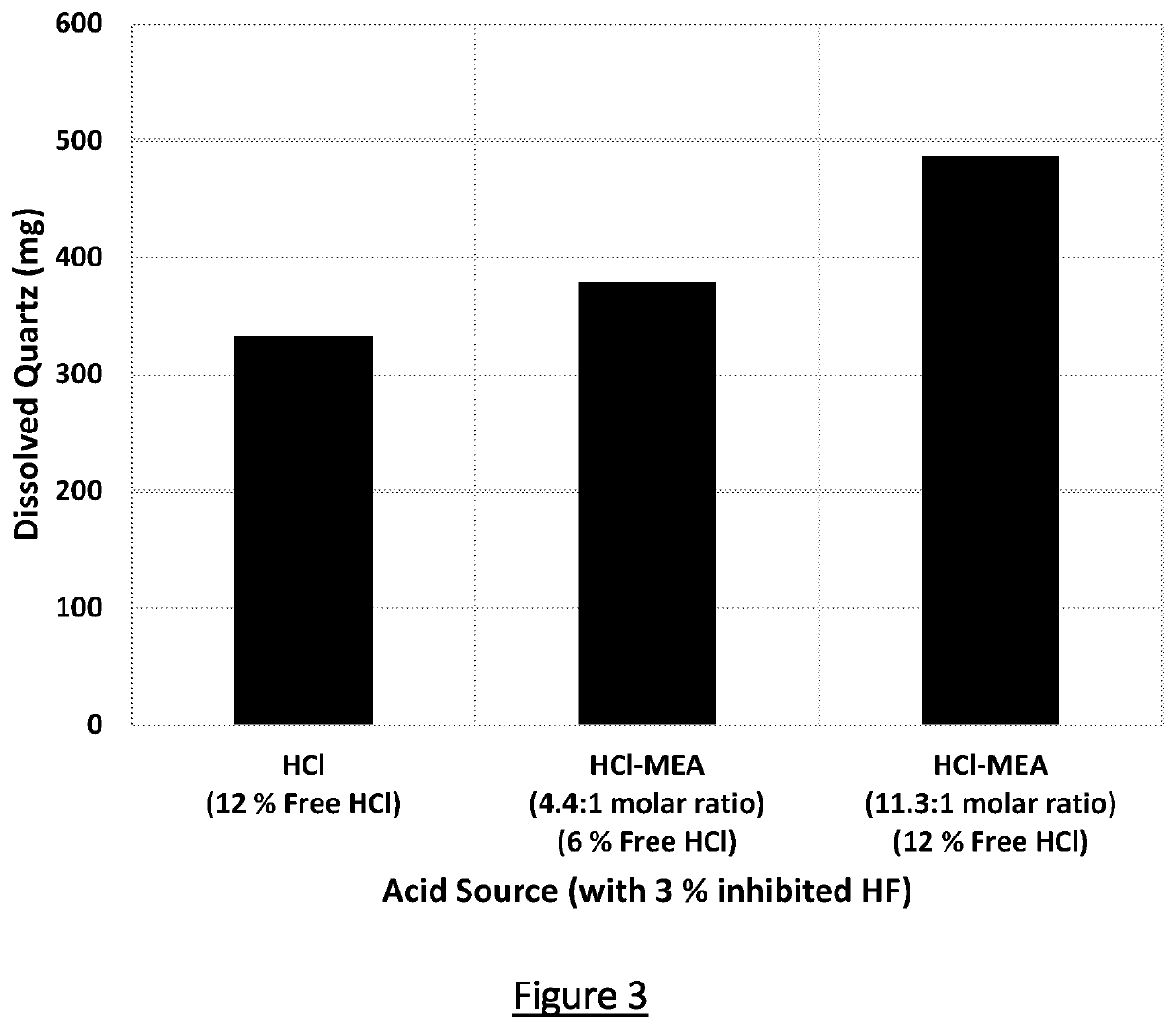

Novel mud acid composition and methods of using such

ActiveUS20200317996A1Sufficient exposure timeReduce pressureDrilling compositionSoil conditioning compositionsFluorhydric AcidPetrology

An inhibited mud acid composition, said composition comprising: hydrofluoric acid in solution; an alkanolamine; and a mineral acid selected from a group consisting of: HCl; MEA-HCl and other modified acids, wherein said alkanolamine and hydrofluoric acid are present in a molar ratio of at least 1:1.

Owner:DORF KETAL CHEM FZE

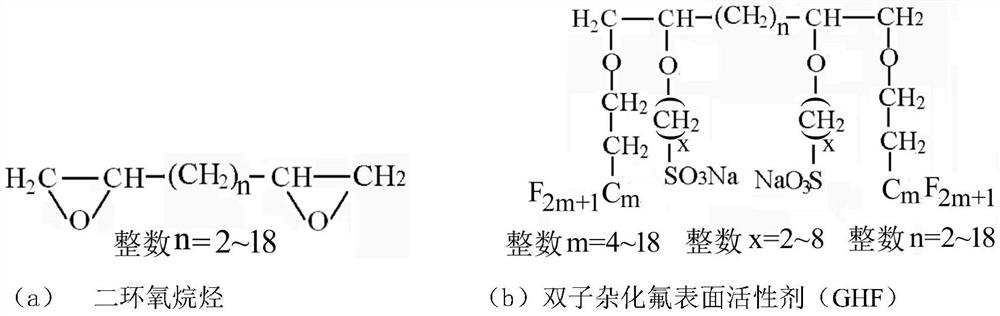

Preparation method of gemini hybrid fluorine surfactant applied as shale fracturing fluid cleanup additive

ActiveCN113548985AStrong salt resistanceImprove solubilitySulfonic acids salts preparationDrilling compositionAlkanePtru catalyst

The invention discloses a preparation method of a gemini hybrid fluorine surfactant applied as a shale fracturing fluid cleanup additive. The preparation method is characterized by comprising the following steps: adding 10-200 parts by weight of a solvent and 0.5-8 parts by weight of a catalyst into a three-mouth reaction bottle provided with a reflux condensing device, dropwise adding a solution containing 20-200 parts by weight of a solvent and 10 parts by weight of 2-perfluoroalkyl ethanol in an ice bath under the condition of introducing nitrogen, carrying out stirring and reacting for 4 hours, then conducting heating to 45-95 DEG C, slowly and dropwise adding a solution containing 20-200 parts of a solvent and 0.5-10 parts of diepoxyalkane, carrying out reacting for 10-36 hours, then gradually and dropwise adding a solution containing 10-250 parts of a solvent and 3-15 parts of halogenated alkyl sodium sulfonate into the three-mouth reaction bottle, continuing reacting for 24-72 hours, maintaining the reaction temperature within 45-95 DEG C, carrying out reduced-pressure distillation on a reaction product to remove the solvent so as to obtain a crude product, and then carrying out silica gel column chromatography separation to obtain the gemini hybrid fluorine surfactant with yield of 60-90%. The fluorine surfactant can obviously reduce the capillary pressure of shale.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Retarder blockage release agent for oil well and method of blockage removal

ActiveCN105255466BUnblock pollutionFree from secondary injuryDrilling compositionClay mineralsDissolution reaction

The invention discloses a slow blockage removing agent for an oil well and a blockage removing method, and belongs to the technical field of oil field exploitation. The slow blockage removing agent is prepared from prepad fluid, main fluid and post-pad fluid, the prepad fluid and the post-pad fluid both take hydrochloric acid as the main component of acid fluid for removing inorganic scale precipitation and dissolving reaction residues, and the main fluid takes glacial acetic acid and fluoboric acid as the main components of acid fluid for stabilizing clay mineral of a reservoir stratum, decreasomg the acid rock reaction speed, enlarging the blockage removing radius and increasing the blockage removing depth. For a fracturing production horizontal well, the treatment fluid is injected into the reservoir stratum in the former stage, the intermediate stage and the later stage, and liquid nitrogen is simultaneously injected, so that residual reaction fluid can be quickly drained after blockage removing construction is performed; pollution blockage near a well bore of the oil well can be effectively removed, the effective permeability near the well bore is increased, the individual-well producing rate is increased, damage caused by excessive acid corrosion to the rock framework of the reservoir stratum can be avoided, and therefore the reservoir stratum can be prevented from being subjected to secondary damage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel inhibitied hydrofluoric acid composition

ActiveUS20200318009A1Overcomes drawbackEasy injectionDrilling compositionSurface treatment compositionsArginineTyrosine

An inhibited hydrofluoric acid aqueous composition, said composition comprising: hydrofluoric acid in solution; and a weak base selected from the group consisting of: lysine, arginine, histidine, glutamine, asparagine, tryptophan, and tyrosine; wherein said weak base and hydrofluoric acid are present in a molar ratio of at least 1:1. Also disclosed is a mud acid using this inhibited acid composition.

Owner:DORF KETAL CHEM FZE

Wireless power transmitting apparatus and wireless power receiving apparatus

InactiveUS20190348854A1Improve the effective permeabilityIncrease powerBatteries circuit arrangementsTransformersElectric power transmissionAdhesive

A wireless power transmitting apparatus can include a substrate; a first transmitting coil and a second transmitting coil disposed on the substrate; a third transmitting coil disposed on the first transmitting coil and the second transmitting coil; and an adhesive disposed between the substrate and the first and the second transmitting coils, in which the substrate includes a first portion disposed inside an inner circumference of the first transmitting coil; a second portion disposed inside an inner circumference of the second transmitting coil; a third portion disposed between the first transmitting coil and the second transmitting coil; and a peripheral portion disposed outside an outer circumference of the first transmitting coil and an outer circumference of the second transmitting coil, in which an inner area disposed inside an inner circumference of the third transmitting coil overlaps the third portion, a part of the first transmitting coil and a part of the second transmitting coil in a vertical direction perpendicular to the substrate.

Owner:SCRAMOGE TECH LTD

Novel corrosion inhibition package

ActiveUS20190390352A1Easy injectionReduce pressureDrilling compositionChemical inhibitorsPhysical chemistrySolvent

A corrosion inhibition package for use with an aqueous acid composition, said package comprising: a terpene; a cinnamaldehyde or a derivative thereof; at least one amphoteric surfactant; and a solvent. Also disclosed are compositions comprising said corrosion inhibitor package. Preferably, the corrosion inhibition package meets the environmental requirements for classification as yellow according to the Norwegian North Sea offshore drilling regulatory requirements.

Owner:DORF KETAL CHEM FZE

Corrosion Inhibition Package

ActiveUS20200224097A1Easy injectionReduce pressureDrilling compositionChemical inhibitorsPropanolActive agent

An inhibition corrosion package for use with an acidic composition, where the package comprises a dialdehyde-containing hydrocarbon component; at least one surfactant; optionally, a propargyl alcohol or derivative thereof; and a solvent. Also disclosed are acidic compositions combining the corrosion inhibition package according to a preferred embodiment of the present invention for use in various industrial operations including but not limited to oil and gas operations. Also disclosed are methods of use of such compositions.

Owner:DORF KETAL CHEM FZE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com