Method and System For Enhancing A Recovery Process Employing One or More Horizontal Wellbores

a recovery process and wellbore technology, applied in the direction of fluid removal, earth drilling and mining, borehole/well accessories, etc., can solve the problems of limiting production rate and resource recovery, affecting the recovery process, so as to enhance the recovery process and facilitate the movement of flowable materials , the effect of increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Heavy Oil Reservoir Simulations Using SAGD

The time and cost involved in conducting field testing is often prohibitive in the oil and gas industry. Therefore, reservoir simulations are commonly relied upon to test new systems and processes before or while field testing is performed. In the present examples, testing was conducted using proprietary reservoir simulation software, which utilizes numerical modeling to mimic fluid flow through porous reservoir media. Reservoirs were modeled using average properties for an Athabasca oil sands deposit.

FIG. 15 shows the 2D results of a reservoir simulation modeling a typical SAGD process in a continuous oil sands reservoir with Athabasca type properties and no vertical permeability impediments. Temperature and gas saturation in the reservoir are shown for 1000 days and 2000 days of steam injection. The injection and production wells are located near the bottom left corner of each block but are not shown. The results illustrate the development...

example 2

Heavy Oil Reservoir Simulation of Split Pay Reservoir Using CSS

A numerical simulation study was conducted to evaluate applicability of the invention to cyclic steam stimulation (CSS) with horizontal wellbores. CSS is typically a single well recovery process where the same well receives a fixed volume of steam and is then produced following injection in a cyclic manner. Horizontal wells are increasingly being used to reduce the cost of field development. The horizontal wells are typically located at the base of the effective pay zone and therefore oil recovery is vulnerable to vertical permeability impediments.

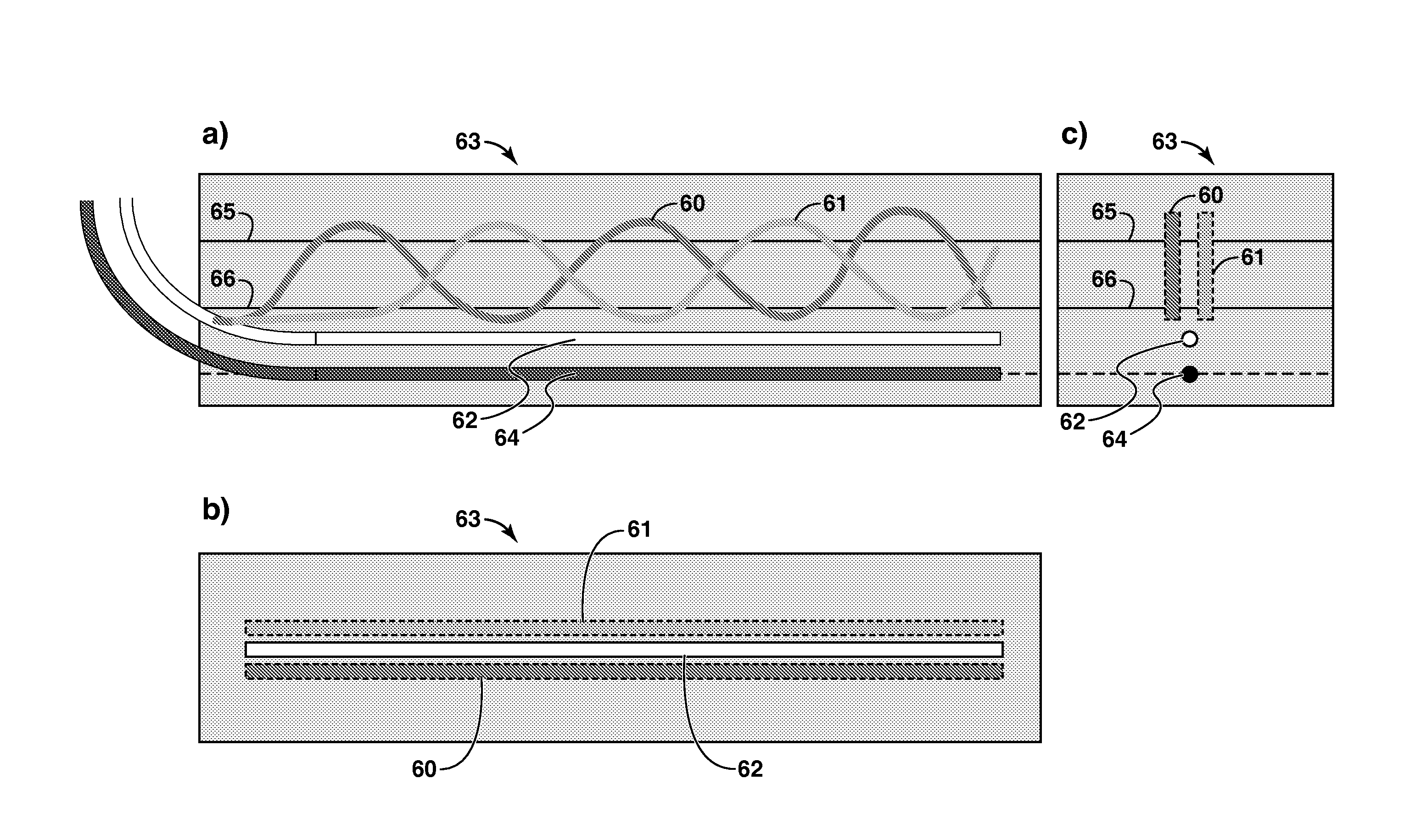

A simulation model based on typical properties of the Cold Lake Clearwater formation was constructed. Referring to FIG. 18, the simulation was designed to mimic two adjacent horizontal wells (white) completed with spaced limited entry perforations (LEP), as discussed in SPE Paper 50429, “Targeted Steam Injection Using Horizontal Wells with Limited Entry Perforations”, T. Boone,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com