Patents

Literature

97results about How to "High molding density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amorphous alloy powder core and nano-crystal alloy powder core having good high frequency properties and methods of manufacturing the same

InactiveUS6827557B2High molding densityLow dependence on frequencyTransportation and packagingMetal-working apparatusOrganic solventShell molding

A method of manufacturing an amorphous alloy core including the steps of mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in liquid phase on the surface of the alloy powder to make a powder of composite particles, molding the power of composite particles, and performing a heating treatment thereon. This invention also discloses a method of manufacturing a nano-crystal alloy core including the steps of (a) mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in the liquid phase on the surface of the alloy powder to make composite particles, molding the composite particles at room temperature, and performing a heating treatment thereon at a temperature higher than the crystallization starting temperature of the alloy; and (b) performing a heating treatment on an amorphous alloy powder at over a crystallization starting temperature to make a nano-crystal phase, mixing a solution made by solving a polyimide / phenolic resin binder in an organic solvent therewith, evenly coating the binder in liquid phase on the surface of the alloy powder to make composite particles, and molding the power of composite particles at 100 to 300° C.

Owner:KIM KYU JIN +3

Preparation of multilayer semitransparent zirconia full-porcelain dental repair material

InactiveCN103121840AHigh molding densitySmall sintering shrinkageChemical compositionRepair material

The invention belongs to the field of porcelain materials and preparation thereof, and in particular relates to a multilayer semitransparent zirconia full-porcelain dental repair material and a preparation method thereof. The material comprises the chemical ingredients such as magnesium oxide and part stable square-phase zirconia, wherein the molecular contents of the magnesium oxide and the zirconia are respectively 2-10% and 90-98%; the part stable square-phase zirconia is added with a modifying agent to be modified, wherein the molar ratio of the modifying agent and the part stable square-phase zirconia is 1: (0.01-0.1); and a coloring agent is added into the modified zirconia repair material, and the coloring agent and the modified zirconia repair material respectively account for 0.1-1% and 99-99.9%. The method comprises the following steps of power preparing, mixing and granulating, two-step forming, plastic discharging and sintering. Compared with the prior art, the material has the advantages of good producing technology repeatability, stable quality, reliable performance and convenience in production.

Owner:ZXTGY BEIJING TECH

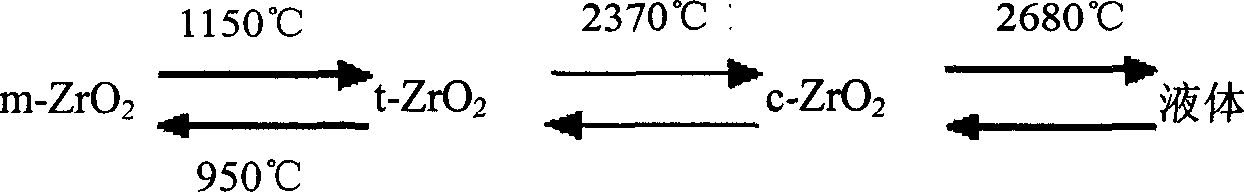

Zirconium oxide full-porcelain dental repair material and its preparing method

InactiveCN1813654AImprove molding qualityReduce the difficulty of operationImpression capsDentistry preparationsPolymer sciencePolyvinyl alcohol

The present invention belongs to a ceramic material and its preparation field. In the particular, it relates to a zirconia full-porcelain dental repairing material and its preparation method. Its raw material composition contains (by wt%) 86-92% of tetragonal-phase zirconia stabilized by 3.0-5.15% of yttrium oxide, 5-10% of flux and 3-4% of adhesive, in which the flux is one kind of boron-aluminum-silicon system glass, hydroxyapatite and beta-stellite or more than one kind of them, and the adhesive is one or more than one kind of polyvinyl alcohol, carboxyl methyl cellulose and polyacrylic acid. Its preparation method includes the following steps: mixing raw materials, garanulating, cold isostatic compaction, moulding and sintering.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Amorphous alloy powder core and nano-crystal alloy powder core having good high frequency properties and methods of manufacturing the same

InactiveUS20020124914A1High molding densityLow dependence on frequencyTransportation and packagingMetal-working apparatusOrganic solventRoom temperature

A method of manufacturing an amorphous alloy core including the steps of mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in liquid phase on the surface of the alloy powder to make a powder of composite particles, molding the power of composite particles, and performing a heating treatment thereon. This invention also discloses a method of manufacturing a nano-crystal alloy core including the steps of (a) mixing an amorphous alloy powder with a solution made by dissolving a polyimide / phenolic resin binder in an organic solvent, evenly coating the binder in the liquid phase on the surface of the alloy powder to make composite particles, molding the composite particles at room temperature, and performing a heating treatment thereon at a temperature higher than the crystallization starting temperature of the alloy; and (b) performing a heating treatment on an amorphous alloy powder at over a crystallization starting temperature to make a nano-crystal phase, mixing a solution made by solving a polyimide / phenolic resin binder in an organic solvent therewith, evenly coating the binder in liquid phase on the surface of the alloy powder to make composite particles, and molding the power of composite particles at 100 to 300° C.

Owner:KIM KYU JIN +3

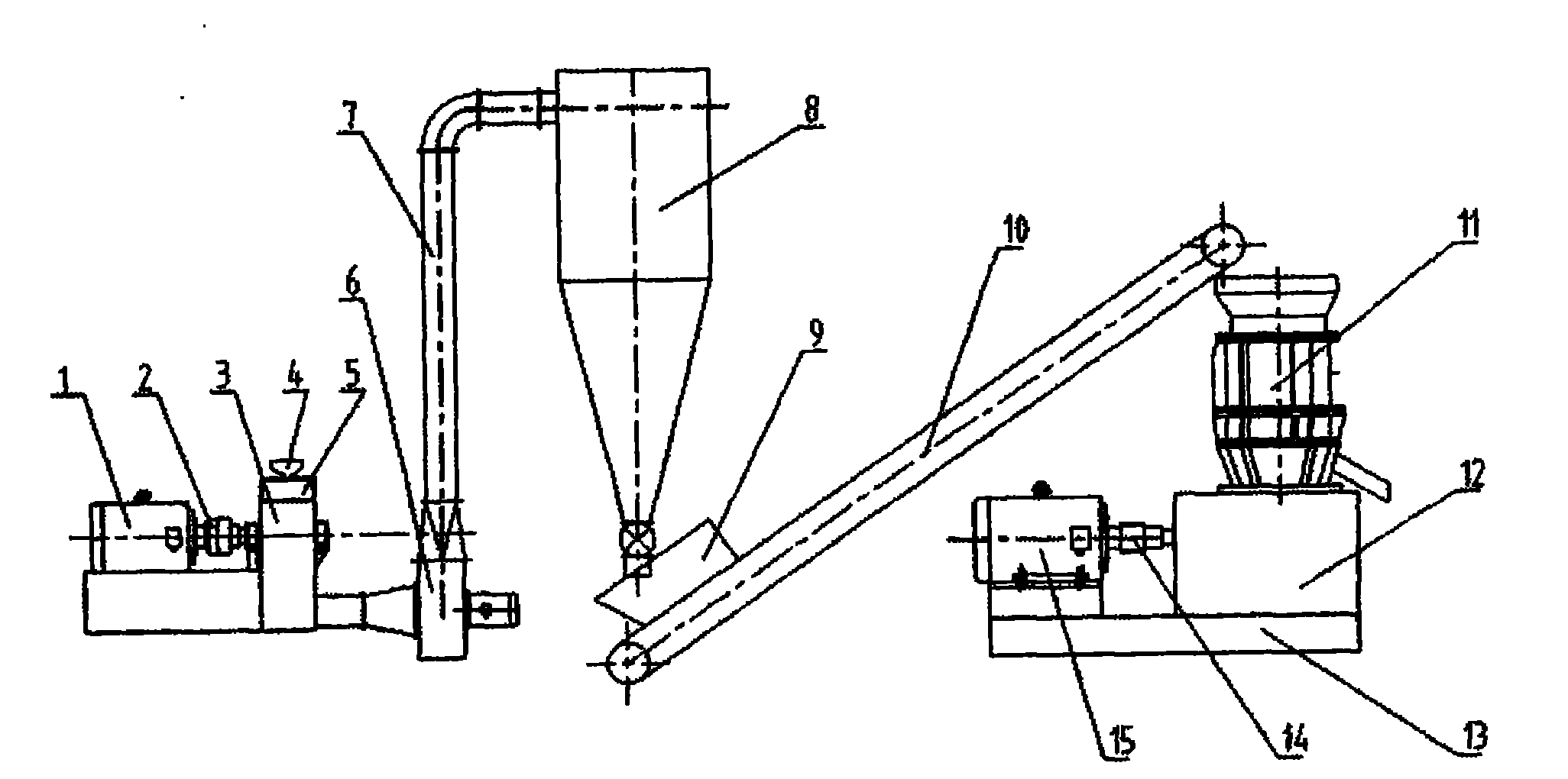

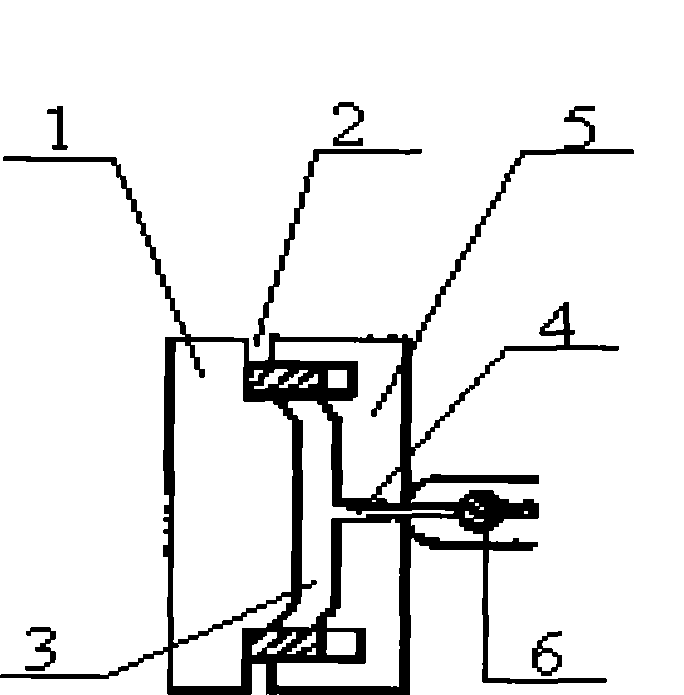

Biomass granulation system and device

ActiveCN101797490ACalorific value stableNo alkali corrosion problemBiofuelsSolid fuelsSlagEngineering

The invention discloses a biomass granulation system and a biomass granulation device. Biomass is delivered to a crusher to be crushed, the crushed biomass is pumped out through a blower and fed into a cyclone dust collector to perform gas-solid separation, and the separated material is made into granules through a biomass granulator; pulverized coal or diatomite can be added into the biomass delivered to the crusher; a temperature sensor is arranged in a molding cavity, the biomass granulator is driven by a variable frequency motor, and the rotating speed of the variable frequency motor is automatically adjusted through a monitored temperature signal; and a straight hole or a conical-straight composite through hole is formed on a flat die of the granulator. The biomass and the additive can be mixed while crushing, so the mixing uniformity of different materials is improved; the provided temperature sensor adjusts the rotating speed of the variable frequency motor and stabilizes the water content of the biomass molding granules; and the straight hole or the conical-straight composite through hole is formed on the flat die of the granulator, the molding time of the biomass granules is prolonged, the molding intensity is increased, and the slag dropping defect of the current granulator is overcome.

Owner:邢献军

Storage iron runner castable produced by adopting waste iron runner material

The invention discloses a storage iron runner castbale produced by adopting a waste iron runner material. The storage iron runner castable comprises the following components in parts by mass: 15-20 parts of waste iron runner material, 20-30 parts of brown fused alumina particles, 3-5 parts of brown fused alumina fine powder, 5-10 parts of electric smelting compact corundum particles, 2-5 parts of electric smelting compact corundum fine powder, 3-5 parts of magnesia-alumina spinel, 10-20 parts of silicon carbide, 2-5 parts of silicon powder, 1-2 parts of activated aluminum oxide micro powder, 4-6 parts of crystalline flake graphite, 0.5-1 part of a silane coupling agent, 3-8 parts of aluminate cement, 1-4 parts of a compound water reducer, 1-2 parts of a compound antidetonant, and 1-2 parts of an antioxidant. The storage iron runner castable makes full use of the waste material, thus greatly lowering comprehensive cost; due to the materials of the different particle sizes, the construction efficiency is improved; for the addition of the crystalline flake graphite and magnesia-alumina spinel powder, the molding density of the castable is improved, the castable is promoted in sintering, and the density, strength, volume stability and residue resistance of the castable are improved.

Owner:长兴煤山新型炉料有限公司

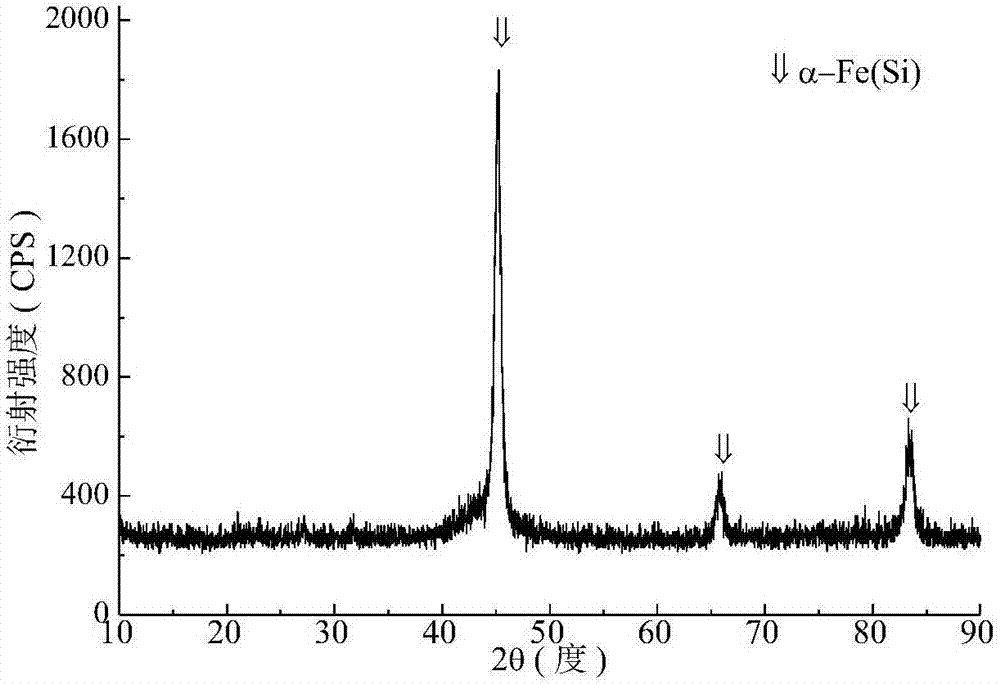

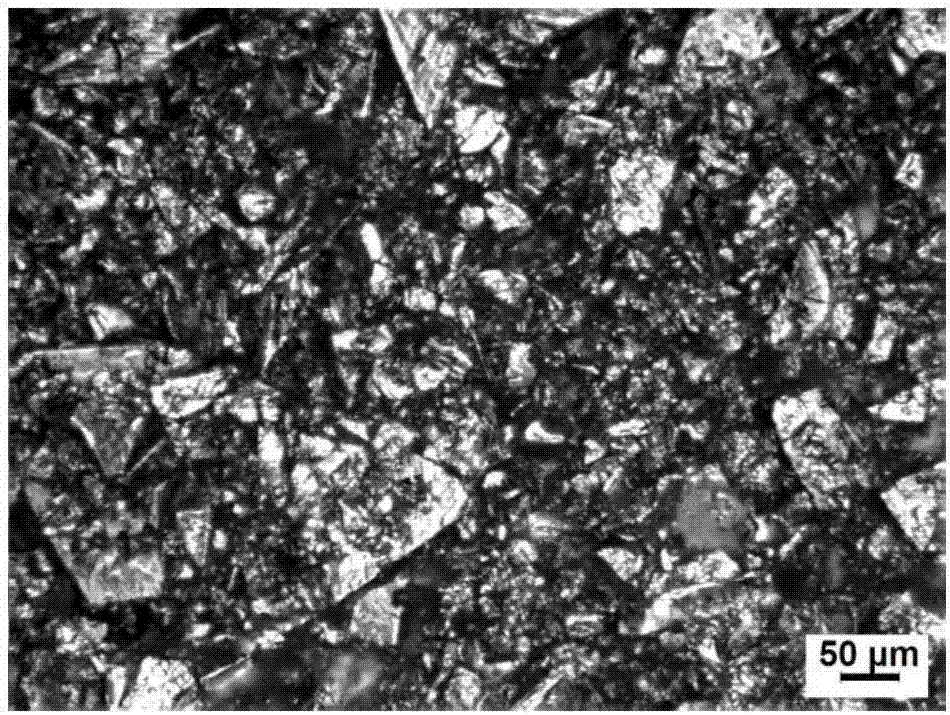

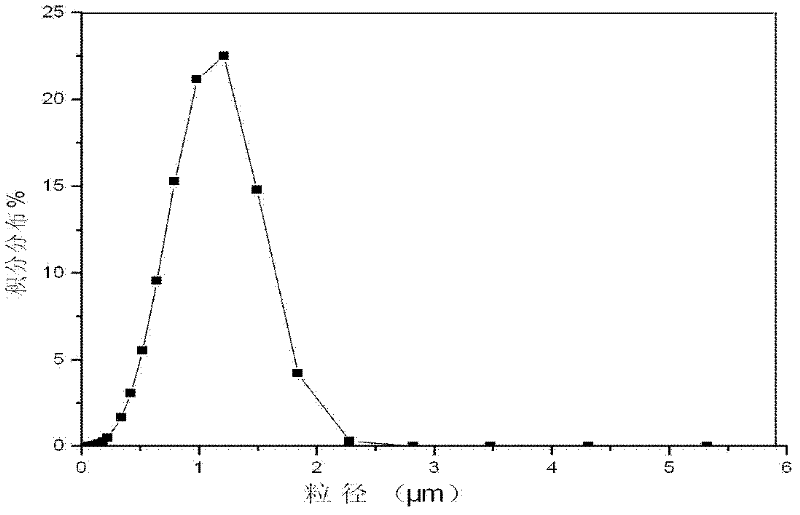

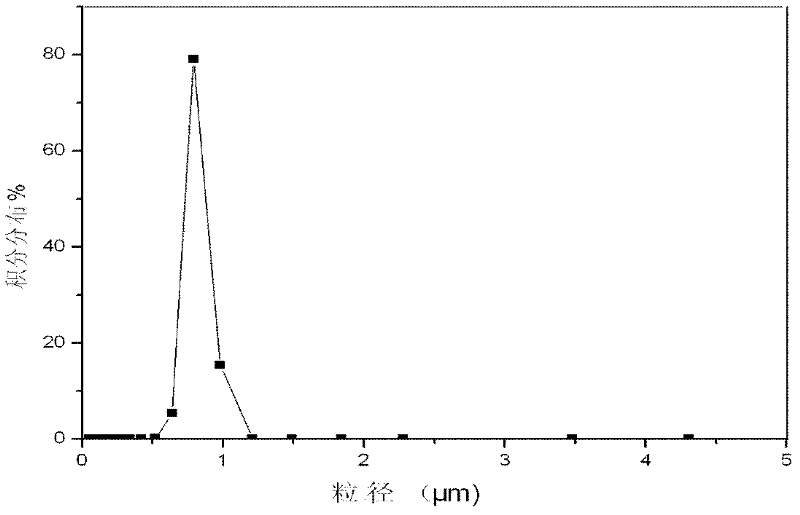

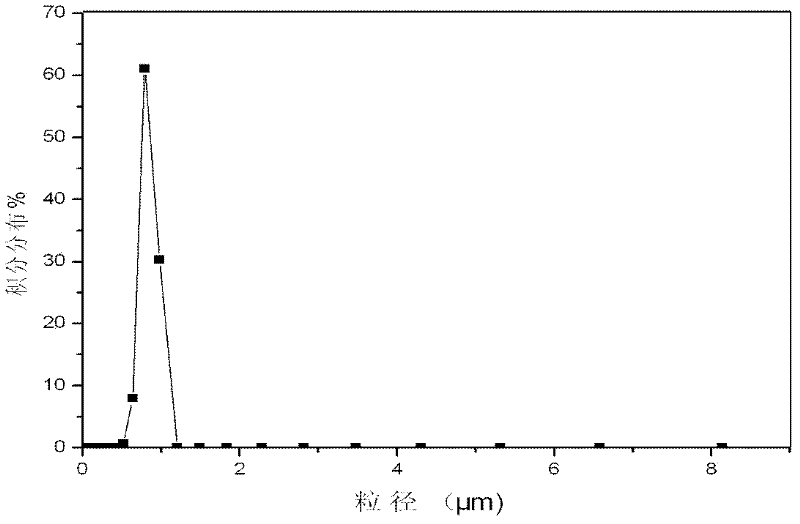

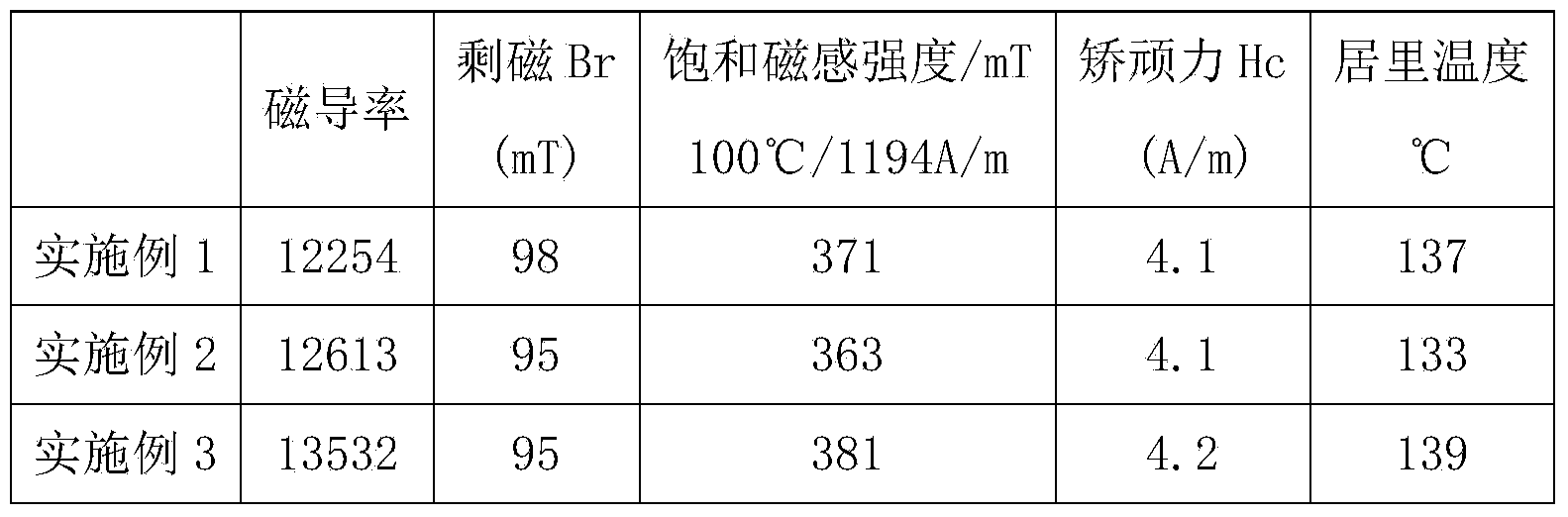

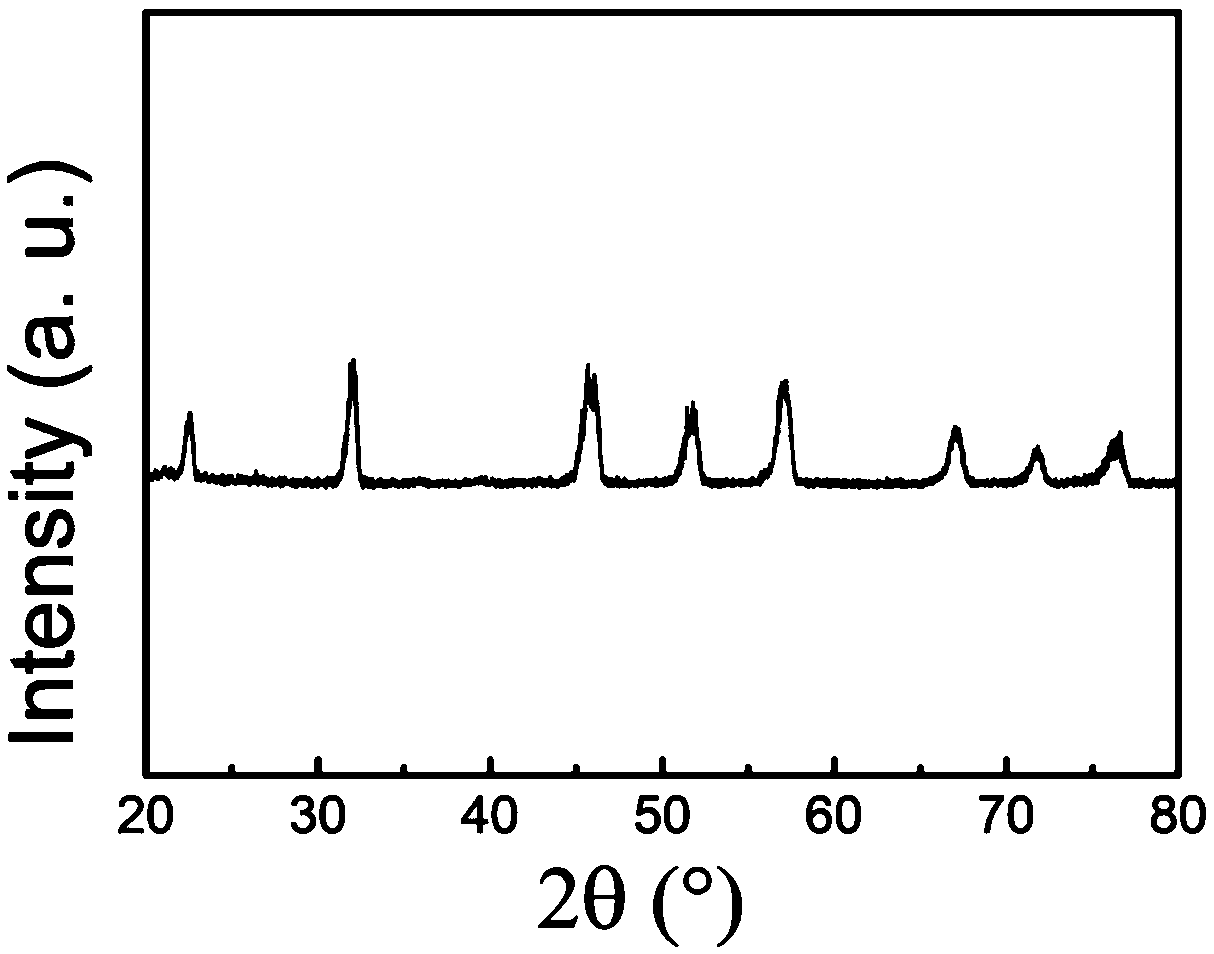

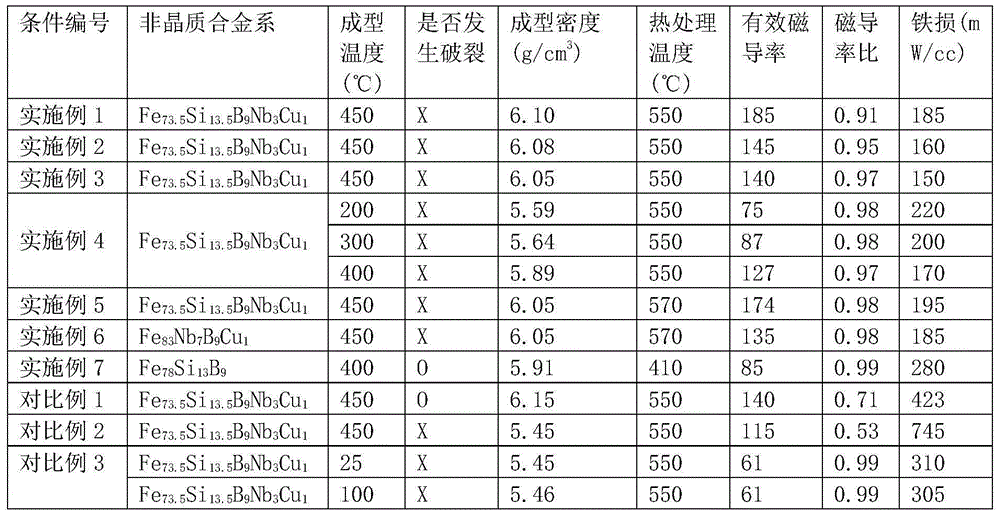

Preparation method of soft magnetic composite powder core

InactiveCN107170575AHigh mechanical strengthGive full play to the advantages of soft magnetic propertiesTransportation and packagingMetal-working apparatusMetallurgyMass ratio

The invention discloses a preparation method of a soft magnetic composite powder core, and relates to a magnet distinguished by the adopted magnetic materials. Amorphous nanocrystalline FeSiM<c>B<d>Cu<e> powder is taken as the main powder; the main powder and auxiliary powder which is formed by at least one of water atomized Fe powder, gas atomized FeNi<50> powder and gas atomized FeSi<3.5> powder are uniformly mixed based mass ratio; the mixed powder is processed by a passivation solution and an insulating agent to form a passivated and insulated thin film on the surface; and next, steps of pressing and shaping and annealing are performed to prepare the soft magnetic composite powder core with excellent comprehensive soft magnetic performance. By adoption of the preparation method, the defects of low saturation flux induction density, relatively high coercivity, high loss and reduction of effective magnetic conductivity under high frequency of the soft magnetic powder core prepared in the prior art can be overcome.

Owner:HEBEI UNIV OF TECH

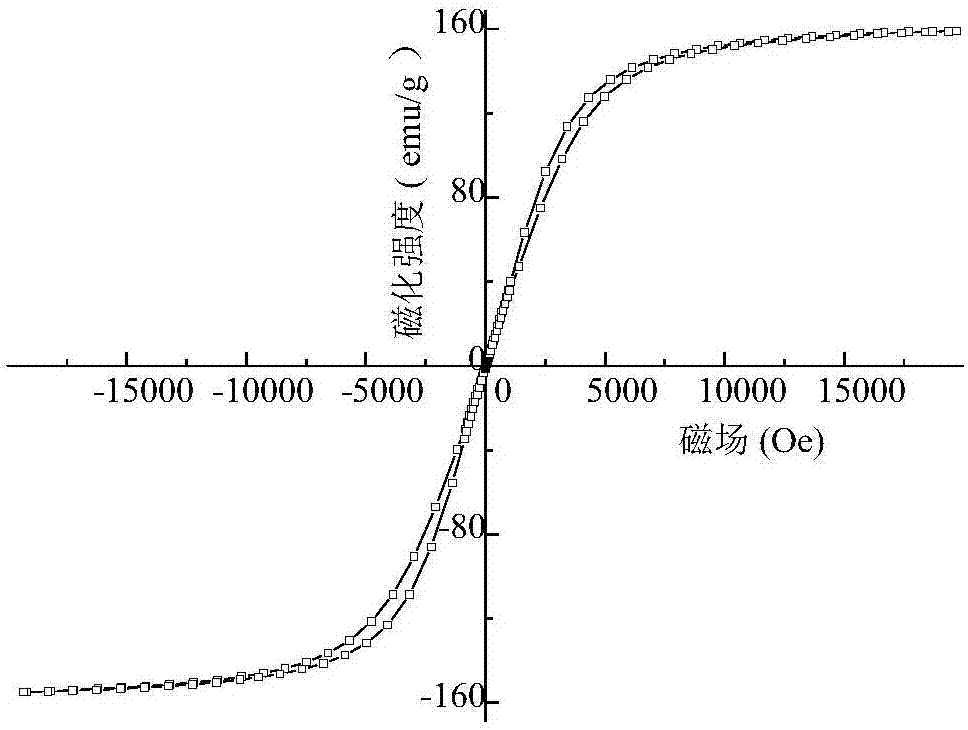

Method for preparing MnZn ferrite with adding silane coupling agent

The invention relates to a method for preparing MnZn ferrite with adding a silane coupling agent. The method comprises the following steps: 1, adding ferrite nanopowder to the silane coupling agent, and mixing with stirring, wherein the chemical formula of the ferrite nanopowder is Mn1-xZnxFe2O4, and x is equal to or more than 0.34 and equal to or less than 0.62; 2, adding an organic binder to the powder obtained in step 1, putting to a mortar, and uniformly mixing to obtain powder; 3, preparing an annular biscuit by carrying out dry press molding on the powder obtained in step 2 at 200MPa; and 4, and sintering to obtain products. According to the invention, the microstructure of the MnZn ferrite is improved, the density and the magnetic property of the MnZn ferrite are improved, the density of a sintered body (the MnZn ferrite) is 4.83g / cm<3>, the saturated magnetic induction intension Ms of the sintered body is 92.18emu / g, and the residual magnetization Mr of the sintered body is 10.68emu / g, and the coercive force Hc is 60.650e; in addition, a doping link in the molding process is omitted, so the molding process is simplified, and resources are saved.

Owner:HEBEI UNIV OF TECH

Method for Producing Composite Soft Magnetic Material Exhibiting Excellent Magnetic Characteristics, High Strength and Low Core Loss

InactiveUS20070243400A1Increasing amount of softHigh strengthMetal-working apparatusInorganic material magnetismRoom temperatureMagnetic characteristic

A method of manufacturing a composite soft magnetic material having excellent magnetic characteristics, a high strength, and a low core loss, having steps of: heating a silicon resin film-coated soft magnetic powder at a temperature of from the room temperature to 150° C. obtained by forming a thin silicon resin film having a thickness of from 0.1 μm to 5 μm on a surface of a soft magnetic powder or an insulating film-coated soft magnetic powder; filling the silicon resin film-coated soft magnetic powder at a temperature of from the room temperature to 150° C. in a mold which is heated at a temperature of from 100° C. to 150° C. and performing compaction at a pressure of from 600 MPa to 1500 MPa, thereby obtaining a compact; and curing the compact at a temperature of from 400° C. to 600° C.

Owner:MITSUBISHI MATERIALS PMG CORP

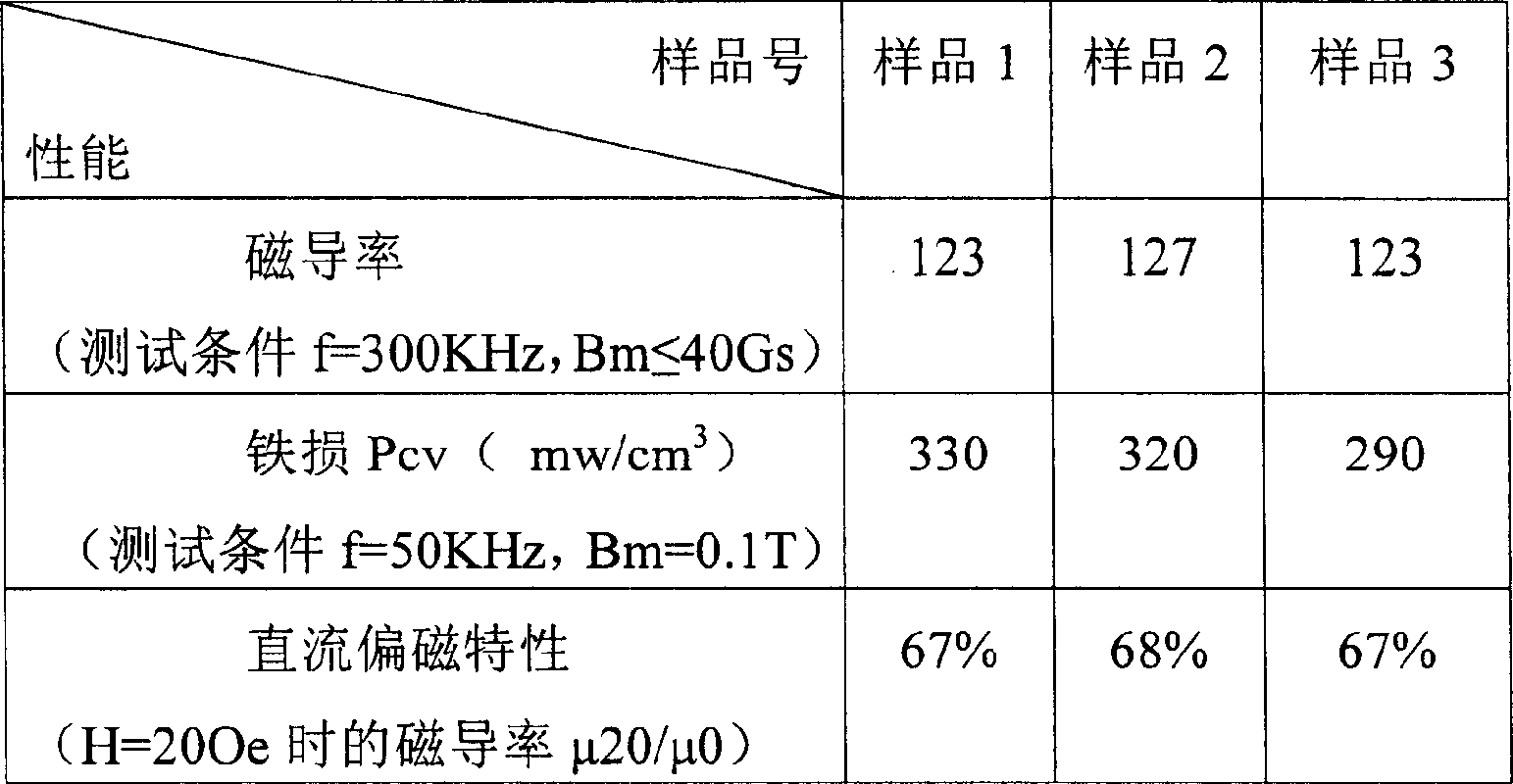

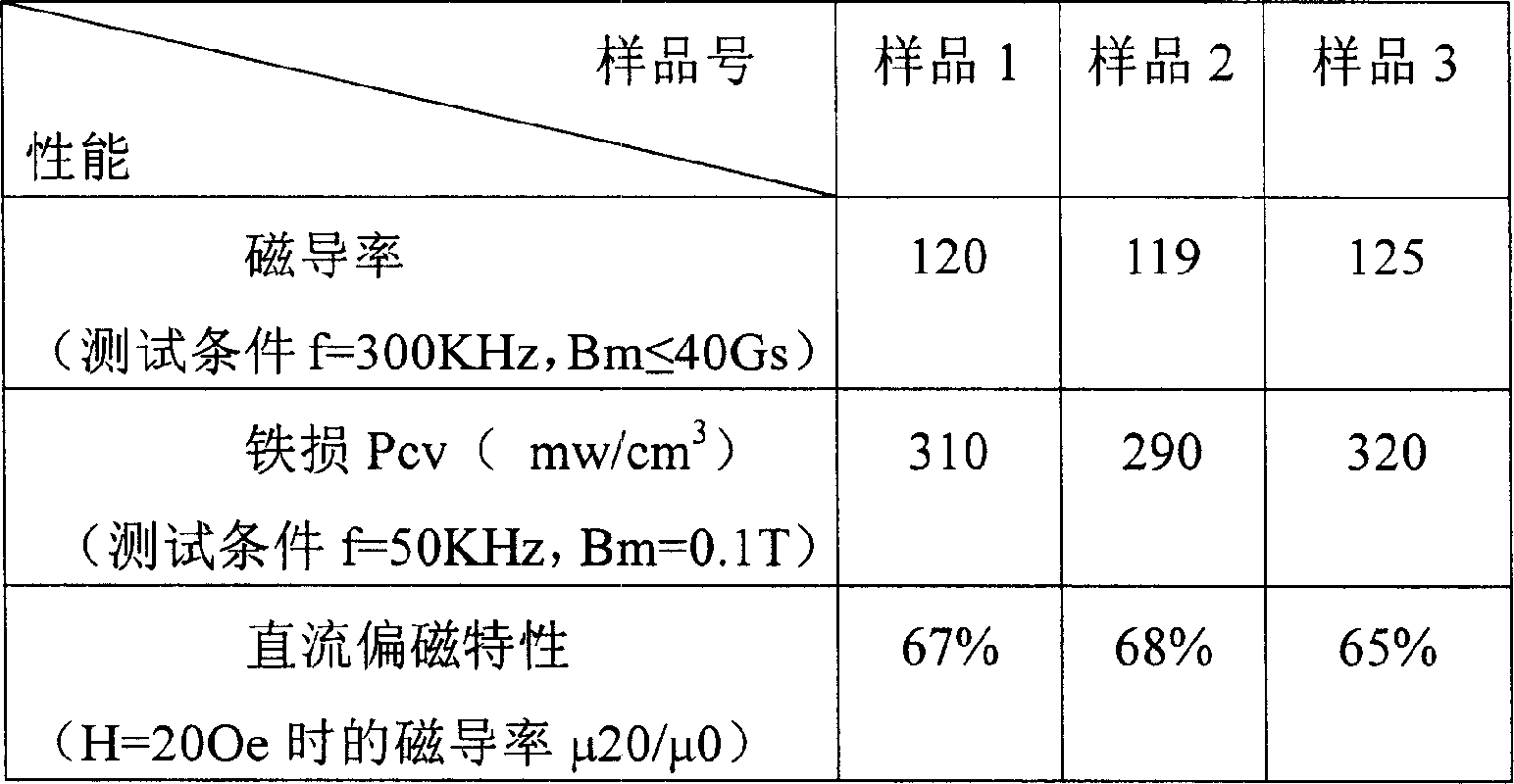

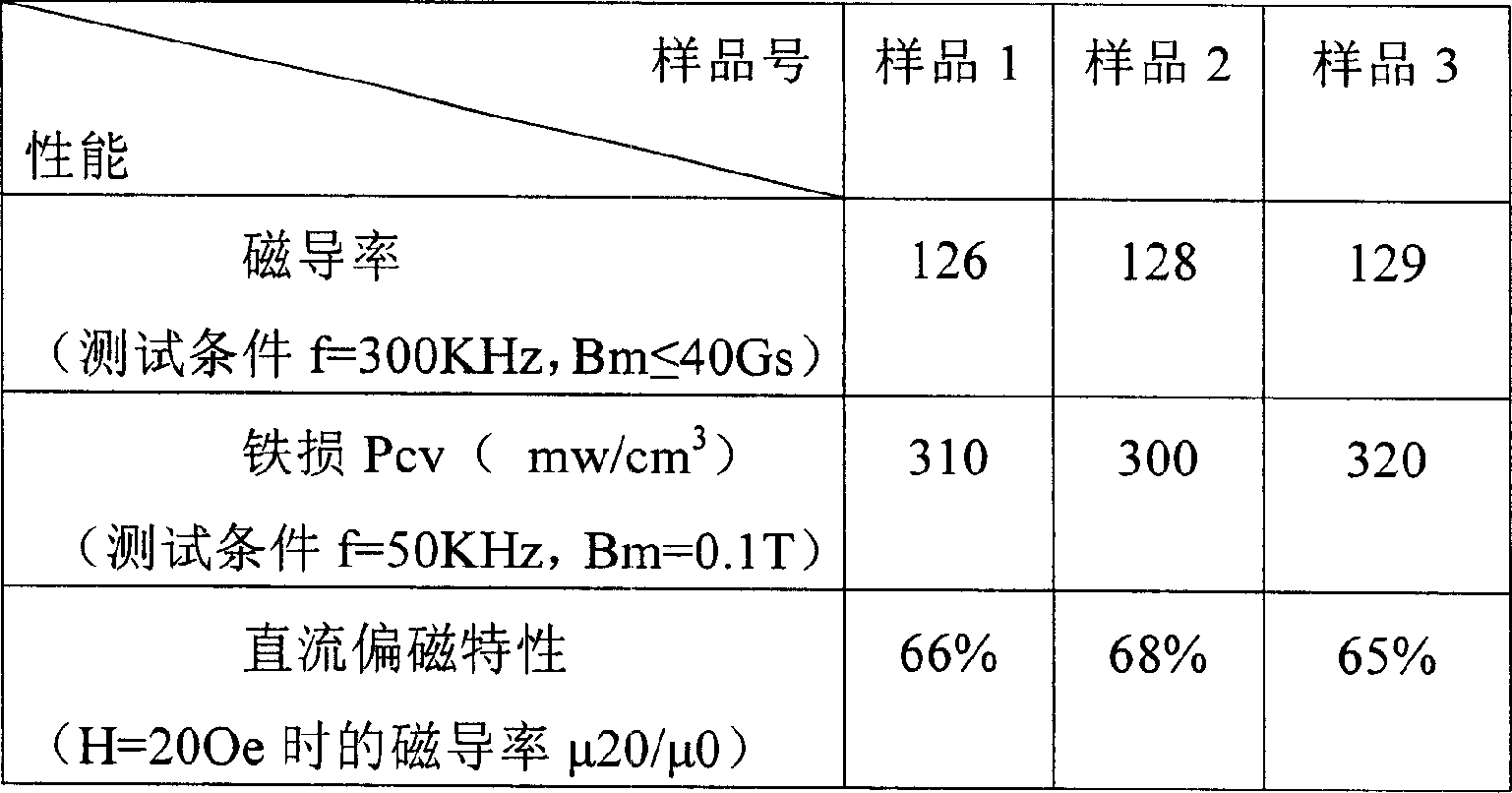

FeSiAl material magnetic core and producing method thereof

ActiveCN1812009AEasy to pressHigh molding densityInorganic material magnetismInductances/transformers/magnets manufactureIngotLubricant

This invention relates to a magnetic core of a FeSiAl material, in which, when the bias property is at H=200e, the magnetic conductivity is mum20 greater or equal to 65% mum0, Ferro loss Pcv at f=50KHz, Bm=0.1T and Pcv is less than or equal to 350mw / cm3, the magnetic conductivity of the material is 125. The preparation method includes: A, applying an ordinary method to smelt FeSiAl alloy board ingot of 0.001-120mm thick to crush it to powder, B, annealing the FeSiAL powder in step A, C, adding insulation agent, bonder and lubricant agent into the alloy powder, in which, the added insulation agent is 0.1-0.8%, the bonder is 0.1-1% and the lubricant agent is 0.1-1% of that of the FeSIAl powder, D, pressing the product in step C to formation to be annealed to get the target.

Owner:北京七星飞行电子有限公司

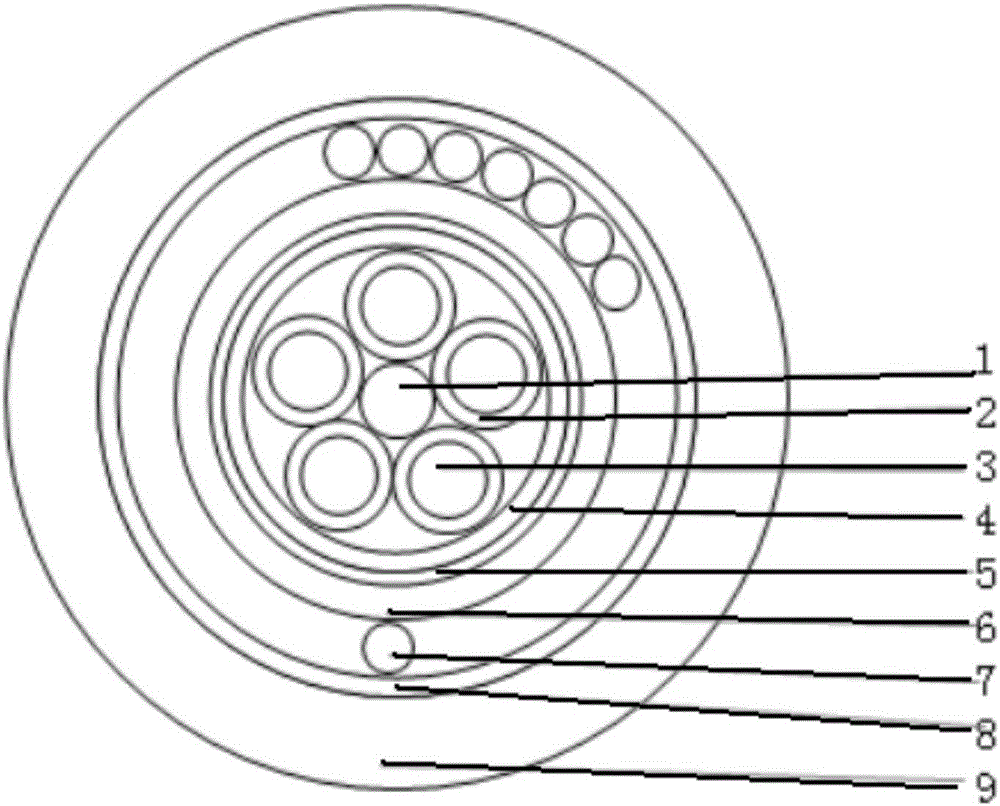

High-grade flame-retardant fireproof optical cable

ActiveCN106125216AHigh viscosityGood compatibilityClimate change adaptationFibre mechanical structuresFiberLow smoke zero halogen

The invention discloses a high-grade flame-retardant fireproof optical cable. The high-grade flame-retardant fireproof optical cable comprises a layer stranded type cable core, the layer stranded type cable core is wrapped by a double-face synthetic mica tape layer, the double-face synthetic mica tape layer is wrapped by a steel plastic composite band layer, the steel plastic composite band layer is externally plastically extruded by a low-smoke halogen-free inner sheath, the low-smoke halogen-free inner sheath is externally provided with at least one armored layer, the armored layer is externally provided with a fireproof layer and a low-smoke halogen oversheath, the low-smoke halogen-free inner sheath and the low-smoke halogen-free oversheath are both prepared by low-smoke halogen-free ceramic polyolefin, and the low-smoke halogen-free ceramic polyolefin comprises 60-70% of matrix polyolefin and 30-40% of an auxiliary agent, wherein the auxiliary agent comprises a plasticizer, white carbon black, 3% of micro-encapsulated red phosphorus, siloxane, 15-28% of a gas-phase fire retardant and 5-7% of a special fire retardant. The ceramic polyolefin is a halogen-free high-oxygen index sheath material and is easily ceramic during high-temperature combustion to form a compact protection layer so as to obstruct flames and heat transfer and accordingly prevent fibers from high-temperature damage.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Low-cost manufacture method of high-quality diaphragm and filter plate

InactiveCN101417498AHigh molding densityExtended service lifeDomestic articlesThermoplasticMolten state

The invention relates to a manufacture method of a diaphragm or a filter plate, with low cost and high precision. When a larger die cavity space is left between an upper die and a lower die used for manufacturing the diaphragm or the filter plate, plastics in molten state in an infection machine charging barrel is quantitatively injected into the large die cavity formed by the upper die and the lower die of the die cavity under low pressure through the flow passage in the upper die or the lower die. Then, the periphery of the upper die and the lower die are treated with complete die-closing in closed state under the action of external force, and after the diaphragm or the filter plate in the die cavity is cooled down, the die is opened and the diaphragm or the filter plate is taken out. The method has the advantages that not only the plasticized plastics in the plastic diaphragm cavity are homogeneously extruded to every part of the cavity to be shaped, but also the low-pressure injection molding of the plastics diaphragm is realized and the demand for the mold locking tonnage of a press is reduced, therefore, resource waste and energy consumption are avoided. The method can be suitable not only for thermoplastics and thermosetting plastics, but also for plastic alloy, blending material, recycled thermoplastics, and the like, therefore, the regeneration and reutilization of the resources can be realized.

Owner:朱兴源

Method for preparing active carbon for super-capacitor from potassium humate in one-step carbonization way

InactiveCN103373728AHigh molding densityIncrease in sizeCarbon compoundsElectrolytic agentCapacitance

The invention provides a method for preparing active carbon for a super-capacitor from potassium humate in a one-step carbonization way. The method comprises the following steps of placing the potassium humate in a reaction kettle, heating the reaction kettle to 180 DEG C at a heating rate of 5 to 20 DEG C per minute under the protection of nitrogen, dehydrating for 0.5h at the constant temperature, then heating the reaction kettle to 600 to 900 DEG C, carbonizing the potassium humate for 0.5h to 3h at the constant temperature, naturally cooling to the room temperature under the protection of nitrogen after the carbonization is ended, sequentially acid-dipping and washing a carbonized product till the product is neutral, and filtering and drying the neutral product to obtain the active carbon for the super-capacitor. The active carbon for the super-capacitor has medium specific surface area (ranging from 80 to 500 m<2> / g), high forming density (ranging from 0.76 to 0.93 g / cm<3>) and high volumetric specific capacitance which can reach 100 to 150 F / cm<3> when the active carbon is in 3mol / L KOH electrolyte, and the active carbon is particularly applicable to the high-energy super-capacitor with limited space.

Owner:HENAN POLYTECHNIC UNIV

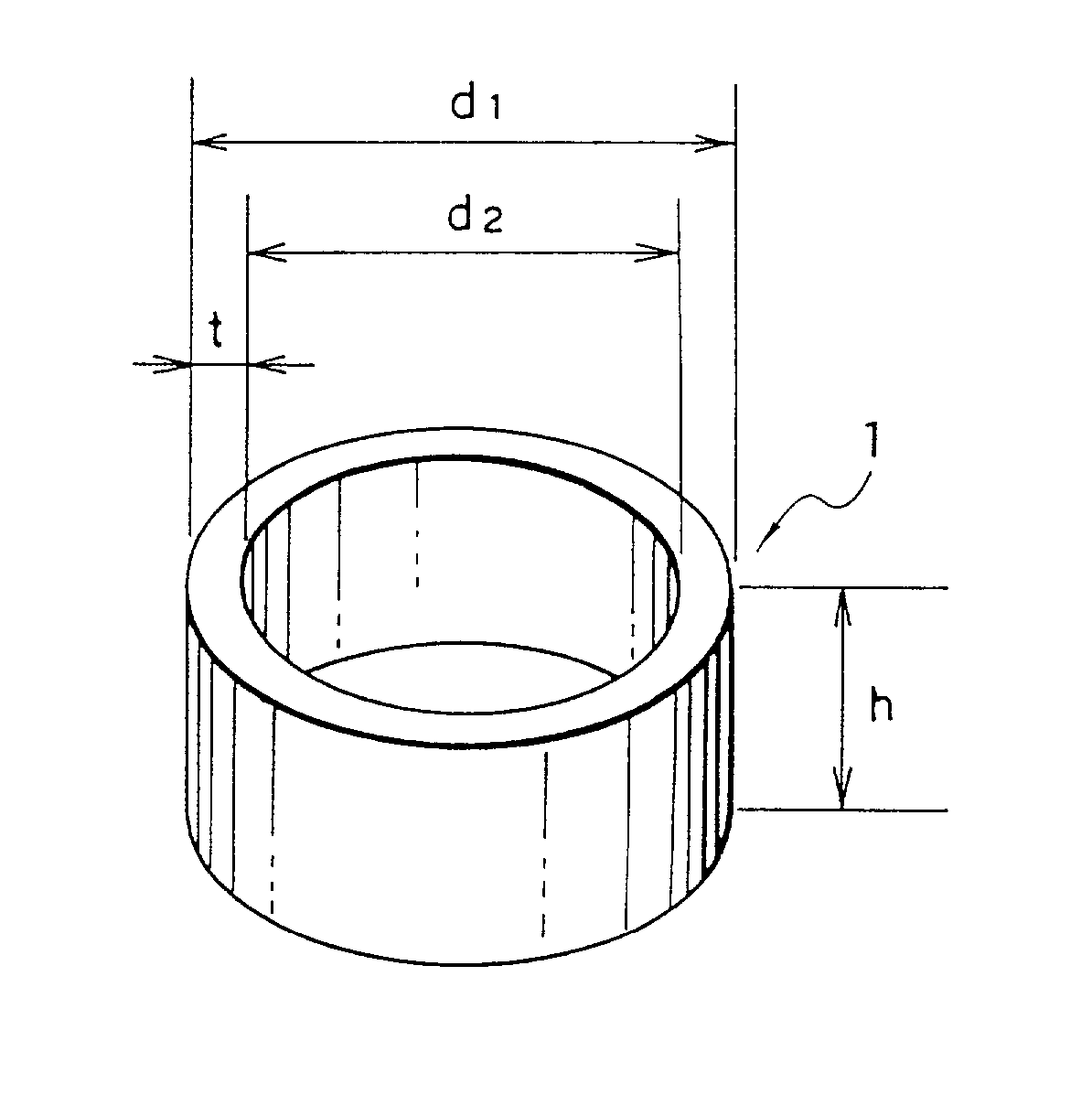

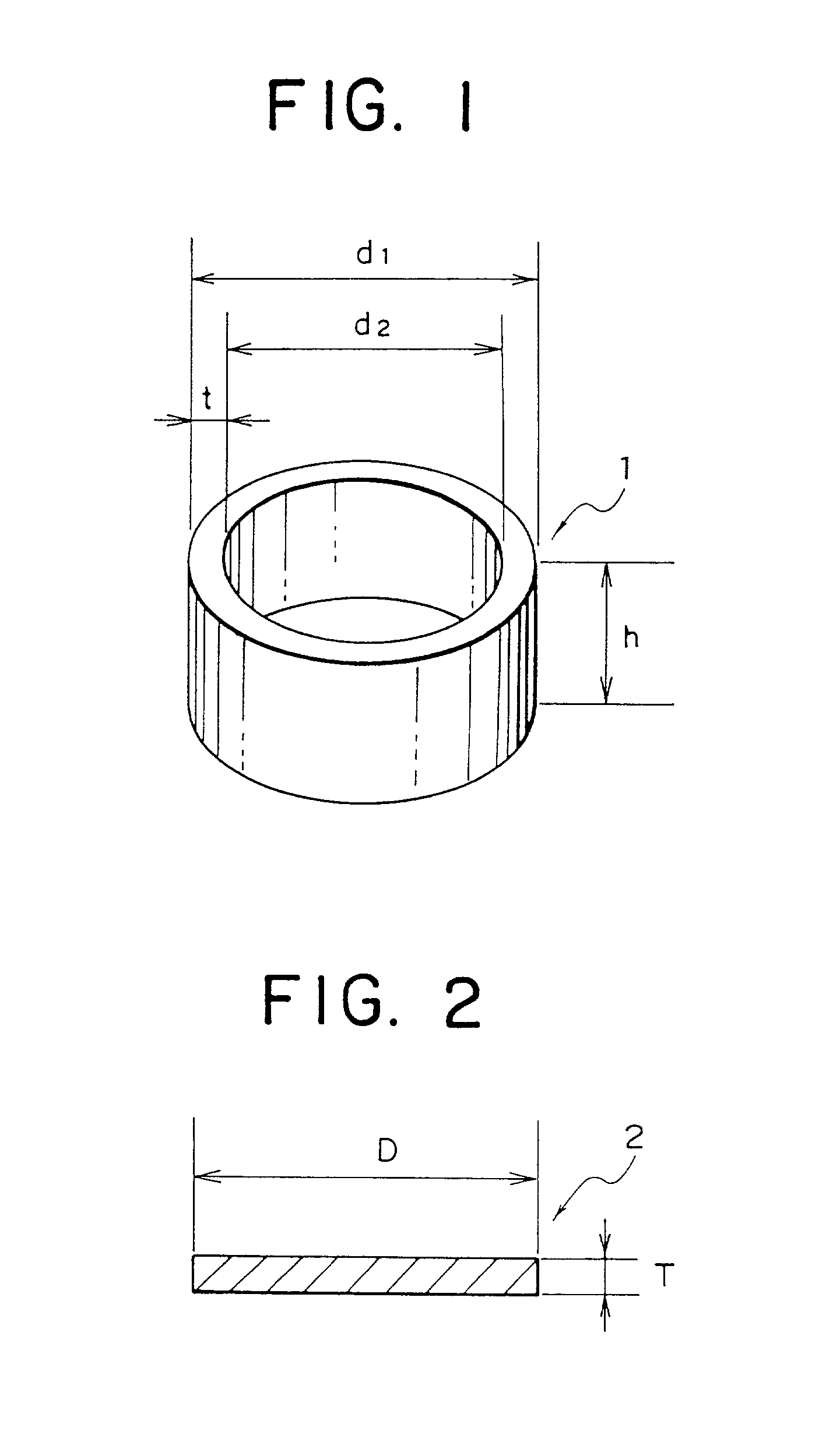

Bond magnet and manufacturing method thereof, and actuator therewith

InactiveUS20020036558A1High molding densityHigh densityNanotechDriving/moving recording headsCompression moldingRare-earth element

A bond magnet comprises a molded body in which a mixture of flake of magnet material comprising rare earth element-iron-nitrogen as main component, TbCu7 type crystal phase as a principal phase and a thickness of less than 200 mum a binder is compression molded. A compression molded body constituting a bond magnet has a density of 6x103 kg / m3 or more. In the step of compression molding a mixture of magnet material and binder, pressure is applied a plurality of times, or pressure is applied while rotating a punch and die, or the binder is cured while applying pressure to obtain such a bond magnet with good reproducibility. Such a bond magnet has excellent magnetic properties and corrosion resistance.

Owner:KK TOSHIBA

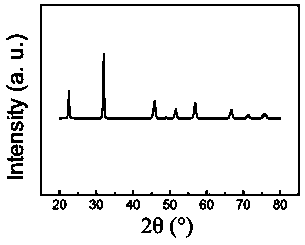

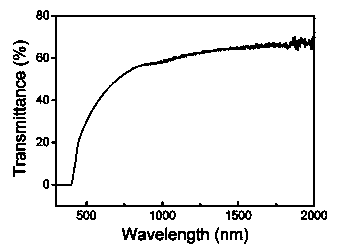

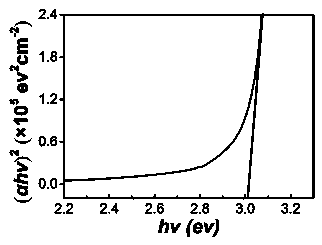

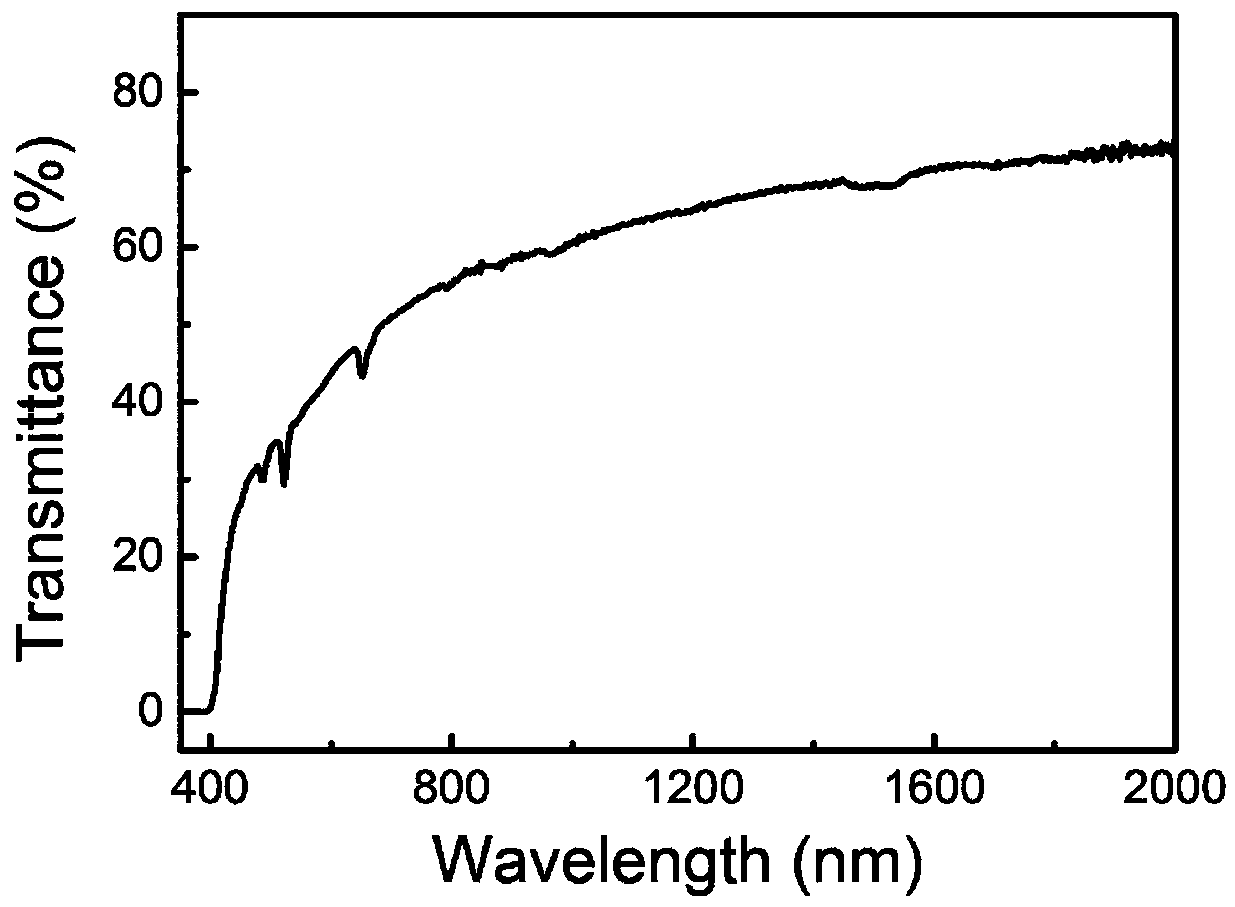

Preparation method of high-transparency potassium sodium niobate-barium strontium titanate transparent ceramic

The invention discloses a preparation method of high-transparency potassium sodium niobate-barium strontium titanate transparent ceramic. The preparation method includes the steps of preparing (K0.5Na0.5)NbO3-xBaSrTiO3 powder, pelleting the powder through dry pressing and molding, and performing sintering at the temperature of 1,200-1,230 DEG C to obtain the potassium sodium niobate-barium strontium titanate transparent ceramic, wherein the potassium sodium niobate-barium strontium titanate transparent ceramic has fine grains, a compact structure, high light transmittance (up to 61% in a near-infrared region) and high electrical property (the relative dielectric constant being 1,370-1,501), and the optical energy band gap is about 3.01 eV. Compared with monocrystal materials, the high-transparency potassium sodium niobate-barium strontium titanate transparent ceramic has the advantages of simple preparation process, low cost, and practical application prospect in manufacture of photoelectric devices.

Owner:FUZHOU UNIVERSITY

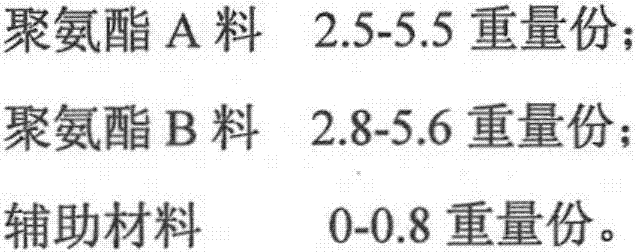

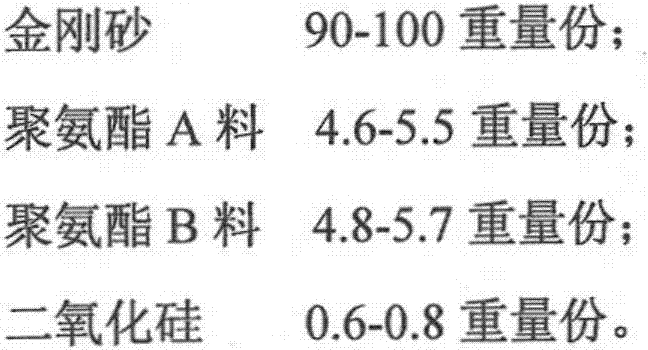

Polyurethane grinding wheel

InactiveCN106938446ALower sintering temperatureHigh energyAbrasion apparatusGrinding devicesMixed materialsGrinding wheel

The invention discloses a polyurethane grinding wheel and a production process thereof. According to the polyurethane grinding wheel, abrasive materials in raw materials are carborundum, and polyurethane is adopted as a binding agent; and the polyurethane comprises a polyurethane material A and a polyurethane material B. The production process includes the steps that material mixing is firstly carried out, wherein the carborundum and the polyurethane material A are put into a material mixing machine to be mixed, and the polyurethane material B and auxiliary materials are sequentially added to be evenly mixed; then a mixed material is screened to be placed into a die to be subject to pressing molding; and finally, a green body is sintered for 8 h to 24 h at the temperature ranging from 125 DEG C to 165 DEG C, and is cooled to be discharged out of a furnace. According to the production process, the polyurethane serves as the binding agent to produce the grinding wheel, the auxiliary materials in an existing grinding wheel recipe can be applied to the method according to the production requirement, and the manufactured grinding wheel has the beneficial effects that the sintering temperature is low, saved energy resources are many, pollution is avoided, the molding density is large, the grinding wheel balance is good, the rotating speed is high, the grinding performance is high, and the production period is short, and the quality of products in the machine tool industry, the bearing industry, the bent axle industry, the engine industry and the steel rolling industry is improved.

Owner:龙口东润砂轮有限公司

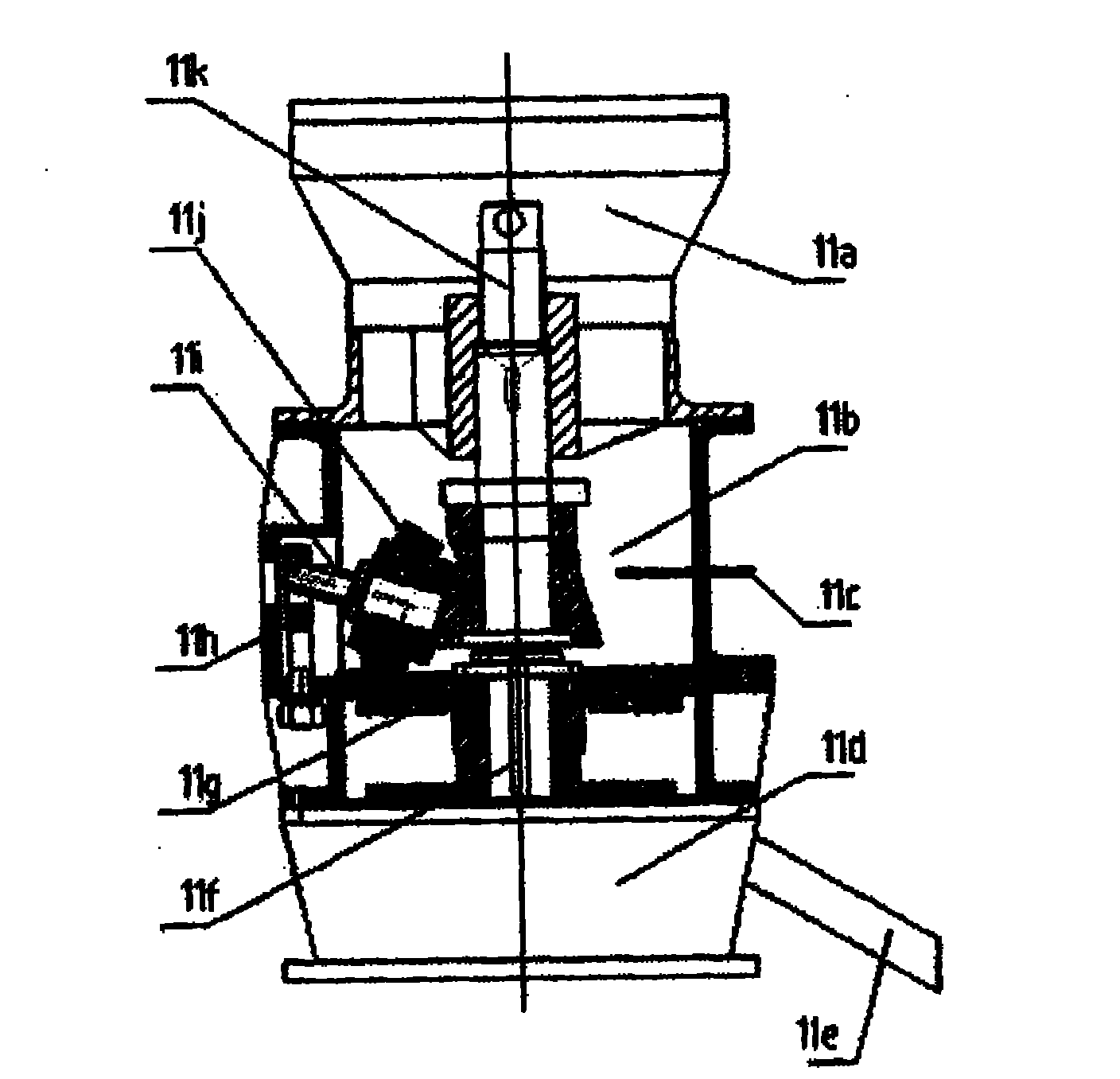

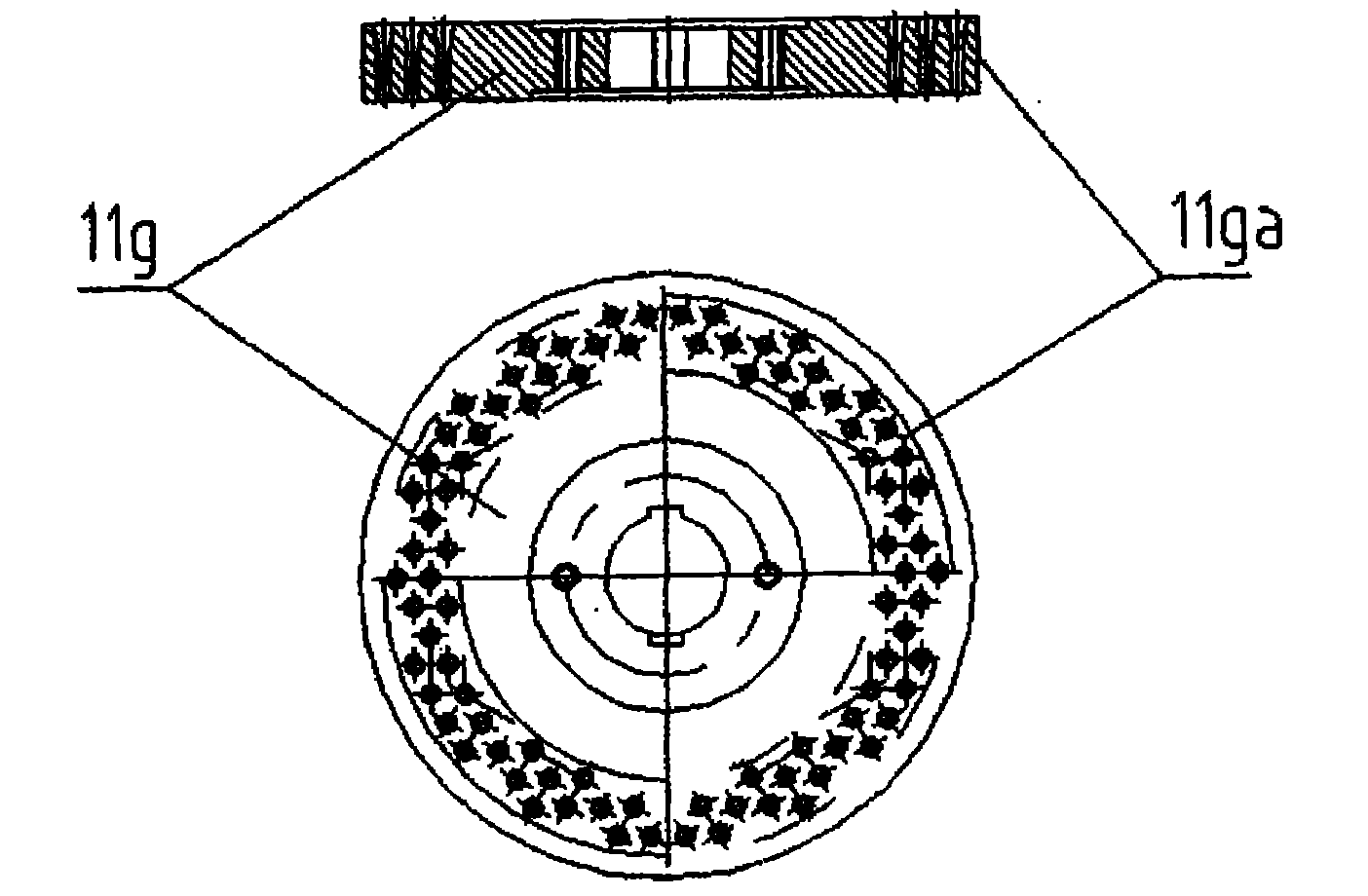

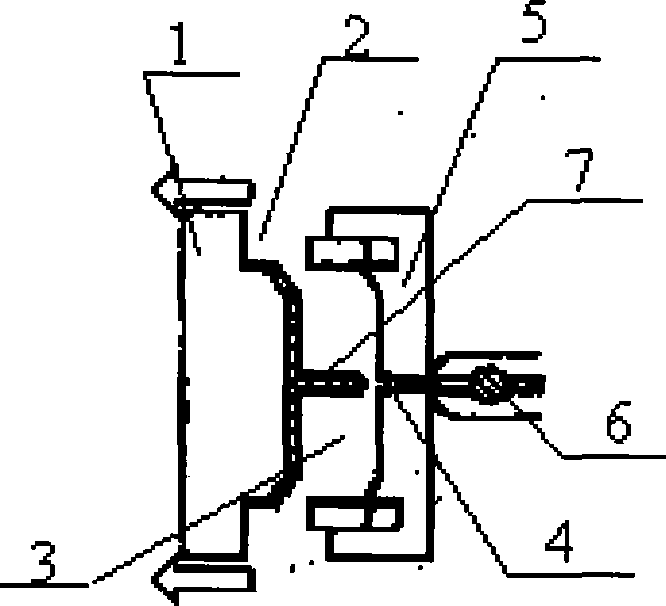

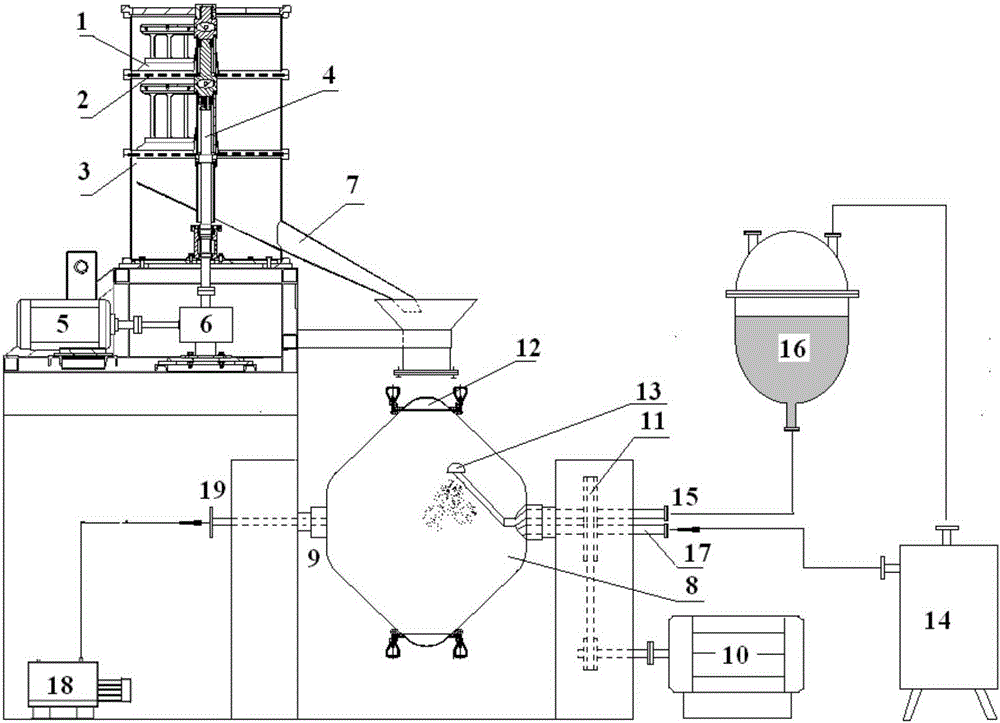

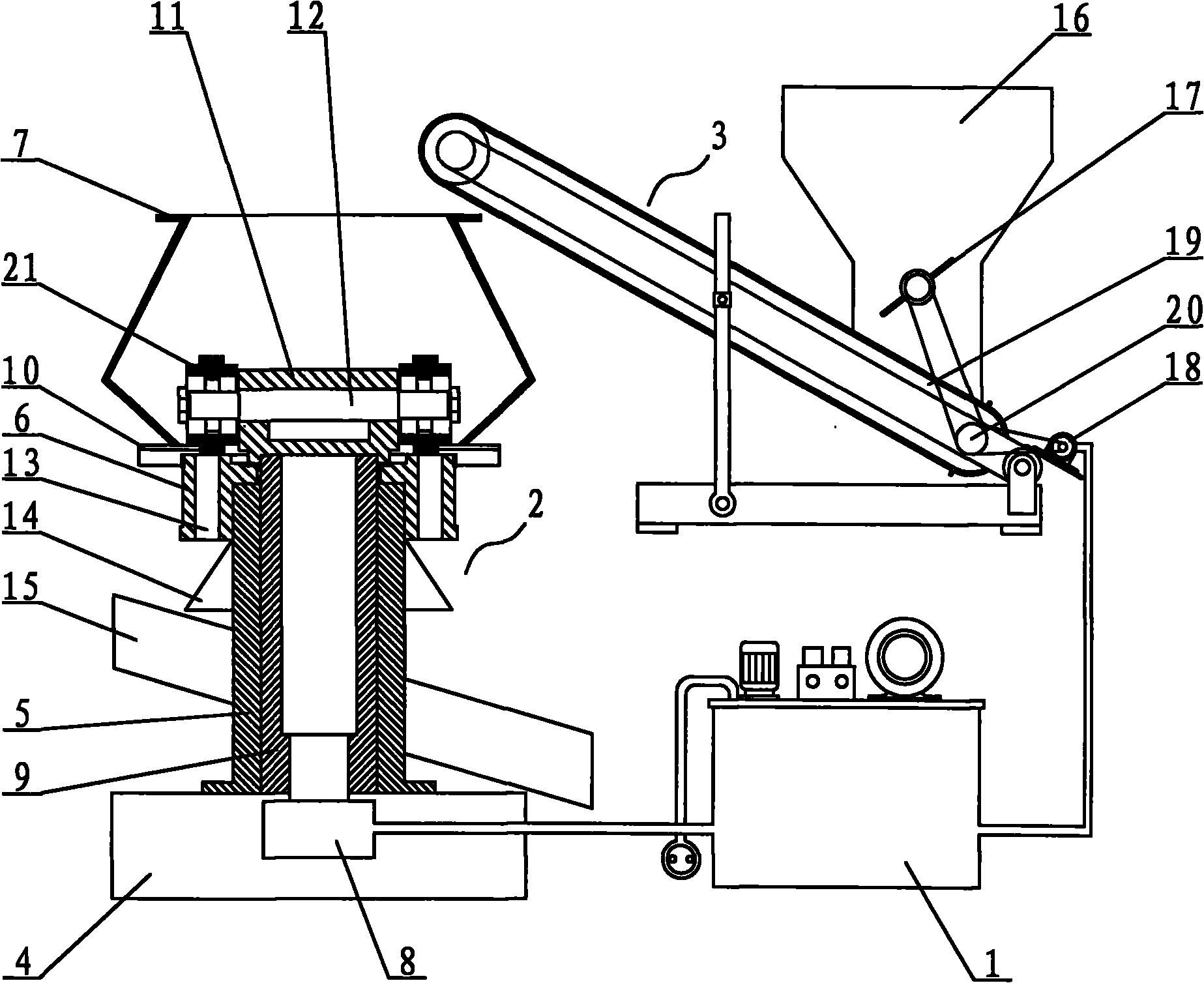

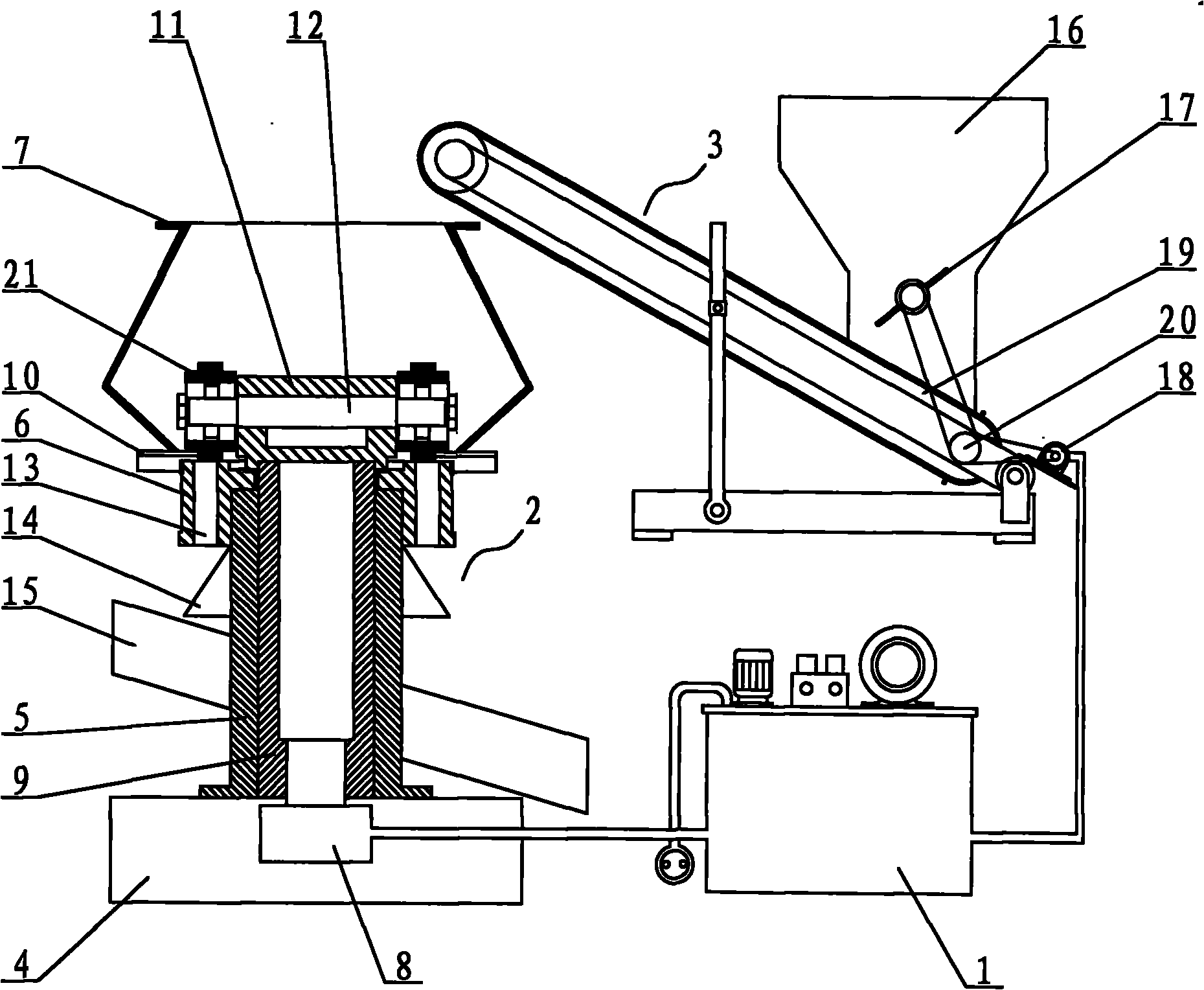

Explosive molding powder atomizing granulating spheroidizing apparatus

ActiveCN105218279AHigh bulk densityImprove fluidityChemical industryExplosive working-up apparatusAir compressionVolumetric Mass Density

The invention provides an explosive molding powder atomizing granulating spheroidizing apparatus. The explosive molding powder atomizing granulating spheroidizing apparatus comprises a primary sieve granulating part and an atomizing spheroidizing part, wherein the primary sieve granulating part comprises a double-layer scraper plate (1), a primary granulating net (2), a secondary granulating net (3), a spline main shaft (4), an explosion-proof frequency-variable motor (5), a reducer (6) and a discharging groove (7), the atomizing spheroidizing part comprises a spheroidizing device (8), a spheroidizing device rotating shaft (9), an electromotor (10), a belt pulley (11), a feeding-discharging opening cover (12), a solvent spray head (13), an air compression station (14), a glue solution tank (16) and a vacuum pump (18). The explosive molding powder atomizing granulating spheroidizing apparatus is suitable for aluminum-containing explosive, and particularly suitable for granulating and spheroidizing forming the JHOL-1 explosive. The JHOL-1 explosive molding powder prepared by adopting the explosive molding powder atomizing granulating spheroidizing apparatus is in a compact spherical shape, high in accumulation density and good in mobility.

Owner:XIAN MODERN CHEM RES INST

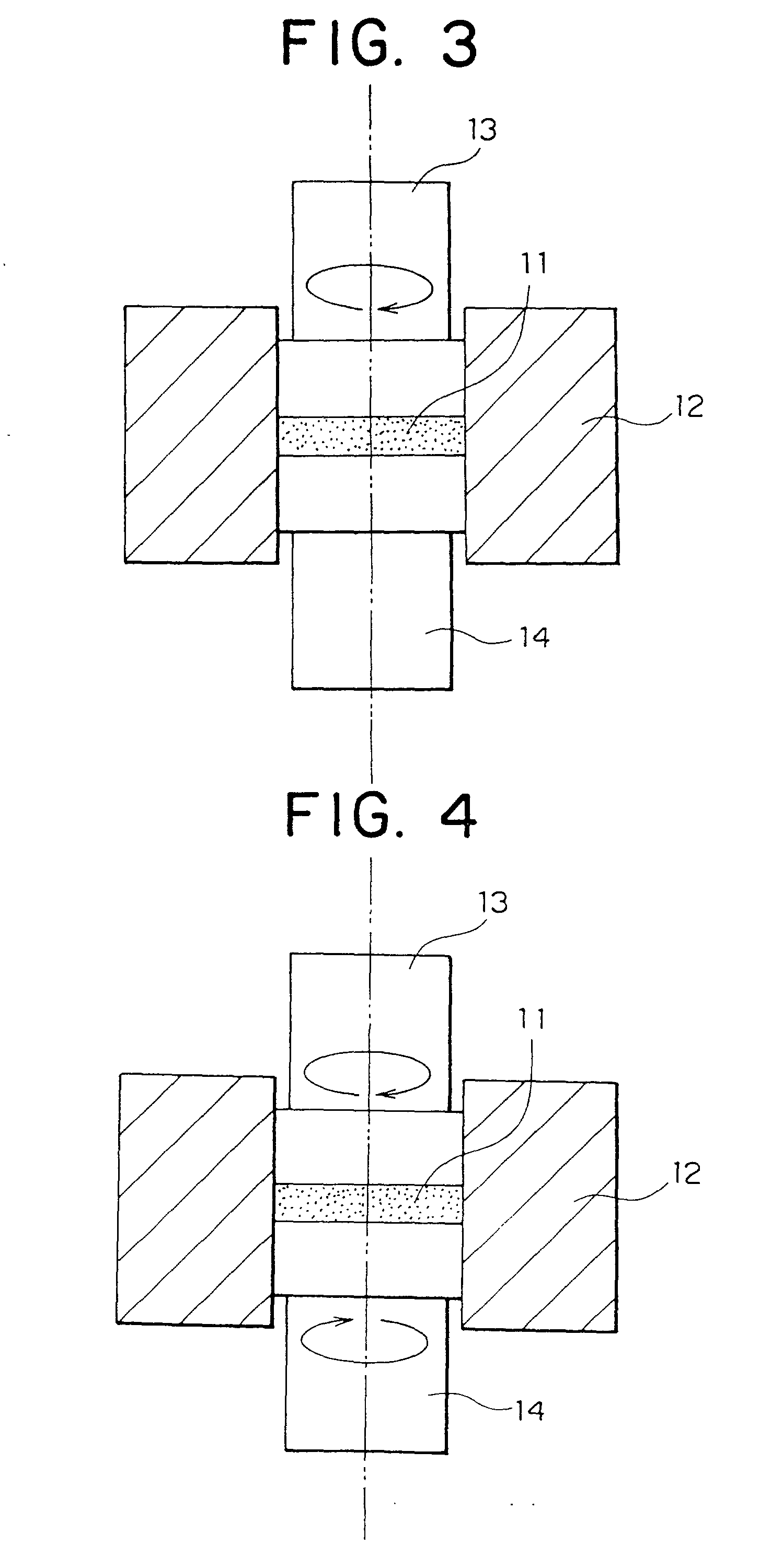

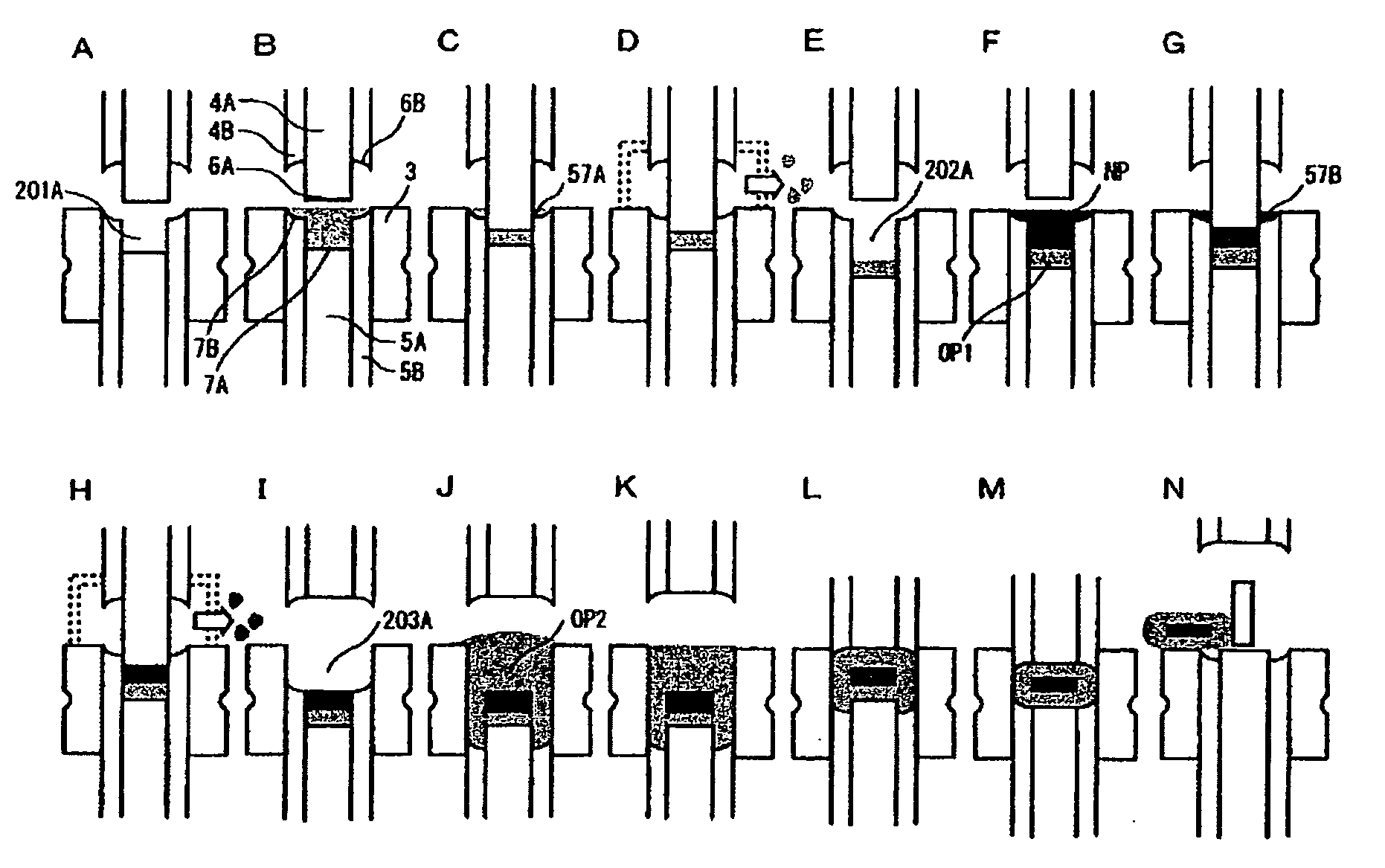

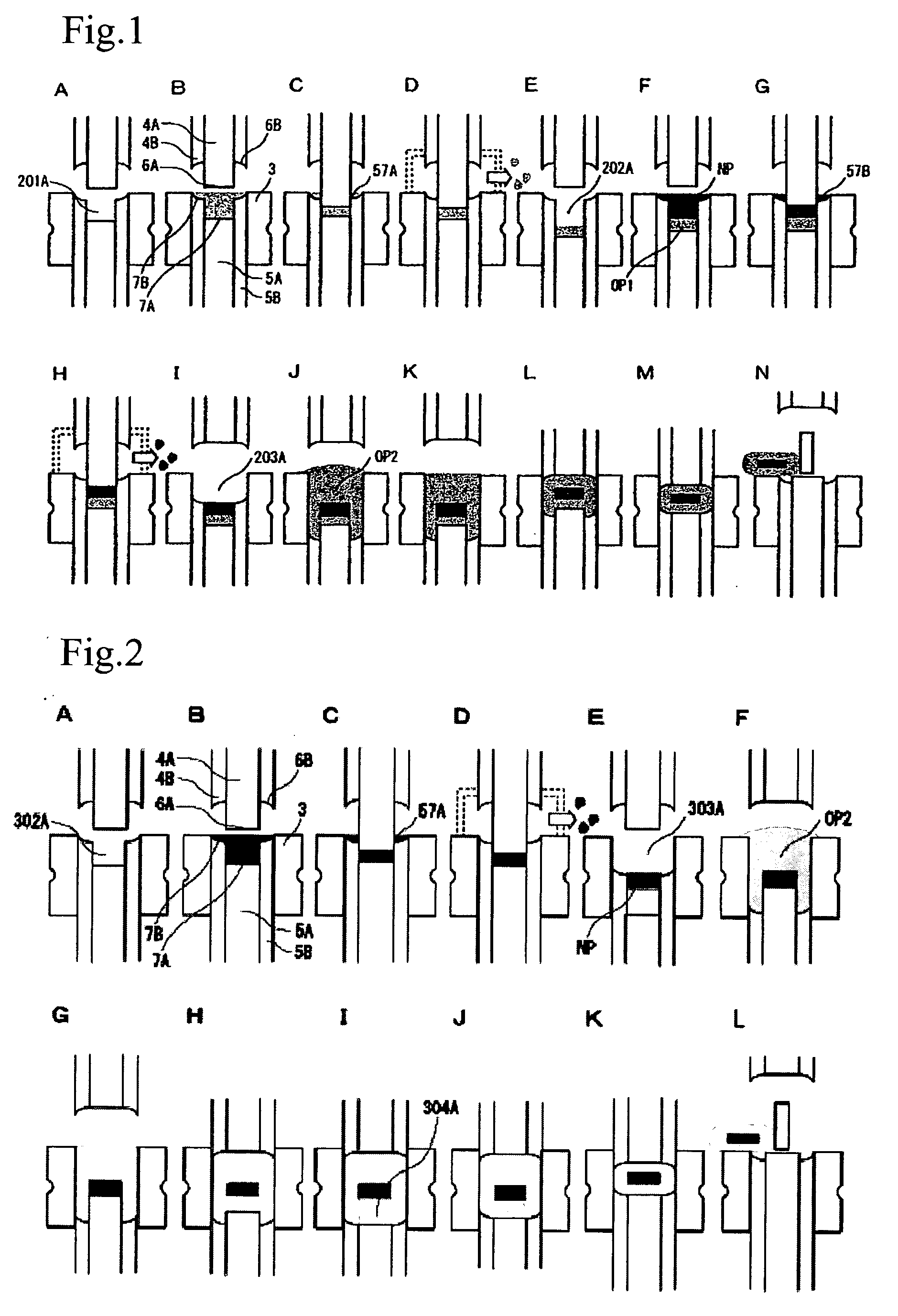

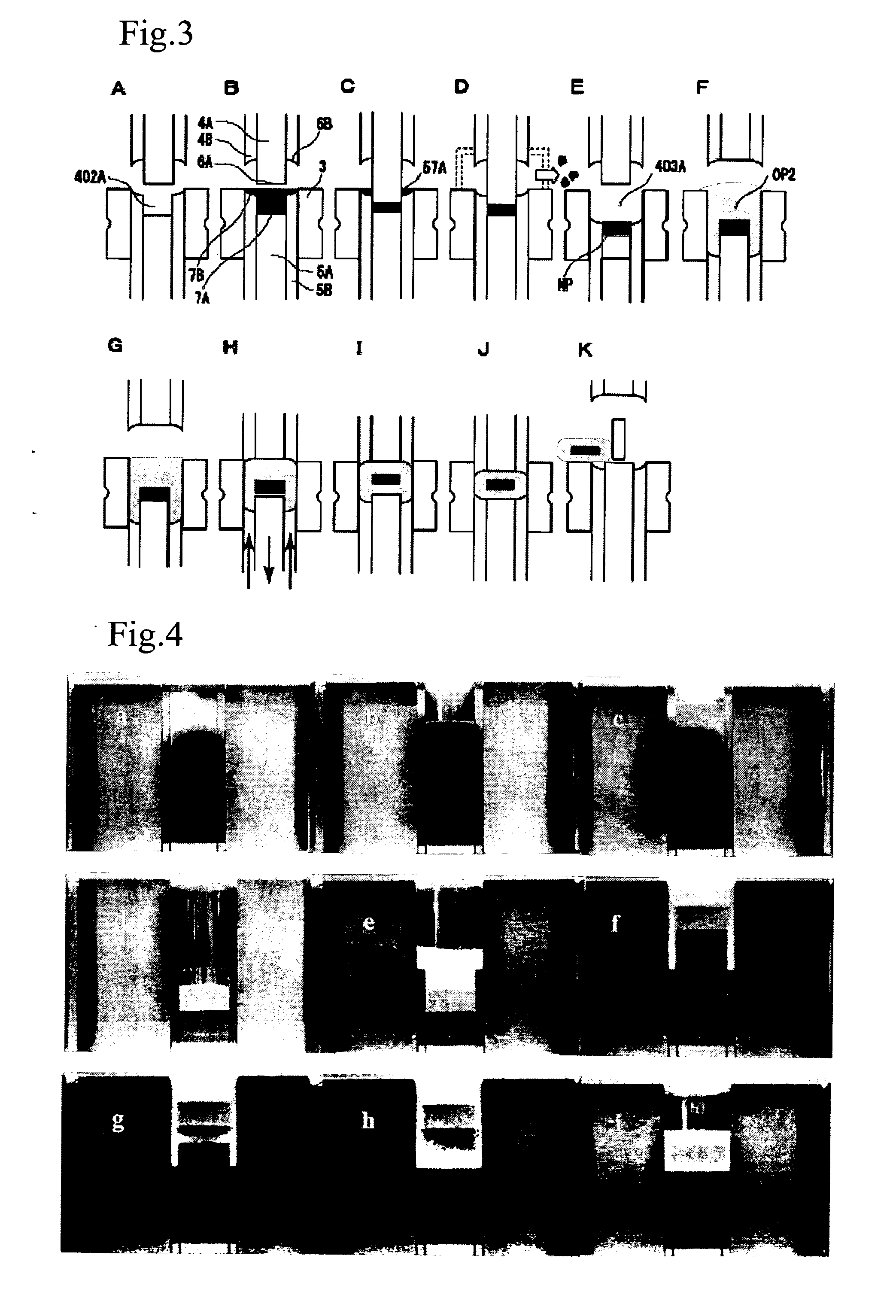

Method of manufacturing a molding with a core

InactiveUS7713455B2High molding densityIncrease volumeMouldsConfectioneryCompression moldingShell molding

The present invention provides a method for manufacturing a molding with a core by using compression molding means having upper and lower double-structured punches; the method comprising the steps of supplying molding material for the core and molding material for the outer layer respectively, the step of compression-molding the molding material for the core and / or the molding material for the outer layer, and the step of compression-molding the whole molding with a core, wherein: the step of supplying the molding material for the outer layer posterior to the step of supplying the molding material for the core is performed until a tip of the lower center punch finally takes a position protruding from a tip of the lower outer punch; and the step of compression-molding the whole molding with a core is performed with the tips of the lower center punch and the lower outer punch aligned with each other. This method can be expected to bring about the effect of enhancing the strength of a portion of outer layer forming the sidewall of the molding and / or the effect of allowing the molding material for the outer layer supplied after the step of supplying the molding material for the core to be led to under the temporary molding of the core thereby making it possible to manufacture a molding with a core through the molding material supply step performed twice.

Owner:SANWAKAGUKU KENKYUSHO CO LTD +1

Method Of Manufacturing A Molding With A Core

InactiveUS20080116606A1High molding densityIncrease volumeMouldsConfectioneryCompression moldingShell molding

The present invention provides a method for manufacturing a molding with a core by using compression molding means having upper and lower double-structured punches; the method comprising the steps of supplying molding material for the core and molding material for the outer layer respectively, the step of compression-molding the molding material for the core and / or the molding material for the outer layer, and the step of compression-molding the whole molding with a core, wherein: the step of supplying the molding material for the outer layer posterior to the step of supplying the molding material for the core is performed until a tip of the lower center punch finally takes a position protruding from a tip of the lower outer punch; and the step of compression-molding the whole molding with a core is performed with the tips of the lower center punch and the lower outer punch aligned with each other. This method can be expected to bring about the effect of enhancing the strength of a portion of outer layer forming the sidewall of the molding and / or the effect of allowing the molding material for the outer layer supplied after the step of supplying the molding material for the core to be led to under the temporary molding of the core thereby making it possible to manufacture a molding with a core through the molding material supply step performed twice.

Owner:SANWAKAGUKU KENKYUSHO CO LTD +1

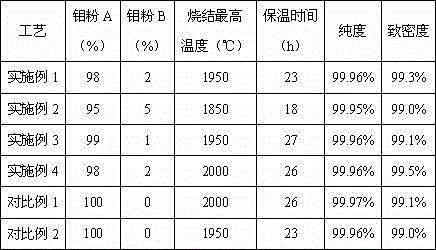

Method for preparing molybdenum target

InactiveCN104561914ALower sintering temperatureHigh charge densityVacuum evaporation coatingSputtering coatingHydrogenEnergy consumption

The invention discloses a method for preparing a molybdenum target. By introducing a small amount of nano molybdenum powder, not only is the forming density improved, but also the sintering activity of the powder is improved, and the sintering temperature is reduced; meanwhile due to vacuum sintering, hydrogen is not used, a function of reducing the sintering temperature is achieved due to vacuum sintering, and a certain purification function is also achieved. The whole preparation method is simple and safe in process, free of waste emission and belongs to environment-friendly techniques; and most importantly, the energy consumption can be greatly reduced, the production efficiency is improved, and the capacity of sintering equipment can be increased by more than 20%. The method has the beneficial effects that the method has remarkable competitive advantages and profit margin in aspects such as manufacturing cost, product property, large-scale production, safety and environment protection.

Owner:YANTAI SHIELD ADVANCED MATERIALS

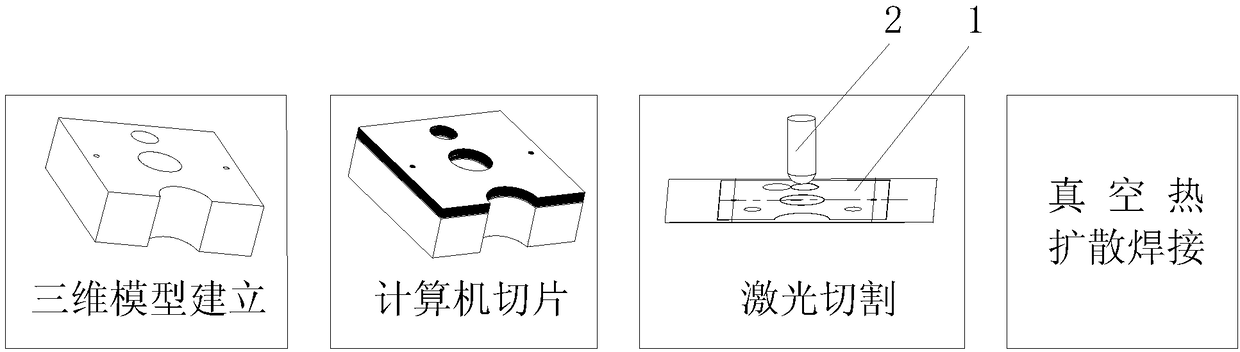

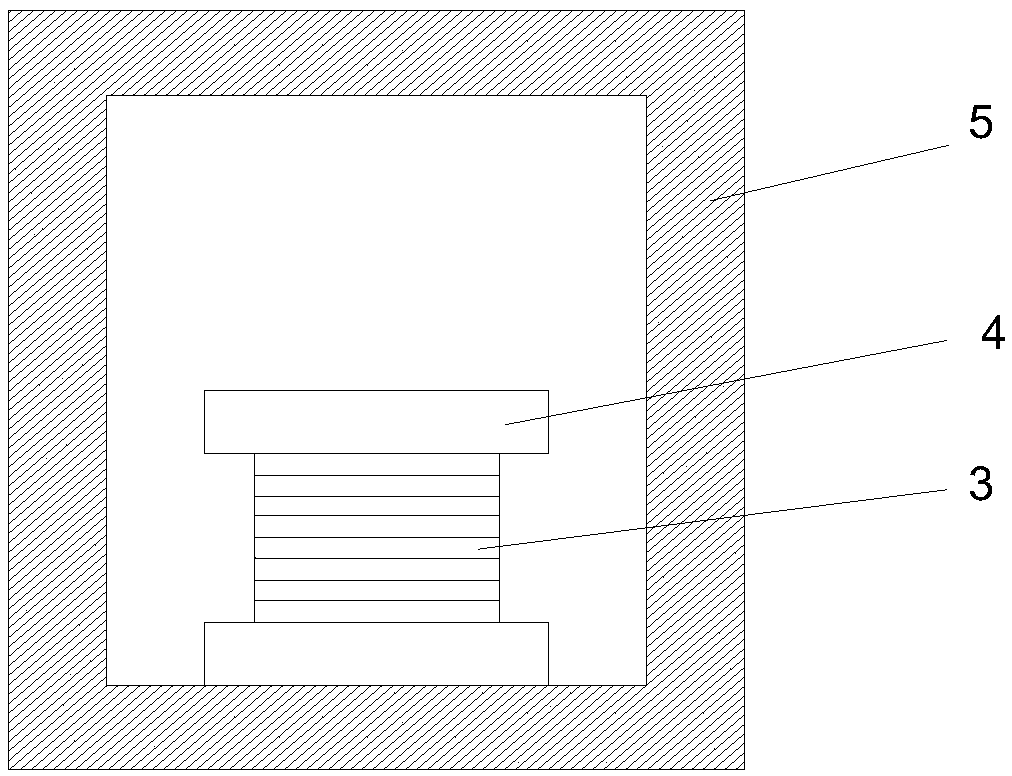

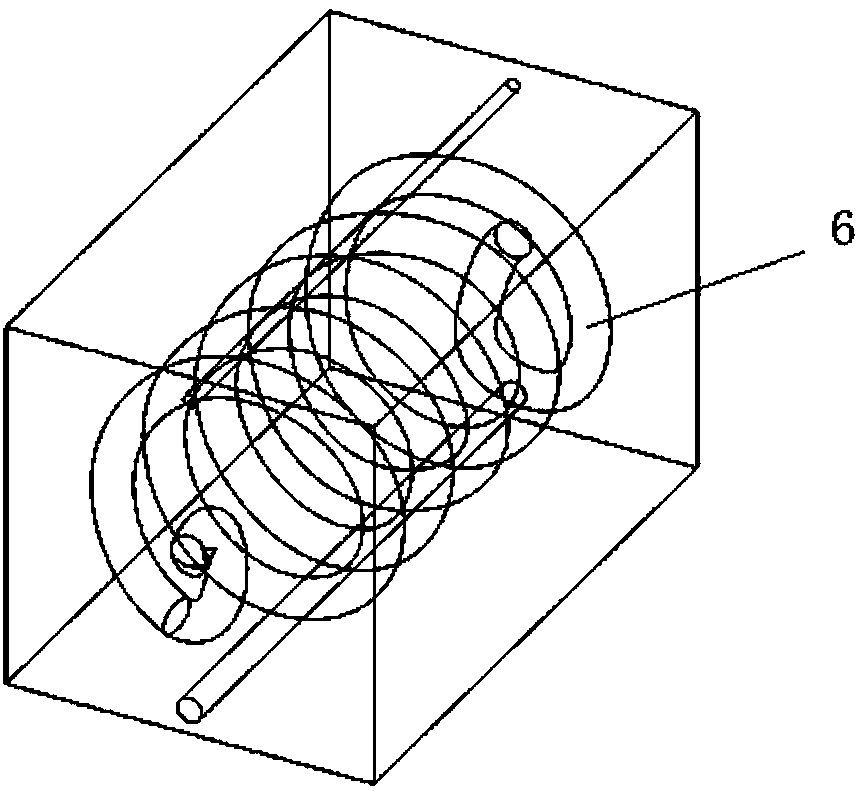

Shape-followed runner radiator based on sheet laminated connection and preparing method of shape-followed runner radiator

PendingCN108213886AShort cycleSave manpower and costSoldering apparatusHeat exchange apparatusThree dimensional modelVacuum pressure

The invention discloses a shape-followed runner radiator based on sheet laminated connection and a preparing method of the shape-followed runner radiator. A runner radiator part model is designed andbuilt in three-dimensional model design software, slice software is guided in to cut and layer the prepared part model according to the appointed thickness, a code file needed by laser machining is generated, a laser cutting system is guided in for cutting so as to obtain metal sheets, the metal sheets are sequentially overlapped, accumulated and clamped layer by layer according to the shape-followed runner sequence, and interlayer containing vacuum pressure thermal diffusion welding is carried out; and a sheet laminating connecting technology is adopted for directly manufacturing the complexrunner radiator with a complex inner cavity, the whole part deformation amount is smaller after manufacturing and molding, the continuity of the inner cavity is excellent, the product performance coincidence is good, meanwhile, the long-period and high-cost die opening process is saved, further optimization design of the runner radiator is facilitated, a runner can be accurately attached to the surface of a complex curve face part, and the molding accuracy and the radiating performance are further improved.

Owner:SOUTH CHINA UNIV OF TECH

A ferrite material with high magnetic permeance

InactiveCN104108926AHigh initial permeabilityReduce magnetic lossMetallurgySodium dodecylbenzenesulfonate

A ferrite material with high magnetic permeance is disclosed. Raw materials of the ferrite material comprise Fe2O3, MnO, ZnO, sodium dodecylbenzenesulfonate, CaO, SiO2, V2O5, MoO3, Bi2O3 and P2O5, wherein the molar ratio of the Fe2O3, the MnO and the ZnO is (50-55):(20-27):(20-28), and based on the weight sum of the Fe2O3, the MnO and the ZnO, the weight percentages of the sodium dodecylbenzenesulfonate, the CaO, the SiO2, the V2O5, the MoO3, the Bi2O3 and the P2O5 are respectively 0.9-1.5%, 0.025-0.035%, 0.002-0.013%, 0.018-0.022%, 0.01-0.02%, 0.02-0.03% and 0.02-0.03%. The ferrite material is prepared by steps of weighing each of the raw materials, granulating, performing dry pressing and moulding, sintering and cooling.

Owner:ZHONGDE ELECTRONICS

Hydraulic forming machine set for moulding and solidifying biomass

InactiveCN101774284AHigh calorific valueImprove rolling effectShaping pressHigh densityMechanical engineering

The invention relates to a hydraulic forming machine set for moulding and solidifying biomass, which comprises a hydraulic station, a feeder, a forming machine and a control cabinet, wherein the feeder comprises a hopper and a conveyer belt; the forming machine is formed by connecting a base, a support cylinder and a die pressing device sequentially; a main shaft is arranged in the support cylinder; the die pressing device comprises a die pressing plate, a connecting plate, a pinch roller shaft and two pinch rollers; the die pressing plate is sleeved at the top end of the support cylinder; a circle of circular discharging die holes are formed on the die pressing plate; the top end of the main shaft is connected with the connecting plate; the pinch roller shaft runs through the connecting plate horizontally; the pinch rollers are respectively sleeved at both ends of the pinch roller shaft; and a track formed by rotating the pinch rollers around the main shaft is positioned above the discharging die holes of the die pressing plate and is in clearance fit with the upper surface of the die pressing plate. The hydraulic mould forming machine set is driven by full hydraulic power, and the pinch rollers perform rotation while performing revolution, so that the biomass is formed by rolling compaction through the discharging die holes, and the hydraulic forming machine set has the advantages of simple integral structure, high hydraulic power, low energy consumption, long service life, good effect of rolling compaction, high density of formed blocks and good burning effect, and is suitable for forming various biomass straws.

Owner:江苏鼎绿科技有限公司

Metal aluminum-zinc composite low-carbon aluminum carbon sliding plate and preparation method

The invention discloses a metal aluminum-zinc composite low-carbon aluminum carbon sliding plate, which is prepared by the following steps of: mixing, aging and forming raw materials; performing heat treatment at the temperature of 150-300 DEG C; and then performing oil immersion, dry distillation, sand removal, hooping, grinding, shell adhesion and coating, wherein the raw materials are prepared from the following materials in percentage by weight: 78-82 percent of corundum, 3-15 percent of aluminum-zinc metal composite powder, 5-8 percent of active aluminum oxide micro powder, 2-4 percent of carbon, 0-5 percent of boron-containing additive and 4-4.5 percent of additional organic binding agent. The metal aluminum-zinc composite low-carbon aluminum carbon sliding plate has excellent thermal shock resistance performance and higher hot-state strength, so that the variation in the steel grade can be adapted better, erosion, scouring and infiltration can be suppressed, and the development towards long life and high efficiency direction of the steel and iron continuous casting can be adapted better.

Owner:ZHENGZHOU UNIV

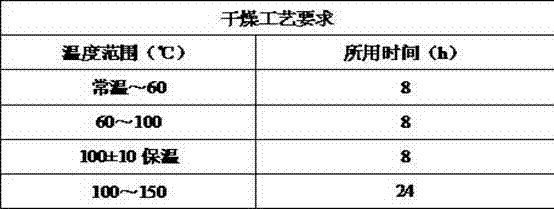

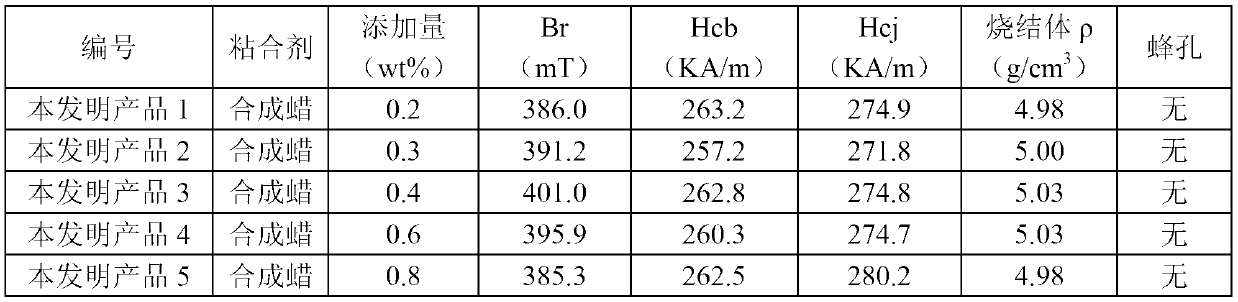

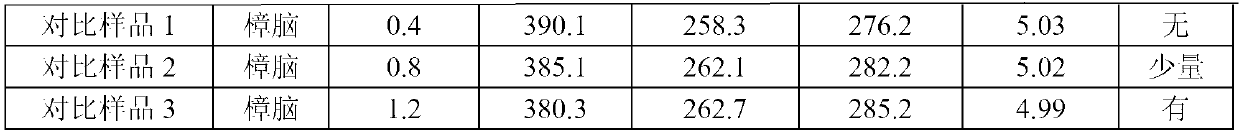

Manufacturing method of dry-type anisotropic strontium ferrite

The invention relates to a manufacturing method of dry-type anisotropic strontium ferrite, which uses Fe2O3 and SrCO3 as raw materials, CaCO3 and SiO2 as additives, and synthetic wax and calcium stearate respectively as a binding agent and a forming assistant. The manufacturing method comprises the following steps: preparing presintered fine powder, preparing a compound concentrated material, preparing fine powder for formation, and forming by sintering. The synthetic wax is used as the binding agent instead the traditional camphor binding agent, thereby reducing the hazards to life and environmental pollution due to use of camphor; and besides, the density of the sintered body can be enhanced to avoid generating bee-holes on the product surface, thereby forming the dry-type anisotropic strontium ferrite with excellent magnetic properties.

Owner:江门江益磁材有限公司

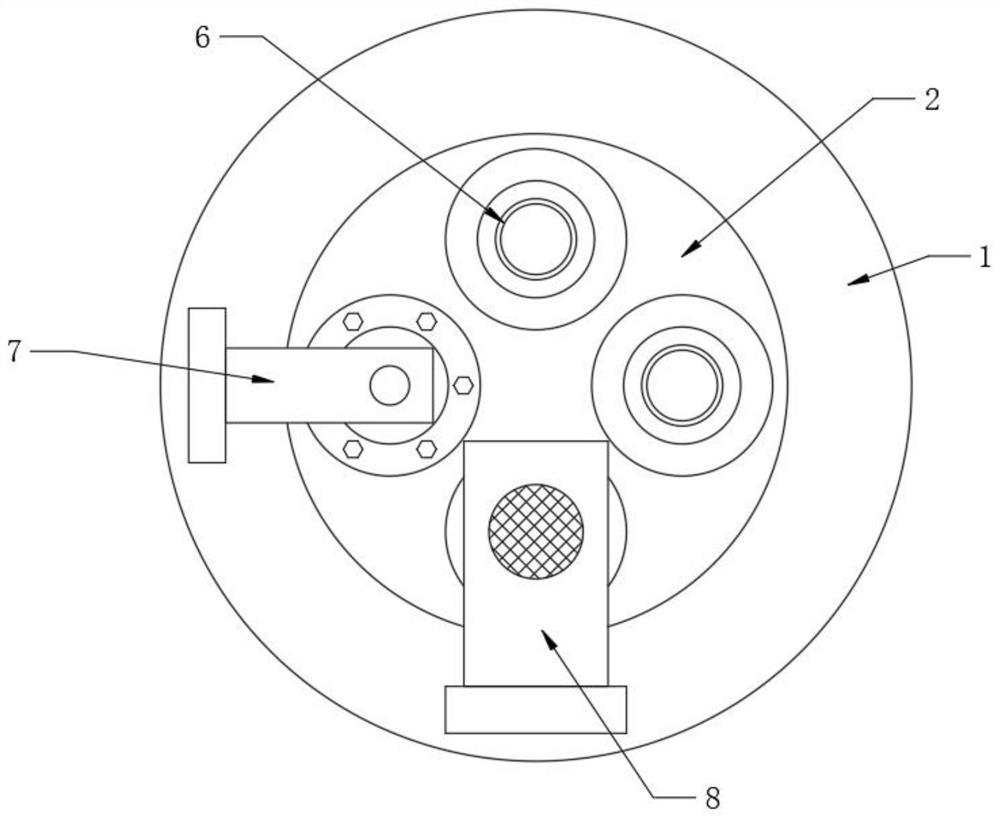

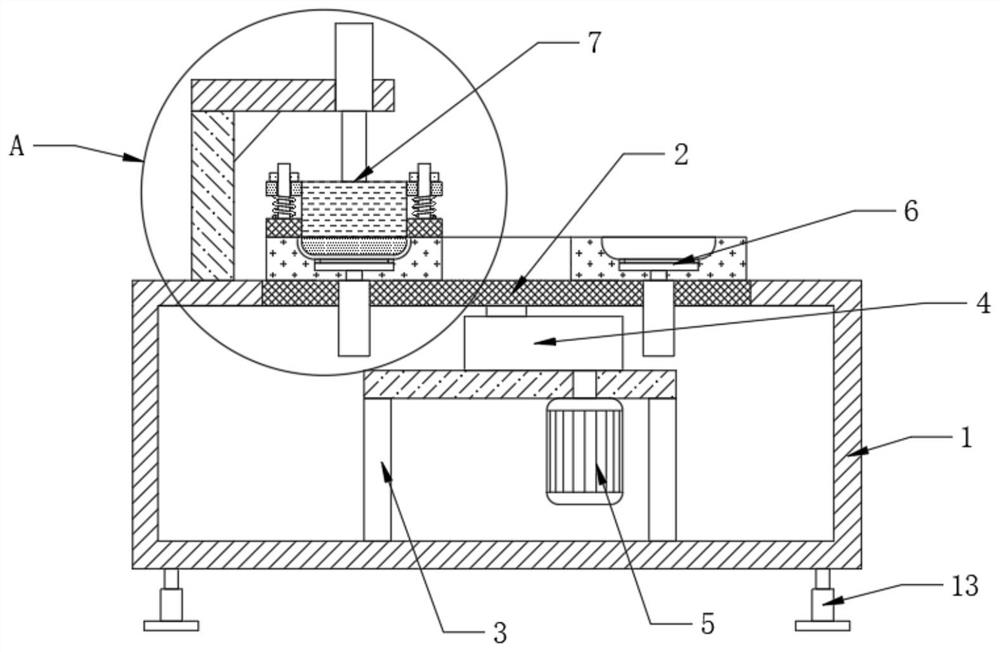

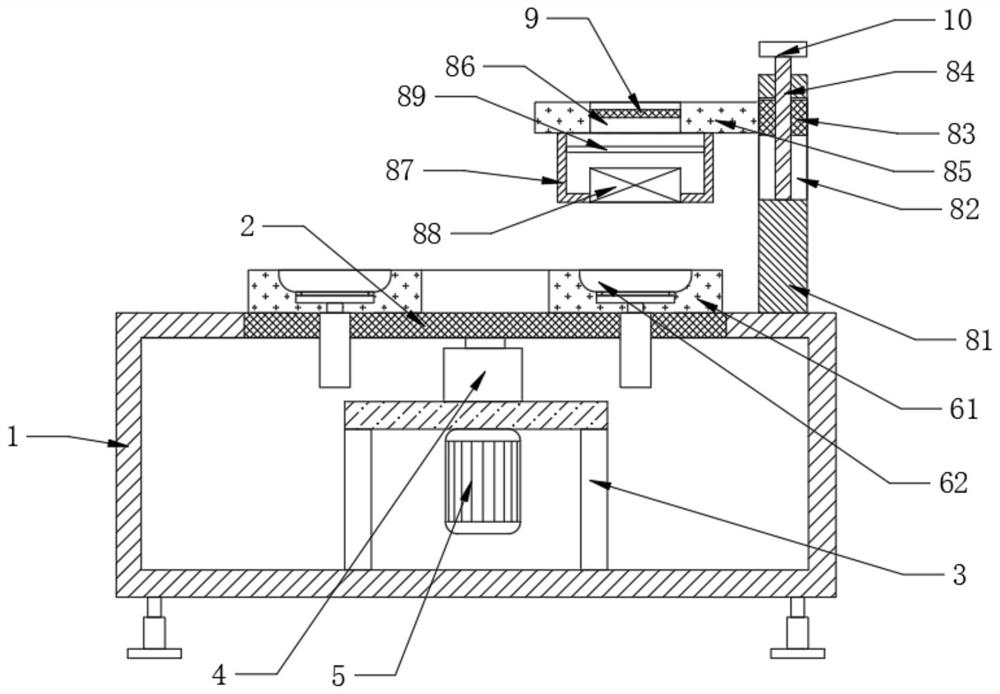

High-density and high-precision celadon forming device

The invention discloses a high-density and high-precision celadon forming device. The device comprises an equipment box, a rotating plate, a mounting frame, a quarter sheave mechanism and a servo motor, the rotating plate is rotationally connected to the middle of the upper surface of the equipment box through a slewing bearing, the mounting frame is fixed to the bottom of the inner wall of the equipment box, the quarter sheave mechanism is fixed to the top of the mounting frame, the servo motor is fixed in the mounting frame, the output end of the servo motor is fixedly connected with the input end of the quarter sheave mechanism, the output end of the quarter sheave mechanism is fixedly connected with the rotating plate, lower die sets are fixed to the upper surface of the rotating plate at equal intervals, an upper die set is fixed to one end of the upper surface of the equipment box, and a drying device is fixed to the end, close to the upper die est, of the upper surface of the equipment box. The high-density and high-precision celadon forming device is high in celadon forming density and high in precision and improves product quality.

Owner:ZHEJIANG UNIV

Environment-friendly biomass fuel and preparation method thereof

The invention discloses an environment-friendly biomass fuel, which comprises the following components in parts by mass: The biomass fuel prepared by the invention has low water content, compact and compact structure of shaped cylindrical granules, is not easy to drop slag, and has a long burning time as fuel.

Owner:苏州米田环保科技有限公司

Preparation method of erbium-doped potassium sodium niobate-strontium titanate transparent ceramics

The invention discloses a preparation method of erbium-doped potassium sodium niobate-strontium titanate transparent ceramics. The method comprises the steps of firstly, preparing Er-doped (K0.5Na0.5)NbO3-SrTiO3 powder, and tabletting and molding by means of dry pressing; shaping by microwave sintering at 1200-1230 DEG C to obtain the erbium-doped potassium sodium niobate-strontium titanate transparent ceramics with a transmittance greater than 45%. The preparation method provided by the invention is simple in processing steps, good in repeatability and easy to operate, and is mainly applied to new electronic products such as environment-friendly smartphones and touch screens as well as optical devices such as high-power solid-state lasers, high-pressure sodium lamps and thermal seekers.

Owner:FUZHOU UNIV

Preparation method for carbon source for synthesizing large-size polycrystalline diamond

ActiveCN108163850AUniform particle sizeHigh molding densityGraphiteUltra-high pressure processesPolycrystalline diamondCarbon source

The invention provides a preparation method for a carbon source for synthesizing large-size polycrystalline diamond. The method uses flake graphite as a raw material, and the carbon source for synthesizing large-size polycrystalline diamond is synthesized through screening, ball milling, fine processing and grading processes. The method allows the carbon source with a uniform particle size and a high molding density to be obtained, and reduces the pressure loss caused by the volume collapse reduction in the synthesis process. The graphitization degree, the porosity, the ash content, the resistivity and the crystal structure of the carbon source obtained by the preparation method can greatly reduce the pressure and the temperature needed by the synthesis of high-quality and large-size polycrystalline diamond, and can achieve the purposes of stable transformation and cost saving.

Owner:ZHENGZHOU ZHONGNAN JETE SUPERABRASIVES

High-permeability amorphous compressed powder core by means of high-temperature molding, and method for preparing same

InactiveCN104884196ASmall change in effective permeabilitySmall changes in magnetic permeabilityTransportation and packagingMetal-working apparatusO-Phosphoric AcidPolyimide

Owner:裵恩英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com