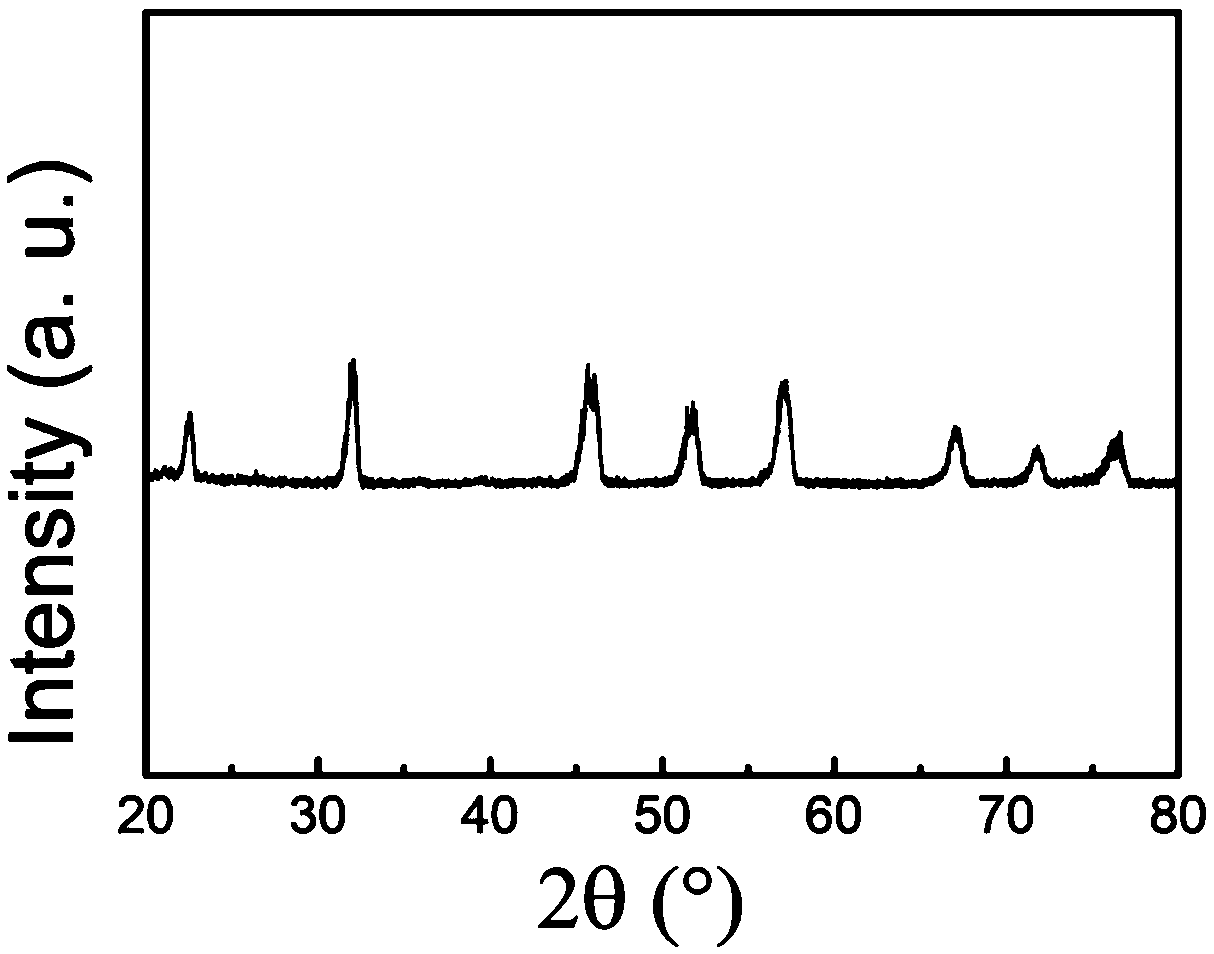

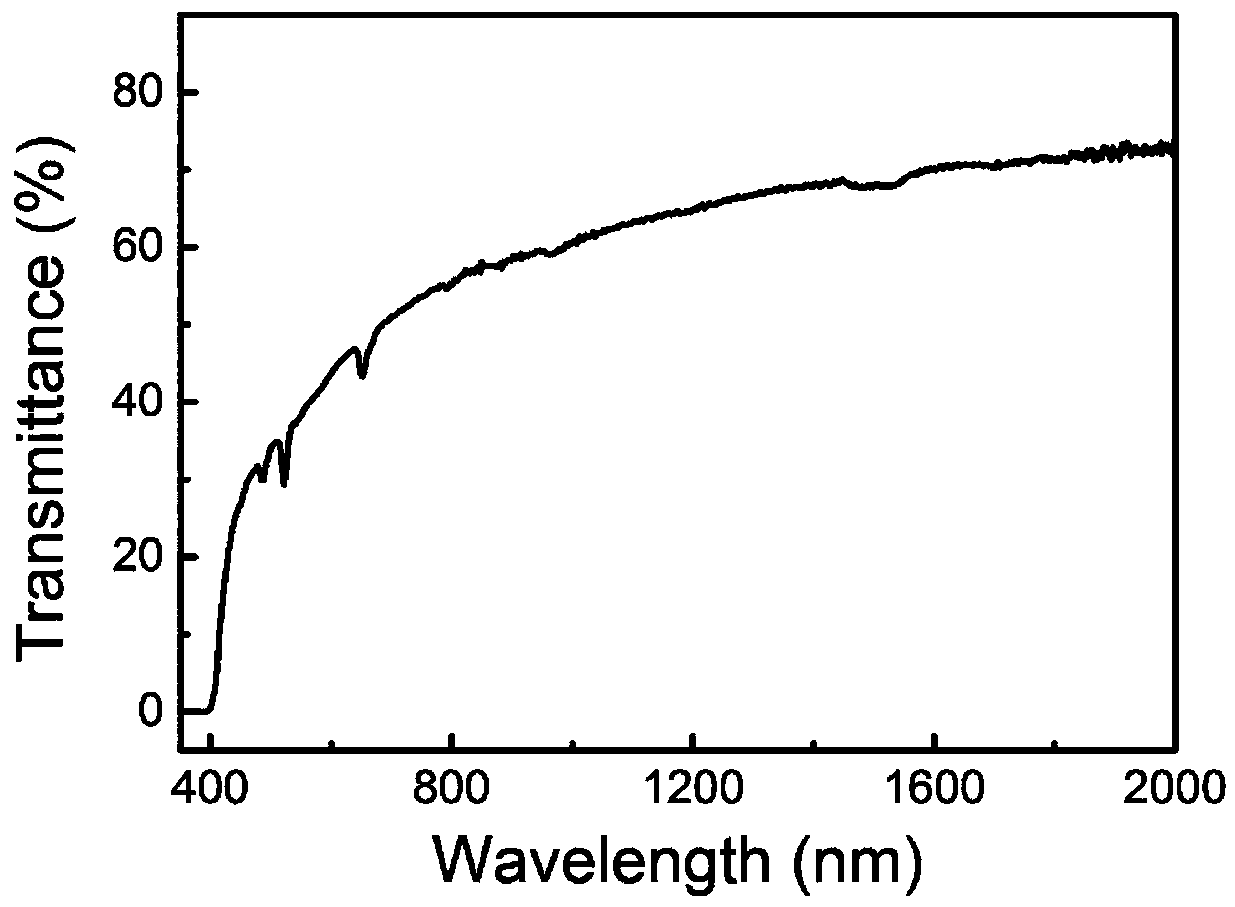

Preparation method of erbium-doped potassium sodium niobate-strontium titanate transparent ceramics

A technology of potassium sodium niobate and transparent ceramics, applied in the field of lead-free piezoelectric materials, can solve problems such as harm to the human body and the environment, and achieve the effects of reducing environmental pollution problems, good ferroelectric performance, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of erbium-doped potassium sodium niobate-strontium titanate transparent ceramics, comprising the following steps:

[0029] (1) Ingredients: according to the chemical composition general formula yEr-(K 0.5 Na 0.5 )NbO 3 -xSrTiO 3 The stoichiometric ratio of the raw material Er 2 o 3 , Na 2 CO 3 , K 2 CO 3 , Nb 2 o 5 , SrCO 3 and TiO 2 Mixed to obtain a mixture, wherein x = 8 ~ 12%, y = 0.5%;

[0030] (2) Ball milling: add ball milling media to the mixture, put it into a ball mill tank for ball milling for 8-12 hours, the ball milling speed is 150-280 r / min, after the ball milling, put the mixture in an oven at 80-85°C The temperature is dried, and then the mixture is put into a mortar for grinding, the grinding medium is ethanol, and the weight ratio of the mixture to ethanol is 1:2 to 1:3;

[0031] (3) Pre-burning: Add the above-mentioned ground mixture into the crucible, after compaction, place it in a muffle furnace, raise the temper...

Embodiment 1

[0039] A preparation method of erbium-doped potassium sodium niobate-strontium titanate transparent ceramics, comprising the following steps:

[0040] (1) Ingredients: According to the general formula of chemical composition 0.005Er-(K 0.5 Na 0.5 )NbO 3 -0.12SrTiO 3 The stoichiometric ratio of the raw material Er 2 o 3 , Na 2 CO 3 , K 2 CO 3 , Nb 2 o 5 , SrCO 3 and TiO 2 Mixed to obtain a mixture.

[0041] (2) Ball milling: add the mixture into the ball milling medium, put it into a ball mill tank and carry out ball milling for 8 h at a milling speed of 150 r / min. After the ball milling, the mixture is dried in an oven at 80°C, and then Then put the mixed material into a mortar for grinding, the grinding medium is ethanol, and the weight ratio of the mixed material to ethanol is 1:2.

[0042] (3) Pre-burning: Add the above-mentioned ground mixture into the crucible, compact it, put it in a muffle furnace, raise the temperature to 800 °C at a heating rate of 3 °C / ...

Embodiment 2

[0051] A preparation method of erbium-doped potassium sodium niobate-strontium titanate transparent ceramics, comprising the following steps:

[0052] (1) Ingredients: According to the general formula of chemical composition 0.005Er-(K 0.5 Na 0.5 )NbO 3 -0.10SrTiO 3 The stoichiometric ratio of the raw material Er 2 o 3 , Na 2 CO 3 , K 2 CO 3 , Nb 2 o 5 , SrCO 3 and TiO 2 Mixed to obtain a mixture.

[0053] (2) Ball milling: Add the mixture to the ball milling medium, put it into a ball mill tank and carry out ball milling for 12 hours at a milling speed of 200r / min. Put the mixed material into a mortar for grinding, the grinding medium is ethanol, and the weight ratio of the mixed material to ethanol is 1:2.5.

[0054] (3) Pre-burning: Add the above-mentioned ground mixture into the crucible, after compaction, put it in a muffle furnace, raise the temperature to 850°C at a heating rate of 4°C / min and keep it warm for 4 hours for pre-burning , and then take out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com