Manufacturing method of dry-type anisotropic strontium ferrite

A strontium ferrite and anisotropic technology, which is applied in the field of dry anisotropic strontium ferrite manufacturing, can solve the problem that the viscosity and lubricity cannot achieve lubrication and dispersion effects, are not suitable for industrial production, and have high hardness. problem, to achieve the effect of good lubricity, forming and density improvement, and improving the degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

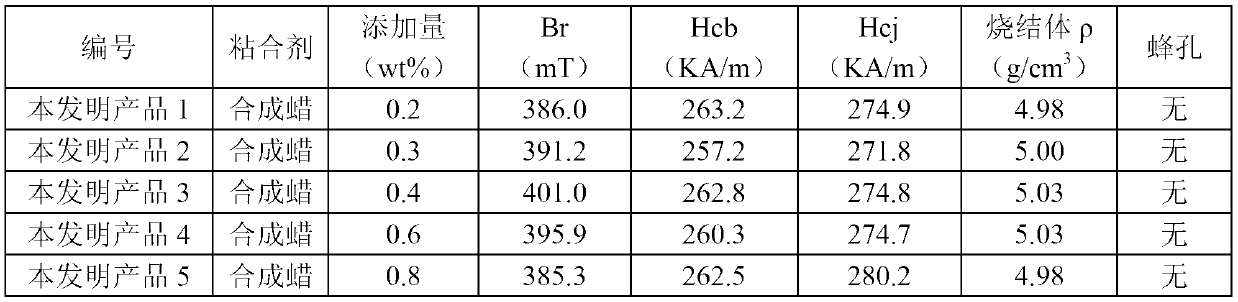

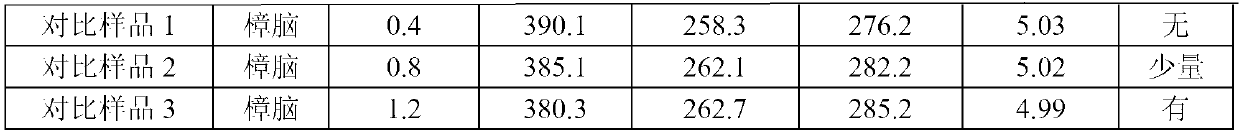

Examples

Embodiment 1

[0026] Adopt following steps to make product of the present invention:

[0027] (1) Preparation of pre-burned fine powder

[0028] Molebi Fe 2 o 3 : SrCO 3 =5.7:1 Weigh the raw material Fe 2 o 3 and SrCO 3 Mixing, drying and calcining to obtain calcined material. Use a vibration ball mill to coarsely crush the above calcined material into a coarse powder with an average particle size of 2-6 μm, and add 0.8wt% of the weight of the coarse powder to CaCO 3 and 0.3wt% SiO 2 Finally, it is finely crushed into a fine powder with an average particle size of 0.8 μm, and then dried to obtain a pre-calcined fine powder.

[0029] (2) Preparation of mixing concentrate

[0030] Weigh the calcined fine powder obtained in step (1) and mix it with synthetic wax, wherein the synthetic wax accounts for 1 wt%, and the pre-calcined fine powder accounts for 99 wt%, put the mixed material into an internal mixer, and mix while heating. When the temperature rises to 75°C, turn on the coolin...

Embodiment 2

[0036] Adopt the following steps to make product 4 of the present invention:

[0037] (1) Preparation of pre-burned fine powder

[0038] Molebi Fe 2 o 3 : SrCO 3 =5.8:1 Weigh raw material Fe 2 o 3 and SrCO 3 Mixing, drying and calcining to obtain calcined material. Use a vibration ball mill to coarsely crush the above calcined material into a coarse powder with an average particle size of 2-6 μm, and add 1.1wt% of the weight of the coarse powder to CaCO 3 and 0.2wt% SiO 2 Finally, it is finely crushed into a fine powder with an average particle size of 0.72 μm, and then dried to obtain a pre-calcined fine powder.

[0039] (2) Preparation of mixing concentrate

[0040] The calcined fine powder obtained in step (1) was weighed and mixed with synthetic wax, wherein the synthetic wax accounted for 6wt%, and the pre-calcined fine powder accounted for 94wt%, and the mixed material was put into an internal mixer, and mixed while heating. When the temperature rises to 75°C, ...

Embodiment 3

[0046] Adopt following steps to make product of the present invention:

[0047] (1) Preparation of pre-burned fine powder

[0048] Molebi Fe 2 o3 : SrCO 3 =5.9:1 Weigh the raw material Fe 2 o 3 and SrCO 3 Mixing, drying and calcining to obtain calcined material. Use a vibration ball mill to coarsely crush the above calcined material into a coarse powder with an average particle size of 2-6 μm, and add 1.25wt% of the weight of the coarse powder to CaCO 3 and 0.1wt% SiO 2 Finally, it is finely crushed into a fine powder with an average particle size of 0.65 μm, and then dried to obtain a pre-calcined fine powder.

[0049] (2) Preparation of mixing concentrate

[0050] The calcined fine powder obtained in step (1) was weighed and mixed with synthetic wax, wherein the synthetic wax accounted for 12wt%, and the pre-calcined fine powder accounted for 88wt%, and the mixed material was put into an internal mixer, and mixed while heating. When the temperature rises to 75°C, tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com