High-permeability amorphous compressed powder core by means of high-temperature molding, and method for preparing same

A technology of high magnetic permeability and dust core, which is applied in the manufacture of inductors/transformers/magnets, magnetic cores/yokes, magnetic materials, etc. It can solve the problems of continuous production, mass production, excessive molding time, etc. problems, to achieve the effect of no surface cracking, good insulation between particles, and high molding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

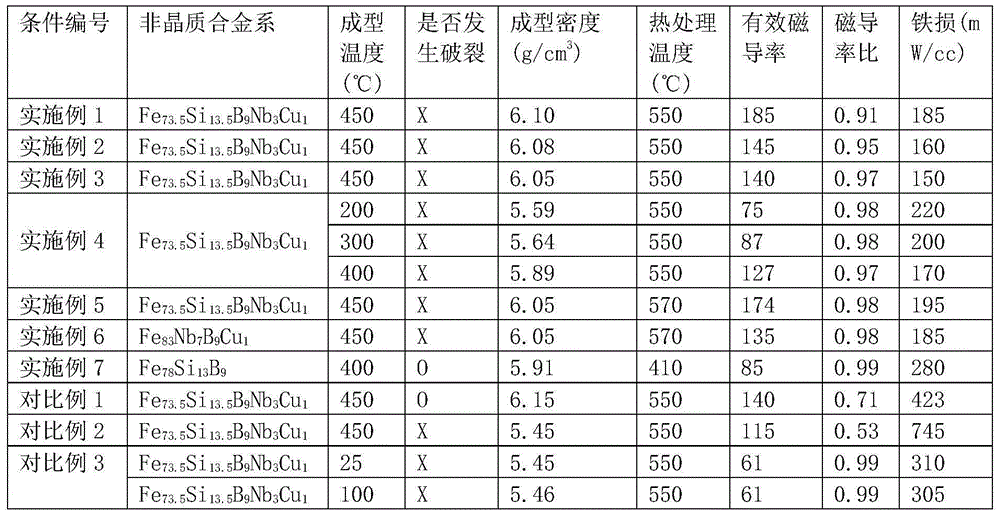

Examples

Embodiment 1

[0034] Example 1, which is the best form for the implementation of the present invention, is made according to the high-pressure water jet method, and is expected to realize nanocrystallization by moderate heat treatment, Fe as an alloy powder in an amorphous state. 73.5 Si 13.5 B 9 Nb 3 Cu 1 (Average particle size about 15μm) 1000g, phosphoric acid (H 3 PO 4 ) 10g was diluted in acetone, and the phosphoric acid coating treatment was performed for the first time. After drying, the solution prepared by dissolving 10g of polyimide in methylene chloride solution was used for the second coating treatment. , carry out drying treatment, and manufacture polyimide. On the surface of amorphous alloy powder with an average particle size of about 15 μm, evenly coat composite particle powder with a thickness of about 1 μm or less. After drying, uniformly mix molybdenum disulfide with an average particle size of 3 μm (MoS 2 ) powder 10g.

[0035] Put the composite particle powder mi...

Embodiment 2

[0041] Example 2 for carrying out the present invention was carried out in the same manner as in Example 1 except that phosphoric acid coating treatment was performed using 25 g of phosphoric acid. Table 1 shows various properties of the nanocrystallized amorphous powder magnetic core thus produced.

Embodiment 3

[0043] Example 3 used for implementation of this invention carried out similarly to Example 1 except having melt|dissolved 20 g of polyimides in methylene chloride and prepared the solution. Table 1 shows various properties of the nanocrystallized amorphous powder magnetic core thus produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com