FeSiAl material magnetic core and producing method thereof

A magnetic core and magnetic permeability technology, which is applied in the field of FeSiAl material magnetic core and the preparation of the above-mentioned material magnetic core, can solve the problems of limiting the performance of FeSiAl material products and the small range of process angles, so as to improve the DC bias characteristics and increase the magnetic permeability. , The effect of reducing hysteresis loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

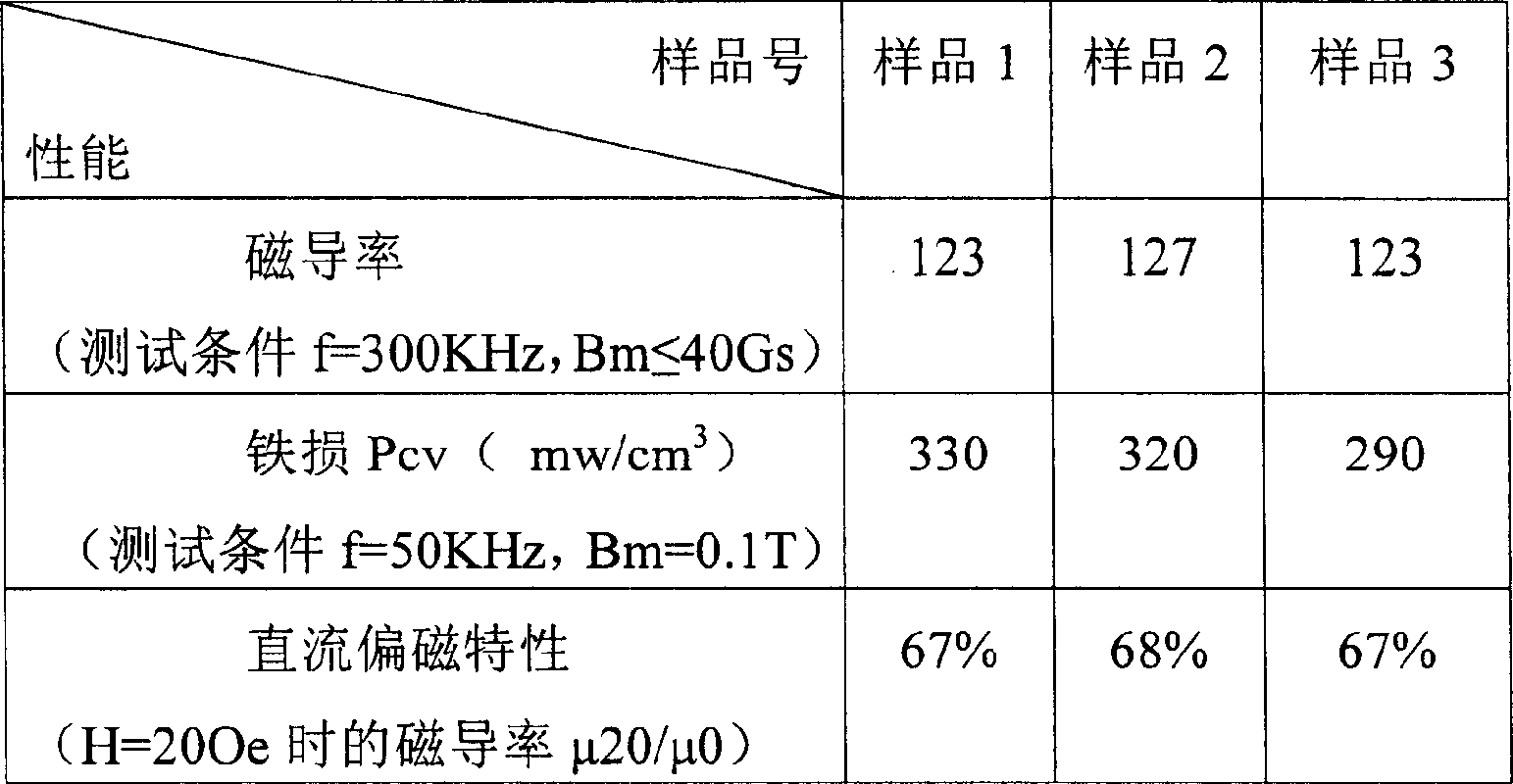

Embodiment 1

[0025] It is smelted by air and cast into a plate. The thickness of the plate is not strictly limited, generally 0.001mm to 120mm. The board is crushed and powdered, and the powder is passed through a -80 mesh sieve, wherein the powder with a particle size of -400 mesh is controlled between 15% and 55% of the total weight. The powder is heat-treated, and the temperature is controlled at 700-1000°C. The atmosphere during heat treatment can be air, nitrogen, hydrogen, vacuum or a nitrogen-hydrogen mixed atmosphere. Then add insulating agent in the powder, insulating agent accounts for the weight percent content of FeSiAl alloy powder is 0.1%, adds binder and accounts for the weight percent content of FeSiAl alloy powder is 0.8%, adds lubricant and accounts for the weight percent content of FeSiAl alloy powder is 0.1%. Among the above additives, the insulating agent can use high-performance mica powder, kaolin or a mixture of the two; the adhesive can use one of epoxy resin, phe...

Embodiment 2

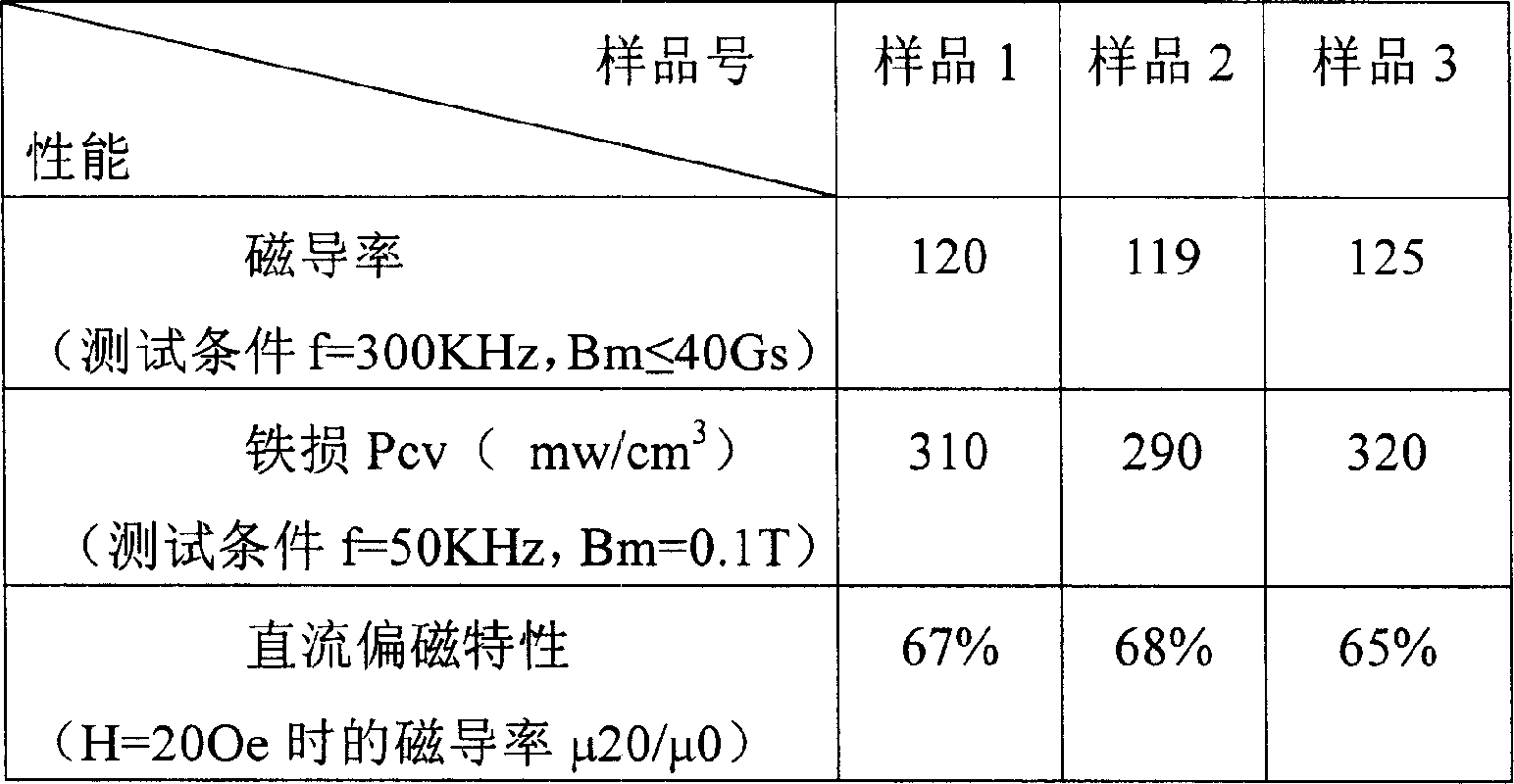

[0030] Various additives added in the powder of embodiment one, wherein the insulating agent accounts for the weight percent content of the FeSiAl alloy powder is 1%, the binder accounts for the weight percent content of the FeSiAl alloy powder is 0.1%, and the lubricant accounts for the FeSiAl alloy powder. The weight percent content is 0.8%. All the other conditions are the same as in Example 1. The properties of the magnetic core prepared in this embodiment are shown in Table 2.

[0031] Table 2

[0032]

Embodiment 3

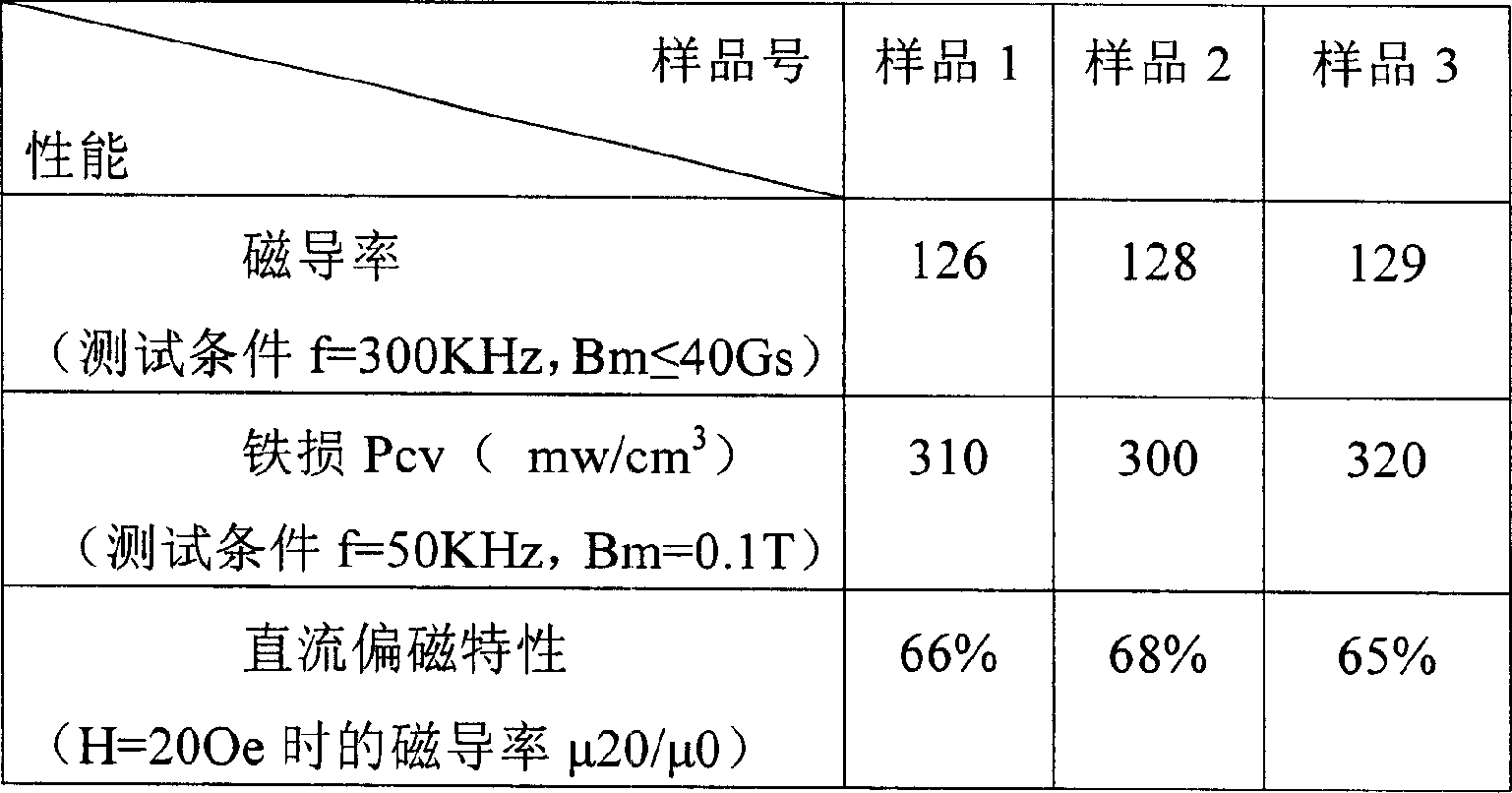

[0034] By the processing step of embodiment one. Heat-treat the pressed ring in a nitrogen-hydrogen mixed atmosphere for not less than half an hour. Its performance is shown in Table 3.

[0035] table 3

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com