Patents

Literature

169results about How to "Reduce hysteresis loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

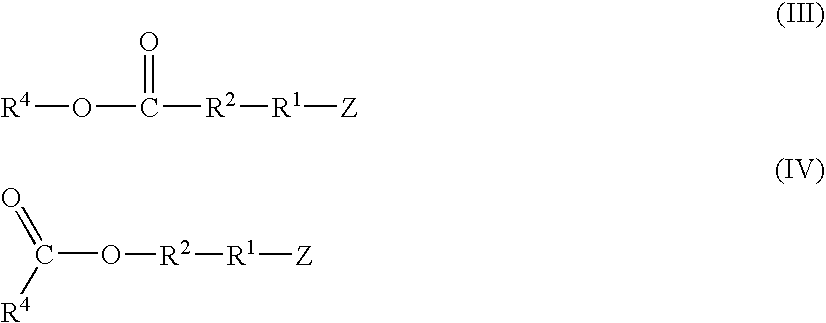

Functionalized high cis-1,4-polybutadiene prepared using novel functionalizing agents

InactiveUS20060004131A1High ci microstructureLower glass transition temperatureInksActive polymerPolymer science

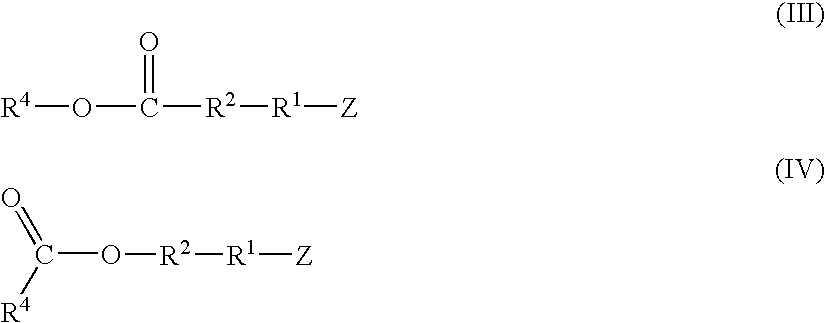

A functionalized polymer prepared by a process comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with a functionalizing agent defined by the formula (I) A-R1-Z (I) where R1 is a divalent bond or divalent organic group comprising from 0 to about 20 carbon atoms, A is a substituent that will undergo an addition reaction with a pseudo-living polymer, and Z is a substituent that will react or interact with silica or carbon black reinforcing fillers, with the proviso that A, R1, and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

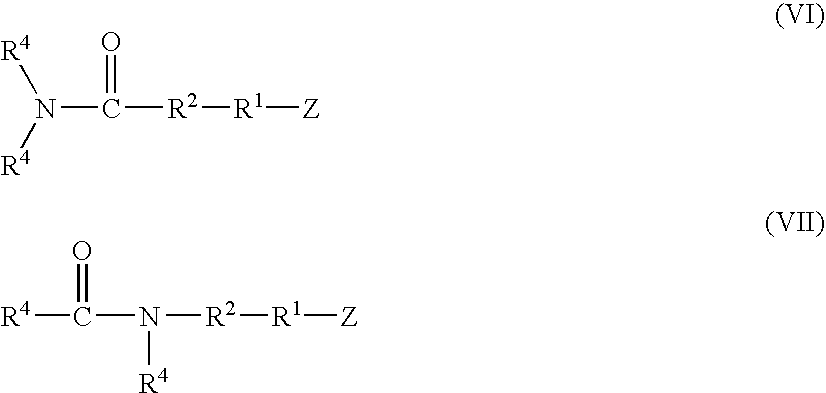

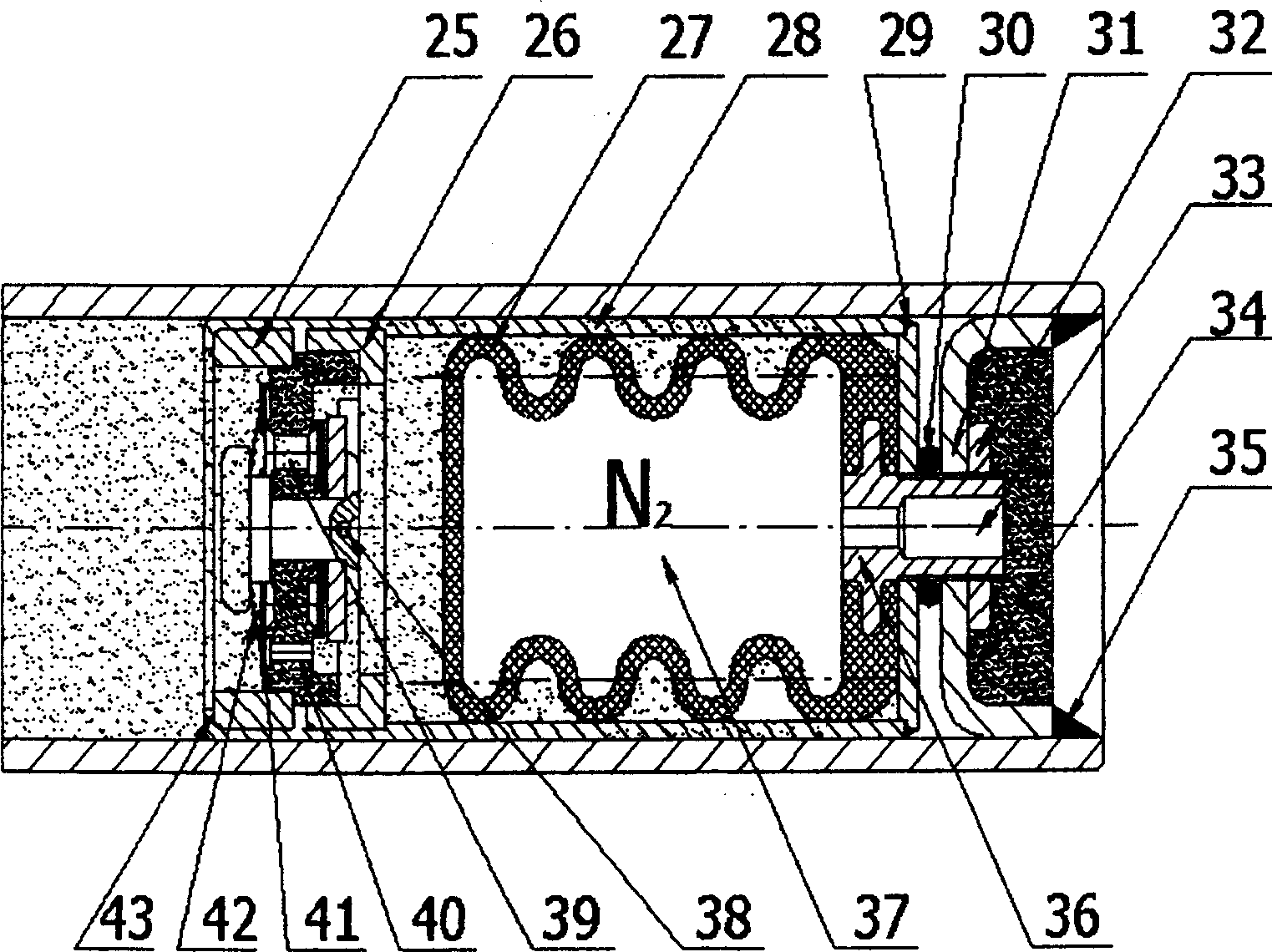

Magnetorheological suspensions damping device for automobile suspension system

InactiveCN1603651AReduce power consumptionSmall currentSpringsNon-rotating vibration suppressionMagnetorheological fluidEngineering

The invention involving a magnetorheological fluid damping device for automobile suspension system.The magnetic field generator of this damping device consists of permanent magnet and electromagnetic coil.On the top of the damping device,there are guide apparatus and damping regulator,the function of which is that to ensure the damping channel is uniform annular duct and to meet the high-damp requirement in the restoration process and low-damp requirement in the compression process of damper seperately.The current in the electromagnetic coil designs of bi-directional and this controls the magnetic field intersity of the damping channel,decreases the excitation current of the electromagnetic coil,reduces energy consumption and decreases damper fever.On the non-controlling conditions,this damping device has the equivalent characteristics of the traditional shock absorber and can instead the passive shock absorber,after equiping corresponding current controller,this device can regulate the damping characteristics of suspension system,which improves the automobile driving safety and ride comfort.

Owner:CHONGQING UNIV

Functionalized high cis-1,4-polybutadiene prepared using novel functionalizing agents

InactiveUS7642322B2Lower glass transition temperatureReduce hysteresis lossInksLanthanideSilicon dioxide

A functionalized polymer prepared by a process comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with a functionalizing agent defined by the formula (I)A-R1-Z (I)where R1 is a divalent bond or divalent organic group comprising from 0 to about 20 carbon atoms, A is a substituent that will undergo an addition reaction with a pseudo-living polymer, and Z is a substituent that will react or interact with silica or carbon black reinforcing fillers, with the proviso that A, R1, and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

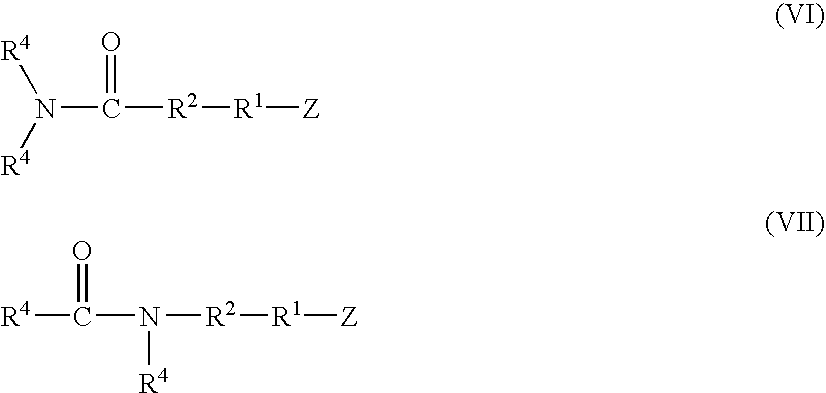

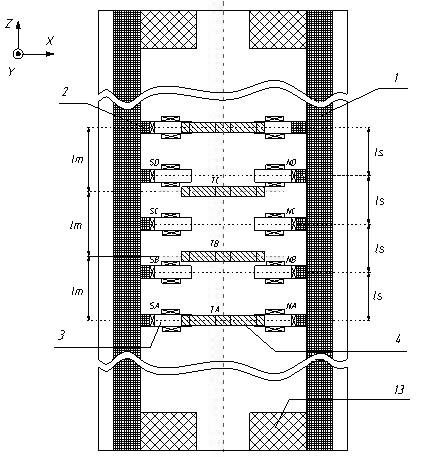

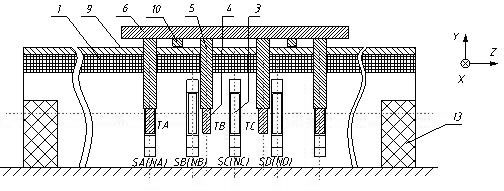

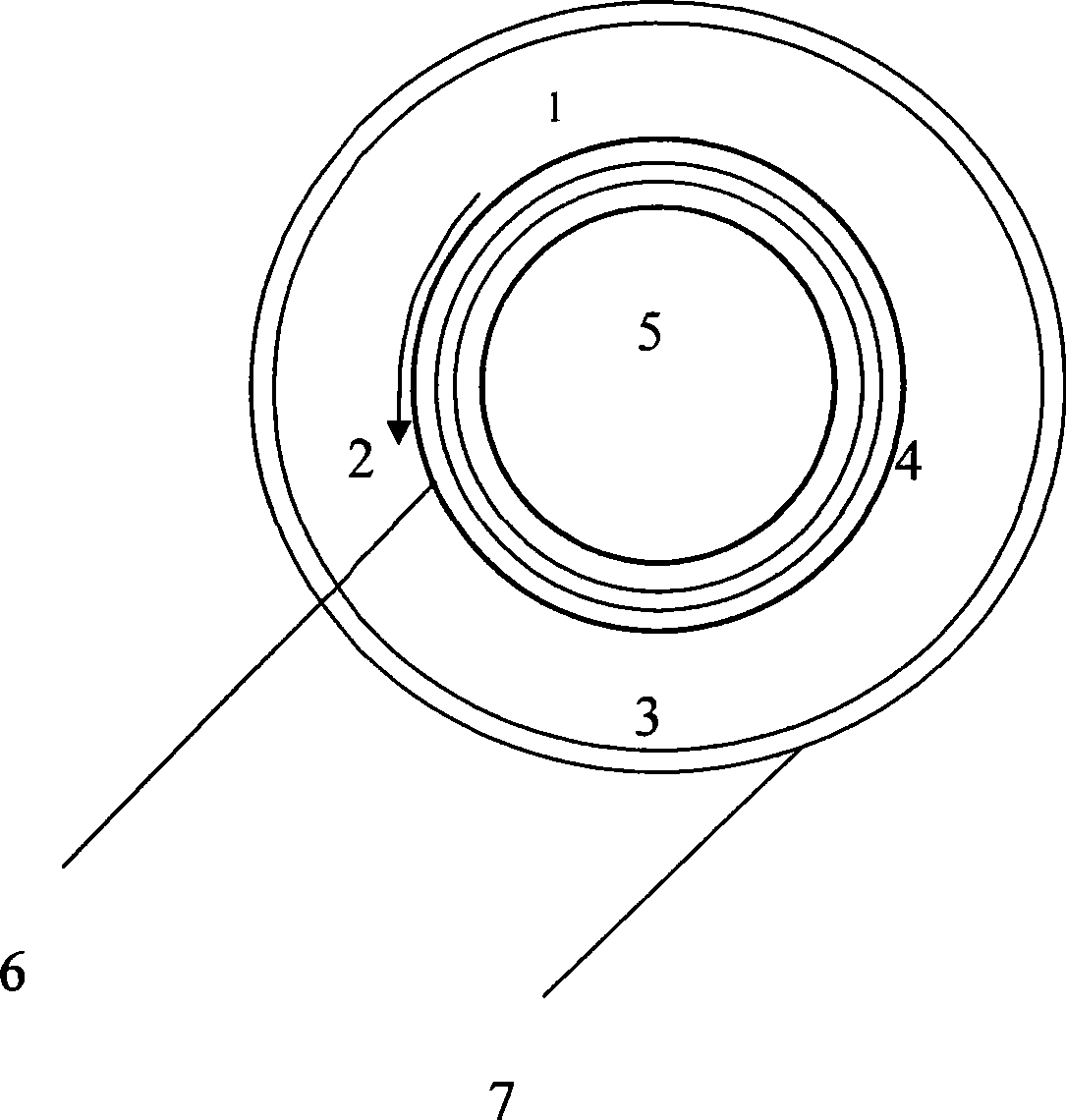

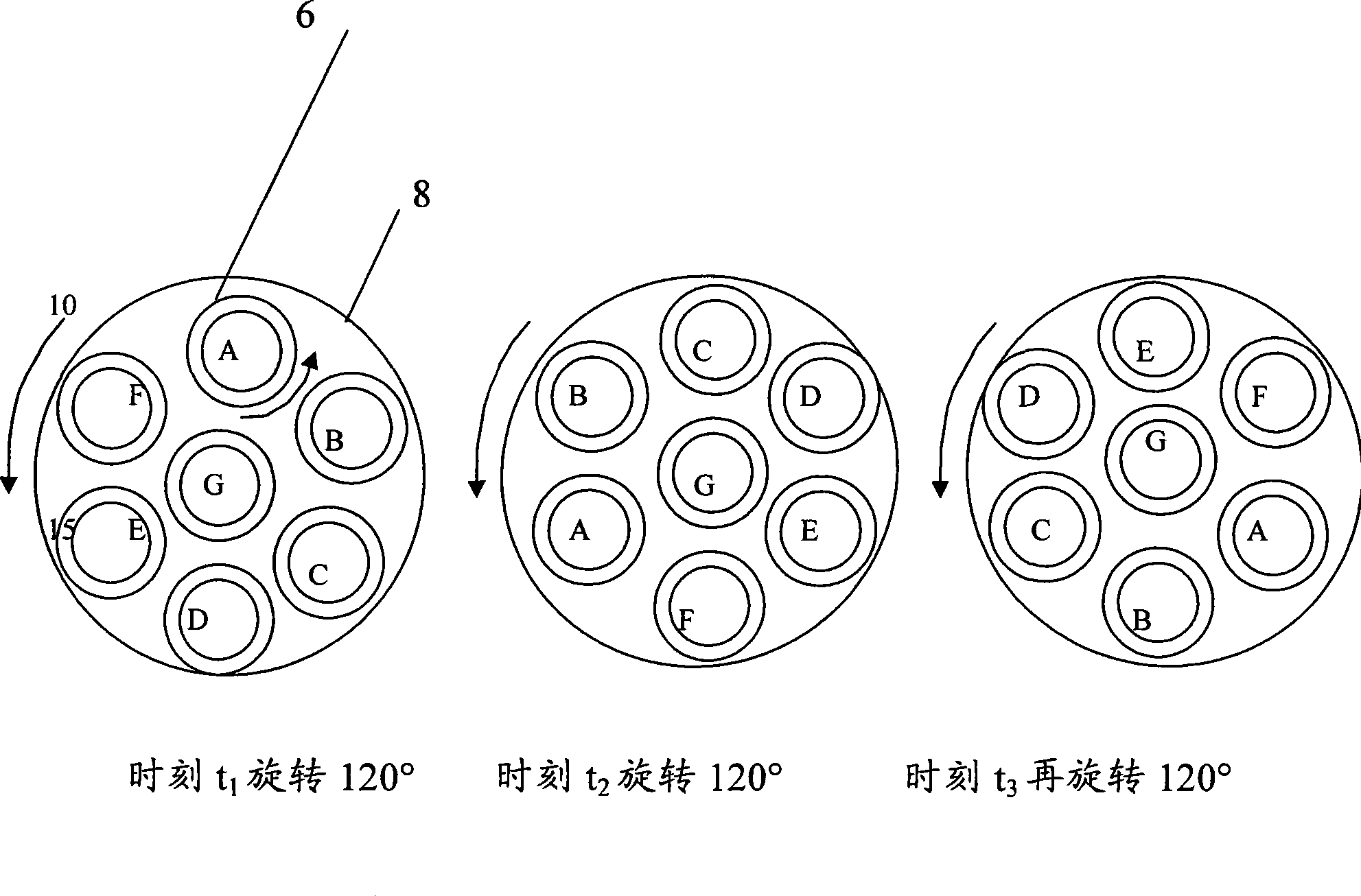

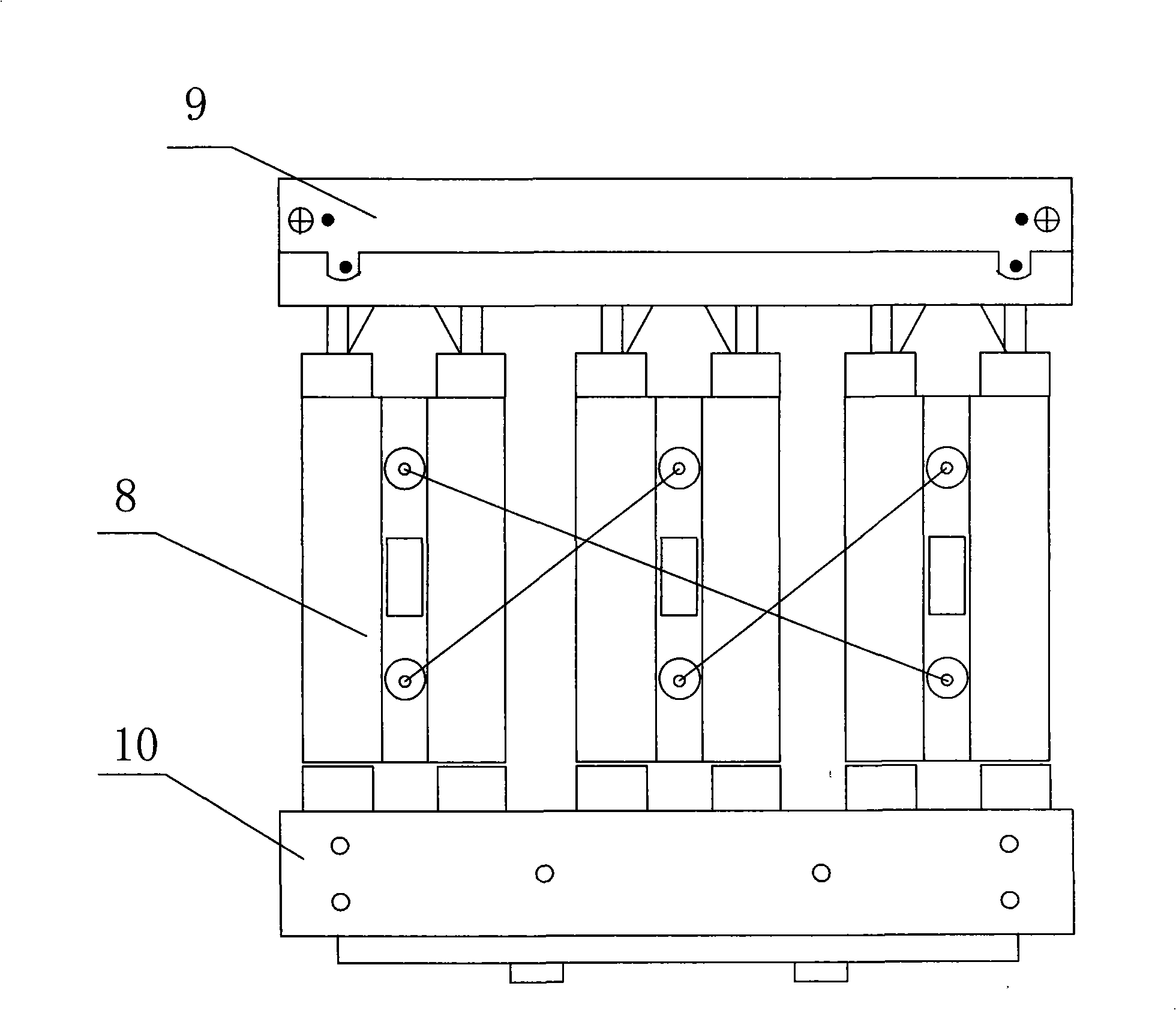

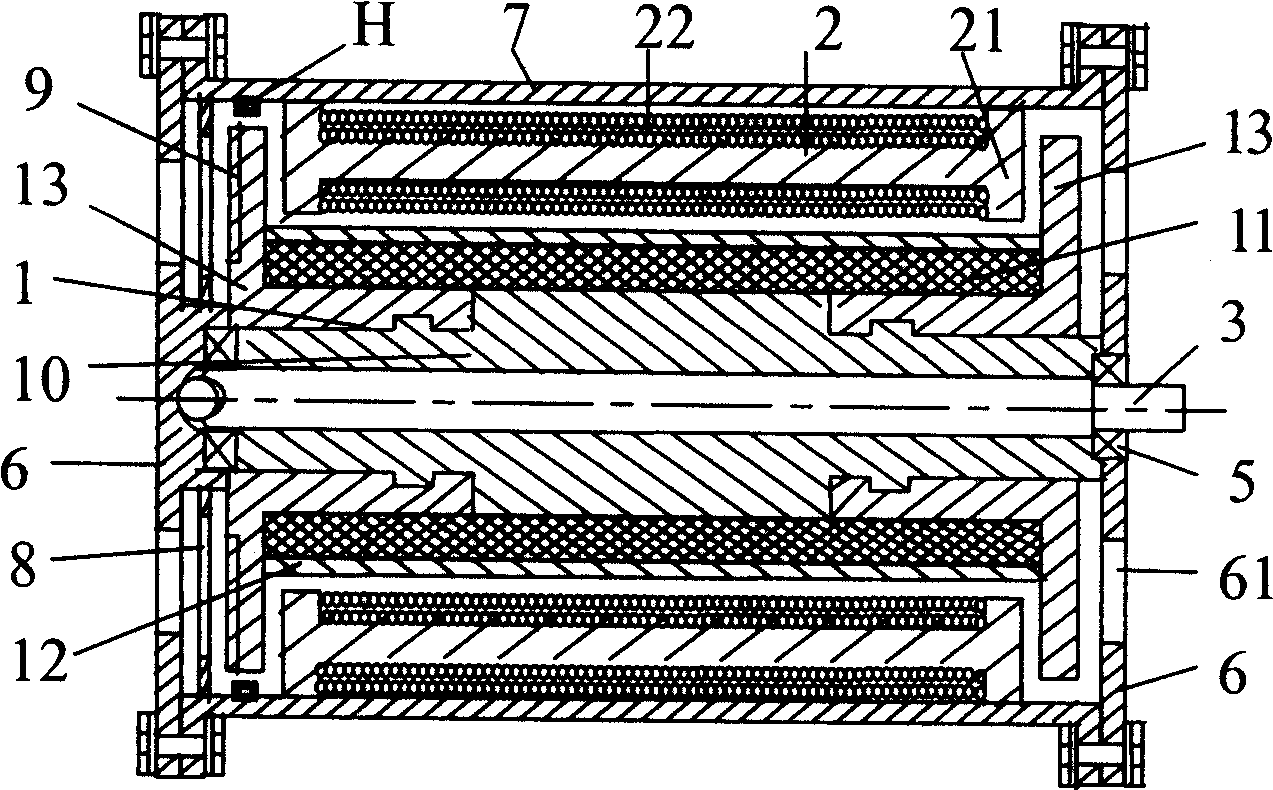

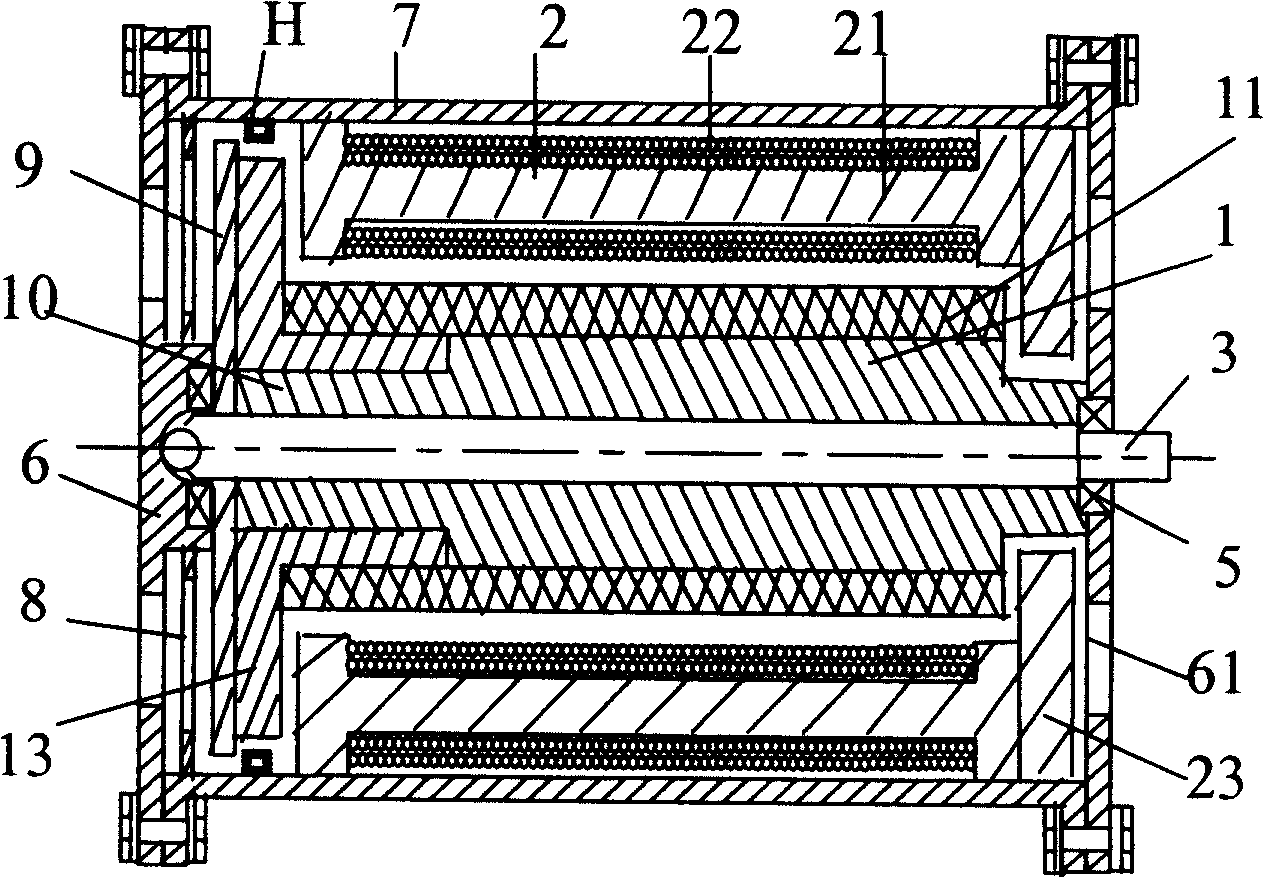

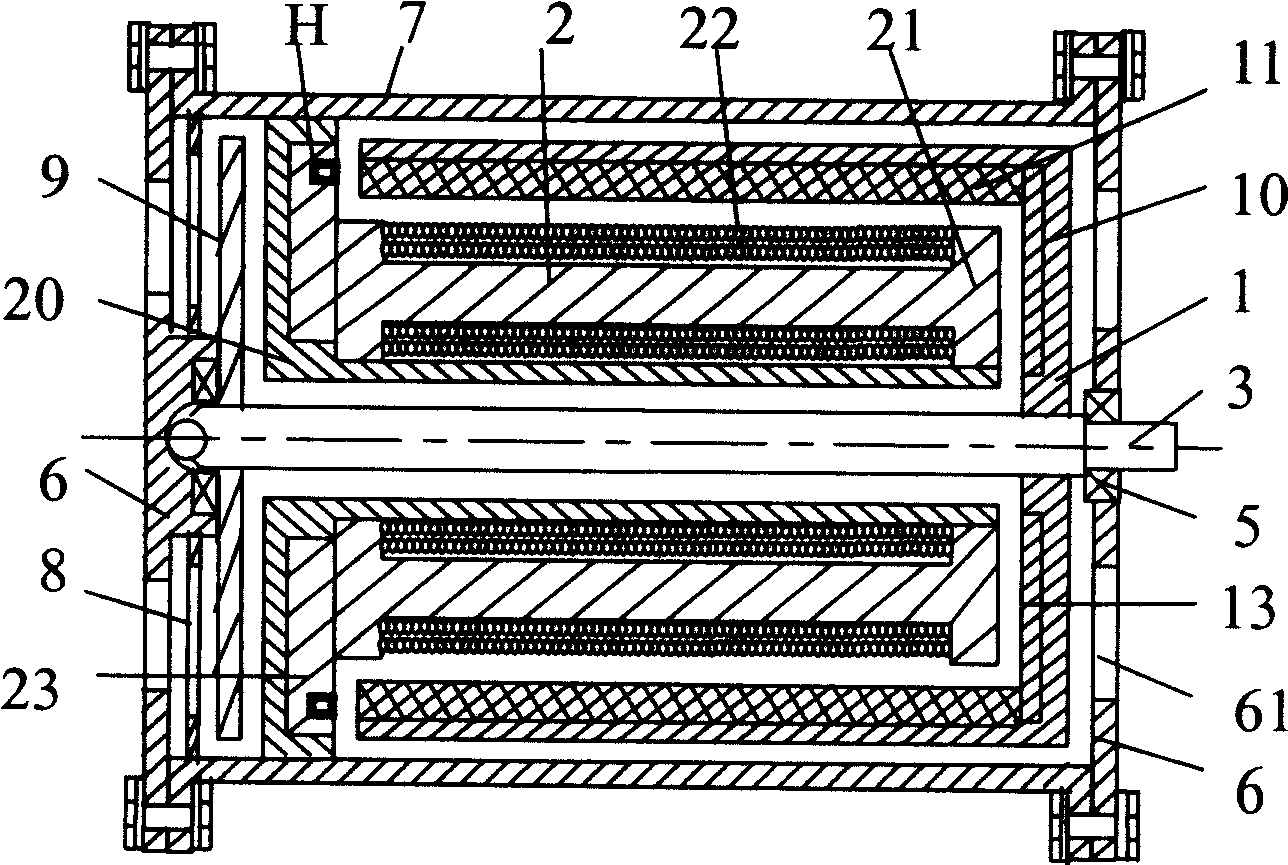

Magnetic suspension bilateral magnetic resistance driving type direct linear transmission device

InactiveCN102185459AIncrease profitSimple mechanical structurePropulsion systemsMagnetic holding devicesEngineeringStator

The invention discloses a magnetic suspension bilateral magnetic resistance driving type direct linear transmission device, which mainly comprises a linear bilateral long base, a bilateral long stator linear magnetic resistance motor, a movement bearing table, a stator base fixed connecting rod, a rotor inter-phase connecting rod, a linear movement displacement sensing ruler, an auxiliary support guide rail pair, a suspended air gap detection sensor, a radiating fan and the like. A magnetic suspension support magnetized loop is multiplexed with a linear magnetic resistance motor stator and rotor magnetized loop, a base is not needed to be used for magnetizing, a moving component is not provided with a permanent magnet and does not need an external power supply, and the transmission device has the advantages of simple and compact structure, low manufacturing cost, high power-to-volume ratio, high electromagnetic thrust, short magnetic circuit path, high inter-phase sealing property, high fault-tolerant capability, zero friction operation and the like.

Owner:NANTONG UNIVERSITY

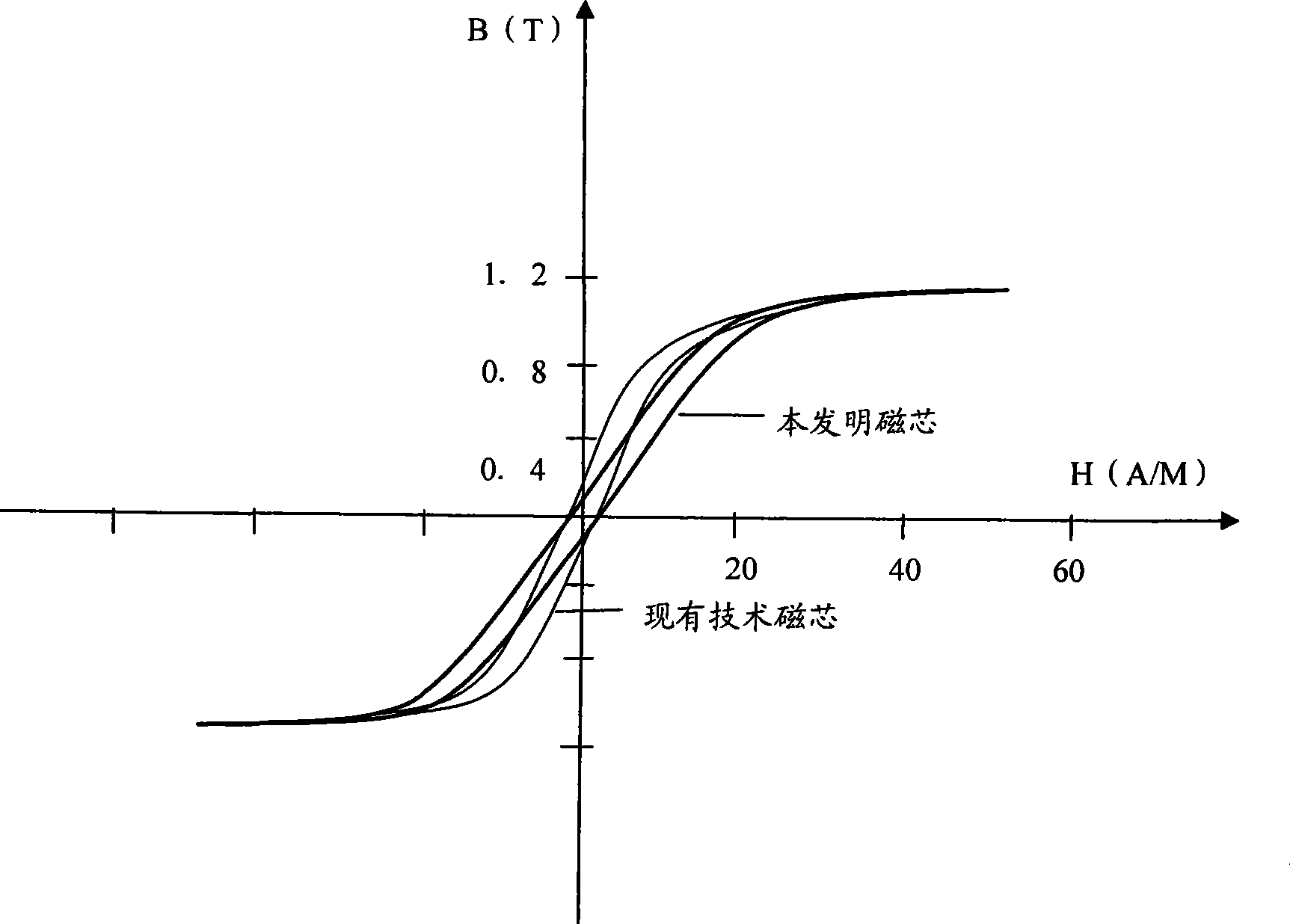

Iron based nanocrystalline magnet core for large power inverter power source and production method

ActiveCN101477868AGood tape making processReduce lossInorganic material magnetismTransformers/inductances magnetic coresPower inverterDownstream processing

The invention relates to a soft magnetic core used for a high-power inverter power supply, and a manufacturing method thereof. The magnetic core is made of an Fe-based amorphous nano-crystalline belt material through winding , and comprises components according to weight percentages as follows: 81%-85% of Fe, 0.01%-5% of Co, 7%-9% of Si, 1.5%-2.5% of B, 1%-2% of Cu, 4%-7% of M, and 0.001%-0.04% of M', wherein M is one or more of Nb, Mo, V, W and Ta, and M' is at least one of Al and Ti. The magnetic core is subjected to anneal in a protective atmosphere or a vacuum; when in anneal, the position of the magnetic core in a furnace is movable or rotatable, a holding temperature is 520-600 DEG C, the holding time is 1-2 hours, and a temperature rise speed is 100 DEG C per hour. The magnetic core manufactured by adopting the method has lower loss, better manufacturing technique properties, and good soft magnetic characteristics; moreover, the downstream processing after the heat treatment is applicable to various technique methods.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Soft magnetic thin strip, process for production of the same, magnetic parts, and amorphous thin strip

InactiveCN101663410AReduce lossHigh saturation flux densityInorganic material magnetismAmorphous phaseVolumetric Mass Density

The invention provides a soft magnetic thin strip which contains nanoscale fine grains and exhibits a high saturation magnetic flux density and excellent soft magnetic characteristics; a process for production of the same; magnetic parts; and an amorphous thin strip to be used in the production. In the invention, an amorphous thin strip is used, which is represented by the composition formula: Fe100-x-y-zAxMyXz-aPa (wherein A is at least one element selected from between Cu and Au; M is at least one element selected from among Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W and Mn; X is at least one elementselected from between B and Si; and x, y, z and a (in terms of atomic percentage) satisfy the relationships: 0.5<=x<=1.5, 0<=y<=2.5, 10<=z<=23, and 0.35<=a<=10 respectively) and permits 180 DEG bending. The amorphous thin strip can give through heat treatment a soft magnetic thin strip having a structure wherein grains of body-centered cubic structure having an average grain size of 60nm or beloware distributed in an amorphous phase with a grain volume fraction of 30% or above.

Owner:PROTERIAL LTD

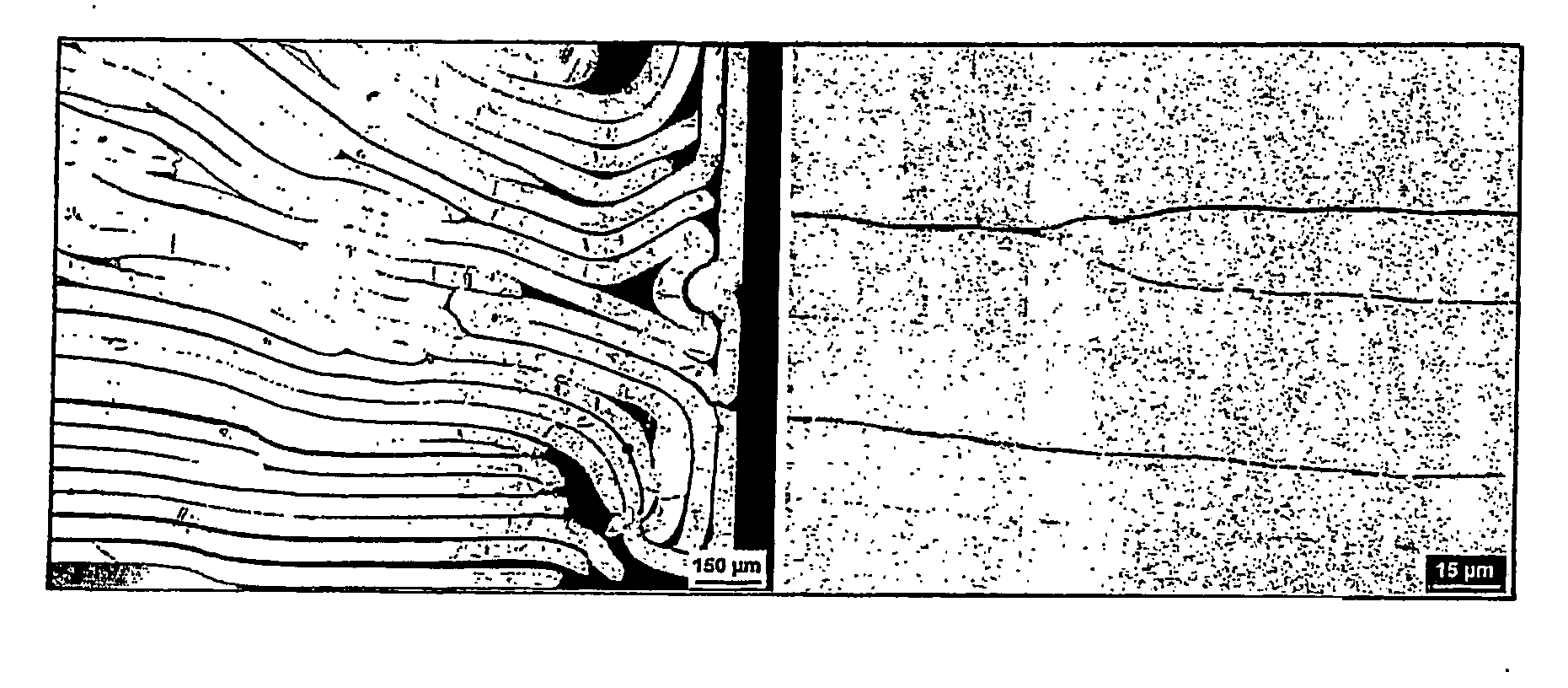

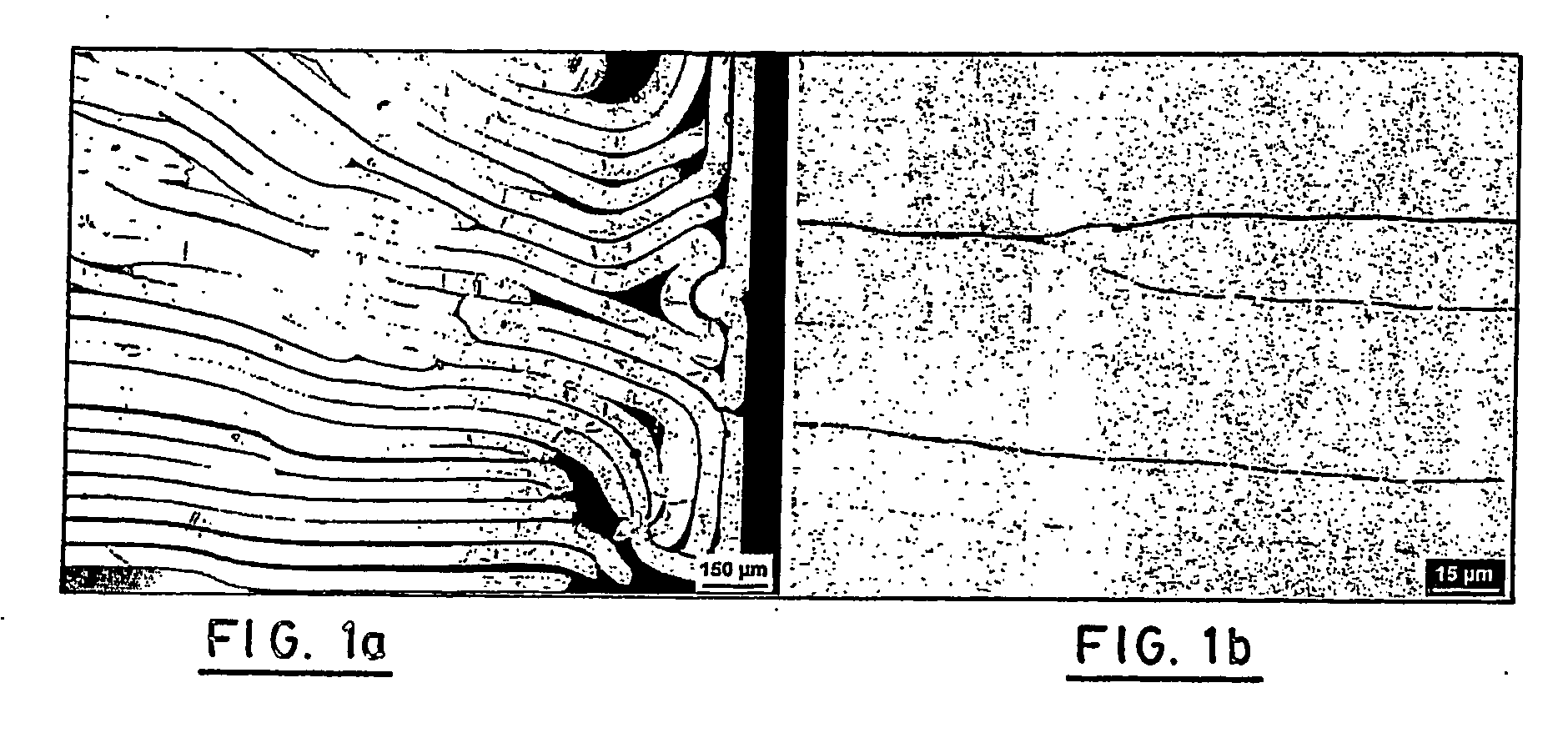

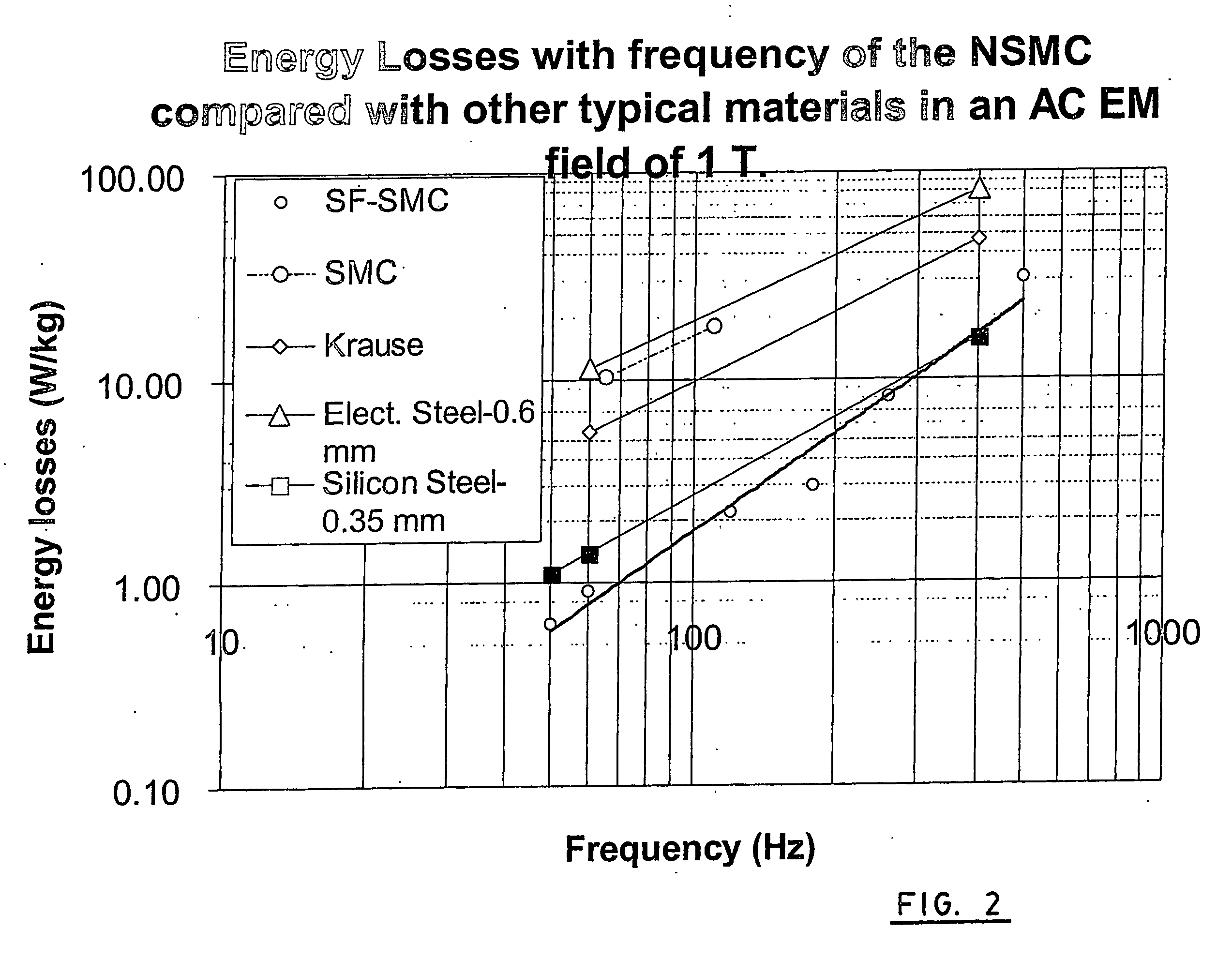

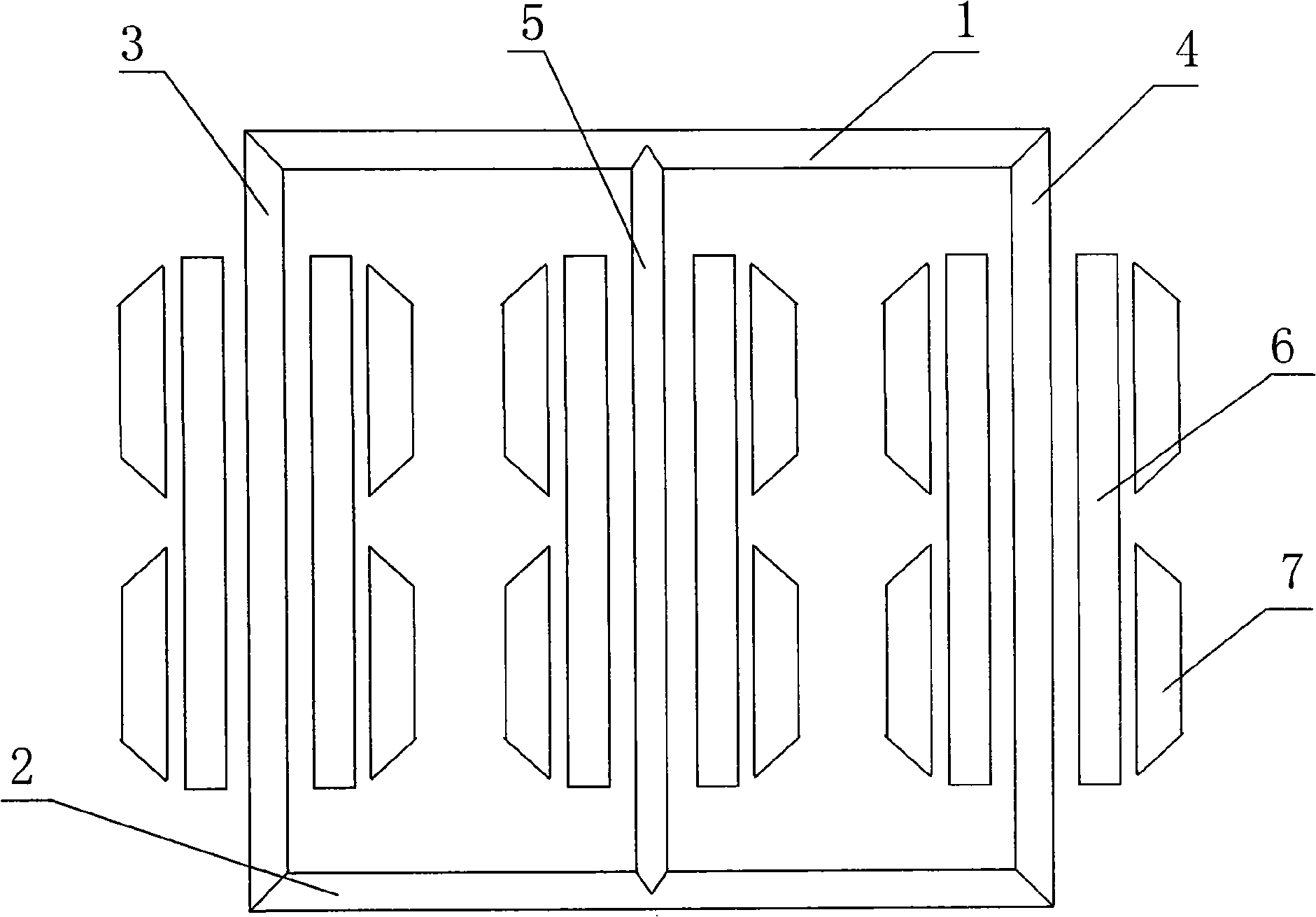

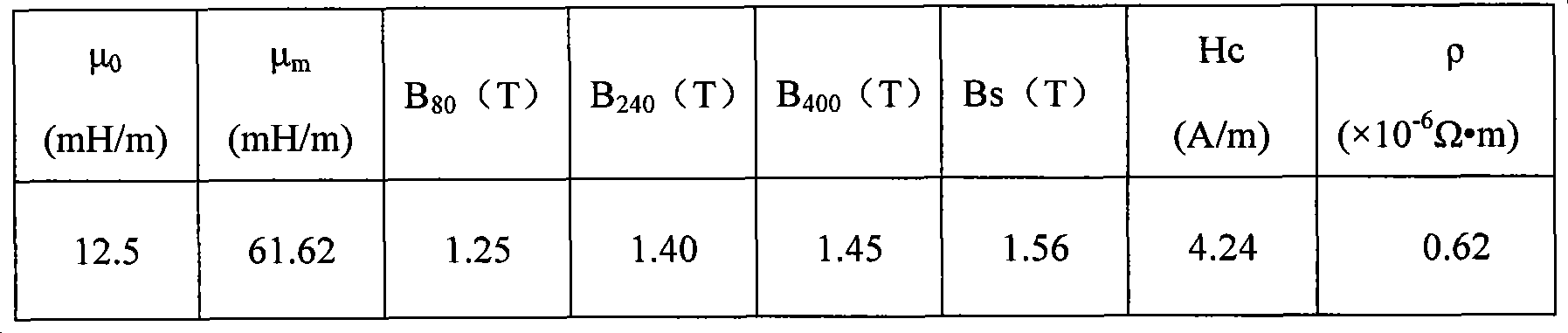

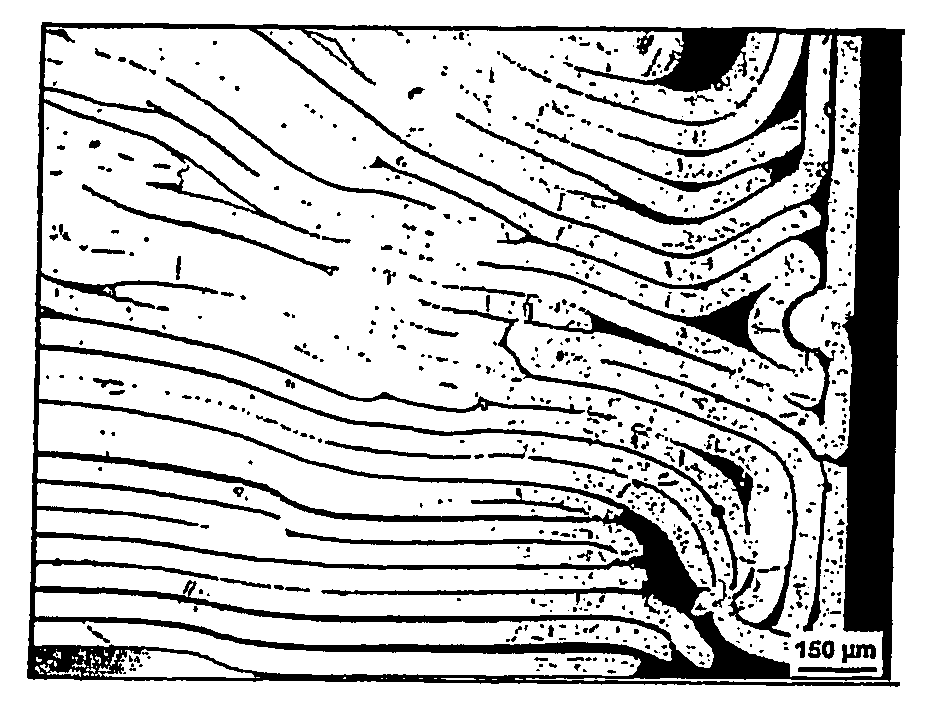

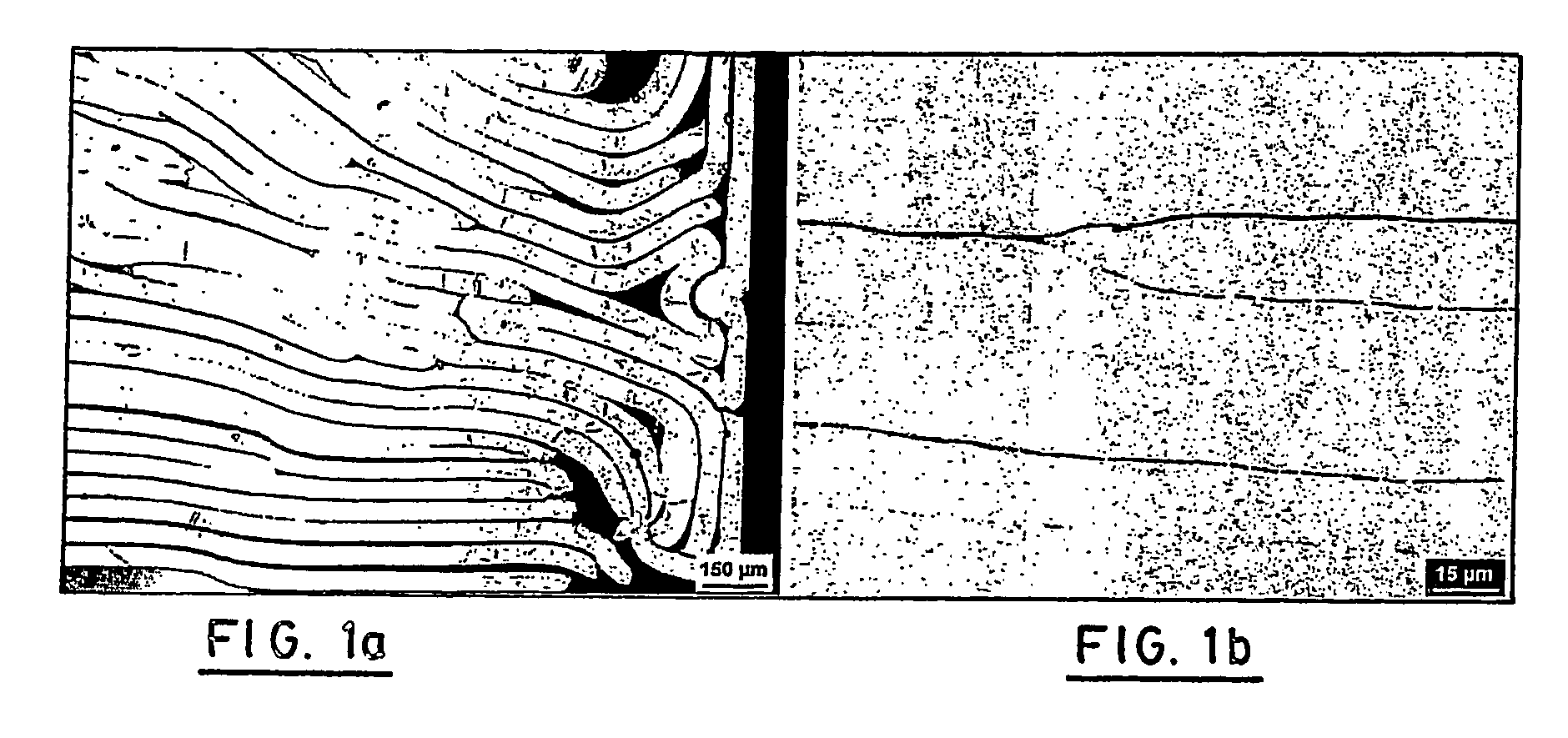

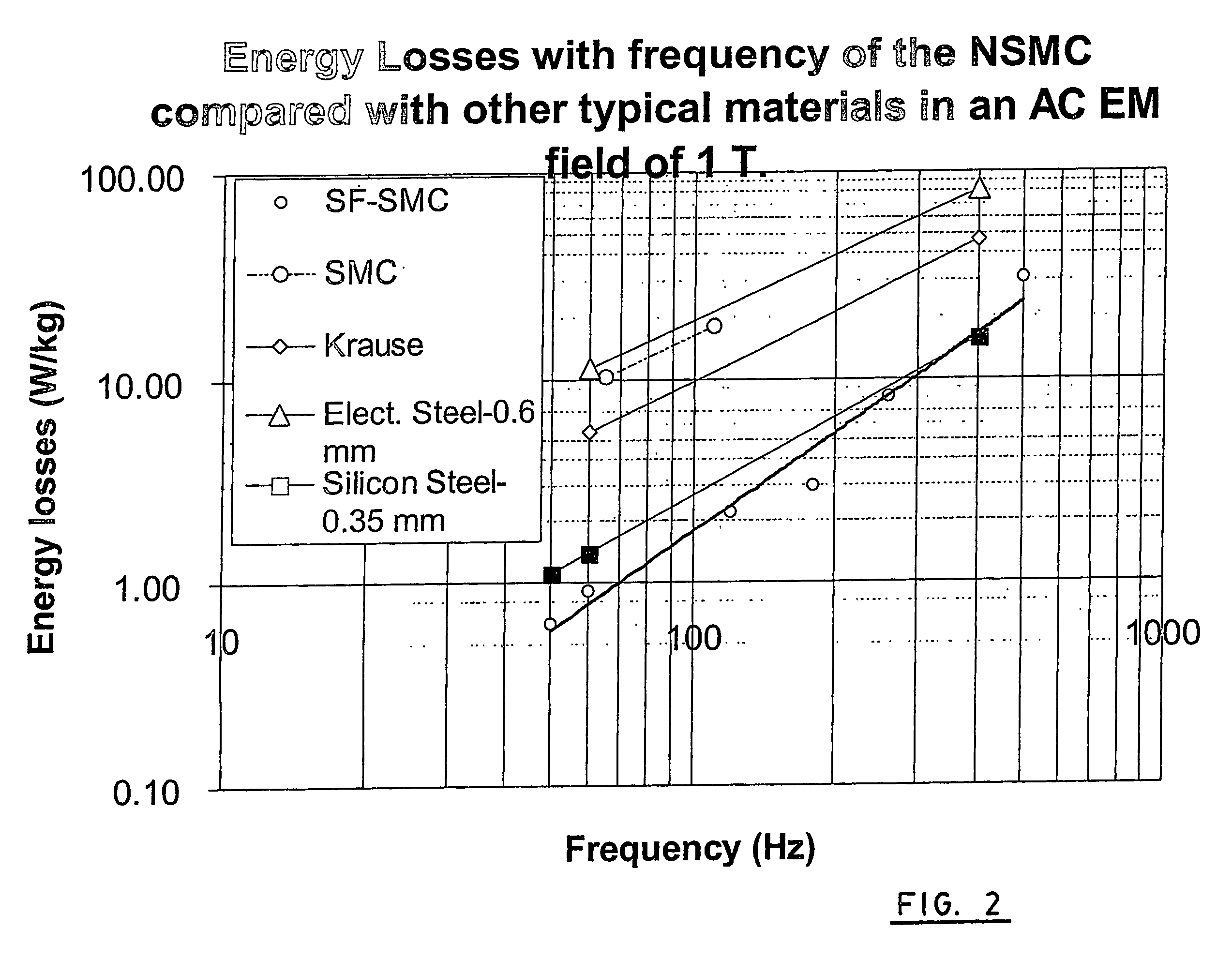

High performance magnetic composite for ac applications and a process for manufacturing the same

InactiveUS20060124464A1Improve magnetic propertiesLower average currentLiquid separation by electricityElectrostatic separationHysteresisTransformer

A magnetic composite for AC applications with improved magnetic properties (i.e. low hysteresis losses and low eddy current losses) is disclosed. The composite comprises a consolidation of magnetizable metallic microlamellar particles each having a top and bottom surfaces and opposite ends. The top and bottom surfaces are coated with a dielectric coating for increasing the resistivity of the composite and reducing eddy current losses. The dielectric coating is made of a refractory material and the ends of the lamellar particles are metallurgically bonded to each other to reduce hysteresis losses of the composite. A process for manufacturing the same is also disclosed. The composite is suitable for manufacturing devices for AC applications such as transformers, stator and rotor of motors, generators, alternators, field concentrators, chokes, relays, electromechanical actuators, synchroresolvers, etc . . . .

Owner:CORP IMFINE INC

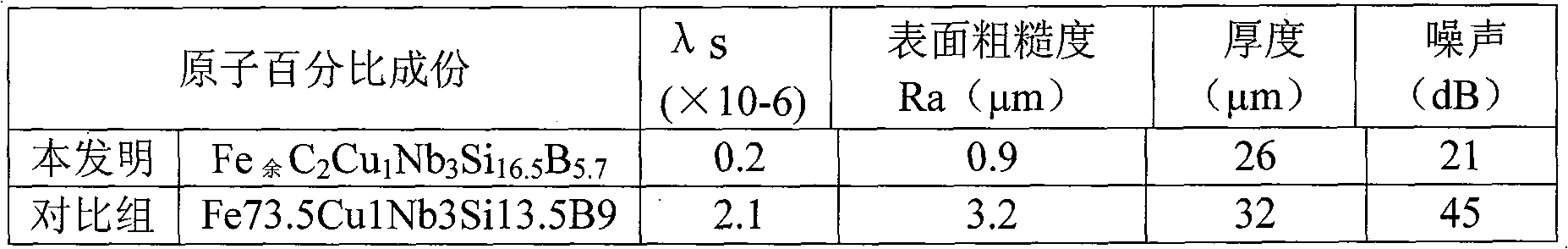

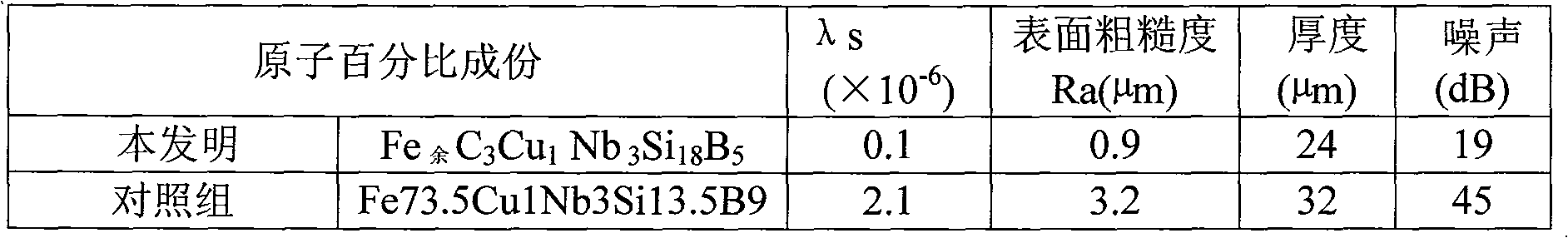

Low-noise transformer core for inverter power supply

ActiveCN101923941AImprove surface qualityReduce hysteresis lossTransformers/inductances magnetic coresFurnace typesVacuum furnaceLiquid steel

The invention discloses a transformer core for an inverter power supply, raw material components comprising C, Si, B, (Nb, Sb, V, Mo, Ta, Cr and W), Cu and the balance Fe are put into a vacuum furnace based on a ratio to be refined, the temperature of liquid steel is 1500DEG C, argon is introduced, sprayed and cast on a high rotating speed copper roller, and water is cooled by differential movement, thus obtaining a low magnetostriction amorphous alloy strip with the length of 20-26 micrometers, the strip is wound into a transformer core and heat treatment is carried out at 530DEG C, the temperature is kept for 2-4 hours, thus crystallizing the alloy and obtaining a nano-crystalline core of a low magnetostriction coefficient lambda s; a direct current magnetic field is applied at the same time of keeping and reducing the temperature during the heat treatment; the position of the nano-crystalline core is changed radically, a compressive stress is applied, the stress is eliminated, and the nano-crystalline core recovers until no adhesion exists between lamellas of the whole core; and two side ends of the nano-crystalline core are respectively coated with an unstressed glue layer, and then the surface of the whole nano-crystalline core is coated with an epoxy resin insulating layer for reducing noise. The transformer core which is ideal at present has good noise reduction effect.

Owner:秦皇岛市燕秦纳米科技有限公司

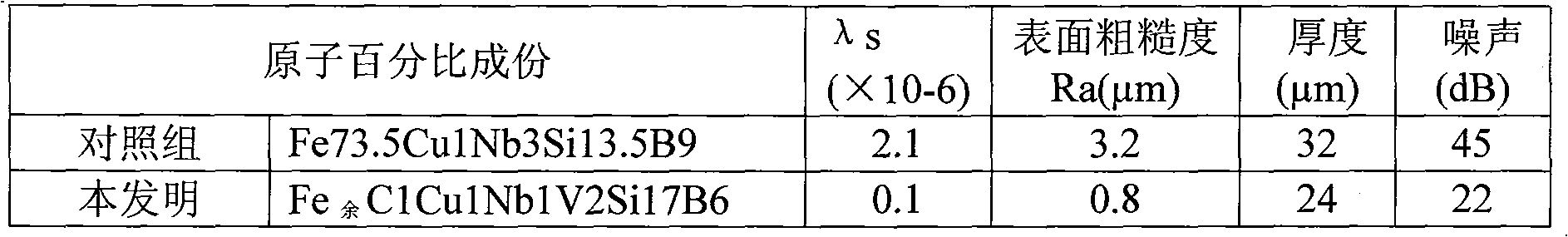

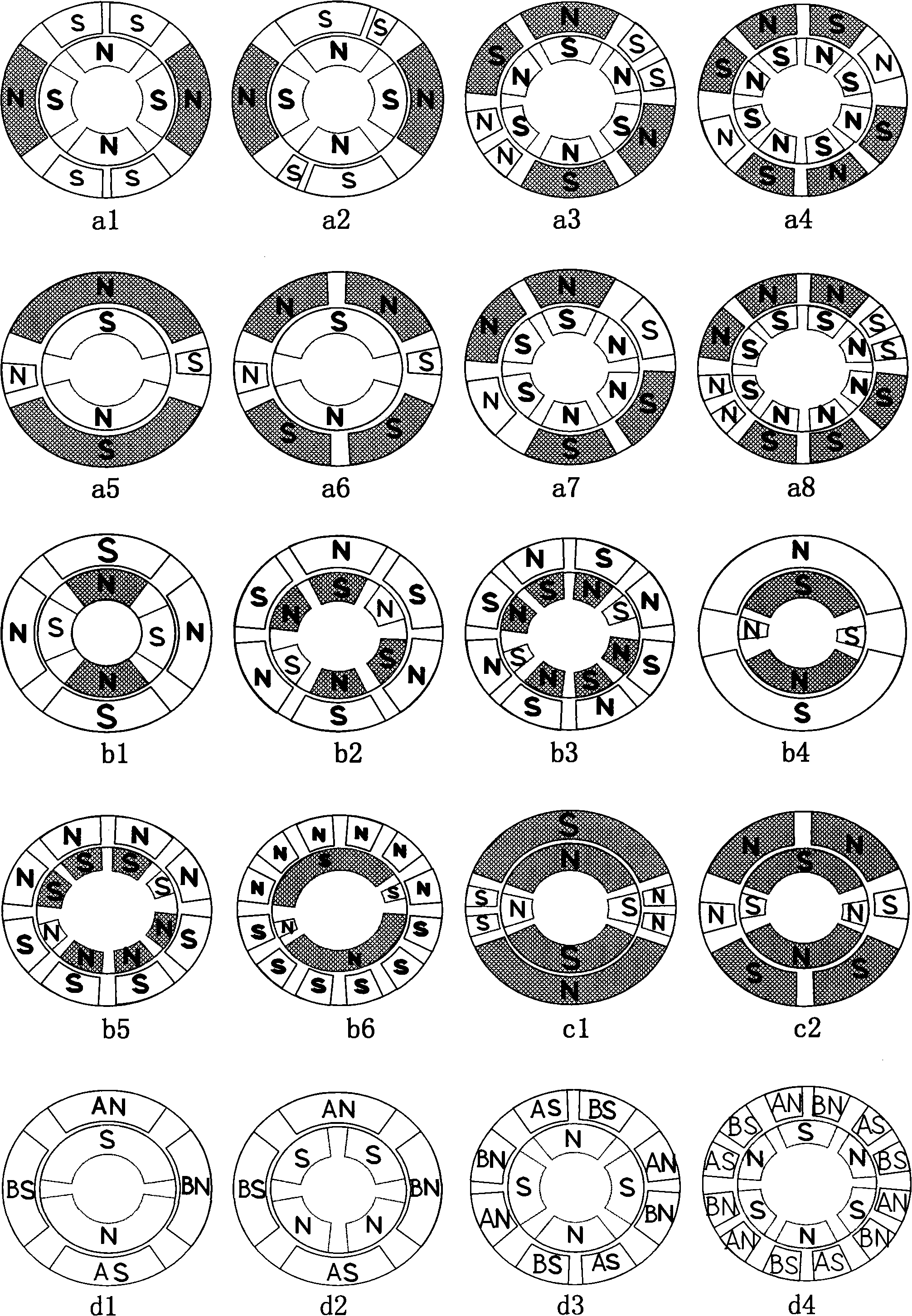

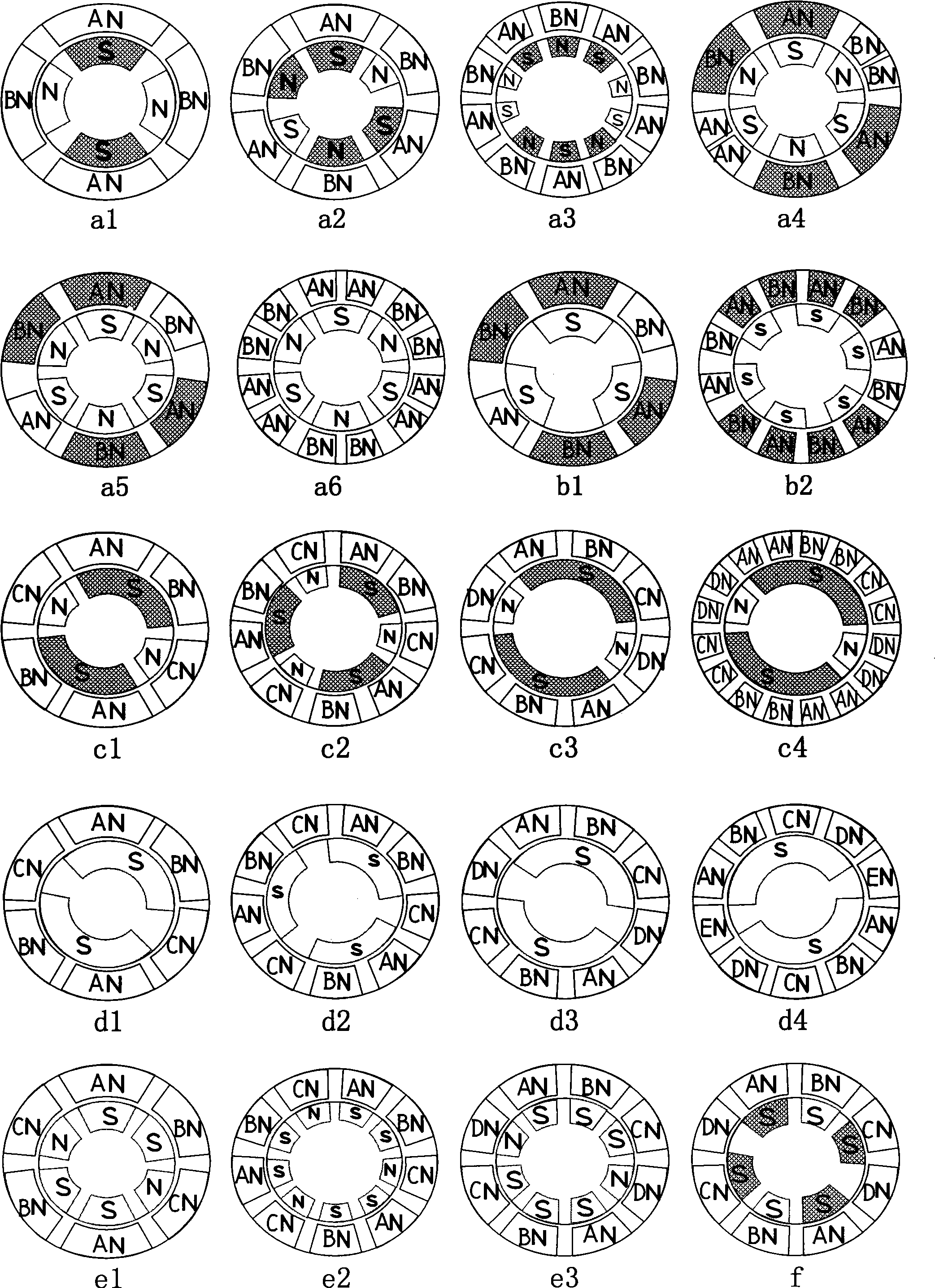

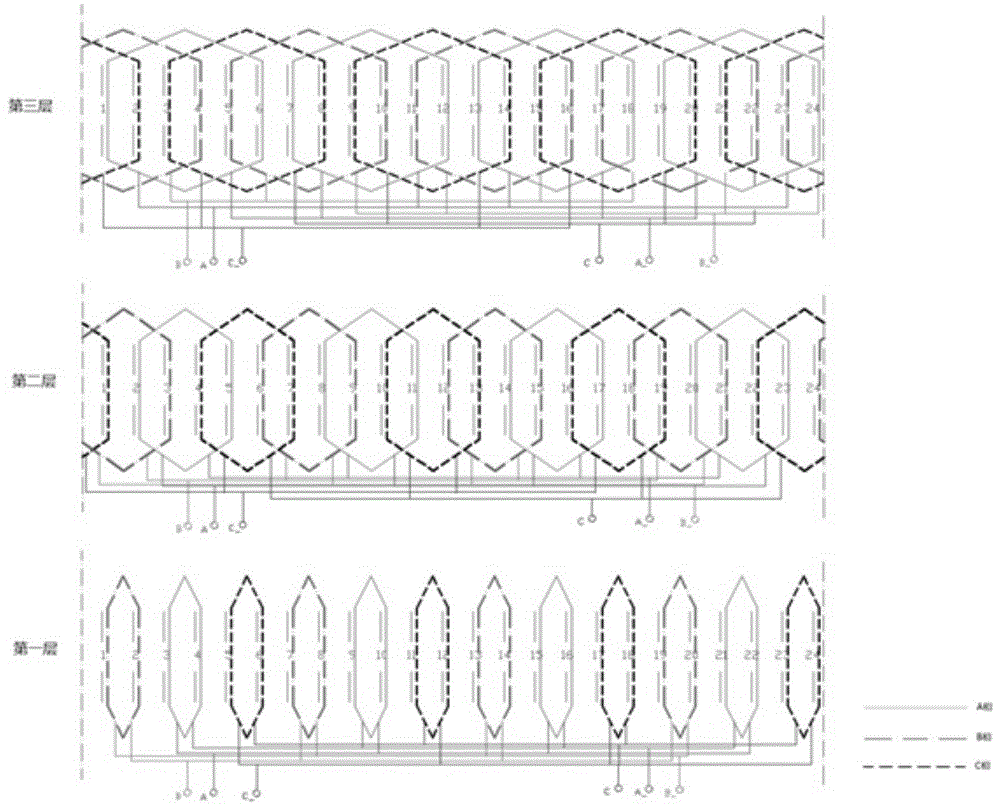

Motor with strong weak air-gap field in alternative distribution

InactiveCN101820190ASmooth startGuaranteed uptimeElectric machinesMagnetic circuit shape/form/constructionPhysicsStator

The invention provides a motor which has low cost, saves energy, has high efficiency, is self-starting, has no blocking, is not asynchronous and has no torque pulsation, wide application range and strong weak air-gap field in alternative distribution. The motor is designed based on the principle that like poles repel and unlike poles attract in magnetic field, the stator (or rotor) adopts magnets which are in the same size and in uniform distribution, and the corresponding rotor (or stator) adopts magnets which are not in the same size, wherein small magnets deflect the same polar distance in the same direction, or the corresponding rotor (stator) adopts magnets which are in the same size, wherein a small number of symmetrical magnets deflect the same polar distance in the same direction; or the stator and rotor all adopt magnets which are not in the same size, wherein small magnets deflect the same polar distance in the same direction; or the stator (or rotor) adopts electromagnets which are in the same size and in uniform distribution and windings of all phases are on and off in turn, and the corresponding rotor (or stator) adopts magnet which does not deflect. The strong weak air-gap magnetic field in alternative distribution along circumference 'strong weak strong weak......, strong strong weak strong strong weak......, strong strong strong weak strong strong strong weak.......' is formed between the stator and rotor, thus the motor can be self-starting and can operate stably.

Owner:王铂仕

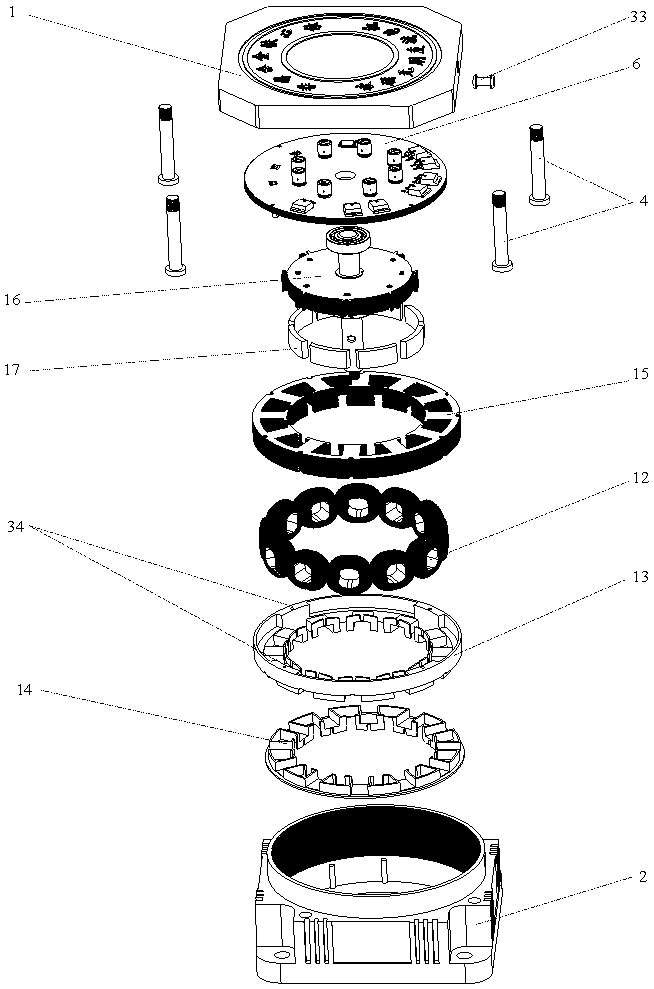

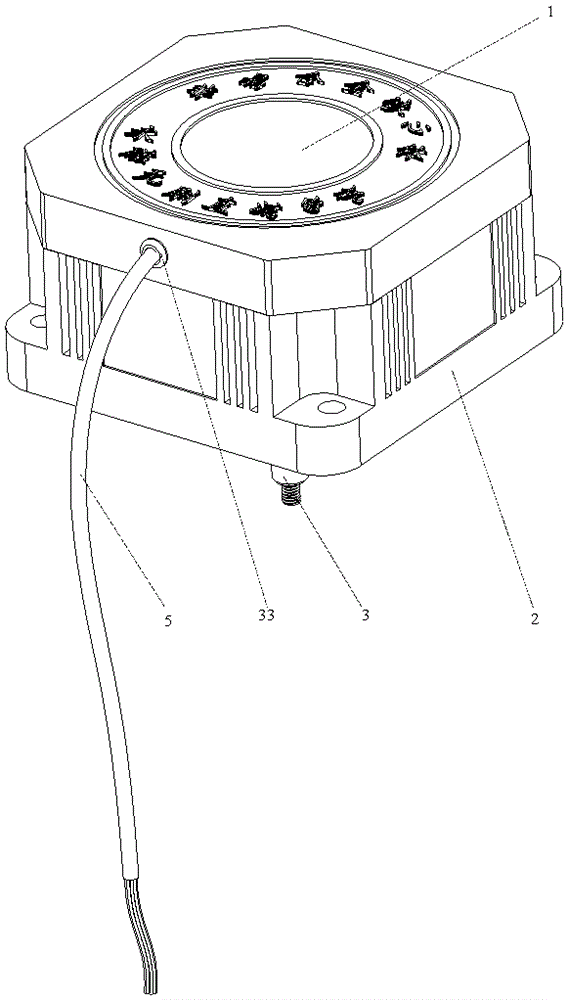

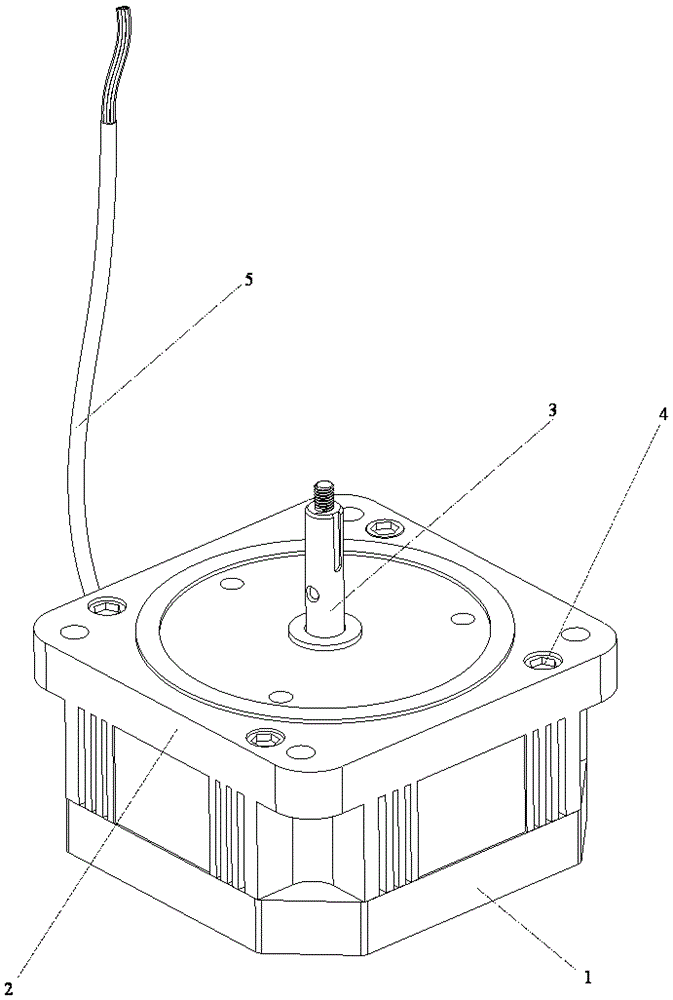

Amorphous alloy iron core permanent magnet brushless direct-current motor

ActiveCN106208545AImprove reliabilityImprove efficiencyAssociation with control/drive circuitsSupports/enclosures/casingsHall elementStator coil

An amorphous alloy iron core permanent magnet brushless direct-current motor consists of the two portions including a motor body and a controller, wherein the motor body portion comprises a motor upper end cap, a motor lower end cap, a motor output shaft, a shaft sleeve, an upper framework, a lower framework, a stator coil, a stator iron core body, a rotor iron core body and neodymium iron boron permanent magnet block, and the controller portion comprises an aluminum metal based printing circuit board, a control cable, a double-core single chip microcomputer, a power VMOS tube and a Hall element. The amorphous alloy iron core permanent magnet brushless direct-current motor is characterized in that both the stator iron core body and the rotor iron core body are formed by superposing iron based amorphous alloy sheets, the stator iron core body is fixed through joint supporting of the upper framework and the lower framework, the stator coil is made by winding an anaerobic copper line, all of controller elements and circuits are integrated on the aluminum metal based printing circuit board, an outer thread is carved on the supporting aluminum metal cylinder of the aluminum metal based printing circuit board, the cylinder is screwed into the inner wall thread of the motor lower end cap during installation to form a motor body and controller mechanical-electrical integrated structure.

Owner:彭希南

Epoxy cast dry transformer

InactiveCN101308721AReasonable designCreative ideaTransformers/inductances coils/windings/connectionsEpoxyLow voltage

Disclosed is an epoxy resin cast dry type transformer, which comprises a low-voltage winding, two high-voltage windings, an iron core, an upper heel piece, a lower heel piece, an upper clamp, and a lower clamp. The low-voltage winding is arranged at the inner layer of the loop and the high-voltage windings are arranged at the outer layer of the loop. The low-voltage winding is made of clutch gold and is provided with an insulating interlayer which is presoaked with DMD resin. The initial loops of the high-voltage windings are located at one end of the whole loop, and the starting end of the first coil of each layer of the high-voltage windings is connected with the finishing end of the last coil of the next layer. The number of the coils of the windings descends from the inner layer to the outer layer, making the windings developing into antiparallelogram structures; a soft gridding cloth layer is arranged between each two adjacent layers; the whole medium is epoxy resin and solvent-free gridding material is arranged between the outer layers of the windings at both ends of the whole loop. The epoxy resin cast dry type transformer is reasonable in design, novel in design, large in power, and small in size, and is convenient to install and easy to maintain. The epoxy resin cast dry type transformer is safe, stable and reliable and is long in service life and low in using cost and requires no daily maintenance. The epoxy resin cast dry type transformer is of strong practicability and is applicable in power supplying departments and power consuming departments.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

Permanent magnetic push-pull brushless motor

InactiveCN101499700ASmooth startSmall excitation lossMagnetic circuit rotating partsStructural associationBrushless motorsElectric machine

The invention provides an energy-saving effective permanent magnetic brushless rotation motor which starts and runs stably and has low cost. The motor owns two air gap magnetic fields at the magnetic poles of two ends; the deformed rotor permanent magnet or stator electromagnet leads the rotor magnetic pole (or stator magnetic pole) to be staggered by a certain of pole distance at the air gap magnetic fields of two ends; furthermore, the air gap magnetic field at one end of the motor is led to be less than the air gap magnetic field at the other end by technical means, thus leading the motor to keep directional rotation without a starting device. The rotor magnetic poles are intermittently arranged in pairs according to N, S and the like. The stator can be a conversion-typed stator and a commutation-typed stator; all coils at one end of the conversion-typed stator have the same polarity (N-pole or S-pole; the polarity of the coils at the other end are all S-pole or N-pole); the polarity of the magnetic pole of the commutation-typed stator coil is intermittently arranged in pairs according to N, S and the like; and the magnetic pole of the alternating current commutation-typed stator is intermittently arranged in pairs according to N, N, S, S and the like. The quantity of the rotor magnetic poles and the stator magnetic poles is configured according to the proportion of 1:1 or 1:2 or 2:3.

Owner:王铂仕

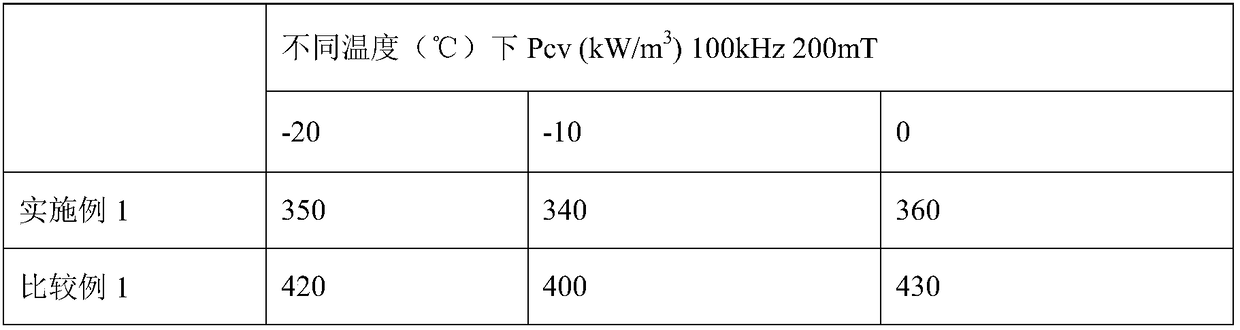

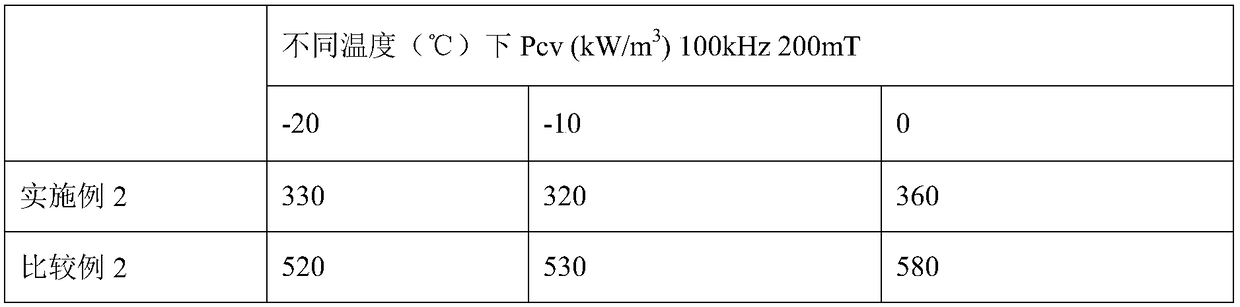

MnZn power ferrite material for reducing negative temperature loss and preparation method thereof

InactiveCN108821760AReduce lossLow Loss MeterInorganic material magnetismInductances/transformers/magnets manufactureNegative temperatureMaterials science

The invention relates to the field of MnZn power ferrite, in particular to a MnZn power ferrite material for reducing negative temperature loss and a preparation method thereof. The MnZn power ferritematerial consists of a main component and an additive, wherein the main component and the content thereof are calculated according to the following oxides: 52.60-52.80mol% of Fe2O3, 9.5-10.2mol% of ZnO and the balance of MnO; and the components of the additive are calculated according to the following oxides based on the total weight of the main component raw materials: CaCO3, ZrO2 and Co2O3, andthe content of ZrO2 must be greater than 0.015wt%. The MnZn power ferrite material provided by the invention can have a low loss at -20-0 DEG C and can be applied to the fields of communication, newenergy and automobiles under negative temperature conditions.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

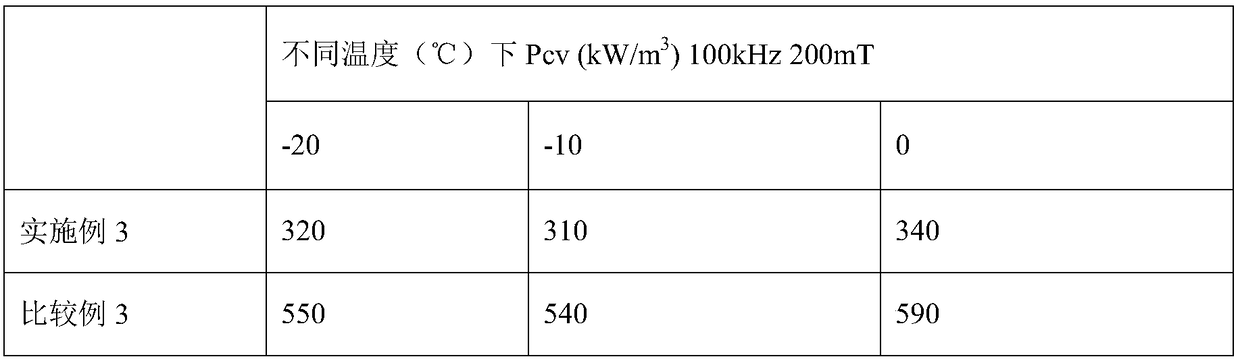

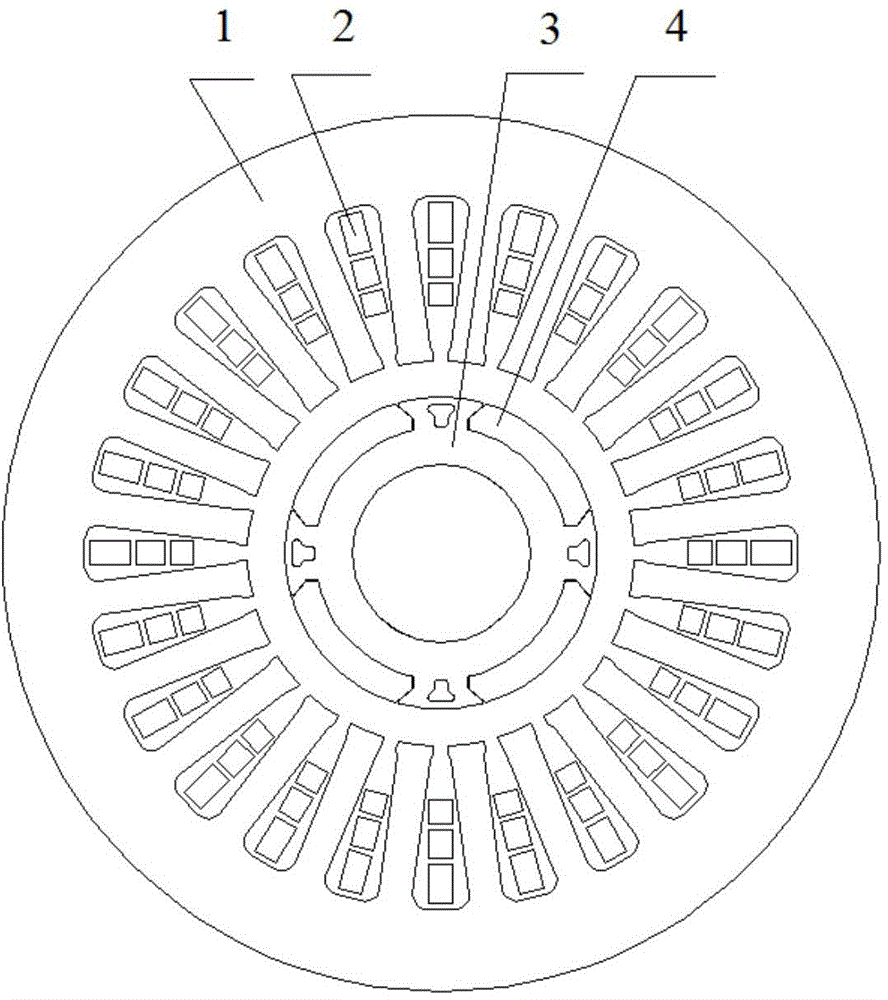

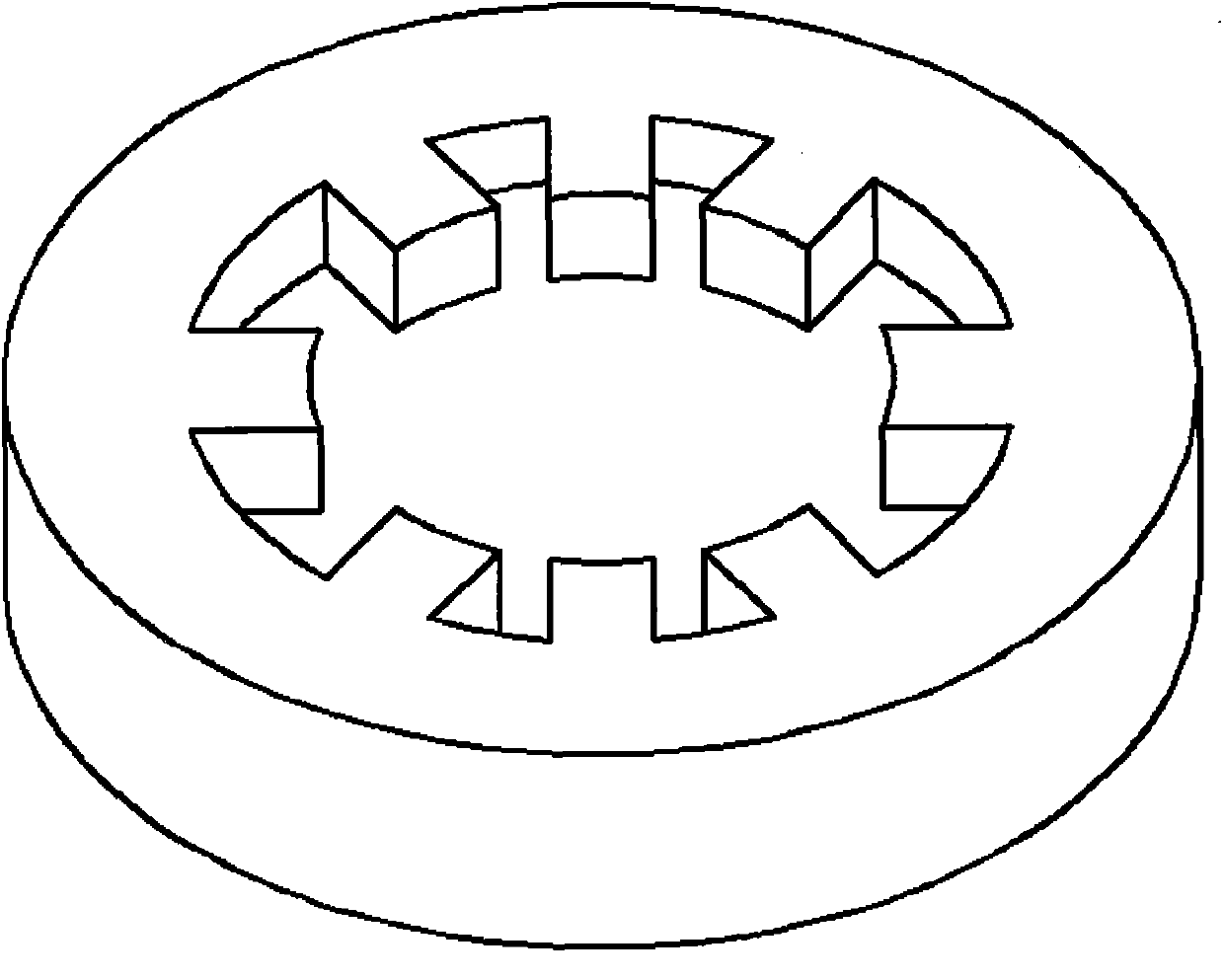

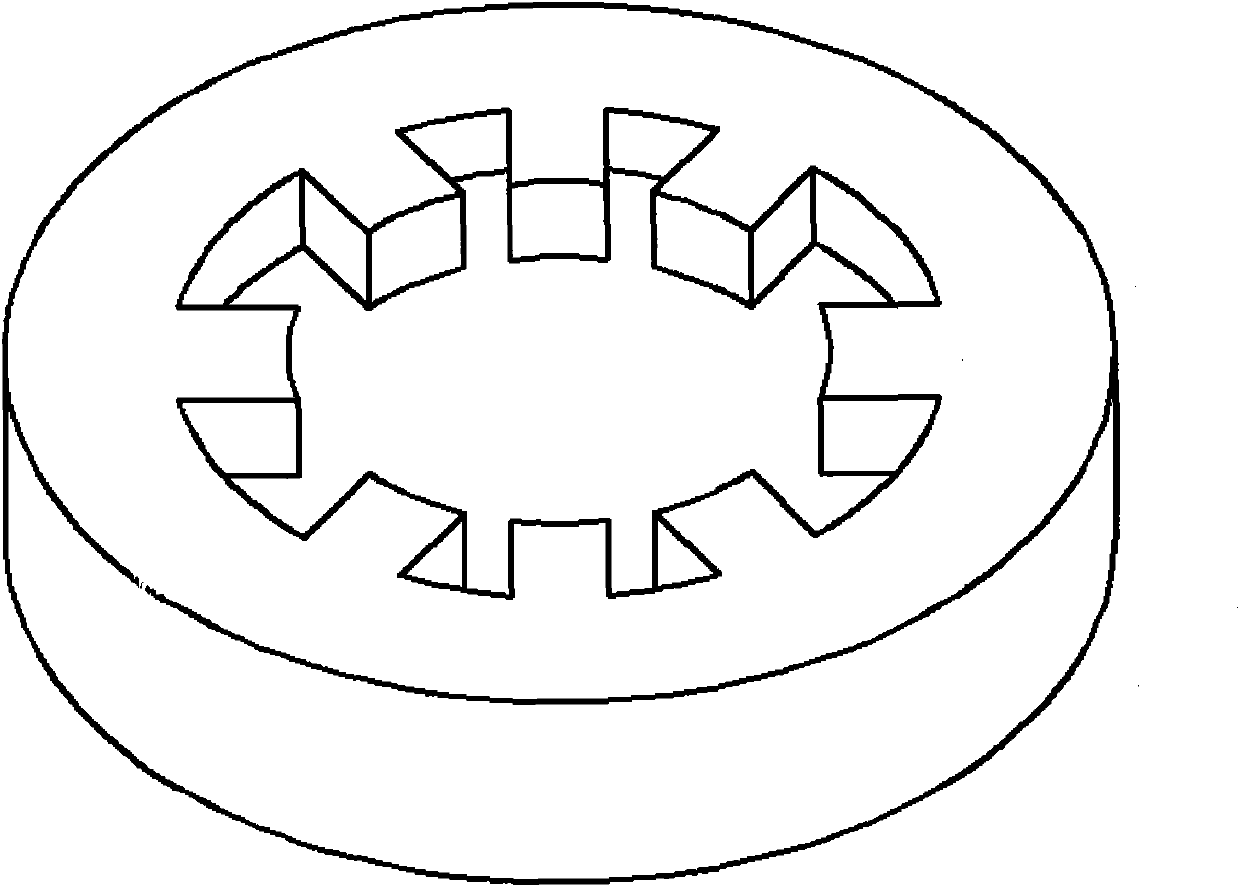

High-speed electric machine electromagnetism structure for air compressor

ActiveCN104795909AIncrease speedImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetConductor Coil

The invention relates to a high-speed electric machine electromagnetism structure for an air compressor. The high-speed electric machine electromagnetism structure for the air compressor comprises a stator core, a stator winding which is arranged on the stator core, a rotor core and a permanent magnet which is clamped on the surface of the rotor core; a plurality of stator grooves are uniformly formed in the circumference of the stator core; the stator winding is arranged inside the stator grooves in a connecting mode of three-layer low harmonic wave concentric winding; a plurality of wedge-shaped grooves are uniformly distributed along the circumference of the surface of the rotor core; a wedge-shaped arm is arranged between the adjacent two wedge-shaped grooves; air magnetic separation holes which are used for improving the gap flux density amplitude are formed in the wedge-shaped arm; permanent magnets are clamped in the wedge-shaped grooves. Compared with the prior art, the high-speed electric machine electromagnetism structure for the air compressor has the advantages of being compact in integral structure, high in rotation speed, high in mechanical intensity, small in harmonic loss and the like.

Owner:TONGJI UNIV

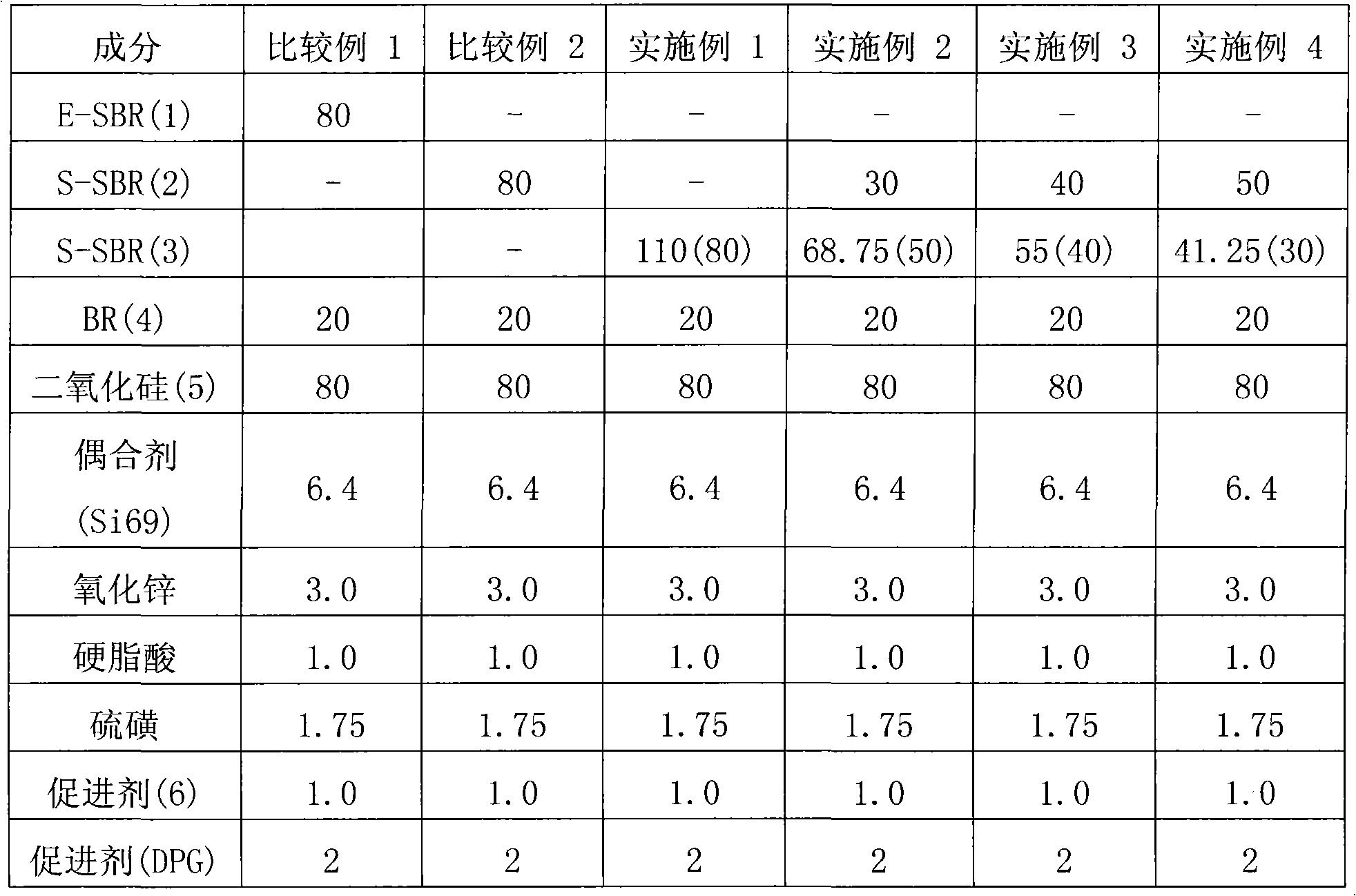

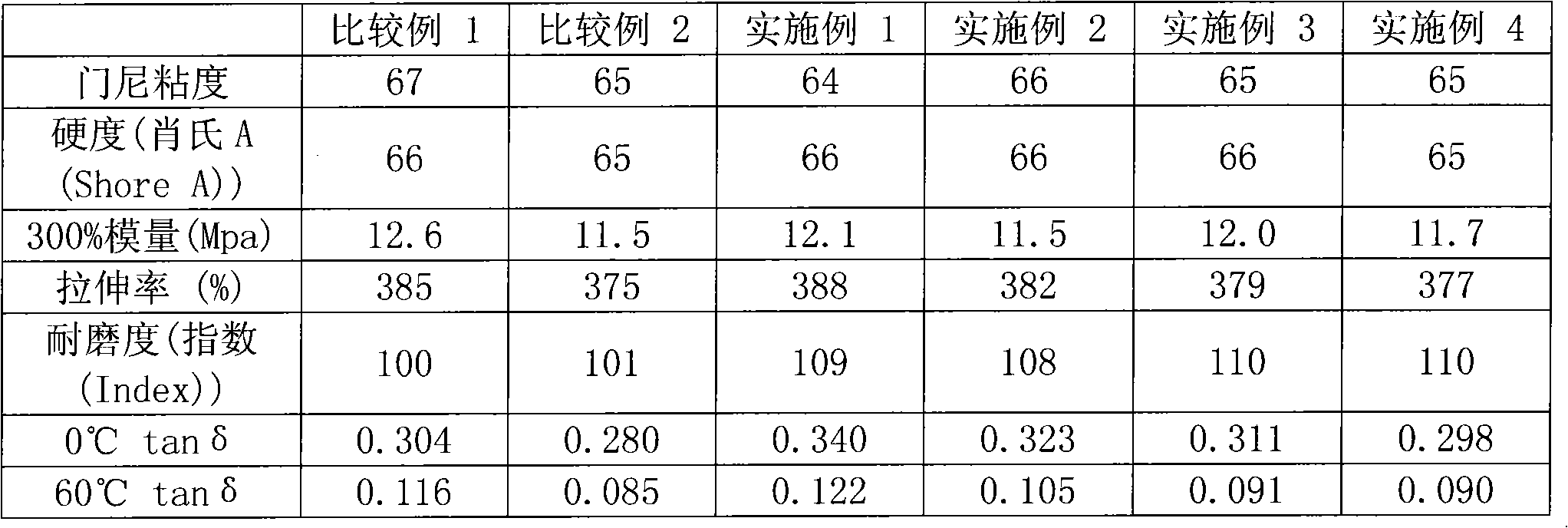

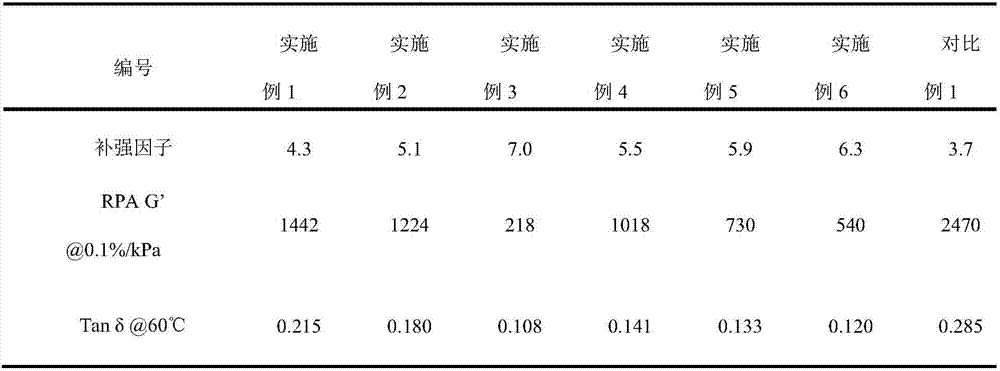

Rubber composition for tire tread and tire manufactured with the same

InactiveCN102101920AReduced braking effectReduce hysteresis lossSpecial tyresRolling resistance optimizationTire beadPolymer science

The present invention provides a rubber composition for a tire tread and a tire manufactured with the same. The rubber composition comprises 100 by weight parts of crude rubber and 60-90 by weight parts of silicon dioxide, wherein the crude rubber comprises 30-50 by weight parts of solution polymerization type styrene-butadiene (S-SBR) rubber and 10-30 by weight parts of butadiene rubber (BR). The content of the styrene in the solution polymerization type styrene-butadiene is 15-25% by weight, and the content of the ethenyl in butadiene is 60-65% by weight. According to the solution polymerization type styrene-butadiene rubber, each module end is modified to a hydrophilic group, and the modules are coupled with each other through tin. The rubber composition for the tire tread has the following advantages: reduced lag loss, maximized low combustion consumption performance, excellent braking performance which is normally reduced because of maximization of low combustion consumption performance, improved machining performance in an unvulcanized state, improved bracking performance in the vulcanized state, improved wearing resistance, improved rolling resistance, etc.

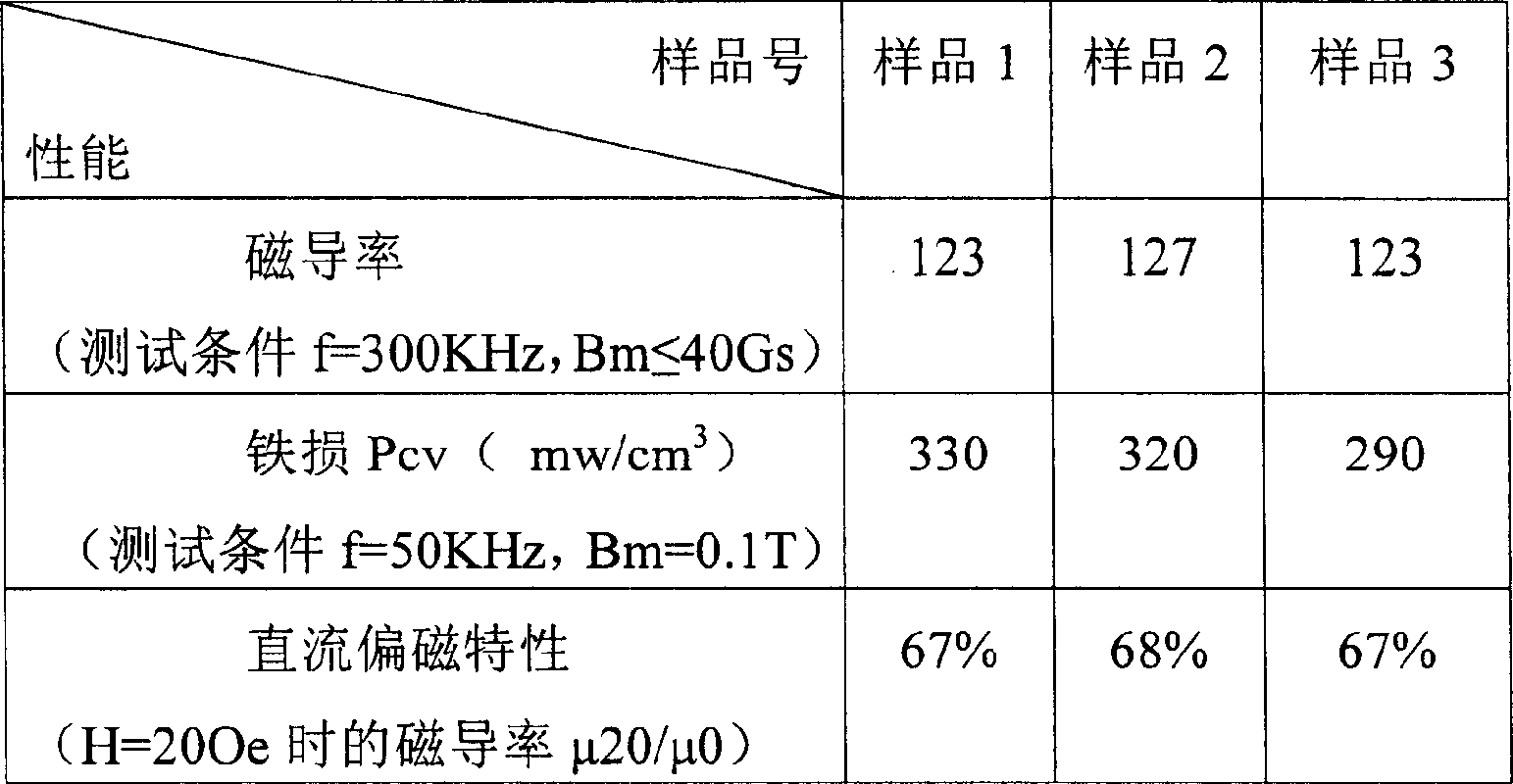

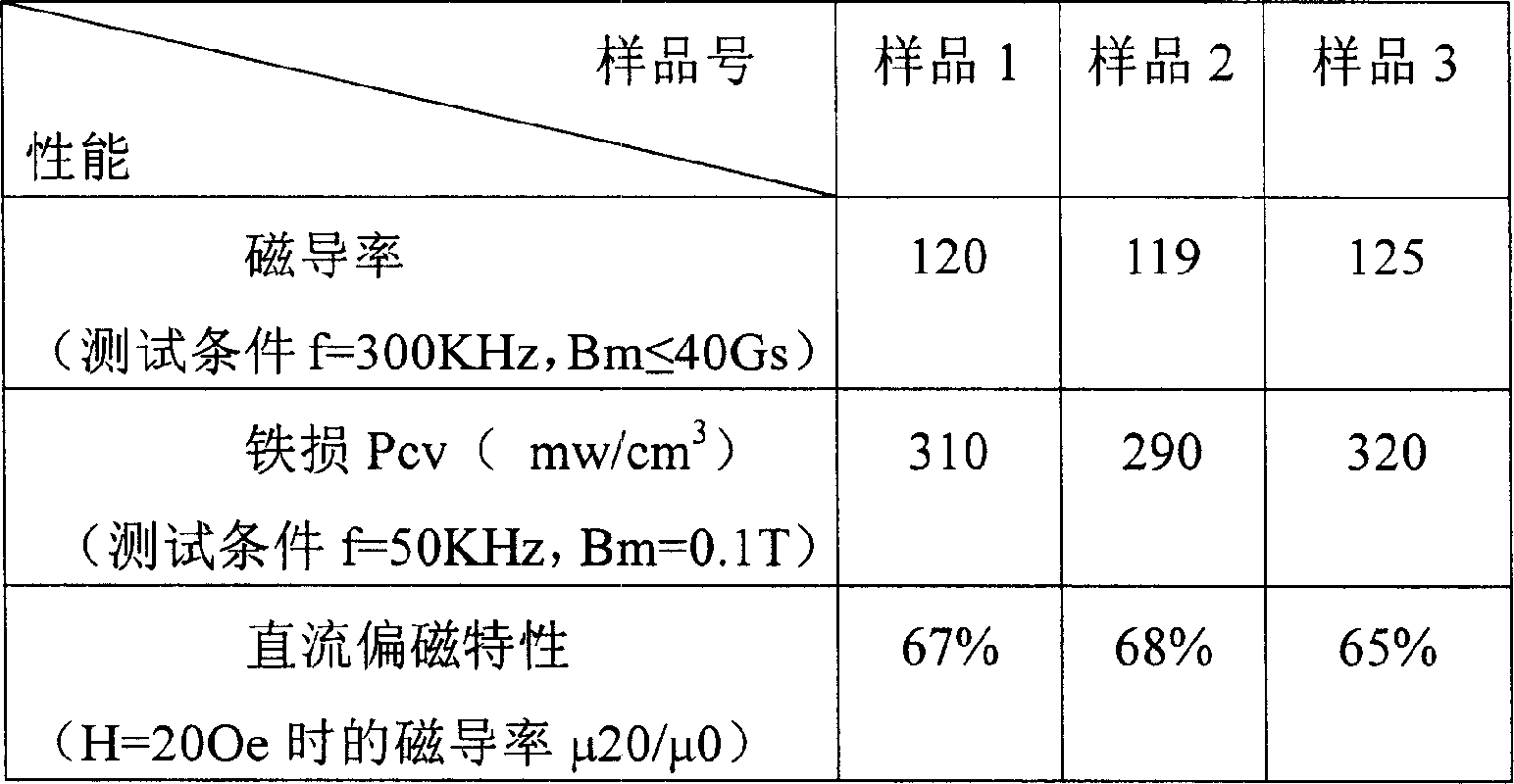

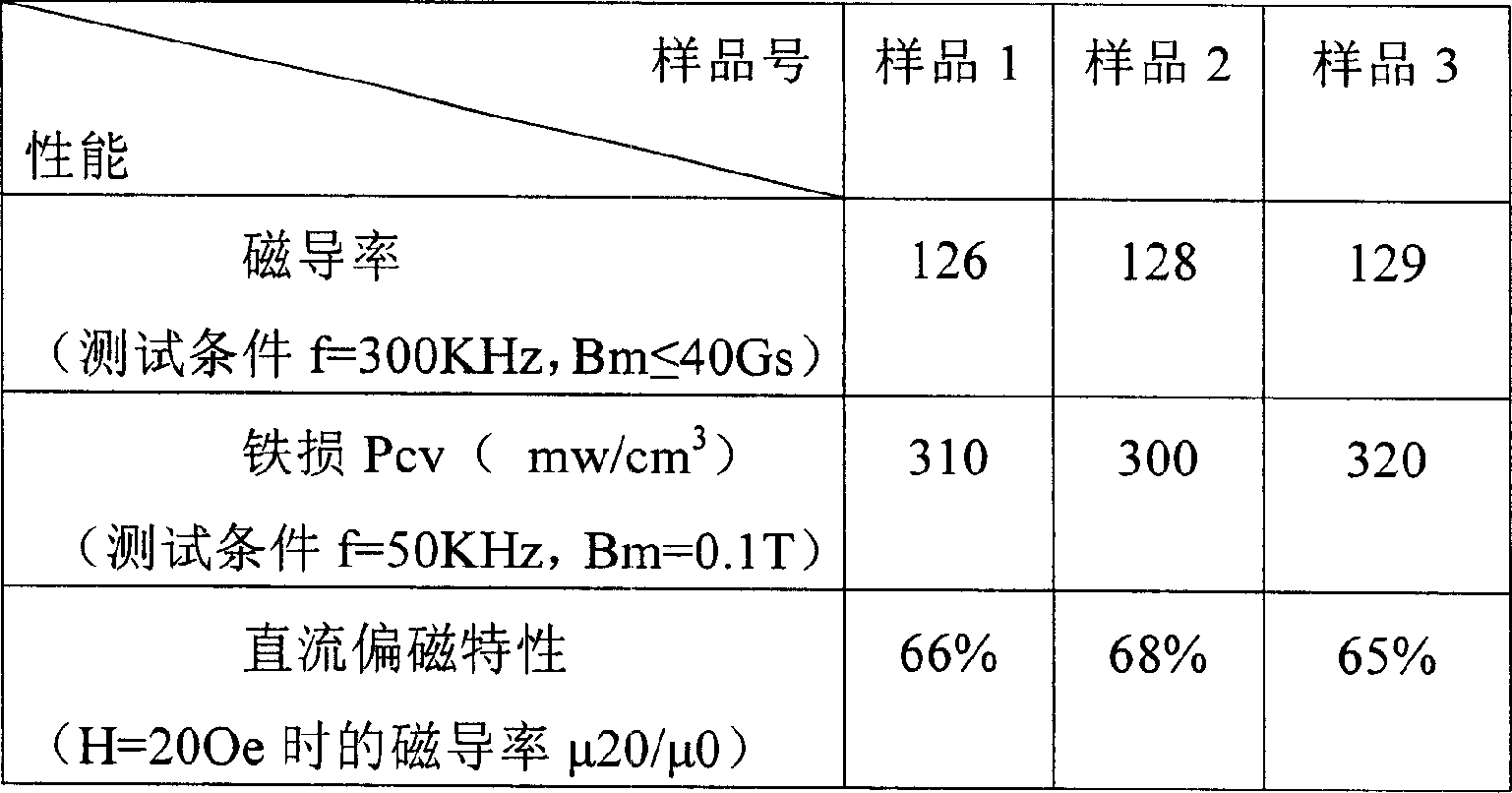

FeSiAl material magnetic core and producing method thereof

ActiveCN1812009AEasy to pressHigh molding densityInorganic material magnetismInductances/transformers/magnets manufactureIngotLubricant

This invention relates to a magnetic core of a FeSiAl material, in which, when the bias property is at H=200e, the magnetic conductivity is mum20 greater or equal to 65% mum0, Ferro loss Pcv at f=50KHz, Bm=0.1T and Pcv is less than or equal to 350mw / cm3, the magnetic conductivity of the material is 125. The preparation method includes: A, applying an ordinary method to smelt FeSiAl alloy board ingot of 0.001-120mm thick to crush it to powder, B, annealing the FeSiAL powder in step A, C, adding insulation agent, bonder and lubricant agent into the alloy powder, in which, the added insulation agent is 0.1-0.8%, the bonder is 0.1-1% and the lubricant agent is 0.1-1% of that of the FeSIAl powder, D, pressing the product in step C to formation to be annealed to get the target.

Owner:北京七星飞行电子有限公司

Poly-mercapto compound-containing white carbon black-filled rubber composite material and preparation method thereof

The invention relates to a poly-mercapto compound-containing white carbon black-filled rubber composite material and a preparation method thereof, belonging to the technical fields of rubber formulas and processes. The poly-mercapto compound-containing white carbon black-filled rubber composite material is characterized by being prepared from 100 parts of unsaturated rubber or blend rubber thereof, 10-100 parts of white carbon black and 0.01-10 parts of a poly-mercapto compound; the rubber composite material is prepared by adding a silane coupling agent with double bonds and compounding ingredients into the raw materials, wherein the molar ratio of the double bonds to mercapto is equal to (0.01 to 1)-((n-1) to n), or not adding the silane coupling agent with double bonds; n is mercapto number of each molecule of poly-mercapto compound. The preparation method not only can flexibly adjust white carbon black-rubber interfacial action according to the varieties of raw rubber and the white carbon black, product performance requirements, raw material cost, and the like so as to achieve the effect superior to the common mercapto silane coupling agents, but is also simple and convenient in anticipatory reaction process so as to easily realize industrial implementation.

Owner:CHENGDU GUIBAO SCI & TECH +1

Method for manufacturing amorphous alloy stator iron core of high-frequency motor

InactiveCN101908796AReduce eddy current lossReduce no-load lossManufacturing stator/rotor bodiesEpoxyAdhesive

The invention relates to the technical field of motor manufacture, in particular to a method for manufacturing an amorphous alloy stator iron core of a high-frequency motor. The method comprises the following steps of: sufficiently and uniformly mixing amorphous alloy powder and an adhesive, wherein conventional amorphous alloy powder is used as a raw material of the stator iron core; and putting the amorphous alloy powder mixed with the adhesive in a die for pressure forming, wherein the amorphous alloy powder and the adhesive are mixed by a proportion of (100:5)-(100:20), the adhesive is prepared from insulating materials such as epoxy resin, and the like, the temperature for mixing the amorphous alloy powder and the adhesive is 120-180 DEG C, pressure in the pressure forming process is70-90MPA, and the pressure maintaining time in the pressure forming process is 5-10 minutes. The invention has the advantages of simple and convenient manufacture, good product consistency and stability and benefit to mass production. Eddy-current loss, no-load loss and magnetic hysteresis loss which are caused by the stator iron core are greatly reduced while working under a high frequency, thereby the purposes of energy saving and high efficiency are achieved.

Owner:李振 +1

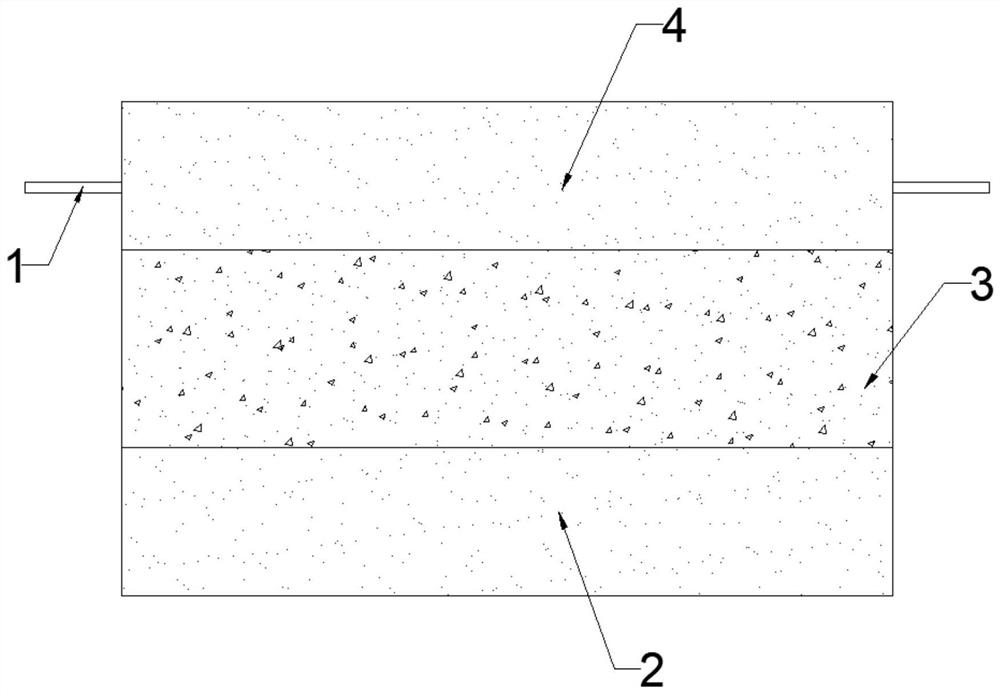

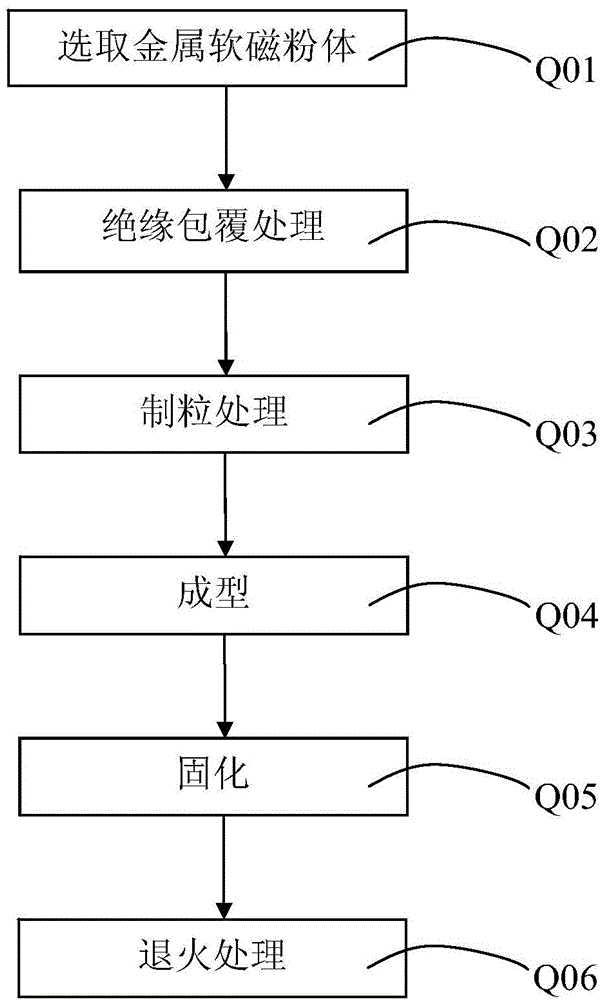

Integrated co-fired inductor and preparation method thereof

PendingCN112435845AReduce hysteresis lossSmall amount of deformationTransformers/inductances coils/windings/connectionsTransformers/inductances noise dampingEngineeringInductor

The invention provides an integrated co-fired inductor and a preparation method thereof. The preparation method comprises the steps: filling a mold cavity with magnetic powder in batches, wherein thetypes of every two adjacent layers of magnetic powder are different, at least one wire is embedded into one layer of magnetic powder, the two ends of each wire extend out of the mold cavity, and thencompression molding and heat treatment are sequentially conducted to obtain a magnetic core, and bending and tinning the wire extending out of the magnetic core to obtain the co-fired inductor. According to the preparation method provided by the invention, the inductor is prepared by adopting an integrated molding process, so that excessive assembly procedures of components are avoided, heat treatment is carried out after integrated molding, stress is fully released, hysteresis loss of materials is reduced, loss of devices is reduced under a light-load working condition, no extra gap exists between a wire and a magnetic core, and air gaps are uniformly distributed in the magnetic core; and the vibration noise of eddy current loss is reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

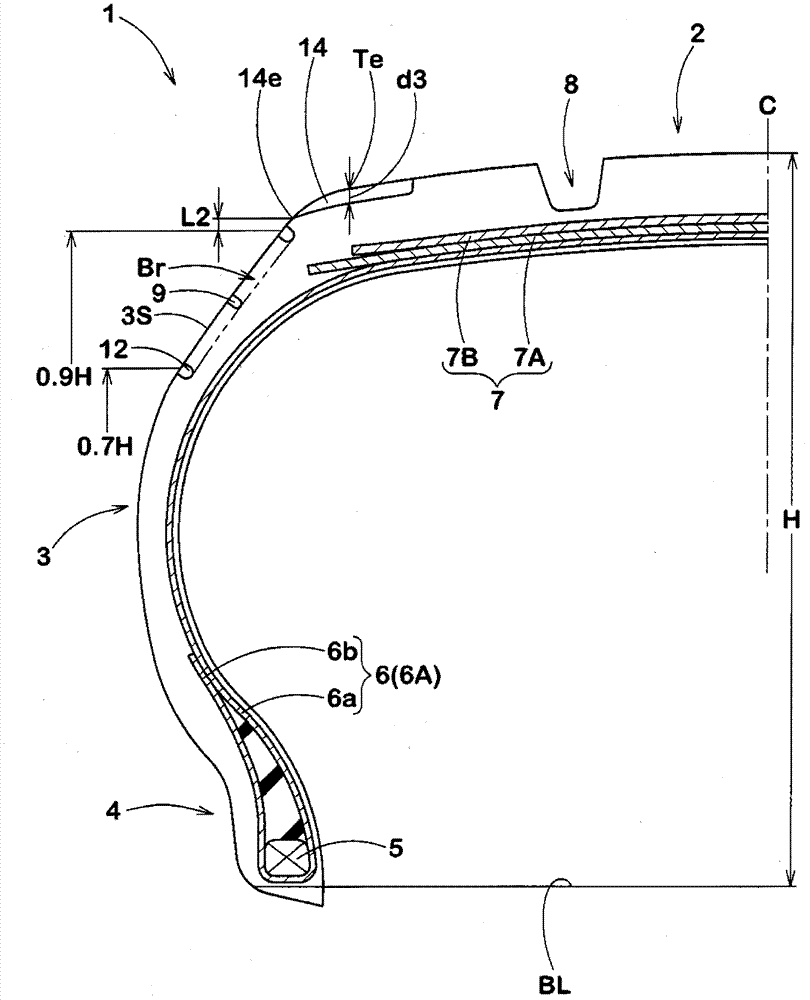

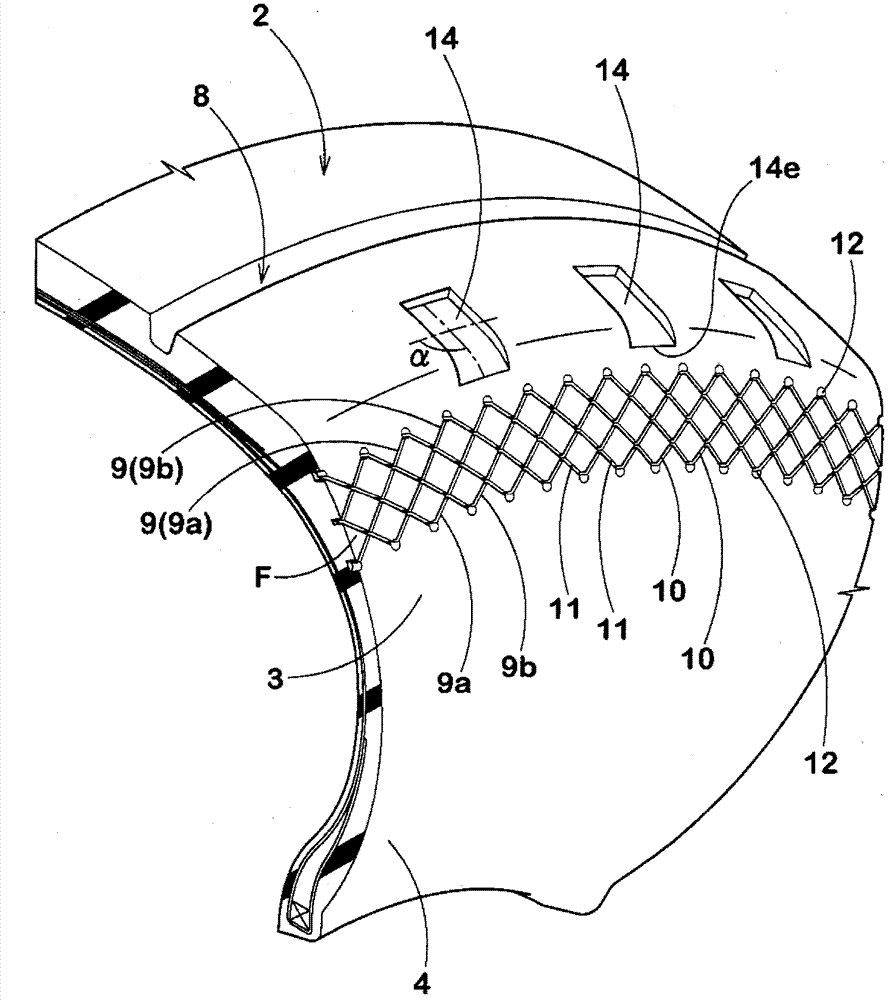

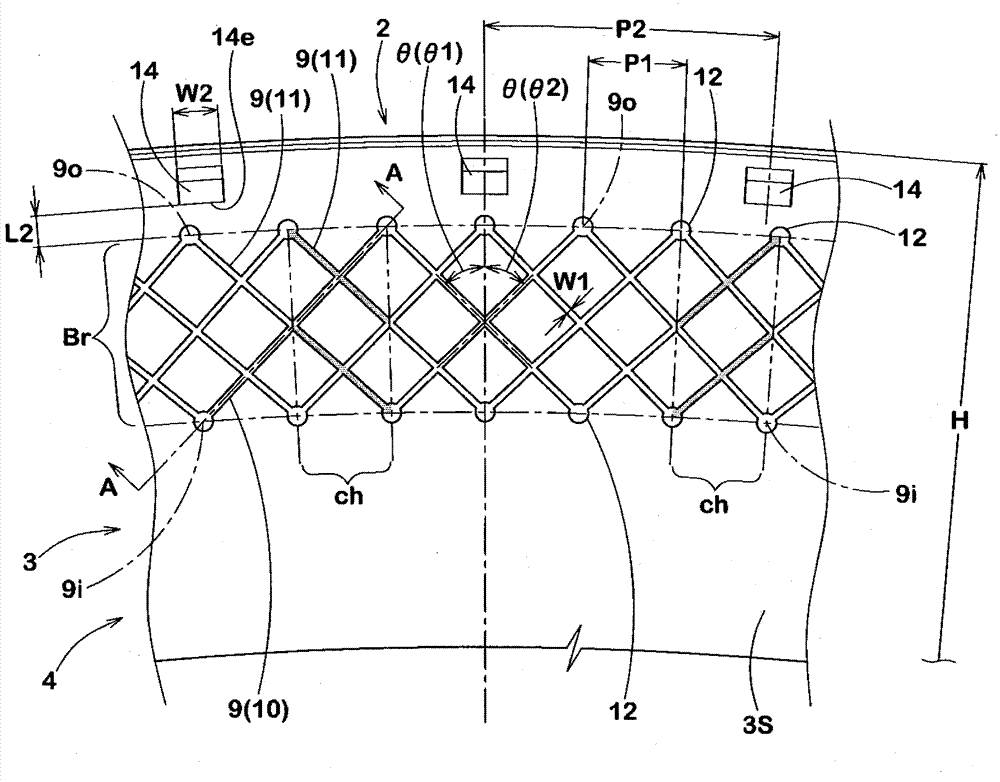

Pneumatic-tyre wheel

InactiveCN102765302AReduce hysteresis lossReduce rolling resistanceTyre tread bands/patternsRolling resistance optimizationInternal pressureRolling resistance

In a pneumatic-tyre wheel, through restricting shapes and allocation positions of sipes, the rolling resistance is reduced. Spipes (9) are arranged at intervals along the tyre circumference on the outer surface (3S) of a tyre side part (3) of at least one part of a pneumatic-tyre wheel (1). Under the unloaded normal state that a rim is assembled inside a regular rim and is filled with standard internal pressure, the sipes (9) are arranged in a tyre wall area which is 70-90% of tyre cross section height (H)away from a tyre bead reference line (BL), and is inclinedly extended in 40-50 degrees in relative to the tyre radiating direction, the sipe width (W1) is 0.5 to 1.0mm, and the adjacent sipes of the tyre circumference are provided with at least parts of overlapping parts (ch) which are mutually overlapped on the tyre circumference.

Owner:SUMITOMO RUBBER IND LTD

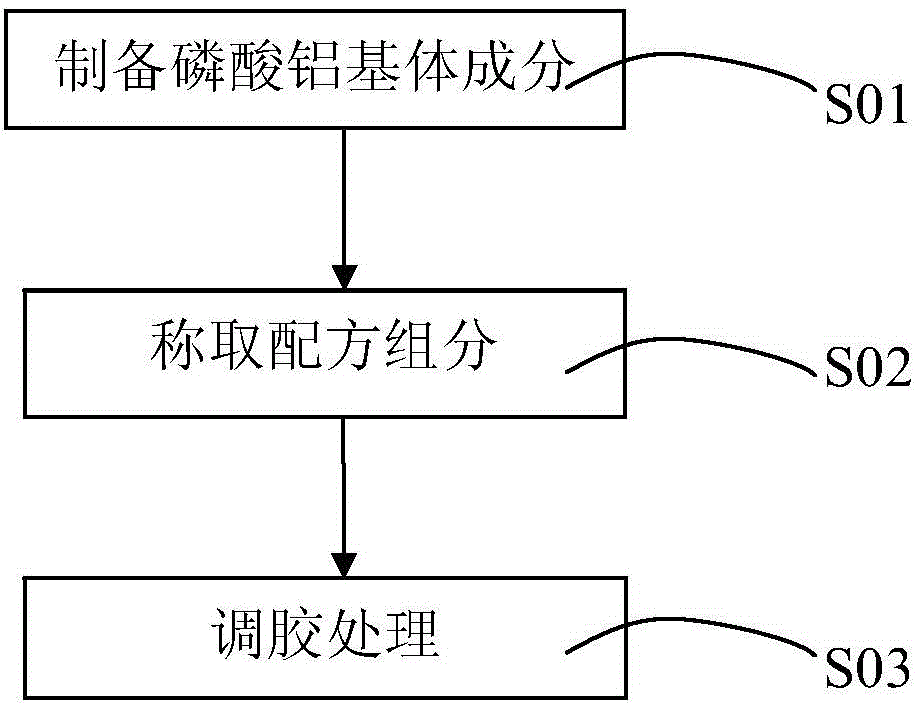

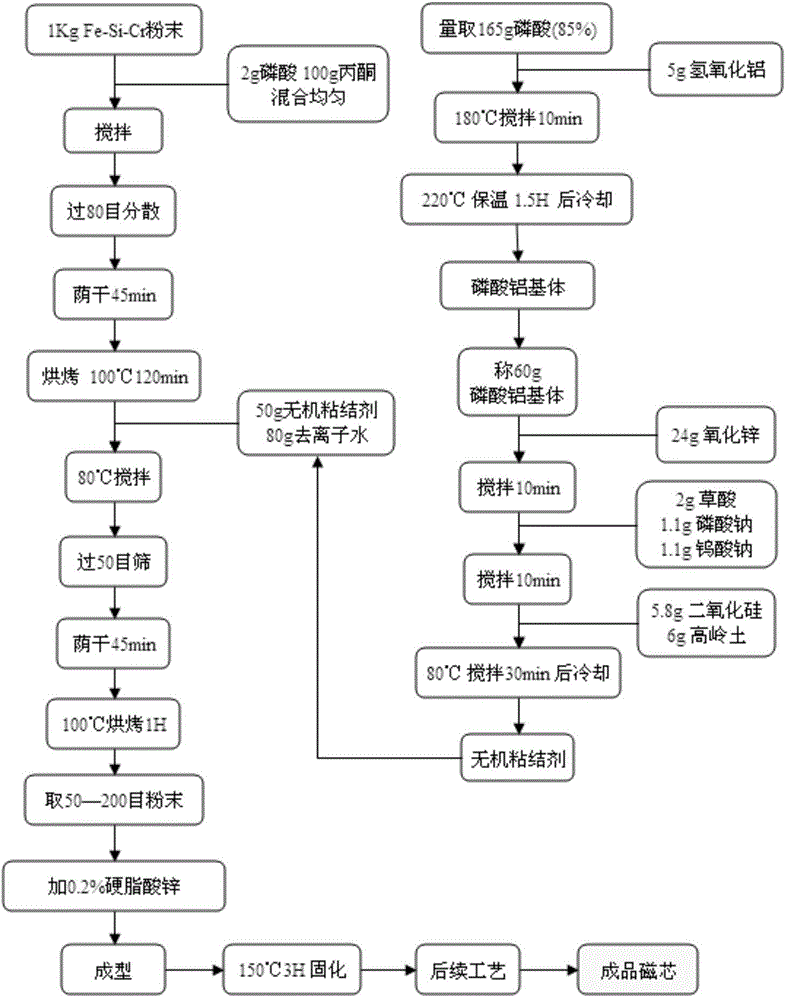

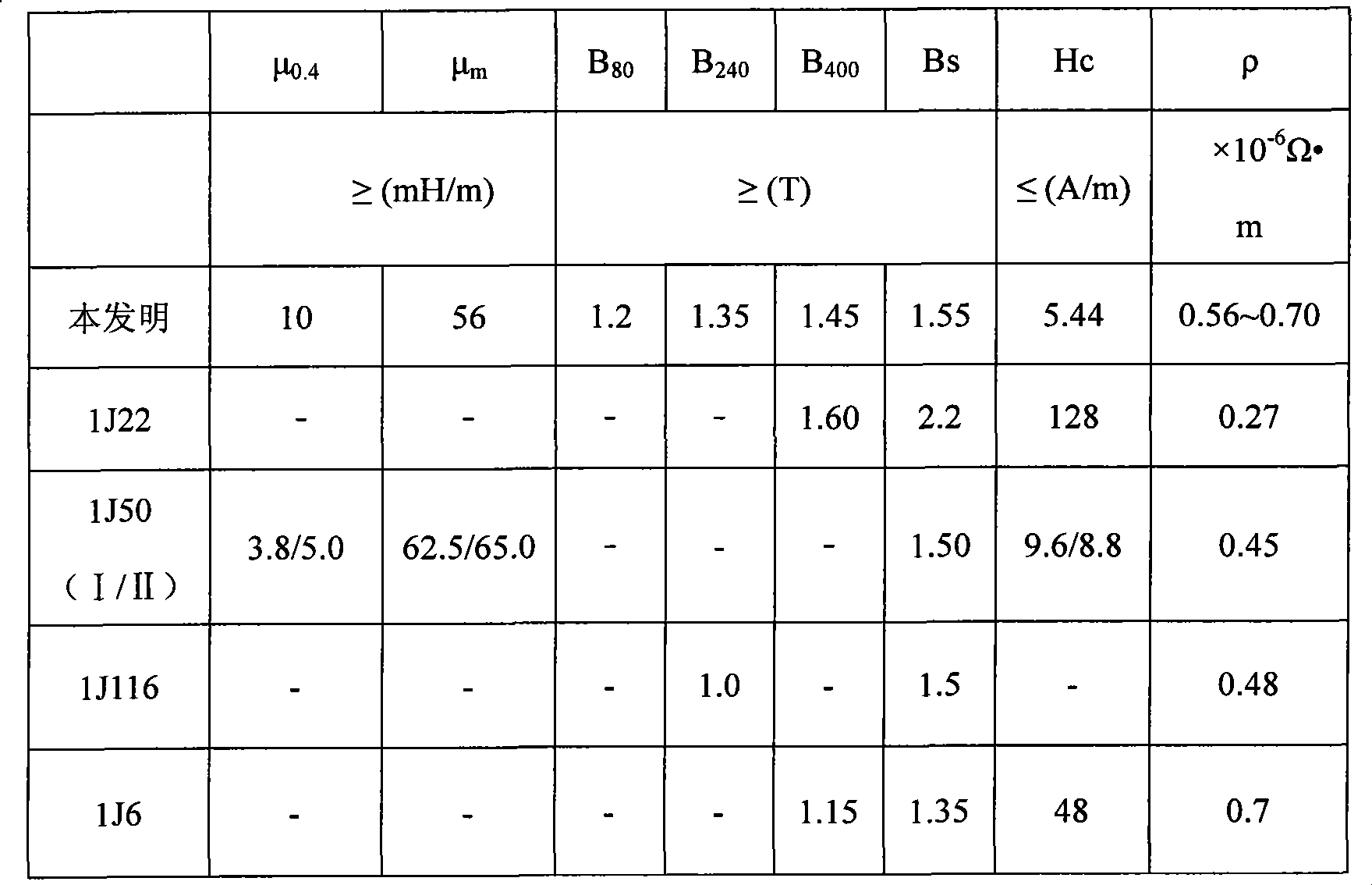

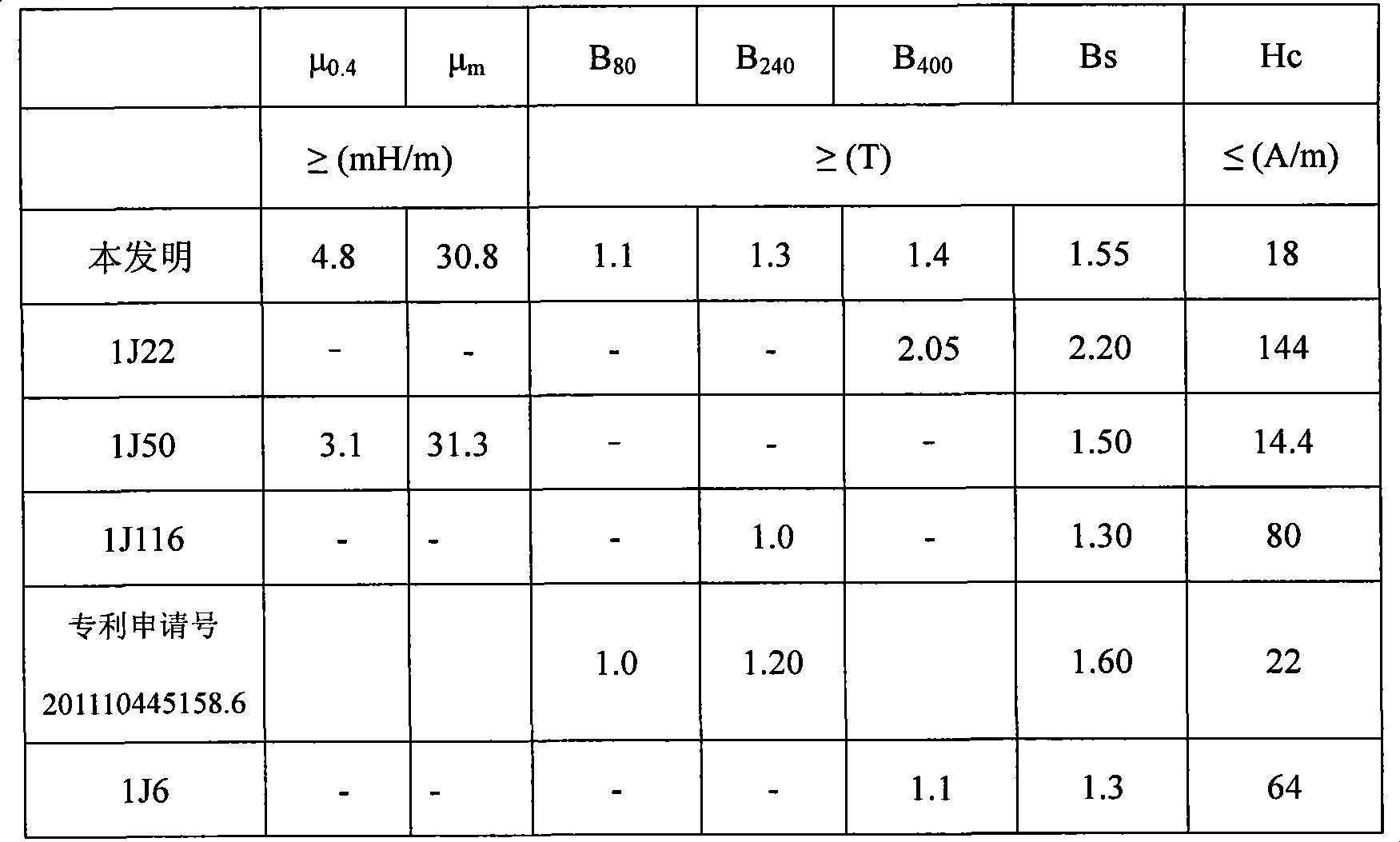

Inorganic binder used for metal soft magnetic powder core and metal soft magnetic powder core

ActiveCN105798284AImprove performanceStability is not affectedInorganic material magnetismTransformers/inductances detailsAging resistanceLow temperature curing

The invention is applicable to the field of metal powder alloy and provides an inorganic binder used for a metal soft magnetic powder core, the metal soft magnetic powder core and a preparation method of the metal soft magnetic powder core. The inorganic binder comprises the following formula components of, by the total weight of 100%, a matrix, a curing agent, a skeletal material and an additive, wherein the matrix is an aluminum phosphate matrix. The inorganic binder serves as the binder of the metal soft magnetic powder core. According to the inorganic binder provided by the invention, the binding effect is good, and meanwhile the requirements for the total inorganic performance, indecomposition of heat treatment, low-temperature curing, the ageing resistance and meeting of the ROSH standard are met.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

Anti-corrosion FeNiCo magnetically soft alloy with high magnetic induction intensity

The invention includes a FeNiCo magnetically soft alloy and a production method thereof, wherein the FeNiCo magnetically soft alloy has high magnetic induction intensity, high magnetic permeability, low coercive force, high stability and good corrosion resistance in a low magnetic field. The FeNiCo magnetically soft alloy comprises the following components by mass percent: not more than 0.02 percent of C, 0.2-0.80 percent of Si, not more than 0.50 percent of Mn, 29.00-35.00 percent of Ni, 25.00-32.00 percent of Co, not more than 5.00 percent of Mo, not more than 0.50 percent of Cu, 0.01-0.55 percent of microelements including 0.001-0.05 percent of rare earth elements, and the balance of Fe and inevitable impurities. The FeNiCo magnetically soft alloy is processed and manufactured by adopting the methods of vacuum melting, forging, hot rolling and cold rolling, and after heat treatment, the FeNiCo magnetically soft alloy has the characteristics of high magnetic induction intensity, high magnetic permeability, low coercive force, high stability and good corrosion resistance in a low magnetic field, and can be manufactured into the transducer, the filter, the electromagnetic valve, the transformer and the like in the field of aviation, aerospace, navigation, electron, electric power and the like.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

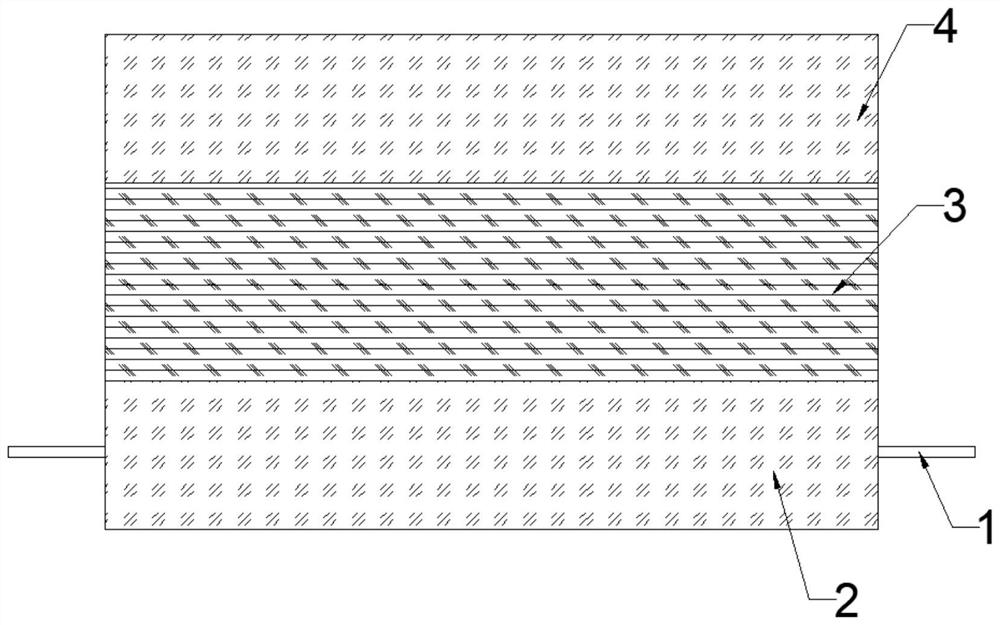

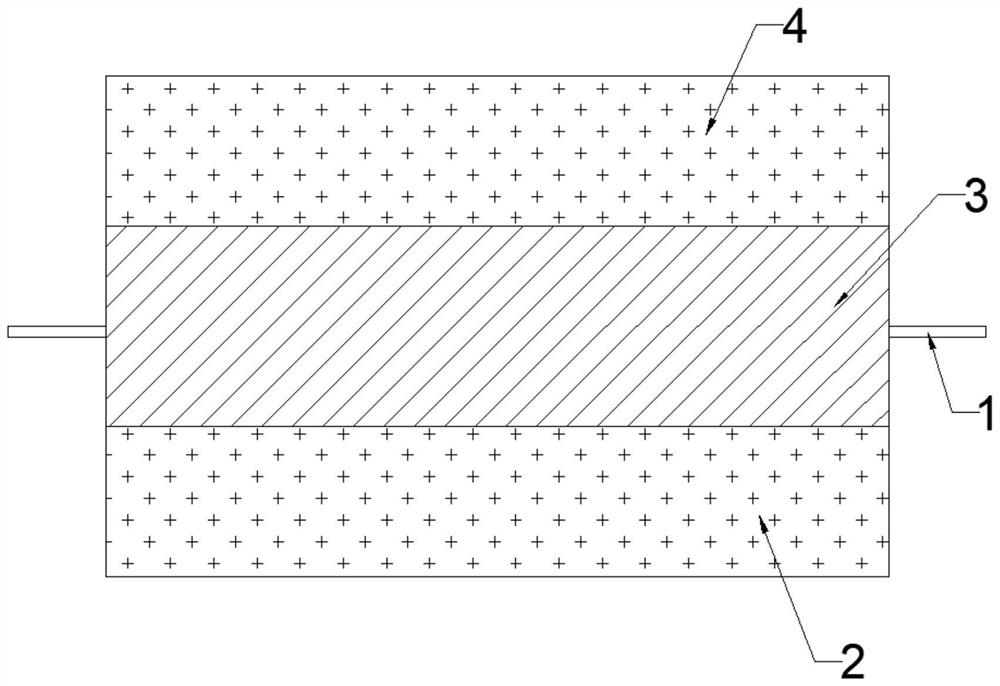

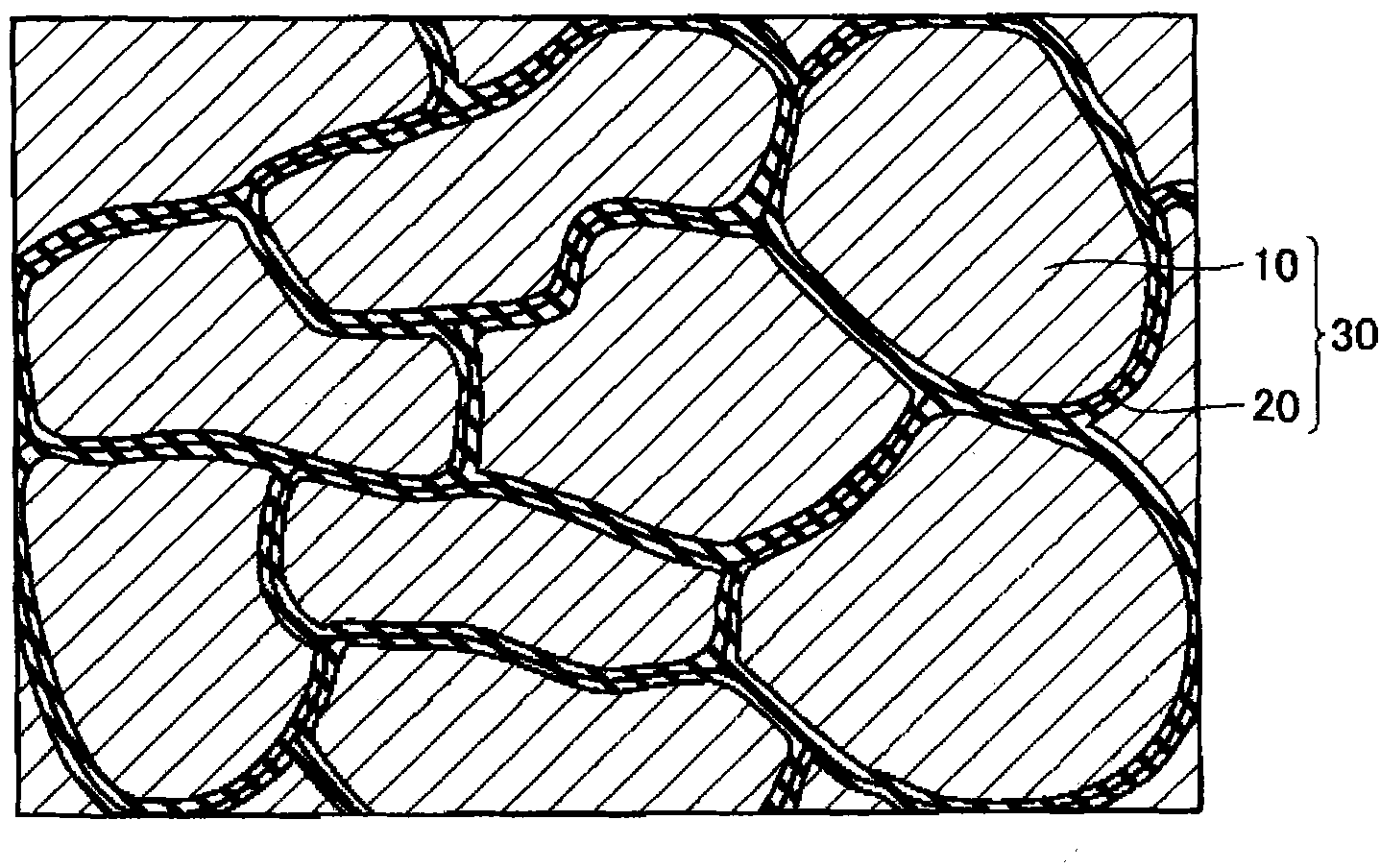

High performance magnetic composite for AC applications and a process for manufacturing the same

InactiveUS7510766B2Improve magnetic propertiesLower average currentLiquid separation by electricityElectrostatic separationHysteresisTransformer

A magnetic composite for AC applications with improved magnetic properties (i.e. low hysteresis losses and low eddy current losses) is disclosed. The composite comprises a consolidation of magnetizable metallic microlamellar particles each having a top and bottom surfaces and opposite ends. The top and bottom surfaces are coated with a dielectric coating for increasing the resistivity of the composite and reducing eddy current losses. The dielectric coating is made of a refractory material and the ends of the lamellar particles are metallurgically bonded to each other to reduce hysteresis losses of the composite. A process for manufacturing the same is also disclosed. The composite is suitable for manufacturing devices for AC applications such as transformers, stator and rotor of motors, generators, alternators, field concentrators, chokes, relays, electromechanical actuators, synchroresolvers, etc.

Owner:CORP IMFINE INC

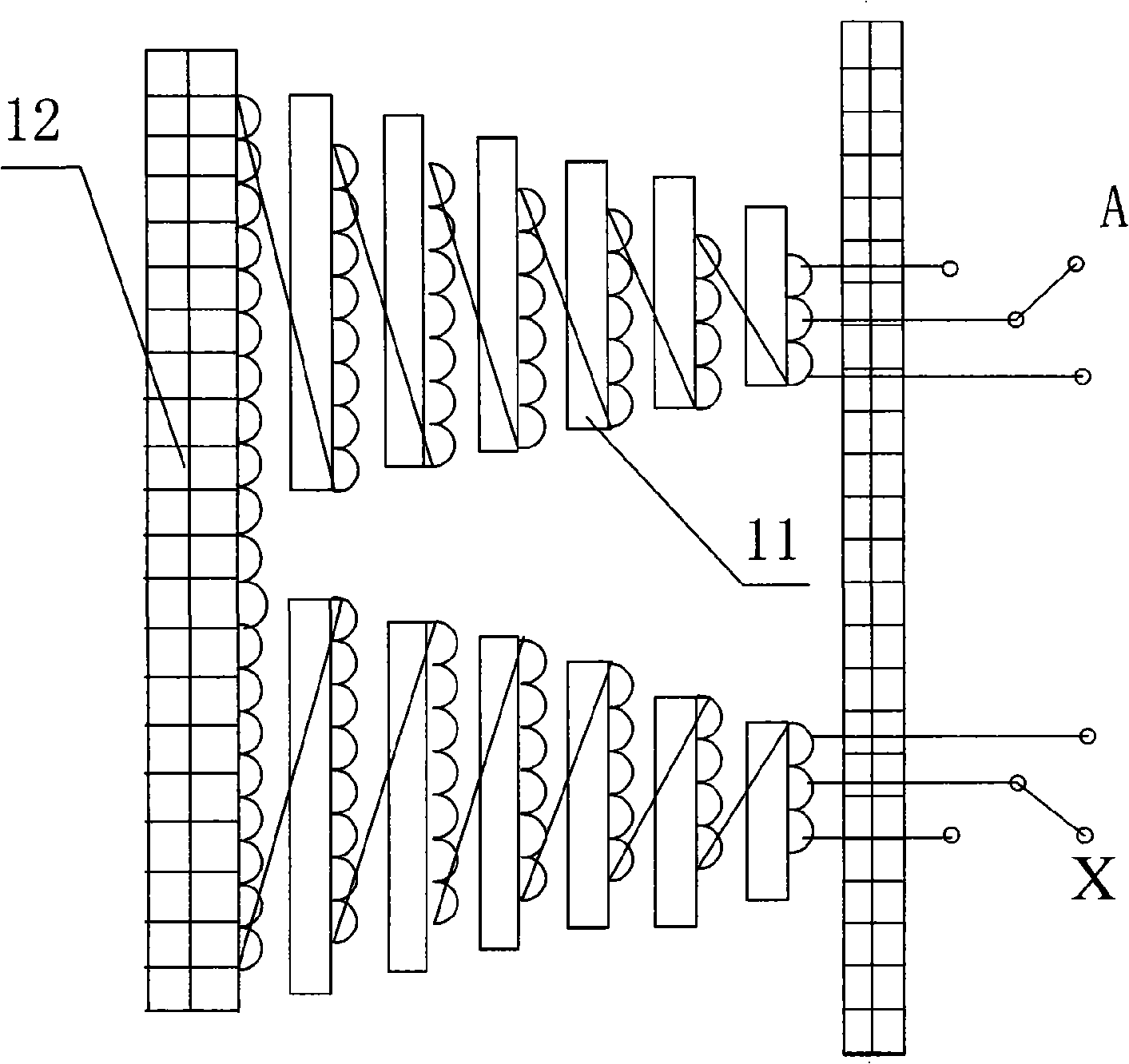

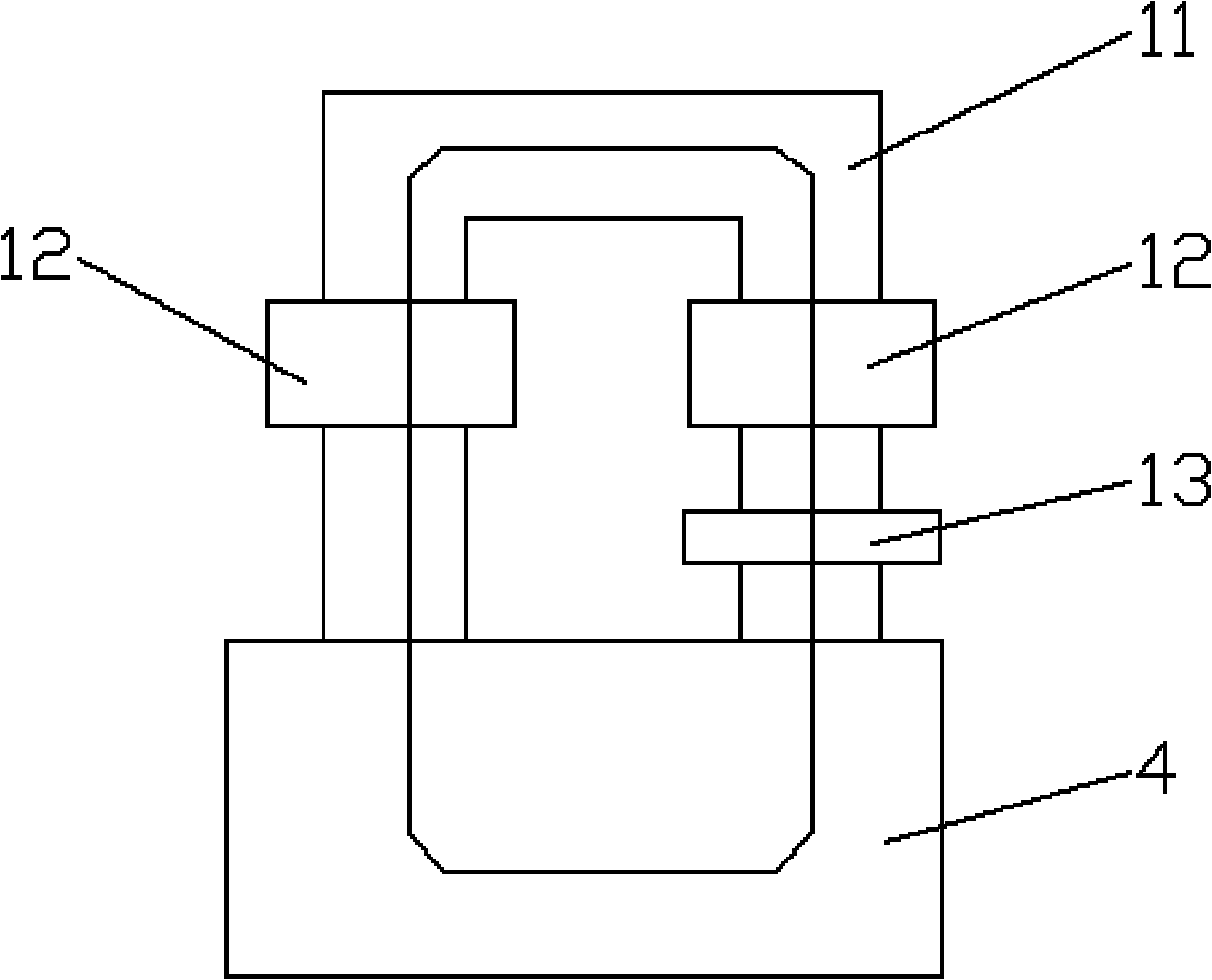

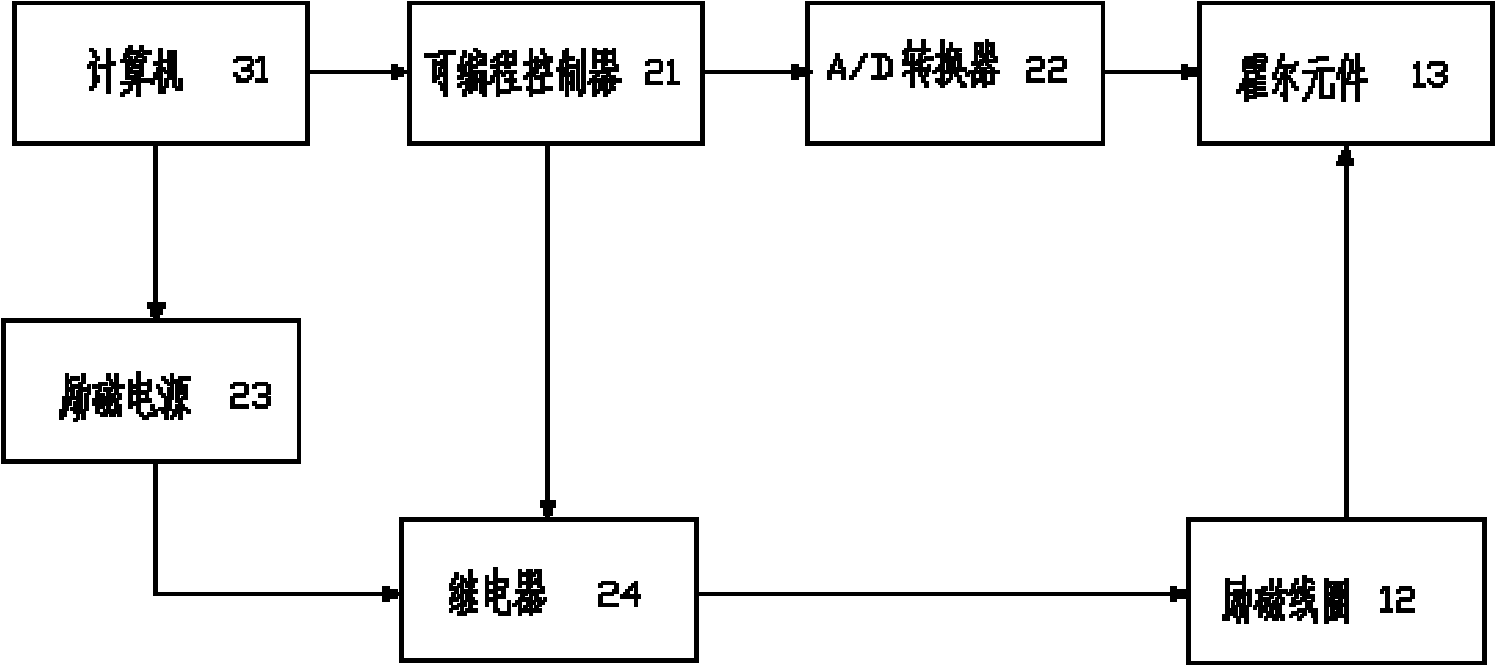

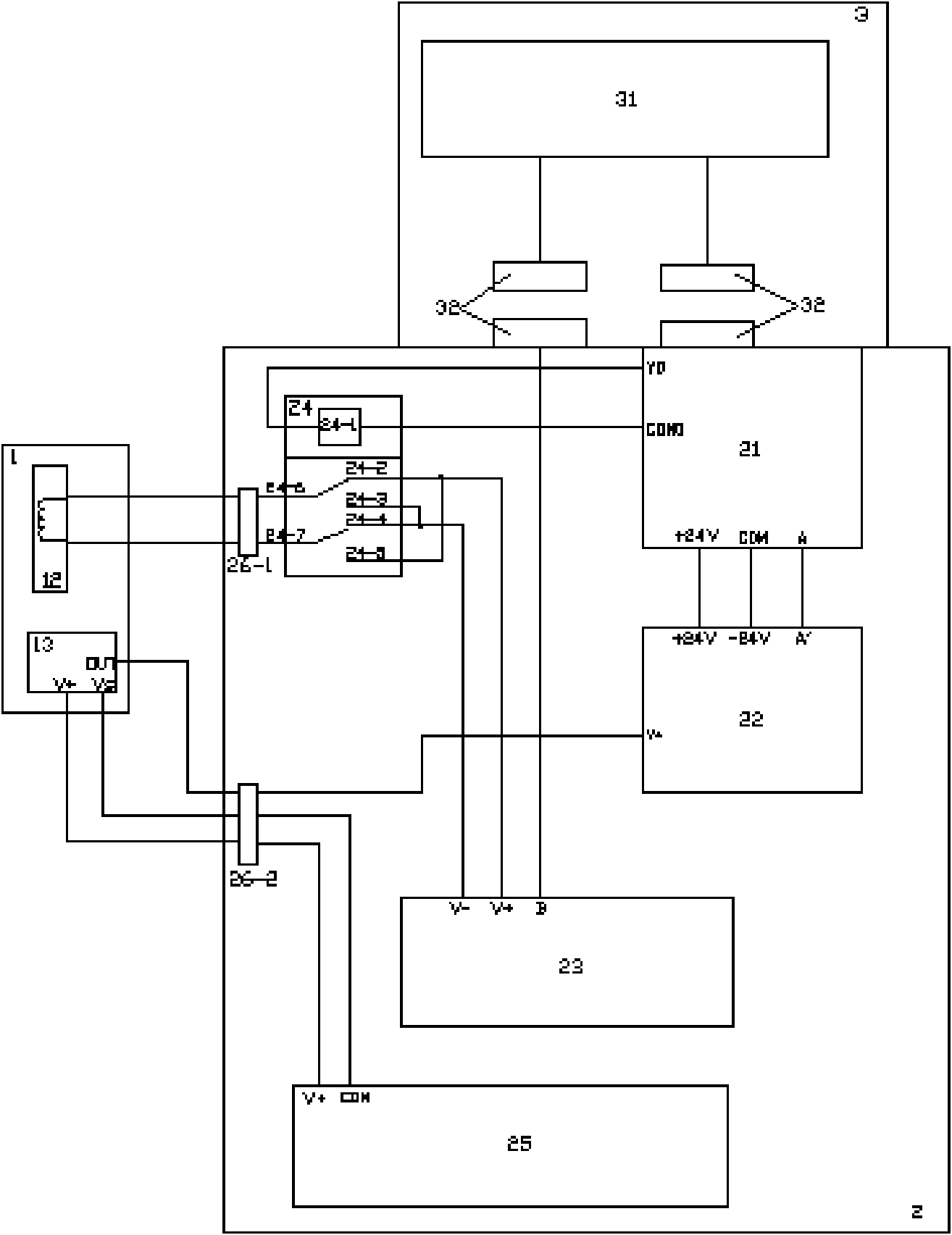

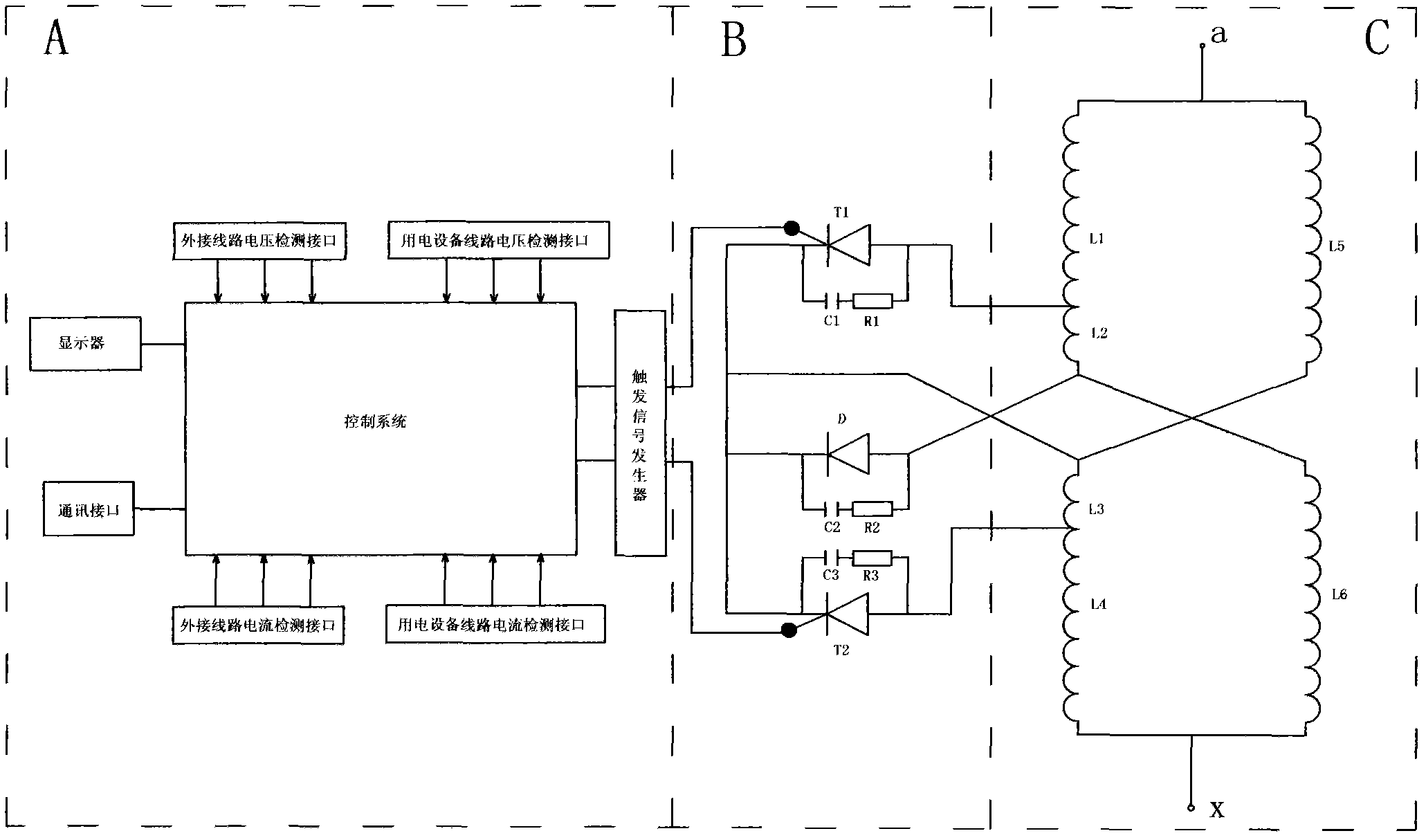

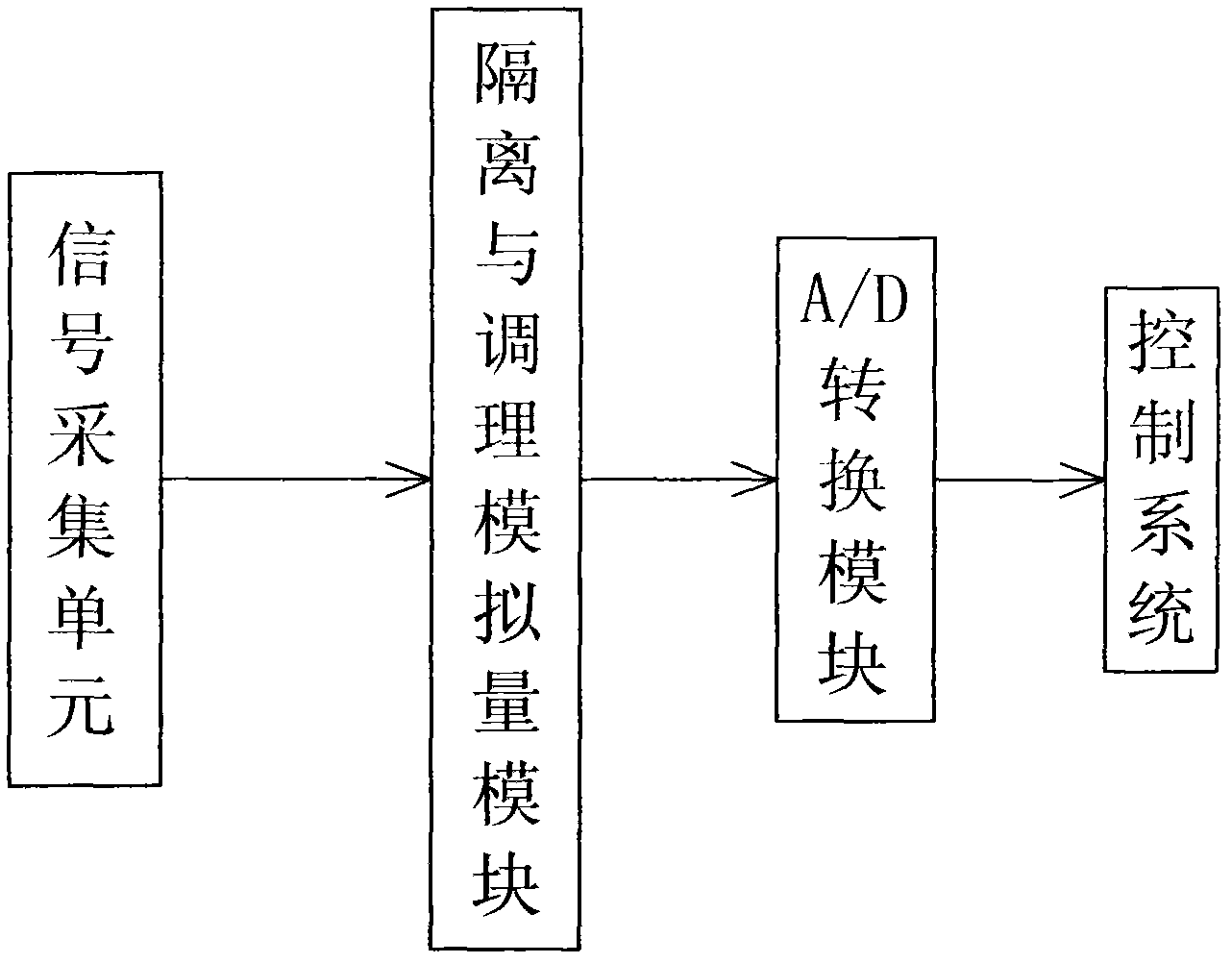

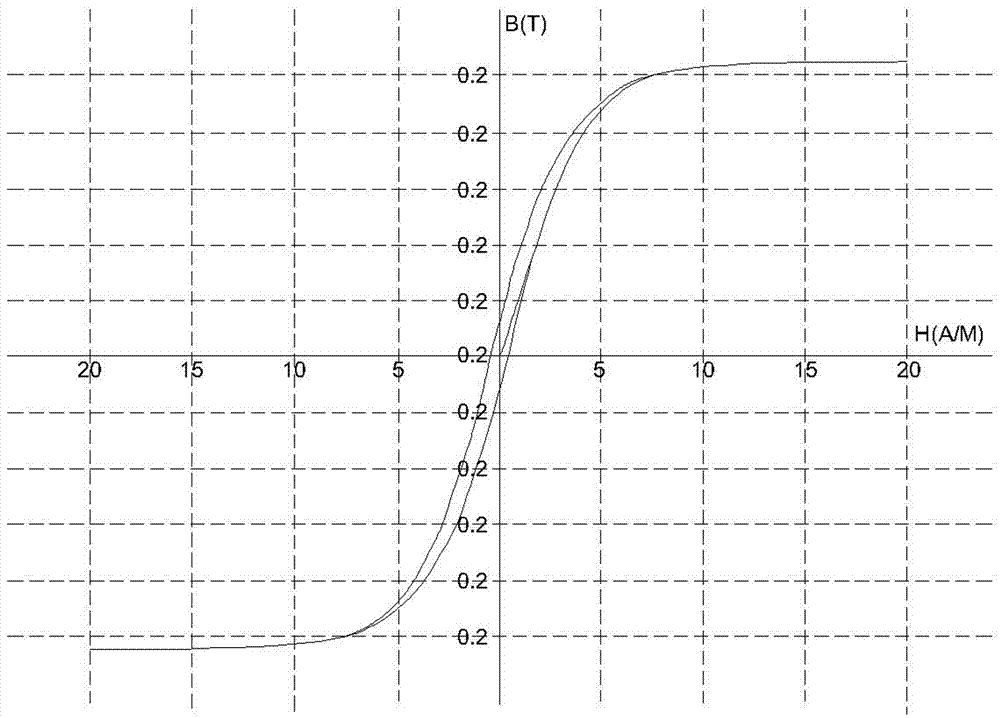

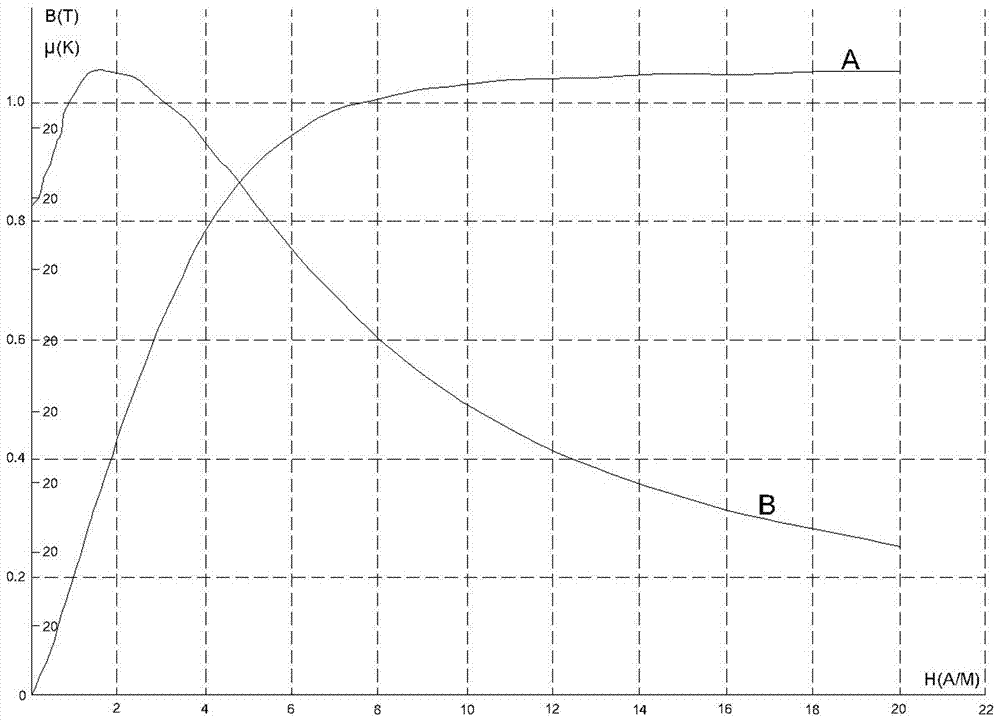

Static magnetic characteristic measuring apparatus

InactiveCN101858962ARealize continuous measurementImprove measurement efficiencyHysteresis curve measurementsContinuous measurementElectricity

The invention discloses a static magnetic characteristic measuring apparatus, comprising a detection module, a control module and an operation module, wherein the detection module comprises an N-shaped magnet, an excitation coil wound on the magnet and a Hall element placed at one end of the magnet; the control module comprises a programmable logic controller (PLC), an A / D converter, an excitation power supply, a relay and a switching power supply; the PLC is electrically connected with the A / D converter; the coil of the relay is electrically connected with the PLC; the ports of the relay arerespectively electrically connected with the excitation coil and the excitation power supply; the output end of the Hall element is electrically connected with the input end of the A / D converter; thepower supply end of the Hall element is electrically connected with the switching power supply; and the operation module comprises an industrial computer electrically connected with the control module. The measuring apparatus dispenses with demagnetization during measuring, thus realizing continuous measurement of the magnetic characteristic parameters and improving the efficiency of measurement.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

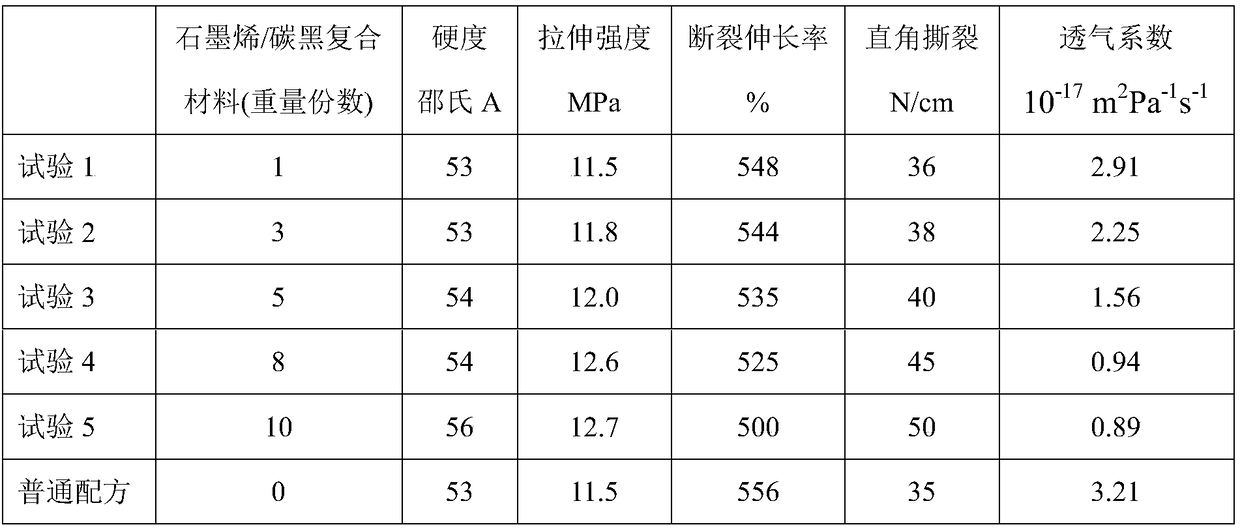

Tyre inner lining glue with graphene/carbon black composite and preparation method of tyre inner lining glue

InactiveCN109161110AImprove wear resistanceExtended service lifeSpecial tyresVulcanizationEngineering

The invention discloses tyre inner lining glue with a graphene / carbon black composite and a preparation method of the tyre inner lining glue. The tyre inner lining glue comprises the components in parts by weight of 100 parts of halogenated butyl rubber, 1-20 parts of a graphene / carbon black composite, 10-60 parts of a filling, 1-20 parts of extender oil, 1-10 parts of a viscosifying agent, 1-5 parts of a processing agent, 1-10 parts of an activator and 0.9-5 parts of a vulcanization system, wherein the graphene / carbon black composite is prepared by a home-position mechanical exfoliation method, self clumping between graphene slices is overcome, and the dispersibility and the compatibility of graphene and carbon black in rubber can be improved. In a tyre inner lining formula, the graphene / carbon black composite is added, and in a banburying mixing manner, the graphene is uniformly distributed in a polymer, so that the effect of separating gas molecules from infiltrating is achieved, the air tightness of the tyre is improved greatly, the service life of the tyre is prolonged, and the using properties of vehicles can be improved in many respects.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

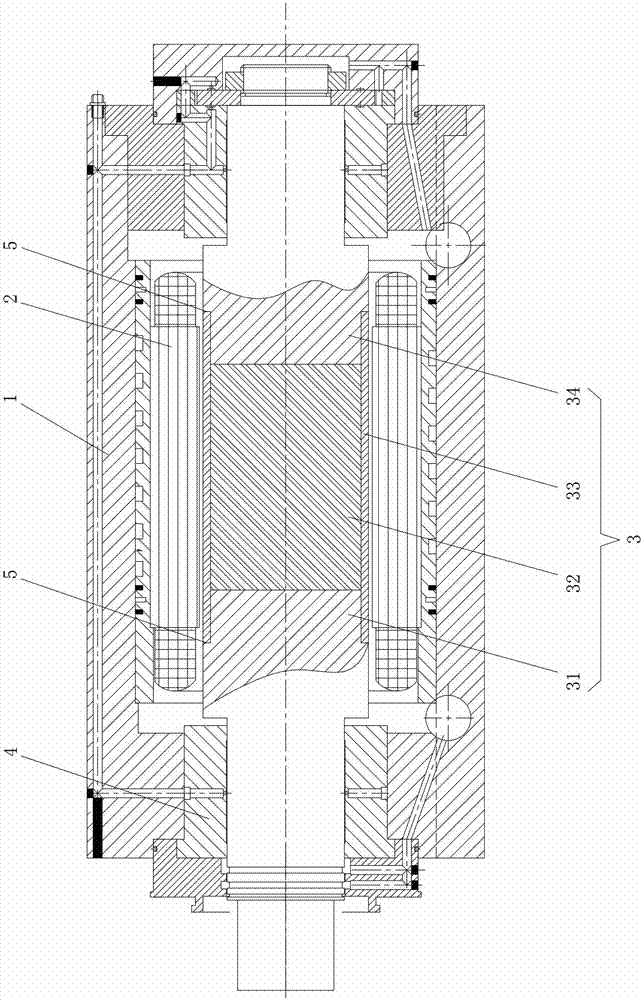

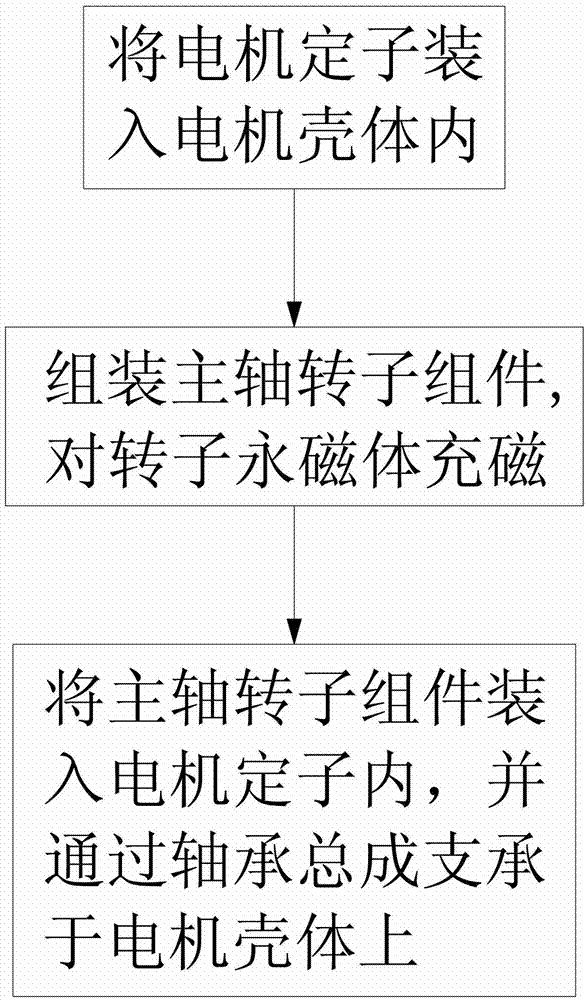

High-speed permanent magnet synchronous motor and assembly method thereof

InactiveCN103117633AIncrease speedImprove efficiencyMagnetic circuit rotating partsManufacturing dynamo-electric machinesPermanent magnet synchronous motorPermanent magnet synchronous generator

Disclosed are a high-speed permanent magnet synchronous motor and an assembly method thereof. The motor comprises a motor shell, a motor stator, a spindle rotor component and a pair of bearing assemblies, the bearing assemblies are separately arranged at the front end and the rear end of the shell, the motor stator is fixed into the motor shell, the spindle rotor component is sleeved in the motor stator, two ends of the spindle rotor component are supported on the motor shell through the bearing assemblies, the spindle rotor component comprises a front rotor half shaft, a rotor permanent magnet, a rotor sleeve and a rear rotor half shaft, the rotor permanent magnet is sleeved in the rotor sleeve, one end of the rotor sleeve is fixedly connected with the front rotor half shaft, and the other end of the rotor sleeve is fixedly connected with the rear rotor half shaft. The high-speed permanent magnet synchronous motor is compact in structure, sufficient in space usage, small in radial dimension and particularly suitable for meeting the requirement on high rotation speed. The assembly method includes the steps: 1) mounting the motor stator into the motor shell; 2) assembling the spindle rotor component and magnetizing the rotor permanent magnet in the spindle rotor component after the spindle rotor component is assembled; and 3) mounting the spindle rotor component into the motor stator, and supporting the spindle rotor component on the motor shell through the bearing assemblies.

Owner:HUNAN UNIV

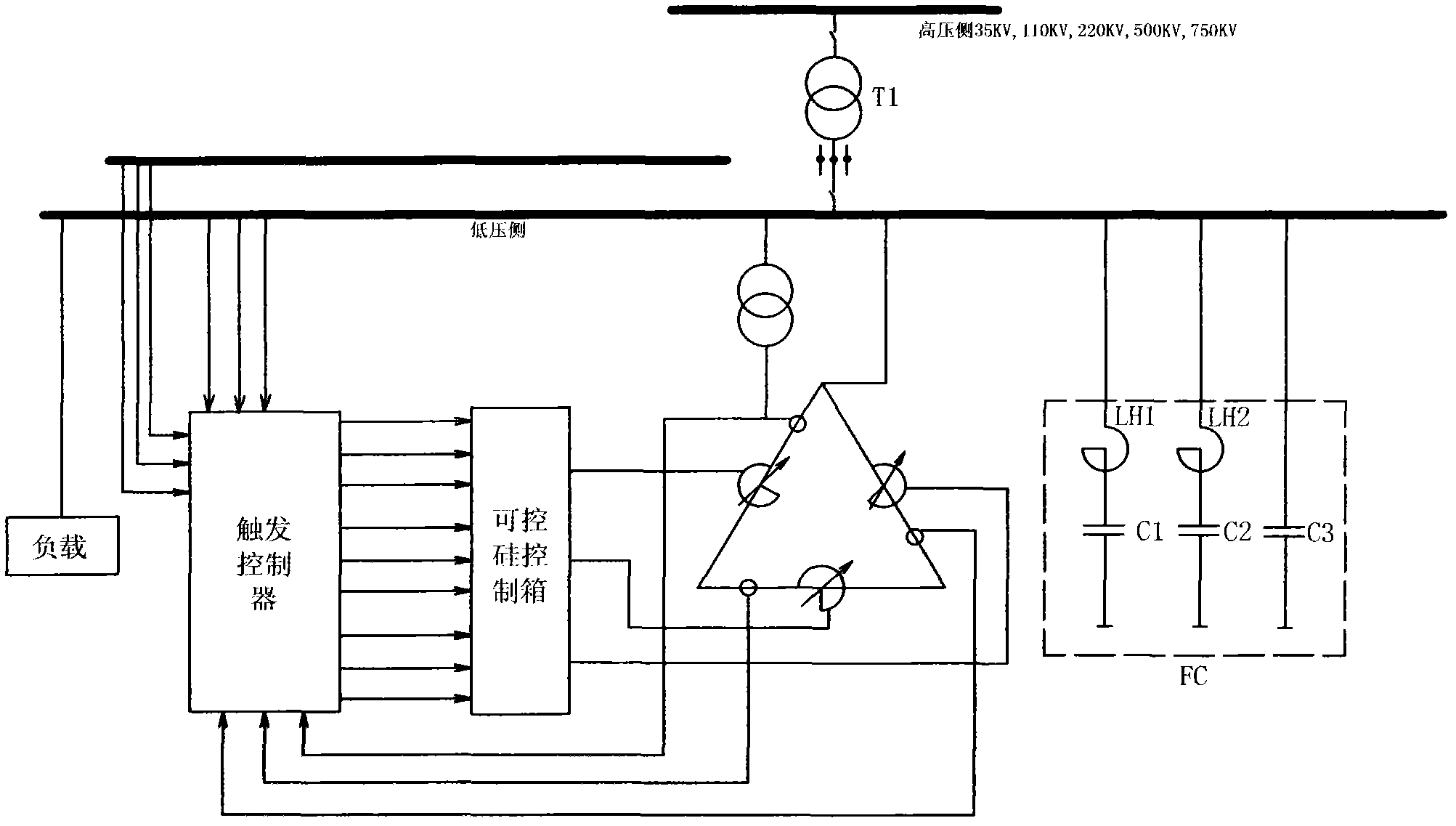

Dynamic reactive compensation system based on magnetic control electric reactor

InactiveCN102810867AIncrease active power outputImprove efficiencyReactive power adjustment/elimination/compensationReactive power compensationOvervoltageEngineering

The invention relates to a dynamic reactive compensation system based on a magnetic control electric reactor. The dynamic reactive compensation system comprises a passive filter FC and an MCR (Magnetic Control Reactor), wherein the passive filter FC is used for reactive compensation and harmonic filter, the MCR is used for balancing an inductive load. The dynamic reactive compensation system disclosed by the invention has the advantages that the reliability if high, 20-year basic maintenance-free running can be realized, and the maintaining and repairing cost can be reduced to a large extent; the response ability is quick, and the response speed can be up to 20ms; the regulating range is large, and the regulating range in more than 100 times can be reached; the occupied area is small, the installation is convenient, and a device can be naturally cooled by adopting an oil immersion mode; the harmonic wave is small and has no pollution to a power grid and has no any bad influence on a capacitor group, and the traditional device is conveniently utilized in a reform occasion; the overload ability is strong, 30-second 100% overload and half-hour 40% overload can be realized; the consumption is less, the MCR is in large capacity, the consumption is less than 0.5%, and in a common system, only 0.8%-1.5% of the consumption can be realized; the overvoltage ability is strong, the voltage limiting ability is good, and the dynamic reactive compensation system has a natural automatic voltage limiting ability; and no electromagnetic pollution works on the environment and the human body.

Owner:青岛海电电气有限公司

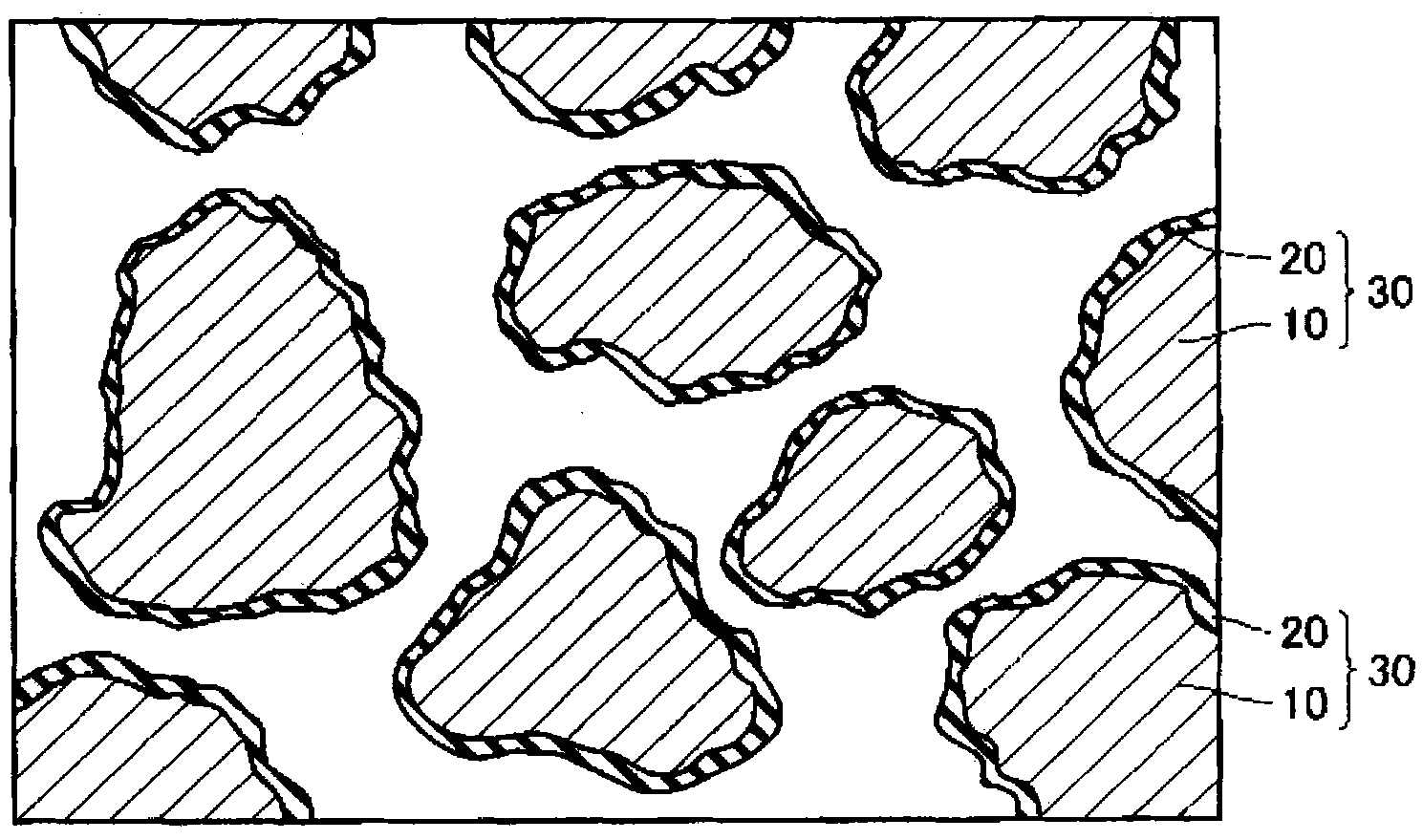

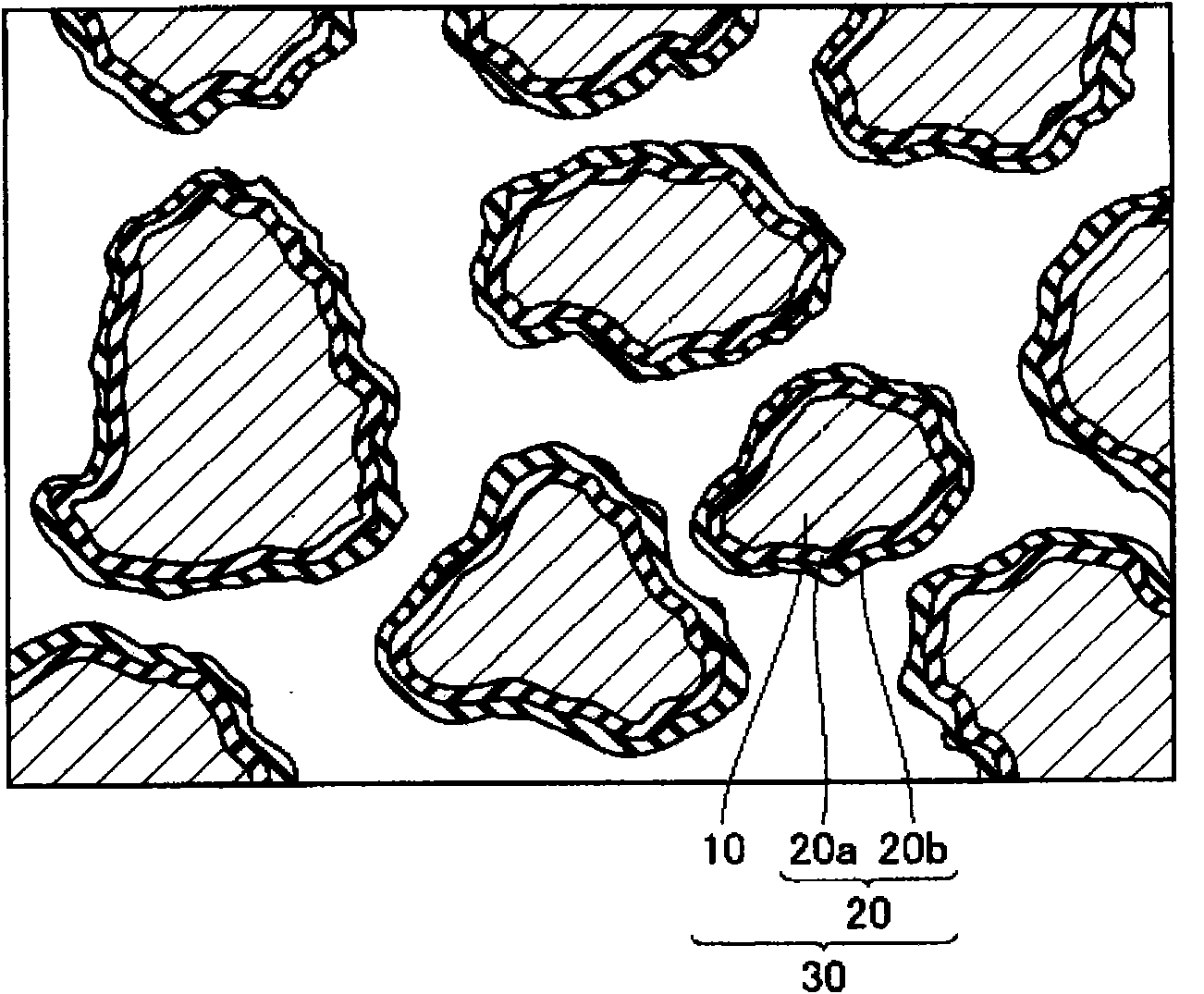

Soft magnetic material, dust core, method for producing soft magnetic material, and method for producing dust core

InactiveCN101790765AImprove heat resistanceReduce hysteresis lossPigmenting treatmentTransportation and packagingMaterials scienceChromium

Disclosed is a soft magnetic material containing a plurality of composite magnetic particles (30) each having an iron-based particle (10) containing iron and an insulating coating film (20) covering the surface of the iron-based particle (10). The insulating coating film contains an organic group derived from an organic acid containing at least one substance selected from the group consisting of titanium, aluminum, silicon, calcium, magnesium, vanadium, chromium, strontium and zirconium. At least one substance in the insulating coating film (20) is bonded with iron in the iron-based particle (10) through the organic group of the insulating coating film (20) which is derived from an organic acid. Also disclosed is a method for producing a soft magnetic material, which comprises a step for preparing an iron-based particle (10) containing iron and a step for forming an insulating coating film (20) covering the surface of the iron-based particle (10). In the step for forming an insulating coating film, an organic acid containing the above-mentioned substance is brought into contact with the surface of the iron-based particle (10).

Owner:SUMITOMO ELECTRIC IND LTD

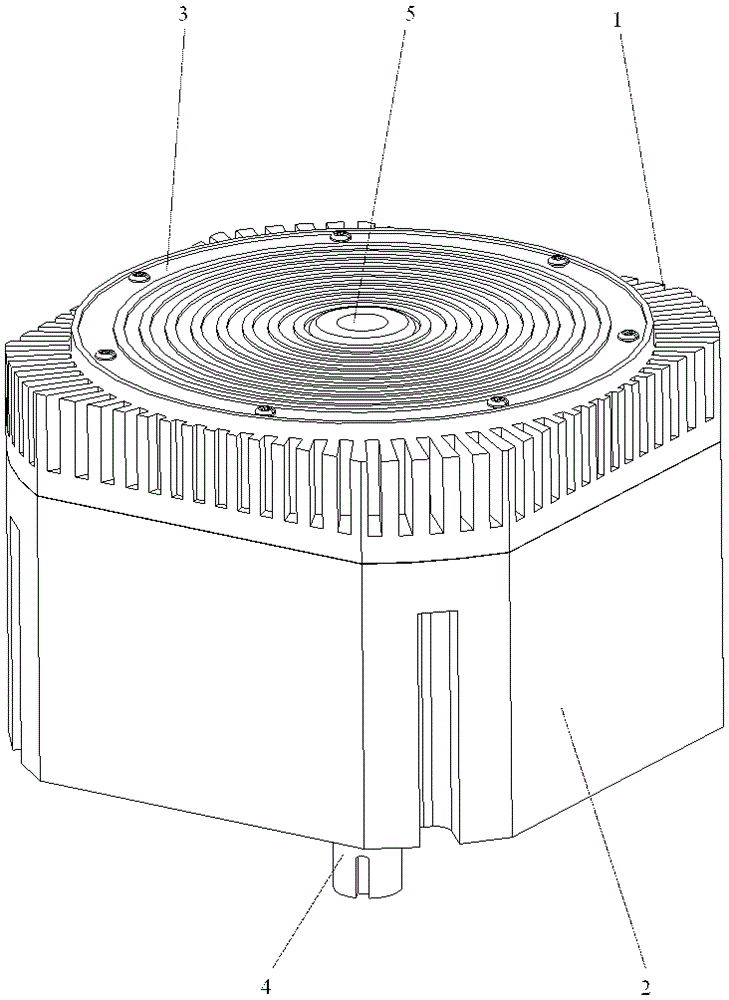

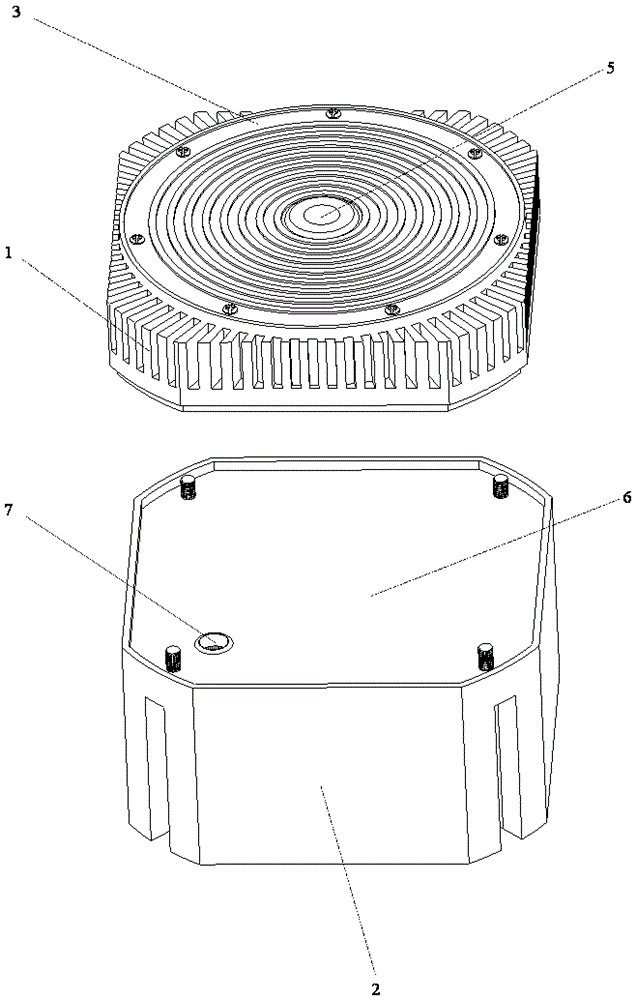

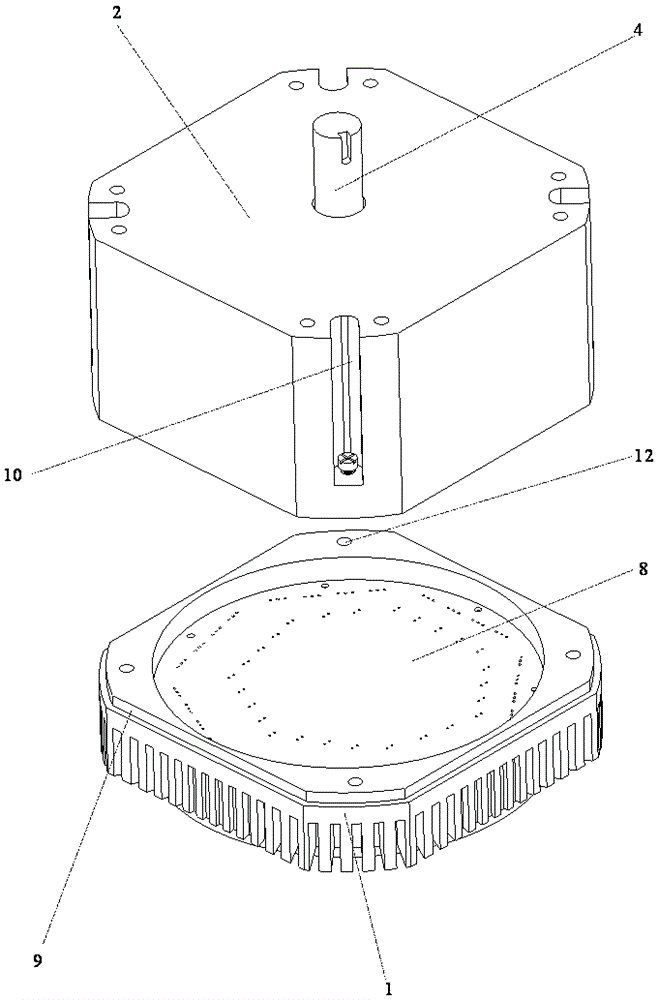

Module type permanent magnet brushless direct-current motor

ActiveCN106169851AImprove reliabilityImprove efficiencyElectronic commutation motor controlAssociation with control/drive circuitsDual coreVMOS

The invention discloses a module type permanent magnet brushless direct-current motor. The module type permanent magnet brushless direct-current motor consists of a motor module and a controller module, and has the following key points: a motor shell (2) is a circular column which is externally octagonal and internally hollow; through combining the motor shell (2) with a separation plate, components such as a rotation shaft, a wire bag, a stator core body, a rotor core body, a bracket and a neodymium-iron-boron permanent magnet required by the permanent magnet brushless direct-current motor are packaged; a controller shell is combined with an end cover to package components such as a PCB board, a VMOS power tube, a dual-core single chip and a driving chip required by a controller; and the motor shell and the controller shell are integrally connected through a fastening bolt. The invention provides a module solution which is low in cost and is capable of carrying out large-scale production and realizing integration of the permanent magnet brushless direct-current motor and the controller, and the module solution is broad in market prospect.

Owner:彭希南

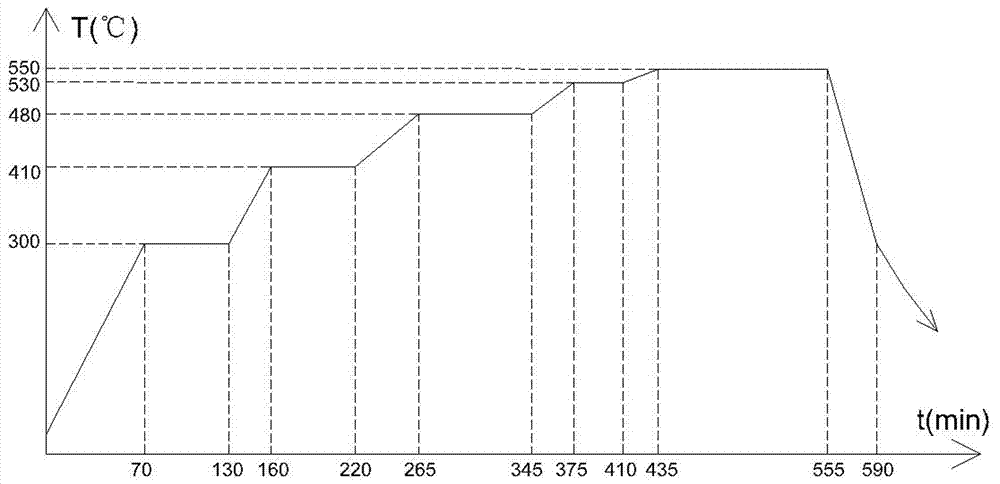

Heat treatment method of iron-based nanometer amorphous magnetic core material

This proposal discloses a heat treatment method for an iron-based nano-amorphous magnetic core material in the technical field of nano-amorphous alloy preparation, including the following steps: 1: Put the iron-based nano-amorphous magnetic core material into a vacuum chamber, Heat treatment of the nano-amorphous magnetic core material; 2: uniformly heat the iron-based nano-amorphous magnetic core material placed in the vacuum chamber from room temperature to 290~310°C, and keep the temperature at a constant temperature for 50~70min; 3: After completing the second step, continue Heat the iron-based nano-amorphous magnetic core material to 400~420°C, and keep it at a constant temperature for 60~70 minutes; 4: After completing the third step, continue to heat the iron-based nano-amorphous magnetic core material to 470~490°C, and keep it at a constant temperature of 75 ~85min; 5: After completing 4, continue to heat the iron-based nano-amorphous core material to 520-540°C, and keep the temperature constant for 30-40 minutes; 6: After completing 5, continue to heat the iron-based nano-amorphous core material to 550~560°C, and keep the constant temperature for 110~130min; 7: After completing 6, cool the iron-based nano-amorphous magnetic core material to room temperature. The method can significantly reduce the hysteresis loss of the iron-based nano-amorphous core.

Owner:贵州鑫湄纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com