Pneumatic-tyre wheel

A technology for pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, rolling resistance optimization, etc., can solve the problem of low hysteresis loss, etc., to reduce rolling resistance, small hysteresis loss, and reduce rolling resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

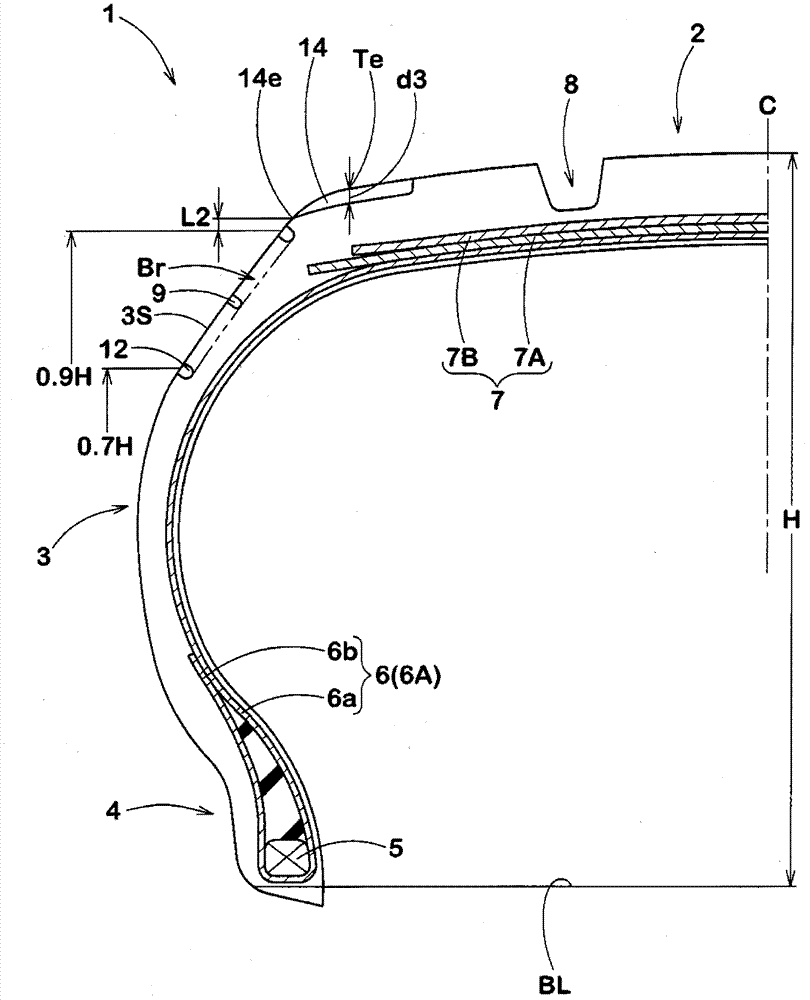

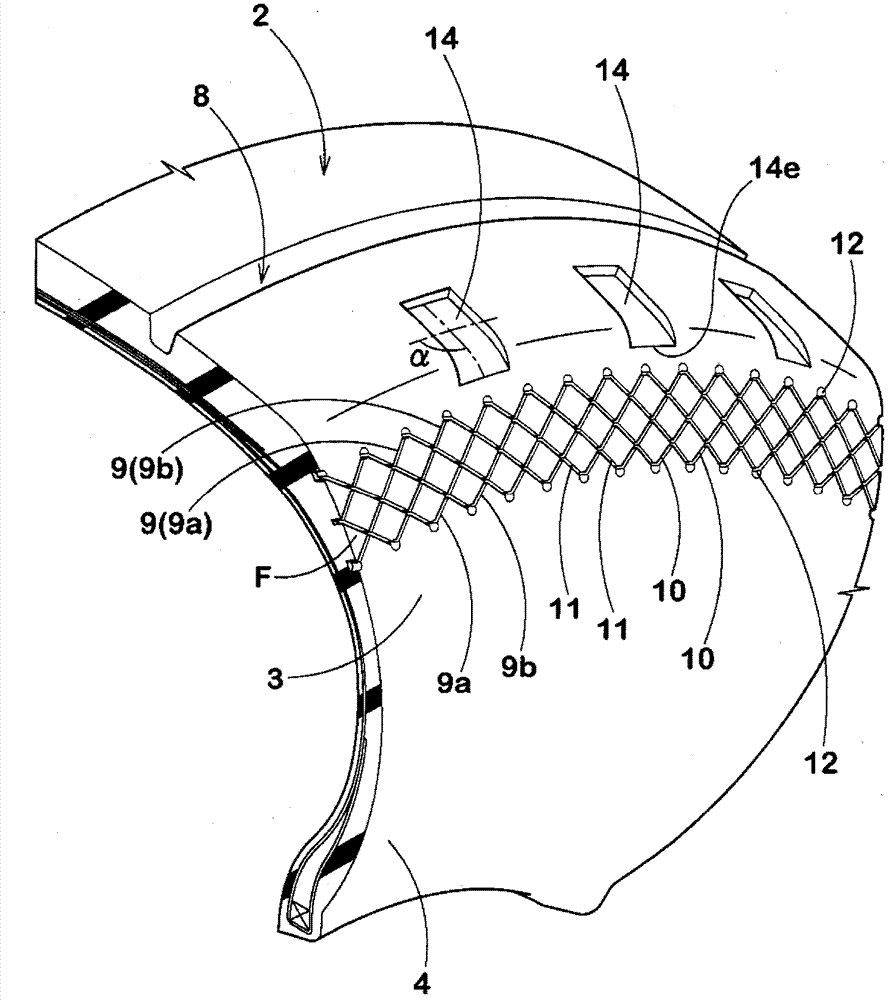

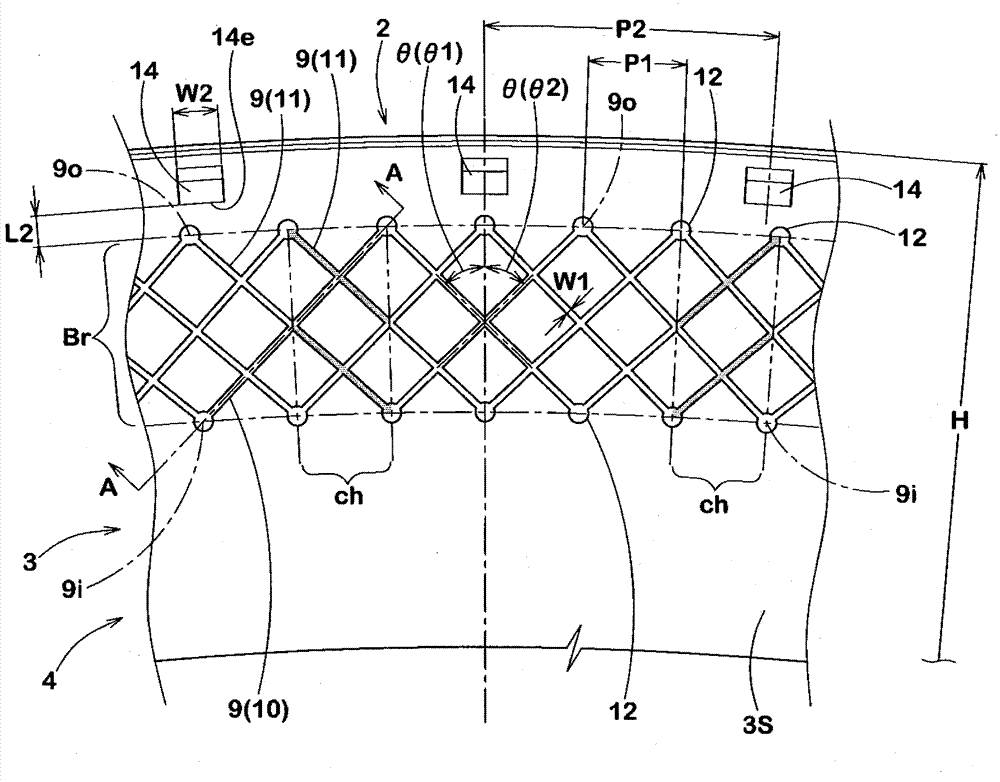

[0044] Manufacturing has figure 1 The basic structure and figure 2 Pneumatic tires (size: 175 / 65R15) with the shape of the sidewall shown and the sipe of the specifications in Table 1 were tested, and their performance was tested. Among them, the common specifications are as follows.

[0045] Tread width: 148mm

[0046] Sipe width W1: 0.5mm

[0047] Tire radial angle of sipe θ: 45 degrees

[0048] Hole: The inner end and outer end of each sipe in the tire radial direction are provided in a perfect circle.

[0049] The depth of the hole d2: 3.0mm

[0050] The test method is as follows.

[0051]

[0052] A rolling resistance tester was used to measure the rolling resistance when the rim was mounted on the above-mentioned pneumatic tire and running on a roller having a diameter of 1.7 m under the following conditions. The result is expressed by an index of 100 in Comparative Example 1, and the smaller the value, the better.

[0053] Rim size: 14×5JJ

[0054] Internal pressure: 230kPa

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com